The new PIC16F131xx family of microcontrollers offered by Microchip is a perfect response to the constant evolution and ever-advancing miniaturisation of electronic equipment. Their functionalities facilitate economical power management and designing controllers with predictable response times.

Ensuring time-predictable circuit behaviour is one of the key requirements for the designers of state-of-the-art embedded systems. In practice, it boils down to limiting the time of response to changes in the controlled processes, i.e. instant response to input data from sensors, communication ports or user interface. It can be ensured by increasing the system’s computational power, but this is in fact a suboptimal method, as it results in wasting large amounts of energy. In order to avoid program-based operation of basic processes, the Microchip microcontrollers utilise core independent peripherals (CIPs). The configurable logic block (CLP) is a new solution integrated in the new family of 8-bit microcontrollers offered by the manufacturer, i.e. PIC16F131xx systems.

Parameters and peripherals

This part of the text discusses the CIP and CLB solutions and the manner in which they make it possible to retain the system’s computational power to manage applications, while they fulfil simpler tasks (operation of buttons and certain displays, recalculating values obtained from converters). However, let us firstly take a closer look at the PIC16F131xx microcontroller specifications and design.

These systems are based on the classic 8-bit Harvard architecture. They come in through-hole (THT) and surface-mounted (SMD) packages. The DIP, DFN, SSOP, TSSOP, SOIC and VQFN packages are available with 6, 12 or 18 input/output pins. A wide range of acceptable supply voltages, i.e. from 1.8 V to 5.5 V DC, is a significant advantage, too. They are clocked with the 32 MHz frequency signal, and the minimum instruction execution time is 125 ns. The systems include from 256 bits to 1024 bits of SRAM operating memory and up to 14 kB of program memory (FLASH).

Designers are provided with an extensive selection of hardware peripherals, such as PWM signal generators, 8- and 16-bit counters/timers, an EUSART serial bus controller, MSSP (Host Synchronous Serial Port) module capable of operating in the I2C or SPI interface operation mode, configurable comparators with reduced response time (50 ns), an 8-bit digitalto-analogue (DAC) converter and a 10-bit analogueto-digital converter with a module enabling computation (ADCC), i.e. hardware-based processing of the values obtained. Note also the CIPs included in the systems presented here.

Microchip has been including CIPs (Core Independent Peripherals) in its products for some time now, both in the PIC® and AVR® product families. They facilitate performing certain tasks (e.g. communication with sensors) in the background, without using the CPU processing power, which thanks to that is entirely available for the main program execution, leading to reduced energy consumption and simplification of the program itself. Dedicated peripherals can be used for data transmission (I2C, CAN, USB), counting down the time (timers), PWM signal generation or handling analogue signals (ADC, OP-AMP, DAC).

The key innovation introduced in PIC16F131xx controllers consists in providing their structure with independent, configurable logic elements (their operation principle results in the fact that this system is treated as a CIP peripheral). This technology is described as CLB (Configurable Logic Block). It ensures functional safety and instant response time. The CLB technology is based on structures used in FPGA systems, i.e. designs ensuring the shortest possible input signal processing times. CLB uses basic logic

gates that can be freely configured by a designer for the purposes of a specific application. Additionally, it facilitates target device miniaturisation by excluding external components and reducing the PCB size. Precise determination of the task execution time is a key advantage of the CLB technology. It results from the fact that, even though these tasks involve relatively complex procedures, their execution is always based on hardware.

The CLB structure in PIC16F131xx microcontrollers includes discrete components creating 32 identical cells, each of which is a basic logic element (BLE). All of them are clocked with the CLBCLK signal leading edge. Depending on the actual needs, a cell simulates a single logic system defined during the programming stage. It can be:

• AND gate (max. 4 inputs);

• NAND gate (2 inputs);

• OR gate (max. 4 inputs);

• NOR gate (2 inputs);

• XOR gate (max. 4 inputs);

• XNOR gate (2 inputs);

• NOT or buffer (1 input and output);

• D or JK flip-flop;

• configurable LUT (Lookup Table) – up to 4 inputs.

Moreover, you get an extensive input and output signal selection. The conditioning values may originate from a 32-bit register available on the program level, or they can represent the status in microcontroller I/O lines, or they can originate from the PWM generator, timer/counter or even the

SPI serial bus buffer. The same is true for the configured gate leads which can be connected to a converter, timer or physical output lines (pins) of a system during the programming stage. Each of the four cell groups can optionally generate an interrupt handled by the program. Note also that the BLE cells come with tri-state outputs.

To sum up: a designer obtains a fully configurable structure that is similar to FPGA and implemented in a state-of-theart, 8-bit microcontroller. The 102 bytes of the internal memory are provided to store settings. Finally, there is also the question of setting up the unit.

Setting up FPGA systems is often considered to be an activity requiring specialist, in-depth expertise. However, the tools for handling PIC16F131xx products are developed in a manner that makes using them quite straightforward. Therefore, even beginner developers are able to quickly master the basics and achieve the intended results.

