NEW HOLLAND

CS520

CS540

CS640

CS660

CL560

REPAIRMANUAL

CL560

CS520

CS540

CS640

CS660

INTRODUCTION

DISTRIBUTIONSYSTEMSA

POWERPRODUCTIONB POWERTRAINC

TRAVELLINGD

BODYANDSTRUCTURE E

FRAMEPOSITIONINGF

TOOLPOSITIONINGG

CROPPROCESSINGK

Foreword(-A.10.A.40)

CS540,CS640,CS520,CS660,CL560

Safetyrules(-A.50.A.10)

CS540,CS640,CS520,CS660,CL560

Drivelineoverview(-A.50.A.51)

CS540,CS640,CS520,CS660,CL560

Basicinstructions(-A.90.A.05)

CS540,CS640,CS520,CS660,CL560

Torque(-A.90.A.10)

CS540,CS640,CS520,CS660,CL560

Conversionfactors(-A.92.A.21)

CS540,CS640,CS520,CS660,CL560

Productidentification(-A.80.A.10)

CS540,CS640,CS520,CS660,CL560

Foreword(-A.10.A.40)

CS540,CS640,CS520,CS660,CL560

TechnicalInformation

Thismanualhasbeenproducedbyanewtechnicalinformationsystem.Thisnewsystemisdesignedtodeliver technicalinformationelectronicallythroughCDROMandinpapermanuals.AcodingsystemcalledICEhasbeen developedtolinkthetechnicalinformationtootherProductSupportfunctionse.g.Warranty.

Technicalinformationiswrittentosupportthemaintenanceandserviceofthefunctionsorsystemsonacustomers machine.Whenacustomerhasaconcernonhismachineitisusuallybecauseafunctionorsystemonhismachine isnotworkingatall,isnotworkingefficiently,orisnotrespondingcorrectlytohiscommands.Whenyourefertothe technicalinformationinthismanualtoresolvethatcustomersconcern,youwill findalltheinformationclassified usingthenewICEcoding,accordingtothefunctionsorsystemsonthatmachine.Onceyouhavelocatedthe technicalinformationforthatfunctionorsystemthenyouwill findallthemechanical,electricalorhydraulicdevices, components,assembliesandsubassembliesforthatfunctionorsystem.Youwillalso findallthetypesofinformation thathavebeenwrittenforthatfunctionorsystem,thetechnicaldata(specifications),thefunctionaldata(howit works),thediagnosticdata(faultcodesandtroubleshooting)andtheservicedata(remove,installadjust,etc.).

ByintegratingthisnewICEcodingintotechnicalinformation,youwillbeabletosearchandretrievejusttheright pieceoftechnicalinformationyouneedtoresolvethatcustomersconcernonhismachine.Thisismadepossibleby attaching3categoriestoeachpieceoftechnicalinformationduringtheauthoringprocess.

The firstcategoryistheLocation,thesecondcategoryistheInformationTypeandthethirdcategoryistheProduct:

• LOCATION-isthecomponentorfunctiononthemachine,thatthepieceoftechnicalinformationisgoingto describee.g.Fueltank.

• INFORMATIONTYPE-isthepieceoftechnicalinformationthathasbeenwrittenforaparticularcomponentor functiononthemachinee.g.CapacitywouldbeatypeofTechnicalDatathatwoulddescribetheamount offuelheldbytheFueltank.

• PRODUCT-isthemodelthatthepieceoftechnicalinformationiswrittenfor.

Everypieceoftechnicalinformationwillhavethose3categoriesattachedtoit.Youwillbeabletouseany combinationofthosecategoriesto findtherightpieceoftechnicalinformationyouneedtoresolvethatcustomers concernonhismachine.

Thatinformationcouldbe:

• thedescriptionofhowtoremovethecylinderhead

• atableofspecificationsforahydraulicpump

• afaultcode

• atroubleshootingtable

• aspecialtool

HowtoUsethisManual

ThismanualisdividedintoSections.EachSectionisthendividedintoChapters.Contentspagesareincludedat thebeginningofthemanual,theninsideeverySectionandinsideeveryChapter.AnalphabeticalIndexisincluded attheendofaChapter.Pagenumberreferencesareincludedforeverypieceoftechnicalinformationlistedin theChapterContentsorChapterIndex.

EachChapterisdividedintofourInformationtypes:

• TechnicalData(specifications)forallthemechanical,electricalorhydraulicdevices,componentsand, assemblies.

• FunctionalData(howitworks)forallthemechanical,electricalorhydraulicdevices,componentsand assemblies.

• DiagnosticData(faultcodes,electricalandhydraulictroubleshooting)forallthemechanical,electricalor hydraulicdevices,componentsandassemblies.

