6-8 Update

A news roundup from the world of print

10 Downtime: Visual Connections appoints Karren Challoner-Miles as CEO

A new CEO and refreshed board for Visual Connections

11 Downtime: Inside the Lamson Paragon & Spot Productions appreciation party

Industry executives and teams meet to celebrate collaboration

12-13 Star Business: Scott Watkins breathes new life into Kwik Kopy Knoxfield

How Scott Watkins has transformed Kwik Kopy Knoxfield

14 Recruitment: Unique printing jobs available at Corrective Services NSW

Trade qualified members of the printing industry can apply for a unique career opportunity with Corrective Services Industries

16-18 Cover Story: CPX grows with Heidelberg CX 104 and Coater installation

James Bennett’s CPX Printing and Logistics has installed its first Heidelberg Speedmaster CX 104, delivering new revenue streams

20-34 2025 ProPrint Awards: Australian printing industry shines at 2025 ProPrint Awards

A recap of the industry’s night of nights and all the winners.

36-40 ProPrint Awards: 2025 ProPrint Awards post-event trophy recipients

The winners who were unable to collect their trophies on the night

42 Case Study: XPS Group expands output with the Ricoh Pro C9500

How a Ricoh Pro C9500 upgrade is driving growth at XPS Group

44 Digital Transformation: How Currie Group is driving non-stop digital transformation

A strong partnership between HP Indigo and Currie Group addresses a range of industry challenges

46 Digital Transformation: How HP is driving digital transformation via innovation

How HP’s technology helps businesses stay ahead

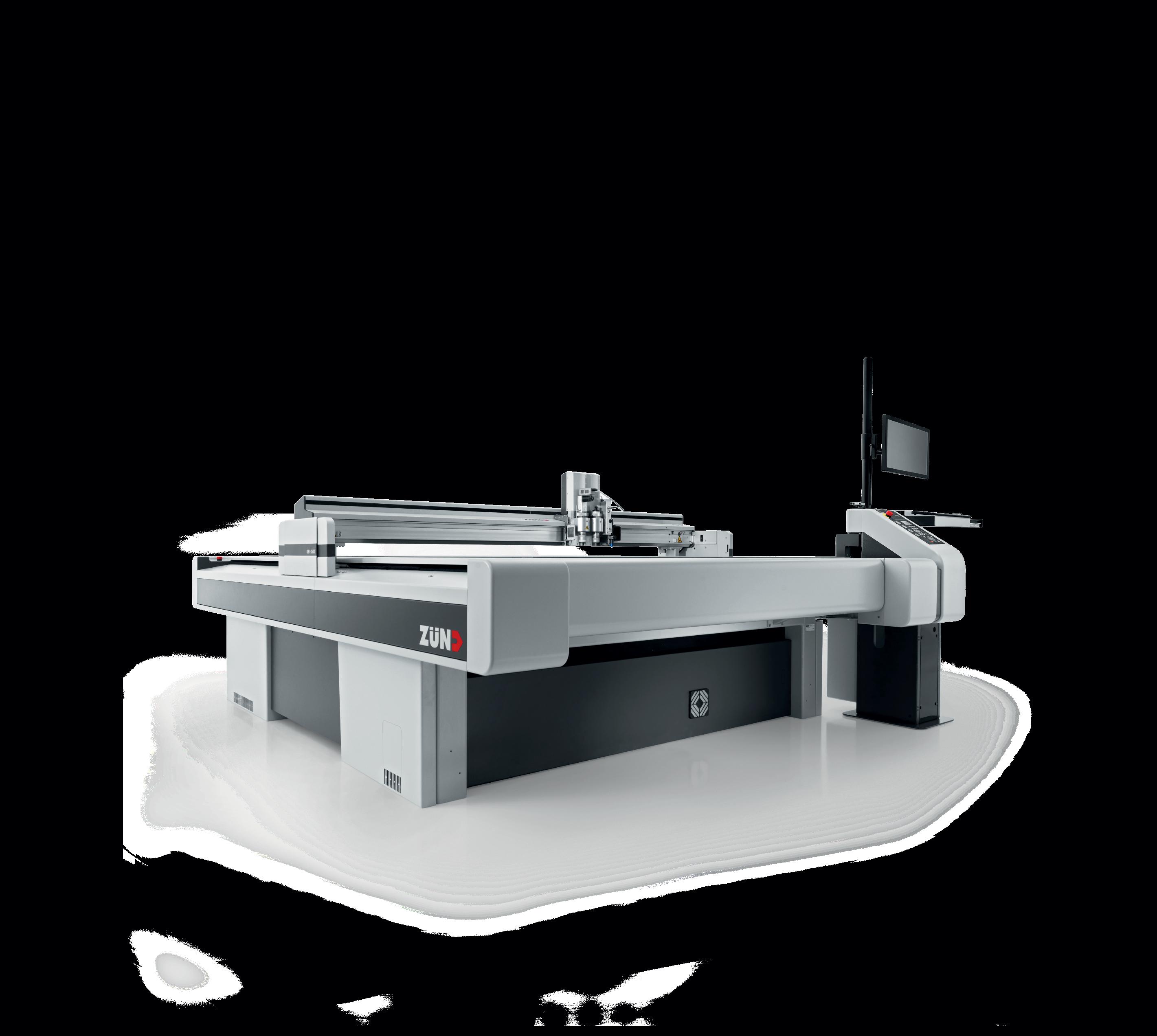

48 Advertorial: Zünd Australia helps unlock new growth

Zünd Australia’s ‘Cutting Beyond’ package has the expertise

50 ProPrint Diary

Keep up to date with the latest industry events

Editor Claire Hibbit, chibbit@intermedia.com.au

Design and Production Manager Sarah Vella, svella@intermedia.com.au

Managing Director James Wells, james@intermedia.com.au

Subscriptions (02) 9660 2113, subscriptions@intermedia.com.au

Printed by Hero Print Alexandria, NSW, 2015

Mailed by D&D Mailing Services Prestons, NSW, 2170

Welcome to the first edition of ProPrint for 2026. As we reflect on the past year, one of the standout moments for both the ProPrint team and the wider industry was the 2025 ProPrint Awards. The event has firmly established itself as the premier celebration of leadership, innovation, and emerging talent across the Australian print industry.

The 2025 ProPrint Awards achieved record sponsorship and attendance, welcoming more than 365 guests. This event’s flagship award categories – recognising

rising stars, key suppliers, and the industry’s most influential printers – also reported record numbers, highlighting strong engagement.

In this issue, we recap the highlights from a memorable evening. We also shine a spotlight on the winners who were unable to attend. The ProPrint team travelled across the country to personally deliver trophies, recognising their achievements and sharing in the celebrations with recipients and their teams.

As we step into 2026, the focus on innovation and technology has never been more relevant. In this issue, we also speak with leading suppliers about how they’re driving digital transformation, embracing AI, and futureproofing their businesses –offering insight into the trends and tools that will shape the year ahead.

Aldus has entered into an agreement to acquire Currie Group.

In an email from Aldus CEO Frank Floriano, sent to ProPrint by the Aldus Group, Floriano said:

“Dear team,

“I am pleased to share that Aldus has entered into an agreement to acquire Currie Group, welcoming the business into the Aldus Group family.

“With completion scheduled for January 2026, this investment reflects our ongoing strategy of supporting market-leading specialist businesses with strong leadership.

