REPORT 2023

ANNUAL

Australian Research Council (ARC) Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals acknowledges the support of the Australian Research Council and the New South Wales and South Australian Governments. We also acknowledge the inkind and financial support from all our national collaborative organisations: The University of Newcastle (administering organisation), The University of Queensland, Deakin University, The University of Melbourne, Monash University, University of South Australia, Curtin University, University of New South Wales and The University of Adelaide. We also acknowledge the support from our Industry Partners: FLSmidth, Jord International, CSIRO and Amira Global, as well as in-kind support from our international partners.

Acknowledgment of Country

The ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals acknowledges the Traditional Owners of the land where we work and live. We pay our respects to Elders past, present and emerging. We celebrate the stories, culture and traditions of Aboriginal and Torres Strait Islander Elders of all communities who also work and live on this land.

www.coeminerals.org.au

UNIVERSITY PARTNERS

INDUSTRY PARTNERS

INTERNATIONAL PARTNERS

OTHER CONTRIBUTIONS TO THE CENTRE

1 OUR INFLUENCE AND IMPACT 20 OUR CENTRE 4 About COEMinerals 6 Message from the Director 7 COEMinerals Governance Structure 9 Message from the Advisory Board 10 Message from the International Advisory Panel 11 Observations from the Research Programs Review Committee 12 Delivering on our Strategy 13 Snapshot updates from our University Nodes 15 Discovering the “Genetic Code” of Every Mineral 21 Bio-inspired Alternatives for Mineral Processing Examples of cross-node collaborative research with Monash 23 24 Driving Sector Transformation with Game-Changing Technology Novel technologies Improving the efficiency of downcomer technologies 27 27 32 The COEMinerals TRL Framework 33 Building a Global Reputation for Excellence Elevating Australian science, education and innovation Research collaboration with leading institutions Research engagement with Australia’s National Science Agency: CSIRO Intractable problem-solving with industry Engaging with government 37 37 39 40 41 41 1 2

2 RESEARCH PROGRAMS 44 OUR PERFORMANCE 74 Program 1 Physics of Novel System Hydrodynamics Overview Program 1: Project Summaries 45 47 Program 2 Chemistry of Novel Hydrophobic and Selective interactions Overview Program 2: Project Summaries 59 61 Program 3 New Engineered Biopolymers and Synthetic Polymers Overview Program 3: Project Summaries 65 67 Strategic Evolution to Research Themes in 2024 Research Themes and 2024 Objectives 70 71 2023 Highlights 75 Operations Overview 77 Gender Equity Diversity and Inclusion 79 Signature Lecture and Seminar Series 80 Future Leaders in Focus 81 Centre Outreach 85 Training and Mentoring Overview 87 Communications and Media 88 Publications 89 Financial Statements 92 COEMinerals 2024 Plans 93 Our Centre in Pictures Peek into some of our labs 95 97 Glossary of Terms 99 3 4

MINERALS FOR OUR FUTURE

MISSION

To develop deep scientific knowledge that enables the establishment of new, transformational technologies in minerals beneficiation, to deliver a sustainable future for Australia’s minerals industry.

VISION

To double energy and water productivity in the mining sector by 2030, maintaining the drive towards the ‘zeroemission mine’ and reduce losses of high value metals during processing by 90%.

STRATEGY

Working in partnership with the minerals industry, Mining and Equipment Technology Services (METS), the community and other stakeholders to provide advice, thought leadership, research, education, people and transformational innovations.

3

4

About COEMinerals 6 Message from the Director 7 COEMinerals Governance Structure 9 Message from the Advisory Board 10 Message from the International Advisory Panel 11 Observations from the Research Programs Review Committee 12 Delivering on our Strategy 13 Snapshot updates from our University Nodes 15

OUR CENTRE

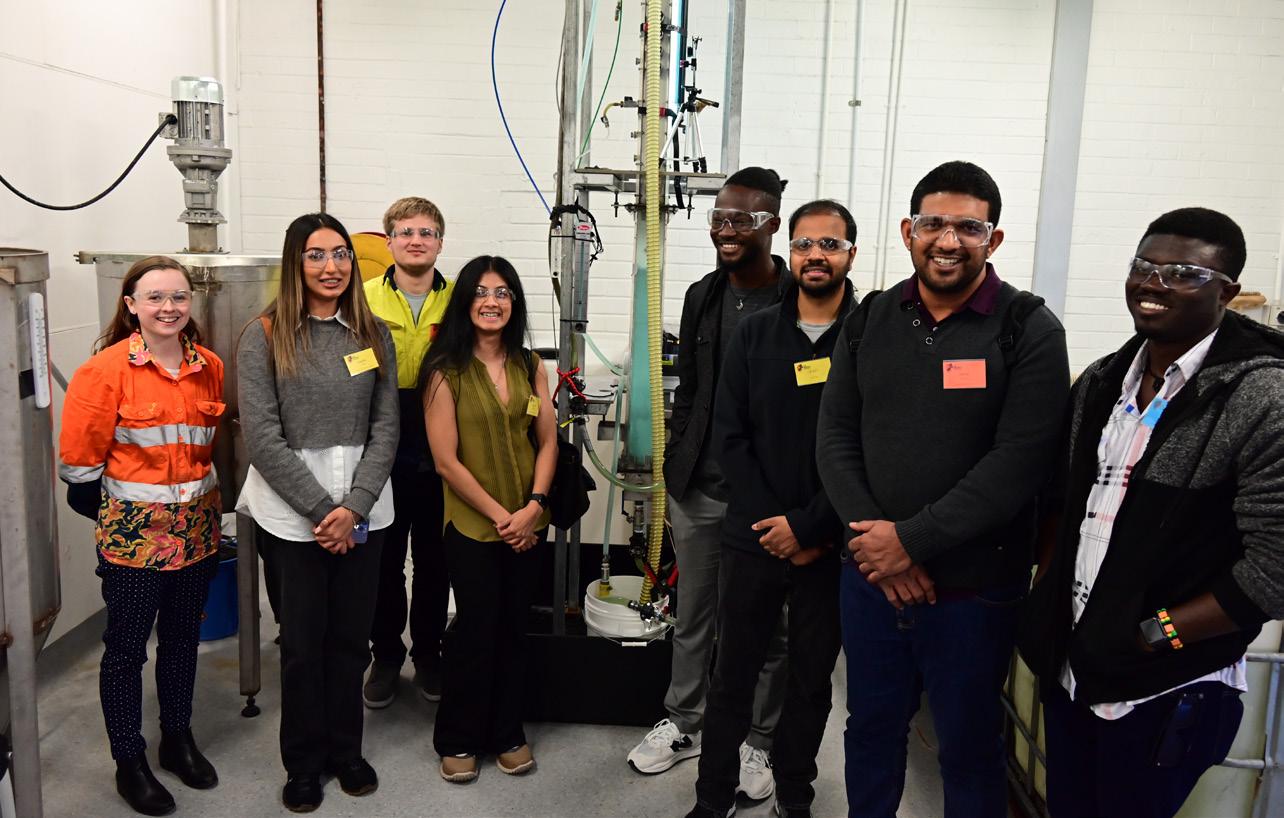

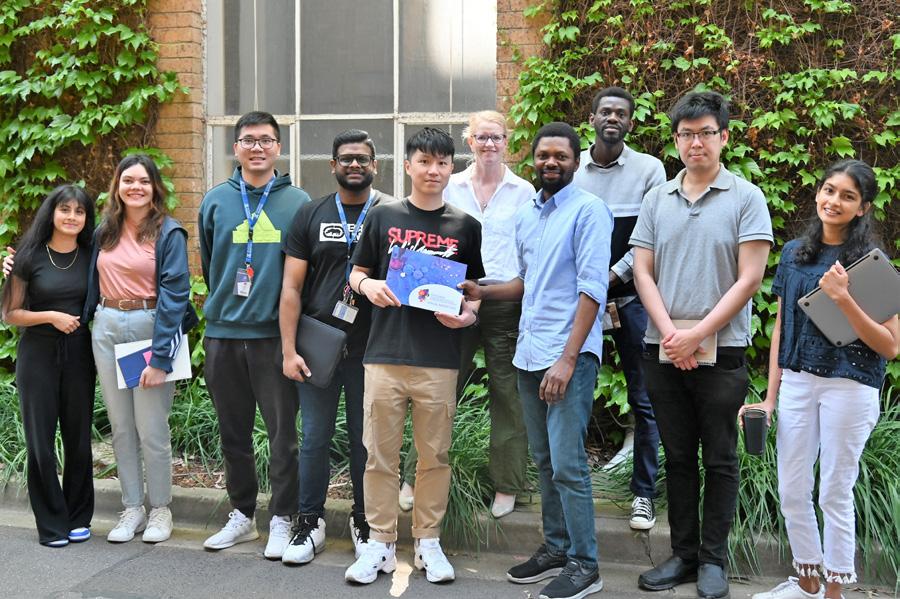

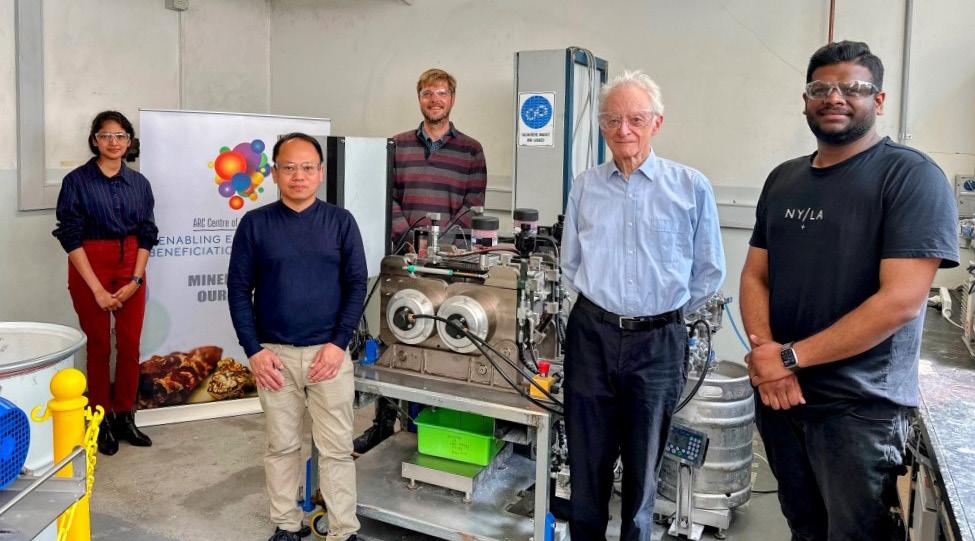

COEMinerals Members at 2023 COEMinerals Annual Conference, representing the following nodes: The University of Newcastle, The University of Queensland, Deakin University, The University of Melbourne, Monash University, University of South Australia, Curtin University, University of New South Wales and The University of Adelaide

5

ABOUT COEMINERALS

The ARC Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals (COEMinerals) is a national research centre, funded by the Australian Government through the Australian Research Council Centres of Excellence funding scheme.

Our Nodes comprise of 9 Australian universities:

The University of Newcastle (UON) (administering organisation)

Curtin University (Curtin)

Deakin University (Deakin)

Monash University (Monash)

The University of Adelaide (UoA)

The University of Melbourne (UOM)

The University of New South Wales (UNSW)

The University of Queensland (UQ)

The University of South Australian (UniSA)

The Centre’s diverse scientific team is addressing key industry and environmental challenges associated with mineral processing. Minerals are a finite resource and many are becoming harder to recover against a backdrop of growing demand for metals to enable cleaner energy solutions as well as medical and other technologies and infrastructure.

The Centre’s science-based, innovative approaches and inventions are resulting in higher minerals (metal) recovery, reduced environmental impact, and lower energy and water consumption during mineral processing.

COEMinerals is currently addressing previously unsolved problems, including finding effective ways to recover Rare Earth Minerals (REM), which are fundamental to permanent magnets (as used in wind turbine generators and in the motors that power electric vehicles), by taking entirely new approaches that include computational chemistry, advanced synthetic approaches and biotechnology.

The Centre is helping to establish a new generation of scientists and research leaders in minerals beneficiation, equipping members to address contemporary sector challenges.

Members work closely with local and international industry, institutions and other experts to gain on-site experience, research feedback and to test, trial and commercialise new technologies and techniques with a view to advancing energy and water productivity in the mining sector; driving towards the ‘zero-emission mine’ and reducing loss of high value metals during mineral processing.

The Centre’s Thematic Objectives

Objective 1 – Early gangue (waste) rejection, achieved through technology advances in coarse particle beneficiation, to minimise energy and water consumption

Objective 2 – Fast, efficient beneficiation to minimise losses of high value metals, achieved through technology advances in fine particle beneficiation, to maximise resource recovery and product grade

Objective 3 – Real time removal of solids from tailings, and rejection of water from solids, achieved through the introduction of novel hydrophobic interactions, and technology advances in dewatering (i.e. eliminating tailings dams)

6

MESSAGE FROM THE DIRECTOR

This past year saw the Centre reach its highly anticipated ‘Mid-Term’ milestone, at least according to the calendar. The good news is the Centre still has nearly 5 more years to run, following the delayed start due to some initial distractions in the early 2020s!

In February, the Centre’s Executive convened in Melbourne for a strategic planning meeting to reflect on, analyse and reset our strategic direction. This meeting set the scene for a year of review and change, including a research program refresh, Centre governance changes and executive leadership succession.

Research approach

With sector transformation as a Centre goal, we overhauled our entire research program in 2023 to ensure we are all working towards delivery of impactful outcomes tied to cutting-edge research and continuous improvement. This change reflects a natural evolution of a highly functional Centre that has made outstanding progress, and which now has highly collaborative connections across projects, teams, and fields of research.

One of the most enjoyable tasks as Centre Director is visiting our Nodes and seeing the wonderful and inspiring work of PhDs (Doctor of Philosophy), Early Career Researchers (ECR), Mid Career Researchers (MCR), Associate Investigators (AI) and Chief Investigators (CI) and gaining their input on the next steps. This feedback has helped inform our future path and the consolidation of projects into 2024. Although our Centre commenced with a series of significant technology advances, I have been especially interested to see the so-called

‘green shoots’ emerging from several groups, and the results of cross-nodal collaborations, including those beyond the formal projects. It became clear that while the Centre commenced with three research programs, aligned with the type of science assessed against relevance to Thematic Objectives, this framework was no longer the best way forward. As a result, the new research projects are aligned directly with three themes, resulting in vertical integration of the science. This means, for example, that new advances with peptides and Reversible Addition-Fragmentation Chain Transfer (RAFT) polymers could be applied to novel reagent delivery systems, which in turn could be applied to novel hydrodynamic separators, all within a given research program. The second phase of the Centre will feature 40 projects across three programs, down from the original 51. You can read more on page 70.

Board evolution

Over the Centre’s duration, we have enjoyed the support of some truly remarkable individuals, who have dedicated some of their valuable time as members of our Centre Advisory Board and International Advisory Panel. The two Boards have provided high-level independent advice guiding us to this point, but we saw a strong convergence between the functionalities of both, and it became increasingly obvious that we would benefit by aligning behind a singular Advisory Board. As a result, the International Advisory Panel formally disbanded in June; some members elected to retire, and others made themselves available for consideration when the new Advisory Board is formed. I especially thank our Chair, Professor Cyril O’Connor from the University of Cape Town, and Dr Barun Gorain, Chief Executive Officer (CEO) of ORE2METAL, Canada.

I also want to thank Denise Goldsworthy, Chancellor Edith Cowan University, and Andrew Hutchinson from the Critical Minerals Facilitation Office for their stellar contributions to the Advisory Board.

Leadership succession planning

I also wish to thank Professor Bill Skinner who has chosen to stand down as our Deputy Director, having several new commitments. Bill remains a Chief Investigator and Program Leader and continues to support the Centre as an ongoing member of the Executive Team. As a smooth transition of Centre leadership, I am delighted to report two members of our executive group are moving into new leadership roles as Co-Deputy Directors: Professor George Franks (UOM) and Professor Chun-Xia Zhao (UoA).

Culture building

In July our research community converged on Newcastle for our second in-person COEMinerals conference. Among the many highlights was a joint keynote presentation from Professor Chun-Xia Zhao and Dr Daniel Yang on their stratospheric advances in applying peptides to minerals and metals; this will be game changing! Please read their feature story presented on page 21. Another highlight was the basket-weaving session led by representatives from ‘Speaking in Colour’, who connected our team to rich Aboriginal culture and learning in a handson workshop. It also helped any tightly wound scientists unwind.

7

Impact as our focus

I am really excited by the possibilities for transformational change to the global industry and beyond, especially through our world leading capability in applying peptides and RAFT polymers to critical and strategic minerals. Our mineral resource separation technologies are also moving along the Technology Readiness Level (TRL) number line, with several undergoing multi-million-dollar full-scale trials, while others are now delivering industry impact to facilitate decarbonisation in ironmaking.

International research excellence is increasingly concerned with societal impact and science as an agent for change, which goes well beyond traditional measures of academic impact. It is also reshaping the mining sector. We continue to address and adapt our work to ensure we are meeting contemporary challenges and that our members are future-work ready whether their career path takes them into academic or industry roles.

Looking to 2024

In terms of addressing and mitigating challenges, we certainly felt the frustration of long lag-times between paper submissions and publishing in 2023. We continue to put effort into attracting diverse PhDs, although it is a very difficult environment given the high and increasing cost of living and low unemployment rate and given there are higher-paying options available. The competitive environment for talent in our dynamic sector has also seen ECRs moving into industry. Overall, we are optimistic about welcoming new members in 2024 in line with our cohort and strategic planning.

I am very proud of our team and our work, and I am sure you will enjoy our latest edition of the COEMinerals Annual Report.

