Lead generation

Enquiry referrals, web analytics, introductions

Market intelligence

Integration with GTMA companies, collective engagement with OEMs, market analysis and appraisal of new sector opportunities

Marketing and promotion

Promotion across digital and print media channels, representation at GTMA and 3rd party events at preferential rates

Networking events across the whole of the UK & Ireland

For

A fast-growing contract manufacturing specialist for the healthcare sector has completed a three-year, £3.5m investment drive as it targets new opportunities.

Europlaz, which has enjoyed 20% year-on-year growth, has recently spent £750,000 on the installation of three additional all-electric injection moulding machines to cope with an increase in orders and this equipment complements robotic technology, Piovan material dryers, a new CMM machine and toolroom/cleanroom upgrades.

Boosted by an increase in capacity at its Southminster facility, the company is focused on both UK and international medical device manufacturers and engineering design houses looking for a strategic partner who can take a project from proof of concept through to routine and large-scale commercial manufacturing.

“There has been a massive surge in demand for our services, which support the development and commercialisation of devices for use in diagnostics, drug delivery, biotech and pharma,” explained Katy O’Keeffe, Marketing & Strategy Director.

“Europlaz is known for our agility and our ability to tackle complex projects, leveraging our design for manufacture experience, our technical knowledge and capabilities that stem from tooling and small batch work to long-term, high-volume production.”

She went on to add: “This, combined with our 40-year track record, has seen us build an impressive long-term client list, including the NHS, GE Healthcare, Johnson & Johnson and Medtronic.

“We know there is a massive opportunity and have responded by continuing to invest in the first eight months of 2024. This takes our total spend to £3.5m over the last three years and we’ve got more technology on order and on its way. This is the perfect time to press the ‘growth’ button.”

Europlaz, which is ISO13485-certified, operates from its state-of-the-art production facility on The Maltings Industrial Estate in Southminster, near Chelmsford.

From here, the family-run business offers injection moulding, assembly, product validation and access to modern cleanrooms, all certified to ISO Class 7 for the manufacture of Class I, Class II and Class III medical devices.

Most of its work is focusing on helping medical device and healthcare businesses commercialise new technology, with recent success stories featuring a home dialysis machine, a patient friendly and easy-touse breath operated inhaler and a bio-artificial liver. Click here to continue reading >

As a global manufacturer and supplier of fasteners and c-class components, Optimas have a wealth of experience in supporting customers who are looking to find greater value in their fastener usage.

Over on stand H150 for the Advanced Engineering exhibition from the 30th – 31st October, Optimas’ experts will be speaking to attendees on how they can simplify their supply chain, reduce their total cost of ownership and explain how they help manufacturers transition to their products and services to ensure a smooth process.

Thinking about whether you need a change in fastener supplier to ensure your operations remain competitive, efficient and aligned with your business goals needs to be the first consideration. This will require a keen understanding of your current challenges, as well as looking towards the future.

You can break down this process with a few key indicators that we have used to help customers understand the benefits of changing fastener suppliers.

• The quality of fasteners supplied is causing product failures, increased maintenance or customer dissatisfaction.

• Their engineering capabilities are not contributing to the innovation of your products.

• Your current supplier is not helping you achieve optimal inventory levels, which is leading to stock shortages or excess and obsolete, affecting your production costs.

The first thing you should start before the search of your new fastener supplier should be to create a comprehensive review which documents your fastener usage. This should include sizes, types, materials, annual volume and seasonal fluctuations in demands. When speaking to prospective new customers, these details are fundamental to ensure a successful supply and provide the service you require.

All of these findings will allow you to effectively communicate your needs and your target outcomes throughout your search for a new partner.

You should look for partners with a strong track record in your industry, including their distribution capabilities a commitment to quality and innovation and as a bonus robust manufacturing.

Having the addition of in-house capabilities, such as manufacturing, enables you to maintain a continued supply of parts and also mitigate against the risk of supply chain disruptions.

To easily evaluate the different fastener suppliers you speak with, create a simple scorecard where you rank these organizations on topics such as financial stability and demand planning capabilities.

A great way to create a comprehensive transition plan is by establishing a cross-functional dedicated project team that includes members from procurement, engineering, operations and quality assurance. That team will then guide all aspects of the process and amongst them a project manager can be nominated as the primary contact to act as the point of call between your organization and your new fastener supplier.

Another important consideration should be to map out any key timelines for the new transition. This should include deadlines for inventory audits, people relationships, data integration, first deliveries, in-plant bin/rack installations and inventory management technology implementation. Setting clear milestones helps track progress and ensures all parties are aligned on expectations.

After the transition is complete, conduct a postimplementation review to assess its successes and identify areas for improvement. Reviewing the transition

objectives against the results with key stakeholders from both parties is a good way of gain insight on the transition.

Furthermore, you should implement regular performance reviews with your new fastener supplier. To help our new customer following the transition phases, we recommend scheduling regular reviews to assess all aspects of the relationship from product quality to service levels, with a dedicated representative, to help maintain our new relationship with the customer.

