17 minute read

Network Rail Track Maintenance Engineering Conference

by The PWI

AUTHOR: Chris Parker

Advertisement

Chris is a Chartered Civil Engineer, and a Fellow of the PWI and ICE. He has worked in the rail industry since 1972 retiring in 2004. His experience covered track and structures, design and maintenance and infrastructure management. After retiring Chris has remained active as a technical writer as well as writing reports for the PWI Journal and other organisations.

This online conference, organised by the Permanent Way Institution on behalf of Network Rail (NR), was introduced by Ian Coleman, Principal Engineer, Track Switches and Crossings, NR. Traditionally this conference has been run annually specifically for Network Rail’s Track Maintenance Engineers. This year, running it online made it possible to open the conference up to the whole maintenance community and beyond. After welcoming everyone, Ian introduced the first speaker:

WELCOME

GARETH EVANS - HEAD OF TRACK, NETWORK RAIL

Gareth commenced with a welcome to the first virtual NR/PWI Track Maintenance Conference. He spoke of the unprecedented times in which we find ourselves, mentioning the pandemic and recent fatalities. Some of the incidents that led to the latter involved passengers, some colleagues, but all were tragic. He discussed briefly the hazards, consequences and controls relating to track engineering, and things like bow-tie visualisation and other techniques relevant to controlling risks. Such things need to be re-examined in the light of recent events, and Gareth asked everyone to take part in this.

Challenge standards, he said, and be involved in working groups. He reminded maintenance engineers of their responsibilities, including the following:

• Know where the high-risk assets are and have them recorded • Work with other asset managers on cross-disciplinary issues • Ensure that teams are trained and competent • Ensure that assets are being appropriately inspected and maintained

He went on to recognise the challenges and risks of manual track inspection, including safety, health, weather, nights, competence, quality, capacity and efficiency. We are responding to these challenges, with initiatives like train-borne or remote monitoring of assets, risk based principles of inspection and maintenance, and much more.

PRESIDENT’S ADDRESS

JOHN EDGLEY PRESIDENT, PWI CHIEF TRACK S&C ENGINEER, NETWORK RAIL

John began by reflecting on a number of current issues:

• Incidents: the recent poor safety performance, with the deaths of colleagues and members of the public, as referred to earlier by Gareth. Have we lost sight of the challenge? What more should we do?

• Covid-19: whilst the pandemic is not over, we can take pride in the way we have pulled together in the last year. John mentioned such things as the development and application of emergency standards and significant innovation that has been used. However, we have been left a legacy in the value for money challenge created by the disappearance of passengers and their revenue.

• Successes: the annual number of derailments has tumbled, as has the number of rail breaks. The track measure of PIM (Precursor Indicator Model - the train accident precursor model) is at an all-time low. The Competence Framework for track has been developed and is coming into use. • Opportunities: John mentioned a long list including the Competence Framework, redesigned cast crossings, composite materials for such things as timbers and bearers, intelligent infrastructure, review of hot weather patrolling and review of S&S inspections.

Moving on to PWI matters, John began by mentioning the Presidents’ themes. Firstly, his own theme for 2020/21, which is industry competence. His objective is a collective industrywide approach with an agreed framework. This should ensure consistent staff development, knowledge and good practice. He identified the themes selected by future Presidents elect. These are Nick Millington, whose theme for 2021/22 is to be Safety and Performance, followed by Peter Dearman in 2022/23 with Electrification.

He said that the PWI as a whole has a focus on support to its members, both individual and corporate. This has been seen in the successful transfer of many Institution activities from face to face over to online formats, in the new Institution website and in the realignment of the PWI Vice-Presidencies with the NR Regions.

KEEPING THE NATION MOVING

LIAM MCQUAID, REGIONAL HEAD OF ASSET MANAGEMENT (TRACK & LINESIDE), NETWORK RAIL (SCOTLAND)

Liam’s theme was the excellent maintenance response to the Covid-19 pandemic. The challenge was to keep freight and essential workers moving on the rails and keeping people safe whilst managing the infrastructure. Teams had to be led remotely and best practice had to be identified and spread effectively. The revised timetables meant fewer passenger trains but more freight. The required level of performance needed to be delivered, but what was that? Delivery of the required response capability meant moving our people about safely and providing them with the necessary support such as welfare facilities and food.

Liam went on to discuss how people were kept safe, whether from Covid or other hazards, how the infrastructure was managed by taking a systems approach to maintenance, how managing people remotely was done and what was done to capture best practice. There are definitely lessons in what he said which are applicable for the future, even after things return to normal.

SAFETY TASK FORCE UPDATE

NICK MILLINGTON DEPUTY PRESIDENT, PWI SAFETY TASK FORCE LEADER, NETWORK RAIL

Nick reminded his audience of the reasons for the setting up of the Task Force in 2019. This was initiated as a result of the upturn in track worker fatalities, a sad reversal of the steady decline that had been occurring over the 10 or 11 years up to 2018.