Laureate Professor Kevin Galvin Centre Director

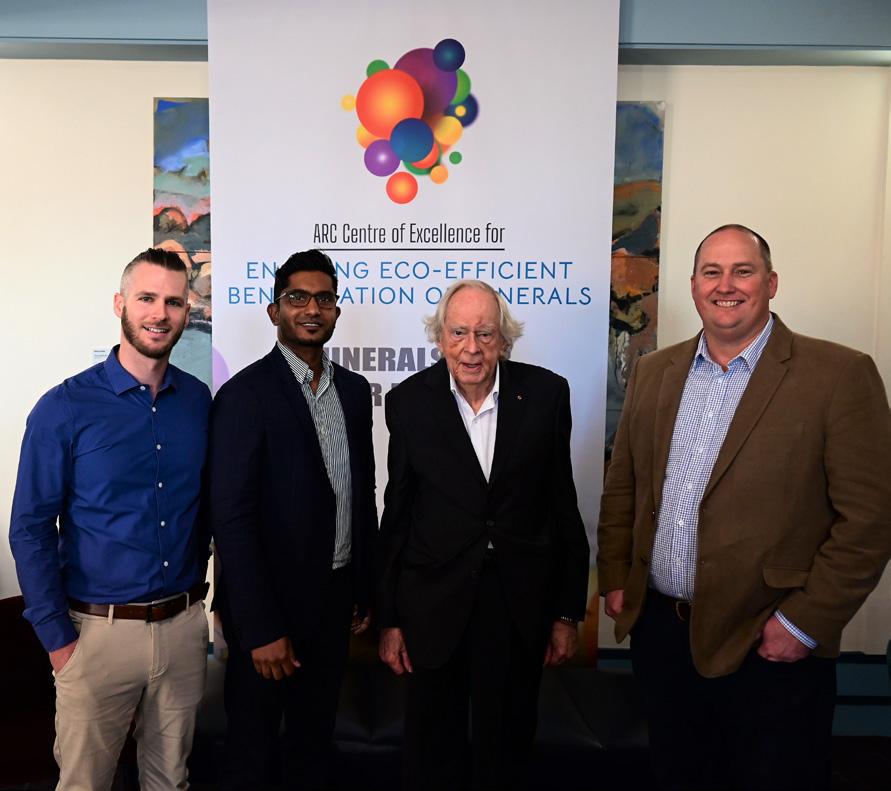

ARC’s Executive Director, Engineering, Information and Computing Sciences, Prof Steven Weller and Centre Director L/Prof Kevin Galvin at the International Flotation Symposium

8

L/Prof Kevin Gavin visiting UoA Node

COEMinerals Governance Structure

Centre Chief Operations Officer

Research Program Review Committee

Executive Committee

Director

Deputy Director

Centre Chief Operations Officer

Node Leaders

Research Program Committee

Program 1

Training and Mentoring Committee

Program 2

Program 3

Stakeholder Committee

Australian Universities

International Organisations Industry Partners

CSIRO

Communications and Media Officer

Executive Committee Members

L/Prof Kevin Galvin

Annemarie Fawkner

Prof San H. Thang

Prof Chun-Xia Zhao

Prof Bill Skinner

A/Prof Elham Doroodchi

Prof George Franks

A/Prof Liza Forbes

Prof David Beattie

Dr Ellen Moon

Dr Susana Brito e Abreu

Chief Investigators

Associate Investigators

International Researchers

Early & Mid Career Researchers

PhDs

Future Leaders Committee

Technical Staff

Professional Staff

Gender Equity

Diversity and Inclusion Committee

Prof Chris Aldrich

A/Prof Seher Ata

Dr Eirini Goudeli

Dr Chris Ritchie

Kim Stockham

International Advisory Panel Director Advisory Board

9

MESSAGE FROM THE ADVISORY BOARD

The COEMinerals Advisory Board provides advice and feedback on the Centre’s Strategic Plan, governance, performance against KPIs and high level advice.

Message from the Chair

It is fair to say that 2023 was the first year since the Centre commenced that we had an essentially uninterrupted opportunity to pursue research and build international links. Dare I say, it was a normal year!

There is no doubt that momentum is now well established and the outcomes from the activities of the Centre are beginning to build strongly and gain real traction.

The demand for all types of minerals and especially rare earths and precious metals will continue to grow significantly in the years to come. Without much-improved pathways to extract and purify these materials, the ambitious agendas for our energy transition will not be met. The focus of this Centre on eco-efficient processing is absolutely spot on.

The challenge for the Centre is to consolidate its progress and now take full advantage of the post pandemic world to grow its outcomes and begin to deliver the technology and innovation improvements we are going to need in the decades

I am confident the world-leading team we have assembled the Centre can be successful in this challenge.

Professor Simon Biggs

COEMinerals Advisory Board Chair

Vice Chancellor and President, James Cook University, Australia

Additional Advisory Board Members

Professor Richard A. Williams, Vice Chancellor, Heriot-Watt University

Ms Denise Goldsworth AO, Chancellor, Edith Cowan University

Mr Andrew Hutchinson, General Manager, Critical Minerals Facilitation Office with the Australian Government Department of Industry, Science, Energy and Resources

Professor Jacques Eksteen, Research Director of the Future Battery Industries CRC (FBICRC)

10

MESSAGE FROM THE INTERNATIONAL ADVISORY PANEL

The Centre’s International Advisory Panel (IAP) provides strategic advice to the Centre Executive with a view to assisting in the achievement of the Centre’s goals.

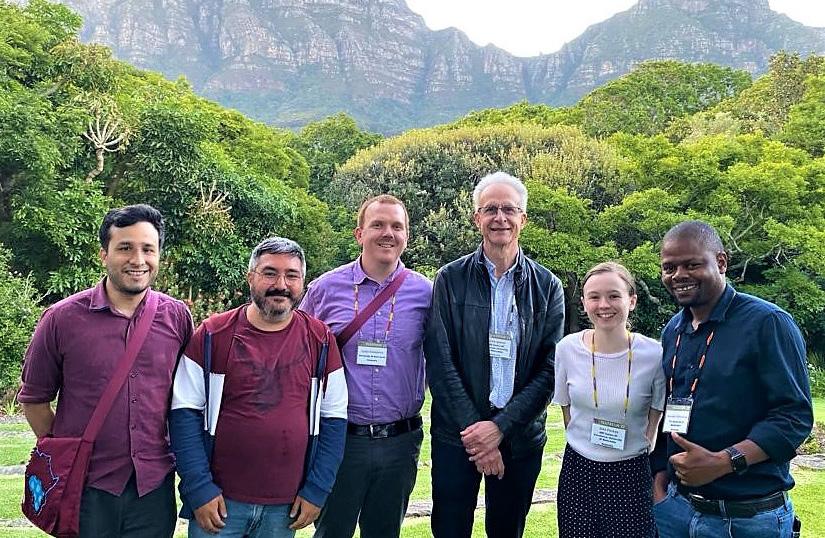

Panel Chair Professor Cyril O’Connor and Panel Member Dr Martin Rudolph attended our 2023 Annual Conference in July, engaging with COEMinerals members.

Message from the Chair

At the outset, the International Advisory Panel wishes to confirm its view, as expressed in the previous annual report, that the leadership of the Centre is world class. The Director of the Centre, Laureate Professor Kevin Galvin, deserves huge credit for his outstanding leadership of this large and complex Centre spread, as it is, across such a diverse range of scholarly activities at many different universities. This should especially be seen in the context of the difficulties experienced by launching the Centre during the COVID epidemic. He will of course be the first to acknowledge the similarly outstanding contributions made by his leadership team including the Deputy Director, the Centre Chief Operations Officer (COO), and the Node Leaders. It is self-evident that without this high-quality leadership team it would not have been possible to achieve much of what is documented in the Annual Report.

In terms of the aims and objectives of the Centre, some highlights particularly worthy of mention include the fact that the Centre has been able to integrate such a broad range of expertise into its program with projects ranging from the

fundamental TRL 1 type to others at a TRL of 6-7 which are already being implemented in operations. Of special note is the fact that the project leaders of all of these projects are clearly sensitive to the manner in which their unique contributions help achieve the overall success of the Centre and its stated objectives.

The Centre has established an enviable national and international reputation for the excellence of its research illustrated by, for example, its many peer-reviewed publications in high quality journals. All of this is being achieved while simultaneously developing high level capacity through promoting a strong interdisciplinary and collaborative approach across many different but related disciplines.

The Panel had an opportunity to witness these strengths first-hand during the Annual Conference, and the International Flotation Symposium that followed, held in July 2023. The quality of the presentations and the post-graduate students who participated in the events were most impressive and reflected extremely well on the successful achievements of the Centre.

In terms of the broader scope of activities of the Centre, with respect to its outreach, these are very impressive and are clearly enjoy as a high priority within the Centre.

Finally, and most importantly, the activities of the Centre have been significantly enhanced by its many strong global linkages with the world’s leading researchers in the general area of mineral processing and related disciplines. The excellent international reputation of the Centre will ultimately

play a significant role in ensuring its long-term sustainability as well as attracting top-class students and researchers to the Centre.

Professor Cyril O’Connor COEMinerals International Panel Chair

Emeritus Professor and Senior Research Scholar, Department of Chemical Engineering, Faculty of Engineering and the Built Environment, University of Cape Town, South Africa

Additional Advisory Panel Members

Dr Martin Rudolph, Head of Department of Processing, for Research Technology, Helmholtz Insititute Freiberg (HIF), Germany

Silvia Cristina Alves França, Director Centre for Mineral Technology (CETEM)

Dr Barun Gorain, President and Chief Executivve Officer Ore2Metal Inc

11

OBSERVATIONS FROM THE RESEARCH PROGRAMS REVIEW COMMITTEE

During 2023, significant progress was made across the board with progressing of a suite of technologies and other sciencebased advances addressing some of the most challenging problems facing mineral processing industries.

Headway was made on solving mineral separation challenges that include energy, water and waste reduction during processing, reducing the size and scale of processing equipment, and improving the recovery of minerals from waste along with other tailings-related mitigation methods. Collectively, the wide-ranging research supports the move towards more eco-efficient and effective processing.

The Centre serves as a rich ecosystem for the development of a spectrum of sciencebased advances, ranging from fundamental research through to relatively mature technology development on the Technology Readiness Level (TRL) scale towards commercialisation. Research is driven in no small measure by collaboration between the different nodes, which has resulted in significant project progress during 2023 which includes developments, not only in high TRL technologies, but also on the fundamental end of the spectrum. Please refer to page 33 for The COEMinerals TRL Framework (adapted from NASA TRLs).

It was pleasing to see the close collaboration between nodes, and between members and industrial partners this year. This is key to facilitating student learning and experiences, as well as Centre research progress, especially as far as

the high TRL technologies are concerned. Most, if not all projects now involve members from multiple nodes and scientific disciplines, setting the scene for a changing project structure according to thematic objectives in 2024.

The role that the Centre’s undergraduate and postgraduate students play, especially in progressing the more fundamental research related to technology, mineral and surface chemistry understanding, bubble interactions and innovative new ‘eco-chemical’ advances should not be underestimated. It has been pleasing to see member research shared and applauded in many international event speaking platforms, papers, published articles and ‘Three Minute Thesis’ (3MT®) competitions in Australia and beyond as the sphere of influence grows for the Centre and researchers.

2023 has also marked another highlight in engagement with the international community via an International Flotation Symposium, organised and hosted by the Centre, leading to new connections and strengthening of existing ones set to fuel future progress.

In 2023 the Centre increased enrolment to essentially full capacity reflecting a dedicated recruitment effort, as well as patience on visa waits, as international students began their Centre roles in 2023 or committed to early 2024 start dates.

Additional Research Program Review Committee

Members:

Centre Chief Investigator, Associate Professor Kym Runge (UQ)

Centre Chief Investigator, Dr Eirini Goudeli (UOM)

Professor Chris Aldrich Centre Chief Investigator (Curtin)

Professor Chris Aldrich Centre Chief Investigator (Curtin)

12

DELIVERING ON OUR STRATEGY

In February 2023, the Centre’s Executive Committee came together in person to review the Strategic Plan to ensure it aligned with Centre Objectives and the expectations of the Australian Research Council (ARC). The existing plan needed updating, given the Centre had evolved over time. As a result, a series of more relevant initiatives emerged, better aligned with the high-level aims of the Centre. The table below is a summary of the revised Centre Strategic Plan, including deliverables to date.

Strategic Objectives Strategic Initiatives

1: To develop and deliver new transformational technologies to the minerals industry

Awareness of industry challenges and opportunities with feedback into the Centre

Independently contribute to the identification of industry challenges and opportunities based on ‘in-house’ capability and innovation.

Formulating an approach for transformational change (technology hydrodynamics and interfacial systems)

Delivery of innovation through collaboration

International and advisory board overview and feedback on research directions

Strategic Deliverables in 2023

The Director has consulted and communicated the new set of research programs and projects covering the duration of the Centre

CIs and project funds were allocated by the end of the year

Program and Theme leaders presented at 2023 Centre Annual conference

Four patents have been granted in 2023

Improvement of >+1 in TRL for six Centre technologies (NovaCell™, XtractOre™, Selective Aggregation, REFLUXTM Flotation Cell (RFC), Graviton and High Pressure Dewatering Rolls (HPDR))

>80% of Centre researchers have been trained in innovation, commercialisation, and stakeholder engagement over the first 3.5years

2: To provide the minerals industry with a diverse and future-oriented technical workforce

50% gender equity targets in all major events/committees/ boards and roles

50% gender equity targets in all staff and members

Support family friendly and flexible work arrangements

Create an inclusive and diverse Centre culture

Foster a culture of indigenous awareness and inclusivity

Awareness of legislation in relation to workplace harassment and discrimination

Dedicated sessions at Annual Conference on cultural awareness and celebration, including Indigenous cultures

A specialist was engaged mid-year to assist us with Gender Equity Diversity and Inclusion (GEDI) policy and awareness and a SharePoint site has been established

37% of Centre members are women

>30% gender equity for all major committees (GEDI, Executive, Training and Future Leaders committees) and events (e.g. 56% of Signature Lecture speakers were women, 42% Seminar speakers were women)

13

Strategic Objectives cont. Strategic Initiatives

3: To provide thought leadership and deep technical training to students and the industry

Monthly Signature Lectures from industry and academic thought-leaders

Internal Research Seminars to all members of the Centre

Technical training to all members of the Centre

Targeted professional training for PhDs and ECRs

Cross-university engagement of all PhDs

Training courses offered to Industry by Centre members

Strategic Deliverables in 2023

38% of all Signature Lecture speakers from industry

Vast majority of PhDs and ECRs received some training in mineral processing and polymers topics

90% of all PhDs and ECRs have had professional training

>50% of PhDs involved in internode university and industry visits by 3.5years

5 workshops delivered to industry participants by Centre members

4: To establish strong links between the minerals industry, community and researchers

Promote and raise awareness of the minerals sector innovation and sustainability with school children to support interest in science, technology, engineering and mathematics (STEM) learning

Grow awareness of COEMinerals across the minerals sector, community, government and other researchers

Build positive reputation through endorsement

Mentoring Panel session on Resume

Writing for PhDs and ECRs

UON PhDs presenting Minerals Magic to primary school students through Children’s University

Minerals Magic was presented to >800 school students in 2023

Communications and media strategy plan was reviewed, updated and implemented in 2023

>50% of PhDs presented technical presentations in 2023

> 10 lectures at international institutions and universities

ECR Dr Casey Thomas (UOM) presenting at UK Colloids 23 conference, in Liverpool, UK

14

SNAPSHOT UPDATES FROM OUR UNIVERSITY NODES

“Curtin has a speciality in the understanding and application of artificial intelligence, process automation in mineral processing.”

Prof Chris Aldrich (Curtin)

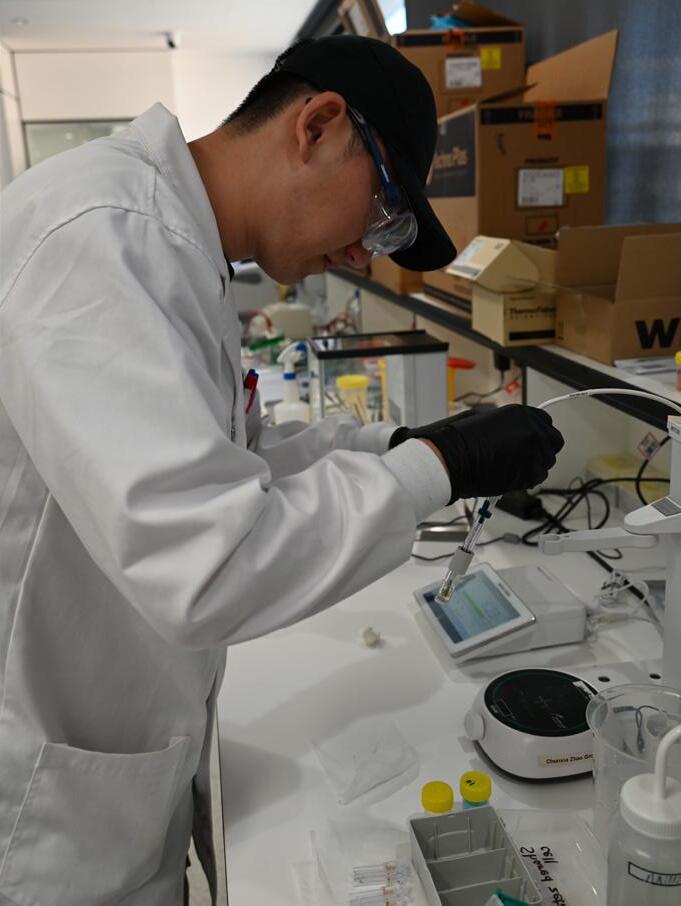

“Collaboration and crossdisciplinary research play a vital role in advancing innovative biotechnology applications for mineral processing. By merging expertise across various fields, we develop sustainable and transformative technologies for the next generation of mineral processing.”

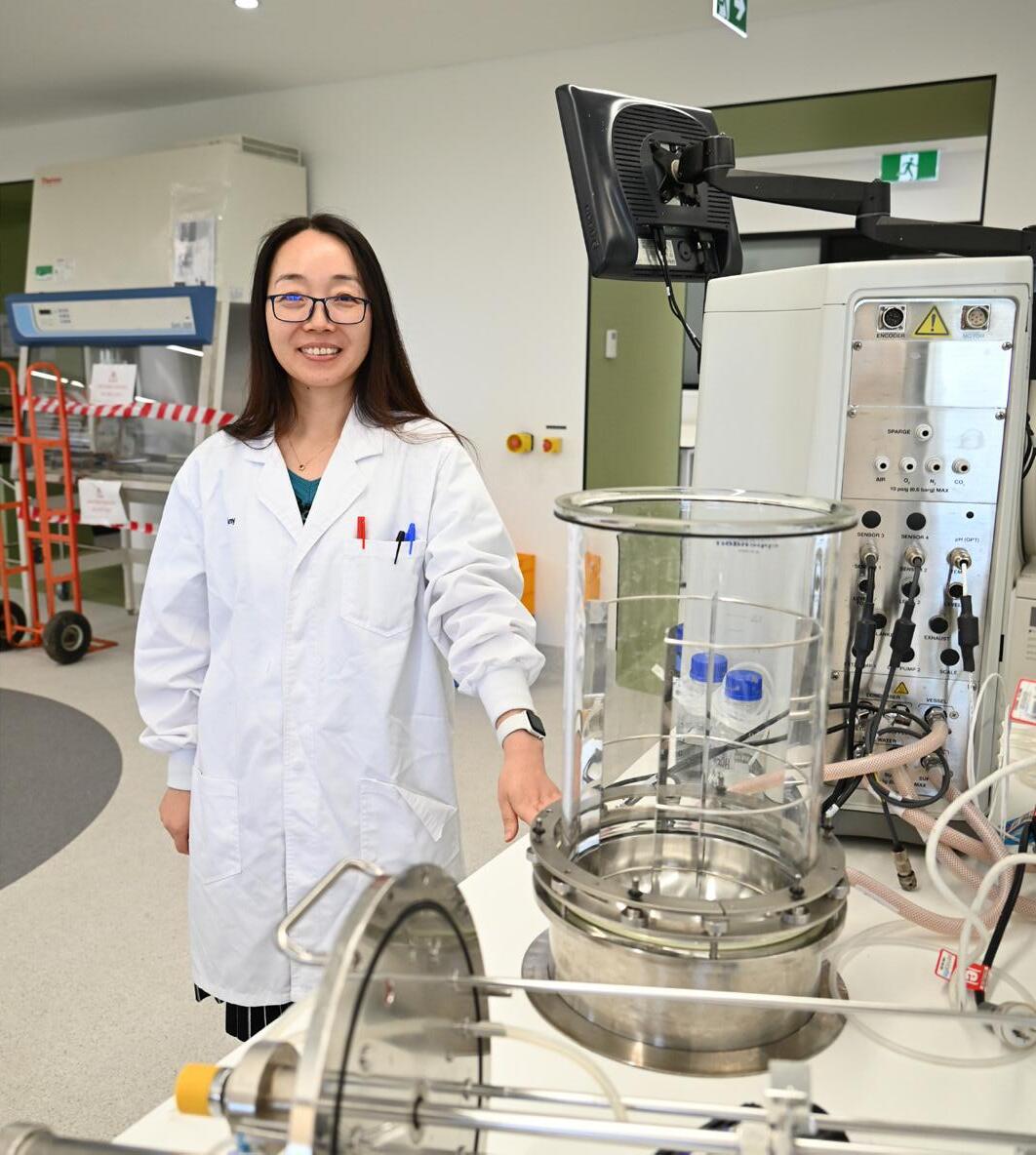

Prof Chun-Xia Zhao (UoA)

“Team engagement, multicultural experiences, novel technology progress and PhD student achievements were just some of the highlights this year for UniSA node.”

