8 minute read

Internet of Things

Implement IIoT projects faster with ready-to-confi gure machine edge solutions

Silvia Gonzalez and Nishita Palkar • Emerson

OEMs and systems integrators are fi nding that they can speed development and reduce risk for edge computing, visualization, analytics, and IIoT project solutions by selecting fi t-for-purpose hardware and so ware combinations.

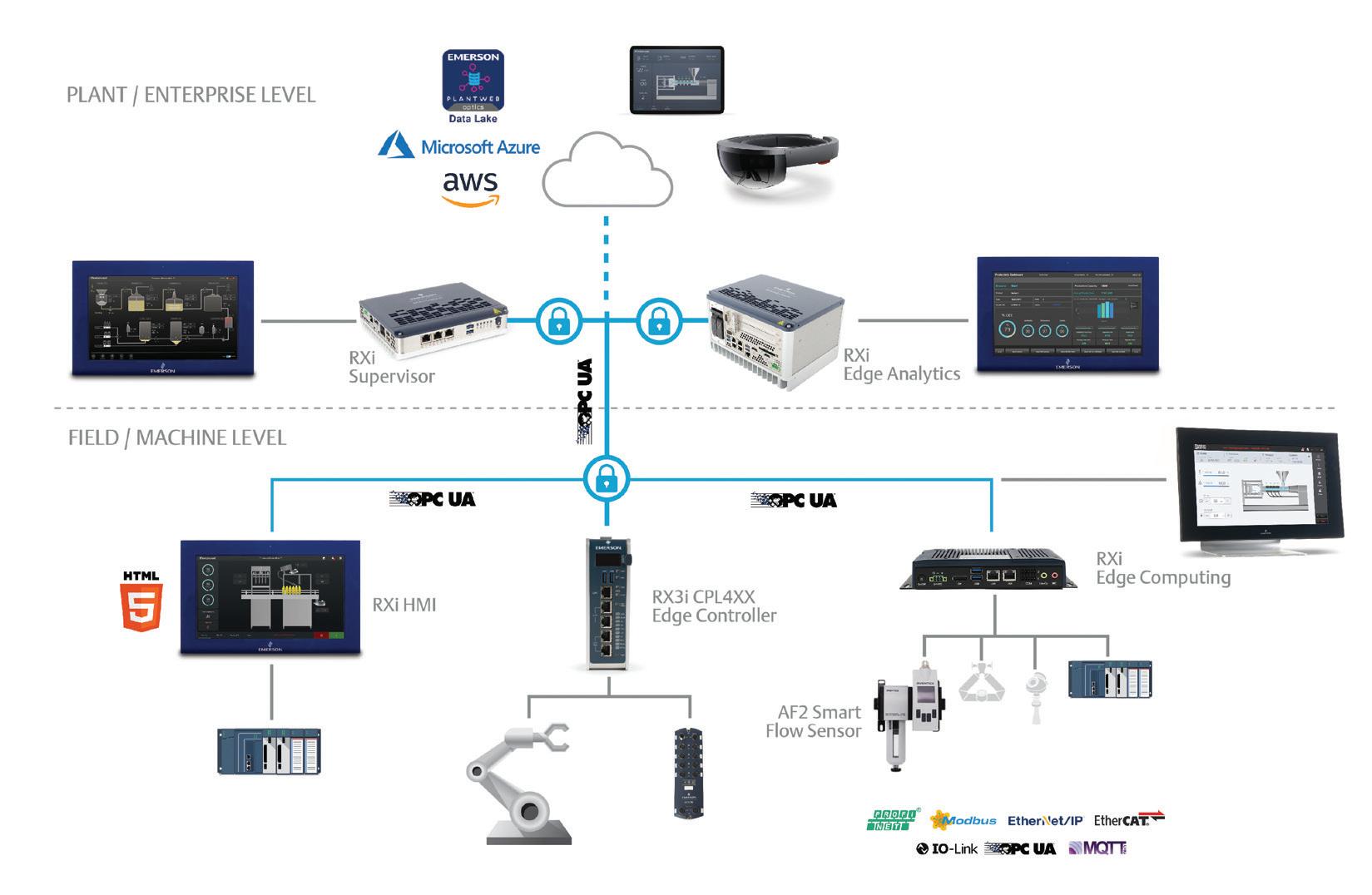

Figure 1: Edge solutions for IIoT projects, such as those from Emerson, help developers streamline the selection and implementation e ort and reduce risk. | Figures all courtesy of Emerson

