Brakes

T rack tension units

Dropbox and final drive

Cab climate control

Fuel

Engine

Engine

Service

Harnesses

Engine

Cold

Wiper

Hydraulic

Capacities (*)

Capacities (*)

Capacities (*)

Capacities (*)

Product identification (*)

Product identification Machine Orientation rear , left) (*)

Safety rules

D180C

Personal safety

This the safety alert used alert you potential personal injury Obey all safety messages that follow this symbol avoid possible death injury .

Throughout this manual you will find the signal words W and CAUTION followed special These precautions are intended for the personal safety you and those working with

Read and understand all the safety messages this manual before you operate service the

DANGER indicates a hazardous situation not will result death serious injury

W ARNING indicates a hazardous situation not could result death serious injury

CAUTION indicates a hazardous situation that, not avoided, could result minor moderate injury .

F AILURE T O FOLLOW DANGER, W ARNING, AND CAUTION MESSAGES COULD RESUL T DEA SERIOUS INJUR Y .

Machine safety

NOTICE: Notice indicates a situation not could result machine property

Throughout this manual you will find the signal word Notice followed special instructions prevent machine property The word Notice used address practices not related personal safety

Information

NOTE: Note indicates additional information that clarifies other information this

Throughout this manual you will find the word Note followed additional information about a other information the The word Note not intended address personal safety property

Safety rules - Ecology and the environment

D180C

air , and water quality important for all industries and life

When legislation does not yet rule the treatment some the substances that advanced technology sound judgment should govern the use and disposal products a chemical and petrochemical nature.

Familiarize yourself with the relative legislation applicable your country , and make sure that you understand this legislation. Where legislation exists, obtain information from suppliers oils, filters, batteries, fuels, antifreeze, cleaning with regard the fect these substances man and nature and how safely and dispose these

Helpful hints

• A void the use cans other inappropriate pressurized fuel delivery systems fill Such delivery systems may cause considerable

• avoid skin contact with all

Most these products contain substances that may harmful your health.

• Modern oils contain not burn contaminated fuels and waste oils ordinary heating

• A void spillage when you drain fluids such used engine coolant mixtures, engine oil, hydraulic fluid, brake fluid, not mix drained brake fluids fuels with Store all drained fluids safely until you can dispose the fluids a proper way that complies with all local legislation and available

• not allow coolant mixtures get into the Collect and dispose coolant mixtures properly

• The air - conditioning system contains gases that should not released into the Consult airtioning specialist use a special extractor recharge the system properly

• Repair any leaks defects the engine cooling system hydraulic system immediately

• not increase the pressure a pressurized circuit this may lead a component failure.

• Protect hoses during Penetrating weld splatter may burn a hole weaken allowing the loss coolant, etc.

Battery recycling

Batteries and electric accumulators contain several substances that can have a harmful fect the environment the batteries are not properly recycled after Improper disposal batteries can contaminate the groundwater , and NEW HOLLAND CONSTRUCTION strongly recommends that you return all used batteries a NEW HOLLAND CONSTRUCTION dealer , who will dispose the used batteries recycle the used batteries properly some this a legal

Mandatory battery recycling

NOTE: The following requirements are mandatory

Batteries are made lead plates and a sulfuric acid

Because batteries contain heavy metals such CONAMA Resolution 401 / 2008 requires you return all used batteries the battery dealer when you replace any not dispose batteries your household

Points sale are obliged to:

• Accept the return your used batteries

• Store the returned batteries a suitable location

• Send the returned batteries the battery manufacturer for recycling

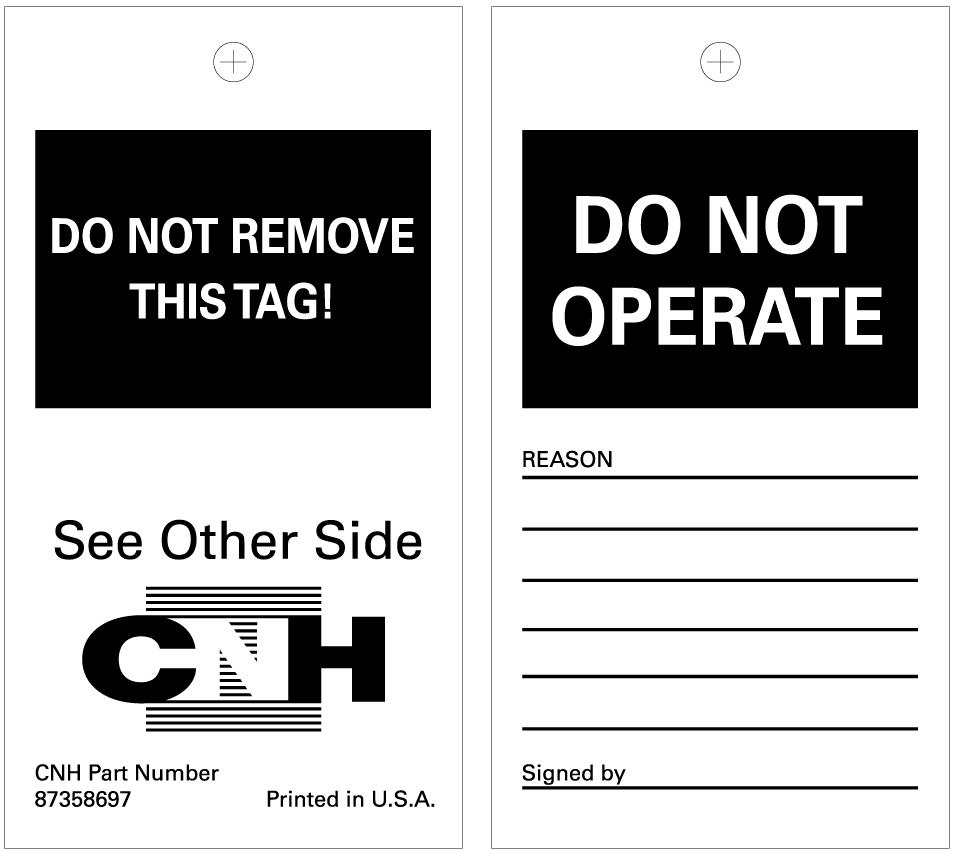

Safety rules - not operate tag

D180C

W ARNING

Maintenance hazard!

Before you start servicing the attach a NOT OPERA warning tag the machine a visible area.

Failure comply could result death serious injury W0004A

Attach a NOT OPERA AG) the machine area that clearly visible whenever the machine not operating properly and / requires

Complete the tag information for the "REASON" the tag attached describing the malfunction service

V alidate the reason for attaching the tag signing your name the designated area the

The tag should only removed the person who signed and attached the after validating the repairs services have been (A)

T Components

NOT REMOVE THIS T AG! - arning) The tag should only removed the person who signed and tached the after validating the repairs services have been

See Other Side - (Reference additional information opposite side the CNH Part Number - (Request this part number from you Service Parts Dealer obtain this NOT OPERA

NOT OPERA - arning!)

Safety rules

D180C

General safety rules

Use caution when operating the machine Raised full tanks and other loads will change the center gravity the The machine can tip roll over when near ditches and embankments uneven surfaces.

Never permit anyone other than the operator ride the

Never operate the machine under the influence alcohol, drugs, while otherwise impaired.

When digging using ground engaging attachments aware buried Contact local utilities determine the locations services.

Pay attention overhead power lines and hanging High voltage lines may require significant clearance for safety .

Hydraulic oil diesel fuel leaking under pressure can penetrate the causing serious injury

• NOT use your hand check for leaks. Use a piece cardboard paper .

• Stop remove key and relieve the pressure before connecting disconnecting fluid

• Make sure all components are good condition and tighten all connections before starting the engine izing the

• hydraulic fluid diesel fuel penetrates the seek medical attention immediately

• Continuous long term contact with hydraulic fluid may cause skin cancer A void long term contact and wash the skin promptly with soap and water

Keep clear moving Loose jewelry , long hair , and other loose hanging items can become entangled moving

W ear protective equipment when

NOT attempt remove material from any part the machine while being operated components are motion.