Prof Bill Skinner (UniSA)

“ At UQ node we pride ourselves on the depth and breadth of our industry collaborations.”

A/Prof Liza Forbes (UQ)

"It was amazing to see our School Education Outreach program, ‘Minerals Magic,’ being delivered to over 600 high school and primary students on the UON campus in 2023. We have had a fantastic opportunity to showcase the Centre’s activities in green and sustainable mineral processing, as well as its critical role in the transition to net zero, to students and school educators."

Dr Mahshid Firouzi (UON)

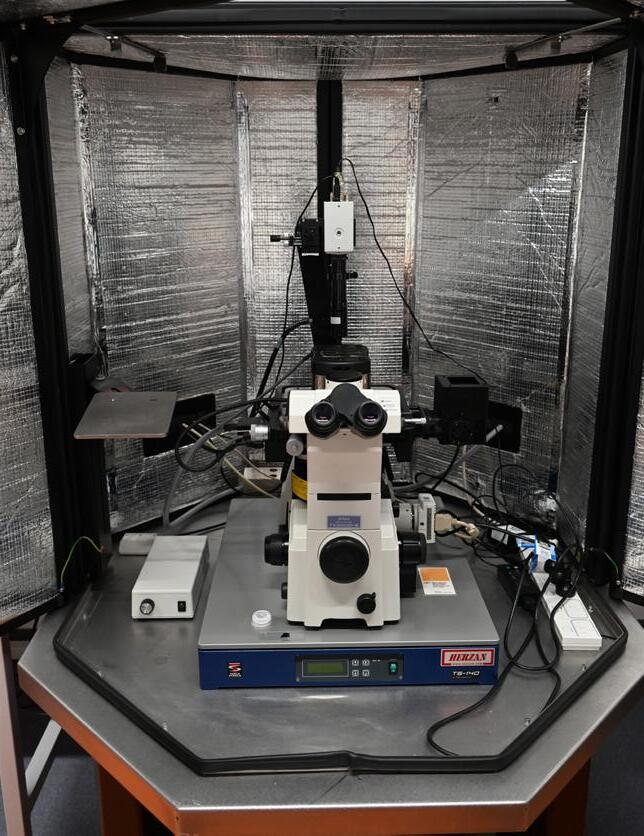

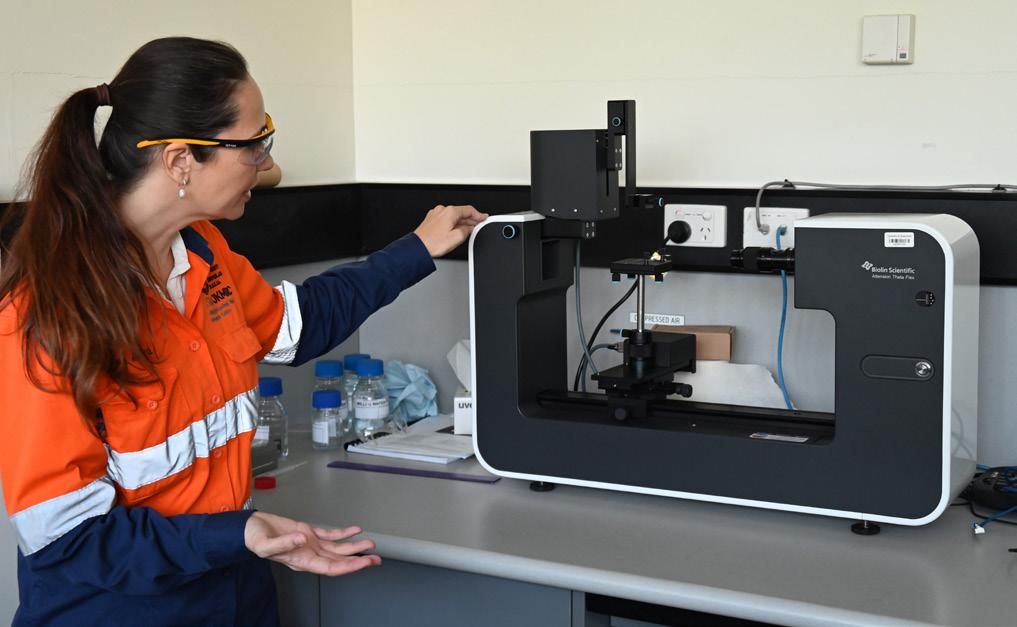

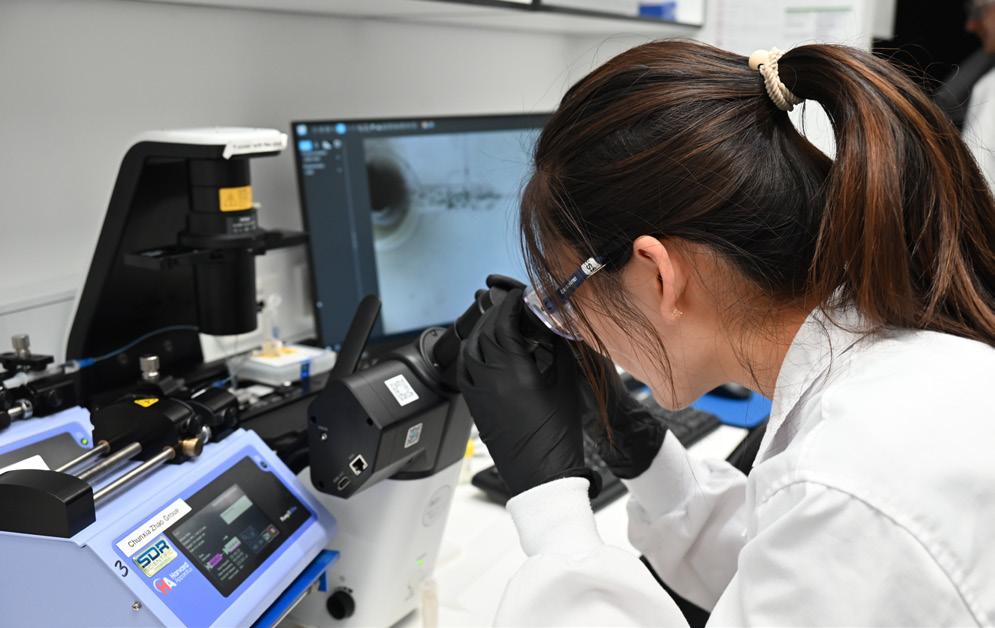

“Deakin node hosted researchers representing 7 projects and 4 nodes in 2023. Not bad for the Centre’s smallest node! We enjoyed exploring the synergies between groups and uncovering more opportunities for collaboration. It is also been great to see so many PhDs getting good use out of some of our niche instruments. ”

Dr Ellen Moon (Deakin)

“UNSW research primarily focuses on froth flotation utilising various methodologies and including modelling, the development of novel experimental techniques and the application of advanced instrumentation such as micro computed tomography and custom-developed X-ray technologies.”

A/Prof Seher Ata (UNSW)

"Monash node is creating bio-inspired chemicals as new alternatives for use in mineral processing. These are being tested in wide-ranging and highly collaborative ways across the COEMinerals node network."

Dr Chris Ritchie (Monash)

“2023 has been a fantastic year for the COEMinerals team at UOM. Most PhDs are progressing through their second year and are all making good progress. The students’ first journal papers are either in review or in their final drafts, ready to submit. Collaborations with other nodes, particularly Monash, UQ, UniSA and Deakin have been very fruitful.”

Prof George Franks (UOM)

15

University of Melbourne

Node’s key focus: Chemical engineering

Highlights of 2023

Technology and innovation

Built a lab device after proof of concept: High-Pressure Dewatering Rolls (HPDR) technology, developed in close consultation with an industry consortium

Novel Pelletiser for dewatering prototype

Building Centre reach and reputation

The long term, close-working relationship between UOM and Tohoku University, Institute of Multidisciplinary Research for Advanced Materials (IMRAM) and Okayama University of Science and Technology resulted in an in-person visit to Japan for multiple members of the team in 2023

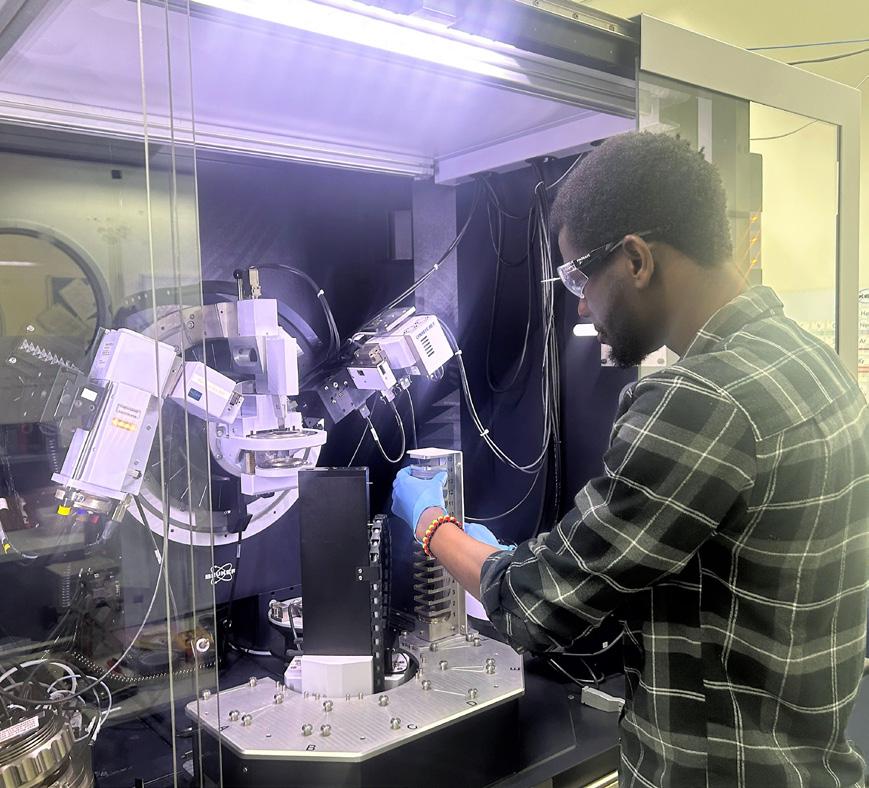

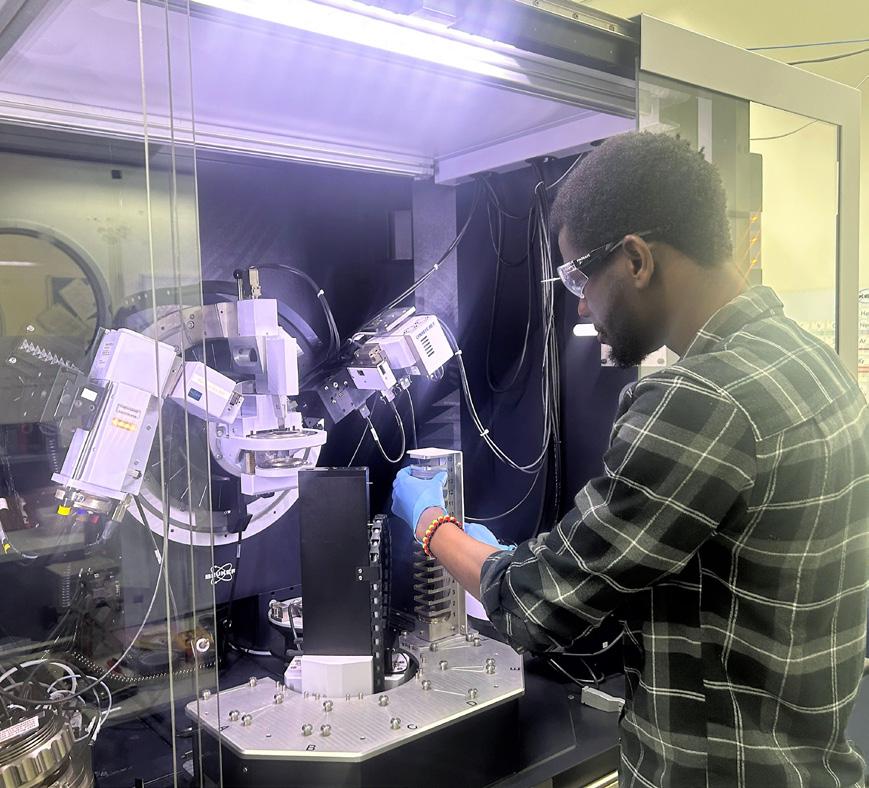

PhD Daniel Dodoo’s collaboration with Australia’s National Science Agency: CSIRO / Mineral Resources to develop X-ray and electron beam techniques

Other

PhD Regina Medeiros and ECR Dr Casey Thomas were awarded Researcher Development and Travel Grant scholarships from the Royal Society of Chemistry to support research in fields relevant to Chemical, Materials and Biomedical Engineering

Curtin University

Node’s key focus: Process Systems and Chemical Engineering

Highlights of 2023

Technology and innocation

University of Newcastle

Node’s key focus: Chemical engineering, physical chemistry, modelling and fluid mechanics

Highlights of 2023

Technology and innovation

COEMinerals-invented technologies featured in multiple international scientific forums (such as the Flotation 23 event in South Africa) and conference and research papers (including multiple studies by Imperial College, UK)

Moisture Reducing Roller Conveying (dewatering) system progressed based on ongoing testing at UON

Building Centre reach and reputation

Advanced machine learning methods are being developed for use in image and vibration analysis of among other fluidised beds to gain better insight into the granular physical phenomena and the behaviour of flotation froth systems

A REFLUX® Classifier (RC™) fractionator was set up at Curtin node to enable on-site testing, with a plan for gold ore testing in 2024

Sink-Hole Fluidiser technology, developed at UON, was transferred to the Curtin node in 2023. Curtin and UON teams work collaboratively on different aspects of data analysis from simulation of this technology

L/Prof Kevin Galvin gave a public lecture, hosted by the Royal Society of NSW (Hunter Branch) on scientific “Invention, Innovation, Impact”

We welcomed global experts in flotation to the Centre-organised International Flotation Symposium in Newcastle, with supporting lab tours

PhD Siân Parkes visited Germany, sharing latest Centre research and innovation during the EIT - European Institute of Innovation and Technology RFC Upscaling Workshop and The Horizon Europe: Marie Skłodowska-Curie Actions (MSCA) ITN FlotSIM school #4 events

UON hosted and updated or contributed advice on various international, clean energy, sustainability, business delegations as well as government representatives on COEMinerals research, innovation and impact

16

Node’s key focus: Flotation and mineral surface chemistry

University of Queensland

Highlights of 2023

Technology and innovation

“We now have further experimental results to support our new discovery about Bubble-Particle Detachment: it does not occur at the three-phase contact line as conjectured a century ago. It is associated with the bubble necking. The new experimental results show that it is kinetically controlled like the Bubble-Particle Attachment. Two papers have been drafted for publication,” Prof Anh Nguyen

A novel tomography application advanced in 2023

Collaborative research with industry saw the development of a novel laboratory-scale fluidised bed flotation device: the JKHFmini

A/Prof Kym Runge and team developed methods to computationally predict the performance of the REFLUX® Classifier using CFD software and calculated a partition curve

Prof Yongjun Peng and team observed a two-fold magnitude in chalcopyrite product grade improvement in RFC flotation, highlighting a significant entrainment reduction

UQ node tested aerosol collectors at Glencore’s Antapaccay project

Building Centre reach and reputation

Prof Anh Nguyen and PhD Quang Dao visited the University of Utah to learn about X-ray tomography techniques for mineral processing

A/Prof Liza Forbes visited The Helmholtz Institute Freiberg (HIF) in Germany in April 2023, resulting in the submission of a joint grant application between Centre CI Dr Susana Brito e Abreu (UQ) and Dr Katrin Pollman (HIF)

Other

UQ node coordinated a field visit to Newcrest’s Cadia operation and A/Prof Kym Runge and her team conducted a field visit to a Newmont mining site

UQ node hosted multiple government and industry representatives to the node, as well as offering training to industry and schools

Deakin University

Node’s key focus: Earth sciences and mineral surface chemistry separations using novel reagents

Highlights of 2023

Technology and innovation

A milestone research paper was published as a result of internode collaboration, co-authored by Dr Ellen Moon and Dr Negin Amini (Deakin) and Prof San H. Thang (Monash). It heralded the first step towards enabling recycled surfactants

Other

Deakin is ‘home-base’ for the coordination and roll out of wholeCentre GEDI

Monash University

Node’s key focus: Polymer chemistry and RAFT polymerisation

Highlights of 2023

Technology and innovation

New RAFT polymer reagents are ‘travelling’ to different Centre nodes to aid in multiple projects.

