4 minute read

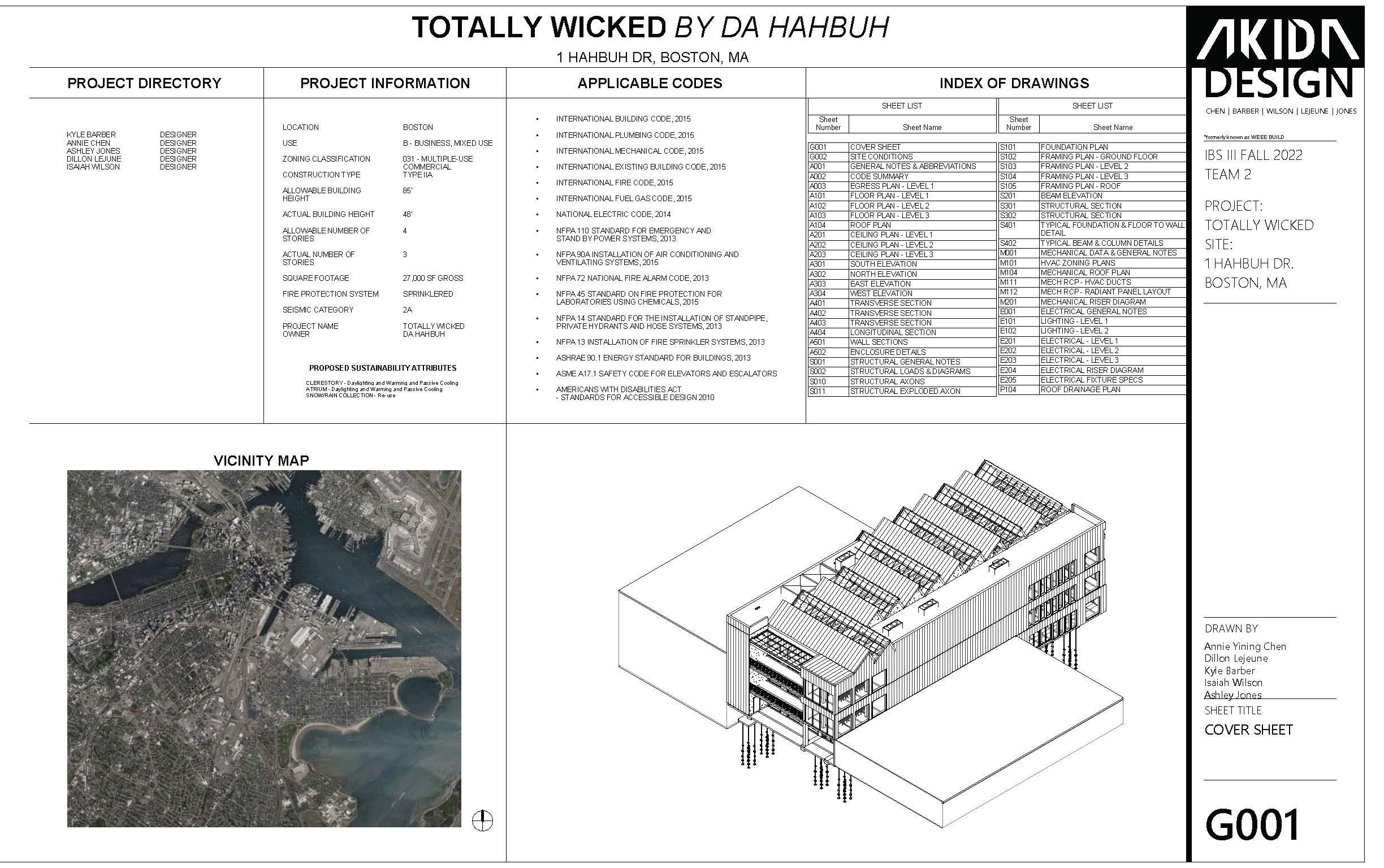

BUZZ STATION

by ychen5

Bus Stop On Georgia Tech Campus

Course: Construction Technology I

Advertisement

Instructor: Charles Rudolph

Fall 2020

Initial Idea

The project aims to provide shelter, seating, and social distancing (to prevent COVID-19) for waiting for passengers on the campus of Georgia Tech. BUZZ, the school mascot, inspires the shape of a beehive/ hexagon. The hexagon develops into an octahedral space and other three-dimensional spaces which connect to it on edge. Each room is segregated from one another.

BASIC IDEA- BOOT ROTATION

The boot rotation is the primary motif and key to initiating the design. In other words, this gesture highlights the central axis— the inclination of the structure. During the design progress, the designers put on the holo lenses, rotated the boots, and synchronized the rotation on the laptop. Afterward, the boots are fixed at an angle, and designers can explore different connections between the nodes.