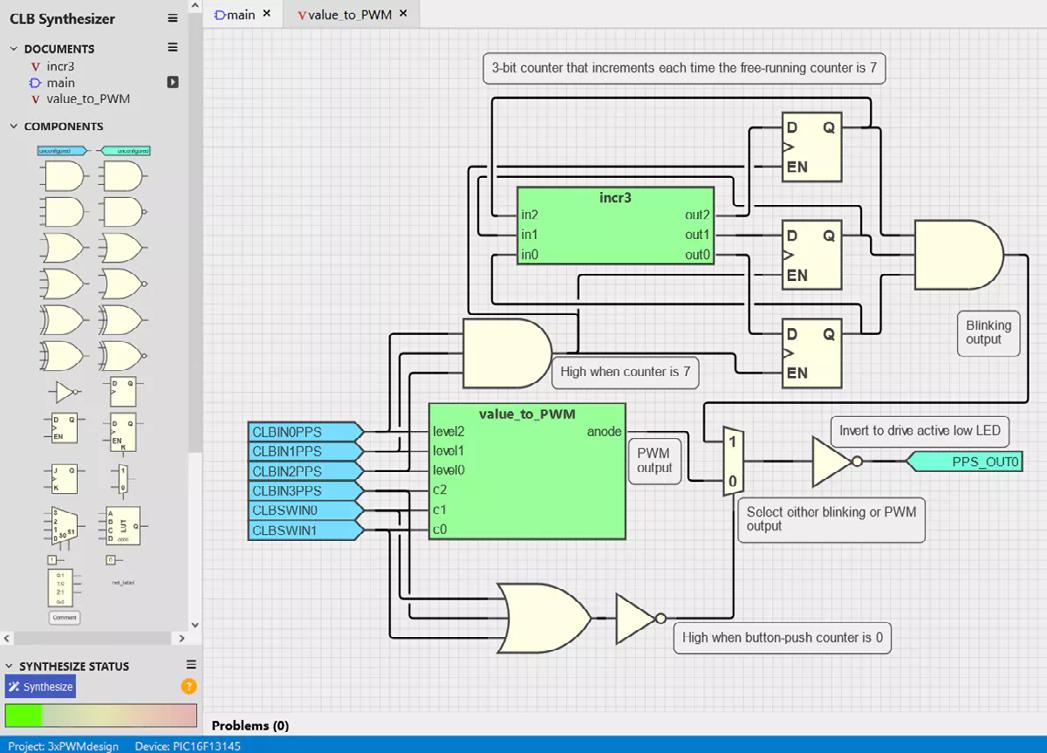

Firstly, a CLB is set up using the dedicated CLB Synthesizer software based on a graphic interface. Its use is equivalent to creating a block diagram, which makes the program quite clear, even if you are not familiar with all the functionalities of this environment.

The software is provided as a plug-in to the proprietary Microchip’s IDE, i.e. MPLAB® X. The tool can be used in a regular browser, as it is made available as a Web-based application. The CLB Synthesizer creates a set-up file which can later be imported to a design or a source file (.clb) written in the VERILOG language.

The diagram is built by dragging blocks and connecting them between one another, with predefined input/output lines. The process of operating MPLAB® involves seven simple steps:

1. Setting up clocking signals.

2. Setting up digital blocks, such as UART, I2C, TMR, etc.

3. Adding analogue peripherals, such as ADCC and DAC.

4. Adding a CLB peripheral to a design by creating a block diagram with components included in BLE cells and defining connections between them and input signals.

5. Synthesis, i.e. creating a set-up file.

6. Finally, a function must be defined and assigned to microcontroller inputs/outputs used in the design.

7. The last step involves generating the Melody code.

Note also that, for educational purposes, Microchip has created a number of practical examples of CLB applications for various task performance. They include, among others:

• handling a shift register for programmable (addressable) WS2812 LEDs;

• hardware-based debouncing of button signals;

• Manchester modulation encoding/decoding;

• multiplexing a 4-bit value into signals controlling a 7-segment display;

• frequency processing.

The video presented here shows one of such applications, i.e. creating a controller for 7-segment LED displays. Note here that this CLB set-up creates a program that operates totally independently from the microcontroller core. In practice, it could replace a dedicated controller system by simplifying and reducing the circuit of the designed device, and also by reducing its energy consumption.

board can be connected to a prototyped circuit using pin connectors.

The Curiosity Nano platform has been created to provide Microchip customers with development kits presenting the capabilities of the latest microcontrollers marketed by the company. The development boards are designed in a convenient format, including an integrated debugger, programming device and access to microcontroller pins. It makes them perfect training and educational tools. Obviously, a dedicated Curiosity Nano has also been developed for the PIC16F131xx product family.