Building Centre reach and reputation

Prof San H. Thang AC attended The Honourable Linda Dessau AC CVO, Governor of Victoria event at Government House as part of a group of 20 prominent Companion of the Order of Australia (AC) recipients

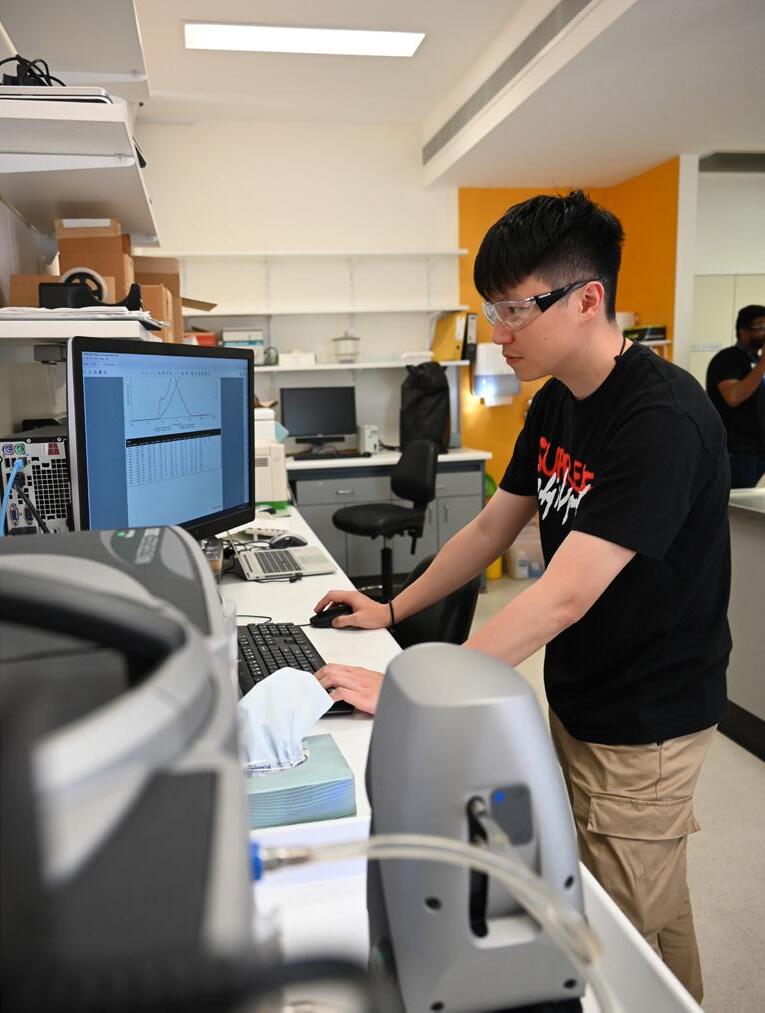

PhD Yuxi Liu collaboration with Australia’s National Science Agency: CSIRO for testing automation utilsiing Chemspeed technology

17

University of New South Wales

Node’s key focus: Froth flotation systems

Highlights of 2023

Technology and innovation

Conducted an investigation into visualising particle behaviour in the froth phase using X-ray facilities at the University of Sydney. This facility enables comprehensive tracking of particles in an entire lab-scale setup. The results observed have not been reported previously, and two journal papers are currently in preparation

Building Centre reach and reputation

A/Prof Seher Ata joined the Capacity Building Committee of the Society of Mining Professors (SOMP), which aims to enhance the exchange of knowledge in teaching and research in mineral processing and promote adoption of new, related technologies throughout Southeast Asia, South America, and Africa

University of South Australia

Node’s key focus: Flotation, mineral surface chemistry, spectroscopy and physical chemistry (bubblesurface and droplet interfaces)

Highlights of 2023

Technology and innovation

A laboratory-scale unit of the Gyratory Rolls Crusher (GRolls®) technology has been installed at UniSA. A related paper was presented at Metplant 2023 and published in ‘Minerals Engineering’. The GRolls® crusher will figure in several COEMinerals projects and associated research and development in 2024

A multi-company project led by Prof Bill Skinner, A/Prof Max Zanin and ECR Dr George Abaka-Wood and AI Dr Richmond Asamoah, ‘Advanced Flotation’, began on site in July, addressing specific flotation challenges, which will run for 3 years

A CRC-Project has been awarded (August) to develop flotation strategies for graphite, which will investigate graphite recovery using several technologies, including the Centre-developed REFLUX™ Flotation Cell (RFC)

Building Centre reach and reputation

ECR Dr George Abaka-Wood was on the organising committee of CRITCON (May 2023) in Adelaide, with multi-node speaker involvement (the first national technical conference to focus on the discovery, characterisation and processing of critical minerals)

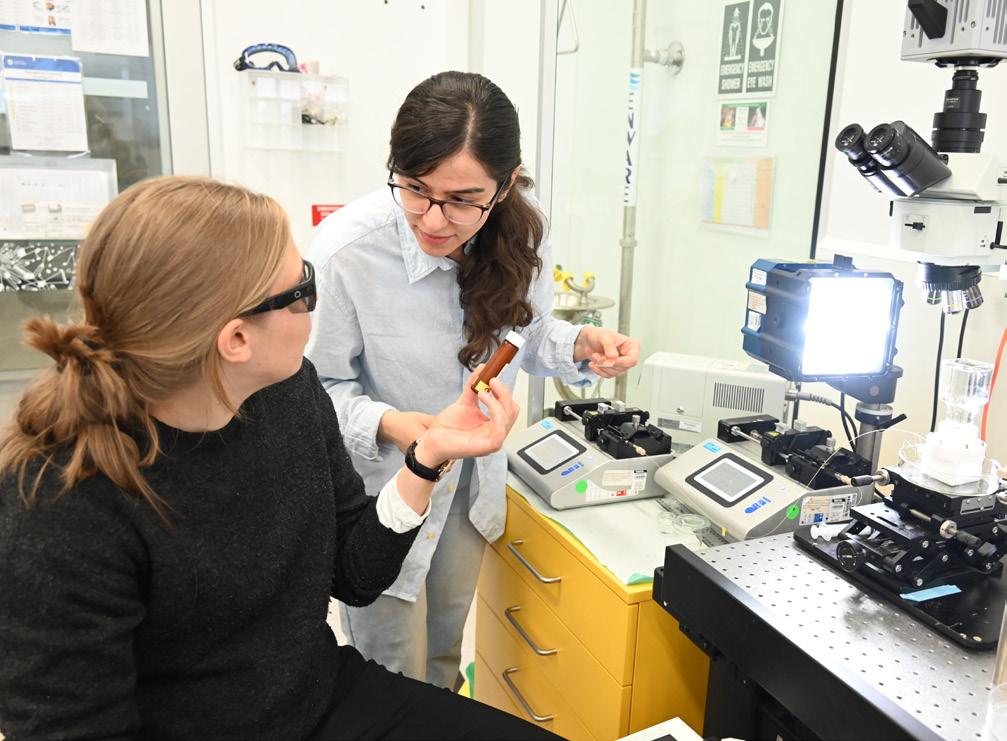

ECR Dr Piotr Pawliszak visited Dr Martin Rudolph’s laboratories at the HIF in September

University of Adelaide

Node’s key focus: Bio-inspired engineering

Highlights of 2023

Technology and research innovation

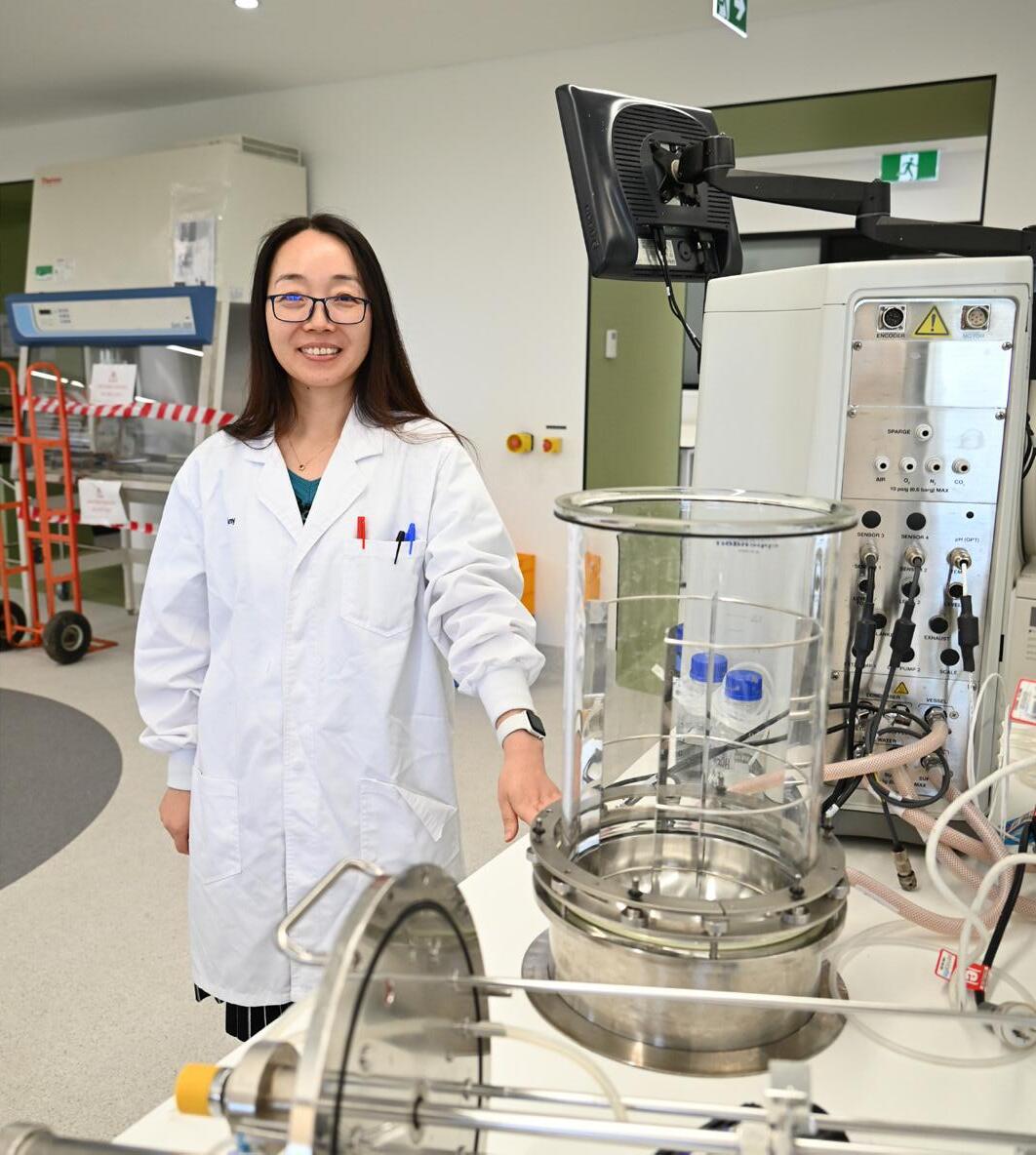

UoA team has discovered a library of peptides exhibiting unparalleled specificity and selectivity in binding to diverse mineral particles. The biomolecules engineered using these peptides showcase a remarkable affinity for mineral particles, achieving a separation factor exceeding 1000. A patent has been filed for this technology

Building Centre reach and reputation

Insights relating to COEMinerals/UoA innovative research was shared in multiple international forums including: The Monash Chemical Society Lecture; The Australian Materials Chemistry Conference (AMCC23) by The Royal Australian Chemical Institute; The International PACRIM conference (Hawai’i); The 2023 Australia New Zealand Micro Fluidics (ANZNMF) Conference (Adelaide); The 2023 International Conference on Materials Innovation (ICMI) (Brisbane)

Other

Prof Chun-Xia Zhao was ranked in the world’s Top 2% Scientists in the field of Chemical Engineering and Chemical Physics by Stanford University

PhDs Matthias Orchard and Yang (Jessica) Li achieved professional and milestones relating to intern-based work experience and/or peer-leadership roles

18

“Multidisciplinary collaboration is at the heart of the research we do within the COEMinerals and it is the foundation for scientific advancement and technology innovation. The advancements in the fundamental knowledge can be translated into practical applications through our strong connections with the minerals industry. The access to state-of-the art research facilities and technology available across the COE nodes further facilitate the high-quality research we do. As we build our research capacity, we are developing the next generation of leaders towards a sustainable future in the minerals industry.”

Chief Investigator, Dr Susana Brito e Abreu

Chief Investigator, Dr Susana Brito e Abreu

19

OUR INFLUENCE

IMPACT Discovering the “Genetic Code” of Every Mineral 21 Bio-inspired Alternatives for Mineral Processing Examples of cross-node collaborative research with Monash 23 24 Driving Sector Transformation with Game-Changing Technology Novel technologies Improving the efficiency of downcomer technologies 27 27 32 The COEMinerals TRL Framework 33 Building a Global Reputation for Excellence Elevating Australian science, education and innovation Research collaboration with leading institutions Research engagement with Australia’s National Science Agency: CSIRO Intractable problem-solving with industry Engaging with government 37 37 39 40 41 41

AND

DISCOVERING THE “GENETIC CODE” OF EVERY MINERAL

COEMinerals is using biomolecular engineering to map minerals and create game-changing transformation for the minerals industry.

The Centre is transforming the field of mineral separations by developing world-leading innovation and capability, identifying, and producing specific peptides with high affinity for minerals and metals.

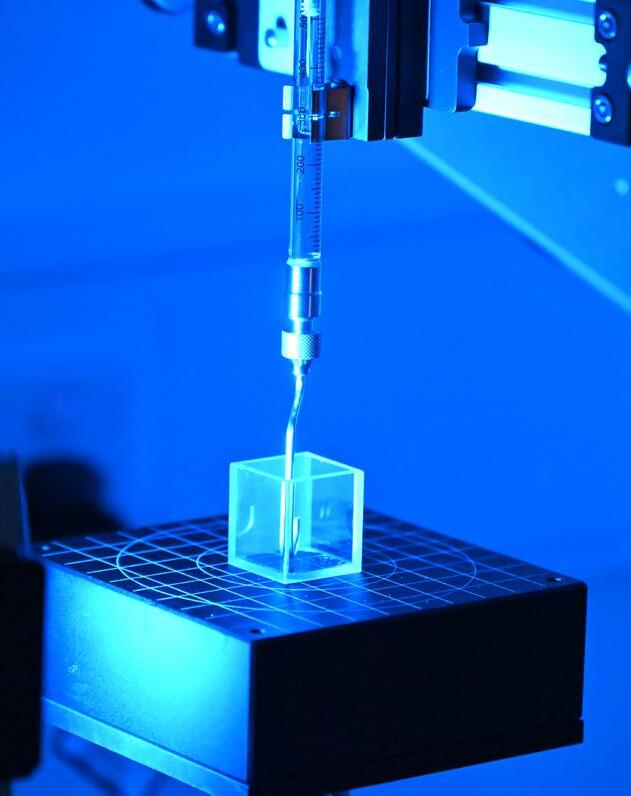

This visionary work, led by Centre Deputy Director Prof Chun-Xia Zhao and her team at the Centre’s UoA node, involves the application of biotechnology, biomimetic nanomaterials and microfluidics for (medical) drug delivery and controlled release to devise bioinspired engineering solutions for mineral processing.

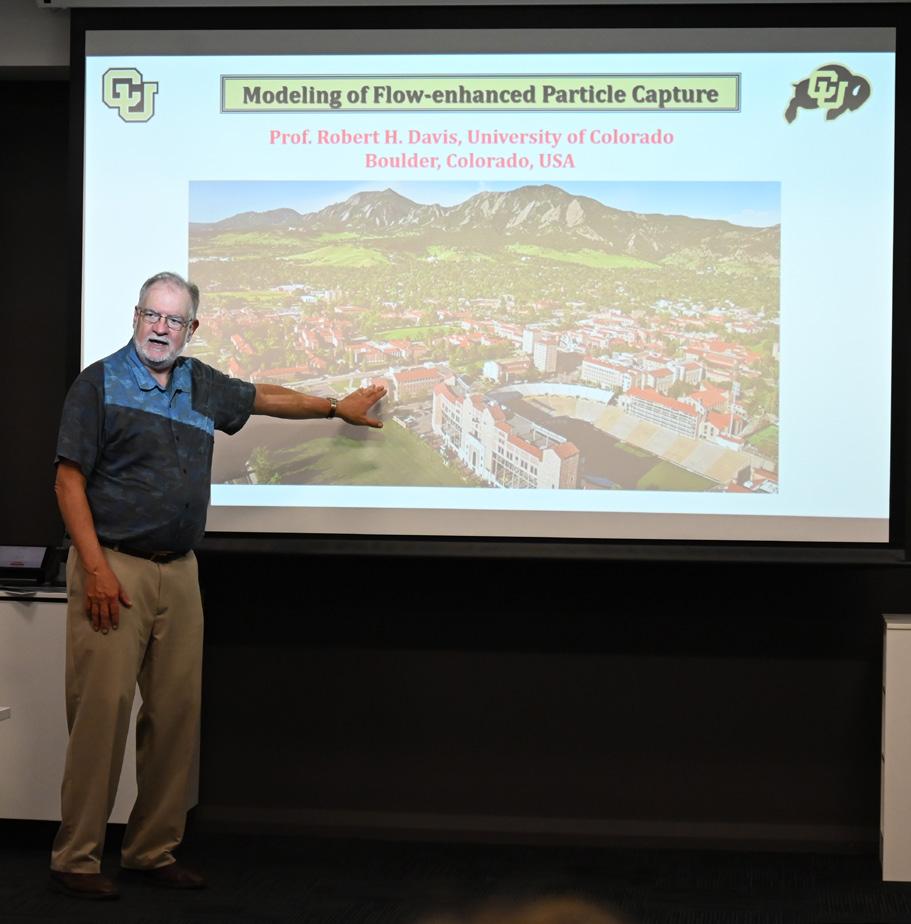

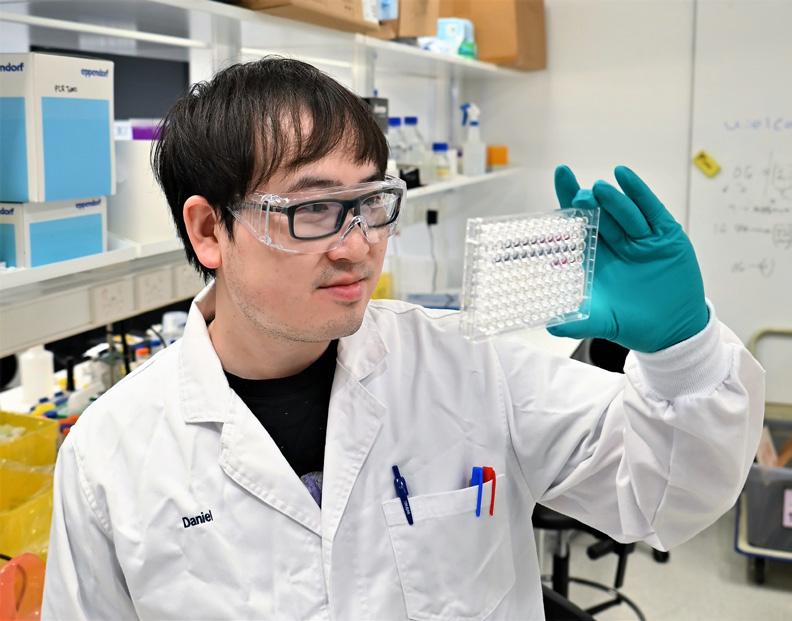

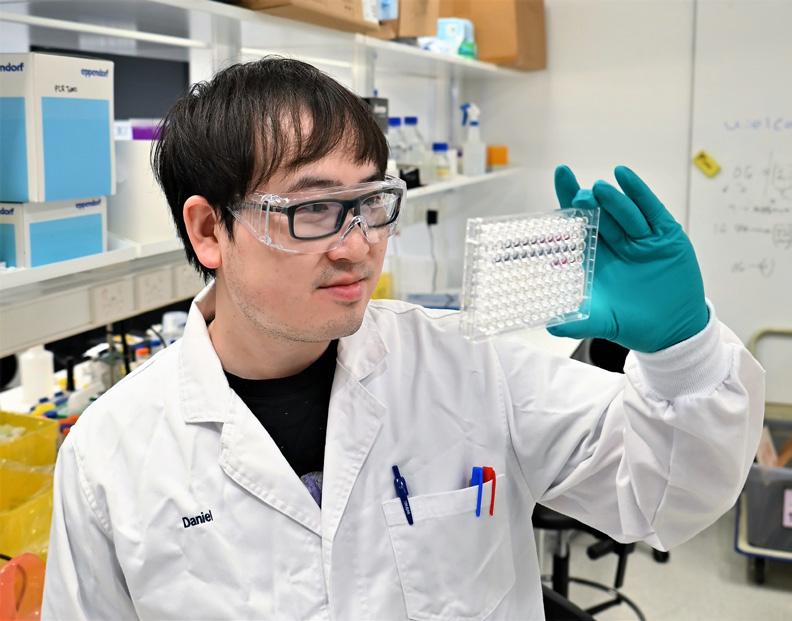

Prof Zhao and Dr Guangze (Daniel) Yang presented a keynote on the fundamental work undertaken by Prof Zhao’s group during the 2023 COEMinerals

Annual Conference in Newcastle. This feature provides insights into their work and its significance for the industry.