He emphasised that the clear evidence shows that working on live railways whilst relying upon human lookout protection is by far the riskiest activity for people. He and his team have been leading the business/industry in the effort to reduce such working, and a massive change has been achieved already. However, further deaths have occurred, and more needs to be done. Network Rail is also legally obligated to eliminate human (lookout) warnings by July 2022.

He went on to discuss the work currently taking place. This is strongly based upon analysis of facts and data. For example, he showed analyses of types of near miss in relation to line speeds and types of protection in use. By far the worst statistically is the use of unassisted human lookout protection.

Further analysis considered the times of day when work was undertaken, showing that midweek mornings were the times when incidents were most likely. This is when the railways are most busy, but also when we are most likely to roster track works.

Since Nick first prepared a slide showing the industry people killed at the start of his current role, there have tragically been several more deaths to add to the graphic; three at Margham, one at Roade and one at Surbiton. It is not surprising that he intends to spend his year as President of the PWI campaigning to remove people from in front of trains.

Progress is being made, with Scotland having gone lookout free some time ago, Western achieving the same status on Monday 22 March this year and East Midlands following soon after on 31 March. Three clear goals have been set:

• No more lookouts • 100% use of track safety equipment for protection from trains • 100% compliance with “019” Safe Working Practices

Nick showed current progress on a complex chart, best seen by looking at his presentation in full. Key points were the fall in open line working from 25% to only 8% and the reduction in the rate of near misses that amounts to almost 50% in 18 months. The Executive Leadership Team (ELT) wish to accelerate the Task Force still further. Six headline risks have been identified and Route plans are being peer reviewed.

RSSB is being very supportive. It has conducted a hazard identification “deep dive”, and Nick showed another detailed slide of the 6 key risks identified.

Finally, Nick talked about the proposed next steps, what engineers need to do now, and offered a free gift! He asked engineers to be leaders, to plan, innovate and challenge and to take pride in what has already been achieved. Lives will have been saved, he said. His free gift was his recommendation of the use of Interflon switch lubricant. Almost 2/3rds of unassisted lookout protection is for switch lubrication. Since using Interflon reduces vastly the required lubrication frequency, this alone would make a significant cut in the reliance on lookouts.

Members can view the recording of the event on YouTube

https://youtu.be/ TKje3FEOPrE

JOHN NELSON - PRINCIPAL ENGINEER (COMPETENCE & CAPABILITY) PERMANENT WAY NETWORK RAIL (NORTH WEST & CENTRAL)

John started with some basics about longitudinal timbers; what they are, what the hazards are, the fact that NR has about 13,000 across the network and how they need very careful maintenance, inspection, repair and replacement if things are not to go wrong. He stated that he had an objective to convince everyone that the use of the MircroDrill for condition inspection is worthwhile.

To emphasise the last point, he offered some very scary examples of the incidents that have been caused recently by failures of such timbers. These ranged from a derailment at Paddington Station in 2017 and another very serious derailment at Wanstead Park in 2021, to a couple of cases where unplanned line blockages resulted from inspections revealing very serious problems at Eskmeal Viaduct in 2020 and at the River LLwchr later the same year.

John described the “roadmap” from Paddington to the future. A working group was set up after Paddington and research has been commissioned. New standards are being produced with new track work instructions and training packages. A new competence for examiners is included. Ellipse is being modified to include a longitudinal timber register. Examples of the current support on offer to TMEs John mentioned included: • The MicroDrill • Composite “timbers” • Remote cameras to view timbers under load • Online training, including interpretation of MicroDrill results

John proceeded to explain more about the MicroDrill, a highspeed drill with a small diameter bit. It is used to drill through a timber in different directions, and during this the resistance to the drill is recorded, both the torque required to turn the bit and the longitudinal force needed to penetrate into the wood.

The recorded data can be viewed graphically, showing the variations as the drilling progresses deeper into the timber, giving an indication of the nature and quality of the material along the length of the drilling. Interpretation requires care and skill, since the resistance of the timber can vary not only due to the presence or absence of decay. Variations also occur due to the orientation of the drill bit relative to the timber grain, for example, or because of the natural variations between different parts of the parent tree such as heartwood.

Future support will come as a result of research projects such as one on timber preservatives like boron gel, from about 15 standardised work instructions including one on use of the MicroDrill, from work modelling timber decay and from examiner training.