Make sure all guards and shields are good condition and properly installed before operating the Never operate the machine with shields removed. Always close access doors panels before operating the machine.

Dirty slippery and platforms can cause Make sure these surfaces remain clean and clear debris.

A person pet within the operating area a machine can struck crushed the machine its NOT allow anyone enter the work area.

Raised equipment and / loads can fall unexpectedly and crush persons Never allow anyone enter the area underneath raised equipment during

Never operate engine enclosed spaces harmful exhaust gases may build

Before starting the machine, sure that all controls are neutral park lock position.

Start the engine only from the operator ’ s the safety start switch the engine can start with the transmission gear . not connect short across terminals the starter solenoid. Attach jumper cables described the Starting gear may cause death serious injury

Always keep all and Slow Moving V ehicle (SMV) emblem clean provide the best possible visibility while operating the

Operate controls only when seated the operator ’ s except for those controls expressly intended for use from other

INTRODUCTION

Before leaving the machine:

Park machine a firm level

Put all controls neutral park lock

Engage park Use wheel chocks

Lower all hydraulic equipment header ,

T urn f engine and remove key

due exceptional you would decide keep the engine running after leaving the operator ’ s then the following precautions must followed:

Bring the engine low idle

Disengage all drive

W ARNING

Some components may continue run down after disengaging drive systems.

Make sure all drive systems are fully

Failure comply could result death serious injury .

Shift the transmission into

Apply the parking

W01 13A

General maintenance safety

Keep area used for servicing the machine clean and dry Clean spilled

Service machine a firm level

Install guards and shields after servicing the machine.

Close all access doors and install all panels after servicing the

not attempt clean, lubricate, clear obstructions make adjustments the machine while motion while the engine

Always make sure working area clear tools, parts, other persons and pets before you start operating the machine.

Unsupported hydraulic cylinders can lose pressure and drop the equipment causing a crushing not leave equipment a raised position while parked during service, unless securely supported.

Jack lift the machine only jack lift points indicated this Incorrect towing procedures can cause accidents. When towing a disabled machine follow the procedure this Use only rigid tow

Stop the engine, remove key and relieve pressure before disconnecting connecting fluid lines.

Stop the engine and remove key before disconnecting connecting electrical

Scalding can result from incorrect removal coolant caps. Cooling system operates under pressure. Hot coolant can spray out a cap removed while the system Allow system cool before removing When removing a cap turn slowly allow pressure escape before completely removing the

Replace damaged worn electrical

Engine, transmission, exhaust components, and hydraulic lines may become hot during operation. T ake care when servicing such Allow surfaces cool before handling disconnecting hot W ear protective equipment when

When follow the instructions the Always disconnect the battery before welding the Always wash your hands after handling battery

INTRODUCTION

Wheels and tires

Make sure tires are correctly not exceed recommended load Follow instructions the manual for proper tire

T ires are heavy Handling tires without proper equipment could cause death serious injury

Never weld a wheel with a tire Always remove tire completely from wheel prior

Always have a qualified tire technician service the tires and wheels. a tire has lost all pressure, take the tire and wheel a tire shop your dealer for Explosive separation the tire can cause serious injury

NOT weld a wheel rim until the tire completely Inflated tires can generate a gas mixture with the air that can ignited high temperatures from welding procedures performed the wheel Removing the air loosening the tire the rim (breaking the bead) will NOT eliminate the This condition can exist whether tires are inflated deflated. The tire MUST completely removed from the wheel rim prior welding the wheel

Driving public roads and general transportation safety

Comply with local laws and

Use appropriate lighting meet local

Make sure SMV emblem

Make sure brake pedal latch Brake pedals must locked together for road

Use safety chains for trailed equipment when provided with machine equipment.

Lift implements and attachments high enough above ground prevent accidental contact with

When transporting equipment machine a transport trailer , make sure properly secured. sure the SMV the equipment machine covered while being transported a trailer

aware overhead structures power lines and make sure the machine and / attachments can pass safely under

T ravel speed should such that complete control and machine stability maintained all times.

Slow down and signal before

Pull over allow faster traf fic pass.