The ‘Green Shoot’ idea

The UoA node work is integrating biotechnology into mineral separation processes.

Scientific advances and applications relating to utilising biomolecules is predominantly in the biotechnology field today. As such, established medical advances associated with the targeted delivery of therapeutic drugs (e.g. for cancer) via peptides or proteins (antibodies) is in the pharmaceutical domain, with application extensions in cosmetics and agriculture. Centre work is drawing on, and applying these well-advanced scientific fundamentals and innovative approaches to target mineral particles during beneficiation (minerals separation). As such, the mechanism being applied for mineral recognition and binding mimics how a cancer-targeting drug can find and attach to an individual cancer cell in a human body.

“We had the idea to uncover the potential of peptides for use as reagents in minerals separation many years ago, because we knew there were some naturally occurring molecules that had selective binding properties with certain materials,” said Prof Zhao.

Centre Director, L/Prof Kevin Galvin, commented, “Eighteen months ago we knew they were on track to achieving amazing things, which was recently

confirmed when I last visited them. We needed to be patient and quiet on this while they locked in the provisional patent”.

Beyond Centre inter-connectivity, the team also collaborates with Centre Associate Investigator Prof David Weitz from Harvard University.

Development of mineral-targeting biomolecules: peptides

The team repurposed phage display technology: a technique traditionally confined to drug discovery and biomolecular studies and recognised by the 2018 Nobel Prize in Chemistry.

“First, we built on existing knowledge to screen different mineral particles using a library of billions of peptide variants, which enabled Centre-funded development of a new ‘library’ of mineral binding peptides.”

This new library or ‘data base’ builds out the understanding of mineral–peptide interactions at a molecular level. Minerals do not have DNA, but for comparative purposes this understanding is akin to cracking the genetic code in humans, but for each and every mineral on earth.

Enhanced understandings of mineral-peptide interactions then informed the creation of new biomolecular peptide variants (designs), and ultimately

21

the creation of new amino acid-based peptides with the affinity to bind to certain minerals and element surfaces.

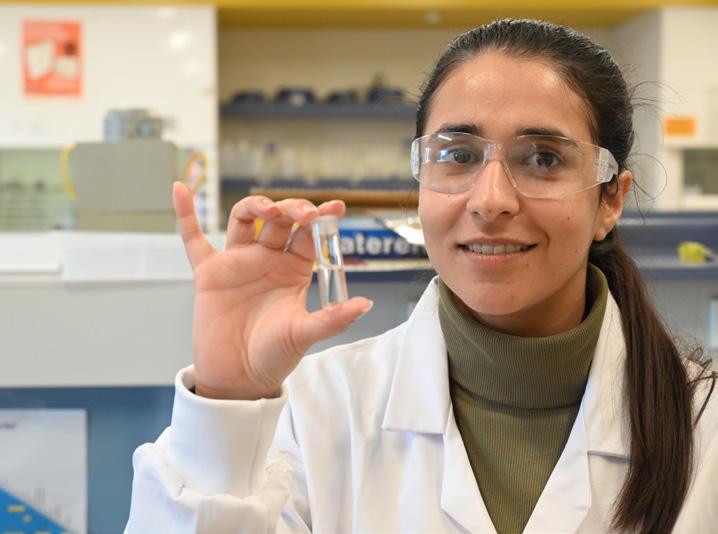

“This stage of peptide-mineral matching, where we created and confirmed exact matches between a bio-based peptide and a mineral was a mammoth process that is now complete,” said Prof Zhao.

Dr Yang conducted and oversaw the lion’s share of this work. He shared that “finding the exact peptide to bind with each REE took a year, but doing so was especially rewarding as there is no efficient or effective way to separate some REEs today, and this knowledge has the ability to change that”.

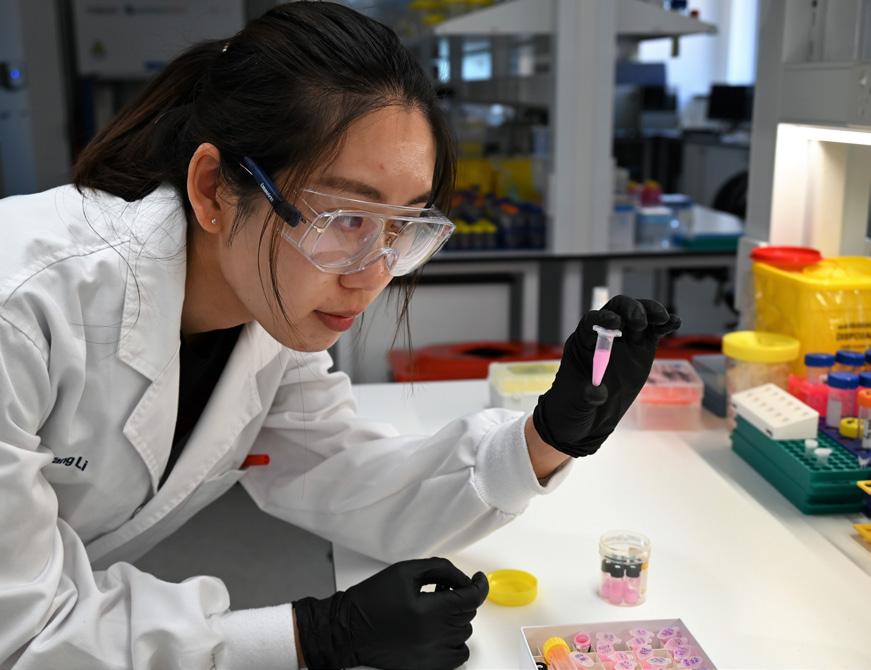

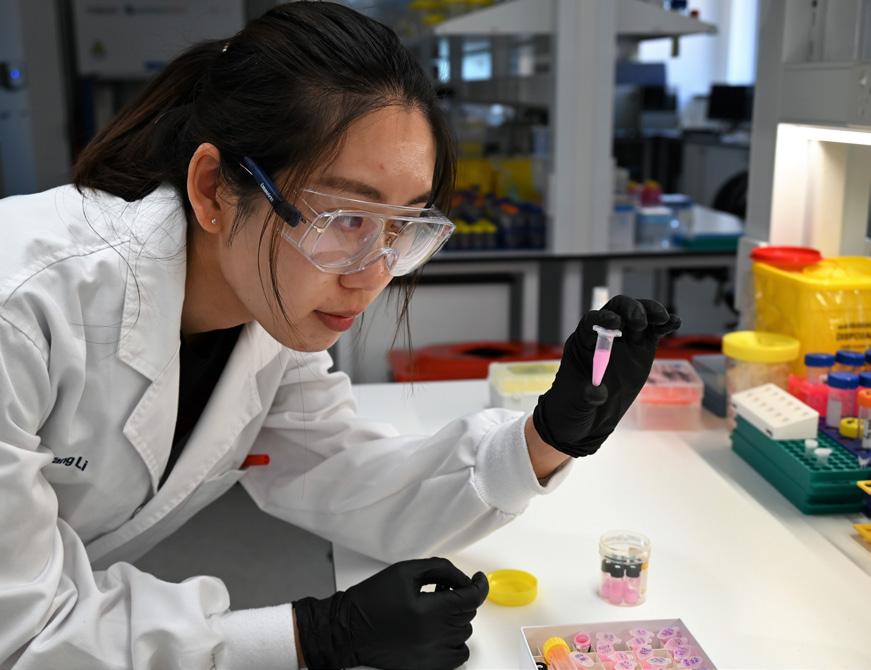

Scientific process efficiency insight

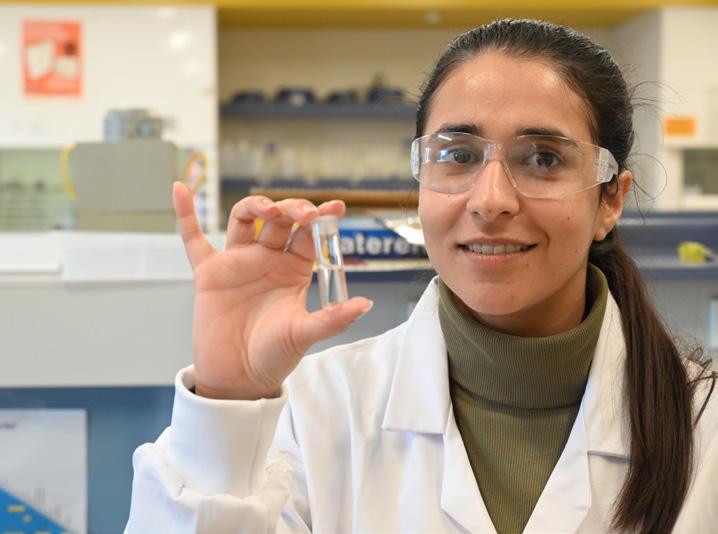

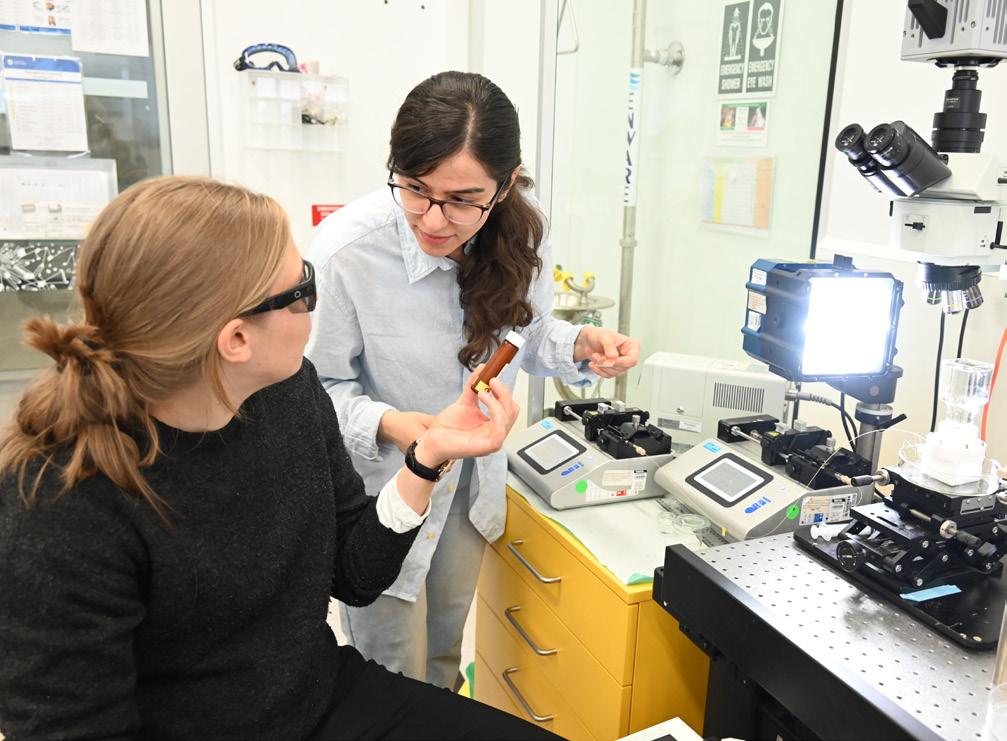

While it may have taken two years, overall lab and project time was significantly reduced by using colour-coding to confirm each mineralpeptide match in a vial. The simple indication of yes/no colour matching after each round of testing enabled the UoA team to quickly ascertain initial results, fast tracking the test-and-learn processes in the lab. (i.e. when a peptide turned the vial mineral ‘blue’, that indicated a ‘match’ and triggered more extensive scientific analysis). This shaved hours, weeks and months of lab time.

Why peptides deliver a new alternative in mineral processing

Mineral processing relies on a limited range of chemical collectors or surfactants delivered in a variety of ways. Peptides operate at another level when it comes to recognising the chemical code of a particle and being highly selective with the ability to lock together with a mineral particle surface (like pieces of lego).

The transformative benefits on the horizon

The peptide mapping project unlocks huge potential for first stage beneficiation of minerals and in downstream hydrometallurgical processing, especially in the boutique area of rare earth minerals, and metal recycling.

“The extraordinary level of selectivity opens the door to novel forms of processing, essential for delivering cost-effective performance at the million tonne per annum level needed by the industry. High selectivity means high mineral upgrades and therefore much smaller cost effective and environmentally acceptable downstream processing,” L/Prof Galvin said.

The Centre research program has been reshaped to help promote further advances, firstly with other game-changing work in novel RAFT polymers at Monash, led by Prof San H. Thang, that can include peptides, as well as finding novel ways to deliver and even recycle the new reagents. The Centre’s innovation in large-scale separation technologies offers further scope for applying the new reagents at scale. This work opens the door to a new era of green chemistry, replacing otherwise toxic collectors currently used in mineral flotation.

Centre researchers across multiple nodes are already applying the peptides to flotation separations. The work includes specific precious metals, REE, critical minerals and clays across multiple nodes. The work offers ways to address specific metals in minerals in an oxidised state.

It is envisaged that an economically viable approach will be identified. The economics become more attractive when the specific peptide can be produced more cheaply in cell factories via E Coli. The cost can be further reduced if the peptides can be recovered and reused.

The economics further improve as the market grows, and when the minerals are upgraded to much higher concentrations.

Explainer: what are peptides?

Peptides are like small pieces of proteins. Imagine proteins as long trains made up of ‘lego blocks’ linked together, where each lego block is a small unit called an amino acid. There are only 20 amino acids that make up the proteins found in the human body. Peptides are like having just a few lego blocks from that train. They are made up of a few amino acids linked together in a chain.