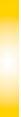

Sydney-based Next Printing has launched Reflekt, a new display solution that integrates its sustainable Re-board walling with a built-in LED screen and mirror system. Next Printing general manager Pranil Chandra said: “Reflekt came from the idea that sustainability has always been at the heart of what we do.

“As printers, we’re always trying to innovate with displays. So, we asked ourselves: how can we combine sustainability with a visually striking, attention-grabbing experience?”

Chandra explained that Next Printing initially worked with standard screen displays built into Re-board – a technique it had used for years.

“But we wanted a point of difference. That’s when we discovered this product –a very thin film that can be mounted onto Re-board structures. With the right screen behind it, it creates the illusion of a mirror, with elements appearing to float through it. This allows brands to showcase new or existing products in a way that captivates audiences, particularly at events,” he said.

Installed as part of a custom walling system, Reflekt’s mirrored surface displays content as required, with animated logos, gliding visuals, and products appearing in soft, shimmering light.

Chandra added, “When we say ‘mirror,’ we’re talking about something far more impactful – structures that can be up to 3m tall and 30m wide. The mirror-film itself has also been used independently by major global brands, including Apple, in their own installations”.

“With more than 75 years of history supporting the print and graphic communications industry across Australia and New Zealand, Currie Group has built a strong reputation for technical capability, customer service and long-term relationships. In this regard, it shares many of the characteristics that have defined Aldus Group over a similar period.

“Currie Group will continue to operate

as an independent business within the Aldus Group. Its leadership team remains in place, and its focus on customers, partners and people remains unchanged. Our role is to support the business and provide stability and backing that allows it to continue to grow.

“Over the coming months, there will be opportunities to learn more about Currie Group and to build connections across the broader Aldus Group. I encourage you to welcome the Currie Group team and take pride in the strength and diversity of the businesses within our group.

“Thank you for your continued contribution to Aldus Group. As we head into the Christmas period, I wish you and your families a safe and enjoyable break, and I look forward to the year ahead.”

According to Chandra, the product works across industries – from FMCG and retail to major tech brands – and is generating significant interest. The company recently developed a case study with New Zealand based Evnex showcasing its impact.

“Reflekt has been the product that’s garnered the most interest and attention of our customers this year,” Chandra said.

“We’re currently in discussions with several major companies about using it for PR events and product launches. While it’s a premium solution, it’s also sustainable. Unlike a full mirror, this thin film minimises material use and, when combined with Re-board and reusable LED displays,

creates a highly eco-friendly solution without compromising the visual impact.

“We’re still analysing its true carbon footprint, but early indications are promising. The film is thinner than a laminate, and because it works in combination with our existing sustainable structures, it adds minimal additional material.

“In today’s market, customers are under pressure to reduce costs, which can make sustainability a challenging sell. We could have reverted to plastics to cut costs, but instead, we focused on innovation that complements sustainability while enhancing audience engagement,” he said.

Note Printing Australia (NPA) recently opened its new training facility in Craigieburn, Victoria, as part of its Apprenticeship Program, providing an on-site resource for its print apprentices.

The program is well established with six apprentices working in the print hall and another three working in pre-production. Named after the press that it houses - the Heidelberg GTO52 - the GTO Training Room will enable NPA’s apprentices to experience live print training on-site without impacting the main production lines, which is a common problem for many print operations trying to give their apprentices training time on the presses.

ProPrint spoke to NPA’s technical training specialist Andrew Reynolds, who has led the establishment of the new program, about the dedicated training facility and how NPA is addressing the challenges of an ageing workforce.

“The primary motivation was to create a structured environment where apprentices could develop a broader skill set beyond what they encounter in day-today production,” Reynolds said.

“NPA produces highly specialised products, which means apprentices often only see a narrow slice of the industry. By introducing the GTO Training Room, we can expose them to a wider range of printing techniques and processes, ensuring they become well-rounded tradespeople,” he added.

ASX-listed IVE Group has signed a binding agreement to acquire 100 per cent of Daily Press, an Australian-based creative agency specialising in digital, social media and performance marketing, for the total purchase consideration of up to $35 million.

Daily Press will be integrated into IVE’s Creative, Content & Integrated Solutions division and will ultimately relocate to IVE’s Sydney head office premises later in 2026. Managing director of IVE Group Matt Aitken said the acquisition of Daily Press is a significant step in advancing the group’s ‘Now to 2030’ strategy and positioning creativity as a core driver of long-term growth.

“Daily Press brings highly complementary digital, social, performance and technology capabilities that enhance our ability to deliver integrated, omni-channel solutions

Reynolds said the new training facility is a key part of NPA’s future workforce development plans.

“The facility is a cornerstone of NPA’s strategy to address the challenges of an ageing workforce,” he said.

“Every retiring tradesperson takes decades of experience with them, so we need to capture and transfer that knowledge to the next generation. By investing in structured, high-quality training now, we ensure a pipeline of skilled professionals who can sustain and grow the business in future. This is not a quick fix – it’s a long-term commitment to building capability and resilience.”

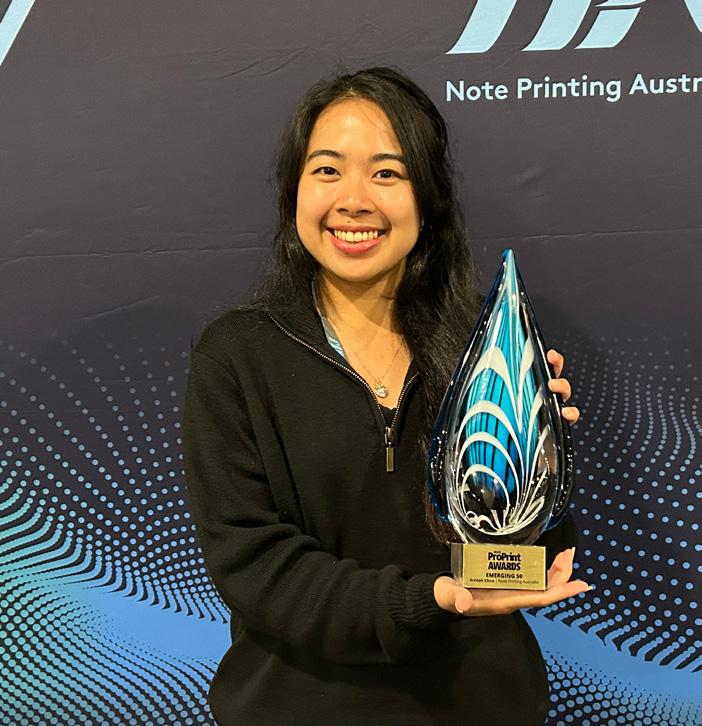

Evidence suggests NPA’s strategy to introduce new talent into their workforce is working. At this year’s ProPrint Awards held in Sydney, NPA had two staff recognised in the Emerging 50 category.

When asked how will apprentices use the facility and what does a typical training

connecting strategy, creativity and execution in a way traditional agency models cannot,” Aitken said.

“We are excited to welcome Wayne Knight and the Daily Press team, and to scale their capabilities across IVE’s broader client base, unlocking value not only within creative & content but across production, logistics, CX & data, merchandise as well as activation services.”

The acquisition is expected to contribute annual revenue and EBITDA of approximately $23.0 million and $5.5 million respectively.

