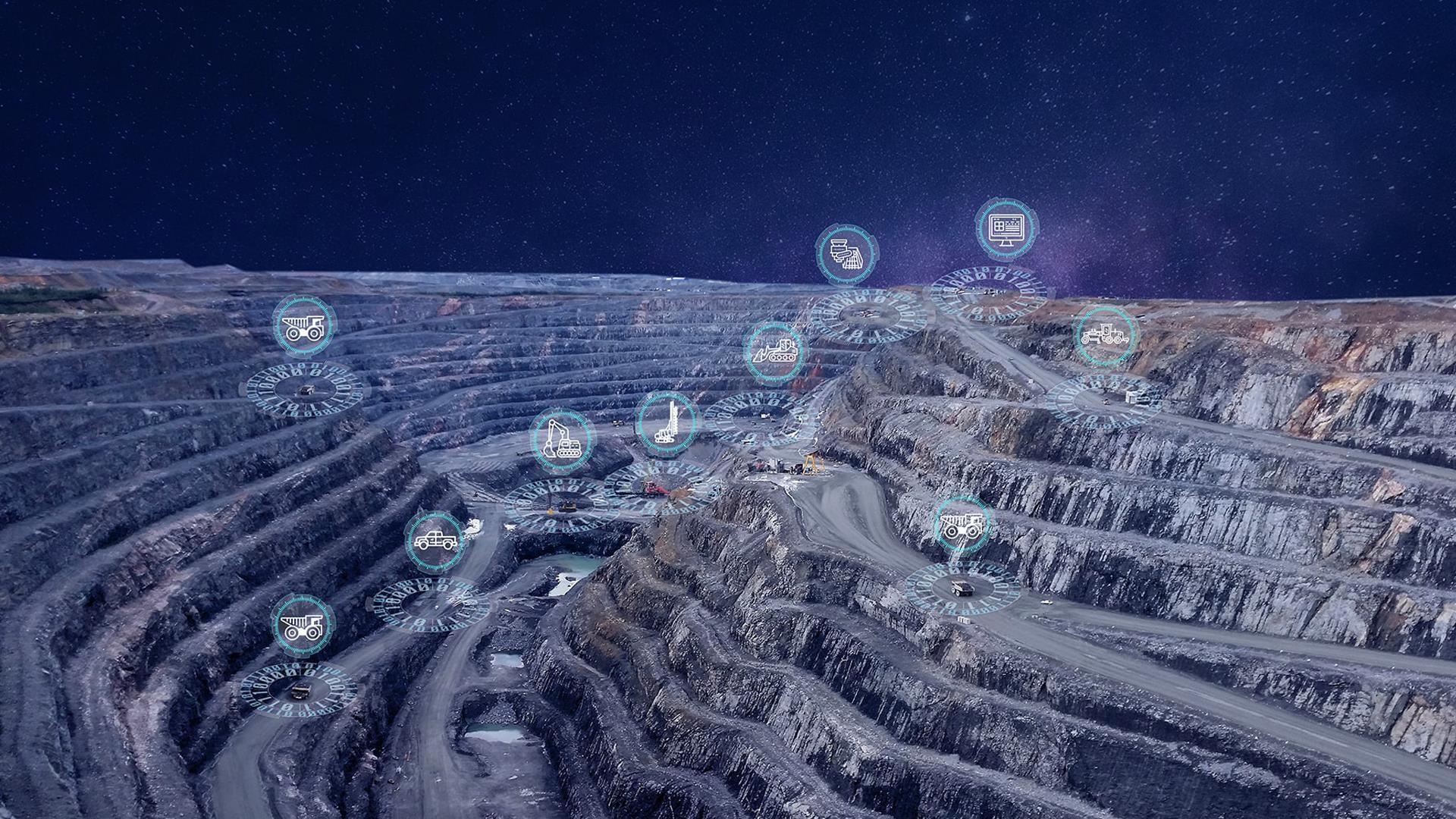

Fleet Management System

Wenco – part of Hitachi Construction Machinery

❖35 Years Fleet Management

❖Digital Mining Solutions

❖Leading Supplier of Heavy Mobile Equipment

❖Reliable Solutions

❖Solution Linkage

❖Focus on Interoperability

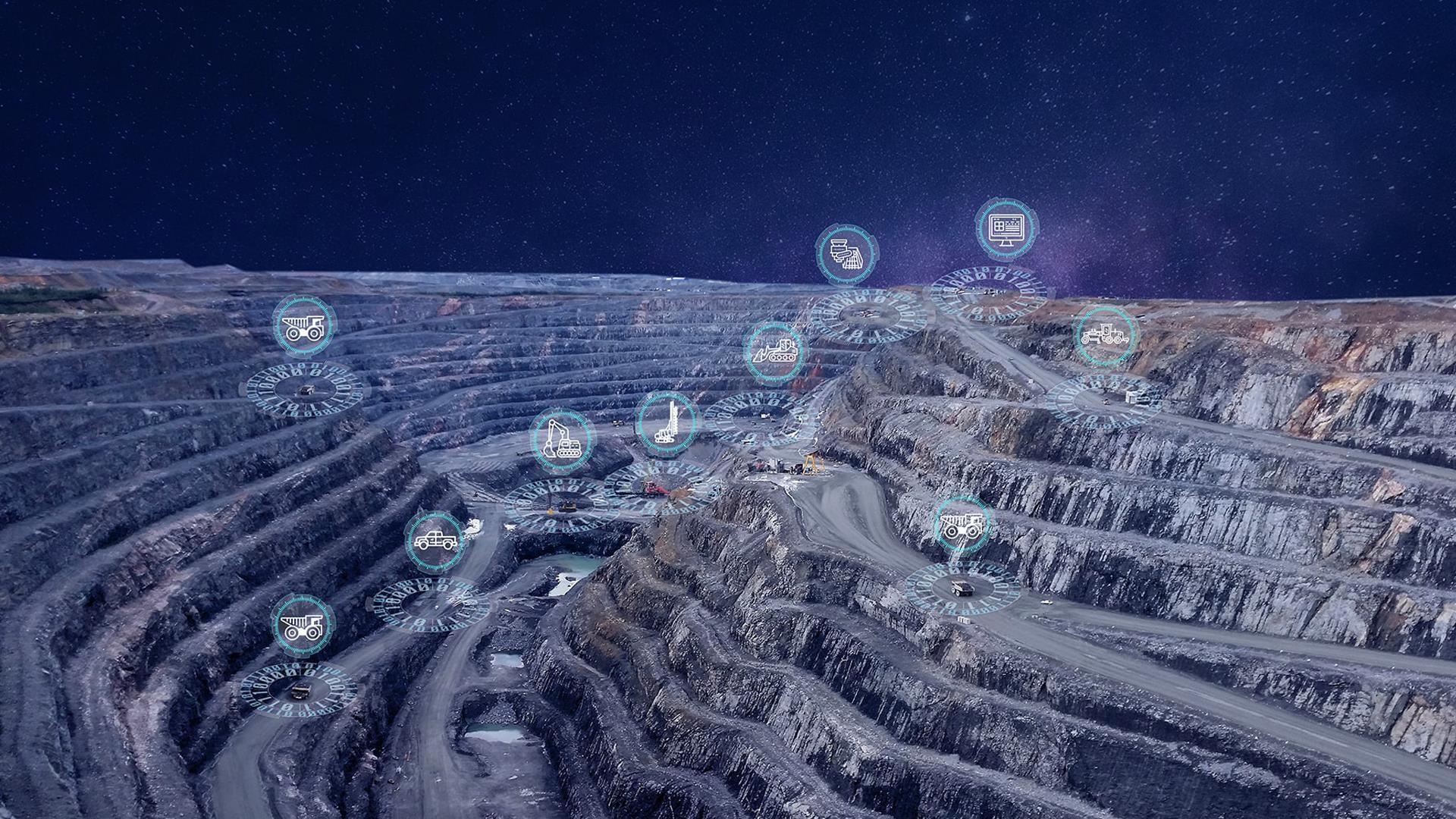

Mining and Construction

Safety Asset Health FMS and Dispatch Machine Guidance

Over 35 years' experience

FLEET MANAGEMENT SYSTEMS - Wenco Company Overview

Headquarters

Vancouver,Canada

Wenco Head Office

Wenco Russia

Sales and Service

Nietis

Hardware Depot

Wenco Services

Wenco USA

Sales and Service

Sedna Services Contractor

Established Sales and Services Offices on Continents

Wenco South America

Sales and Service

Additional Partner Sales and Services

Wenco

Kazakhstan

Sales

