16 minute read

Chapter Six During a Time of Crisis

CHAPTER

Six

Advertisement

The AGC, the construction industry, and the entire nation are grateful for your efforts due to the events of September 11.

Inscription on a Weeks Marine award

RECEIVED FROM THE ASSOCIATED GENERAL CONTRACTORS FOR ITS EFFORTS FOLLOWING THE SEPTEMBER 11 TRAGEDY

During a Time of Crisis

The tragic events of September 11, 2001, forever changed the landscape of New York City and had a deep impact on every American. Weeks Marine was at Ground Zero within 24 hours after the first plane hit the World Trade Center to support the cleanup effort in any way necessary: navigating a way for the US Army Corps of Engineers to approach the area, setting up a pier and barges, and ferrying steel and other materials out of the site. Weeks even ferried people out of Manhattan using its tugboats.

Within the first 75 days after the tragedy, Weeks loaded almost 350,000 tons of steel and debris from the World Trade Center site onto 25,000 trucks and 400 barge loads to be hauled away from downtown Manhattan. By

January 2002, the company still had three barge-loading facilities in operation at the site, with additional Weeks tugs being used to pull other barges to and from piers and recycling/landfill facilities.

The twin towers of Manhattan’s World Trade Center had been a prominent feature in views such as this one of the Statue of Liberty . The World Trade Center collapsed following the September 11 terrorist attacks on the structure . Surrounding buildings were heavily damaged by the debris and massive force of the falling twin towers . Cleanup efforts were expected to continue

for months . (U.S. Navy photo by Chief Photographer’s Mate Eric J. Tilford. (Released))

Left to right: Richard N . Weeks; Dave Vosseller, Construction Division; and Richard S . Weeks at the World Trade Center site .

For its work at the site, Weeks was recognized at the annual Admiral of the Ocean Sea Awards Dinner on November 9, 2001. The inscription on the award read, “To the crew and management of Weeks Marine in honor of the men and women of the waterborne companies and agencies in the Port of New York/New Jersey, who, on September 11, 2001, at risk to their own lives, repeatedly sailed into harm’s way to evacuate and provide transportation for the survivors of the terrorist attacks on the World Trade Center.”

Working 24/7

Before long following the 9/11 tragedy, Weeks had 63 employees on-site at Ground Zero, working in 24-hour shifts. The assignment materialized quickly after the tragedy occurred, because CEO Richard S. Weeks asked the Hudson River Park Trust whether its pier site could be dredged to make room for a staging area to help with the effort. Once the trust agreed, Weeks got to work. John Devlin, who started at Weeks in 1985 and retired in 2018, remembered how Weeks was able to play such a large role in the cleanup efforts:

They wouldn’t have gotten that job done as fast or as well as they did if it wasn’t for Weeks Marine. I went over on a boat the morning after the collapse and squirreled my way into a meeting and immediately just started meeting people and talking to people and hit the right people, had the right ideas.

2001

Weeks completes a job for the US Army Corps of Engineers Baltimore District to perform maintenance and dredging of 4.6 million cubic yards of material from the Baltimore Harbor inner channels and anchorages.

2001

Weeks begins a project dredging 232,000 cubic yards in the Potomac River to facilitate the creation of construction access for a crew working to replace the Woodrow Wilson Bridge, which connects Maryland to Virginia.

2001

Weeks is awarded a $1 million project by the New York City Economic Development Corporation to make improvements to the Wall Street Ferry Pier.

2001

Weeks wins a $13.8 million bid to rebuild several piers at Hudson River Park in New York, which requires the firm to build 130,000 square feet of recreational piers.

