water@watermanaustralia.com

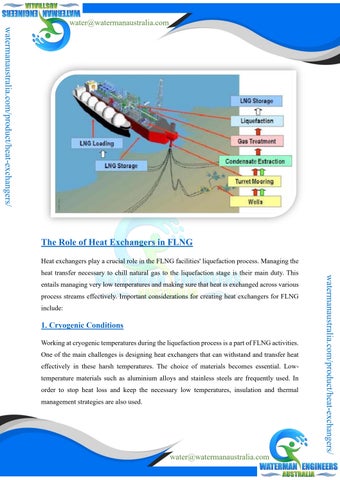

watermanaustralia.com/product/heat-exchangers/ The Role of Heat Exchangers in FLNG Heat exchangers play a crucial role in the FLNG facilities' liquefaction process. Managing the entails managing very low temperatures and making sure that heat is exchanged across various process streams effectively. Important considerations for creating heat exchangers for FLNG include:

1. Cryogenic Conditions Working at cryogenic temperatures during the liquefaction process is a part of FLNG activities. One of the main challenges is designing heat exchangers that can withstand and transfer heat effectively in these harsh temperatures. The choice of materials becomes essential. Lowtemperature materials such as aluminium alloys and stainless steels are frequently used. In order to stop heat loss and keep the necessary low temperatures, insulation and thermal management strategies are also used.

water@watermanaustralia.com

watermanaustralia.com/product/heat-exchangers/

heat transfer necessary to chill natural gas to the liquefaction stage is their main duty. This