Wenco West Africa Service

TecWise Brazil Sales and Service

Vareli

Sales and Service

Hexindo

Sales and Service

OpenWorld Services Contractor

WencoAfrica

Sales and Service

WencoAustralia

Development, Logistics, Service

HCA

Sales and Service

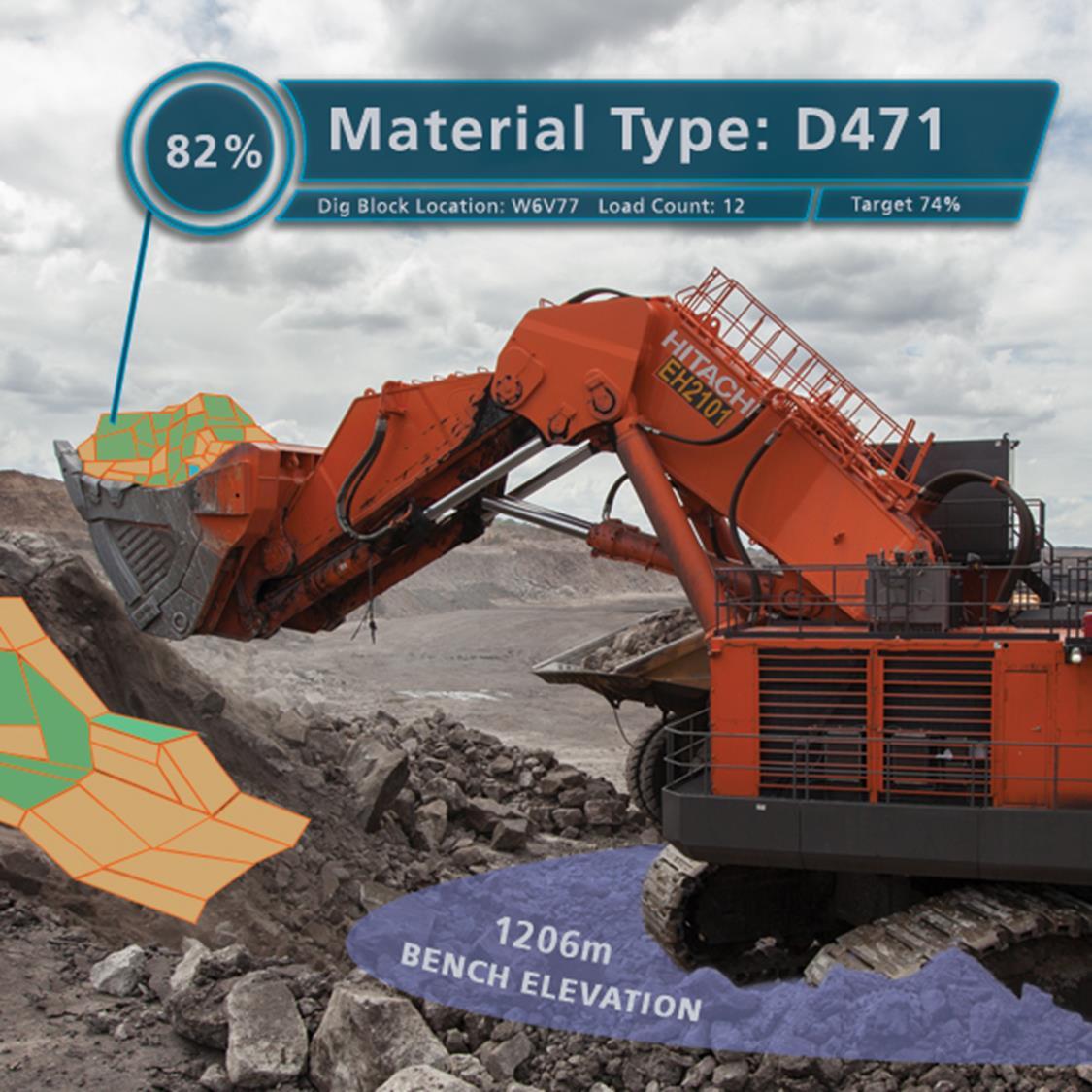

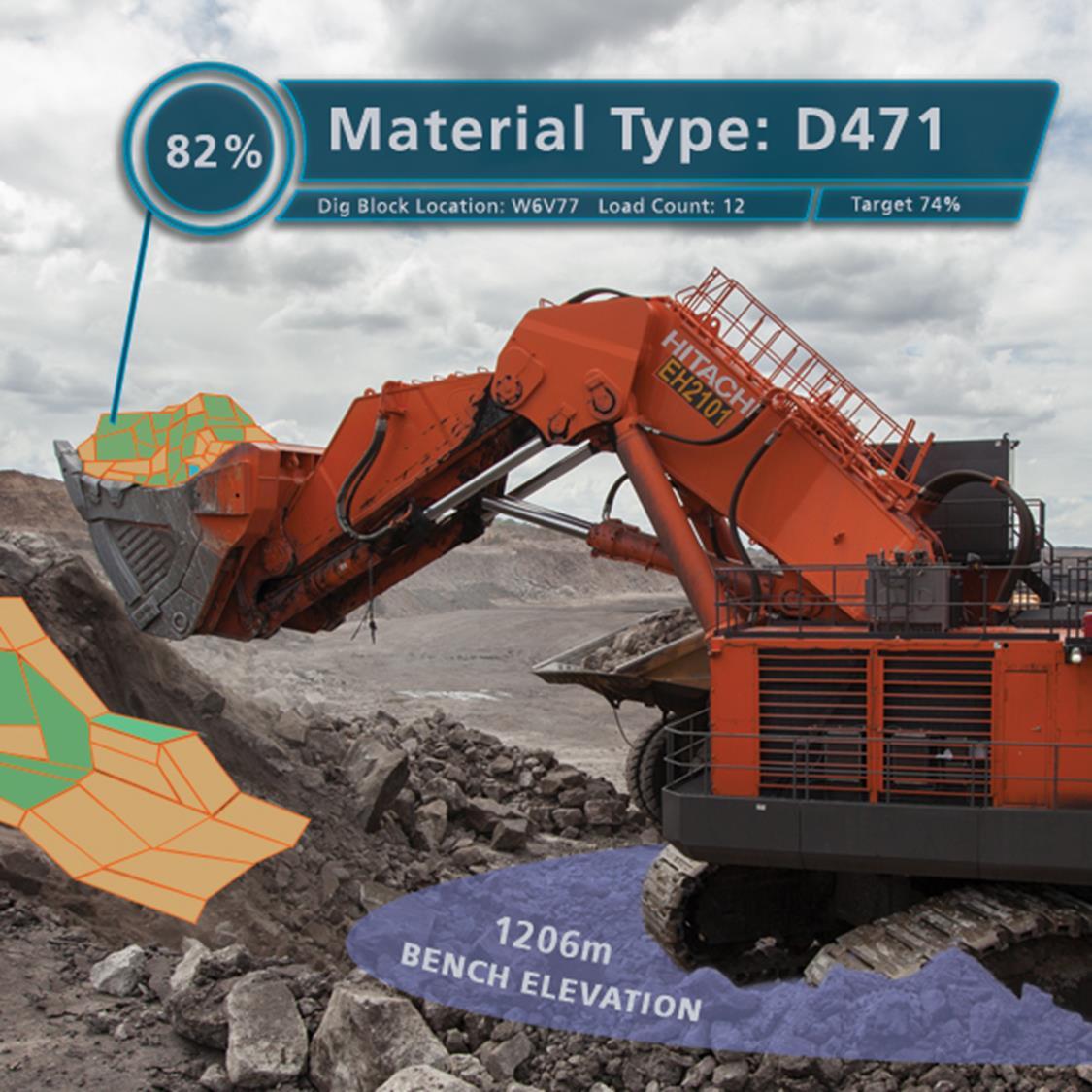

Wencomine Suite

Wencomine

Situationally Adaptive User Interface

Disruptive Technology Partnerships

• Interoperability

• Wenco integrated with 3rd party bucket ore grade material quality

sensing technology

• Measures quality of ore inbucket and shares with FMS

• FMS informs operators, updates actual qualities in truck load, and sets dump assignments accordingly

• Potential to work with a wide range of minerals, including Co, Cu, Fe, Mn, Mo, Ni, Zn...

How is Wenco different?