Optimas’ onsite team at Advanced Engineering will also demonstrate Optimas’ capabilities to minimize supply chain risk through their global sourcing leverage and readily available inventory, as well as explain why utilizing a dual-source fastener provider with nearshoring manufacturing capabilities can support and exceed the demands of your manufacturing industry.

Furthermore, visitors will be able to discuss Optimas’ advanced Vendor Managed Inventory (VMI) solutions which streamline supply chains, improve forecast accuracy and maximise profits.

For more information, please visit optimas.com

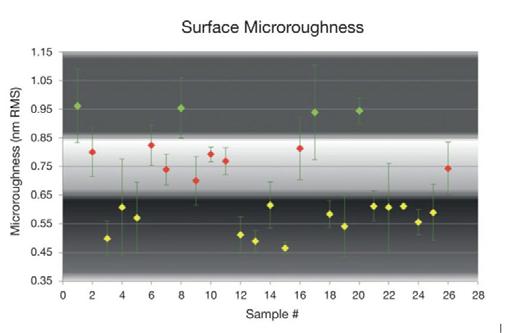

Optical Surfaces Ltd. has pioneered a pitch-polishing technique, that produces consistently low surface microroughness on off-axis parabolic mirrors used as key focusing elements for high power laser experiments.

Microroughness is a component of surface texture, it can be determined by looking at deviations from the mean line profile of a mirror surface. Several renowned plasma physics groups have reported that as microroughness becomes more pronounced, it causes effects akin to mild scattering which limit the focusing performance of off-axis parabolic mirrors. Using their proprietary pitch polishing technique - Optical Surfaces has shown that microroughness can be controlled during the manufacturing process of off-axis parabolic mirrors at consistently below 1nm RMS. This technique is enabling production of a new generation of ultra smooth mirrors thereby helping advance the frontiers of high-power laser physics.

Off-axis parabolic mirrors combine the achromatic and diffraction limited imaging properties of a parabolic mirror with the ability to deviate the light path offaxis, which is useful for most imaging systems. Offaxis parabola offer the ability to focus collimated light without introducing spherical aberration. Additionally, unlike a centred parabolic mirror, an off-axis parabolic mirror advantageously allows more interactive space around the focal point without disrupting the beam. These mirrors are especially suitable for broadband or multiple wavelength high power laser applications.

Using proprietary production techniques, and benefiting from a uniquely stable manufacturing environment, Optical Surfaces highly experienced and skilled engineering team are world renowned for producing fast focusing OAP mirrors with unmatched surface accuracy, surface microroughness and surface slope errors.

In recent years – Optical Surfaces have been selected by world leading high power laser research groups including AWE, ELI, LULI and CLF Rutherford as well as a growing number of academic centres of excellence to provide key off-axis parabolic mirrors and other related optics for a range of demanding high-power laser applications.

selection of off-axis

For further information on off-axis parabolic mirrors with exceptional low microroughness for high-power laser experiments please contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

To download a copy of the study ‘How microroughness impacts optical performance’ please visit: www.optisurf.com/index.php/news/technical-tips/

Optical Surfaces Ltd has been producing high precision optical components and systems for nearly 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant, and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable.

Articulated Pipework Torsion In Hoses Rotating Cylinders

Swivel joints allow pipework to pressure 1/4” to 40” and beyond.

Vacuum to over 20,000psi

Stock and bespoke production.

Unique bearing/seal design for longer life.

ISO 9001 CE marked where applicable.

Tel: +44(0)1663 735003

E-mail:

Developed and verified ‘for industry, by industry’, EEMUA 231 Mechanical Integrity courses with reality built in for industrial engineers at every career stage. For efficient hands-on work with primary containment – to prevent loss of hazardous substances

Satisfy industry requirements at each competency level – Awareness, Basic application, Practitioner.

Certificated courses – by robust examination, valid up to 5-years

CPD-approved courses

Flexible delivery to suit learners and companies – Blended, Live online, Classroom, E-learning, In-house

Available to all – free or discounted to EEMUA Members Courses throughout each year, including:

Mechanical Integrity Practitioner Certificate (MIPC®) – blended, live online learning for on-site application of EEMUA 177, 231 and 232 guidance, and the PSSR ACOP – certificated for 5 years via a proctored exam and portfolio assessment – Continuing Professional Development approval –Learning on the Next course begins 21 October 2024 for 27 weeks, at 4 hours per week. The MIPC course adapts to engineering needs of each Learner, company and site by a 2-hour induction to fit work from 23 September 2024.

EEMUA 231 Mechanical Integrity Basics – certificated via exam – blended, online learning – Basic application competency level – 4 hours of learning per week for 3 weeks – Next course starts 3 February 2025

EEMUA 231 Mechanical Integrity e-learning – at Awareness level – immediately available on-demand – with Continuing Professional Development approval

EEMUA 231 Mechanical Integrity In-house training – running over 1 day or 2 half-days – set at Awareness level – by arrangement, for your choice of time, location, and method of learning – Continuing Professional Development approval.