We had the right equipment. We had the availability. We came up with the idea of selling the scrap rather than just throwing it out in the ocean, which made millions in payback. Just the fact that we had all the equipment for everything they needed done for, you know, almost a year, we were there. They had no place for us to get into, so the first thing we did was have a dredge come in and just dig the bottom out ASAP. And I mean it was like the Corps of Engineers was behind us. We did this in record time, dug out a berth for ourselves. We came in with the 524, set it up. We set up a landing area. Set up the pier, set up barges, because we had a flock of barges that we used. We wound up using the sanitation barges also from the city.

Because the roads around the site were closed, Weeks was in a unique position to ferry the steel away from the site because it had access to a vast array of marine equipment. If an extra barge was needed as part of the effort, Weeks would bring one in, with its tugboats hauling the equipment onto the site. Weeks also coordinated with interested parties to sell the steel that it recovered from the site on behalf of the Port Authority of New York and New Jersey, so multiple parties were involved in the multifaceted job.

Because all parties were united in their efforts to contribute in any way possible, there were resources aplenty and everyone worked cohesively to meet the same end goal. “Anything you wanted and needed, it was there, and it was go, do what you have to do and get it done—let’s move,” said

2001

Weeks is awarded the job of installing a deep seawater pipeline in Hawaii.

2001

On September 11, two commercial airliners are intentionally flown into the buildings of the World Trade Center, reducing the Twin Towers to rubble and leading to the deaths of more than 2,700 people. A third plane is flown into the Pentagon and a fourth plane is diverted from its intended target and flown into a field in Shanksville, Pennsylvania.

2001

The next day, Weeks is on site at Ground Zero, helping to create a central site for the removal of steel and debris.