EV06M52A is a development kit equipped with the PIC16F13145 microcontroller. The circuit includes a USB-C port for power supply and programming. The LDO MIC5353 regulator supplies voltage to the microcontroller. Optionally, the circuit can be fitted with an RTC quartz-crystal resonator (32.768 kHz). The power supply and programming status is indicated by a green LED. A yellow LED connected to one of the microcontroller outputs can be operated by the microcontroller. The board also features a button.

Functions of the development kit can be extended by applying adapters dedicated to Curiosity Nano boards.

The above-mentioned products are equipped with universal (female) pin connectors to mount the Curiosity Nano board. As far as the AC164162 is concerned, the circuit comes with several interesting components, such as three connectors compatible with the mikroBUS™ standard used in the Click modules offered by Mikroe. Note also that the TME product catalogue includes more than one thousand of various models of these boards. The PCB also features the Xplained Pro extension connector. Moreover, the entire unit can be supplied by batteries, as the adapter comes with an integrated charging and power management system that is compatible with lithium-ion and lithium-polymer cells

As 3M® exits the market with its discontinuation of the Novec fluids range, many companies are now considering options, to find suitable replacements. However, choosing the right alternative isn’t as simple as picking the first product that claims compatibility. There are critical factors to consider ensuring that the replacement you choose not only meets your current needs but also sets you up for long-term success. Here’s what you need to know when searching for a 3M® Novec replacement.

The first and perhaps most crucial step in selecting a replacement is ensuring your supplier is well-established and reputable. With over 55 years of experience, Fraser Technologies has been a trusted partner to many worldclass clients. The company has a proven track record of helping clients navigate complex regulatory transitions, including those from legacy chemicals like CFCs, HCFCs, and HFCs. This depth of experience ensures that Fraser Technologies is not just offering products but providing expert guidance through this latest transition away from 3M® Novec products.

The market is flooded with cheap alternatives, many of which come from less reputable sources. These products often suffer from multiple issues, such as questionable longevity of supply, inconsistent quality, and inadequate

product stewardship—including insufficient testing, lack of safety data, and potential legal issues like patent or IP infringement. Fraser Technologies only supplies high-quality chemicals and products, partnering with industry leaders like Chemours™, known for their rigorous quality controls. By choosing Fraser Technologies, you can avoid the pitfalls of inferior products and ensure you are working with materials that meet the highest standards.

Click here to continue reading this article >>

Dichroic beamsplitters from Optical Surfaces Ltd are commonly used as light guiding optics in telescope spectrographs and to enable multichannel CCD cameras to simultaneously acquire images in different colours.

Beamsplitters operate by dividing an incident beam of light into two parts. One part is transmitted through the beamsplitter, the other is reflected. In a dichroic beamsplitter the light is either reflected or transmitted based on wavelength. By varying the coating on a dichroic beamsplitter you can change the reflection to transmission ratio at specific wavelengths.

Dr Aris Kouris, Sales Director at Optical Surfaces Ltd. said “We are internationally recognised as a leading provider of high precision optical components for terrestrial and spaceborne telescope spectrographs. Spectrographs are the ‘go to’ scientific instruments used to study the chemical / physical conditions that exist through a cross-section of space. Combined with a terrestrial or spaceborne telescope a spectrograph can reveal the details that are stored in the spectral distribution of light from a distant star or galaxy”.

He added “To achieve state-of-the-art image quality from telescope spectrographs it is essential to be able to produce dichroic beamsplitters with minimal flatness error and wavefront error both before and after coating. Operating in a uniquely stable manufacturing environment our team of experienced optical craftsmen routinely produce an ultra-high precision

finish on all surfaces of beamsplitter blanks up to 500mm in diameter. Typical beamsplitters are manufactured to a surface accuracy of lambda/20 p-v at 633 nm, a surface quality of 10/5 and microroughness of less than 1 nm rms. Our dichroic beamsplitters can be supplied with an extensive range of coatings designed to operate at the required angle of incidence. Using proprietary techniques, we can correct for coating induced distortion”.

Optical Surfaces Ltd is a highly respected supplier of high precision dichroic beamsplitters to the global astronomy community. For further information on custom beamsplitters please visit: optisurf.com/prisms-beamsplitters-filters-fibres/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com

Expanded Beam Performance added to ODU MINI-SNAP®, ODU MEDI-SNAP® and ODU-MAC®.

The innovative Expanded Beam Performance (EBP) technology, which is already available in the robust AMC Series T connectors, is now also available for the MINI-SNAP Series K, MEDI-SNAP, ODU-MAC Silver-Line and ODU-MAC WhiteLine product lines.

As a non-contact lens technology, Expanded Beam Performance products offer a game-changing interface for fibreoptic systems. EBP technology achieves numerous advantages, including low attenuation, virtually no cleaning or maintenance requirements and a long service life.

These advantages make EBP the ideal solution for applications where maximum reliability and performance are required.