Also...

External Corrosion Seminar –by EEMUA and AMPP Benelux –Haarlem, NL – 10 October 2024

online-learning@eemua.org

+44 (0) 20 7488 0801 www.eemua.org

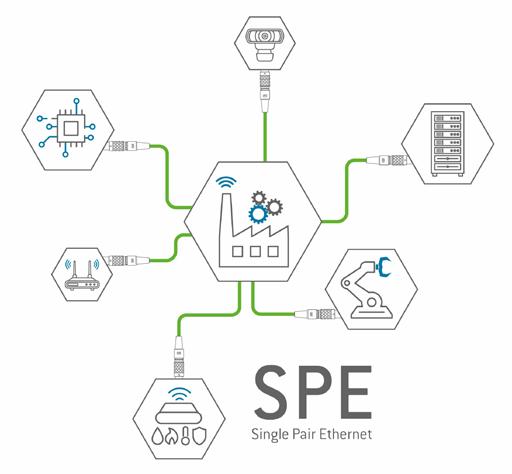

The Industrial Internet of Things (IIoT) is driving connectivity and is supporting Industry 4.0 Innovations, by connecting machines, devices and systems in the manufacturing and other business sectors.

Single Pair Ethernet (SPE) now plays a decisive role in this context, enabling both the transmission of data and the power supply (PoDL) via a single pair of wires.

This significantly reduces the complexity of the network architecture and makes integration simpler and clearer.

This simplicity is particularly important in industrial environments where hundreds or even thousands of sensors and actuators need to communicate seamlessly and reliably.

The technology is also convincing when compared to conventional data rates for the operation of mobile applications such as those deployed in the automotive or agricultural industries.

Single Pair Ethernet offers the following advantages:

• Lean and clear network architecture

• High flexibility and scalability

• Better responsiveness through high convergence of IT with operational technology

• Weight savings for more efficient mobility

• Higher range & data transmission rate

ODU MINI-SNAP® SPE Assembly

ODU connectors for SPE meet the MultiGigabitBaseT1L standard to IEEE 802.3ch, delivering a reliable transmission rate of 10 GBit/s over a maximum 15m of shielded cable.

If the cable length is increased up to 40m, then the ODU connection solution provides a transmission rate of up to 1 Gbit/s (1000Base-T1), meeting the requirements of IEEE 802.3bp

ODU high-quality cable assemblies inc connectors are in accordance with IEC 63171-2.

If needed, lower transmission rates such as 100Base-T1 or 10Base-T1L for the handling of simpler protocols over longer distances are also possible. Strong armour for the nervous system In applications that are subject to regular maintenance or require high-frequency tool replacement, conventional connection interfaces quickly reach their limit as they are only suitable for a few mating cycles. ODU MINI-SNAP® SPE connectors can be deployed in tough environments and thereby withstand up to 5,000 mating cycles while offering an extremely small sized footprint.

Modular connectors from the ODU-MAC® series, on the other hand, not only offer an extremely long service life with at least 10,000 mating cycles, but also the option of integrating SPE in a modular connector as a hybrid solution.

ODU offers SPE connection solutions that are particularly resistant - they withstand extreme temperatures, shocks & vibrations and contamination from moisture & dust.

A reliable data transmission system with many advantages over conventional technology.

ODU UK Ltd

Tel: 0330 002 0640

Email: sales@odu-uk.co.uk Web: www.odu-connectors.com/uk

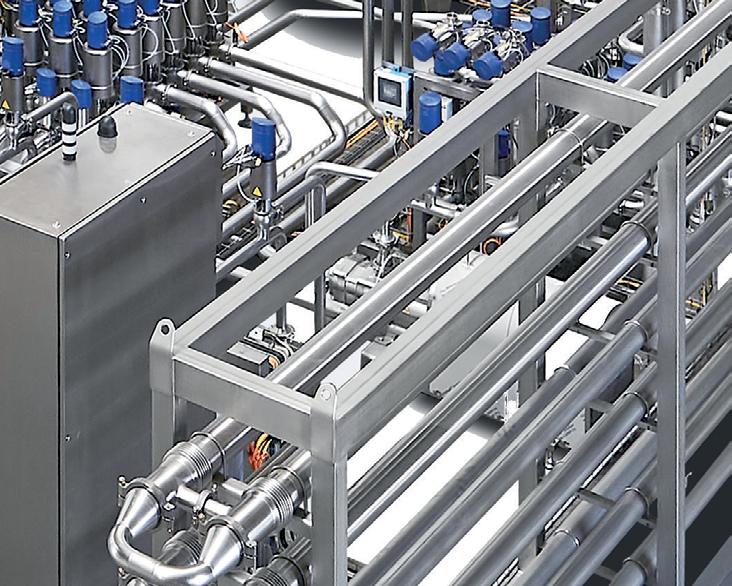

Titan’s robust flowmeter technology is proving industry recommended in helping beverage manufacturers solve sticky situations. Soft drinks are typically formulated from a combination of water (which may be carbonated) and a syrup flavouring. Soft drinks manufacturers such as Coca Cola, use a twin dispense system to carefully combine and control each fluid to the exact concentration, ensuring the quality and consistency of flavour that their customers expect.