• Focus on:

➢ Usability & situational awareness

➢ Interoperability – sharing data

➢ Producing understandable data at the highest quality

• Scalable System

➢ Supports systems with less than 10 units up to hundreds

➢ Core system comes with more included functionality than competitors, with ability to add on value-added modules

• Easy to use, easy to administer, easy to upgrade

➢ Upgrade the system in a matter of hours –not days, weeks, or months

➢ Modern Windows operating systems everywhere

How is Wenco different?

• Customers should never be left behind or forced to upgrade

➢ Endeavors to maintain backwardscompatibility

• Flexibility

➢ Wenco’s onboard hardware can run 3rd party applications and share its GPS signal to those applications

➢ Our databases are open and freely accessible, with comprehensive documentation to make it easy

• Customers own their data

• Best-in-industry Technical Support model

➢ Dedicated Support Specialist that knows your mine, knows your people

• Supporting standards – ISO, ISA-95

• Moderator in ISO Autonomy group

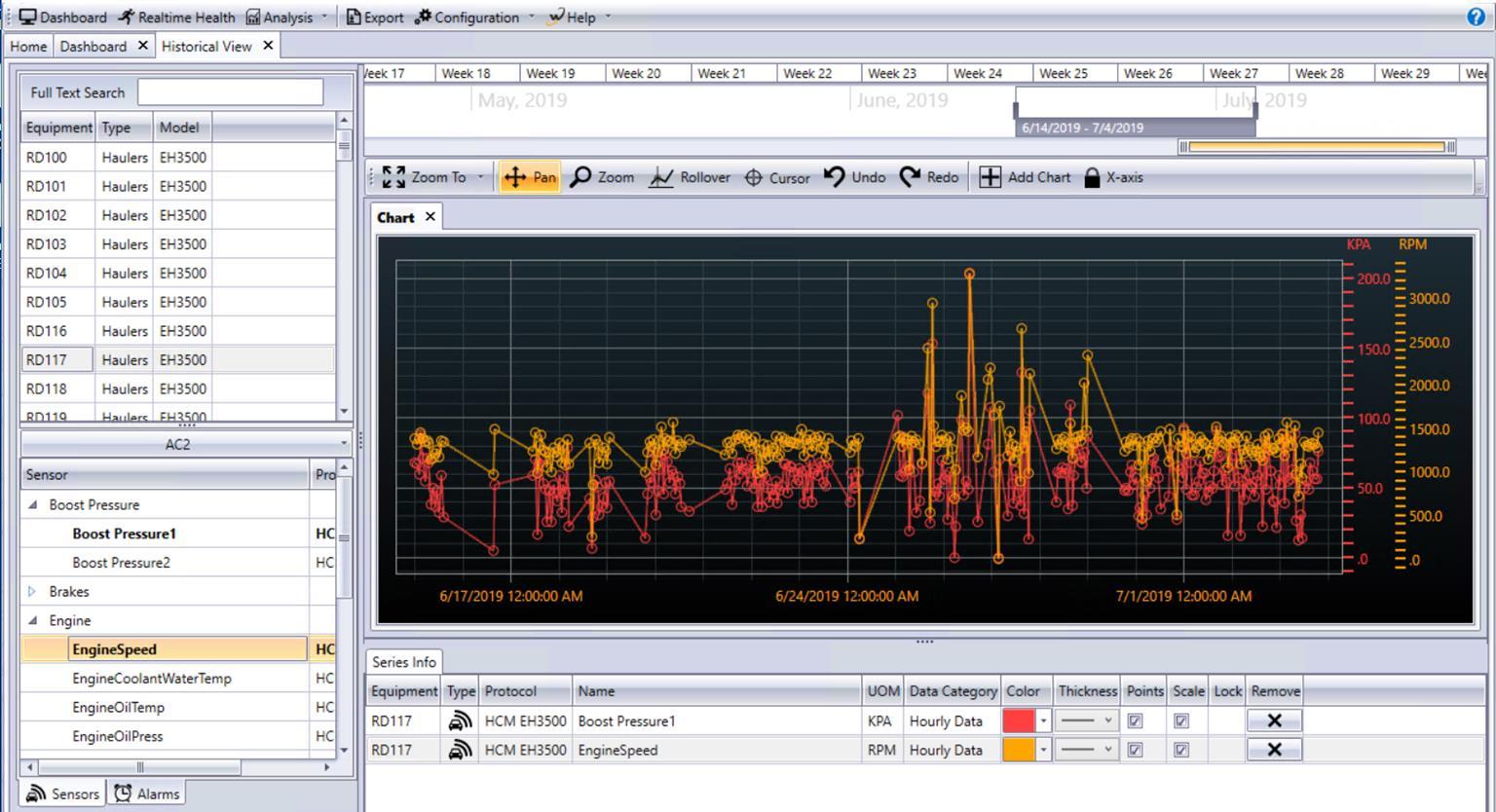

What is Ready Line?

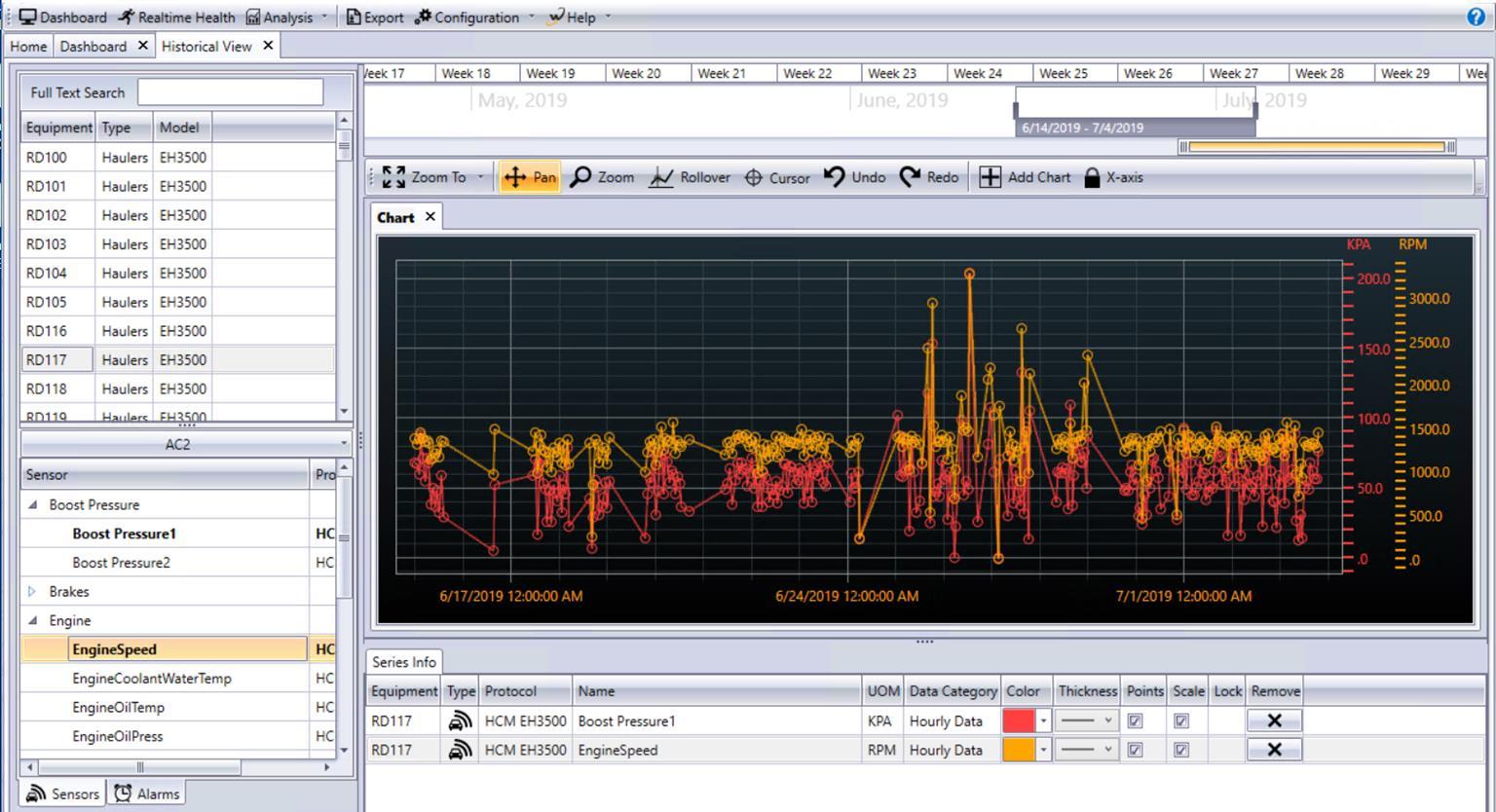

Ready Line Historical View

Wenco e-Learning

Wenco Learning Components

• Learning Element

➢ Narrated visual content

• Post-test

➢ Ensures learner competency

• Workbook

➢ PDF reference material learners can keep

• Completion Certificate

➢ Proof of learning and competency

Executive Summary

❖Scalable solutions to meet your requirements today

❖Immediate quantifiable benefits from the moment you turn it on

➢ Maximise the Utilisation of your fleet

➢ Production record keeping and optimisation

➢ Operator Safety via Proximity Detection warnings

➢ Tyre Pressure and temperature monitoring

➢ We integrate with other leading technology providers to create value for you across the whole operation