• Servicedata(removedisassembly,assemble,install)forallthemechanical,electricalorhydraulicdevices, componentsandassemblies.

Sections

Sectionsaregroupedaccordingtothemainfunctionsorasystemsonthemachine.EachSectionisidentifiedby aletterA,B,Cetc.TheamountofSectionsincludedinthemanualwilldependonthetypeandfunctionofthe machinethatthemanualiswrittenfor.EachSectionhasaContentspagelistedinalphabetic/numericorder.This tableillustrateswhichSectionscouldbeincludedinamanualforaparticularproduct.

SECTION A-DistributionSystems B-PowerProduction C-PowerTrain D-Travelling E-BodyandStructure F-FramePositioning G-ToolPositioning H-WorkingArm J-ToolsandCouplers K-CropProcessing L-FieldProcessing

PRODUCT

TractorsXXXXXXXX

Vehicleswithworkingarms:backhoes, excavators,skidsteers,..... XXXXXXXXX Combines,forageharvesters,balers,.... XXXXXXXXXX Seeding,planting, floating,spraying equipment,.... XXXXXXXXX

Mountedequipmentandtools,.....XXXX

INTRODUCTION

ThismanualcontainstheseSections.ThecontentsofeachSectionareexplainedoverthefollowingpages.

Contents

INTRODUCTION

SectionContents

SECTIONA,DISTRIBUTIONSYSTEMS

ThisSectioncoversthemainsystemsthatinteractwithmostofthefunctionsoftheproduct.Itincludesthecentral partsofthehydraulic,electrical,electronic,pneumatic,lightingandgreaselubricationsystems.Thecomponents thatarededicatedtoaspecificfunctionarelistedintheChapterwhereallthetechnicalinformationforthatfunction isincluded.

SECTIONB,POWERPRODUCTION

ThisSectioncoversallthefunctionsrelatedtotheproductionofpowertomovethemachineandtodrivevarious devices.

SECTIONC,POWERTRAIN

ThisSectioncoversallthefunctionsrelatedtothetransmissionofpowerfromtheenginetotheaxlesandtointernal orexternaldevicesandadditionalProcessDrivefunctions.

SECTIOND,TRAVELLING

ThisSectioncoversallthefunctionsrelatedtomovingthemachine,includingtracks,wheels,steeringandbraking. Itcoversalltheaxlesbothdrivenaxlesandnon-drivenaxles,includinganyaxlesuspension.

SECTIONE,BODYANDSTRUCTURE

ThisSectioncoversallthemainfunctionsandsystemsrelatedtothestructureandbodyofthemachine.Including theframe,theshields,theoperator’scabandtheplatform.

SECTIONG,TOOLPOSITIONING

ThisSectioncoversallthefunctionsrelatedtothe finaland/orautomaticpositioningofthetooloncethetoolis positionedusingtheWorkingArmorthemachineframe.

SECTIONK,CROPPROCESSING

ThisSectioncoversallthefunctionsrelatedtocropprocessing.

INTRODUCTION

Chapters

EachChapterisidentifiedbyaletterandnumbercombinatione.g.EngineB.10.AThe firstletterisidenticaltothe Sectionletteri.e.ChapterB.10isinsideSectionB,PowerProduction. CONTENTS

TheChapterContentslistsallthetechnicaldata(specifications),functionaldata(howitworks),servicedata (remove,installadjust,etc..)anddiagnosticdata(faultcodesandtroubleshooting)thathavebeenwritteninthat Chapterforthatfunctionorsystemonthemachine.

Contents

TECHNICALDATA

POWERPRODUCTION

ENGINE_10.A

ENGINE-Generalspecification(B.10.A-D.40.A.10)

CS540

FUNCTIONALDATA

ENGINE-Dynamicdescription(B.10.A-C.30.A.10)

CS540 SERVICE

ENGINE-Remove(B.10.A-F.10.A.10)

CS540

DIAGNOSTIC

ENGINE-Troubleshooting(B.10.A-G.40.A.10)

CS540

INDEX

TheChapterIndexlistsinalphabeticalorderallthetypesofinformation(calledInformationUnits)thathavebeen writteninthatChapterforthatfunctionorsystemonthemachine.