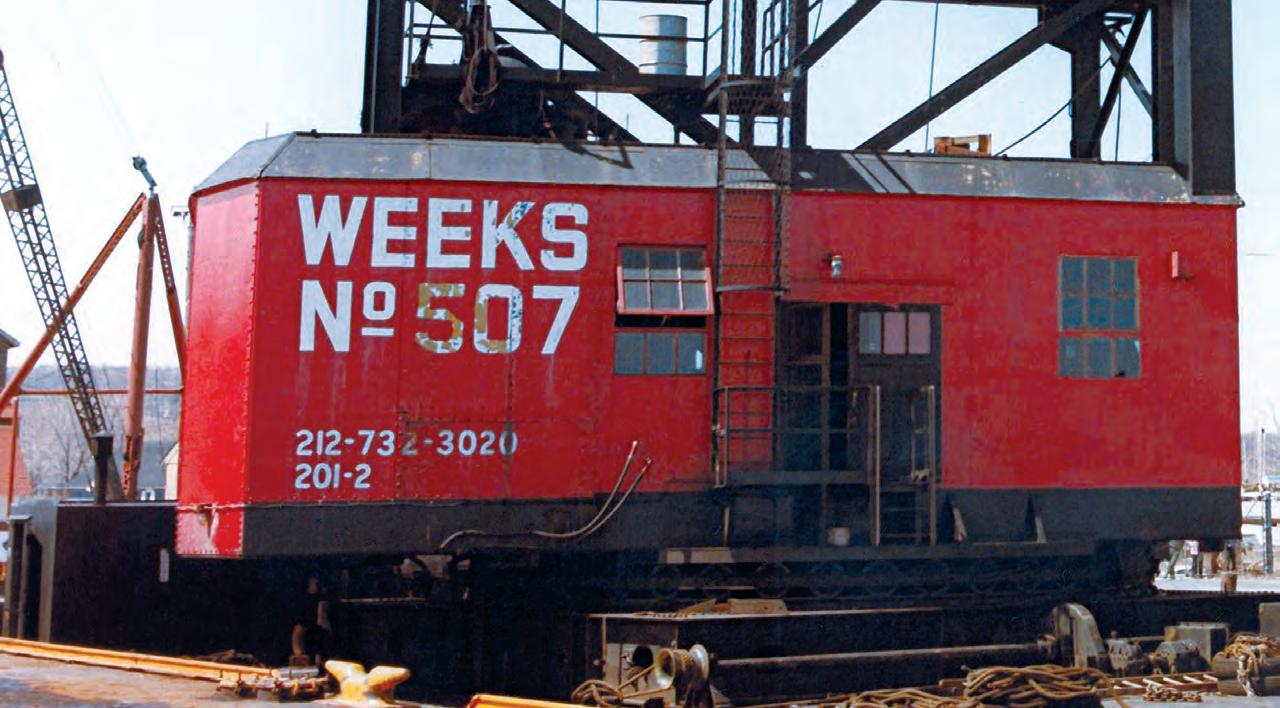

The Weeks 504 crane at Pier 6 removing steel trucked in from the demolished World Trade Center .

2001

In November, Weeks is recognized for its post-9/11 work at the annual Admiral of the Ocean Sea Awards Dinner.

The WMI Journal announces Healy Tibbitts’ world record-setting pipeline installation . Joe Patella, general manager of yards and equipment, who joined the company in 1987.

Major Projects

In addition to Weeks’ landmark work at the World Trade Center site, the company completed several other major projects during the early aughts, including Puerto Rico’s Carraizo Reservoir in 2001 and Hawaii’s Fort Kamehameha Sewer Outfall Extension in 2003. Weeks also performed work on a deep seawater pipeline in Hawaii in 2001. The deep seawater pipeline project was a “unique, one-of-a-kind, deep water intake pipeline for the National Energy Laboratory of Hawaii,” said Rick Heltzel, president of Healy Tibbitts. Weeks bid the job in early May 2001 and was awarded the contract by the end of the month. The project required the company to have the pipeline installed by October 31, 2001. “We had a little over five months to do something that nobody had ever even tried to do before,” Heltzel said. The project involved the installation of a 55-inch diameter, high-density polyethylene pipe that was 9,000 feet long in depths of water ranging between 85 and 3,000 feet. Because Weeks had a limited amount of space where it could work, the team broke the 9,000-foot pipe into nine

2001

Weeks earns a world record for Healy Tibbitts’ work installing the deepest 55-inch-diameter highdensity polyethylene pipeline.

2002

In January, Weeks still has three barge-loading facilities in operation at Ground Zero to help with the cleanup effort from the September 11 tragedy.

2002

Weeks completes the Coke and Sulfur Export Terminal for Sincor in Jose, Venezuela.

2002

The Associated General Contractors honors Weeks for its efforts on September 11.

MAINTAINING EQUIPMENT

Equipment is one of the keys to Weeks Marine’s success, and ensuring that its machinery was up-to-date and well maintained has always allowed the company to have an advantage when bidding on large jobs . Richard N . Weeks, now the company’s chairman, had a knack for evaluating machinery and getting a good deal, said CEO Richard S . Weeks . “We bought a lot of equipment that we didn’t need to support our business, but we bought it, I guess you could say, speculatively . Sometimes good, sometimes not so good . Nobody bats a thousand,” he said .

Because Weeks had a wide range of equipment on hand, the company was able to secure large projects as a result of it having a wealth of resources and capabilities that its competitors did not have .

pieces that were each 1,000 feet in length, but could be connected with flanges. “We had to join those nine strings of pipe to form one, 9,000-footlong pipe length, and that was a big operation, 24 hours a day for about three days,” Heltzel said. “We had to keep tension on the offshore end, and as you can imagine, with pipe growing to 9,000 feet—well, that’s a small harbor, so, eventually, the tail was in the harbor, and you had 7,000 feet out in the open ocean.”

Weeks towed the pipeline 25 miles down the coast while keeping a close eye on the weather, since plastic pipe is heat sensitive and can weaken in warm temperatures. The specifications of the project required Weeks to flood the pipe and lower it to the bottom of the seafloor after the sun set so the pipe could cool down appropriately. After one false start when the company was unable to initially place the pipe, a second attempt proved successful, and Weeks completed the job within the required five-month period.