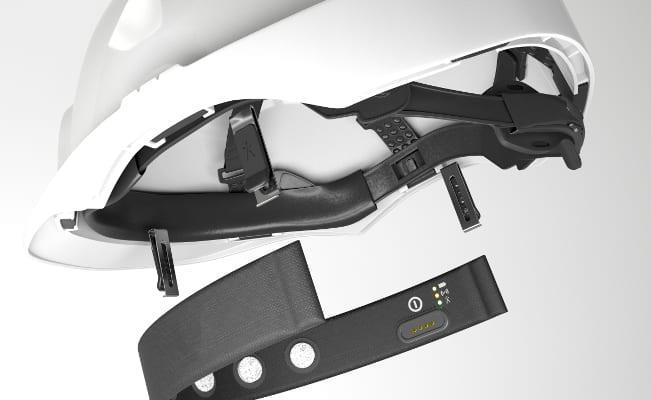

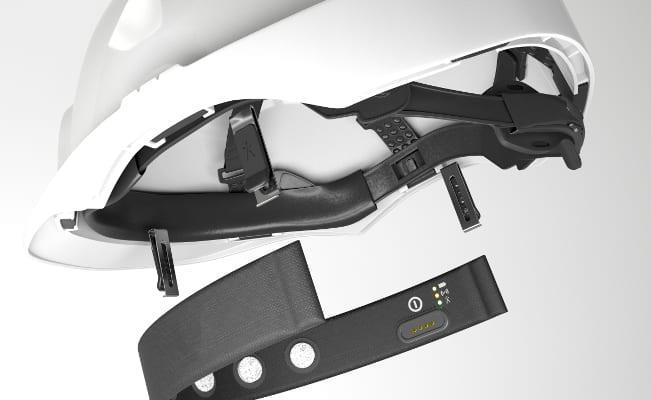

Smart Cap Fatigue Monitoring

Fatigue Monitoring

• Keeping your workforce safe and alert helps them be more productive, less distracted, more focused, and kinder on equipment.

• Proactive rather than reactive – instead of tracking and alarming when micro sleeps occur, Smart Cap eliminates them.

• Smart Cap empowers every user with early warnings so they can take action to prevent fatigue events.

• Measuring fatigue at the source – SmartCap’s wearable technology uses EEG (brainwaves) to provide the earliest possible detection of fatigue.

Discreet and Comfortable

• SmartCap’s Life Band can be clipped into almost any headwear, including hard hats and caps, to make them virtually disappear – or worn on their own

• Once appropriately adjusted, users report forgetting that they’re even wearing them