The total purchase consideration for

session look like, Reynolds explained, “The GTO Training Facility complements the offsite education apprentices receive through Holmesglen TAFE. A typical session begins with theory-based instruction, followed by hands-on practice in a simulated press room environment using a real press.

“The key advantage is that they can learn without the time pressures and quality demands of a live production environment, which fosters confidence and deeper understanding.”

According to Reynolds, the types of competencies and skills NPA is aiming for the apprentices to gain via this training room include workplace safety, machine maintenance, lithographic plate making, ink colour matching and setting up and producing lithographic print.

He said these competencies are difficult to teach during live production because of time constraints and the risk of errors impacting customer orders. “By training apprentices on older, basic equipment, we strengthen their problem-solving and decision-making skills, which directly benefits production efficiency,” he said.

“This approach also instils a lean mindset early in their careers, promoting continuous improvement and waste reduction. Furthermore, the facility allows us to repurpose dead stock – unused paper and board - reducing waste and freeing up valuable floor space. This not only supports sustainability but also provides apprentices with experience across a variety of substrates, enhancing versatility.”

Looking ahead, NPA has plans to continuously evolve the facility to meet business demands.

Daily Press is up to $35.0 million, comprising:

• $25.0 million payable in cash on completion.

• up to $8.0 million payable in deferred consideration subject to the achievement of agreed performance hurdles over the first and second 12-month periods post completion.

• up to a further $2.0 million in deferred consideration (up to $1.0 million per each 12-month earnout period) based on performance against stretch targets.

IVE expects to unlock annual cost synergies of approximately $1.0 million through the in-sourcing of print, distribution and activation services currently outsourced by Daily Press, with further revenue and cross-sell synergies expected as creative-led engagements flow through IVE’s broader production, logistics, CX & data, merchandise and activation capabilities.

Founder and CEO of Daily Press Wayne Knight will remain with the business post completion.

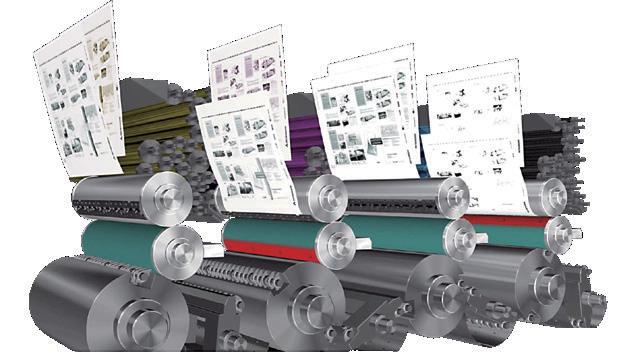

Marking 15 years in the industry, Special T Print has launched Sprint, a new online platform aimed at making print ordering faster and more efficient.

“We’ve spent the last 15 years building a reputation for quality, reliability and service,” said managing director Corey London.

“Now we’re looking to the future, combining that same commitment with smarter tools and systems,” he added.

According to London, the platform was developed to better serve customers with print-ready artwork and to expand Special T’s digital presence.

“Sprint allows customers to approve proofs instantly and reorder previous jobs, reducing turnaround times and simplifying workflow,” he said.

The platform allows users to upload artwork, access instant pricing, and

Breen Printing expanded its operations in December when the company started operating from a second site just across the road from its current premises in Healesville, Victoria. Co-owners Kirsty and Luke Woodhead said they’re enjoying having the two premises because they can now “streamline” the company’s operations.

Luke told ProPrint the move to a second site has been “on the cards for some time” because the company has experienced “significant growth” over the past few years and they were aware they needed more room for expansion.

He said then the factory across the road became available at the time when they were ready to make that step. “And so, we were excited by the fact that we were able to still grow the business and do it in Healesville. We were initially thinking our second site was going to have to be somewhere like Bayswater - or somewhere that was more industrial... But it just worked out really well when this site became available.”

Kirsty added, “We’re now stepping into that medium business space so this is a big leap for us, but we were bursting at the seams last year, so the leap is needed to grow”. Luke agreed, saying, “The original

request custom quotes. According to the company, the development of Sprint reflects Special T Print’s ongoing investment in innovation and its commitment to keeping production local, with every order managed and produced in Australia.

“We win work on quality, expertise, and guidance, and we guarantee every job will be done well and on time, no matter the size,” London said.

“With Sprint, we’re taking that same promise online and have spent the past year refining it from the inside out.

plan was to get running before the end of the year, which we did. We actually achieved it.”

He added that while the second site was in “the perfect location”, when they first acquired it, it was a bit dilapidated and needed some repairs: “There was no real bathroom, no real tea room, no offices. So, we’ve had to do all that. We’ve done all the repairs, we’ve fixed up the floor, we’ve built the offices, built the amenities and everything else and now it’s all fully functional,” he said.

“We’ve also installed a Konica C7100 digital press that went in at the beginning of December. And we’ve moved our AGFA flatbed printer over to the new site as well and we’ve ordered a large flatbed cutter through Smartech. So that’s arriving at the beginning of March - it’s being built at the moment,” Luke said.

Kirsty added, “We chose to purchase from Konica because we have a strong working relationship with the technicians, some of whom have been working with us for years. We think this is an important

“While technology has changed, the core of print remains the same: how you put ink on paper, how you care for your clients, and how you deliver on your promises. For us, adding value for our clients is always the priority.”

In addition to Sprint, Special T Print has expanded its fulfilment and distribution capabilities through Stack Store & Send. From personal items to bulk stock, it provides flexible storage and shipping solutions for both individuals and businesses, supporting short- and longterm needs.

factor to consider when purchasing, as they become a big part of your team.”

“Our new machine is now our third showroom model purchase from the Konica Melbourne showroom and it seems to have become a bit of a trend for us. This allows us to purchase in a more economical way and knowing the machine will operate most efficiently. We’ve recently purchased second-hand finishing equipment including a perfect binder, booklet maker, a 20-station saddle stitcher with a three-knife trim, and a large cross folding machine,” Kirsty said.

According to Luke, the new equipment at the second site will support growth in specialised areas such as small-run, largeformat packaging and point-of-sale (POS) display items. “We already do some of this type of work, but the new site has allowed us to bring more of it in-house and launch new products into the market,” he added.

Plus the new equipment gives them booklet capability and brings the opportunity to do larger volumes. “Just being able to free up the space in the original factory so we can focus on the offset work has already made a big difference in our workflow because we were very tight,” Luke said. “So, that’s kind of freed us up and the workflow in the original factory is running much more smoothly. And having the space across the road to be able to do the large format work is really helping to streamline that work more efficiently. In the longer term, it’s about extra capability - being able to open up extra markets for us such as point-ofsale-display products as well.”