Index

POWERPRODUCTION-B ENGINE

ENGINE-Dynamicdescription(B.10.A-C.30.A.10)

CS540

ENGINE-Generalspecification(B.10.A-D.40.A.10)

CS540

ENGINE-Remove(B.10.A-F.10.A.10)

CS540

ENGINE-Troubleshooting(B.10.A-G.40.A.10)

CS540

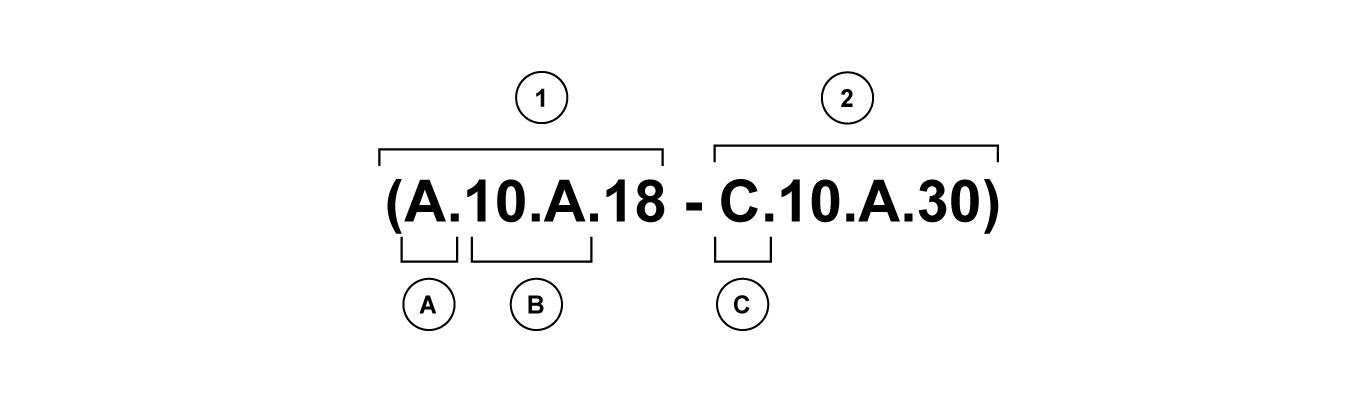

InformationUnitsandInformationSearch

Eachchapteriscomposedofinformationunits.EachinformationunithastheICEcodeshowninparentheseswhich indicatesthefunctionandthetypeofinformationwritteninthatinformationunit.Eachinformationunithasapage referencewithinthatChapter.Theinformationunitsprovideaquickandeasywayto findjusttherightpieceof technicalinformationyouarelookingfor.

exampleinformationunitStackvalve-SectionalView(A.10.A.18-C.10.A.30)

InformationUnitICEcode A10.A18 C 10.A.30

ICEcodeclassification Distribution systems Primary hydraulic power

Navigatetothecorrectinformationunityouaresearchingforbyidentifyingthefunctionandinformationtype fromtheICEcode.

• (1) Functionand (2) Informationtype.

• (A) correspondstothesectionsoftherepairmanual.

(B) correspondstothechaptersoftherepairmanual.

(C) correspondstothetypeofinformationlistedinthechaptercontents,Technicaldata,FunctionalData, DiagnosticorService.

(A) and (B) arealsoshowninthepagenumberingonthepagefooter. THERESTOFTHECODINGISNOTLISTEDINALPHANUMERICORDERINTHISMANUAL.

• Youwill findatableofcontentsatthebeginningandendofeachsectionandchapter. Youwill findanalphabeticalindexattheendofeachchapter.

• Byreferringto (A), (B) and (C) ofthecoding,youcanfollowthecontentsorindex(pagenumbers)andquickly findtheinformationyouarelookingfor.

PageHeaderandFooter

Thepageheaderwillcontainthefollowingreferences:

• SectionandChapterdescription

Thepagefooterwillcontainthefollowingreferences:

• PublicationnumberforthatManual,SectionorChapter.

• Versionreferenceforthatpublication.

• Publicationdate

• Section,chapterandpagereferencee.g.A.10.A/9

Importantinformation

AllrepairandmaintenanceworkslistedinthismanualmustbecarriedoutonlybystaffbelongingtotheNEW HOLLANDServicenetwork,strictlycomplyingwiththeinstructionsgivenandusing,wheneverrequired,thespecial tools.

Anyonewhocarriesouttheaboveoperationswithoutcomplyingwiththeprescriptionsshallberesponsiblefor thesubsequentdamages.

Themanufacturerandalltheorganizationsofitsdistributionchain,including-withoutlimitation-national,regionalor localdealers,rejectanyresponsibilityfordamagesduetotheanomalousbehaviourofpartsand/orcomponentsnot approvedbythemanufacturerhimself,includingthoseusedfortheservicingorrepairoftheproductmanufactured ormarketedbytheManufacturer.Inanycase,nowarrantyisgivenorattributedontheproductmanufacturedor marketedbytheManufacturerincaseofdamagesduetoananomalousbehaviourofpartsand/orcomponentsnot approvedbytheManufacturer.