Experiential Intimacy

A Play With Vr By Hololens

Simultaneous Manufacture

Course: Advanced Production

Instructor: Keith Kaseman, William S. Reynolds

Location: 723 CherrySt NW, Atlanta, GA

Team: Yining Chen, Moath Rabahbah, Jiayong Lu, Sophie Myers, Bhoomika Taneja

Responsibility: Hololens Design Progress+ Manufacture

Spring 2022

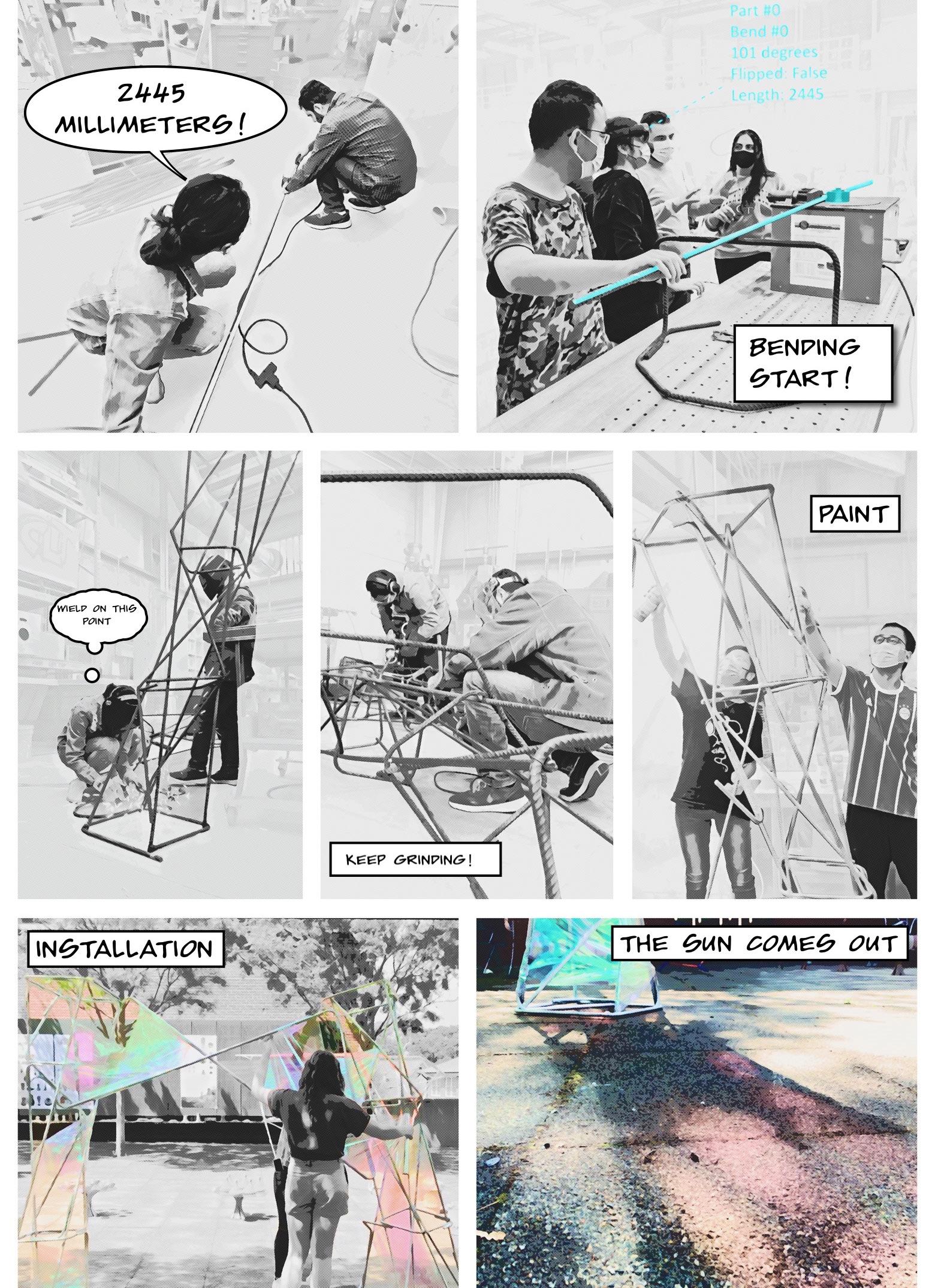

DESIGN PROCESS- DIGITAL FABRICATION

The project aims to integrate various design tools, including laptops, holo lenses, and boots. These three main incentives determine the configuration of the project. The design process demands several team members operate simultaneously. The holo lenses need to be connected to the grasshopper script on the laptop and the QR Code from the boots, so they can accurately capture the hand gestures and locate the two structures and the nodes on them to initiate the design process.