22

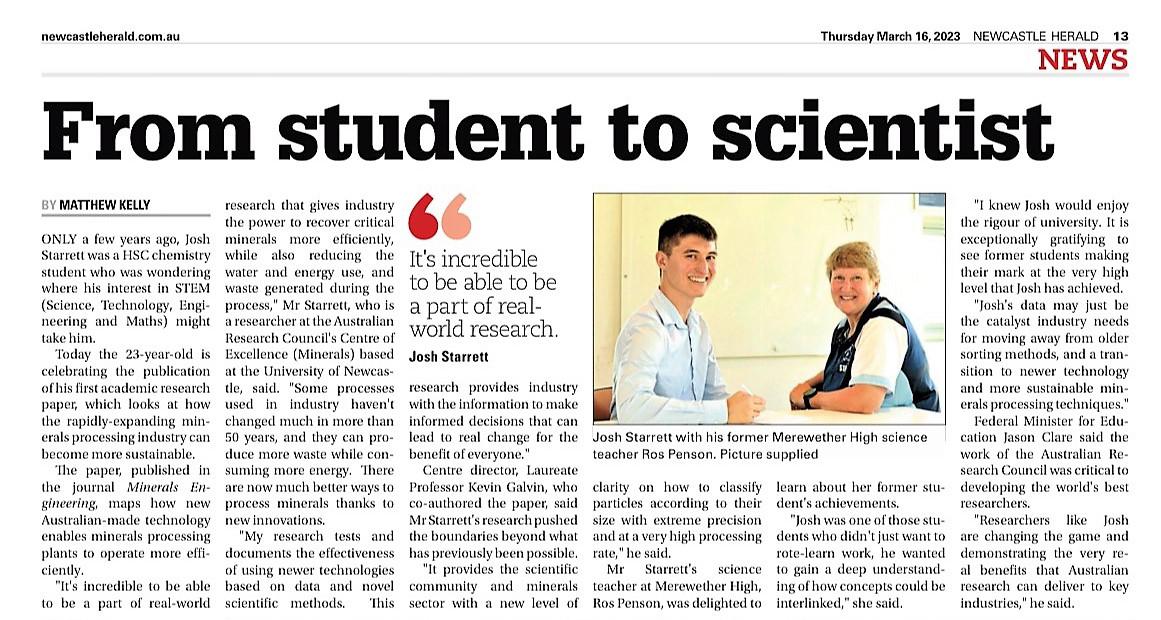

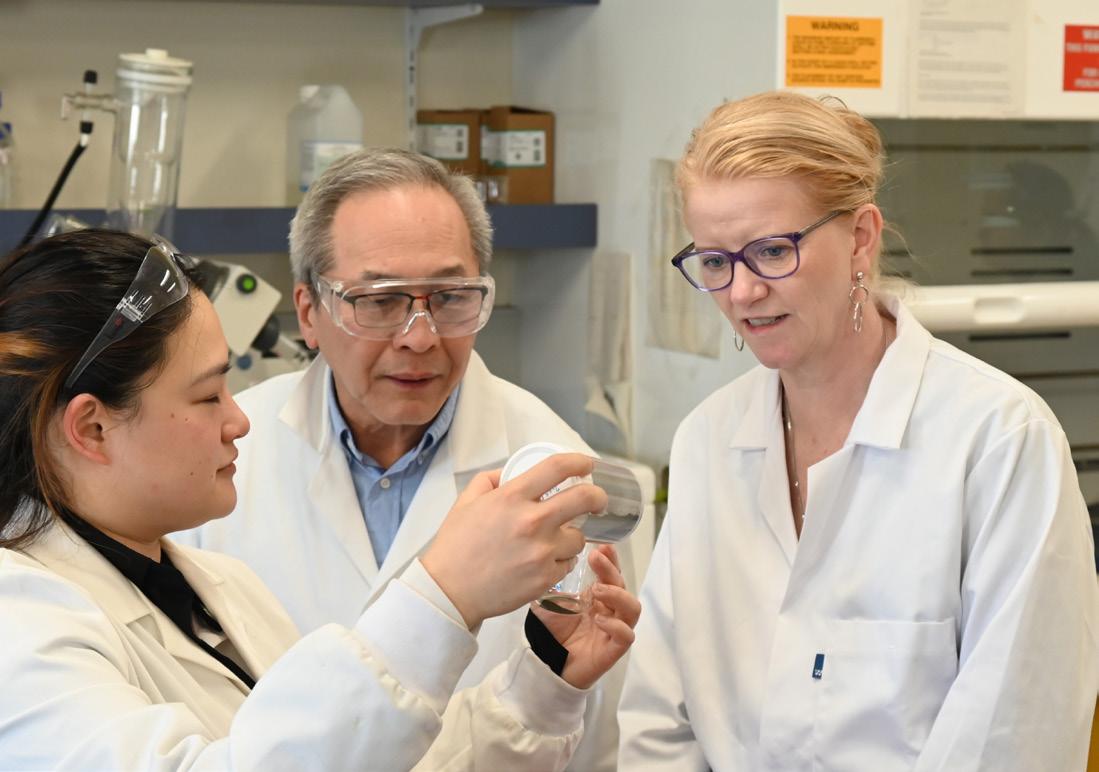

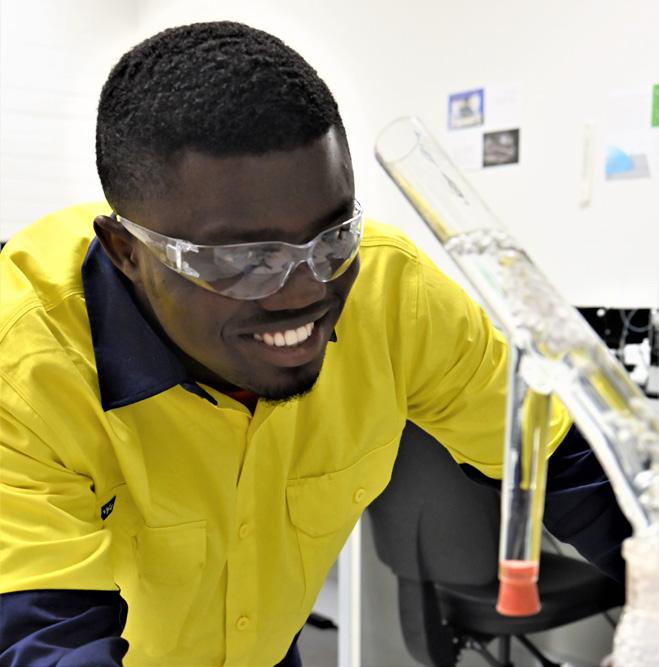

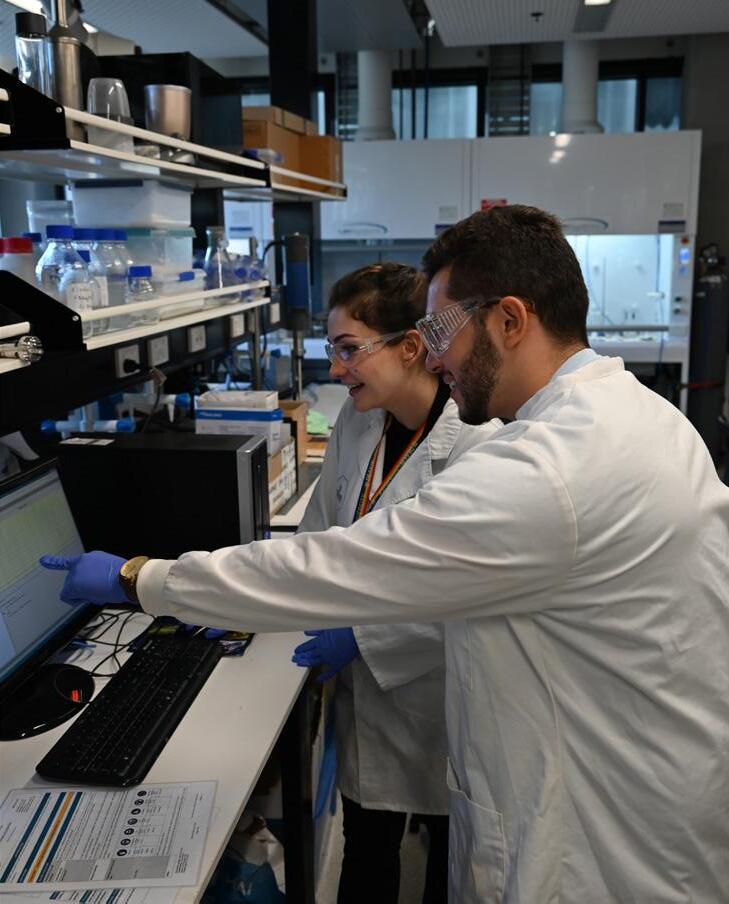

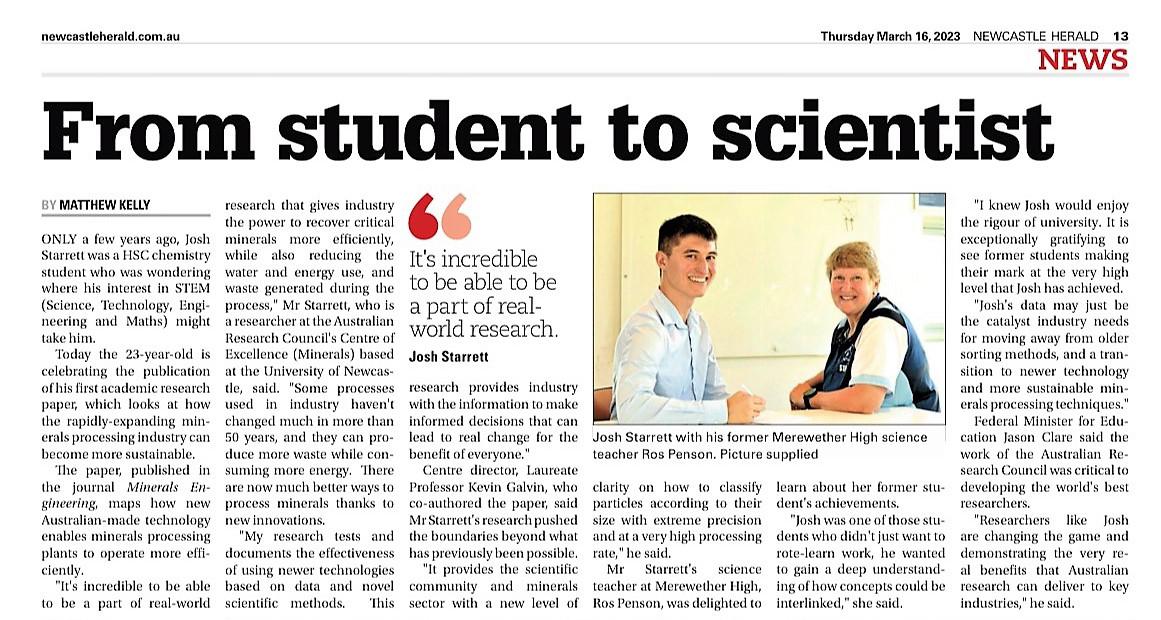

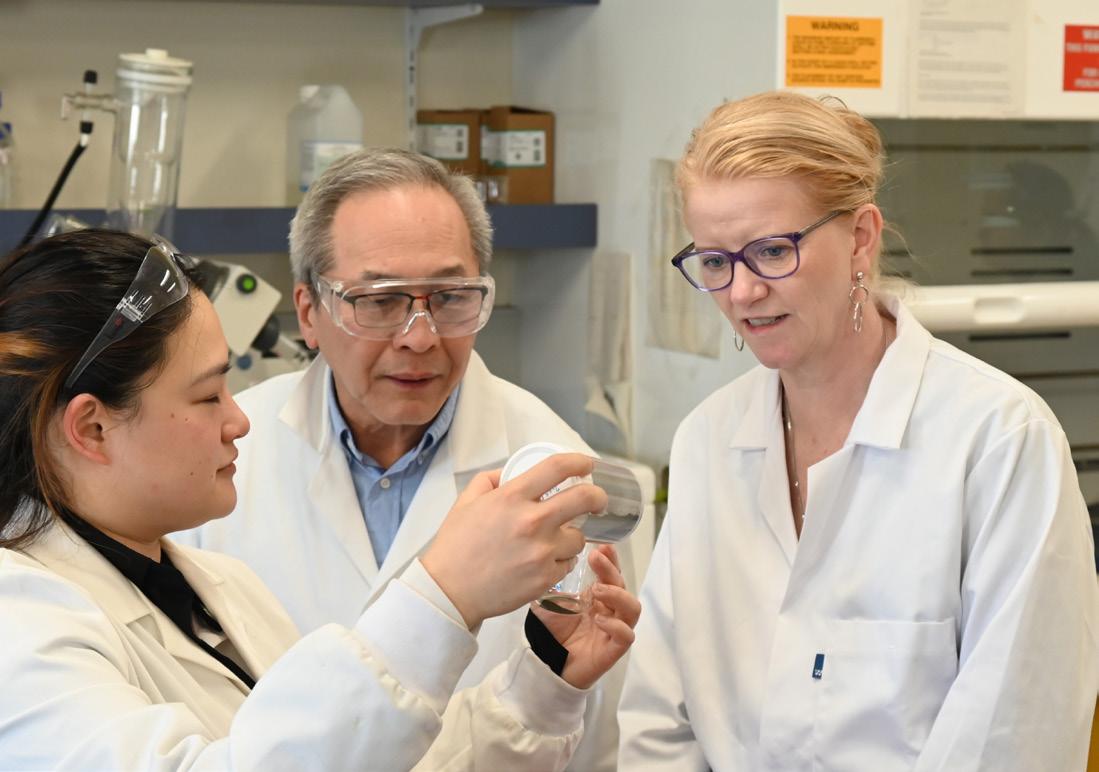

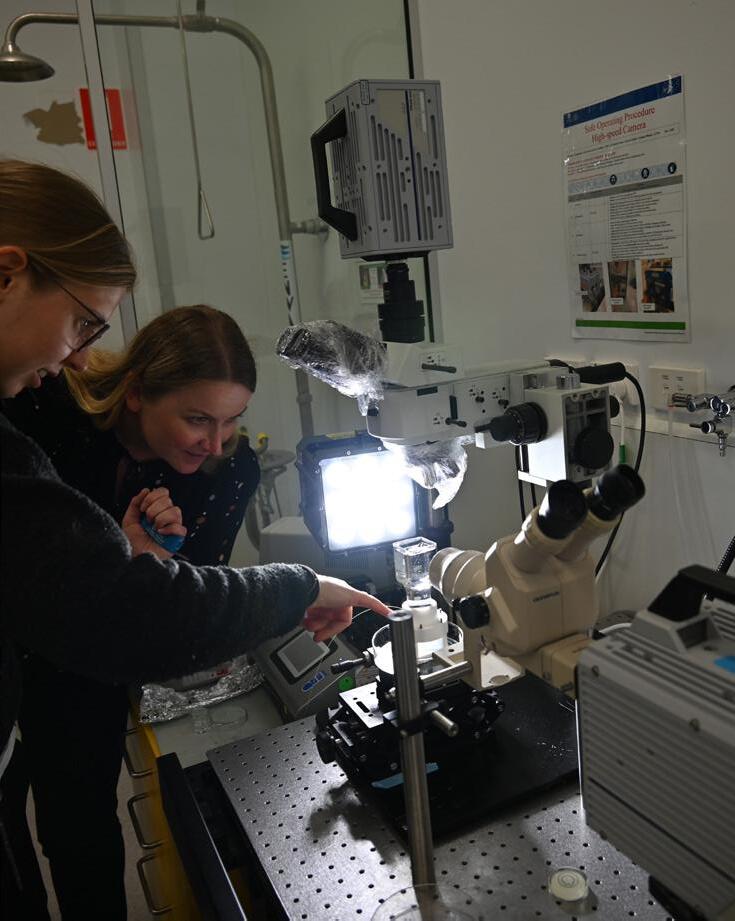

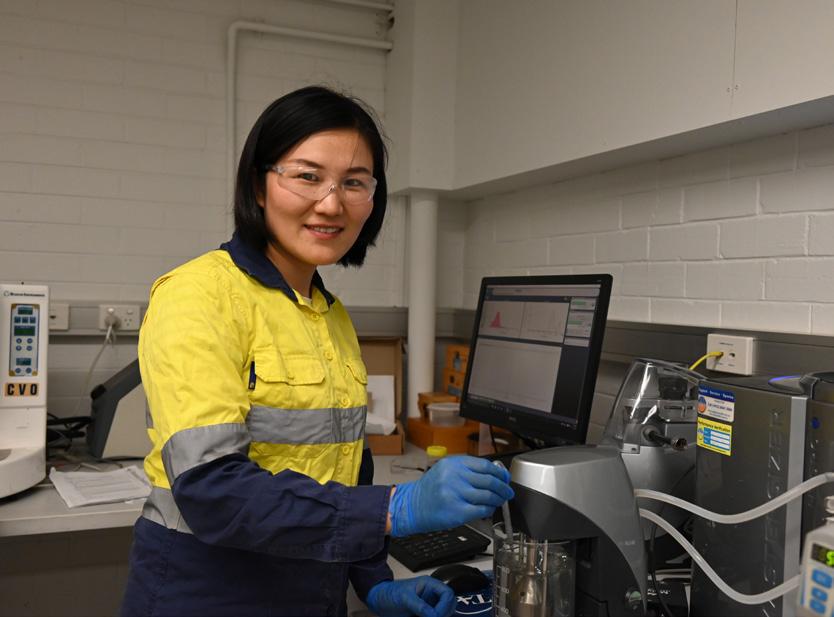

Picture Page 21 - UoA Node (L-R) PhD Ricky Zhao, ECR Dr Daniel Yang, CI Prof Chun-Xia Zhao and PhDs Matthias Orchard and Jessica Li

PhD Alisha Debas

BIO-INSPIRED ALTERNATIVES FOR MINERAL PROCESSING

COEMinerals is applying novel chemistry to enable the replacement, recovery, regeneration and reuse of the chemicals that enable minerals separation and recovery at various stages of mineral processing.

The end goal is offering industry more-sustainable and effective alternatives to the chemicals used today, thereby minimising the environmental impact of mining operations, and delivering cost and other efficiencies.

Beyond creating less waste, recycling ingredients would reduce or remove the need for chemicalwaste storage (post-processing), which today relies on ‘tailings dams’. Further, early testing indicates the new additives being created by COEMinerals may be more effective and efficient at minerals separation than currently utilised chemicals.

Monash node plays a central role in this widereaching work, guiding the chemistry with close engagement with researchers across nodes.

Novel chemistry: RAFT polymer, biomolecule and biodegradable ingredients

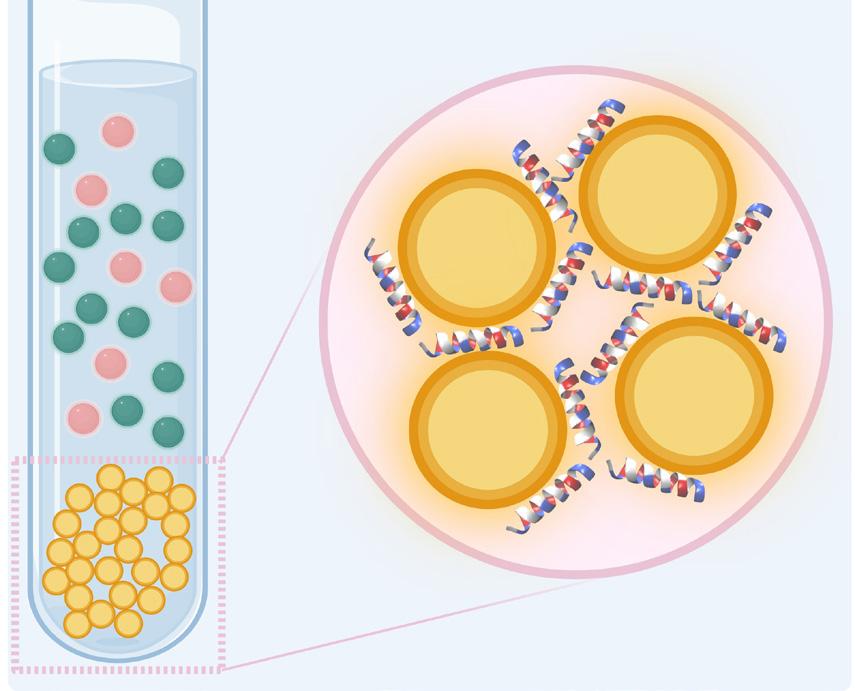

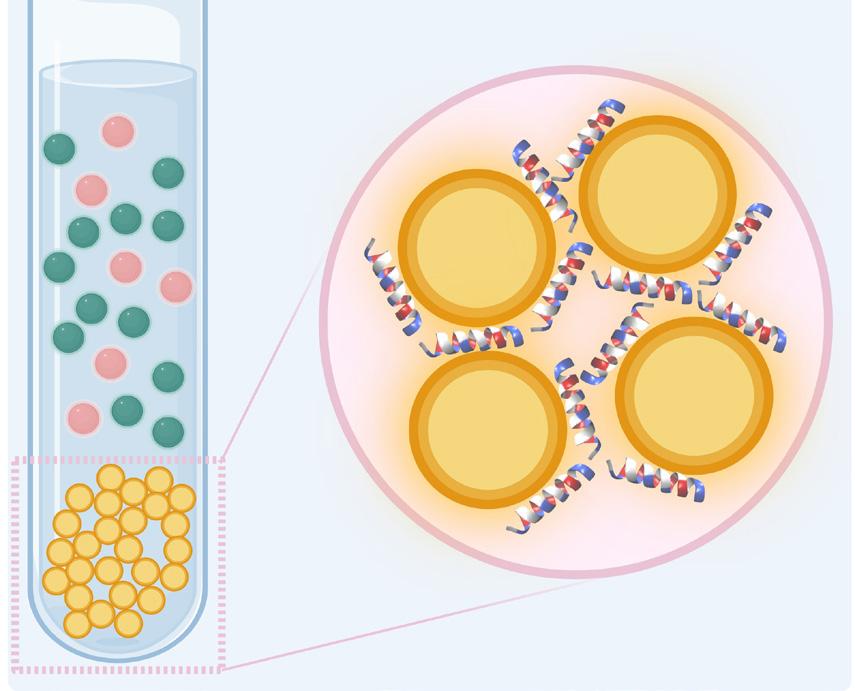

Collaboration between multiple COEMinerals members and university nodes, and across multiple projects is delivering world-leading capability in applying Reversible Addition− Fragmentation Chain-Transfer (RAFT) polymers to critical and strategic mineral separations.

RAFT polymers are being designed and synthesised to improve the ‘froth flotation’ minerals separation process in various ways, with the incorporation of specific chemical functionalities that selectively target minerals of value and enable effective mineral recovery.

“Everyone is engaged in the mindset of development,” shared CI Prof San H. Thang, AC (Monash).

Further, new biomolecules and bio-inspired polymer-based reagents are biodegradable,

removing waste and increasing the overall sustainability of minerals separation processes. A series of stimuli-responsive biomolecules and synthetic molecules (frothers or collectors) accommodate and adapt to changing pH, temperature and naturally occurring light conditions.

The novel, bio-inspired chemical collectors using plant-based chromophores (also known as ‘coloured molecules’, as they absorb a particular wavelength of light and emit a colour as a result) testing reveals these intriguing molecules have dual properties: improving foaming during flotation and increasing selectivity that enables them to specifically bind with certain mineral particles.

Dr Chris Ritchie (Monash) who directs this work explained, “Thus far, our efforts have centred on understanding the chemistry of these new compounds and their interactions. However, we are now expanding these efforts through extensive collaboration across the Centre, with the goal of achieving transformative impact within the mineral processing sector.”