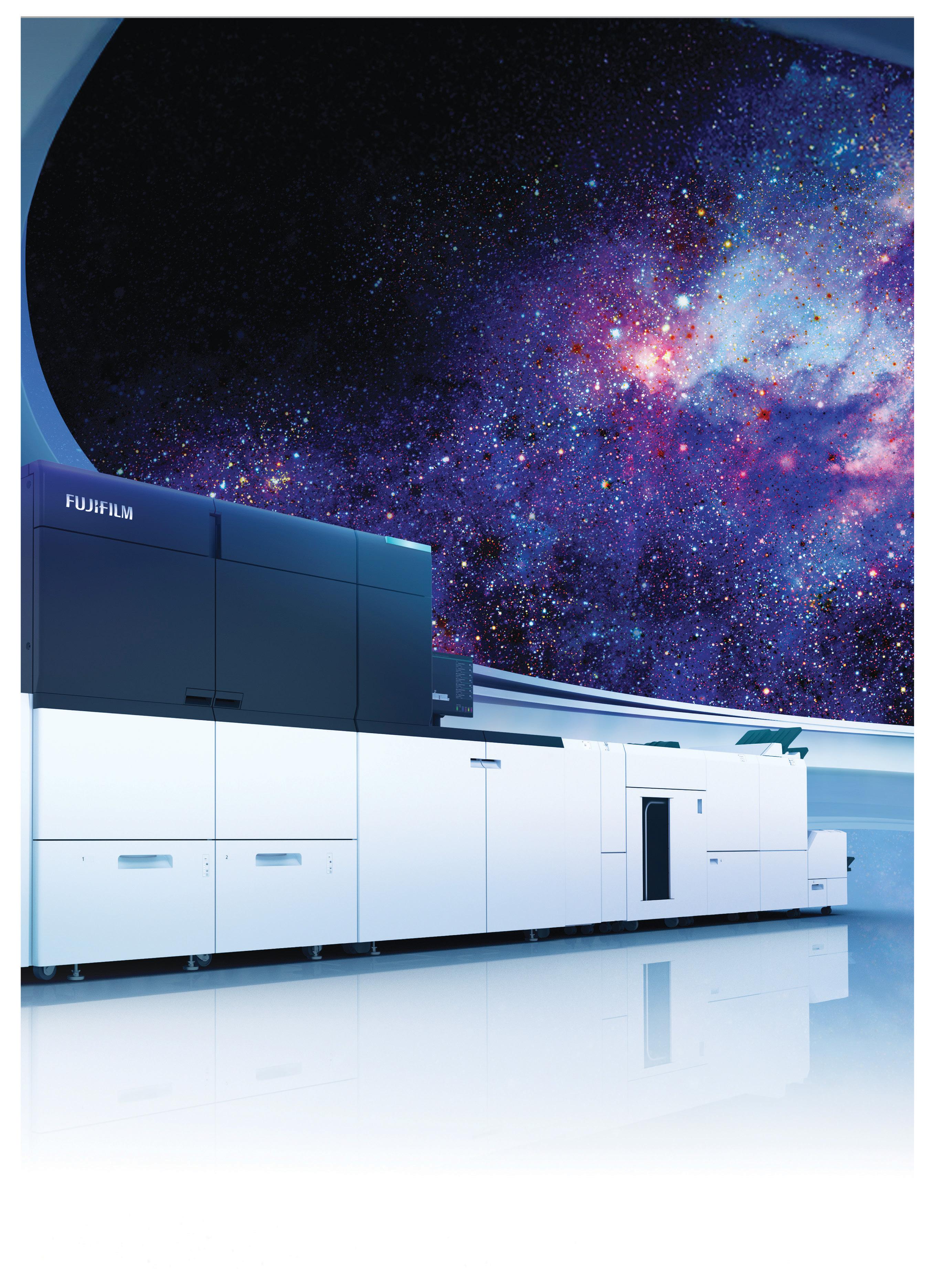

Redefine Commercial Printing Standards and elevate production with Next-Gen High-Speed Inkjet

PRODUCTIVITY

•High productivity

•560mm paper width

•High machine uptime

QUALITY

•New Inkjet 1200dpi PHs

•New saturated ink SC2

•Enhanced image quality

USABILITY

• Energy-efficient drying

•Easy operation

•Offset-coated papers

AGILITY

•Optimised integration

•Precision paper sensing

•Complete New Platform

At Visual Connections’ recent annual general meeting, the supplier association promoted executive general manager Karren Challoner-Miles to CEO.

Visual Connections president, Mitch Mulligan, said Challoner-Miles has led the organisation through a challenging period of transition and her promotion reflected her “outstanding leadership”.

“Transitions are always challenging, but the board is delighted with the impact Karren has made over the past few months, and the positive progress we are already seeing in the association. We are very confident in a strong future with Karren at the helm,” Mulligan said.

New board positions were also announced

following the departure of Pozitive’s Andrea Trumble.

Adrian Fleming, general manager Australia & New Zealand for Print IQ, was confirmed as the latest board member. Fleming joins Epson Australia managing director, Craig Heckenberg, as newcomers to the board. Heckenberg was appointed to replace long-term board member, John Wall, who resigned at the end of the financial year.

The new board comprises:

• Mark Canavan, marketing and vendor relations manager, Graphic Art Mart

• Adrian Fleming, general manager Australia & New Zealand, Print IQ

• Craig Heckenberg, managing director, Epson Australia

• Mitch Mulligan, managing director,

Böttcher Australia

• Ian Martin, general manager – trade, Ferag Australia

• Alex McClelland, managing director, ORAFOL Australia

• Luke Wooldridge, national product manager, HVG Graphics Media

Mulligan said the two most recent appointments bring fresh perspectives, insights and talents to the Board at a time when the organisation is undergoing the next stage of ‘generational transformation’.

“As our members will know, this year has seen a real ‘changing of the guard’ at Visual Connections, with a revised strategy, refined approach ,and some exciting new initiatives and priorities,” he said.

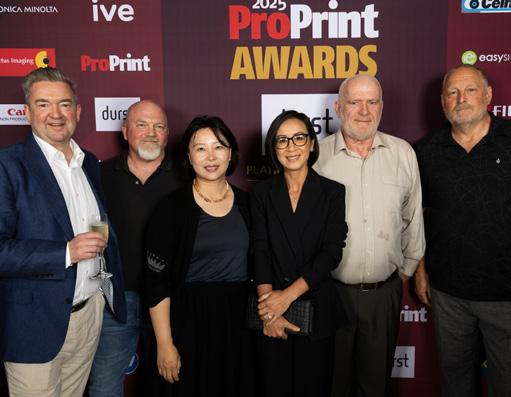

Industry executives and teams came together to celebrate partnership and collaboration.

Lamson Paragon Group CEO Rodney Frost and Spot Productions CEO Simon Carmody, together with their respective teams, welcomed dozens of senior industry executives to their Appreciation Party, held at the Nags Head Hotel in Glebe, in Sydney’s inner west.

The much-anticipated annual event brought together key figures from across the industry for an evening of networking, conversation and celebration, as the hosts took the opportunity to thank colleagues and partners for their continued support over the past year.

Eighteen months after taking the reins, 2025 ProPrint Emerging 50 winner

Scott Watkins has transformed Kwik Kopy Knoxfield, revitalising the long-standing franchise with record-breaking results.

Since acquiring the 25-year-old Kwik Kopy Knoxfield site in Melbourne, former marketing executive Scott Watkins has overhauled the franchise, driving 140 per cent growth in its first year – the highest in Kwik Kopy’s national and international network.

“I grew up in a family of small business owners, so our dining table conversations were always about staff and running a business,” Scott Watkins, owner of Kwik Kopy Knoxfield told ProPrint of his journey to the print industry.

“I studied a Bachelor of Business at university, but I wanted to get out of uni as soon as I could. I didn’t really enjoy it. My goal was to finish and graduate so I could start working. I landed a job at MercedesBenz Australia Pacific, initially in their inventory purchasing team, and eventually progressed into their marketing team.”

