7 minute read

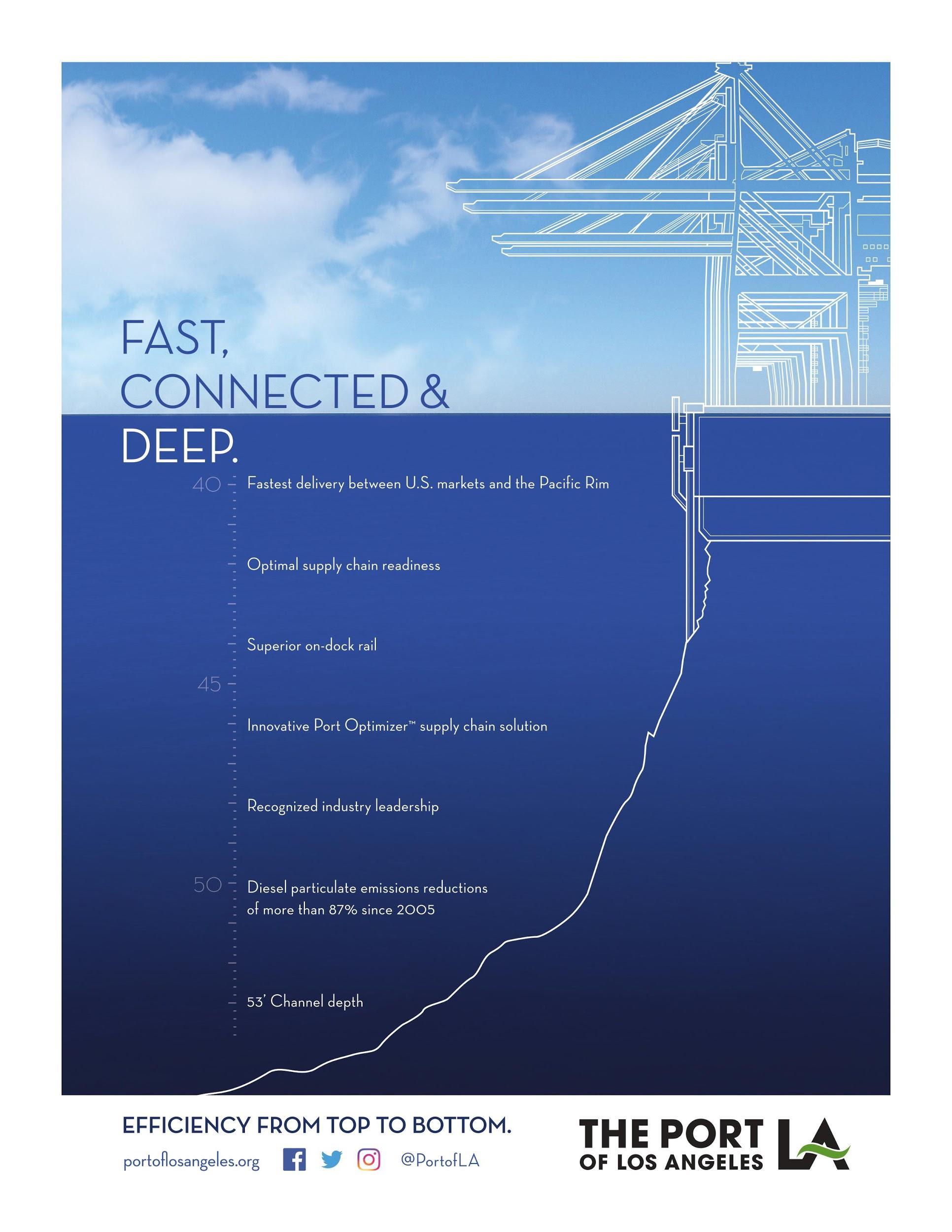

Port of Los Angeles - a smart story of high speed & volumes The large US port is investing millions in a platform that will bring more visibility. Series : Smart

Port of Los Angeles : a smart story of high speed & volumes

An interview with Christopher Chase who is the Marketing Manager at the port of Los Angeles. He has 25 years of experience in the shipping industry with 18 of them at the port in the business development area of the port where he interacts daily with customers. He also has experience in railroads, trucking industry, container terminals and container lines

Advertisement

The large US port is investing millions in a

platform that will bring more visibility.

In a series of articles and interviews The Logistics Point is going to shed light on what

Smart ports are. The first interview is with Christopher Chase, marketing manager at the

Port of Los Angeles. He talks about how his team is creating a digital platform that will

enable all stakeholders to communicate and plan better. Christopher also explains how the

industry has evolved during the past two decades and what are the biggest obstacles

that it faces.