Monash group photo: PhDs Samadhi Fernando and Yuxi Li, CIs Dr Chris Ritchie and Prof San H.Thang, ECR Dr Tina Hsia and PhD Alisha Debas

23

Prof San H. Thang

Monash

and Deakin

Examples of cross-node collaborative research with Monash

PhD Samadhi Fernando (Monash)

Thermoresponsive RAFT polymer-based surfactants (P39)

COEMinerals is unlocking the potential for recyclable polymers that improve selectivity during mineral processing. The first research paper on this topic, released in 2023 proves novel RAFT polymer-based reagents (created at Monash) can replace current chemicals to recover ultrafine mineral particles. It also offers proof-of-concept that one day these polymer ingredients will be fully recyclable and reusable by industry. The project combines environmental engineering, chemical engineering and chemistry, and application of scientific methods typically used in the food, biotechnology, and pharmaceutical sector now being adapted for the first time to recover fine mineral particles. These efforts mark an initial move towards future environmental advantages rooted in circularity.

“Not only are the new reagents more effective and efficient at capturing (agglomerating) fine mineral particles than the chemicals used today, but they are designed to one day be recoverable and reusable,” said CI Dr Ellen Moon (Deakin), with Prof San H. Thang adding, “We’re confident future Centre work will unlock the key to fully recyclable polymer recovery (potentially via simple cooling or heating) which then removes chemicals from mining waste, and ideally, reduces the liquid components of mining waste, which today is stored in tailings dams.” A next step in the research is to test newly created, bio-inspired polymers to further improve environmental-related outcomes.

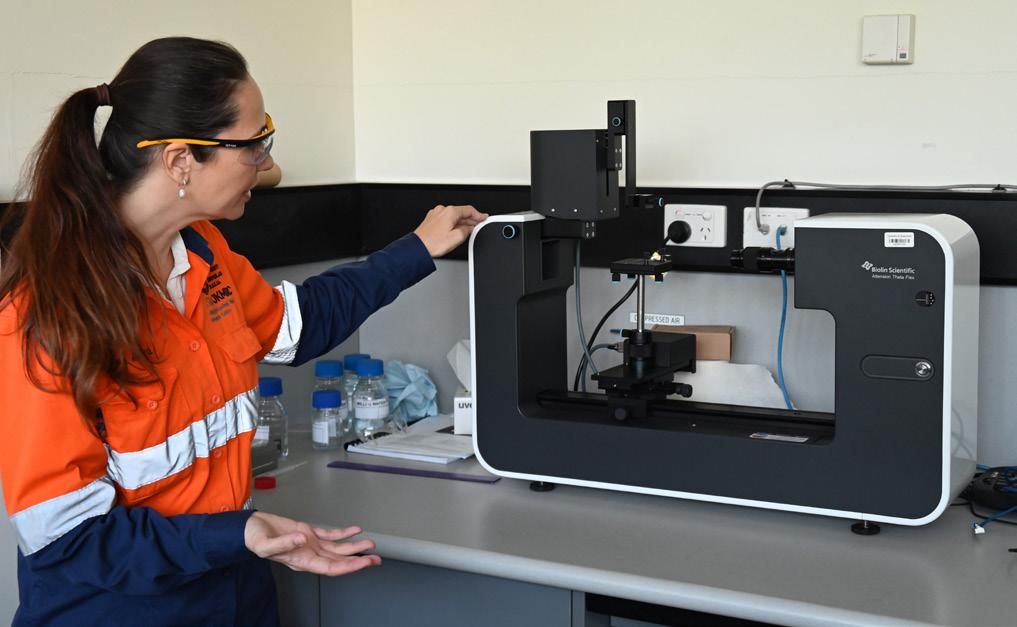

Investigation of particle hydrophobicity (P50)

Measuring the change in surface hydrophobicity of mineral surfaces following treatment with chemical reagents is relatively straightforward when the mineral surface is large and homogeneous. Conducting such experiments on small clay particles or flocculated materials presents significant challenges. Ongoing collaborative work between Monash and Deakin nodes aims to correlate

reagent dosing with the change in macroscopic properties of aggregated clay particles following chemical modification to establish a leading indicator for assessing reagent dosing requirements for flocculation-flotation experiments moving forward.

Monash and UNSW

Stimuli responsive RAFT polymer testing (P50)

Reagents developed at Monash have been investigated by CI A/Prof Seher Ata and her team to determine the critical micelle concentration of reagents using the pendant drop method. This work has set the scene for more elaborate experiments and collaborations ahead.

Note: ‘P’ refers to Project numbers i.e. P39

UNSW Node group: PhD Sayed Anzoom, AI Dr Ghislain Bournival, CI Prof Seher Ata and PhD Minuk Jung

ECR Dr Negin Amini (Deakin)

24

Monash and UniSA

“Understanding how two bodies, including how a single oil droplet may interact with mineral surfaces is not only an exciting scientific challenge, but this knowledge has great potential to transform research and new approaches in studying the fundamental acts of flotation: collision, attachment and detachment, as well as corelating them with flotation recovery,” CI Prof Marta Krasowska (UniSA).

“Polymers can be selective in their adsorption and can stop a mineral from floating. They can often also be derived from benign biological materials, making mining more environmentally sustainable,” shared CI Prof David Beattie (UniSA).

Bio-inspired small molecules via Quartz Crystal Microbalance analysis (P36)

Experiments indicate that Vitamin E based small molecules, produced by Monash, exhibit exceptional selectivity for chalcopyrite (copper) particles.

Quartz Crystal Microbalance (QCM) analysis proved that they are “super selective” towards copper particles/surfaces and adsorb at such surfaces, while they do not adsorb at surfaces that mimic gangue (i.e. waste) particles such as silica during flotation.

Stimuli-responsive surfactant adsorption onto clays (P46 and P50)

Selective reagents can adsorb on and flocculate clay particles, rendering the particles highly hydrophobic (water repelling), which means they have potential utility as both flocculants and reagents for reverse froth flotation. Testing is now underway to better understand their adsorption profiles, using in situ measurements of vibrational spectroscopy.

Surface interactions of stimuli-responsive frothers (P49)

In addition to the adsorption of reagents to solid particles, understanding the air-water interface is critical in the design of new frothers. Synchrotron

small and wide-angle X-ray scattering experiments are scheduled to test their response to pH, light and temperature stimuli in 2024. Profile analysis tensiometry and dilational rheology (i.e. studying the matter-flow) will also be conducted to investigate the kinetics of adsorption of such frothers at the surface as well as the mechanical properties of the adsorbed layer.

Monash, UOM and UniSA

Testing biopolymer emulsions for Chalcopyrite (copper) recovery (P34)

The UniSA and UOM teams are using tailored surfactants for forming smart emulsions for collection of coarse particles in flotation. These surfactants have a number of jobs to perform, including making the emulsions stable before deployment, and ensuring oil droplet attachment and spreading over rough surfaces consisting of more than one mineral type. The work will eventually allow large particles to be collected, reducing the energy expenditure that arises from grinding ore.

Monash and UOM

Emulsion stabilisation with a new surfactant (P33 and P34)

UOM is testing Monash’s bio-inspired, Vitamin E based small molecules as a surfactant for chalcopyrite (copper) separation. Results demonstrate that new surfactant improves the stability of kerosene emulsions, compared to a commercially available surfactant commonly used in

the mineral processing industry. Improving emulsion stability over time by preventing oil drops from coalescing is important as it makes the emulsion more stable. A related scientific discovery relates to improved understanding of the influence of the surfactant molecular weight on the stability of emulsions. This may have other applications, given improving emulsion stability is also important for things like making salad dressings that do not separate and shampoos that remain stable over long period of time.

RAFT polymers as collectors and flocculants (P44 and P48)

Dual-functional RAFT polymers with different molecular weights have been synthesised by the Monash team. They can function as mineral particle collectors and flocculants (which help tiny mineral particles to stick together and/or to rising bubbles for separation and surface collection). To enhance selectivity towards chalcopyrite (copper), the polymers are incorporated with acetylcarbamothioate (-O-C(=S)-NH-CO-CH3) functionality. The effectiveness of these new RAFT polymers as a flocculant was compared with a xanthate-based polymer of similar molecular weight in flocculation experiments. The flocculation efficiency was assessed by measuring the changes in turbidity (i.e. when solid particles or sediment remain suspended in a liquid) readings of chalcopyrite suspensions containing particles smaller than 25 micrometres (µm). (For perspective, one µm is one-thousandth of a millimetre – very small!) The results demonstrated a significant reduction in turbidity within 3 minutes after treatment with the novel RAFT polymer, highlighting its strong flocculation capabilities.

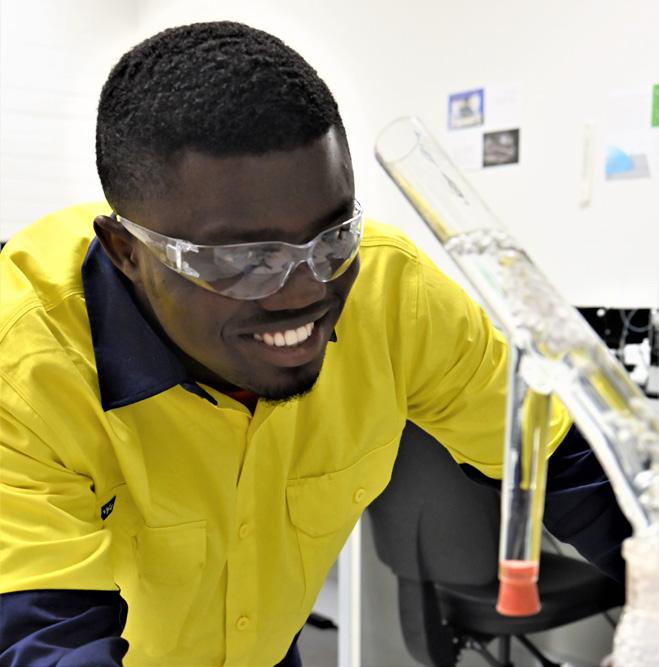

Page 26: PhD Regina Medeiros (UOM) and UON PhDs Sonia Khandaker and Rocky Mensah

25

Photo above: PhD Rupinder Kaur (UniSA)

Flocculation of clays using novel surfactants (P46 and P50)

Small molecule reagents developed at Monash have been successfully employed in the flocculation of kaolinite (clay minerals) at loadings comparable with those used in industry. The reagent with low molecular weight opens the door towards their use as flocculation flotation additives. Ongoing benchmarking against other reagents is underway.

“The collaboration between the emulsion experimentalists at UOM node and the polymer chemists based at Monash has been instrumental in trialling novel reagents in emulsion applications. The synergy between the groups is fantastic,” shared CI Prof George Franks (UOM).

Monash and UON

RAFT polymer / polyacrylamides (water-soluble synthetic linear polymers) (P46)

Adsorption testing is occurring on different mineral oxides, including iron oxides for Monashmade polymers. Analytical chemistry techniques enable molecular scale adsorption testing to ascertain which novel polymers offer the best prospect for the separation

of iron oxides and gangue silica via selective adsorption. A related paper is due for publication in 2024.

Bio-inspired small molecules as frothers and collectors (P46 and P48)

UON is testing novel reagents made by the Monash team using bio-inspired small molecules (based on Vitamin E and cardanol). The Vitamin E derivatives are being tested as new surfactants and the cardanol derivative, with carboxylic acid functionality, for hematite (iron oxide) flotation. This novel small, bio-inspired collector is being benchmarked against the commercial collector, sodium oleate. Ultimately, the team is aiming for commercial application after a successful trial stage.

Monash, UoA and UON

Bio-inspired small Vitamin E based molecules as novel collectors (P42)

Combining the strengths of Monash and UoA teams, the cross-node team is synthesising bioinspired small molecules (Vitamin E derivatives and peptides) and RAFT polymers with peptide segments (the amino acids attached to the chainend of the polymer) using a peptide-containing thiocarbonylthio RAFT agent. The resulting innovative new reagents are being evaluated as novel mineral particle collectors in froth flotation for REE minerals at UON.

Monash, UON and Germany

Testing bio-inspired small molecules and RAFT Polymers as frothers and collectors (in changed conditions) to aid recovery of lithium ions

A COEMinerals project was conducted as part of The Australia-Germany Joint Research Cooperation Scheme. PhD Siân Parkes (UON) visited Germany to help test four Monash-made RAFT polymers for recovering ions present in a range of lithium (including lithium ferrous phosphate, also known as lithium iron phosphate, LFP, which is a lithium-ion battery technology popular in solar, off-grid, and other energy storage applications and batteries).

The end goal is to recover, recycle and reuse them. The research found that polymer selectivity could be manipulated by changing pH, and minerals recovery was improved for iron (up to 100), zinc and silicon (up to 50). The results were shared during the Chemeca 2023 conference in Auckland, New Zealand. A collaborative journal article is due in 2024.

The use of chemicals (for chemical emulsions or as surfactants, reagents, collectors, frothers, flocculants) is wide-reaching in mineral processing. They are added to solutions containing ore and mineral particles to selectively enable some particles to attach to each other and/or to bubbles, to help them float or sink, and/or remain in a stable ‘froth’ for collection as part of mineral processing ‘flotation’ methods.

Many traditional methods of froth flotation consume high volumes of one-off use chemicals. By the end of 2027, it is estimated the global market for collectors used in mineral processing would reach US$100 billion1 as these chemicals are a crucial enabler for separating minerals. In general:

o frothers/surfactants stabilise froths during flotation mineral processing

o reagents help mineral or other particles to float

o collectors help minerals/metal surfaces repel water

o flocculants help suspended particles attached and aggregate (stick together)

26

DataIntelo.MiningCollectorsMarketResearchReport, 2023; p 112.

DRIVING SECTOR TRANSFORMATION WITH GAME-CHANGING TECHNOLOGY

COEMinerals is at the forefront globally in developing new technology options and process solutions to support first stage beneficiation of minerals:

Removal of waste ore at coarse particle sizes to preconcentrate the ore (which reduces energy consumption in grinding hard rock and water losses to tailings)

More efficient processing of fine particles to maximise resource recovery and concentrate the product (to reduce emissions during downstream processing)

More effective solid-liquid separation to recover more water (to ideally eliminate tailings dams)

Technologies emerging from COEMinerals are assessed against a Technology Readiness Level (TRL) scale, a systematic metric used to assess the maturity of a particular technology. While TRLs are noted on the following pages, please refer to The COEMinerals TRL Framework and correlating tables on pages 33-36.

Novel technologies

The Gyratory Rolls Crusher + (GRolls ®) (P1 and P9)

Developed in South Australia with Centre (UniSA node) involvement, the GRolls® technology reduces energy and water consumption during comminution. COEMinerals CI Prof Bill Skinner co-authored a research paper, with findings presented at the Metplant event in 2023 by Mr Mark Drechsler of CBSM Mining Services Pty Ltd 1

Notes: ‘P’ refers to Project numbers i.e. P9 + yet to be fully evalutated against The COEMinerals TRL Framework

1 https://www.linkedin.com/in/ACoAAAXY8RcB1f_hX7OdO1QCGGUghv9a5r7Tz08

Moisture reducing roller conveying system+ ( P29)

This dewatering system recovers water from coarse stream tailings and product streams following beneficiation. The water recovery also leads to reduced transport costs for trains, trucks, and shipping, and reduces the volume of tailings. Centre members are looking to further improve the dewatering through continuous testing.

Technology inventor, CI Prof Ken Williams (UON) commented, “We are striving to remove as much water as possible with this system so it can be retained and reused, further reducing overall water consumption during mining and mineral processing. With international patents now in place, the next step is bridging the ‘gap’ between invention and commercialisation by sourcing a commercial partner”.

The first stage of mineral processing, where minerals are liberated from the host rock, is energy intensive. Historically, all the mined feed was ground to liberation sizes, leading to excessive energy consumption, and increased volume of tailings and hence water loss. Declining ore grades, environmental, economic and social factors are adding to the challenge of mineral recovery and concentration, resulting in significant intractable challenges for industry and society.

27

GRolls® technology

The JKHFMini+ - developed in a parallel project (P41)

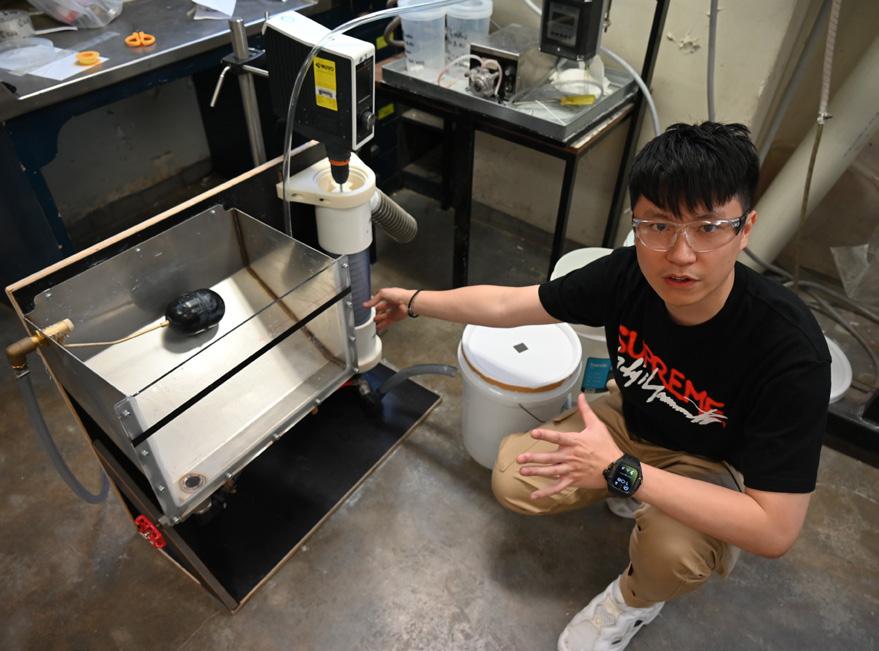

Researchers from UQ node are undertaking research to advance the HydroFloat®, a coarse particle flotation technology (commercialised by Eriez International and installed at several mining operations worldwide) involving the aeration of a fluidised bed to achieve recovery of coarse particles that cannot be recovered in conventional flotation. Improved coarse mineral flotation means less grinding is needed, which can save up to 50% of the energy used in mining operations 2 A key outcome of the collaborative research, involving Eriez and supported by the Collaborative Consortium for Coarse Particle Processing research program 3, has been the development of a new laboratory-scale fluidised bed flotation device at the UQ node named the JKHFmini. The JKHFmini enables rapid and efficient testing for essential operations such as ore amenability and metallurgical evaluation, circuit modelling and design, and routine metallurgical assessment. The device and testing procedures were developed to use only 1-2 kg of sample per test, similar to the scale used in batch flotation tests.

The JKHFmini has been used to assess the coarse flotation behaviour of two copper ores. The device has also been taken to a mine site to compare its performance to a full-scale HydroFloat®. Researcher Lizette Verster (UQ) shared, “This is a real game changer and has enabled us to undertake so much new work that was not previously possible”.

