9 minute read

3. The next transformation – packaging

3.

The next transformation – packaging

Advertisement

How and why is this transformation and disruption occurring right now? What is really going on? The easiest way to describe this phenomenon is technology through the demand for a transformation.

Every disruption always starts from a change in market needs and new demands. Here, the digital technology works as an enabler to execute a transformation. Technology disruptions are from day one a well-planned and often long-time development made on top of already developed technology. HP, for example, spends millions of dollars in R&D in this area every year, working hard to meet all transformations and new needs trying to nail the right timeslot and window. Doing this in advance, before new needs are visible, is a challenge in itself – aiming to close the gap between the present and the future. It takes a great deal of R&D-time and courage. It is even harder to spot a technology cut in an existing chain of processes (disruption), making a chain of processes shorter, faster, and cheaper using new technology. As Steve Jobs said: “A lot of time people don’t know what they want before you show them”. Henry Ford used the same theme in the early days of Ford Motor Company: “If I had asked my customers what they wanted, they would have said a faster horse”. There are many stages here that will save both time and money. Cutting links in a chain with new technology, disrupting steps inside a process, replacing analog (manual) steps (links) in a process (chain), changing analog to digital – making more with less, and adding more value to the chain.

The need and demand for a change grow constantly every day. We as Homo Sapiens (the thinking human) are driven from our 200,000-year-old DNA. The DNA made for hunting, protecting, surviving, and striving forward. We’re in constant progress for new needs and demands within our self or at least within our own group where we live and belong. A group can be our family, community, or the company we work in. The overall progress for more needs in many cases is constant in these three blocks within our daily circle of sleep, work, and private time. If you’ll push harder within the company side, it will mean a lower drive within the family, etc. The period of time between changes also plays an important role. Far too many try to change in a hurry and end up with no change at all. The longer it takes between transformations, the more new needs and demands will be accumulated to drive a transformation. It’s the same as when you try a too big change – it ends up as a real U-turn. In that case, the change drifts too far away from the basement of the process. The distance between where the process originates and where it aims gets too big. The result will be no change at all. It’s important that the change is based on where in the chain it hooks into the existing process and where it hooks on the other side of the chain. Strong and clear hooks will secure a strong chain with new processes, now shorter, more flexible, faster, and more value = profit.

Packaging today has all of that criteria for achieving a really big change. A big change, but at the same time sensible and practical. It’s still on a stable ground with a stable process, not having been transformed in a very long time. The new steps can use all the existing grounds for reaching the next level. Our society around the products and around the packaging have changed and developed, but the packaging itself has in many cases stayed the same. It’s still often made in a manual and analog fashion. A huge reason for this is a lack of priority of packaging as a marketing tool. Today packaging in many ways is the most important marketing tool for selling more of a product, not only protecting the product. We also see a faster time-to-market (T2M) where everything goes faster and faster. Delivering today is on demand, not waiting 10-12 weeks for a change. On top of that, we notice increasing demands for new and environmentally friendly media that fits in our upcoming demand of a circular society. New digital technology will play a big part of this transformation and comes from a close related industry, the commercial print market – a market that was transformed in our last low economy. This build-up of drivers through plenty of new needs and demands creates a grand opportunity for the ones who change. Consequently, it will also close the door for the ones who stand still and simply do the same. The difference from the transformation of the commercial printing industry is that the basic digital