Future-proof EBP technology impresses with optimum performance

• Low attenuation levels

For maximum signal quality and low latency, EBP solutions achieve attenuation levels that are even lower than the outstanding values of conventional physical contact (PC) solutions

(SM) < 0.35

Multimode (MM) < 0.15 dB

Singlemode (SM) >

Multimode (MM) > 45

• No cleaning or maintenance required

Ferrule cleaning is only necessary in the case of extreme soiling. Under normal conditions no maintenance is required, the maximum service life can be achieved without a single cleaning process.

• Long service life

Contactless transmission means there is no wear on the contact elements, so that at least 50,000 mating cycles can be achieved.

AMC Series T Expanded Beam Performance

The previously available combination consists of EBP technology and a robust circular connector for harsh environments. With its innovative 3-in-1 locking system, non-reflective surface and high resistance to external influences, the AMC Series T has already proven its worth as an EBP solution.

MINI-SNAP Series K Expanded Beam Performance

The classic circular metal connector characterized by its safety and flexibility. This is available with the proven push-pull locking system and protects the fibre-optic transmission with an IP68 protection class. The smallest 12-lens plug on the market.

MEDI-SNAP Expanded Beam Performance

Made of high-quality plastic, the Medi-Snap is up to 75% lighter than comparable products. Its features make it ideal for mobile applications, especially in the medical sector.

ODU-MAC Silver-Line & White-Line EBP module

Integration into a modular connector enables the hybrid use of EBP technology with other media such as electrical signals or air and fluids. The robust interfaces enable automatic or manual docking with a high number of mating cycles.

With the extension to the MINI-SNAP, MEDI-SNAP and ODU-MAC series, ODU now offers solutions for an even wider range of industries and applications. Further information about Expanded Beam Performance can be found at https://odu-connectors.com/uk/technologies/fiber-optic/

ODU UK Ltd

Tel: 0330 002 0640 :: Email: sales@odu-uk.co.uk :: Web: www.odu-connectors.com/uk

Titan Enterprises’ popular Pulsite® Link pulse and analog converter, a successful addition to Titan’s line of liquid flow measuring instruments, is now available with the useful additional design feature of an LCD display.

Based on customer demand, developing a display model of the Pulsite® Link will enable local indication of flow rate and total or both, from the installed pulse flowmeter. A local and remote reset for the totaliser is also featured with the display option, along with full PC integration via the USB and Titan’s interface software. However, incorporating the display was not without its challenges from an R&D perspective!

Neil Hannay, Senior Development Engineer with Titan Enterprises, says: “Fitting the display and the required electronics into such a small space without redesigning the whole unit certainly presented a challenge.”

“Working closely with our PCB manufacturer, this issue was overcome by the ingenuity of design involving specialist mounting,” Neil continues. “The single PCB was remodelled into a compact design that was mounted onto the display within the unit’s restricted dimensions.”

The Pulsite® Link helps users convert common pulse output flow metres, such as Titan’s precision turbine flowmeters and positive displacement flowmeters, to scaled and linearised analog and NPN/PNP outputs. With over a hundred units sold since it was first launched, it is ideal for general industrial use.

The opportunity to incorporate a few bug fixes into Titan’s proprietary Interface Software have also been made alongside the product development. The interface software that supports The Pulsite® Link, as well as the Atrato® and Metraflow® ultrasonic flowmeters, allows the user to configure and test the system via USB and a computer. The USB stick

supplied with the Pulsite® Link can be inserted into the unit without needing to disassemble it, allowing for real-time monitoring and data-logging via a Windows PC.

The Pulsite® Link is an ideal instrument to connect to customer devices for increased accuracy on mechanical flow devices, data monitoring, test rigs and control systems.

For full technical specification: flowmeters.co.uk/product/pulsite-link-pulse-analogconverter/.

To discuss an optimised flow measurement device for your specific application or process please contact Titan Enterprises on +44 (0)1935 812790 or email sales@flowmeters.co.uk. Or visit our website for further information.

Titan is a leading design and manufacturer of innovative end user and OEM high-performance flow meters, used within a wide range of environments and applications.

• Compact, robust, reliable

• Excellent accuracy and repeatability

• Measure low to high flow ranges

• High chemical resistance

• OEM bespoke design capability

REQUEST A QUOTE TODAY +44 (0)1935 812790

From day one, Learners on the EEMUA MIPC® training build a unique workbook of mechanical integrity know how tailored to each Learner, site and company. Combining live online classes, e-learning, and one-to-one sessions with expert Tutors, enhanced by Mentor support and guidance throughout, EEMUA's Mechanical Integrity Practitioner Certificate course gives professionals the flexibility to learn on-site or on-call.

Developed and verified by industry to satisfy industrial engineering’s requirements f or primary containment in old and new equipment – i including pressure systems

K Keeps practitioner-level engineers on top of industry developments and good practice – so that valuable practitioners are most effective wherever they’re needed on-site.

E Enterprise-class, blended, live online system for productive learning – on-site or on-call.

A Adapts to the engineering needs of each Learner and their company via an Induction of 2 hours prior to the course – to fit work schedules from September 2024.