Dispense systems assure consistent and accurate measures of syrup are supplied during the dispensing of each soft drink. For low viscosity syrups or flavour additives and the diluent being dispensed alongside, both can be controlled and monitored using a turbine flowmeter. Titan’s NSFApproved 800 series and Beverage flowmeters are widely used within the food and drinks industry for this purpose. These meters are the industry proven choice of many being both effective and reliable flow sensors, with some manufacturers also using them as low-cost alternative flow switches.

0.01 to 500 l/min, using the low differential pressure across the body to drive a pair of toothed oval gears, one of which contains chemically resistant magnets.

As syrup increases in viscosity, positive displacement oval gear flowmeters are used for accurate dosing. Due to the nature of syrup viscosities – sugar free syrup has a lower viscosity than full sugar syrup for example – oval gear flowmeters can address variable viscosity fluids to measure the rate of syrup flow. Where a higher level of accuracy is required, oval gear flow meters can also be calibrated specifically for the syrup type. Dispensing equipment software is then capable of switching between multiple calibrations for an individual flow measurement device, enabling multi-syrup dispense using a single oval gear ‘syrup meter’. So, although temperature and viscosity of syrups are variable parameters, the flow rate of the syrup is ultimately of prime importance to the total volume dispensed to ensure the correct flavour is achieved.

Based on its OG2 model design, Titan Enterprises developed a syrup meter against Coca Cola’s OEM specifications for their multi-soft drink dispense machines. Manufactured in a polymer material as opposed to standard stainless steel, the syrup meter is a low-pressure, low-cost design alternative using food grade polymers. Titan’s oval gear range of flowmeters are capable of measuring flows from

Typically, separate thick syrup and water lines are necessary for soft drink dispensing systems, requiring a flowmeter for each line. However, the beverage industry is evolving fast, with dispensing machines becoming more compact and modular, and capable of adding flavours and CO2 at the point of sale rather than at the bottling plant. This lends itself to OEM designs incorporating the oval gear and turbine mechanics into one flow device designed to fit the space limitations of the customer’s equipment. Titan has developed dual-line flowmeters providing a solution that suits smaller spaces, a single unit being able to measure both non-viscous and viscous liquids side by side at the point of dispense.

“These type of product developments can translate into big environmental and financial savings for the beverage industry”, says Neil Hannay, Senior Development Engineer with Titan Enterprises. “Higher viscosity concentrate of key ingredients requires less transport, energy and CO2 when diluted at point of sale to deliver a fresh end product.” In addition to reducing transport and maintenance costs, venues are able to hold less stock, saving on storage and fridge space.

Visit Titan’s website for further information on Titan’s range of turbine and oval gear flowmeters.

To discuss a liquid flow measurement solution for your specific OEM application, contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk

TR Fastenings, part of the Trifast plc group of companies, has relaunched its patented EPW self-extruding thread-forming screw, engineered to significantly cut assembly time and cost. A revolutionary fastening solution, proudly designed and manufactured in Europe, the TR EPW creates its own internal thread in thin sheet metal, and suits the HVAC, automotive, electronics, medical and telecoms industries.

Why is the TR EPW a game changer?

Unlike traditional flow drill products, the EPW screw can be easily installed by hand with an electric screw driver making it extremely convenient and versatile. It works by aligning to the pilot hole in the sheet metal, forming an extruded collar and creating a robust thread profile before tightening and clamping securely, all in one easy step.

Other key features:

• Can be installed manually and via robotic systems

• Easily removed and fully reusable for a strong, longlasting joint

• Excellent vibration resistance to keep the assembly secure

• High radial compression on the screw thread for a superior hold

• Suitable for electrical earth connections

• Lightweight, practical and strong

• Manufactured in-house in Europe

Manufactured in Europe by TR for global markets

Designed, developed and patented by TR, the EPW is an innovative high strength fastener manufactured in TR’s own factory in Italy and available to global markets in a range of materials, sizes and head styles. Surface coatings include standard zinc plating, highly corrosion resistant zinc nickel and organic zinc flake. Effective in use with thin sheet metal, the EPW creates fixtures that are easy to disassemble, enabling users to recycle or reuse parts as and when required.