Watkins spent nearly 10 years at Mercedes-Benz Australia, leading national marketing functions, before being

headhunted by Wurth, a major global private company, to join the leadership team of Wurth Australia. Over 14 years, he led marketing and product strategy, introduced new systems and programs, and helped grow the business from $40 million to $200 million.

His desire to run his own business eventually led him to stumble across a Kwik Kopy franchise while scrolling on his phone one night.

“I had many people reporting to me, and within that team, we hated the word ‘outsource’. We never liked outsourcing anything. I had my own graphic design team and my own print production team, so I was very familiar with print and, of course, graphic design from a marketing perspective. I’ve always enjoyed being in a tactile environment – somewhere you’re touching and feeling things,” he said.

“Coupled with wanting to run my own small business, one night I was scrolling on my phone, looking at businesses for sale.

That’s when I stumbled across a Kwik Kopy business for sale and thought, ‘This looks interesting’. I sent it to my dad and brother, and they both agreed. We did our due diligence, and I met Peter Fiasco [Kwik Kopy’s head of franchising]. However, that site didn’t work out, which was disappointing because I had already gotten excited about potentially purchasing it.

“A few days later, Peter called me and said, ‘We don’t want to lose you. We think you have something to add to our brand, so why don’t you reach out to this other Kwik Kopy owner and see if she’d be interested?’ I called the owner on Thursday, and by Sunday night, we’d shaken hands and signed heads of agreement.”

When Watkins acquired Kwik Kopy Knoxfield, he launched what he describes as an aggressive strategic roadmap.

“By 2pm on day one, we were already putting up new signage and bringing in landscapers. That weekend, we completely overhauled the space – new

furniture, desks, kitchen, freshly painted bathrooms, new blinds, landscaping, and a thorough cleanup. The whole place was totally refreshed,” he said.

Alongside the renovations, Watkins invested heavily in new equipment.

According to Watkins, Kwik Kopy Knoxfield is the only Kwik Kopy franchise printer in Victoria with a Canon Colorado.

Within six weeks, Watkins had signed a deal with Konica Minolta, replacing the existing printers with new digital presses, including a rollover flatbed application table highlighting the commitment to signage and wide format printing.

“I brought two staff members with me and kept the production manager, who was happy to stay on for a period. We brought graphic design in-house and

added a customer service salesperson.

The business transitioned from a small B2C printer to being heavily focused on design, print and signage,” he said.

Under Watkins’ leadership, Kwik Kopy Knoxfield has shifted to a B2B client base, with transport, trucking, and automotive now among its core market segments. Most recently, the business served as the print partner for the Melbourne Build Expo, which attracted 30,000 visitors.

“Previously, the business was focused on ‘candlestick makers’ – no offence to people that make candles from home –but that wasn’t the direction I wanted. I saw Kwik Kopy as a B2B partner, providing real marketing solutions, from pre-digital design to signage, targeting business-to-business

customers. That’s what we are focused on,” he mentioned.

“We experienced 140 per cent growth in our first year – a record for Kwik Kopy in Australia and internationally.”

Watkins is now focused on sustaining growth and building a strong team culture.

“I want to continue growing. I’ve recruited what I believe is the best team we’ve ever had in these four walls. My goal is to ensure my staff have fun, grow, learn, and earn a respectable income. It’s not just about me making money. It’s about supporting our staff and customers,” he said.

“I recruited a young guy as a print room helper to help with finishing and to learn how to use some equipment. He had never touched a printer before in his life but just wanted a job where someone looked out for him, and he’s since become my unicorn.”

The importance of attracting and retaining talent is also crucial to business success, said Watkins.

“One of the reasons I bought my own business was to get out of corporate life. I was frustrated with the processes around staff retention. There was constant churn, mainly due to environment, social, and financial factors. That’s not what I want. I want the best team who love being here and truly enjoy their work,” Watkins said.

“It’s been incredibly rewarding to celebrate our success. We held a one-year party with our suppliers, and the Kwik Kopy Australia team. It was special, it made us step back and think, ‘Wow, we’ve achieved this in a year’. For me, that was remarkable and incredibly humbling.”

In October 2025, Kwik Kopy Australia was acquired by Fortidia, and Watkins said he’s confident about the change in ownership.

The Fortidia Group closed FY2024 with €1.4 billion (US$1.5 billion) in system-wide gross revenue, generated through its network of more than 3,130 business solutions centres, and €22 billion (US$23 billion) in gross merchandise value traded via its digital e-commerce platform.

Under Fortidia, Kwik Kopy Australia will retain its brand, leadership, and franchise teams.

“I think it’s fantastic. What we’ve seen [Fortidia] do with AlphaGraphics in the US is very promising. We now have greater infrastructure and stronger support networks. There will always be short-term changes, but long-term, I’m genuinely excited. I believe this will only benefit our brand, our systems, and ultimately our customers and staff.”

Corrective Services NSW is offering printing industry members 12 weeks paid training plus an attractive salary in a role where they train inmates in print work.

Trade qualified members of the printing industry are invited to apply for a unique career opportunity with Corrective Services Industries (CSI) – a Work and Education program within Corrective Services NSW (CSNSW).

For more than 30 years, CSI employs trade overseers who are educators that train inmates to gain employment skills and qualifications while in custody, to assist with work release programs and future pathways to employment.

Positions are now available with an attractive salary package at the Wellington Correctional Centre in the Central West of NSW, located around four and a half hours from Sydney.

The position of trade overseer includes 12 weeks of paid training as a correctional officer in Sydney and once the training is complete, a uniform is issued, followed by a graduation ceremony.

According to Wellington’s senior overseer for CSI Print, Sarah Bennett, trade overseers are there to guide and mentor the inmates using the print equipment. “This is an ideal role for someone who would like to give back and demonstrate the creativity and enjoyment that the printing industry can deliver,” she said.

There are two print teams operating daily within the Wellington facility with approximately 30 inmates working in each group. The flexographic unit features two Rotometrix label printers which have the

ability to print and die cut in one pass, producing labels used for CSNSW including the food service facilities. The offset printing unit features two Heidelberg GTO 52 printers and creates printing materials used within CSNSW, including accommodation, security and compliance manuals.

“There is also digital printing work which can include internal CSNSW materials such as marketing material, stationery, and business cards. This can also include work, potentially from other NSW Government agencies, as well as some externally sourced trade printing work,” Bennett said.

“Each morning, after their morning routine, trade overseers and inmates join a ‘toolbox talk’ to discuss the current projects within the printing production pipeline. Trade overseers then spend the day assisting the inmates and mentoring them by passing on their printing experience to ensure that deadlines are met and safety is maintained.

“Each day features two ‘shifts’ – from 9.00am to 11.30am and then from 12.30pm to 3.00pm in the afternoon,” Bennett said.

“The print shops are designed to replicate a real-world working environment to provide work readiness capability for people in custody and to enhance their opportunities to gain employment postrelease, reducing recidivism and enhancing community safety.

“The major positive is the inmates are learning new skills that they’re able to use on the outside and there are lots of examples where this work has assisted with integration back into the community after incarceration. There are also opportunities for inmates to participate in TAFE traineeships with many graduating with Cert 2 in Printing and Graphic Design.

“This is a job that suits people of all ages and it’s ideal for someone who loves print and is looking for a new challenge.

“It’s a very rewarding job – particularly when you connect with the inmates by providing positive feedback – and it feels like you’re making a difference in their lives that in many cases they have not experienced before. Providing people in custody with the opportunity to participate in meaningful work and develop skills they can use in the community, significantly enhances the opportunity for post-release employment.”