I In-depth training to fit work schedules – 4 hours per week for 27 weeks.

C CPD-approved with industry recognised 5-year certification via robust exam.

Registration open now. Learning starts 21 October 2024.

For more information please contact: online-learning@eemua.org +44 (0)20 7488 0801 www.eemua.org

Popular podcasts explore Microchip’s approach to innovation and look into how embedded control technology improves all our daily lives.

Microchip Technology (Nasdaq: MCHP) a leading provider of smart, connected and secure embedded control and processing solutions, has announced the return of two of is popular podcasts “Microchip is…” and “Beyond the Microchip,” with new episodes now streaming.

This season of the “Microchip is…” podcast picks up where series one left off, with each episode highlighting a different area of Microchip’s product offering. Episodes will explore the technological landscape and relevant engineering challenges, while providing an in-depth look at Microchip’s approach, products and service offerings. Confirmed topics for episodes in

series two include atomic clocks, medical applications, security, dsPIC® Digital Signal Controllers and both wired and wireless connectivity.

Part of SICK’s extensive range of sensors for extreme conditions, the robust, reliable, and customisable IMG sensor provides stable detection for demanding industrial machinery

Global industrial sensor expert SICK has unveiled the latest in its extensive product range with the IMG inductive sensor, designed specifically to provide stable detection in harsh environments. With machinery manufacturers and system integrators increasingly being called out to sites to carry out minor maintenance and repairs, the reliability, robustness and repeatability of components is crucial.

As rising skills and labour shortages continue to affect the manufacturing industry, particularly among maintenance technicians, OEMs and equipment suppliers are receiving more requests for site visits from field service engineers. Ensuring parts are robust and reliable can reduce the burden on equipment suppliers, as well as enhancing their reputation by preventing costly stoppages.

SICK’s IMG inductive proximity sensor for metal detection is designed specifically for industrial machines that require precise switching points and a high level of repeatability in harsh environments. For example, IMG sensors are perfect for the machine tooling industry, where they can be used for detection of tool turret position, tool detection on the turret or to determine the lock/unlock position of the turret.

SICK’s sensor range provides reliability, robustness and repeatability

Part of SICK’s wide range of industrial sensors, the robust mechanical design of the IMG family of sensors features innovative SICK technology to deliver stable and repeatable detection at a highly competitive price point. In addition, SICK sensors come with fast order times and can be customised to suit customers’ specific design requirements.

The SICK IMG inductive sensor family operates in environments where many inductive sensors fail to perform. Suitable for end position and home position detection, as well as simple speed detection tasks, the robust device is impervious to shocks, vibration, oil, cooling lubricants, and weather effects such as rain, snow, mud and frost.

Machine manufacturers looking for the highest levels of consistency, longevity and reliability from their components can benefit from sensors across SICK’s extensive range, which includes inductive, capacitive and magnetic sensors designed specifically for use in harsh environments.

SICK sensor technology experts are always on hand to work with design teams and engineers to ensure they identify the right sensor to meet customers’ specific needs. Machinery manufacturers can also work with SICK sensor specialists to customise or modify sensors to suit their specific machine.

SICK UK Market Product Manager - Presence Detection, David Hannaby, says, “IMG combines robustness and stable detection in a great value product. We know that industrial machinery manufacturers are experiencing added pressures as a result of labor and skills shortages in manufacturing, including additional callouts. The tough IMG sensor family is designed for machines operating in harsh environments where reliability and stable detection is critical.

“IMG is already available in countless variations, but at SICK we want our customers to achieve the optimal performance from our products. That’s why, rather than designing to fit our sensors, our experts can work with your engineering and design teams to provide you with samples and help you select and modify the best-possible sensors for your needs.”

Learn more at sick.com

Lily Brothwood, Business Operations Manager at Intelect

Founded in Middlesborough in 1997 by four directors who themselves began their careers as apprentices, Intelect has always recognised the transformative potential of technical education. This belief in the value of hands-on learning led to the launch of Intelect’s apprenticeship scheme just a year after its inception, in 1998.

For us, the decision to invest in apprenticeships was both personal and strategic. The company was acutely aware of the growing skills gap in the UK engineering sector, a challenge that continues to hinder businesses’ access to qualified talent. According to data from the Institution of Engineering and Technology (IET), nearly half of engineering firms (49%) struggle to recruit workers with the necessary skills. Through our apprenticeship program, we’ve taken proactive steps to counter this issue, ensuring we have a steady pipeline of skilled workers who are trained in the specific needs of the business.

Our apprenticeship scheme is something we’re really proud of, and it continually reinforces the company’s dedication to technical education. Just this year we were ranked by the government in its Top 50 SME Apprenticeship Employers rankings for 2024. By regularly bringing new talent into the business, our apprentices not only inject fresh ideas and perspectives, but also cultivate a unique workplace culture that values innovation and growth.