printing technology now has developed and is ready, and it will work as the base within packaging. A fast T2M is a given in many aspects of our business lives today, but in packaging there are still months of waiting for making a change. The environmentally friendly media is also increasingly becoming a very important and strong customer demand. With more focus on refined, exclusive and dedicated packaging, in combination with more variations and smaller runs, digital fits perfectly into the equation. In the commercial transformation it was also a competition against electronic displays. Information that was printed in the past like newspapers and manuals were now read on a display, like the iPad or a screen. At the same time, as the digital transformation happened, this market was losing around 10% every year (in Sweden alone SEK 100 million per year and the losses continue today), newspapers alone even more. We also see marketing managers and CMOs relocating their investment from plain printed advertising towards packaging that sells the product in side. I call for this transformation of the packaging industry to become even bigger; we can reach a so-called “flip” happen in this market. A flip will change many things including high investments, a lot of money going in, and very high expectation of the ROI (return of investment). One thing is that this market is also growing a lot. Brand owners invest more money in their packaging and here it won’t be a competition with any electronic displays as seen in the commercial transformation. It’s hard to store a liter of milk inside of an iPad (if you get my point). Physical packaging will always be around, not only to protect the product but also to market and most importantly sell more, increase the value of the product.

When market change, somebody wins, somebody also has to lose. With the number of winners, we’ll see in the packaging industry, there will also be a lot of losers. They are the ones that act as the commercial ones in the past, didn’t transform or only invested in a digital machine (no matter which technology) and stayed inside their old business model of selling analog and digital as separate products with no added value. They added a secondary product, accepted less quality for less money. They’ll excuse themselves thinking “it’s all an add-on service, so we won’t lose our customers to someone else”. Instead, they lost more; they missed the value and a great opportunity plus they had to lower their margins even more. To create a new business model in a transformation is crucial, adding value will adding margins. It may be the difference between success or failing. Old ways of calculating are often based on the fixed cost of setting up the machine for a job, which was the big part of the cost while the printing itself was a smaller part of the cost. To this fixed setup-cost and make-ready-time, a cost per volume of sheet/meter was added. Then, a margin was added, a margin that still is under heavy pressure because of low added value. A constant drop in run-length per job did so the setup and make-ready-time obtained most of the work-time and cost – instead of the actual printing time. This made the old business model obsolete and out of date.

The new business model is instead opposite, first based on time to print, how much you can print per time-unit or shift divided by the cost per time-unit or shift. Then, use then the market prices for your value as a base for setting your selling prices and you will find more profit per job. Those jobs that are still too long and have low value can still be produced conventionally, either you are big enough to fill at least one analog press with those jobs or have stopped doing them and instead buy this specific production from a company that still hasn’t transformed their business.

Looking at the label market, this transformation has already started. It’s in process at least on the presses side, although not everyone has done the real mental transformation getting a new business model. Today, digital for labels increases with around +30% YoY (year-over-year) and is now moving into a balancing phase migrating analog to digital. Most of all the label jobs today (passing 80%) will favor cost-wise being made digitally. Still, most of all the labels in meter or square meter are being produced conventionally. In terms of value, a converter that prints 30% of their volumes digitally receive as much as 70% of their gross margin from digital.

In the segment of flexible packaging and folding cartons, the first wave of digital presses is already installed and up and running production this year in the Nordics, +100 machines worldwide. From the brand owner’s perspective, they see new needs and demands for shorter T2M and more variations and producing on demand not to stock. This demand is huge and comes from us consumers. All this happens in a world of polarization. We’re going toward super globalization and urbanization at the same time as a demand for super localization also growing. Brand owner’s demands to be both local and global at the same time are essential and necessary. Right now, the big ones are realizing that they are losing market shares to fast growing local brands. Most likely it’s a totally new process for them to change the big brand company towards customers new demands. The packaging market is ready for this transformation. Are you ready? All the needs and demands for a change is in place, but we have a lot of work to do to make it happen. We must understand and define ourselves in our own market, categorize, going through and doing a lot of homework. A good thing is that all of you start almost at the same time and everyone must go through a lot of pain (yes, it will hurt) and you need to go outside of your own comfort zone. “If things are easy, everyone can do it, and if everyone can do it, there will be no money in it”. I hope this book will provide some added value as you join the ride.