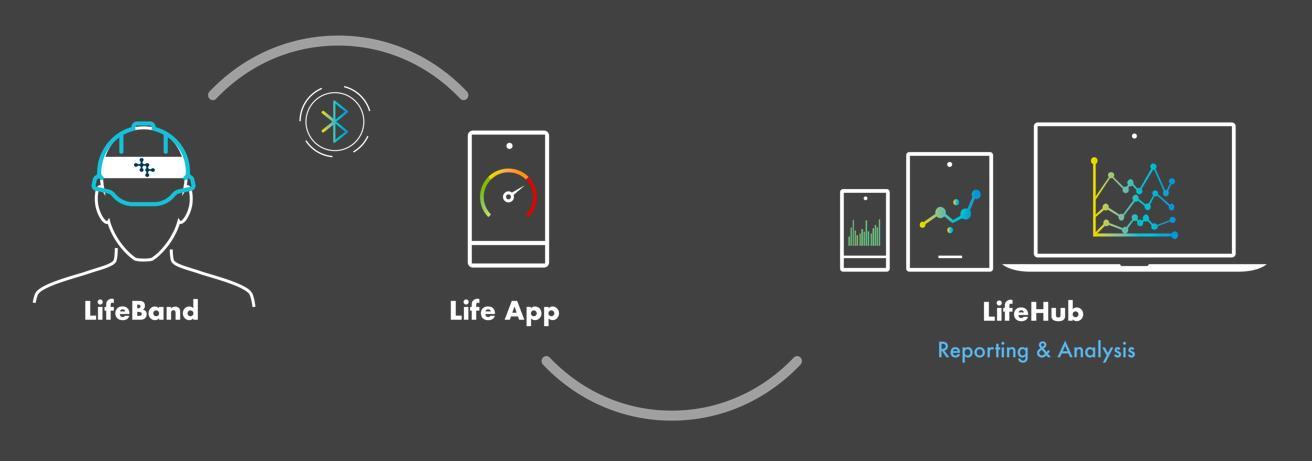

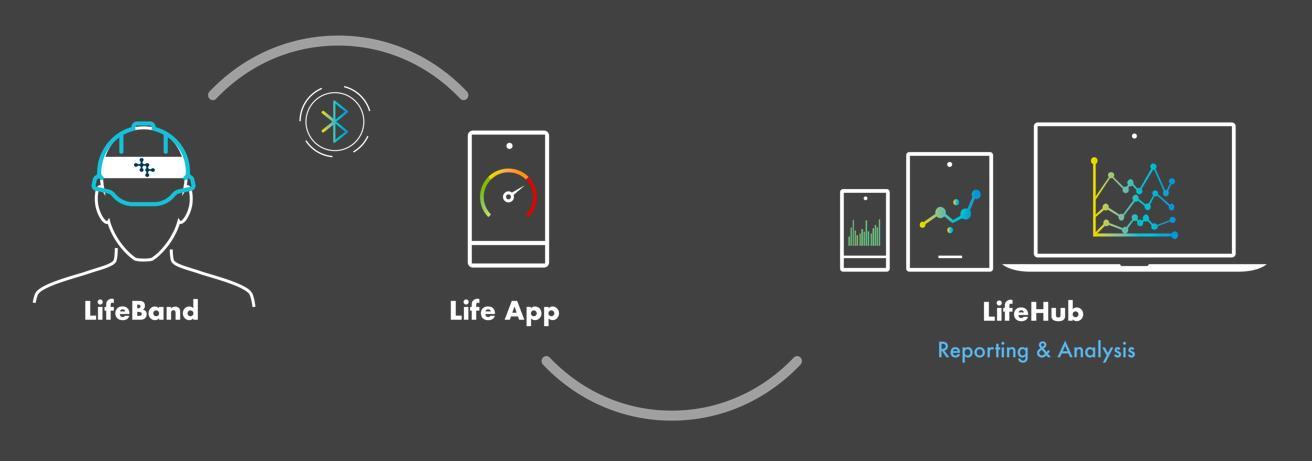

The SmartCap Life Solution

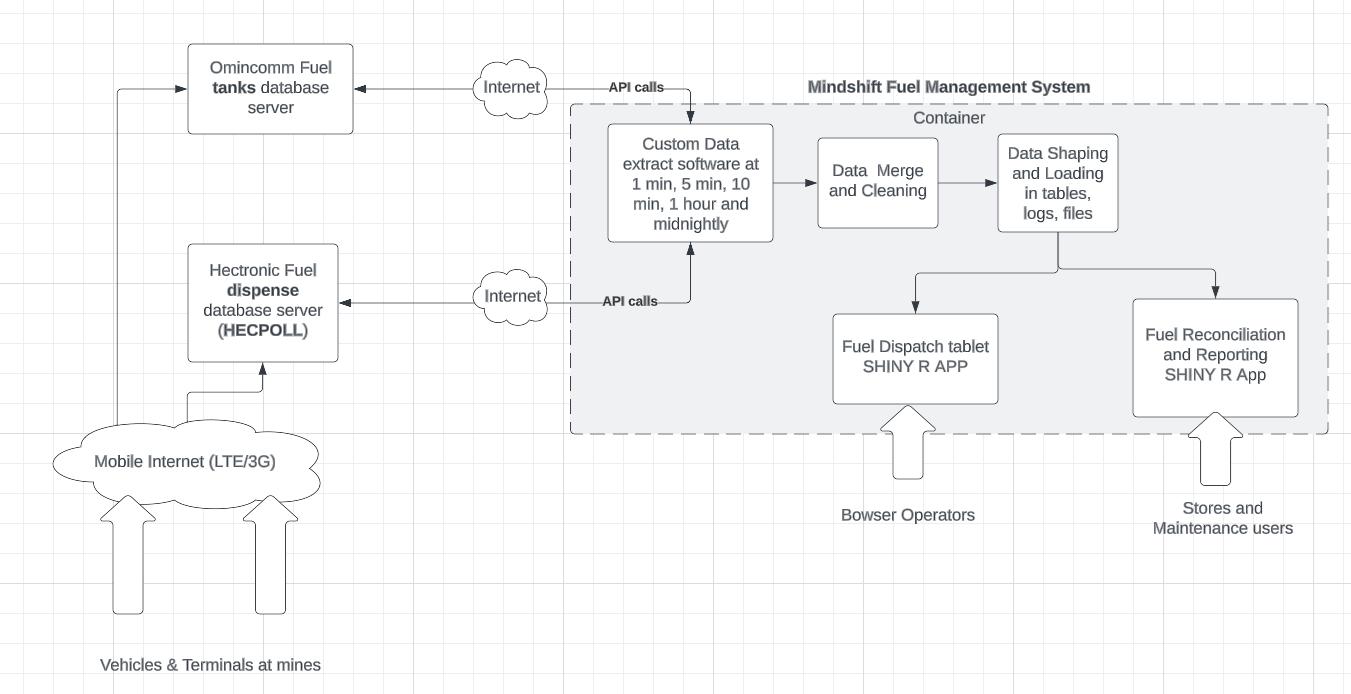

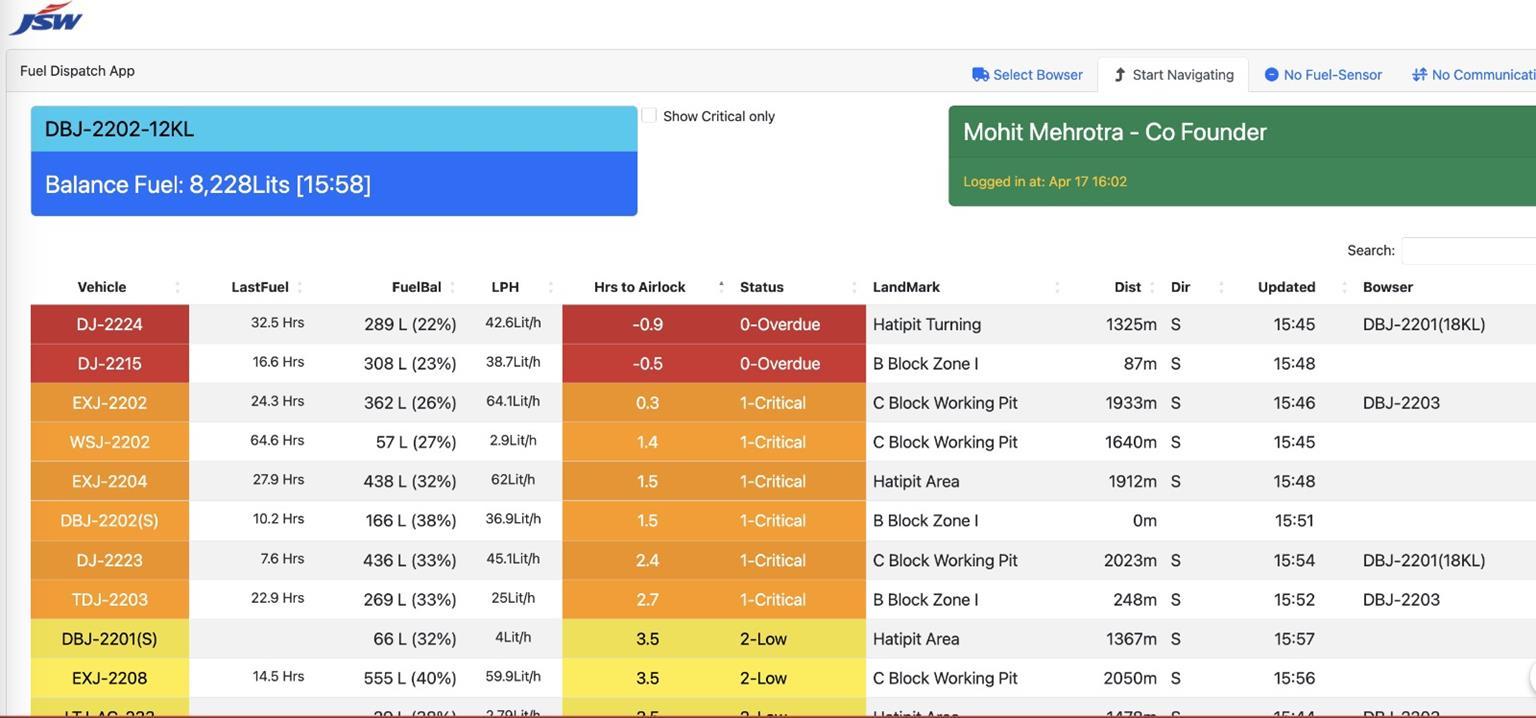

Introduction and Objective of FMS

• To Reduce excessive & redundant supervision

• ON time fuel delivery to earthmovers

• Paper Logs and trouble in accurate fuel reconciliations.

• Optimize refueling operation – reduce wastage, reduce refueling time, prevent frauds, reduce idle time of fleets.

• RFID Based Authorized refueling.

• Real-time fuel monitoring of each HEMMs / Assets

• Fuel Inventory Management

• Web Based and Mobile application for remote monitoring of end-toend Fuel transaction and status.

• Static leak detection in fuel tanks & storage units.

• End to End transparency and better control over refueling operations and bring clear visibility on overall fuel expenditure