There are also great values to our apprentices – they have the opportunity to “earn while they learn,” gaining practical experience while receiving a salary. This approach empowers them both professionally and personally, providing a clear career path and the potential for long-term employment with the company.

The business’s commitment to its apprentices doesn’t end with their initial training. We embrace a ‘train to retain’ ethos, offering a clear progression path that encourages apprentices to take on more responsibilities as they advance in their careers. This commitment to development is in our retention rate, with 54% of apprentices choosing to remain with Intelect after completing their programs. Today, over 40% of the workforce is made up of current and former apprentices, a testament to the success of the scheme and the quality of the training provided.

Even for those apprentices who choose to move on, the skills and experience they gain at during their time with us equip them to excel anywhere in the industry. This means there is a positive impact on the engineering sector more widely too.

Another positive impact has been the ties we’ve been able to establish in the local community. We’ve built relationships with educational providers and young people, through our apprenticeship offering. Over the years, training providers have grown in number and include: JTL Training, Middlesbrough College, Hartlepool College, and Teesside University. These partnerships have been instrumental in shaping the company’s apprenticeship program, providing valuable feedback and helping to identify passionate talent. Our ongoing collaboration has meant that the apprenticeship scheme remains relevant, effective, and aligned with industry needs.

Looking ahead – we hope to keep reaching more people. We’re aiming to expand our apprenticeship offerings to accommodate the growing demands of the engineering sector. Currently, we employ between 40 and 50 apprentices at various educational levels, from Level 2 to degree-level qualifications. As we continue to grow, we are eager to bring in more apprentices across a wider range of levels, particularly in response to the increased emphasis on STEM (Science, Technology, Engineering, and Mathematics) education.

Click here to read the full article >>

For those interested in learning more about how apprenticeships can benefit their business click here

You can secure your plant, or you can access your production data—but not both. At least, that was the conventional wisdom for decades. Now Industrie 4.0 and competitive pressures are pushing companies to find a way to access production data securely. The good news is, it can be done.

Some options are better than others, though. For example, VPNs are not a safe bet. VPNs effectively extend the security perimeter beyond the plant network to include the IT network. A security breach on the VPN exposes all systems on both networks to attack.

Another option is to combine OPC and MQTT for in-plant and plant-to-cloud security. This approach draws on the strengths of both protocols but falls short when it comes to NIS 2 recommendations to isolate networks using a DMZ. The OPC UA protocol is too complex to reproduce through a DMZ, and the QoS guarantees in MQTT cannot propagate well through a DMZ, making data at the user end unreliable.

A secure tunnel/mirror implementation, on the other hand, can support connections across a DMZ because it can mirror the full data set at each node. It provides access to that data, both for qualified clients as well as the next node in the chain. Good tunnel/mirror software can guarantee

consistency, so that the data for any client or intermediate point in the chain will be consistent with the original source.

For secure access to your production data, keeping all inbound firewall ports closed and isolating networks with a DMZ, the best approach is tunnel/mirroring. DataHub Tunneller software from Skkynet offers a secure way to connect OT and IT systems for real-time data flow without compromising on cybersecurity, enabling companies to remain competitive without sacrificing security.

Read the white paper.

For data protocols that are difficult to connect, the DataHub Tunnel/Mirror provides easy-to-configure, secure and robust networking. Eliminate the hassles of DCOM, detect network breaks quickly and recover from them smoothly. Access your remote data, not your plant systems. Connect and share data among locations with no DCOM or Windows security issues.

The DataHub Tunnel/Mirror goes beyond the basics, letting you integrate your data without exposing your network. Simply better networking.

Amsterdam, Netherlands – 1-2 October – With only four weeks remaining until the Intelligent Automation Conference 2024, excitement is building as the event gears up to take place at the RAI Amsterdam on October 1-2. This highly anticipated gathering will bring together top experts, innovators, and decision-makers from across the globe to explore the future of intelligent automation. The conference will feature an expanded roster of new speakers, interactive sessions, and cutting-edge demonstrations, all designed to equip attendees with the insights and tools needed to drive innovation in their organizations.

The conference is delighted to announce the addition of several speakers to the already stellar lineup:

• Maximo Alves, Head of Data Engineering & Governance at Just Eat Takeaway.com - Key topics include data governance, scalability, and the use of emerging technologies such as AI and machine learning in data strategy optimization.

• Joseph Corasaniti , Head of Technical Operations, Bank Network at Stripe – This session will provide an in-depth exploration of how no-code and low-code automation platforms can revolutionize business operations.

• Masood Alam, Chief Data Architect at The Scottish Government – This session explores the transformative potential of intelligent automation through the seamless integration of multiple technologies.

• Daria Ignatova, Program and Adoption Director Delivery Excellence at Pegasystems – This session will focus on explaining what being an autonomous enterprise means, and what it looks like in practical terms at various organizations across industries.