Safetyrules(-A.50.A.10)

CS540,CS640,CS520,CS660,CL560

WARNINGANDDANGERSYMBOL

Thiswarningsymbolpointsoutimportantpersonalsafetymessages. Carefullyreadthefollowingsafetyregulationsandobserveadvised precautionsinordertoavoidpotentialhazardsandsafeguardyourhealth andsafety.Inthismanualthesymbolisaccompaniedbythefollowing keywords:

WARNING-Warningsconcerningunsuitablerepairoperationsthatmay jeopardisethesafetyofRepairpersonnel.

DANGER-Specificwarningsconcerningpotentialhazardsforoperator safetyorforotherpersonsdirectlyorindirectlyinvolved.

ACCIDENTPREVENTION

Mostaccidentsorinjuriesthatoccurinworkshopsaretheresultofnon-observanceofsimpleandfundamental safetyregulations.Forthisreason,INMOSTCASESTHESEACCIDENTSCANBEAVOIDEDbyforeseeing possiblecausesandconsequentlyactingwiththenecessarycautionandcare.

Accidentsmayoccurwithalltypesofmachine,regardlessofhowwellthemachineinquestionwasdesigned andbuilt.

Acarefulandjudiciousservicetechnicianisthebestguaranteeagainstaccidents.

Preciseobservanceofthemostbasicsafetyruleisnormallysufficienttoavoidmanyseriousaccident

DANGER

M871-Shutdownthemachine,removekey,besureallmovingpartshavestoppedandallpressureinthe systemsisrelievedbeforecleaning,adjustingorlubricatingtheequipment.

SAFETYRULES

Generalguidelines

• Carefullyfollowspecifiedrepairandmaintenanceprocedures.

• Donotwearrings,wristwatches,jewellery,unbuttonedorloosearticlesofclothingsuchas:ties,tornclothing, scarves,openjacketsorshirtswithopenzipsthatmayremainentangledinmovingparts.Itisadvisedtowear approvedsafetyclothing,e.g.:non-slipfootwear,gloves,safetygoggles,helmets,etc.

• Donotcarryoutrepairoperationswithsomeonesittinginthedriver’sseat,unlessthepersonisatrained technicianwhoisassistingwiththeoperationinquestion.

• Donotoperatethemachineoruseanyoftheimplementsfromdifferentpositions,otherthanthedriver’sseat.

• Donotcarryoutoperationsonthemachinewiththeenginerunning,unlessspecificallyindicated.

• Stoptheengineandcheckthatthehydrauliccircuitsarepressure-freebeforeremovingcaps,covers, valves,etc.

• Allrepairandmaintenanceoperationsmustbecarriedoutusingextremecareandattention.

• Servicestepsandplatformsusedintheworkshoporelsewhereshouldbebuiltaccordingtostandardaccident preventionregulations.

• Disconnectthep.t.o.fromtheandlabelallcontrolstoindicatethatthemachineisbeingserviced.Any partsthataretoberaisesmustbelockedinposition.

• Brakesareinoperativewhenmanuallyreleasedforrepairormaintenancepurposes.Useblocksorsimilar devicestocontrolthemachineintheseconditions.

• Onlyusespecifiedtowingpointsfortowingthemachine.Connectpartscarefully.Makesurethatallpins and/orlocksaresecuredinpositionbeforeapplyingtraction.Neverremainnearthetowingbars,cables orchainsthatareoperatingunderload.

INTRODUCTION

• Whenloadingorunloadingthemachinefromthetrailer(orothermeansoftransport),selecta flatarea capableofsustainingthetrailerortruckwheels.Firmlysecurethemachinetothetruckortrailerandlockthe wheelsinthepositionusedbythecarrier.

• Electricheaters,battery-chargersandsimilarequipmentmustonlybepoweredbyauxiliarypowersupplies withefficientgroundinsulationtoavoidelectricalshockhazards.

• Alwaysusesuitablehoistingorliftingdeviceswhenraisingormovingheavyparts.

• Takeextracareifbystandersarepresent.

• Neverusegasoline,dieseloilorotherinflammableliquidsascleaningagents.Usenon-inflammable,non toxiccommerciallyavailablesolvents.

• Wearsafetygoggleswithsideguardswhencleaningpartswithcompressedair.

• Reducetheairpressureaccordingtothelocalregulationsinforce.

• Donotruntheengineinconfinedspaceswithoutsuitableventilation.

• Neverusenaked flamesforlightingwhenworkingonthemachineorcheckingforleaks.