Follow correct towing procedure for equipment with without

Make sure the booms are locked the cradles with the locking pins

Fire and explosion prevention

Fuel oil leaked spilled hot surfaces electrical components can cause a fire.

Crop bird flammable material can ignite hot

Always have a fire extinguisher near the

Make sure the fire extinguisher(s) maintained and serviced according the manufacturer ’ s

least once each day and the end the day remove all trash and debris from the machine especially around hot components such battery , More frequent cleaning your machine may necessary depending the operating environment and conditions.

least once each day , remove debris accumulation around moving components such cleaning More frequent cleaning your machine may necessary depending the operating environment and

Inspect the electrical system for loose connections frayed Repair replace loose damaged not store oily rags other flammable material the not weld flame cut any items that contain flammable Clean items thoroughly with non - flammable solvents before welding flame -

not expose the machine burning

Promptly investigate any unusual smells odors that may occur during operation the

General battery safety

Always wear eye protection when working with not create sparks have open flame near battery

V entilate when charging using enclosed

Disconnect negative ( first and reconnect negative ( last.

When welding the disconnect both terminals the battery not weld, grind, smoke near a battery .

When using auxiliary batteries connecting jumper cables start the use the procedure shown the ator ’ s manual. not short across terminals.

Follow manufacturer ’ s instructions when storing and handling

Battery post, and related accessories contain lead and lead W ash hands after This a California Proposition

Battery acid causes burns. Batteries contain sulfuric acid. A void contact with skin, eyes, clothing. Antidote ternal): Flush with water Antidote (eyes): flush with water for minutes and seek medical attention immediately Antidote (internal): Drink large quantities water not induce Seek medical attention ately

Keep out reach children and other unauthorized

Instructional seat safety

Passengers are not permitted ride the

The instructional seat used only when training a new operator when a service technician diagnosing a

When required for the purposes training only one person may accompany the operator and that person must seated the instructional

When the instructional seat the following precautions must followed:

• Machine should driven only slow speeds and over level

• A void driving highways public

• A void quick starts

• A void sharp

• Always wear correctly adjusted seat

• Keep door closed all

INTRODUCTION

Operator presence system

Y our machine equipped with operator presence system prevent the use some features while the operator not the operator ’ s

The operator presence system should never disconnected the system the system must

Reflectors and warning lights

Flashing amber warning lights must used when operating public Refer Chapter 5 T ransport ations for complete identification and operating

Seat belts

Seat belts must worn all

Seat belt inspection and maintenance:

• Keep seat belts good

• Keep sharp edges and items that can cause damage away from the

• Periodically check slack take - and mounting bolts for damage and wear .

• Replace all parts that have damage wear

• Replace belts that have cuts that can make the belt weak.

• Check that bolts are tight the seat bracket

• belt attached make sure seat seat brackets are mounted securely

• Keep seat belts clean and dry

• Clean belts only with soap solution and warm water

• not use bleach dye the belts because this can make the belts

• Refer Chapter 4 Operating Instructions for proper use and adjustment seat

INTRODUCTION

Air - conditioning system

The air - conditioning system under high not disconnect any The release high pressure can cause serious injury

The air - conditioning system contains gases that are harmful the environment when released into the not attempt service repair the repair , recharging must performed only a trained service

Personal Protective Equipment (PPE)

W ear Personal Protective Equipment (PPE) such hard eye heavy hearing tective clothing, etc.

Not Operate tag

Before you start servicing the machine, attach a Not warning tag the machine area that will

Hazardous chemicals

you are exposed come contact with hazardous chemicals you can seriously The paints, adhesives, coolant, etc. required for the function your machine can hazardous. They may attractive and harmful domestic animals well

Material Safety Data Sheets (MSDS) provide information about the chemical substances within a product, safe dling and storage first aid measures and procedures taken the event a spill accidental MSDS are available from your dealer

Before you service your machine check the MSDS for each used this This information indicates the associated risks and will help you service the machine safely Follow the information the manufacturer well the information this manual when servicing the

Dispose all and containers environmentally safe manner according local laws and Check with local environmental and recycling centers your dealer for correct disposal information.