The EPW offers cost-effective solutions to users, thanks to its versatility of use, ease of installation and its reliability. It can be used for a variety of materials, including steel (0.4-1mm thick) and aluminium (0.4-1.5mm thick), complementing an already comprehensive product range that includes self-clinch fasteners, blind rivets, welding products and more. Enrico DeAngelis, Engineering Manager at the TR Italy manufacturing facility, commented: “The EPW screw represents a significant commitment on our part to provide the finest possible product designs allied to the very best in quality, functionality and versatility. Relaunching this fastener now is perfect timing as customers are coming to us for more cost-effective solutions for thin sheet metal. The success that we feel this product will bring is due to a culmination of factors, including of course the investment that TR has made.”

www.trfastenings.com

When the requirements of a specific flow application or the industrial process demands cannot be adequately met by a standard flow meter, turning to a customised application-engineered measurement device may be the solution.

Titan Enterprises works with OEM (Original Equipment Manufacturer) customers in developing modified and bespoke liquid flow meters outside of their standard range of oval gear, turbine and ultrasonic flow sensors, driving partnership innovation in key sectors. Through these OEM collaborations, companies can leverage advanced sensor technology, specialised expertise and customised solutions to address challenging liquid flow applications and environments.

Complex industrial production processes often involve high pressures and temperatures, posing safety risks and potential for error. Standard ‘off-the-shelf’ liquid flow meters can be difficult to install in small spaces or hard-to-reach areas, intricate pipe systems, and environments with variable flow rates or hazardous atmospheres. Where a standard flowmeter may not adequately handle such demanding conditions, an application-optimised flow meter may satisfy such needs. Designed to be integrated into existing equipment and to match the exact OEM requirements of the process application, Titan has the experience and engineering skills to develop and manufacture a tailored flowmeter solution.

Trevor Forster, Managing Director of Titan Enterprises, says: “The way we work with customers from research, development, through to production, has enabled us to solve many OEM application issues. Through that process, we’ve helped customers decrease their assembly times, improve efficiency, and provide extra functionality.”

This synergy accelerates the development and implementation of precise, reliable, and efficient flow measurement systems, enabling more accurate monitoring and control in various industrial applications.

Neil Hannay, Senior Development Engineer with Titan Enterprises, explains: “Titan’s flow meters are typically incorporated into much larger industrial systems where accurate, reliable recording or control are required. OEM customers come to us with a problem or need and we scope out a bespoke design concept that has the potential to solve this.”

From budget costing, research and test through to prototypes and full production, Titan have developed optimised flow metering solutions for a diverse range of applications, including:

• Disposable flowmeters for medical applications

• Fuel metering systems for F1 racing cars

• Bespoke turbine flowmeters for agrochemical dosing applications

• Monitoring coolant delivery to laser systems

• High pressure, intrinsically safe oval gear units for offshore oil drilling additive injection

• Dual-flow meters for the beverage industry

To discuss a bespoke flow measurement solution for your unique OEM application, contact Titan Enterprises on +44 (0)1935 812790 or sales@flowmeters.co.uk

Industrial process heating equipment and solutions specialist Babcock Wanson has launched the LVPack low-voltage industrial electric boiler, with steam outputs from 600 kg/h to 8400 kg/h and a design pressure of up to 18 barg.

Specifically designed to provide maximum efficiency – over 99%, as all incoming electrical energy is converted into thermal energy – with zero CO2 and NOx emissions, the LV-Pack has been introduced to help meet European requirements for energy optimisation and reduction of greenhouse gas emissions.

Being electric with no emissions also makes for easy installation and commissioning as there is no requirement for chimneys, fuel supply networks or storage tanks. In addition, periodic monitoring of atmospheric emissions is not required. The boiler is delivered to site and, once connected to the electricity, the feed water and the steam network, is ready to operate.

The LV-Pack low-voltage industrial electric boiler is also easy and economical to use. The control and instrumentation allow for

Babcock Wanson’s boiler operating modes to be used which provide integrated monitoring and regulation of all the equipment in the boiler house, as well as providing real-time monitoring and data logging. These modes include BW3DAYS with tests every three days and BW7DAYS which tests every seven days. LV-Pack boilers are also fitted with the Navinergy monitoring interface, which enables both on-site and remote monitoring of operating parameters.

A further important feature of the new LV-Pack boiler is its precise pressure control with multiple power stages which it to react quickly to load changes. This makes it possible to make quick starts to absorb available grid power when needed.

As you would expect from Babcock Wanson, LV Pack boilers are made to a high standard, with robust construction for increased lifespan. They are made up of steel shells and flat bottoms held in place by tie rods that accommodate immersion heaters, offering numerous advantages in terms of performance, implementation and also for periodic maintenance operations. They are designed to allow both quick start-up and quick steam production, while protecting the immersion heaters from excessive stresses.

The LV-Pack is the latest addition to Babcock Wanson’s range of electric boilers. In addition to these, Babcock Wanson offers a complete range of products and services for boiler houses and other process heating needs. The company aims to help optimise customer’s energy production with high quality products and efficient service.