HINMAN GATE- SUMMER

The silver rebar gate sits sturdily in the courtyard, with the breeze dabbing and birds chirping. The summer is hot, and the coldness of the color on the rebars and the holographic plastic sheets cools down the fever. The sheets are iridescent: they shine brightly, as the green cinnamon leaves shine under the sun. Everything is in crazy colors— the trees, the gate, the shadows, like a midsummer fantasy in the backyard.

The rapid advancement of urbanization and the dramatic rise of the urban population lead to a drastic increment in the output of municipal solid waste. The nation’s waste has exceeded 250 million tons, with an average annual compound growth rate of 2.1%. Therefore, the government tends to treat this garbage quickly and effectively to prevent the garbage siege phenomenon and severe air, water, and soil pollution.

As an industry representative, Liming Resources dedicates to reusing all accessible sources to protect the urban environment. Liming Resources officially launched the research on waste and nutrients in July 2019. Based on the systematic analysis of the nutrient composition, the researchers analyzed pollution characteristics of the biogas residue from the anaerobic fermentation of food waste in the region and the ability of partial biogas residue to be carbonized and used as a biochar base fertilizer. The agricultural safety of biogas residue and the effect of biochar and carbon-based fertilizer on improving the fertility of farmland soil were studied.

This collaborative project with Shanghai Liming Resources Recovery Co. Ltd focuses on recycling methods of constructive and domestic waste in Shanghai. Eventually, with the research data and documentaries of the research process, these dumped materials are reformed and reconstructed into an interesting, monumental, and natural lab for future experimentation on reproducing fertilizers from the residue of incinerated domestic waste.

Rebar Revival

Trash To Treasure

Course: Material Diversion

Instructor: Debora Mesa Molina

Location: Shanghai, China

Collaborator: Shanghai Liming Resources Reuse Co., Ltd. (Client)

Shanghai Jiading Jiaxi Blower Limited Company (Manufacturer)

Spring 2021

Due to an increment in urban reconstruction, the city will abandon more wasted constructive materials like rebars. The large-scale sculptural piece could be constructed on a riverbank or coast to celebrate the re-bloom of the material in our daily life. LED light tubes are attached to the framing. The recovered rebars accompany the city’s revival- both old and new materials are included and utilized. When night comes, the city is still wide awake. The lights on the rebar monument and the city lights twinkle in the darkness. With great lighting, the monument functions as a lighthouse gallery introducing the magic of recycling to the citizens. The lights are on from early morning to late night. The celebration of the old material on the water in the city is always on.

Field Trip and Material Hunting

This project involves field trips, resource gathering and selection, and industry collaboration. Visiting the Resource Company to browse the recycling progress and products could inspire the use of material, and understanding the industry’s ultimate goal could promote an ideal project built for this environmentally friendly space. The final selected material is a colossal rebar piece disassembled from a vast machine- it primarily functioned as a filter that sorts the waste.

Material Gathering and Transportation Oxyacetylene Rebar Cutting on Site

After several design experimentations, including sketching and modeling, the pieces are cut into designated sizes on-site for the intended design and more accessible transportation. Two process gasses, Oxygen (O2) and Acetylene (C2H2), were mixed in the oxygen-acetylene torch. Separate compressed gas cylinders stored both gases. The gases were mixed at the correct proportions and ignited. Gas valves on the torch were adjusted precisely to the volume flow of the gasses. With the help of an additional oxygen blast trigger, the nozzle released extra oxygen. The supplemental O2 reacted with the metal to produce iron oxide and process heat, which is essential for the cutting process.

Shapes+ Body Exploration

This process tests a series of explorations of the shape and accessibility of furniture. Use sizes to categorize the sitting prototypes: Small, Medium, Large, and Extra Large. After a bunch of installation and testing with the body, decide on prototypes to use in the final design.

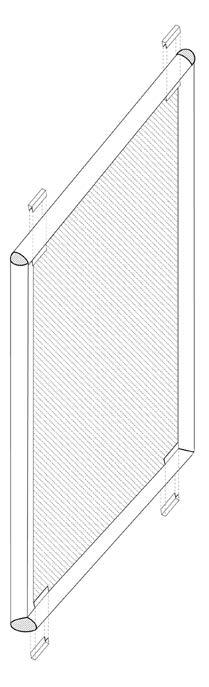

Framing + Facializing

Installation- Wielding

On-site Installation

A. Progress of Rebar Meshes Welding to the Rebar Frame (Electrowelding)

Lay the piece flatly on the ground due to safety concerns. The progress produces many sparks and flames, so gloves and goggles are required.

B. Steel Slots Welding & Installation of Acrylic Panels (Gas Shielded Welding) Mosiac the acrylic panels to the welded frames while the piece stands straight up. Use a ladder during the installation of the components at higher levels.

After the pergola is complete, it is transported back to the Liming Resources as an educational, artistic piece. This project’s construction could happen in different places. Designers could transform it into a public gallery in the city center or make it into a monumental structure in the suburban area, an evidence representing human intrusion into nature in this prosperous industrialized era.