BAKERY, GRAINS & CEREALS

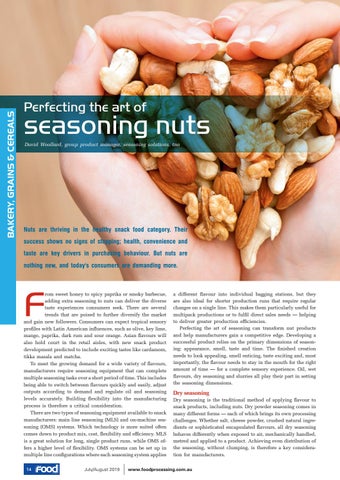

Perfecting the art of

seasoning nuts David Woollard, group product manager, seasoning solutions, tna

Nuts are thriving in the healthy snack food category. Their success shows no signs of stopping; health, convenience and taste are key drivers in purchasing behaviour. But nuts are nothing new, and today's consumers are demanding more.

F

rom sweet honey to spicy paprika or smoky barbecue, adding extra seasoning to nuts can deliver the diverse taste experiences consumers seek. There are several trends that are poised to further diversify the market and gain new followers. Consumers can expect tropical sensory profiles with Latin American influences, such as olive, key lime, mango, paprika, dark rum and sour orange. Asian flavours will also hold court in the retail aisles, with new snack product development predicted to include exciting tastes like cardamom, tikka masala and matcha. To meet the growing demand for a wide variety of flavours, manufacturers require seasoning equipment that can complete multiple seasoning tasks over a short period of time. This includes being able to switch between flavours quickly and easily, adjust outputs according to demand and regulate oil and seasoning levels accurately. Building flexibility into the manufacturing process is therefore a critical consideration. There are two types of seasoning equipment available to snack manufacturers: main line seasoning (MLS) and on-machine seasoning (OMS) systems. Which technology is more suited often comes down to product mix, cost, flexibility and efficiency. MLS is a great solution for long, single product runs, while OMS offers a higher level of flexibility. OMS systems can be set up in multiple line configurations where each seasoning system applies 14

July/August 2019

a different flavour into individual bagging stations, but they are also ideal for shorter production runs that require regular changes on a single line. This makes them particularly useful for multipack productions or to fulfil direct sales needs — helping to deliver greater production efficiencies. Perfecting the art of seasoning can transform nut products and help manufacturers gain a competitive edge. Developing a successful product relies on the primary dimensions of seasoning: appearance, smell, taste and time. The finished creation needs to look appealing, smell enticing, taste exciting and, most importantly, the flavour needs to stay in the mouth for the right amount of time — for a complete sensory experience. Oil, wet flavours, dry seasoning and slurries all play their part in setting the seasoning dimensions.

Dry seasoning Dry seasoning is the traditional method of applying flavour to snack products, including nuts. Dry powder seasoning comes in many different forms — each of which brings its own processing challenges. Whether salt, cheese powder, crushed natural ingredients or sophisticated encapsulated flavours, all dry seasoning behaves differently when exposed to air, mechanically handled, metred and applied to a product. Achieving even distribution of the seasoning, without clumping, is therefore a key consideration for manufacturers.

www.foodprocessing.com.au