2002

Weeks begins placing stone on the US Army Corps of Engineers South Jetty Rehabilitation in Ocean City, Maryland.

2002

Weeks pitches in when a power line running under Long Island Sound malfunctions, assisting Con Edison as it works to bring the power lines back up.

2002

Weeks’ tugboat Carolyn, originally built in 1968, undergoes a repair and rejuvenation plan and is brought back into operation.

Pipe installation in progress .

2003

Healy Tibbitts’ work at Pearl Harbor on the Fort Kamehameha Outfall project sets a world record for microtunneling.

Weeks cranes at work on New York City’s FDR Drive.

Above: Dock construction for a coke sulfur export facility in Jose, Anzoátegui, Venezuela .

Below: Healy Tibbitts pile driving on the site of the Kewalo Basin Harbor in Honolulu, Hawaii .

In January 2001, the company began a project dredging 232,000 cubic yards in the Potomac River to facilitate the creation of construction access for a crew that was working to replace the Woodrow Wilson Bridge, which connects Maryland to Virginia. The following month, Weeks was awarded a $1 million project by the New York City Economic Development Corporation to make improvements to the Wall Street Ferry Pier. Just a few weeks after that, Weeks won a $13.8 million bid to rebuild several piers at Hudson River Park in New York, which required the firm to build 130,000 square feet of recreational piers. Work was coming in quickly, but Weeks was able to supply the right pieces of equipment and assign the right staff members to perform each job to specifications.

International Recognition

Weeks’ work in the aftermath of September 11 brought the firm international recognition. “The day they brought the last piece out of the pit, I was in Ireland,” said John Devlin. “I walked into a little coffee shop and the newspaper had a picture of that piece coming out, and there was a Weeks flag there.”

At about the same time, Weeks gained international attention after putting in a seven-day-weekly schedule to complete a project on the Coke and Sulfur Export Terminal for Sincor in Jose, Venezuela. The company worked on the foundations to support the ship loaders in March 2002, driving piles

SIGNIFICANT PROJECTS

Healy Tibbitts’ work on the island of Oahu, Hawaii, at Pearl Harbor on the Fort Kamehameha Outfall project set a world record for microtunneling in 2003 . “The project has successfully installed two microtunneled drives of concrete pipe, each 58-inch diameter by 1,300 lf,” Weeks Marine wrote in May 2003 .

“One of the most unique features was that the complete length of each drive was below the ocean surface . This required the installation of a jacking pit cofferdam located over one mile offshore in a shallow reef area exposed to the open ocean waves,” the company said .

To complete the project, Weeks used 50-foot sheet piles driven to a -38-foot tip elevation to install the cofferdam . The tops of the sheets remained at +12 feet in elevation to prevent wave action from overtopping the cofferdam .

Prior to its 2003 world record, in 2001, Healy Tibbitts set a world record when the company installed the deepest 55-inch-diameter high-density polyethylene pipeline . At 9,000 feet in length, the pipeline was installed at a depth of 3,000 feet in a single piece at Keahole Point, Hawaii .

The project had the goal of providing clean deep ocean water to businesses nearby . “What makes this project incredible is the fact that the contract was only awarded to Healy in mid-May of this year,” Weeks said in October . “In that five-month time span, an enormous effort went into engineering and executing this one-of-akind pipeline .

NIMBLE DURING EMERGENCIES

Weeks Marine’s quick reaction to the September 11 emergency was indicative of the way the company was able to step in quickly to assist during times of need . In one situation, Weeks pitched in when a power line running under Long Island Sound malfunctioned on May 22, 2002 . By 8:00 the next morning, the Weeks 566 was in position, loading construction equipment to transport to the site of the problem .