John concluded by mentioning the Long Timber Open Forum, which meets regularly to discuss relevant issues and challenges and promotes good practice. He issued an invitation to anyone to attend. They can arrange to do so by contacting John at: john.nelson@ networkrail.co.uk

TRACK STANDARDS SURVEY: END USER FEEDBACK

IAN COLEMAN - PRINCIPAL ENGINEER (TRACK, SWITCHES & CROSSINGS) NETWORK RAIL Ian took the floor himself for this presentation. He began by thanking those that had responded to this survey, about 50 by the time of the Conference, he said. He asked people to continue to participate up until the end of the week of the Conference. A separate open forum was planned to take place on 28 April 2021. He then went into some detail about the responses received to date.

IMPROVEMENTS IN MAINTENANCE

JASON WARDELL, PROGRAMME ENGINEERING MANAGER, NETWORK RAIL (EAST MIDLANDS)

Jason gave an update on the workbank optimisation workstreams and infrastructure forward plan. He spoke about a number of pilot studies such as the Track PLPR Pilot, the Track Geometry Pilot and the Rail Profile Management Pilot.

The new standard NR/L3/TRK/7014 “Inspection and Maintenance of Permanent Way using Risk Based Maintenance (Plain Line CWR Track)” has been published. This focusses on reliability centred maintenance. The next standards work will be rewriting the Track 001 modules using reliability-based maintenance philosophies. Jason gave some details of the planned workshop events and identified the people who will be leading these.

He continued by describing various other work, such as that on slide chair lubrication and the lubrication of fishplates, work on train-borne monitoring of S&C, work on curve and switch lubrication work on the uses of drones (UAVs).

He finished by appealing to people to say what else would help them to perform their roles more effectively.

Feedback to: tim.flower@networkrail.co.uk please.

MANAGEMENT SELF-ASSURANCE COACHING

CHRISTIAN NICHOLSON, HEAD OF ASSURANCE CHRISTIAN BELL, FUNCTIONAL AUDIT MANAGER NETWORK RAIL (SOUTHERN)

Between them, the two speakers described how a year ago work was begun to improve Management Systems Auditing (MSA) and get away from a culture of box-ticking.

The existing MSA question set was used as the basis, an evidencebased approach was employed, and results were recorded in IRIS (Incident Reporting and Investigation Software). A risk-based question set is under development and staff feedback is welcome.

The presenters reviewed what has been found to date, when they are now in the second round of delivery of the process. Most findings focus on safety, especially management checks on safe working practices (SWPs). Indications were found of wider issues with SWPs, and this has led to an 019 compliance programme on Southern Region.

The MSA coaching pilot has received positive customer feedback, led to an increase in action numbers and quality and the process has been approved by the Route Director and Director Route Asset Management (DRAM). Enhanced audit outputs have resulted, and real value has been added.

CRAIG GREEN - PRINCIPAL ENGINEER LYNNE GARNER - SENIOR PROJECT ENGINEER RICHARD QUIGLEY - SENIOR ENGINEER NETWORK RAIL (NORTH WEST & CENTRAL)

Ian Coleman gave a brief resume of what professional registration is, described the three levels of registration and discussed why it matters to individuals. He offered a brief review of the routes by which registration may be achieved with the PWI. He considered that registration used not to be a big issue within the rail industry, but that has begun to change significantly, with increasing emphasis on the need to demonstrate that people are professionally competent. Ian’s introduction was followed by each presenter in turn describing briefly their own path to registration: Craig achieved EngTech in 2017 before proceeding to CEng in 2019. He and his whole team got EngTech registration together. They found the PWI process simple and valued having mentors/ sponsors. Craig had found registration helpful in his career progression. Lynne achieved CEng registration in 2020. She found the PWI very supportive, with a clearly defined process. She recommended finding a good mentor and remembering that the whole of one’s career may be of use. She has found that registration has opened up for her senior roles where professional qualifications are essential prerequisites.

Richard made very similar comments to the others concerning his progress to IEng registration in 2018 by the Technical Report route in 2018. He briefly described the route. He emphasised the need for self-motivation in completing the registration process. In all this, the first and important step has to be to join the PWI. Go to the PWI website at: www.thepwi.org or contact profeng@thepwi.org Craig, Lynne and Richard all offered their support with the process, and with finding suitable mentors. Network Rail staff were reminded that they should add their professional qualifications to their profiles on ORACLE.

TRACK MAINTENANCE IN THE USA

WILLIAM ROTHERY, NETWORK RAIL CONSULTING

William began with a brief introduction to Network Rail Consulting. The organisation operates in the USA and Canada, the Middle East and in Australasia and Asia. It has several offices in North America and also in Sydney, Australia and in Riyadh.