Designers of automated machinery and systems must truly

be multi-discipline masters to combine mechanical, electrical, and automation elements into a comprehensive whole. The degree of complexity is only increasing as end users and OEMs demand more data and analytics om their systems. Seamless access to edgesourced data used to support analytics is necessary to develop insights for improving operational performance while enabling broader business possibilities, such as enhanced support and machine-as-aservice. These capabilities rely on eff ective edge solutions, which are combinations of hardware and so ware providing connectivity and computing for fi eld-located assets. Some larger organizations employ dedicated staff to handle the specialized aspects of automation engineering, but many companies must outsource the eff ort to systems integration (SI) fi rms. With so many interrelated details involved with choosing the right automation hardware, so ware, and networking, implementers of all types could use a way of streamlining the design process. Some product vendors have recognized this need and off er ready-to-confi gure combinations of hardware and so ware to fulfi ll various edge computing, visualization, analytics, and industrial internet of things (IIoT) roles. These proven and optimized solutions signifi cantly reduce the complexity of selecting, confi guring, and supporting automation and IIoT solutions om diff erent sources. This allows developers to focus their eff orts more on creating

valuable applications and less on integrating various sub-components.

Edge solution challenges An ideal edge solution delivers substantial benefi ts and practical value to users at various levels: • Visibility: A clear portrayal of automation system status is applicable to operators on the factory fl oor, in the control room, and working remotely, as well as ont o ce personnel. • Actionable information: Comprehensive analytics are important to higher-level personnel, engineering, and maintenance to optimize production, improve quality, expand sustainability, minimize waste, and boost uptime. • Ease of use: Simple yet scalable edge solutions help designers and engineers e ciently create interoperable designs, which are convenient for users to work with and readily maintainable over the long haul.

Industrial automation and data handling projects typically require some arrangement of PLC and other edge controllers, HMIs, PC computing, networking, HMI/SCADA so ware, analytics so ware, and—now more commonly—cloud computing. It is becoming common to incorporate edge solutions into new designs, but it is equally important to select technologies that can be retrofi tted into existing and legacy applications. For new and retrofi t edge solutions, designers and engineers sometimes use an approach of selecting many makes and models of hardware and so ware so they can openly connect to all sorts of edge data sources. However, there are technical and fi nancial problems associated with these highly customized integration eff orts, o en leading to increased risk and project duration (Figure 1). Users would rather focus their eff orts on solving problems like improving reliability, equipment health, performance, and e ciency, rather than worrying if edge computing hardware and so ware will work together. Some typical concerns are: • How much eff ort and time will it take to choose a range of hardware and so ware? • Is the hardware suitable and reliable for always-on industrial service? • Are the various so ware packages compatible and do they interact securely? • Are enough standard protocols available for connecting with the entire ecosystem? • Does the selected hardware off er su cient computing performance? • Is the solution su ciently scalable, without being overly specifi ed? • What happens if a user gets far into procurement/development and fi nds an incompatibility? • What is the commercial impact of ordering om many suppliers? • What are the long-term support costs?

Internet of Things

Obviously, many issues must be addressed when speci ing an edge solution before the confi guration work can even begin. Therefore, it can be advantageous to build edge solutions on proven combinations of fi t-for-purpose hardware and so ware.