With just four weeks to go, attendees can look forward to a dynamic and immersive experience, including:

• Expert-Led Sessions: Participate in over 150 sessions led by industry experts covering AI, machine learning, robotic process automation (RPA), and digital transformation.

• Live Demonstrations: Witness the latest innovations in intelligent automation technology through live demonstrations from leading solution providers.

• Networking Opportunities: Connect with industry professionals from around the world, fostering collaboration and knowledgesharing within the automation community.

• Panel Discussions: Join thought-provoking panel discussions as industry leaders debate the challenges and opportunities presented by the rapid adoption of intelligent automation.

• Exhibition Floor: Explore cutting-edge products and services from over 200 exhibitors showcasing the latest advancements in automation technology.

With just four weeks left, now is the time to secure your spot at the Intelligent Automation Conference 2024. For more information and to register, please visit: intelligentautomation-conference.com/europe

This event is part of the TechEx event series. One ticket provides access to 8 co-located events, including Edge Computing Expo, IoT Tech Expo, AI & Big Data Expo, Digital Transformation Week, Cyber Security & Cloud Expo, Unified Communications Conference, Data Centres Congress, and the Intelligent Automation Conference. Join over 7,000 attendees, connect with 150 speakers, and chat with over 200 exhibitors.

For more information and to register, please visit techexevent.com/europe/.

LiftEx 2024, the flagship event of the Lifting Equipment Engineers Association (LEEA), will take place on 16-17th October 2024 at the West Hall at Olympia in London – a great central location for a truly global industry.

The exhibition floor at Olympia will be packed with almost 100 exhibitors showing their solutions to improve productivity, efficiency and safety for end users. These will feature the latest lifting products including hoists, mobile and overhead cranes, steel chains, wire rope, winches, shackles, web slings, rigging, spreader beams, height safety and load monitoring equipment, IT solutions and more.

Crucially, your visit will contribute to improving safety with advice from experts on the LEEA stand, while free training sessions and presentations will be delivered by LEEA Accredited Training Scheme members at the ATS Seminar, which is being held across both days.

Set to be the best yet, LiftEx 2024 is supported by sponsors including YOKE, the manufacturer of lifting fittings for chain, wire rope and webbing slings; Rope and Sling Specialists, one of the largest independent

companies in the field of lifting equipment engineering in the UK; and Headline Sponsor RiConnect Inc, which offers powerful software known as RiConnect that is designed to streamline equipment management and ensure regulatory compliance and traceability.

The many networking opportunities during the event will include the annual LEEA Awards ceremony will be held at the iconic Dorchester hotel on the evening of 16 October 2024.

For engineers, LiftEx 2024 offers the perfect chance to gain vital lifting related knowledge and insights, as well as an opportunity to meet LEEA members

and discuss ways they can help achieve best lifting practice.

For those interested in exhibiting, a few stands remain available. Sponsorship packages are also available for the exhibition and Awards Dinner.

Requests will be dealt with on a first-come, firstserved basis, so please contact Leah Phelps on +44 20 3488 2865 or at enquiries@L2Events.com or visit: events.leeaint.com/liftex-london-2024

The UK’s biggest event dedicated entirely to mechanical, WHAT’S INCLUDED IN YOUR FREE PASS?

Join thousands of design engineers this October! Source the latest products, services and innovations available to the sector.

9-10 October 2024

Coventry Building Society Arena

ACCESS FREE SESSIONS AND WORKSHOPS

The Engineer, Eureka and New Electronics curate an informative programme for EDS covering the latest trends, opportunities and challenges for design engineers.

EXPLORE THE INNOVATION ZONE

From robotics innovation to Creative Hubb

Ltd’s EOD bomb disposal suit, make sure to stop by the

COMPETE IN THE GAMES ZONE

Back by popular demand, don’t miss the immersive F1 racing simulators and games area. Get ready for even more activities, stay tuned!

STOP BY THE NTU SHOWCASE

Meet the next generation of product design engineers! Nottingham Trent University’s product design students are back showcasing their projects.

REGISTER YOUR FREE PASS TODAY

VISIT OUR START-UP ZONE

Meet the newest industry game-changers and cutting-edge advancements. Discover their products and innovative solutions.

CHECK OUT THE ROBOT HOUSE

The Robot House from the University of Hertfordshire will be showcasing their state-of-theart robots and pioneering research in human-robot interaction.

• ‘By Industry, For Industry’, practical guidance for everyday and irregular situations and tasks

• Readily accessible for all in the industry –wherever they are, whatever time they have

• FREE task and procedure checklists

•

•

•

Articulated Pipework Torsion In Hoses

Rotating Cylinders

Swivel joints allow pipework to pressure 1/4” to 40” and beyond.

Vacuum to over 20,000psi.

Stock and bespoke production.

Unique bearing/seal design for longer life.

ISO 9001 CE marked where applicable.

Tel: +44(0)1663 735003

E-mail:

The UK arm of one of the world’s largest chain manufacturers is proud to celebrate its 15th anniversary in the UK this month (August 2024).