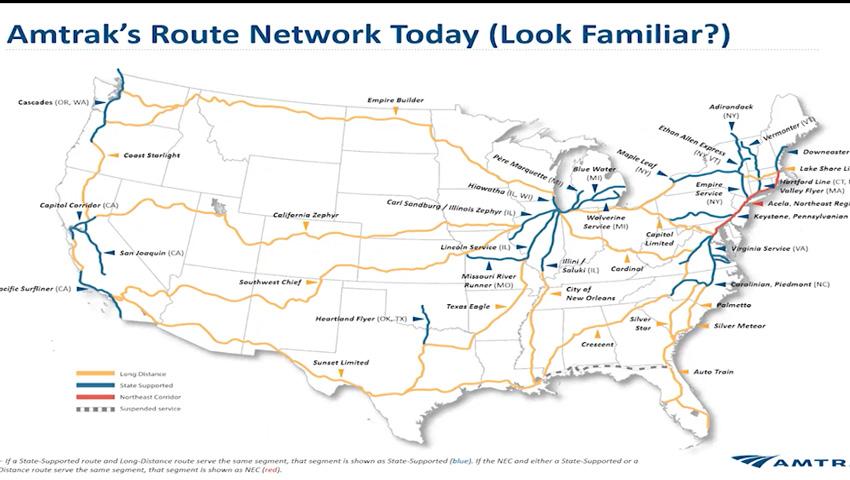

Moving on to his main topic, he introduced the US railways with a few statistics: the freight network has about 140,000 route miles, owned by 7 Class 1 railroads, 22 Regional and 584 local ones. The industry turns over about $80bn pa, employing about 167,000 people. It is big business, moving about the same annual tonnages as the road haulage industry.

William described how the industry is regulated by the Department of Transport (DoT) which covers the freight railroads, and the Federal Railroad Administration (FRA), covering the local transit agencies (which include non-rail transport as well). There is also the National Transportation Safety Agency (NTSB).

The railroads belong to a trade body, the American Association of Railroads (ARR), which owns TTCI, the railway research body many will be familiar with. The other rail industry body is AREMA, the American Railroad Engineers’ and Managers’ Association, a close equivalent to the PWI. All of these industry bodies assist their members and also provide feedback from the industry to the regulatory bodies.

Federal Track Safety Standards (known as FRA Part 213) apply particularly to the freight railroads and Amtrak, the passenger rail organisation. These standards are a mix of minimum requirements and prescriptive actions. Reliability centred maintenance and similar approaches have not been encouraged up to now. Change has been slow, William quoting that it has taken 10 years to get the FRA to authorise continuous ultrasonic rail inspection, for example. Some railroads had obtained “temporary” waivers to permit them to apply it, but these had run for years in some cases. William showed example pages from a couple of standards to illustrate their nature. Tracks are categorised by speed alone, for example, with tonnages not mentioned in the standard. Maintenance delivery is quite different from what we are used to. Trains tend to be very long (up to 2 miles) and heavy, but widely separated in time. This and other factors mean that it is feasible to safely carry out quite significant maintenance works between trains in a way that would be impossible here. This, combined with other factors like union rules and custom and practice, results in the widespread use of long fleets of separate, small, single purpose machines where we would use one or a few multi-purpose ones. Each tends to be worked by one specialised operator/maintainer, and each can be put onto the track, or removed from it, quickly and easily. William described how sleeper (tie) changing is done, as an example.

William noted that plant tends to be quite dated and simple to his eyes, and for example rail cranes tend to be small and few railroads have access to Kirov type machines.

Timber is the almost universal material for ties/sleepers, as the timber sleeper is cheap and readily available. The speed and nature of traffic means that there is no requirement for very high track standards, the emphasis is upon maintaining a safe operational standard and minimising disruption. Timber sleepers are adequate for this, and being lighter than concrete ones, are easier to change with small, simple plant in the windows between trains.

One difference in practice that William considered of possible benefit here was the use on slow speed locations of guarded switches. These have a specially shaped check rail at the switches. The switch tip slides under this in the open position, and so is protected from damage by wheels passing on the adjacent stock rail. The check does make it difficult to inspect the switch tip unless it is practicable to swing it to the closed position, but that was the only disadvantage that he could conceive of.

For the future, he said that the railroads are well funded and appear to have a secure future. The federal agencies are beginning to open up to new ideas, and this is bringing changes to standards, new rolling stock, new components and revised processes. Train borne track inspection methods are beginning to be applied, and the next step, he foresaw, would be to adopt reliability centred maintenance approaches.

CLOSING COMMENTS

JOHN EDGLEY PRESIDENT, PWI CHIEF TRACK S&C ENGINEER, NETWORK RAIL

John said that the conference had left him feeling encouraged and proud, thanks to the energy and enthusiasm shown by all. He thanked the PWI, particularly Kate Hatwell, for organising the conference, Liam Jackson and Ian Coleman for their major contributions, and everyone else who had been involved, not least the speakers. The strong message he had taken from the event was the message that this is all about people working together, listening, learning and having the courage to speak up when they need help.