For more information, please contact Babcock Wanson on 020 8953 7111 or info@babcock-wanson.com or go to www.babcock-wanson.com/products/industrial-electric-boilers/lv-pack/

Part of SICK’s extensive range of sensors for extreme conditions, the robust, reliable, and customisable IMG sensor provides stable detection for demanding industrial machinery

Global industrial sensor expert SICK has unveiled the latest in its extensive product range with the IMG inductive sensor, designed specifically to provide stable detection in harsh environments. With machinery manufacturers and system integrators increasingly being called out to sites to carry out minor maintenance and repairs, the reliability, robustness and repeatability of components is crucial.

As rising skills and labour shortages continue to affect the manufacturing industry, particularly among maintenance technicians, OEMs and equipment suppliers are receiving more requests for site visits from field service engineers. Ensuring parts are robust and reliable can reduce the burden on equipment suppliers, as well as enhancing their reputation by preventing costly stoppages.

SICK’s IMG inductive proximity sensor for metal detection is designed specifically for industrial machines that require precise switching points and a high level of repeatability in harsh environments. For example, IMG sensors are perfect for the machine tooling industry, where they can be used for detection of tool turret position, tool detection on the turret or to determine the lock/unlock position of the turret.

SICK’s sensor range provides reliability, robustness and repeatability

Part of SICK’s wide range of industrial sensors, the robust mechanical design of the IMG family of sensors features innovative SICK technology to deliver stable and repeatable detection at a highly competitive price point. In addition, SICK sensors come with fast order times and can be customised to suit customers’ specific design requirements.

The SICK IMG inductive sensor family operates in environments where many inductive sensors fail to perform. Suitable for end position and home position detection, as well as simple speed detection tasks, the robust device is impervious to shocks, vibration, oil, cooling lubricants, and weather effects such as rain, snow, mud and frost.

Machine manufacturers looking for the highest levels of consistency, longevity and reliability from their components can benefit from sensors across SICK’s extensive range, which includes inductive, capacitive and magnetic sensors designed specifically for use in harsh environments.

SICK sensor technology experts are always on hand to work with design teams and engineers to ensure they identify the right sensor to meet customers’ specific needs. Machinery manufacturers can also work with SICK sensor specialists to customise or modify sensors to suit their specific machine.

SICK UK Market Product Manager - Presence Detection, David Hannaby, says, “IMG combines robustness and stable detection in a great value product. We know that industrial machinery manufacturers are experiencing added pressures as a result of labor and skills shortages in manufacturing, including additional callouts. The tough IMG sensor family is designed for machines operating in harsh environments where reliability and stable detection is critical.

“IMG is already available in countless variations, but at SICK we want our customers to achieve the optimal performance from our products. That’s why, rather than designing to fit our sensors, our experts can work with your engineering and design teams to provide you with samples and help you select and modify the best-possible sensors for your needs.”

Learn more at sick.com

26th February 2025

Location: Worcester Meet the Toolmaker

27th February 2025

Location: Worcester Manufacturing Solutions Ireland

11th-12th June 2025

2 days of training sessions

Includes the LEEA Accredited Training Scheme Seminar FREE TO ATTEND

LiftEx is the premier networking exhibition for the lifting equipment and height safety industries, now in its 19th year. Attended by professionals involved in operating, inspecting, and testing lifting equipment in the Engineering sector.

REGISTER YOUR VISITOR TICKET NOW

• Gain or renew your 5-year Certificates of Competence*

• Courses based on EEMUA 159

• English, Dutch, German and French language options

• Select from courses throughout year, including:

TankInspector courses*

28-30 October 2024 – in English

– classroom – London, UK

10-12 February 2025 – in English – live online

17-19 February 2025 – in Dutch – live online

Storage Tanks e-learning

On-demand – in English or Dutch In-house courses

By arrangement for your choice of: time, language, location

Also...

TankAssessor courses*

14-17 October 2024 – in Dutch –classroom – Rotterdam, NL

4-7 November 2024 – in German –live online

25-28 November 2024 – in English – live online

16-19 June 2025 – in French – classroom – Paris, FR

TankBasics courses

3 March - 11 April 2025 – in English – blended learning (live online, e-learning, and more)

External Corrosion Seminar – 10 October 2024 – Haarlem, NL – by EEMUA and AMPP Benelux

Alarm Management Seminar – 24 October 2024 – Manchester, UK

More choices, information and registration at www.eemua.org and events@eemua.org

technologies such as solar and fuel cells. micrometal and its subsidiaries, leaders in PCE, is at the forefront of this innovation, delivering high-precision components that are essential for optimising the efficiency and reliability of renewable energy systems.

“Renewable energy technologies, particularly solar and fuel cells, require components that not only meet stringent technical specifications but are also produced with minimal material waste and high repeatability,” explains Jochen Kern, Head of Sales & Marketing at micrometal. “Our expertise in PCE allows us to create intricate metal parts with extremely fine tolerances, which are critical for enhancing the performance of these energy systems.”

PCE is a versatile and precise manufacturing process

energy sector, where components like metal contacts, current collectors, and flow field plates must be manufactured to exacting standards to ensure optimal electrical conductivity, minimal resistance, and efficient heat dissipation.