Over the past decade and a half, Donghua Limited has established itself as a trusted name and has become a leading player in the industry, known for its commitment to quality, innovation and customer satisfaction.

Donghua Limited - the UK subsidiary of the Hangzhou Donghua Chain Group - opened its doors in Wolverhampton in 2009. Its dedication to excellence and its commitment not to sell direct to end-users, has earned it a loyal customer base of Product Partners, Stockists and Distributors across the UK and Ireland.

The company offers a comprehensive range of products from the Group’s extensive portfolio including conveyor chains, attachment chains, agricultural chains, leaf chains, roller chains and sprockets.

Over the years, Donghua has expanded its product offering and services, ensuring it meets the evolving needs of customers. The latest products launched in the UK have been the EXL and X3 roller chains.

The company’s on-site technical chain workshop provides in-house built custom chain and universal attachment chain solutions, alongside chain cutting, measuring and matching of chain, and hot dip lubrication services.

The range of Donghua branded lubrication sprays and chain tools offers customers’ additional chain accessories they can stock so endusers can further enhance chain performance and longevity.

With a focus on delivering exceptional customer service, Donghua was revolutionary in introducing the UK’s first app focused on chain identification. The Chain ID App, launched in 2017, has proved a popular tool for engineers who need to identify replacement chain quickly.

“We are incredibly proud to celebrate 15 years of success in the UK,” said Bob Wellsbury, Managing Director of Donghua Limited. “This milestone is a testament to the hard work and dedication of our growing team, as well as the loyalty of our customers.”

“As we look to the future, we remain committed to providing innovative chain solutions and an exceptional, high quality service to our customers.”

To read Donghua Limited’s special anniversary newsletter, visit: www.donghua.co.uk/chaintorque-newsletter/

As a global manufacturer and supplier of fasteners and c-class components, Optimas has a wealth of experience in supporting industrial producers who are looking to find greater value in their fastener usage.

The process of changing fastener suppliers can seem daunting; however, we have broken down five key considerations when thinking about changing partners. (...cont)

Before making any decisions, consider whether you need to change your fastener supplier to keep your operations competitive, efficient and aligned with your business goals. This requires a keen understanding of your current challenges as well as looking towards the future.

You can break down this process with a few key indicators that will help uncover the benefits of changing fastener suppliers.

• The quality of fasteners supplied is causing product failures, increased maintenance or customer dissatisfaction.

• Your current supplier is not helping you achieve optimal inventory levels, which is leading to stock shortages or excess and obsolete, affecting your production costs.

• You are finding challenges in communication and the supplier does not provide you with a specific team to address your needs.

• Their engineering capabilities are not contributing to the innovation of your products.

As you consider these indicators, think about the longterm goals of your business and the role a supplier partnership plays in achieving them. The right supplier

will grow with you, offering solutions that anticipate future challenges and opportunities.

The first task to do before searching for your new fastener supplier is to create a comprehensive review that documents your fastener usage. This can include sizes, types, materials, annual volume, seasonal fluctuations in demand and more. These details are fundamental to ensure a successful supply and provide the service you require.

Next on the task list is thinking about the pain points in your fastener supply chain operations. For example, are you having quality issues or are the current costs too high for your operations?

All of these findings will allow you to effectively communicate your needs and target outcomes throughout your search for a new partner.

After identifying the need for change and preparing your organization for a supplier transition, the next step is selecting the right partner. Look for partners who have a proven track record in

your industry. They should have strong distribution capabilities, a commitment to quality and innovation, and ideally, robust manufacturing capabilities as well.

The addition of in-house capabilities, such as manufacturing, enables you to maintain a continuous supply of parts and also mitigates the risk of supply chain disruptions.

To easily evaluate the different fastener suppliers you speak with, create a simple scorecard where you rank these organizations on topics such as:

• Financial stability

• Demand planning capabilities

• Implementation plans

• Localized customer support

• Technology capabilities

• References and case studies

After selecting the right fastener supplier, the next step is to collaborate with your new partner on a comprehensive transition plan.

A great way to do this is by establishing a dedicated, cross-functional project team that includes members from procurement, engineering, operations and quality

assurance. That team will then guide all aspects of the process. Among them, a project manager can be nominated as the primary contact to act as the point of call between your organization and your new fastener supplier.

Another important consideration is to map out key timelines for the transition. This should include deadlines for inventory audits, data integration, first deliveries, in-plant bin/rack installations and inventory management technology implementation. Setting clear milestones helps track progress and ensures all parties are aligned on expectations.

After the transition is complete, conduct a postimplementation review to assess its successes and identify areas for improvement. Reviewing the transition objectives against the results with key stakeholders from both parties is a good way of gaining insight on your new partner.

Furthermore, you should implement regular performance reviews with your new fastener supplier. This meeting can include all aspects of the relationship-from product quality to service levels and future product roadmaps with dedicated representatives to help elevate your new relationship with the partner.