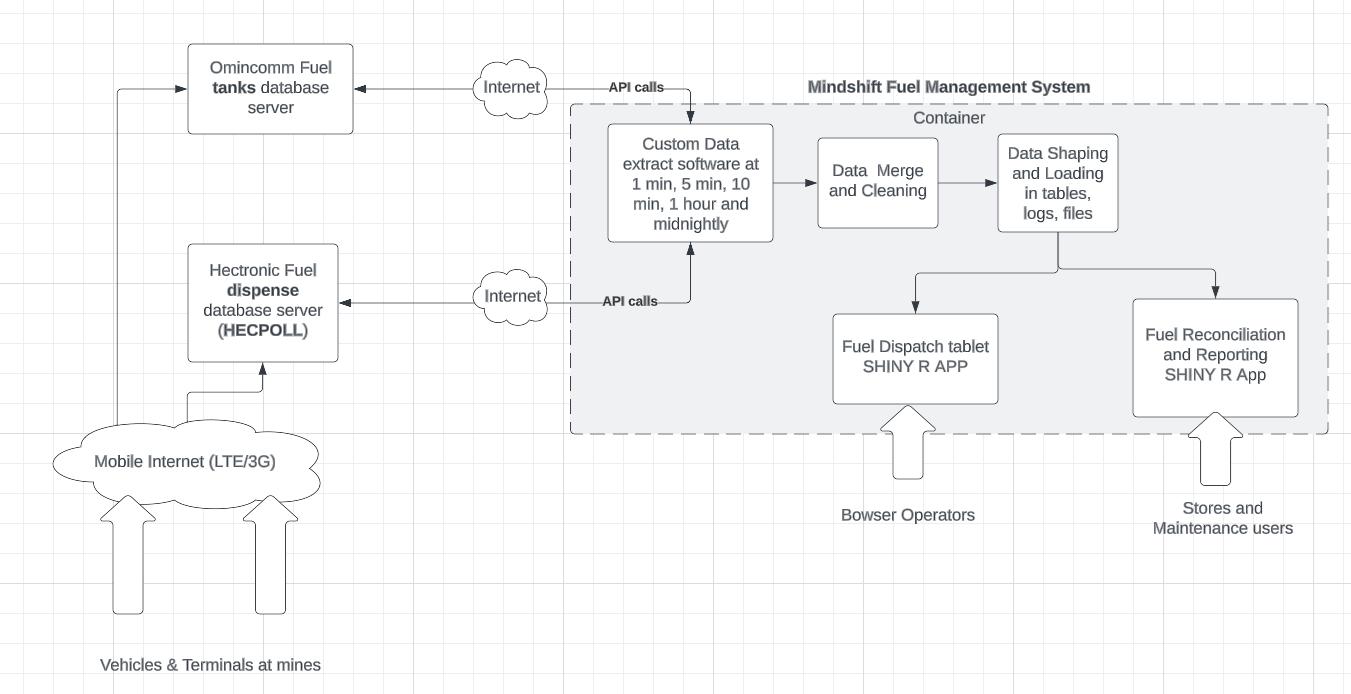

DATA FLOW SCHEME & ANALYTICAL WEB UI, MOBILE APP

Fu el lo w Fu el lo w Omnicom m LLS 5

Teltonika

Bowser fuel tank

BOWSER SOLUTION WITH IOT

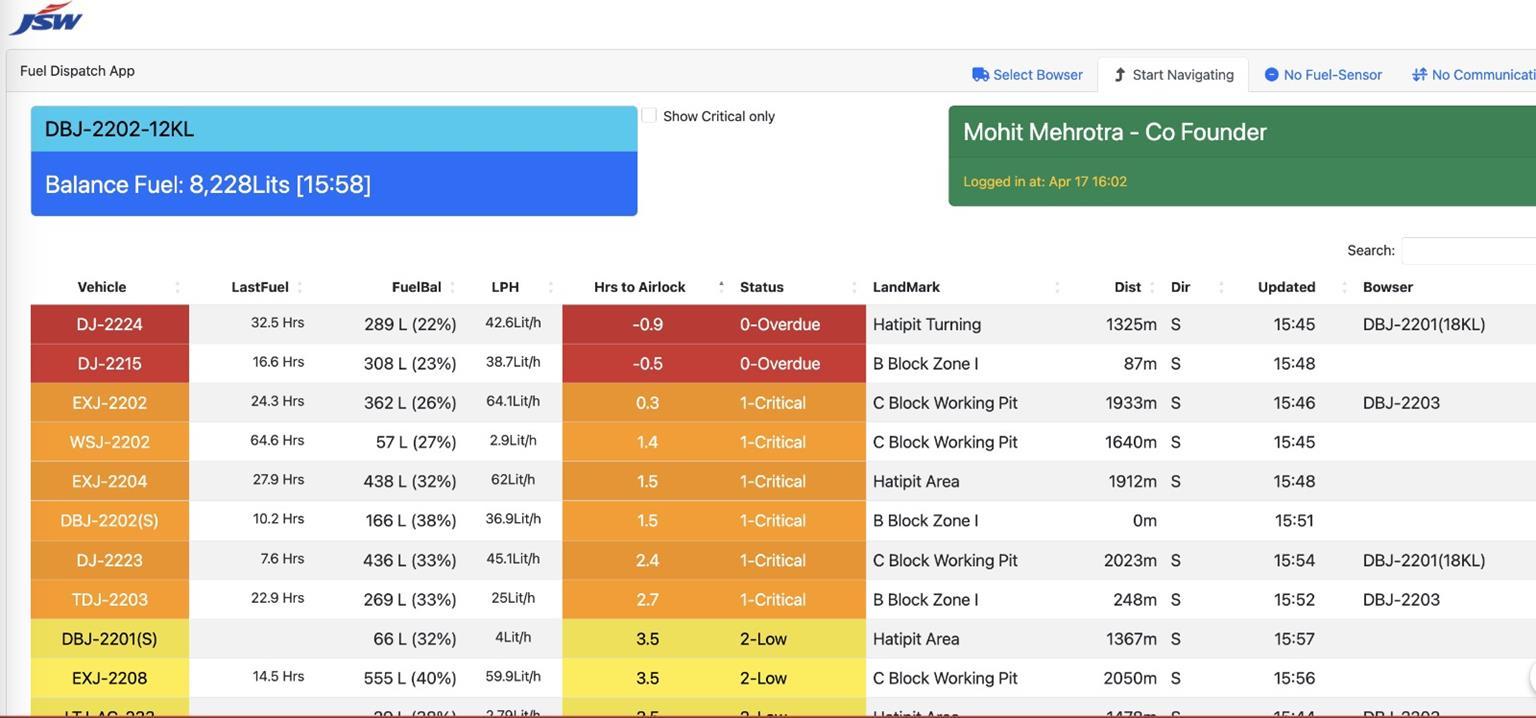

The intuitive user interface of the mobile web application is designed to display geo location, live fuel levels, consumption rates and estimated time to refuel.

It also offers a task selfassignment capability allowing coordinated peer to peer selfregulating dispatch systems.

BOWSER OPERATOR DISPLAY UNIT – SHOWING CRITICAL LEVELS

• Optimize every load

• Eliminate overload

• Eliminate re-load

• Faster turnaround

• Enhanced utilization of capital equipment capacity

• Measure productivity

• Ton per hour

• Daily or Shift production

• Truck loads

Load Once Load Right – Loader Weighing

▪

Accuracy: with 1% of a full bucket load for tipper loading

▪ If the full bucket value is 5 tones, the reading will be in the range of 4.95 t –5.05 t