Integrated solutions address issues Even for developers with signifi cant automation experience, it is a di cult task to select and validate compatibility with the variety of hardware and so ware products needed to build an edge solution. Many of these implementers fi nd ready-to-confi gure hardware and so ware combinations— off ered by a single vendor with deep industrial experience—are the best way to address platform selection concerns, and can proceed into development rapidly. There are many benefi ts to selecting platform hardware/so ware combinations for creating edge application solutions: • Operators gain increased visibility because a comprehensive platform provides options for local, mobile, control room, and cloud HMI functionality. • Actionable information is enabled with on-site edge processors and/ or cloud-based computing to deliver analytics. • Developers and maintainers fi nd improved ease of use because they only need training on one set of tools and capabilities to deploy a solution with IIoT, local HMI, and plant analytics. • Engineering is simplifi ed because the eff ort associated with research, testing compatibility, and interoperability has already been performed, initially and for fi rmware/so ware upgrades. • Overall project execution time, and therefore time-to-market, is reduced, because developers can focus on the project, and not compatibility issues. • Users build a productive relationship with one vendor, beginning with selection and ordering, through development, and into support. • Pre-installed so ware, with activation and licensing om one supplier, is more straightforward to implement and support. • The overall cost/benefi t is typically favorable for choosing a fi t-for-purpose tailored edge solution, as compared with a mix-and-match endeavor.

For the ready-to-confi gure approach to be eff ective, there must be enough options to cover common use cases, as described below.

Tailored solutions for real-world cases Edge solutions are necessary to fulfi ll many roles, and sometimes more than one role at a time. They typically involve hardware more capable than a standard PLC, but o en do not need IT-grade computing. In most cases, an edge controller—a deterministic PLC that

Figure 2: Emerson o ers edge

solutions in combinations to address typical automation and data processing roles for visualization, edge computing, edge control, supervisory, and analytical.