What is a ‘smart port’ and how will it improve the service you provide?

For us a Smart Port takes advantage of the digital transformation in the world and applies

it to the core issues or operations, depending on what you need. The idea is to evolve with and be able to fight deficiencies within the

supply chain that the digitisation maybe able to provide.

Our Smart Port project - Port Optimizer, is a visibility tool which we are working on with GE

Transportation with the idea of sharing information in a common place amongst all

supply chain stakeholders. Much of the information is available but it is not always

easy to find and many people in the supply chain are not sharing it because there is no

direct financial relationship. We are trying to promote efficiency in our port, utilise our

physical infrastructure better and share

information about the cargo coming in and out, its movements around the port with the

appropriate stakeholders.

What deficiencies are you trying to solve?

There are big deficiencies that we have come

across over the last number of years. There is so much cargo moving in such a high speed.

Sharing data with people will improve planning. Most importantly sharing the

information on one platform will stop them wasting time looking for it. You really see the

improvements as truckers are being more efficient; better planning on the pick-up or

delivery cycles on containers to and from one of our port terminals.

We are currently working on getting the data once the cargo arrives at a terminal or a

shipping line overseas. Ideally it would go as far as you could in the supply chain but at this

point it is going to the pick-up. Right now it stops at the port facility but we are designing

the system and working with our partners to do as much as can and we can always

expand it in the future.

How are people going to be affected by all

this?

We are trying to provide a system of systems.

We are not changing anybody’s existing systems. We are just trying to be the link that

allows those systems to talk to each other and share the appropriate information. Whatever

people are doing today in their existing jobs doesn’t change. We are just putting the

information that they put into the computer systems and we are linking it together. So this

is a process that will drive deficiencies away and will enable better planning to allow people

to do their jobs better. This system doesn't change the way people operate we are just

taking data that is already input and utilising it.

What investments are you going to put into the project?

GE Transportation responded to a public bid and we have been working on this for about

three years. Our current contract goes out for another three years. It is about $15 million

dollar contract. We view this kind of

technology investment as similar to the hard infrastructure where we spend hundreds of

millions of dollars.

How can large and small ports deal with the challenges brought up by

digitalisation?

I don't think digitalisation looks at whether you

are small or large. Ports around the world are doing different things and it just depends on

what their needs are. A smaller port can have as much need for digitisation as a large port.

And it is really just a question of what are they trying to solve and what they need to do. The

biggest advantage is that small and large ports can talk to one another as they digitise

and get the right information at the right time.

How is the role of ports changing in today’s insecure and volatile

macroeconomic environment?

The ports are always in between a lot of

things because we are a hand off point where you physically have to change your mode of

transportation and in many cases the

ownership of that cargo. If you look back there were always macro events affecting the

industry. Right now it is some of the trade battles, a number of years ago it was the

economic downturn. We are always dealing with weather and economic instabilities.

Today’s macroeconomic environment is an interesting situation. The US economy is

strong. We have these issues with trade but we are still seeing very good volumes of cargo

because we are a retail focus environment which remains strong.

What are the biggest obstacles to growth

for the industry?

For ports it is shifting manufacturing locations.

As manufacturers move their supply chains around the world our volumes can go up and

down. This is one of the reasons for pushing for digitalisation. We think it will help us be

more competitive because we are making it a place customers want to bring their cargo to.

Also if the growth of mature economies such as the US is going to keep pace with other

parts of the world.

How can ports be part of the movement to protect the environment?

There has always been an environmental movement but I think it depends on what part

of the environment we are talking about. Our part is to help unify ports as it is very hard

with different rules. The IMO 2020 fuel change

is very helpful because everybody is playing from the same set of rules.

We don’t want to say that electric trucks are better than hydrogen trucks which are better

than something else. We want to create a platform in which people work together. In

Southern California cleaning the air is our biggest issue. For forty years we have been

working on cleaning the water and that has been very successful. We try to lead the way

and experiment with things. Some of that local effort has become national and international

activity.

How would you say the industry has

changed over the years?

Ten years ago Vietnam wasn’t even on our

radar map and now it is our second or third source of cargo depending on the year. If you

go back 25-30 years Japan was a leading trading partner and it still is but their volumes

have changed and they are not growing the same way as places like China, Vietnam,

Thailand and Indonesia are. We start seeing more manufacturing in places like Eastern

Europe too. Since I first started it has been a lot more cargo moving. Some amazing

efficiencies have come about and that is probably the biggest change.Every day is

something different, every year we are refining and changing how we do things.

If you are going to the Industrial Warehousing and Logistics Conference 2020 in London at the end of January why not let me know as it would be

great for me to meet you there!! Drop me an email nick@thelogisticspoint.com