2 minute read

Falcon ZF Frankenstein

WE TAKE A LOOK AT WHAT THE TEAM AT THE GEARBOX FACTORY IN AUCKLAND’S EAST TAMAKI DID TO TACKLE THIS UNIQUE ZF 6HP26 UPGRADE

The team at the Factory never shy away from a challenge. The photo here shows a ZF 6HP26 transmission housing completely split in half as a result of a driveshaft failure, causing one enormous mess.

Advertisement

Their customer’s Ford Falcon with a Barra engine is pushing close to 1000hp. What The Gearbox Factory did next was truly impressive — they merged a 6HP26 with a 6R80. This had been done before in Australia and knowing that it could be achieved meant relying on the experience of the

Drivetrain

Factory’s highly trained technicians.

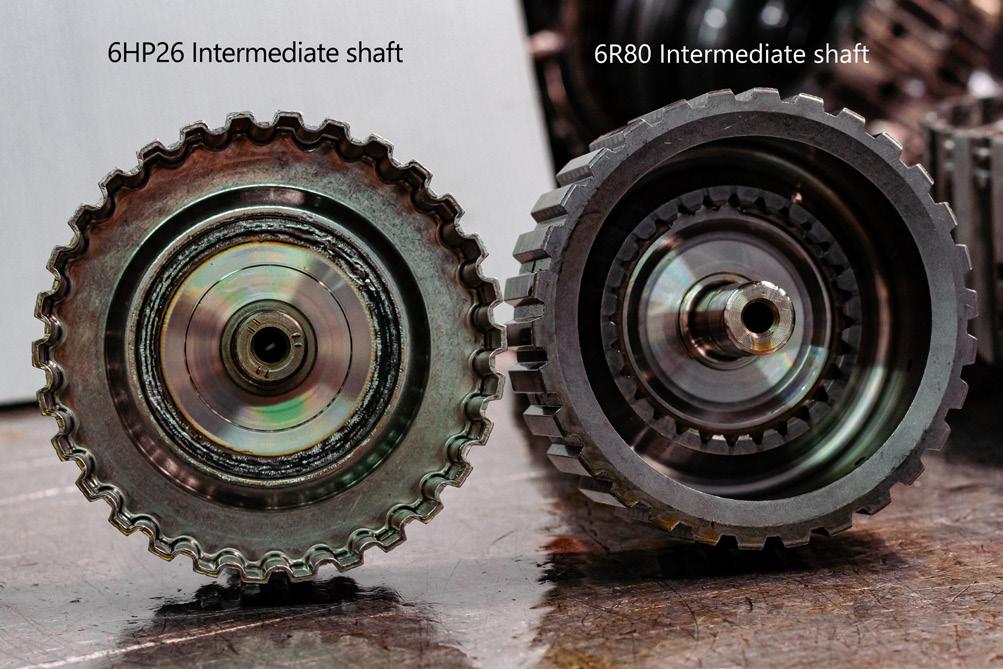

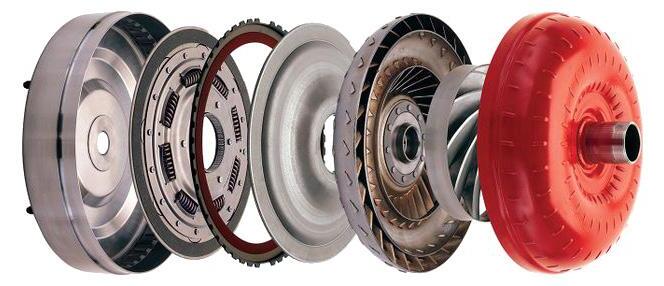

The team adopted the 6R80 Ranger components to the replacement housing, upgraded the valve body, and fitted high-energy frictions to handle the power increase. The Gearbox Factory technicians were then able to cut apart and merge both torque converters into one (all done from their in-house dedicated torque converter machine shop).

The trans was finally assembled and transformed from a stock ZF to a fully overhauled 6HP26/6R80, that can handle their customer’s 1000Hp.

Here is some history about the Barra engine — the inline-6 fitted to the Ford Australia Falcon was manufactured between 2002 and 2016.

These engines are unique to the Australian manufactured Falcon and the crossover SUV Ford Territory and were developed and manufactured in Geelong,

Victoria. The Barra was first introduced in the BA Falcon, named after the ‘Barramundi’ code name used during the development of the BA update engine.

The 6HP26 was the transmission of choice behind these engines which has been used by automakers worldwide for over 14 years and are capable of handling up to 600Nm of torque. However, rebuilding a stock 6HP26 was not something their customers were looking for. Enter the 6R80 — the US-produced Ford 6R80 transmission is based on the robust ZF 6HP26 design. These units are capable of handling up to 1000Nm of torque, they feature an increase in strength to key components, and hold a larger friction surface than the stock ZF.

To find out more about what The Gearbox Factory service, or any enquiries on transmission related issues and upgrades, call 0800 443 272, 09 274 8340, or visit gearboxfactory.co.nz.

WE ARE SPECIALISTS IN AUTOMATIC AND MANUAL TRANSMISSION SERVICES, REPAIRS (INCLUDING TRANSFER CASES, DIFFERENTIALS AND WHEEL BEARINGS) ON ALL MAKES AND MODELS OF AUTOMOTIVE VEHICLES AND LIGHT TRUCKS

DSGs & DCTs

Dual clutch transmissions are hugely popular. We cover all repairs and servicing with the latest diagnostic equipment available.

CVTs

Continuously variable transmissions are a significant part of overall sales each month, therefore the equipment and knowledge that we have accumulated from years of experience repairing these complicated transmissions, has given us an unparalleled edge.

DIFF Audit

Often overlooked but not by us, the time to get your diff looked at is when you first hear a noise, to avoid more costly repairs down the track.

Torque Converters

The Gearbox Factory has been rebuilding torque converters for cash trade customers for over 48 years. With a significant increase in production capacity, The Gearbox Factory team is now able to offer a torque converter reconditioning and repair service to the motor industry.