| Figures all courtesy of Emerson

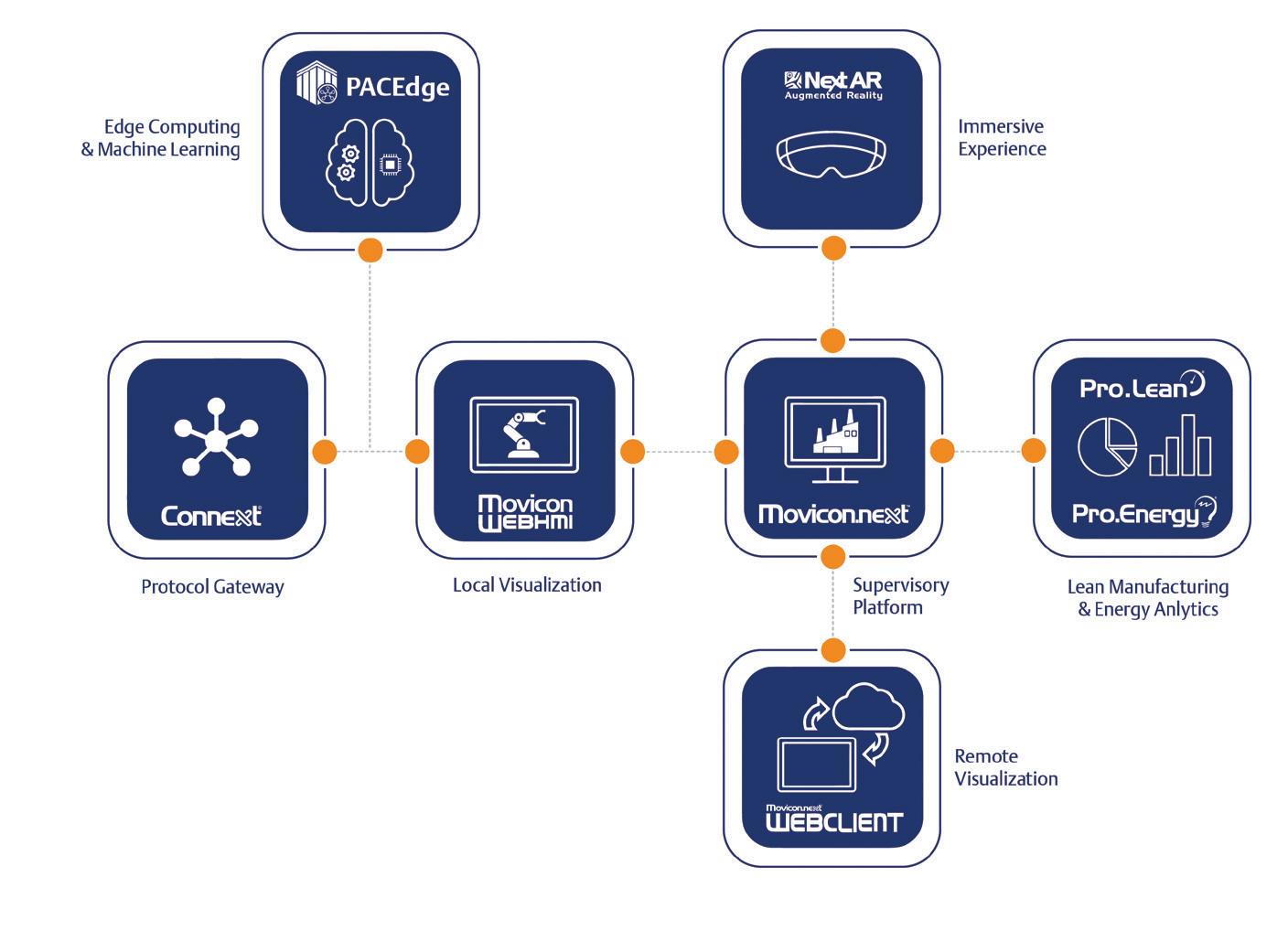

also includes general-purpose Linux computing—or an industrial PC (IPC) are the hardware platforms of choice (Figure 2). A range of connectivity, visualization, and analytical so ware needs to run on this hardware (Figure 3).

Following are fi ve of the most typical edge solution roles: • Visualization: Improving visibility into machine operation and performance, and empowering operators with quick access to critical information. • Edge Computing: Harnessing data om any source and using machine learning to create real-time insights immediately accessible to operators. • Edge Control: Combining deterministic (PLC), non-deterministic (Linux), and visualization capabilities in a single device for real-time process optimization. • Supervisory: Simpli ing access and visibility to plant-wide analytics and performance om a single, integrated platform. • Analytical: Creating comprehensive views of plant operations, performance, and overall equipment eff ectiveness.

Here’s how one OEM used a ready-toconfi gure edge solution to add valuable edge computing capabilities to their equipment.

OEM adds edge-based asset health option End users everywhere have become aware of the ways that digital transformation and intelligent automation can improve production, reliability, quality, and sustainability. OEMs are taking heed and developing or updating their equipment to support key performance indicators (KPIs) necessary for improving uptime and increasing e ciency. One consumer packaged goods machine OEM had already successfully automated their equipment with a PLC, HMI, AC drives, pneumatics, and I/O sensors. Building analytics into the existing PLC and HMI would take signifi cant work. However, by speci ing an analytical edge solution consisting of an IPC and ready-to-confi gure so ware, it was possible to add a complete asset health monitoring suite to the equipment as an option, without impacting the underlying real-time control functions. This platform makes it easy to monitor the PLC-derived calculations, drives, pneumatics, and IO-Link sensors. Data are stored in a historian and made available for trending and analysis. Information is available for the overall asset, for subsystems, and for individual components. The OEM benefi ted om improved equipment visibility, remote access, a wide range of dashboards indicating KPIs, and alert notifi cation early warnings for component life cycles and failures. Access via any device capable of hosting a web browser—such as a laptop, smartphone, or tablet— ensures information can be viewed by credentialed users, wherever they are at any time. By developing on a ready-toconfi gure solution, the OEM preserved their investment in existing automation and was able to quickly deliver a requested and valuable option for their customers. Ready-to-confi gure combinations streamline edge solution deployment Industrial automation hardware and so ware has progressed rapidly over the years. The newest ontier is providing edge solutions that can connect with, analyze, and visualize fi eld-sourced data. While some of this functionality is possible with traditional technologies or custom-assembled hardware/so ware, there is a better way. Ready-to-confi gure combinations of proven industrial hardware and so ware provide fi t-for-purpose options for quickly establishing edge computing platforms. These pre-engineered combinations let developers focus their eff orts on developing innovative edge solutions, while minimizing the time and risk typically associated with these types of projects. End users, and their OEMs and SIs, are fi nding that using edge solution platforms is the best way to implement IIoT projects adding immediate value and capabilities to their systems. DW

Figure 3: Edge solution hardware generally consists of edge controllers

or industrial PCs, running pre-tested interoperable combinations of connectivity, visualization, and analytical so ware.

| Figures all courtesy of Emerson