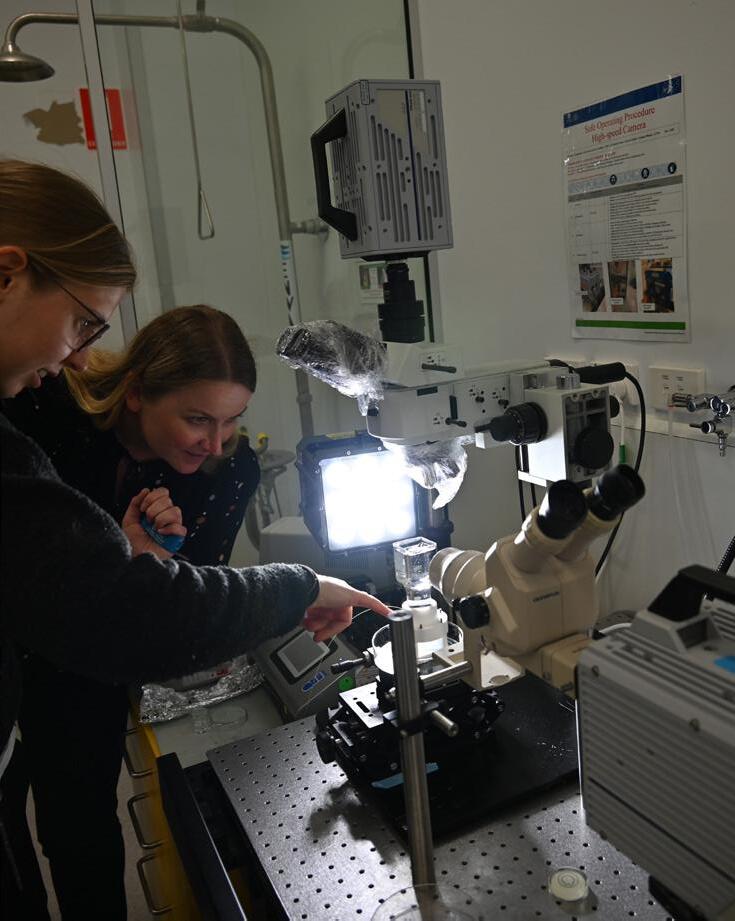

Novel tomograph y application for 3D Imaging + (P2 and P3)

The project team, led by CI A/Prof Kym Runge (UQ) is researching a novel method of creating a composite 3 dimensional (3D) image of particles, and the grains within it, based on the manipulation and analysis of data from X-ray micro-CT (XRT). XRT has the potential to non-invasively and non-destructively measure the composition and surface exposure of mineral particles without the stereological problems associated with analysis of 2 dimensional (2D) images generated with conventional techniques like Mineral Liberation Analysis (MLA). As part of the project, the UQ node

is developing Open Access, user friendly software to analyse the images sourced from the XRT and transform the images into information.

The aim of this project is to advance the application of XRT for mineral processing applications by exploring whether XRT can be used in conjunction with 2D Scanning Electron Microscopy (SEM) information to enable characterisation of mineral liberation. The project utilises new analytical equipment at UQ in collaboration with other universities, enabling higher resolution expectation maximisation (EM) data to be obtained, suitable for fine scale mineral analysis as well as more accurate segmentation analysis. The work provides the opportunity for 3D stereological analysis and interpretation of 2D imagery at a level not previously attainable. A next step will be to link the tomography and surface chemistry to build a comprehensive picture of the geochemistry.

A/Prof Kym Runge commented: “Techniques that help industry make better decisions are important, as some decisions take 10-15 years to materialise and involve significant expenditure. Our work is about trying to get better information and faster”. 2

ECR Dr Farhana Diba (UQ)

ECR Dr Farhana Diba (UQ)

Ballantyne, G., Powell, M.& Tiang, M. Proportion of energy attributable to comminution. Proceedings of the 11th Australasian Institute of Mining and Metallurgy Mill Operator’s Conference, 2012. 25-30.

Collaborative Consortium for Coarse Particle Processing Research (CPR) - Sustainable Minerals Institute - University of Queensland (uq.edu.au) JKHFmini arrangement used to assess coarse particle flotation

3

Novel pelletiser for dewatering (P43) (TRL 1.8)

The result of collaboration between COEMinerals team members at Deakin and UOM: The system involves the dewatering of small hydrophobic flocs, forming agglomerates that become progressively denser, rejecting water. Ultimately, this technology could create dry, stackable tailings. CI Dr Ellen Moon (Deakin) shared, “We were inspired to use the approach in an entirely new way”. The team have developed a small prototype pelletiser for testing, ahead of demonstrating to potential industry partners.

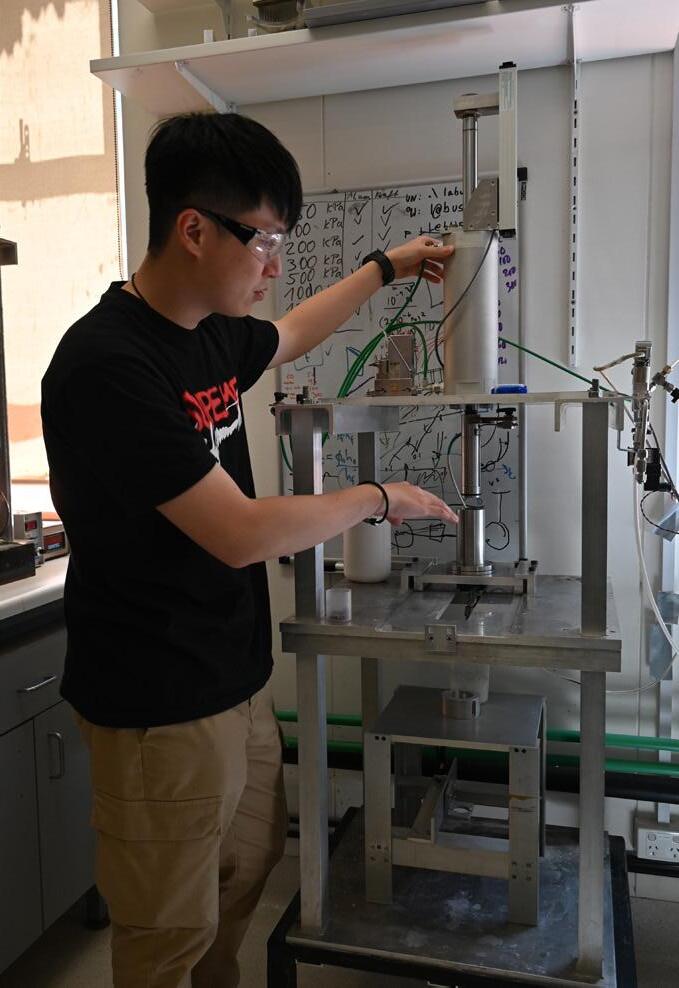

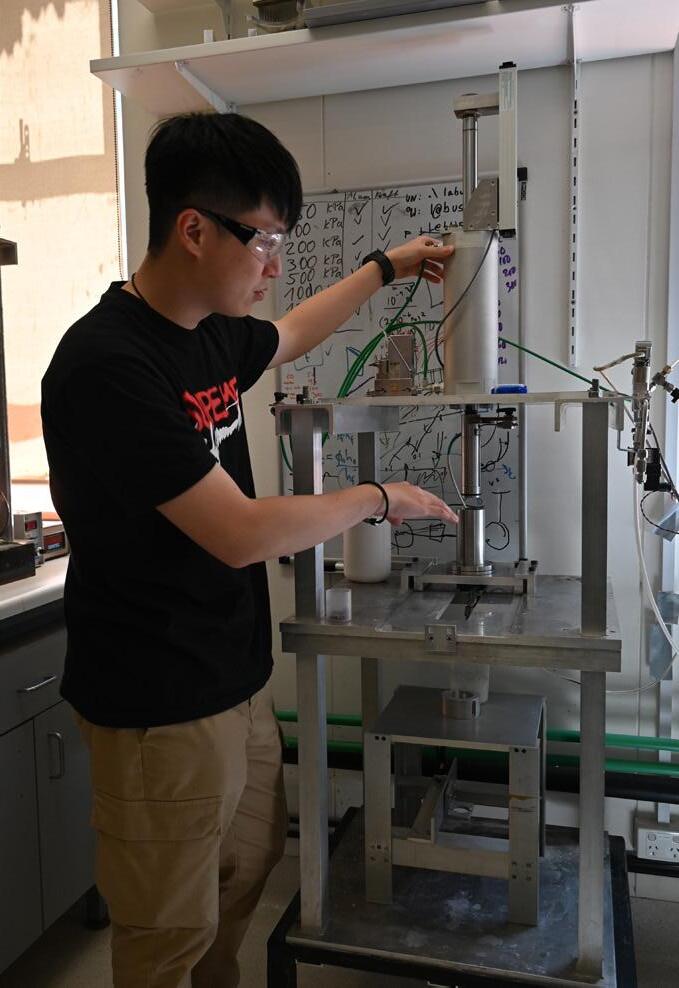

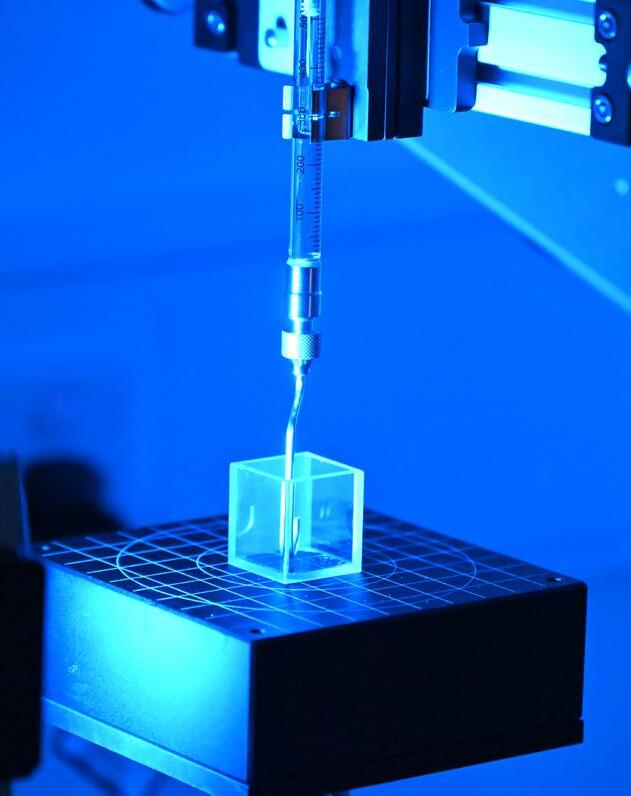

High Pressure Dewatering Rolls (HDPR) technology (P28) (TRL3.8)

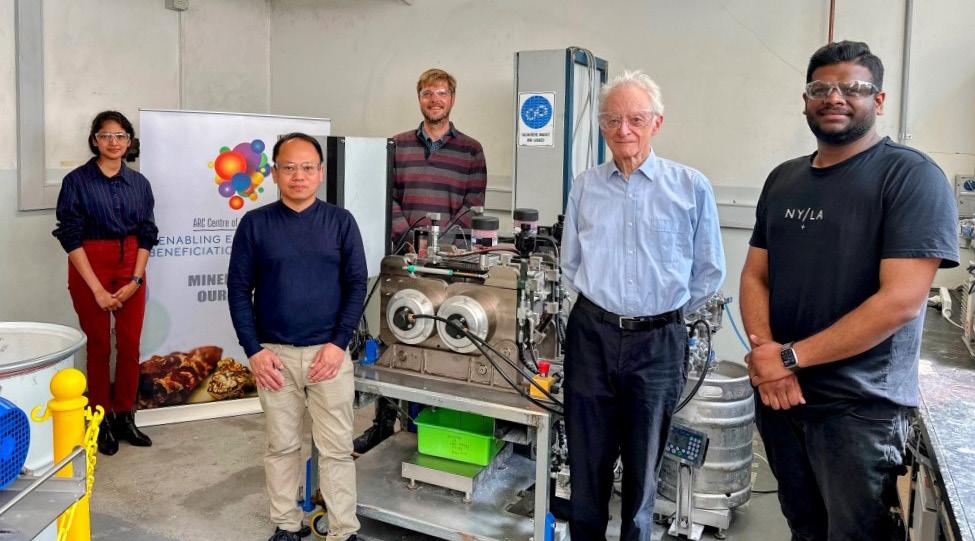

UOM node members are undertaking a project with BHP’s ‘Think and Act Differently’ team to evaluate the performance of the developed HPDR technology for improving tailings storage and water recovery. The project is being performed in close collaboration with former Chief Scientist of Australia Prof Robin Batterham AO and COEMinerals AI Prof Peter Scales.

Engagement with industry has allowed demonstration of the HPDR for fine, clay-rich mineral tailings from one of the world’s largest mines, achieving comparable cake moisture as filter presses, which are the current industry option for high pressure filtration of fine tailings. High pressure is necessary to maximise water recovery and reduce new water usage as well as producing a stackable ‘filter cake’ out of the tailings, which improves tailings management and storage. However, filter presses are batch operated, require filter cloth washing and replacement, and can have limited versatility due to fixed plate width.

“The finer the particles, the more difficult they are to separate from liquids using existing pressure and filtration technologies,” explained project leader CI A/Prof Anthony Stickland (UOM).

The HPDR uses a metallic filtration surface, which removes the need for filter cloths and therefore has no operating cost for new cloths, no operational downtime for replacing cloths and no contaminated waste from old cloths, although the longterm robustness of the metal filter surface and roll design at full-scale in harsh mineral processing environments is yet to

be shown. Due to a variable gap between its rolls, the HPDR can cope with varying feed materials and process conditions, which can occur during mineral processing when shifting to different parts of the ore body. The device is inherently scalable by increasing the roll diameter and length while maintaining a short filtration pathlength between the rolls. So far, the HPDR has successfully filtered copper and nickel tailings in a laboratory-scale prototype at a scale of ~100 kg/h. The project team aims to partner with an equipment manufacturer in 2024 to design and build a full-scale version for onsite longer-term testing.

ECR Dr Nilanka Ekanayake (UOM) commented: “Working closely with the mining industry provides access to bulk tailings samples for testing. Further, the close collaboration helps us to navigate problems more easily to have a better understanding of realistic challenges to implementing a new device”. She added her hopes that, “should the device perform as expected during on-site implementation tests, the technology will support environmental, social and governance (ESG) goals by significantly boosting water recovery, recycling and concurrently cutting down on the need for liquid-tailings related storage and related risks”.

29

Above: PhD Azeez Aregbe (UOM). Right: ECR Dr Nilanka Ekanayake, Technican Raul Cavalida, CI A/Prof Anthony Stickland, Prof Robin Batterham AO and PhD Sajid Hassan

The Sink-Hole Fluidiser (P16) (TRL 2.4)

Developed at UON, this technology was transferred to the Curtin node in 2023 to assess gold ores. This is a dry separation technology (i.e. no water used) producing sharp separations based on mineral density. The new technology goes beyond water reduction benefits during beneficiation. It predominantly uses upward flowing air and vibration to sort and separate mineral particles in the size range from 2-10 mm, by exploiting density differences between the gangue (waste) and mineral particles. A Discrete Element Model (DEM) was developed through 2023 providing an improved understanding of the novel separation mechanism ahead of the next stage of research. Further work is underway to better understand the granular physical phenomena enabling separation.

The NovaCell™ - Centre partner Jord International (TRL 5.5)

Jord International (Jord) has successfully delivered test work programs for both local and international clients for the NovaCell™, invented by L/Prof Graeme Jameson. Jord expects demand for test work to grow in 2024 and has secured a partnership with a commercial laboratory in Chile to meet

international testing demand. It is expected that by Q3/4 2024, this facility will support the test work requirements of clients in the Americas.

The first NovaCell™ pilot plant is housed in 20-foot shipping containers, for ease of transportation and mobilisation, and can be operated on a continuous basis at 2 tonnes per hour (tph) of solids. The design includes all the required pumping, tanks, and classification requirements, with a fully integrated process control system. The NovaCell™ pilot plant will soon be transported to an operating copper mine, where its performance in coarse particle flotation (CPF) will be investigated. The NovaCell™ pilot-scale metallurgical results will provide a good indication of the expected performance at full-scale. Thus, the early months of 2024 will be significant in validating the NovaCell™ technology and advancing the product to the final stages of commercialisation. Multiple clients have secured use of the NovaCell™ pilot plant leading to the need for Jord to build a second pilot plant.

Spreading the word to industry: Jord and Capstone Copper presented a paper investigating the potential impact of the NovaCell™ technology as a substitute to the existing technologies at Pinto Valley Mine, located in Arizona, USA. The findings suggested a 27% increase in copper production and a 15% reduction in carbon emissions per tonne of copper. Pinto Valley mine is one of the locations where the NovaCell™ pilot plant will be trialled.

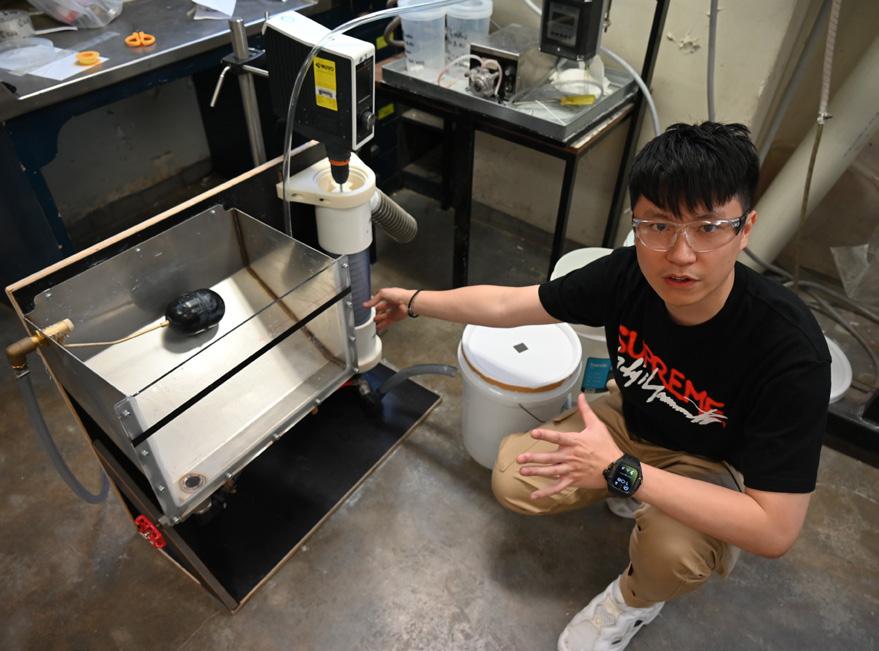

The XtractOre™ - Jord International (TRL 5.0)

After extensive research at a laboratory scale, the first full-scale demonstration plant was constructed and commissioned during 2023 by Jord and UON, which attracted funds from The Australian Coal Industry’s Research Program (ACARP). The XtractOre™ technology is poised to deliver a 10- to 100-fold increase in the speed of fine particle separation, using a concentrated water in oil emulsion as a binder. The expected benefit to mineral processing is a step change increase in the grade and recovery of valuable minerals, including substantial capital expenditure (CapEx) savings due to the substantially reduced footprint.

XtractOre™ emulsion

binder production unit for 5 m3/h

NovaCell™ pilot plant in Jord International’s fabrication warehouse

NovaCell™ pilot plant in Jord International’s fabrication warehouse

30

XtractOre™ full-scale facility showing the main emulsification pipe and orifice plate and trough designed for 500 m3/h

The REFLUX™ Flotation Cell (RFC) – trial and life cycle data analysis underwayFLSmidth (TRL 7.0)