7

Accuracy & Precision

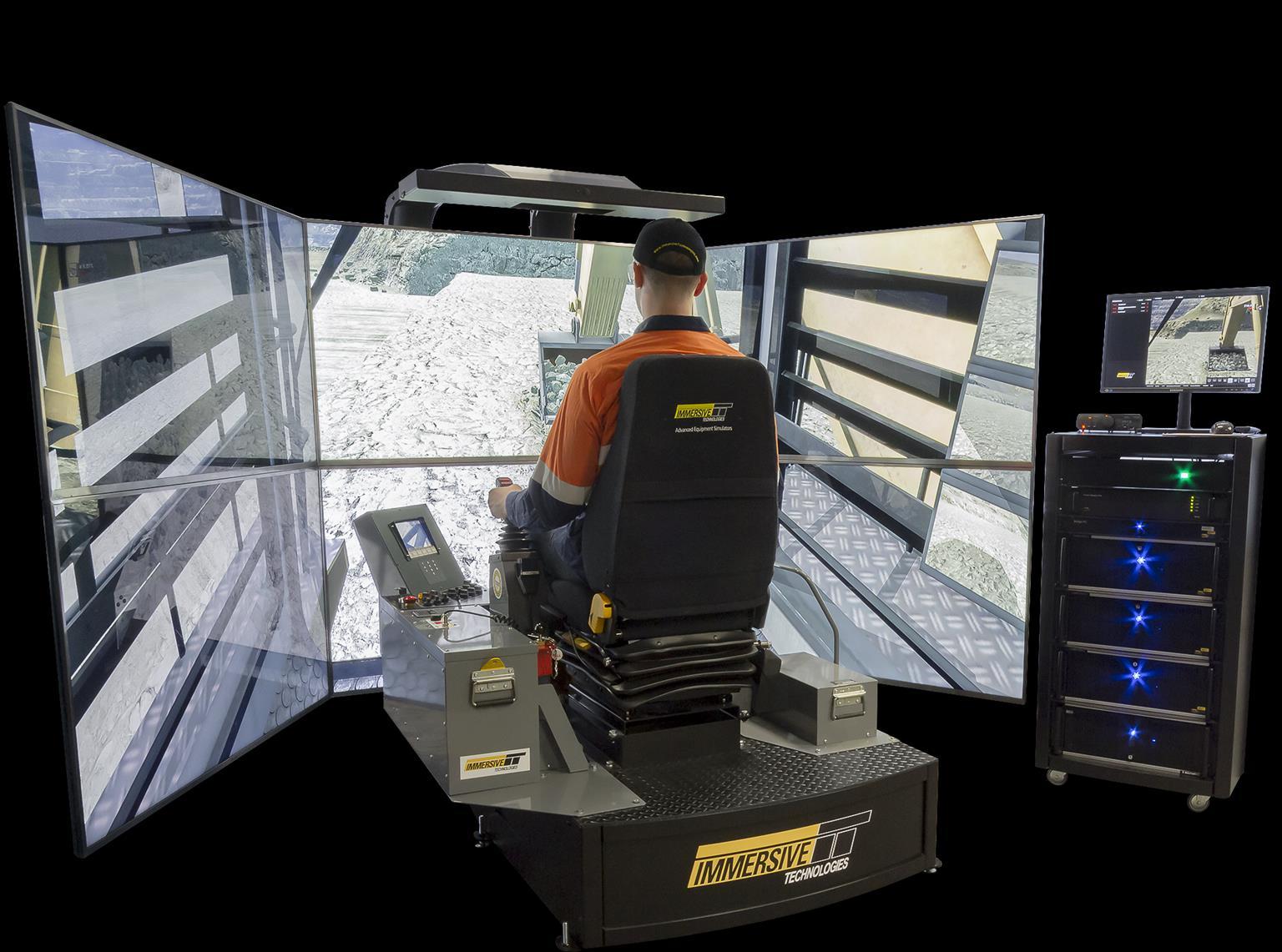

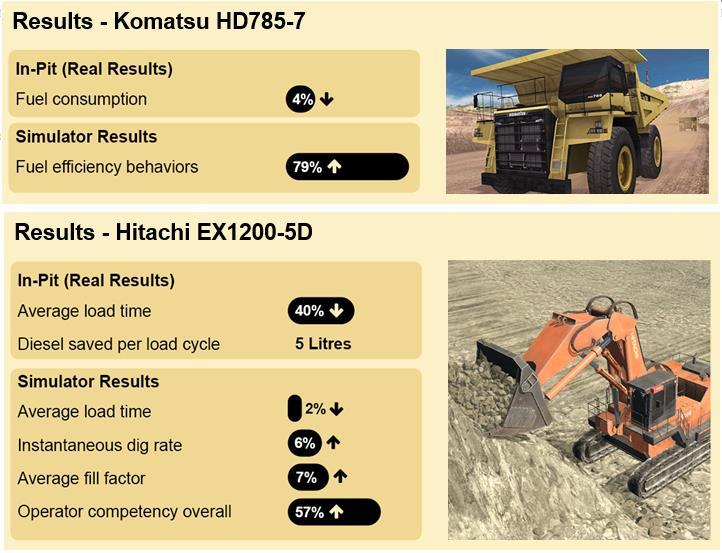

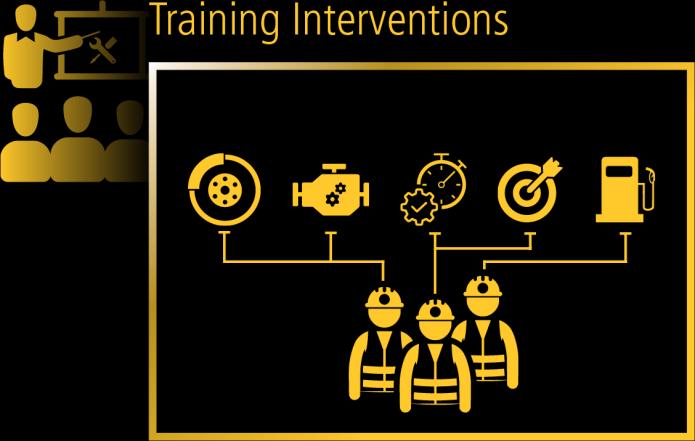

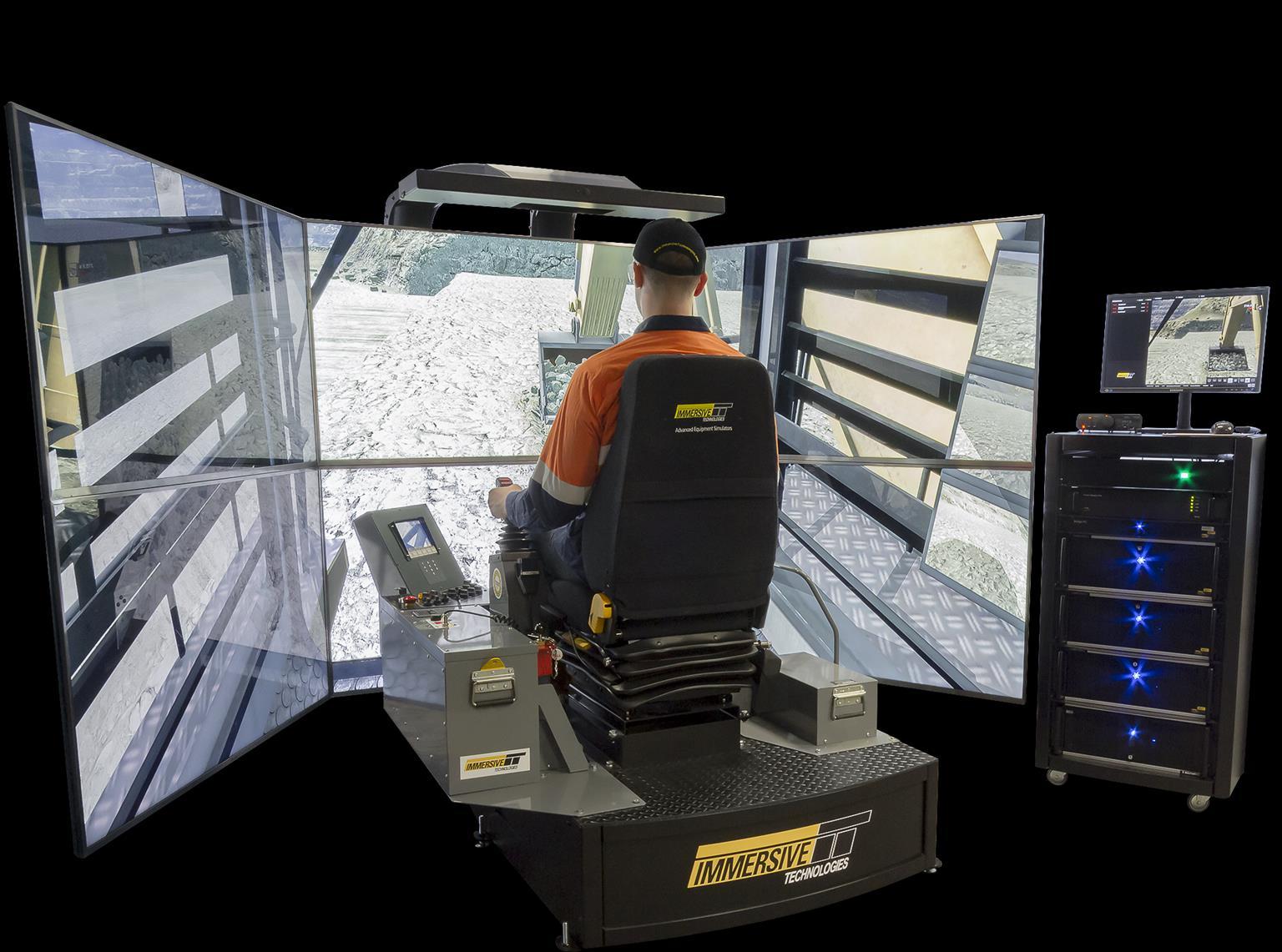

BLENDED LEARNING SOLUTION

MEDIUM FIDELITY WORKFORCE DEVELOPMENT

KOM HD785-7

KOM PC1250-8 EXCAVATOR

Custom Mine

Customer

Site

Support Program 12 Month Embedded Trainer

CAT 777E TRUCK LIEBHERR R9200 EXCAVATOR Custom Mine Site Technology Customer Support Program 12 Month Embedded Trainer HIGH FIDELITY WORKFORCE DEVELOPMENT

BLENDED LEARNING SOLUTION

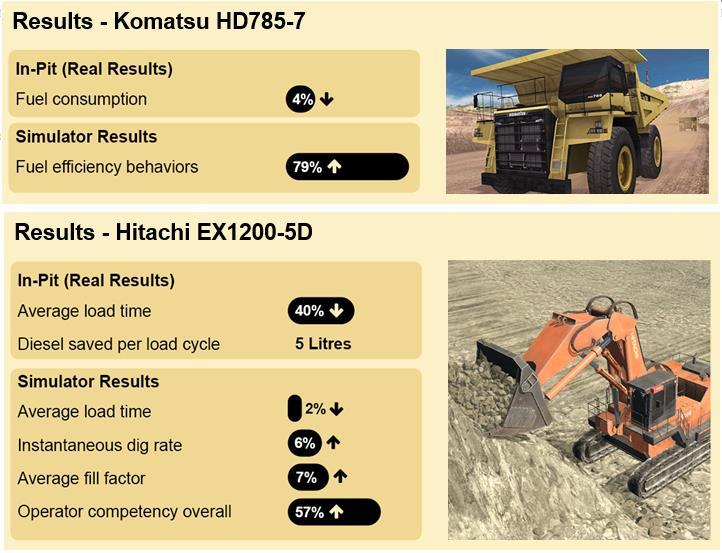

OUR SOLUTION IN ACTION

TATA STEEL CASE STUDY

Video: Atul Kumar Bhatnagar, General Manager - Ore Mine and Quarries – TATA Steel