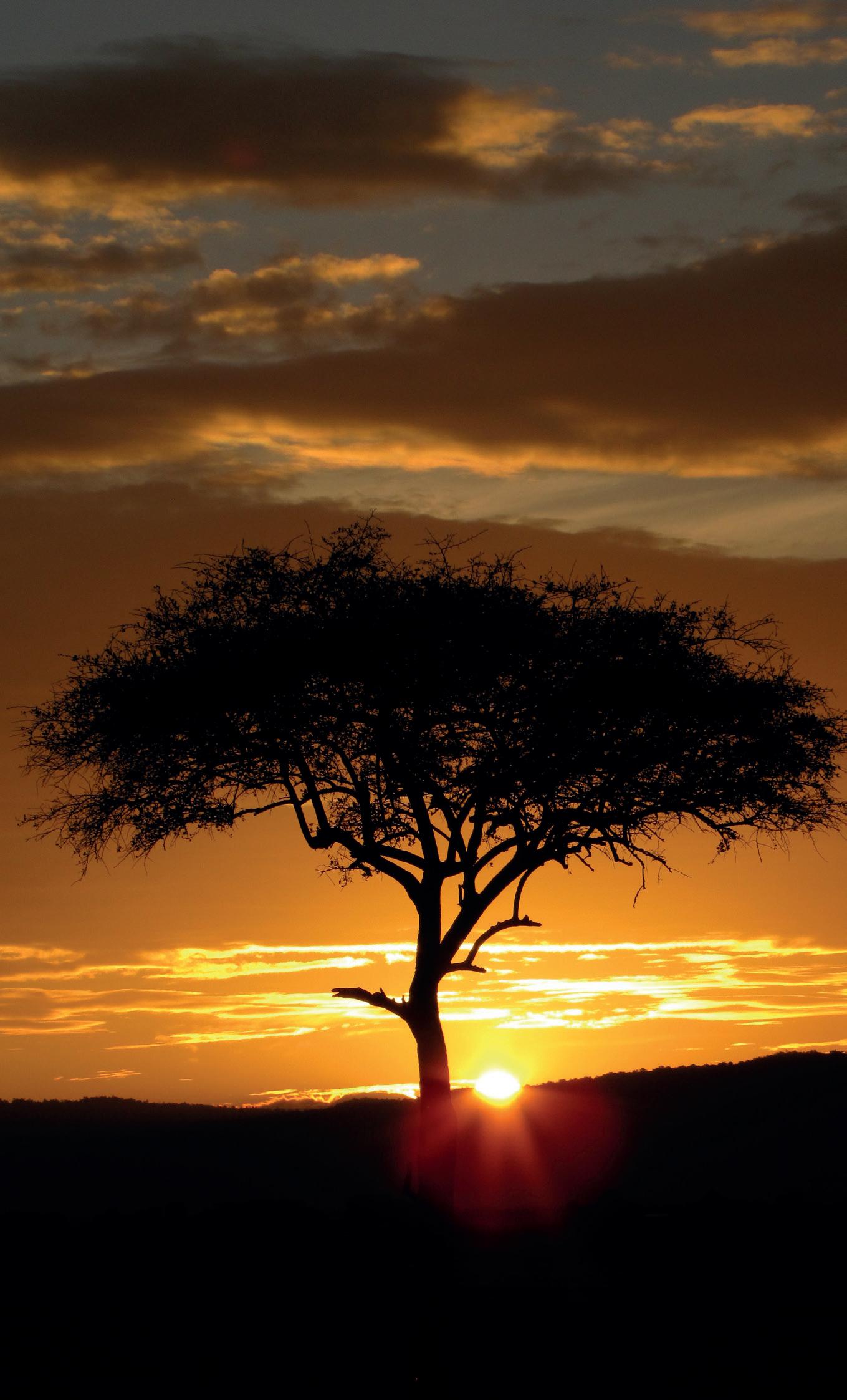

22 “The best time to plant a tree was 10 years ago. The second-best time is now.”

- A Chinese Proverb.