Are you trade qualified looking for a new challenge?

CSI is a Work and Education program within Corrective Services NSW. We provide an extensive range of products and services for the day-to-day operation of NSW Correctional Centres. CSI also manufactures and supplies product and services in partnership with the private sector and Government. We specialise in import replacement work, supporting Australian businesses to keep manufacturing onshore.

Our commitment is to empower inmates to gain employment skills and qualifications while in custody. We continue to surpass industry benchmark performance for correctional industries globally with innovation at the forefront. We treat land, resources, and people with great respect.

CSI Trade Overseers are trade qualified personnel in each of the business units responsible for the management, supervision, and training of people in custody whilst they are at work. This involves coaching, instructing, and encouraging inmates as members of a team to develop their work skills to contribute to the productivity outcomes of the business unit. Overseers are critical in providing technical expertise, a safe work environment, and positive role modelling demonstrating ethical business practices, honesty, and integrity.

We have a number of roles in our Print units across several locations across NSW. If you have:

• Certificate III or greater in Printing and or Graphic Arts

• Certificate III in Correctional Practice or capacity to complete within specified timeframes

• Current NSW Driver Licence and preparedness to drive to locations as required

• General understanding of capabilities around the use of computers and electronic platforms to access relevant departmental programmes and applications

If you are interested in hearing more, please call David Rickwood - 02 4582 2411.

Speak to our team today to find out more. This document contains statements related to our current and future operations and is subject to change without notice. All diagrams, drawings, products, machinery, and any other types of images in this document are for display purposes only. Compliance to AS/NZS ISO 9001:2015 Quality Management Certification, applies to select Business Units. While the information in this document has been presented with all due care, Corrective Services NSW does not guarantee or warrant, and accepts no legal liability whatsoever arising from or connected to, the accuracy, reliability, currency or completeness of any material contained in this document.

For further information

Call 02 4582 2420

Email csi@correctiveservices nsw gov au

Visit csi.nsw gov au

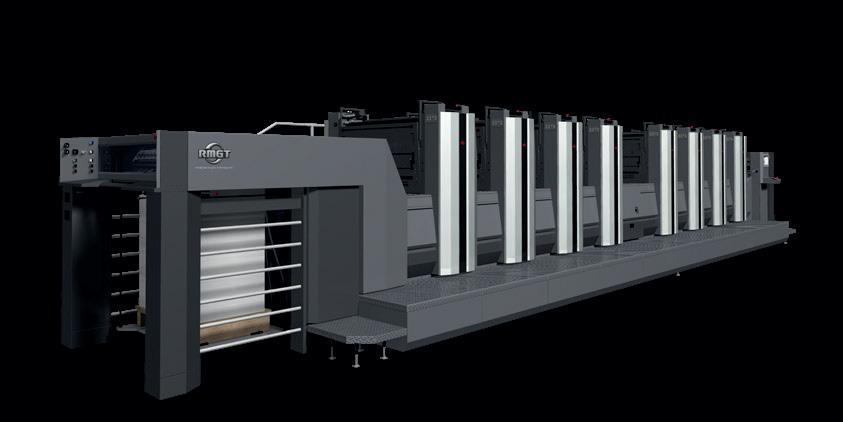

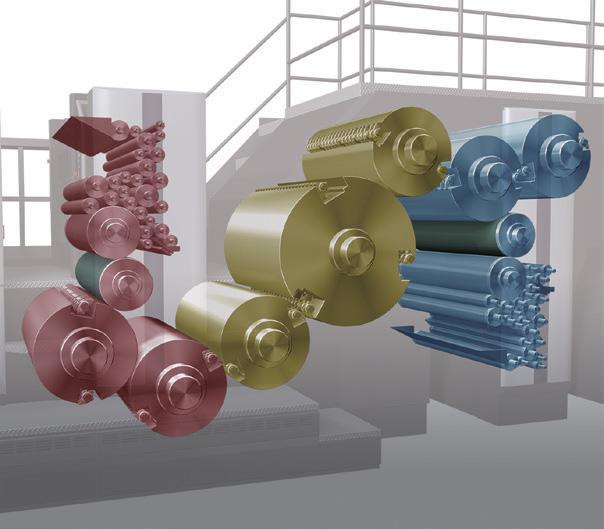

A life-long relationship with Heidelberg has helped CPX Printing and Logistics become one of the leading offset, digital, and large format printing companies in Queensland.

CPX has recently installed its first Heidelberg Speedmaster CX 104 6-colour press with coater in Brisbane. Replacing a Speedmaster XL 75, the CX 104 has delivered the business with immediate growth and efficiencies as well as providing additional revenue streams through a sharp increase in trade printing, and further expansion opportunities into new areas such as packaging.

Supported by Prinect workflow software, the CX 104 complements a multitude of Heidelberg equipment within the CPX business including a Speedmaster SM 52 offset press, Suprasetter A106 platesetter, two Stahlfolder TH 82 folding machines, two Polar 115 high speed cutters, and a ST 350 binder.

The newly installed CX 104-6+L press comes with the latest push-to-stop features from Heidelberg. This includes all press and colour settings, automatic plate change, and blanket and impression cylinder wash, without the need to touch a button as all the relevant information for an automated job change comes from the fully integrated Prinect Production workflow from Heidelberg. The Prinect Inpress Control minimises make ready times and make ready sheets and ensures colour consistency throughout the print run without the need to pull a sheet.

In addition to commercial and digital print products such as books, posters, and flyers, CPX offers its clients large-format signage as well as personalised printing

for small to medium clients – through to universities and government departments.

Following a process of continuous investment in new equipment, mainly with Heidelberg, CPX has created the ability to produce the vast majority of its work in-house, reducing lead-times, creating efficiency and maximising customer service.

Even before he started CPX in 1995, James Bennett’s journey with Heidelberg began when he became a printer almost 50 years ago.

“I was born in Darwin and I am a printer by trade. I have been in the industry since I was 16 years old – and the entire time I

have worked with Heidelberg equipment – the first press I touched was a Heidelberg KORD,” Bennett said.

“I completed my apprenticeship under Gary Coleman at Colemans Printing in Darwin and I then moved into the government printing office working in the secure printing department. I then moved to Brisbane and joined Neta Printing, which had just installed its first Heidelberg MO A2 press and needed someone who could run this machine.”

Bennett then joined the Brisbane office of SOS Print + Media Group in 1985, now owned by Pegasus Media & Logistics. After 10 years, Bennett decided to go out on his own with business partner Steve Dougherty and start CPX.

“When we started CPX in 1995, our first press was a single colour Heidelberg GTO 52 purchased for $89,500 and we would print everything on that. We printed during the day and then I would visit the site in the evening and print through the night as we only had one press and couldn’t afford another printer or staff another shift – that was our profit shift.

“To start with, we couldn’t even afford our own factory – we borrowed floorspace from another printer and when he went home, we would keep going and provide him with some extra money for power during the night.

“After our first three months, we moved to our first factory in Bowen Hills and bought a platesetter and a guillotine,” Bennett said.

The CPX business reached a turnover of $1 million after its first 12 months and then after a conversation with SOS owners – Michael Peel and Andy von Faber-Castell – the decision was made to merge the two businesses and retain the CPX brand in the market.