Over the course of the next few days, Weeks brought in its 541 and 520 equipment, as well as two tugs, to support Con Edison as it worked to bring the power lines back up . Weeks also created temporary landing areas at the site that allowed the Con Ed staffers to work more effectively . The job was completed by June 29, 2002, ahead of schedule . “One of the unique aspects of Weeks is, we are so flexible, we are so nimble, that projects or circumstances that other companies can’t respond to because they are maybe too bureaucratic or decisions take too long to be made,” said Patrick Whelan, former executive vice president and general counsel, who joined Weeks in 2012 . “We can be anywhere on moment’s notice . We pride ourselves on being responsive 24 hours a day, seven days a week . Our projects don’t stop on Christmas Day or New Year’s Day or Thanksgiving Day . We work, and that creates a culture where we’re responsive to anyone, anytime, anywhere .

In 2002, Weeks was booked for a project rehabilitating the bridge on FDR Drive in Manhattan.

using the Weeks 750 jack-up barge and setting large precast concrete units weighing up to 250 tons using the Weeks 526. Weeks completed the project in May 2002, and demobilized its equipment out of the area and directly to Aruba, where the company was working to rehabilitate reef berths one and two for Coastal’s refinery.

Weeks completed the first phase of its $8.5 million project rehabilitating Aruba’s Reefs in just two months and then moved on to the second phase in the summer. Working amid nine-foot waves in an unusually rough seascape, Weeks was able to drive new piles into the sea, remove and install loading arms, and move significant amounts of cargo into the area via barge. “During rough seas, it was at times necessary to ‘double-handle’ materials from the [narrow access] trestle to the Weeks 750 and then to the Weeks 526,” the company said.

Above: At Iroquois Point Beach, Weeks was awarded a project that tasked the company with armoring a below-sea level pipeline with stone .

(Photo by Ed Gross/The Image Group (tighawaii.com).)

Opposite: Aerial view of Iroquois Point, Hawaii .

(Photo by Ed Gross/The Image Group (tighawaii.com).)

Entering Drilled Shaft Work

In 2002, Weeks partnered with another firm and subcontractor to enter the drilled shaft work category in the marine industry, sparking a robust period of activity for the company. Rick MacDonald, retired head of Weeks’ construction division, recalled the firm’s burgeoning project roster during this time period:

I remember in 2002, early on, we booked the Iroquois pipeline, and that was largely armoring the pipeline with stone, and then FDR Drive over on the East Side of Manhattan. It was a rehab project, but we put a temporary bridge. It was a $60 million detour in the East River to put traffic on while we did the rehabilitation. And we did a joint venture with Skanska. That was

Weeks’ entrance into drilled shaft work on the water. We had done some drilled shaft work before, but not self-performed it. And so on this particular project, it was hard rock drilling, on the East River with five-knot currents, sloping 45-degree rock, 30,000 PSI rock, and trying to drill a straight hole on a rock slope. We did it successfully, and we did 64 of these big caissons, and that actually really enhanced our capabilities on a lot of other projects and gave us a real capability to bring to our joint venture partners. Not that we didn’t have others, but this foundation work is very risky, and our partners liked that we had a good understanding of it.

Weeks also racked up one particularly large job in Baltimore’s Inner Harbor, which the company completed on January 1, 2001. The US Army Corps of Engineers Baltimore District tapped Weeks to perform maintenance and dredging of 4.6 million cubic yards of material from the harbor’s inner channels and anchorages. The company used two of its large clamshell dredges with 26-cubic-yard buckets to dredge, then loaded the material into barges, which was later disposed of approximately 15 nautical miles from the dredge site.

For Weeks, the early 2000s marked not only an increase in the length and breadth of projects the company took on. It also proved exactly how well Weeks was able to operate in the midst of national tragedies. In the years to come, Weeks would step up to the challenge in the face of two more national tragedies, in the aftermaths of Hurricanes Katrina and Sandy.

Above: In 2002, Weeks booked this project rehabilitating the bridge on FDR Drive in Manhattan .

Opposite: A Weeks crane performing dredging work on Iroquois Point Beach in Hawaii .