Automated material handling (AMH) has revolutionised the way goods and materials are made, moved, packed, stored, and shipped. It continues to evolve through innovations in robotics, AI, machine vision, and RFID technologies.

AMH optimizes logistics and manufacturing operations, increasing efficiency, enabling faster, more precise material movement with increased accuracy and enhanced worker safety. AMH and Warehouse Management Systems (WMS) provide real-time data on operational performance, material flow, and inventory levels benefitting the entire organization, from procurement to accounting.

Mechanical equipment includes check-in machines, sorters, conveyors, stackers, totes, bins, and trolleys. Conveyors utilise, rollers, or chains to move goods between locations. They can be straight, curved or inclined, making them customizable to the materials transported.

Industrial robots and cobots have the torque capacity to handle large payloads for applications such as palletising, while having the dexterity, speed, and accuracy for more delicate tasks such as pick and place. Automated Guided Vehicles (AGVs) navigate autonomously along predefined paths or use mapping technology.

Automated Storage and Retrieval Systems (AS/RS), combine hardware, such as cranes, shuttles, and conveyors, as well as software that controls movement

and maximizes storage density. WMS control the flow of materials from the time they enter a facility until they are packed and shipped out, optimising the entire AMH process through real-time inventory management.

Electrical connectivity involves the network of systems, components, and devices used to power, control, and communicate. Connectivity is essential for ensuring smooth and efficient operations, as well as enabling data exchange for monitoring, control, and power optimization. It plays a crucial role in enhancing productivity, safety, and overall system performance.

Sensors play a vital role in detecting objects, measuring distance, or monitoring conditions. Connectivity facilitates the integration of sensors with the central control system, enabling real-time data acquisition and decision-making. Actuators perform physical actions based on control signals, are interconnected to execute various tasks, such as opening and closing gates, activating brakes, or controlling robots.

PLCs are at the heart of electrical connectivity in material handling controlling and automating processes based on input from sensors. They coordinate the movement of materials, manage traffic flow on conveyors, and synchronize the operation of different machines, enhancing the system’s overall efficiency. The information is presented on a Human-Machine Interface (HMI), providing a Graphical User Interface (GUI) allowing operators to interact with the material handling system.

AMHs rely on communication networks for high-speed data transfer via industrial ethernet protocols such as Profibus or PROFINET, and wireless technologies facilitate seamless data exchange, enabling real-time monitoring, diagnostics, and optimization.

connectors in AMH applications

Connectors are the essential small pieces and backbone to keep data and power transmission running. They must be robust to withstand extreme temperatures, dust, moisture, vibration, and other mechanical stresses. Constructed from corrosionresistant materials they should provide protection to IP67 or higher to guard against dust, moisture, and other contaminants. A reliable locking mechanism is required to prevent accidental disconnection to ensure stable and secure electrical connections.

Connectors must provide low resistance and impedance to minimize power loss and ensure efficient energy transmission. They should also have minimal signal interference to maintain reliable data communication and electromagnetic shielding where required.

Compatibility in terms of the electrical and mechanical specifications of the equipment is important to ensure easy integration and interchangeability. Industry standard M12 and M8 automation connectors and cord sets manufactured by binder are a good choice offering IP67, IP68 and IP69K with coded variants for handling signal, AC & DC power and high-speed data up to 10Gbit/s for Ethernet and PROFINET etc.

What’s next for Automated Material Handling?

Robotics, machine vision, and RFID offer new ways to make AMH even more efficient, cost effective, and sustainable. Integration of Industry 4.0, AI, and big

Author’s bio

David Phillips has been the managing director of binder UK since it was established in 2009. An experienced sales and marketing professional of 30 years he’s spent the last 20 years in the connector industry. Prior to binder he was the sales director for an independent distributor.

He says “binder is focused on markets which require high-performance, high-quality interconnection solutions”.

data is transforming systems with real-time data and intelligent decision-making enabling predictive maintenance, optimized workflows, and increased efficiency.

As technology continues to advance, efficient and reliable circular connectors, vital for successfully operating AMH systems, will play an increasingly significant role in enabling intelligent, data-driven, and sustainable material handling processes.

www.binder-connector.com/uk/news/automatedmaterial-handling info@binder-connector.co.uk

The UK’s biggest event dedicated entirely to mechanical, WHAT’S INCLUDED IN YOUR FREE PASS?

Join thousands of design engineers this October! Source the latest products, services and innovations available to the sector.

9-10 October 2024

Coventry Building Society Arena

ACCESS FREE SESSIONS AND WORKSHOPS

The Engineer, Eureka and New Electronics curate an informative programme for EDS covering the latest trends, opportunities and challenges for design engineers.

EXPLORE THE INNOVATION ZONE

From robotics innovation to Creative Hubb Ltd’s EOD bomb disposal suit, make sure to stop by the

COMPETE IN THE GAMES ZONE

Back by popular demand, don’t miss the immersive F1 racing simulators and games area. Get ready for even more activities, stay tuned!