Video testimonial as follows:

https://youtu.be/HRsETNW3IYE

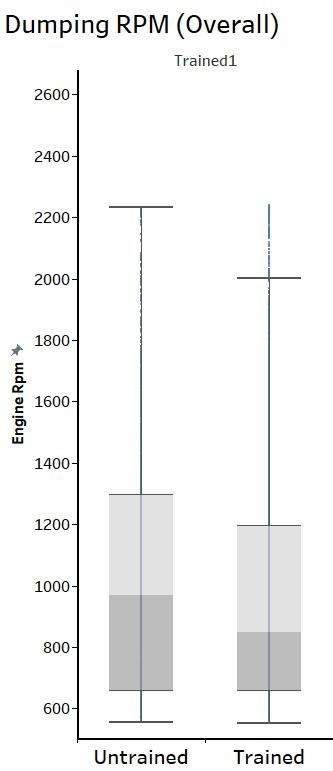

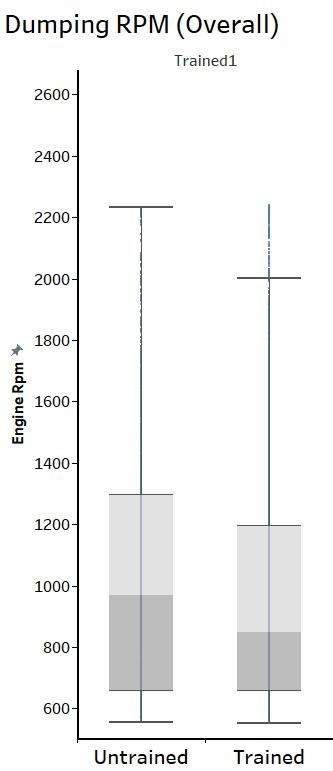

Dumper Operator Training

There has been a reduction of 13 % in dumping RPM after training

There has also been a reduction in the 75th percentile by 8%, indicating operator’s tendency of unloading at lower RPM -8%

971 847 0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 Median Dumping RPM 1200 -13% Trained Untrained

Dumping RPM (Median) Target

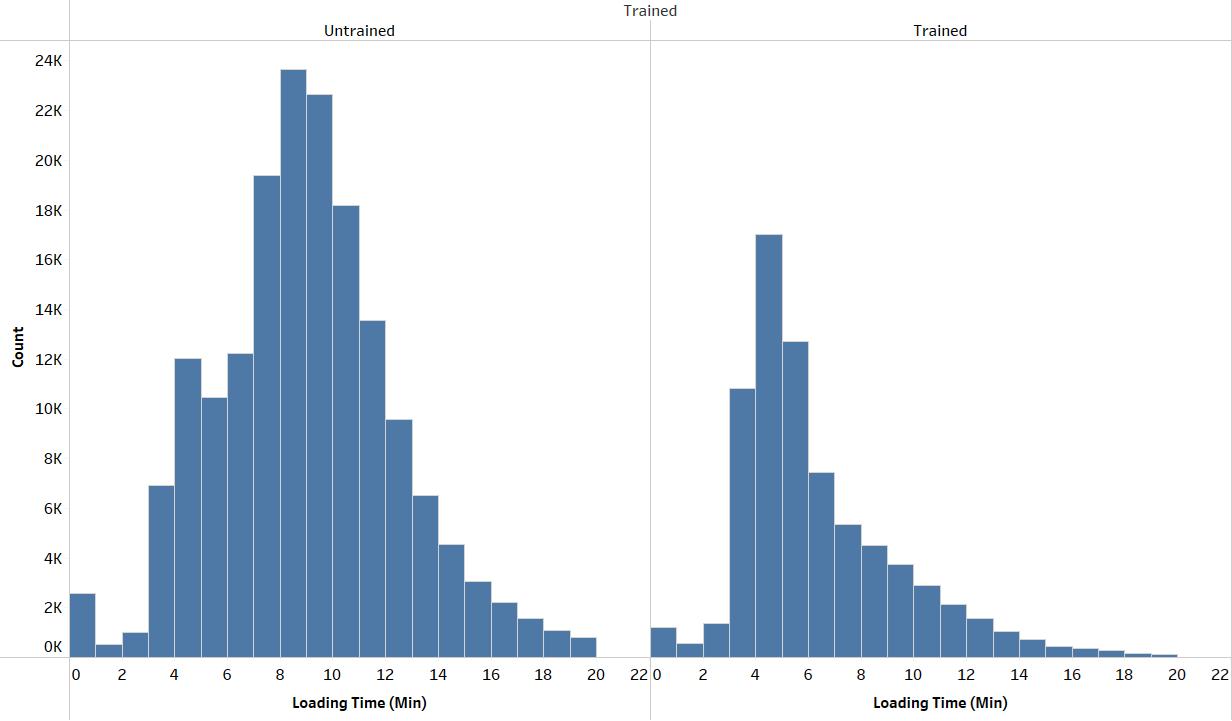

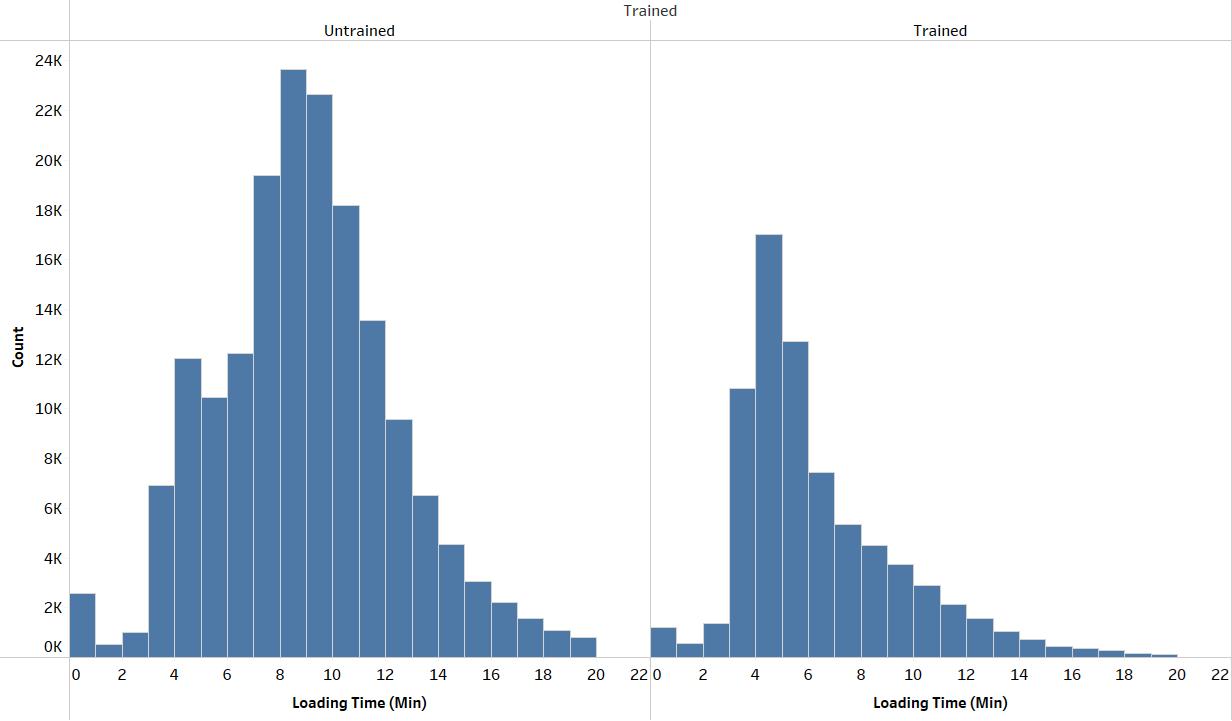

Shovel Operator Training

Loading time (Min) - Histogram

A shift in the mean loading time has been observed from 8.9 min to 5.4 min after training

8.9 5.4 0 1 2 3 4 5 6 7 8 9 Median Loading Time (Min) 4.2 Untrained Trained 5 L HSD saved per loading cycle Target

CONTINUOUS IMPROVEMENT APPROACH

Operating Data

Analytics

Intervention

Results

ANALYSIS AND ALIGNMENT INTO ACTION Mine

Performance

Training

Real

THANK YOU