“We had a very long relationship with SOS and it ended well – even though we didn’t always agree on everything to do with the business – but that reflects a good partnership with strong and robust communication,” Bennett said.

“When we merged the two businesses –we had three Heidelberg presses – SOS had an SM 74 two-colour, an SM 52 twocolour and there was our single-colour press. We then bought a new SM 52 A3 five-colour press and then later we bought a second one. The next press we bought was after we traded in one of the fivecolour presses and bought a CD 74 sixcolour press in 2016. We have also bought a lot of other pieces of equipment from Heidelberg over the years including cylinders, platens, and guillotines as well. Wherever possible, Heidelberg has always been our main press supplier.

“Ever since we started CPX, we have worked very closely with Heidelberg over the years. For example, when we bought the Stitchmaster ST 350, Heidelberg helped move it up to our factory and then helped us completely rebuild and refurbish it.”

Bennett said Heidelberg is a business that CPX has always been able to rely upon over the last three decades.

“In 2022, when our factory was flooded, all of our presses were written off. Michael Collins [general manager of service at Heidelberg] went over and beyond to help as we needed to keep printing to save the business. The flood happened in February and we were printing again by May. The team from Heidelberg helped me with a replacement XL 75 as they realised we needed a press straight away. The entire team put in extra shifts and extra people to get the machine to us – and also included pulling the old press out and cleaning the new press – and whilst all this was taking place, cutting edge flood mitigation technology was being installed to ensure the technology was protected in the future. It was incredible that we were up and running within 10 weeks of the flood. I know that could not have happened without a relationship like the one we have with Heidelberg.

“In 2024, Gareth Price [CPX GM] and I travelled with Heidelberg to Drupa. During this trip we visited 10 separate Heidelberg customers – and this experience would transform my business.

The European customers we met had at least one, and sometimes up to three or four Speedmaster CX and XL machines operating in their factories – it was very impressive. These customers were also very generous with sharing information and explaining the importance of efficiency by investing in robotics, automation and the development of their own software and coding to futureproof their business.

“At the time, we were in the market for a new Heidelberg A2 press with all of

the bells and whistles. I loved the idea of being 30 per cent more productive and my production staff were also very comfortable with this because we understood the capabilities of an A2 press.

“I asked the same question to every Heidelberg customer we visited in Europe – ‘where is your half sheet press doing your covers and your small jobs?’ and the answer I received was the same – ‘we don’t have a half-sheet press’.

“My takeaway from asking the same

question 10 times to 10 different businesses and not finding any half-sheet presses made me think – ‘I need an A1 press’– and this is why we have invested in our new Heidelberg CX 104 press which Dierk Wissmann [national sales manager from Heidelberg] helped us with. His advice and knowledge of the market was key to our purchase decision.

“A dear friend of mine – Tom Lusch from Platypus Packaging – who passed away in 2024, once gave me some great advice – if you’re going to invest in new technology, it’s absolutely imperative that the new technology brings something new to the business – whether it’s a new product or service or efficiency – it must deliver something you are currently not doing.

“The CX 104 now brings a number of advantages to our business in addition to speed and additional capacity. It also allows us to print entire 16-page sections for the first time and in the future, we have the opportunity to enter the packaging market which is one of the fastest growing areas in printing.

“Just 10 months into owning the CX 104, the success we have achieved is significantly greater than we expected. If you told me 10 months ago that we would be as busy as we are and the opportunities that would open up – I would not have believed you.

“Our previous XL 75 was a half-sheet press with five colours and coater – and we were running two shifts a day at 15,000 sheets per hour. Now we have the CX 104 full sheet press with six colours and a coater, running 16-page sections at 16,500 sheets per hour.

“When we installed the CX 104, we knew that it was a long-term decision and to fill that press we needed to double our workload. Our production team understood that this would take time, and I told my team not to get stressed if we couldn’t fill the two shifts. However, we have grown so fast that three months after the CX 104 was installed, we were filling these shifts and the work has not stopped.

“The CX 104 has also provided us with the capacity to take on more trade work. Before we installed the CX 104, the percentage of trade work within our business was probably a very small part of our overall turnover, but now over the last 10 months, this has grown considerably. Since we installed the CX 104, we have a press with the capability to match our reputation and integrity in the marketplace, with Heidelberg there with us as our biggest partner – every step of the way to support our success and be there for our future.”