Store fluids and filters accordance with local laws and Use only appropriate containers for the storage chemicals petrochemical substances.

Keep out reach children other unauthorized

Additional precautions are required for applied Obtain complete information from the manufacturer distributor the chemicals before using

Utility safety

When digging using ground - engaging aware buried cables and other

Contact your local utilities appropriate determine the locations

Make sure the machine has suf ficient clearance pass all Pay special attention overhead power lines and hanging

High voltage lines may require significant clearance for safety Contact local authorities utilities obtain safe clearance distances from high voltage power

Retract raised extended necessary Remove lower radio antennas other Should a contact between the machine and electric power source occur , the following precautions must taken:

• Stop the machine movement immediately

• Apply the park brake, stop the engine, and remove the key .

• Check you can safely leave the cab your actual position without contact with electrical stay your position and call for help. you can leave your position without touching lines, jump clear the machine make sure you not make contact with the ground and the machine the same

INTRODUCTION

• not permit anyone touch the machine until power has been shut f the power

Electrical storm safety

not operate machine during electrical

you are the ground during electrical stay away from machinery and Seek shelter a protected

electrical storm should strike during remain the not leave the cab operator ’ s not make contact with the ground objects outside the

Mounting and dismounting

Mount and dismount the machine only designated locations that have steps, not jump f the

Make sure and platforms remain clean and clear debris and foreign Injury may result from slippery

Face the machine when mounting and

Maintain a three - point contact with and

Never mount dismount from a moving

not use the steering wheel other controls accessories handholds when entering exiting the cab operator ’ s

W orking heights

When the normal use and maintenance the machine requires working heights:

• Correctly use installed and

• Never use railings while the machine

• not stand surfaces which are not designated steps

not use the machine a ladder , platform for working

Spraying

• sure clean and flush all residual chemicals from the sprayer before changing another type some may necessary remove the end caps from the spray bars thoroughly flush the boom plumbing. some cases a decontamination solution recommended the chemical manufacturer .

• Always follow chemical manufacturers safety instructions when mixing and applying herbicides and chemicals prevent serious harm people the

• Observe all Federal and State A regulations and all State and Federal codes and / laws regarding application and waste disposal herbicides other

INTRODUCTION

Roll over and tip over

• T ravel speed should such that complete control and machine stability maintained all Where avoid operating near embankments and Reduce speed when crossing and muddy

• not operate the unit terrain outside its grade and stability Operating the sprayer outside its limits may result a roll over tip over

• Operating the unit steep grades may result a machine overturn. the operator ’ s responsibility make a judgment weather , road ground conditions permit safe operation a ditch rough

• Use caution when operating the machine Raised full tanks and other loads can change the center gravity the The machine can tip roll over when near ditches and embankments uneven

• not operate the unit near the soft shoulders canals, brooks, other waterways banks which are mined The unit may sink sideways and roll over

• not operate the unit poorly constructed underrated ramps. The ramps may collapse and cause the sprayer roll over Always check the condition and rating ramps before

• not operate the unit without using the seat

• not operate the unit beyond its limits dynamic stability High abrupt maneuvers fast and sharp cornering increase the risk roll over

Basic instructions - Important notice regarding equipment servicing

D180C

All repair and maintenance work listed this manual must carried out only qualified dealership strictly complying with the instructions and whenever the special Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall responsible for any subsequent

The manufacturer and all the organizations its distribution including - without limitationlocal reject any responsibility for damages caused parts and / components not approved the facturer , including those used for the servicing repair the product manufactured marketed the manufacturer any warranty given attributed the product manufactured marketed the manufacturer case damages caused parts and / components not approved the manufacturer .

The information this manual - - date the date the the policy the manufacturer for continuous Some information could not updated due modifications a technical commercial changes the laws and regulations dif ferent case refer your NEW HOLLAND CONSTRUCTION Sales and Service

Thanks very much for your reading,

Want to get more information,

Please click here, Then get the complete manual

NOTE:

If there is no response to click on the link above, please download the PDF document first, and then click on it.

Have any questions please write to me: admin@servicemanualperfect.com