STOP BY THE NTU SHOWCASE

Meet the next generation of product design engineers! Nottingham Trent University’s product design students are back showcasing their projects.

VISIT OUR START-UP ZONE

Meet the newest industry game-changers and cutting-edge advancements. Discover their products and innovative solutions.

CHECK OUT THE ROBOT HOUSE

The Robot House from the University of Hertfordshire will be showcasing their state-of-theart robots and pioneering research in human-robot interaction.

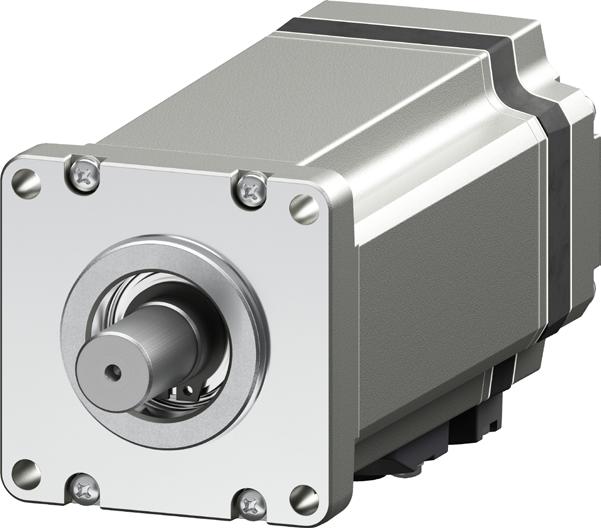

Oriental Motor, a leader in precision drive technology, has announced the launch of the AZX Series, an advanced range of highprecision servo motors. The AZX Series promises unparalleled performance and flexibility, catering to a wide range of industrial applications where precision and reliability are paramount.

The AZX Series is designed to offer the precision and reliability of advanced servo motors. With superior control and feedback features, the AZX Series is an ideal solution for applications requiring precise movement and high torque at high speeds. This makes it perfect for demanding industrial environments where accuracy and performance are critical.

Key Features of the AZX Series include:

• Battery-free absolute encoder: the AZX Series is equipped with Oriental Motor’s patented ABZO sensor, a mechanical-type multi-turn absolute sensor that retains positioning information even when powered off. This eliminates the need for external sensors and batteries, reducing maintenance and operational costs.

• High torque and speed: the AZX motors deliver high torque at high speeds, making them suitable for positioning applications with extensive travel, such as ball screw or belt driven applications. The motors achieve superior performance in the high-speed range compared to conventional models.

• Ease of integration: the AZX Series maintains the same basic operations as the existing AZ Series, allowing for seamless integration into existing systems. This compatibility extends to network-compatible drivers that support EtherCAT, EtherNet/IP and ProfiNET, simplifying wiring and reducing installation errors.

• Enhanced positioning and control: the AZX motors feature built-in positioning operation functions and various sequence capabilities, which can be configured using the MEXE02 support software. This simplifies the programming and enhances the operational flexibility of the host system.

Applications and benefits include the fact that the AZX Series is designed for long-term reliability without the need for complex tuning. This makes it ideal for diverse applications across industries such as medical, automotive, and food processing.

It’s also a very cost-effective solution. By eliminating the need for batteries and reducing wiring requirements, the AZX Series offers a cost-effective alternative to traditional servo and stepper motors. Last but not least, following the kaizen principle of continuous improvement the AZX Series reflects Oriental Motor’s commitment to innovation and quality in precision drive technology.

Pierce Ferris, UK Divisional Manager at Oriental Motor, comments: “The launch of the AZX Series is a significant milestone for us. It provides our customers with enhanced flexibility and performance, allowing design engineers the option to utilise both stepper and servo technologies. The battery-free design and high torque capabilities at high speeds make it a versatile and cost-effective choice for a wide range of applications.”

For more information, please visit: Oriental Motor UK

Blended online learning for all who work on design, specification, commissioning, operation, repair, maintenance, or refurbishment of ageing and new underwater energy production equipment.

The EEMUA 194 Subsea Engineering Basics course encompasses the distilled know how of the industry captured in the practical, ‘how to’ guidance of EEMUA Publication 194.

Course Tutors incorporate all this industry know how with decades of their own expert materials corrosion experience – for effective learning with reality built in.

• Blended online learning combines live classes, 1-1 tutorials, session recordings, e-learning and more.

• Real-time interaction with Tutors ensures Learners’ immediate and correct understanding.

• In-depth course in manageable sessions over 3 weeks to fit busy schedules of Subsea Engineers.

• Enables valuable team members to be where they’re needed – on-site using the collected experience of industry to deepen their own understanding of realworld subsea engineering.

• Certification to industry requirements by exam.

• Course adapts to engineering needs of each Learner and company, through Induction.

Registration open now for the next course Induction of 2 hours to fit diaries in October 2024

Learning starts 4 November 2024.

Find out more at www.eemua.org, by contacting online-learning@eemua.org, or calling EEMUA on +44 (0) 20 7488 0801