• Allmovementsmustbecarriedoutcarefullywhenworkingunder,onornearthemachine.Wearprotective equipment:helmets,gogglesandspecialfootwear.

• Whencarryingoutcheckswiththeenginerunning,requesttheassistanceofanoperatorinthedriver’sseat. Theoperatormustmaintainvisualcontactwiththeservicetechnicianatalltimes.

• Ifoperatingoutsidetheworkshop,positionthemachineona flatsurfaceandlockinposition.Ifworkingona slope,lockthemachineinposition.Movetoa flatareaassoonasissafelypossible.

• Damagedorbentchainsorcablesareunreliable.Donotusethemforliftingortowing.Alwaysusesuitable protectivegloveswhenhandlingchainsorcables.

• Chainsshouldalwaysbesafelysecured.Makesurethatthehitch-uppointiscapableofsustainingtheloadin question.Keeptheareanearthehitch-uppoint,chainsorcablesfreeofallbystanders.

• MaintenanceandrepairoperationsmustbecarriedoutinaCLEANandDRYarea.Eliminateanywateror oilspillageimmediately.

• Donotcreatepilesofoilorgrease-soakedragsastheyrepresentaserious firehazard.Alwaysstorerags inaclosedmetalcontainer.Beforeengagingthemachine,makesurethattherearenopersonswithinthe machineorimplementrangeofaction.

• Emptyyourpocketsofallobjectsthatmayfallaccidentallyunobservedintothemachineinnercompartments.

• Inthepresenceofprotrudingmetalparts,useprotectivegogglesorgoggleswithsideguards,helmets, specialfootwearandgloves.

• Whenwelding,useprotectivesafetydevices:tintedsafetygoggles,helmets,specialoveralls,glovesand footwear.Allpersonspresentintheareawhereweldingistakingplacemustweartintedgoggles.NEVER LOOKDIRECTLYATTHEWELDINGARCWITHOUTSUITABLEEYEPROTECTION.

• Metalcablestendtofraywithrepeateduse.Alwaysusesuitableprotectivedevices(gloves,goggles,etc.) whenhandlingcables.

• Handleallpartscarefully.Donotputyourhandsor fingersbetweenmovingparts.Wearsuitablesafety clothing-safetygoggles,glovesandshoes.

INTRODUCTION

Start-up

• Neverruntheengineinconfinedspacesthatarenotequippedwithadequateventilationforexhaustgas extraction.

• Neverplacethehead,body,limbs,feet,handsor fingersnearrotatingandmovingparts.

Hydraulicsystems

• Aliquidleakingfromatinyholemaybealmostinvisiblebut,atthesametime,bepowerfulenoughtopenetrate theskin.Therefore,NEVERUSEHANDSTOCHECKFORLEAKSbutuseapieceofcardboardorwoodfor thispurpose.Ifanyliquidpenetratesskintissue,callformedicalaidimmediately.Failuretotreatthiscondition withcorrectmedicalproceduremayresultinseriousinfectionordermatosis.

• Inordertocheckthepressureinthesystemusesuitableinstruments.

WheelsandTyres

• Makesurethatthetyresarecorrectlyinflatedatthepressurespecifiedbythemanufacturer.Periodically checktherimsandtyresfordamage.

• Standawayfrom(atthesideof)thetyrewhencheckinginflationpressure.

• Donotusepartsofrecoveredwheelsasincorrectweldingbrazingorheatingmayweakenandeventually causedamagetothewheel.

• Nevercutorweldarimmountedwithaninflatedtyre.

• Toremovethewheels,lockallwheels.Afterhavingraisedthemachine,positionsupportsunderneath, accordingtoregulationsinforce.

• Deflatethetyrebeforeremovinganyobjectsthatmaybejammedinthetyretread.

• Neverinflatetyresusinginflammablegases,asthismayresultinexplosionsandinjurytobystanders.

RemovalandRe-fitting

• Liftandhandleallheavypartsusingsuitablehoistingequipment.Makesurethatpartsaresustainedby appropriatehooksandslings.Usethehoistingeyeboltsforliftingoperations.Extracareshouldbetakenif personsarepresentneartheloadtobelifted.

• Handleallpartscarefully.Donotputyourhandsor fingersbetweenparts.Wearsuitablesafetyclothingsafetygoggles,glovesandshoes.

• Avoidtwistingchainsormetalcables.Alwayswearsafetygloveswhenhandlingcablesorchains.

Drivelineoverview(-A.50.A.51)

CS540,CS640,CS520,CS660,CL560

MAINOUTPUTSHAFT

1.Engine

2.Rotarydustscreen

3.Chaffspreaderdriveshaft(Ifinstalled)