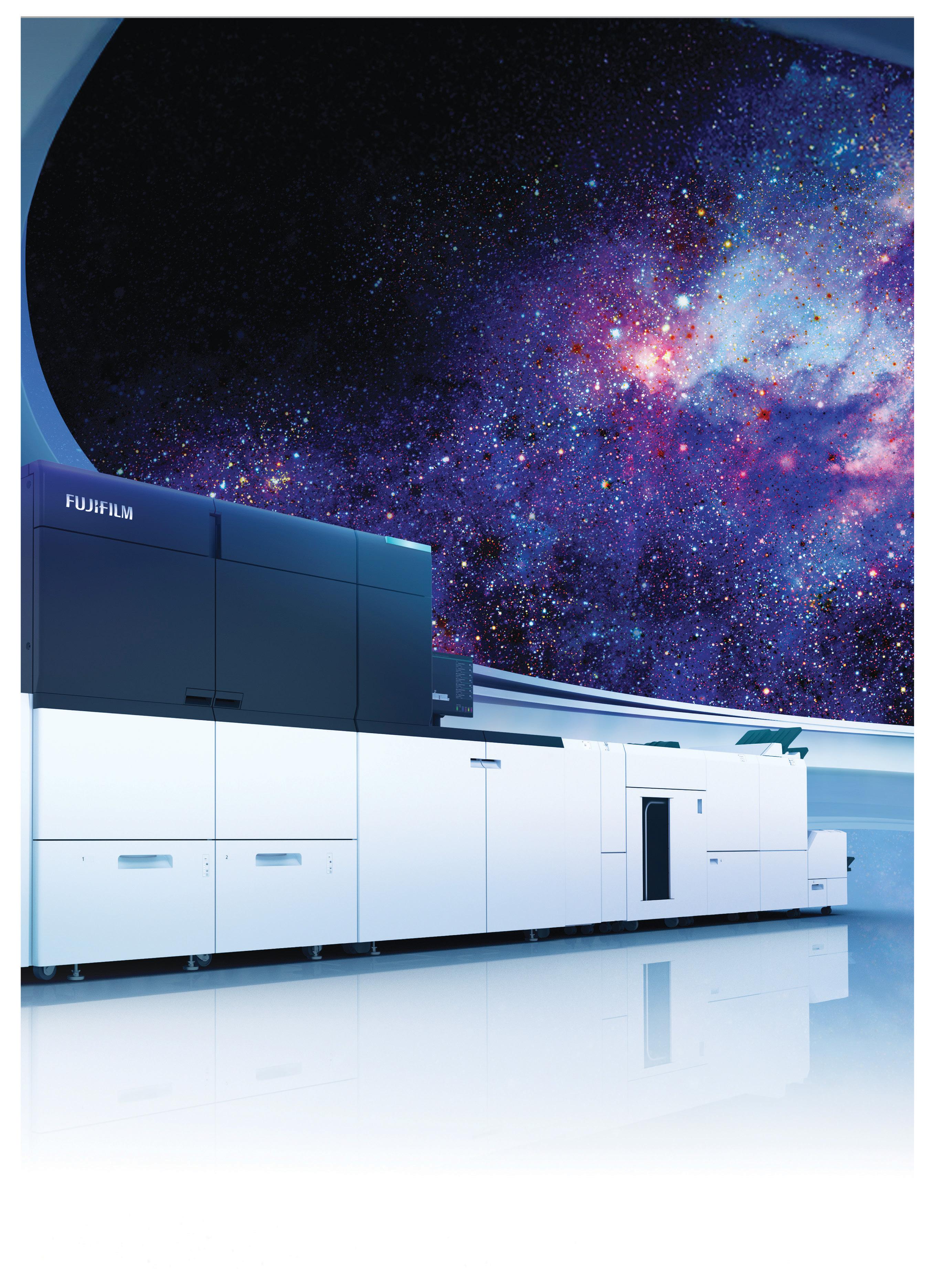

Built for quality, efficiency, and reliability – with over 950 installations in more than 60 countries, it is the globally best-selling press from HEIDELBERG of the current generation. The Speedmaster CX 104 impresses with flexible configurations, seamless integration into the Prinect workflow and strong performance in everyday use. A genuine HEIDELBERG – made for print shops that won't settle for less.

› heidelberg.com/en/cx104

The ProPrint Awards brought together the industry’s brightest talent, innovators, and leaders for a record-breaking evening at Shangri-La Sydney.

The ProPrint Awards has firmly established itself as the premier event celebrating leaders, innovators, and emerging talent across the Australian print industry.

Hosted by comedian Sam McCool, the 2025 ProPrint Awards achieved record sponsorship and attendance, welcoming more than 365 guests.

This year’s flagship award categories – recognising rising stars, key suppliers, and the industry’s most influential printers – all reported record numbers of entries, reflecting strong engagement from across the industry.

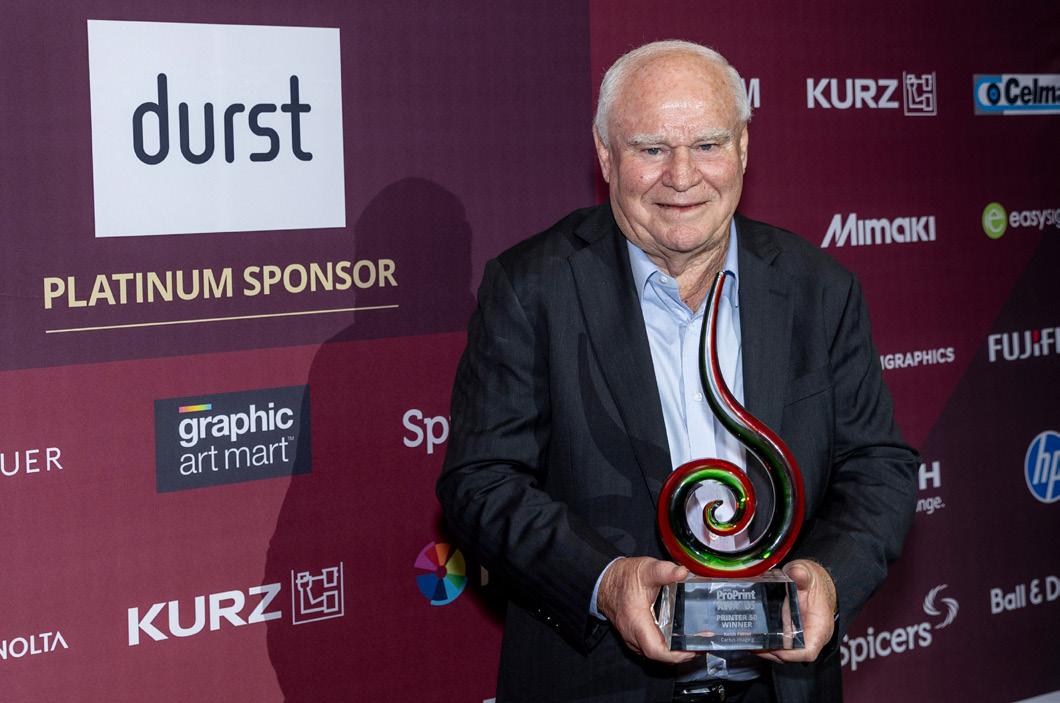

Among the highlights was the prestigious Printer 50, a peer-voted honour celebrating senior leaders and innovators who are actively shaping the future direction of the sector.

Emerging talent also took centre stage. The Geoff Selig

Scholarship was presented to an outstanding young talent, while the LIA announced its Graduate of the Year winners at the ProPrint Awards for the first time, further strengthening the event’s role in supporting the next generation of industry leaders.

The success of the 2025 ProPrint Awards was made possible through the generous support of its sponsors:

Platinum sponsor: Durst Oceania

Gold sponsors: Ball & Doggett, Celmac, Easy Signs, FUJIFILM, HP Australia, IVE Group, Koenig & Bauer and Konica Minolta

Silver sponsors: Cactus Imaging, Canon Production Printing Australia, Graphic Art Mart, Kurz Australia, Mimaki Australia, Omnigraphics, PAKKO, Ricoh Australia and Spicers Australia

Auditing partner: PKF

The ProPrint Awards Printer 50 recognises the senior leaders and innovators shaping the Australian printing industry. The top 25 leaders are ranked through peer voting, while the remaining 25 are listed alphabetically. The 2025 Printer 50 category saw a record number of nominations, with the top honour awarded for the second consecutive year to Keith Ferrel, co-founder and general manager of operations at Cactus Imaging.

ADVANCED AUTOMATION FOR HIGH VOLUME PERFORMANCE.

UNLOCK CREATIVE OPPORTUNITIES WITH WHITE ON OUR S MODELS.

The AccurioPress C14010/S & C12010/S high-speed production print range delivers high-volume performance, exceptional colour quality, versatile media handling, and outstanding accuracy and consistency to expand digital print capabilities and applications, with the added 5th colour White option available on our S Models.

Highlighting the next generation of print professionals, the Emerging 50 celebrated a diverse and dynamic group of talented individuals from across the print sector.

For over a century we’ve been the trusted partner behind Australia’s leading brands.

From print foundations to today’s omnichannel solutions, we deliver clarity, connection and impact

The Supplier 50 celebrated those who supply and service the print industry, acknowledging their commitment to excellence and their dedication to delivering exceptional service and expert advice.

Your trusted printing partner for…

Easy Pop Up Gazebos

Easy Mailer Boxes

Easy Flags

Easy Media Walls

Easy Flyers

Easy Posters

Easy Vinyl Banners

Easy Booklets

Easy Stickers

Easy Coasters

Easy Light Box Displays

Easy Umbrellas

Easy Label Rolls

Easy Pull Up Banners

Exceeding Print – because there is still so much more to discover.

The future still holds so much worth discovering. To help preserve it, Koenig & Bauer is committed to protecting the environment through sustainable printing processes and increasingly e cient machines. Non-ecological packaging can be replaced, waste reduced, and resource-saving practices advanced.

Alongside supporting numerous initiatives and projects, Koenig & Bauer's roadmap includes achieving complete CO₂ neutrality across its production plants by 2030.

Koenig & Bauer (AU)

Rayne Simpson +61(03) 9548 7277

rayne.simpson@koenig-bauer com.au

koenig-bauer com

Recognising exceptional individual contributions, the 2025 ProPrint Awards honoured achievements in sustainability, industry leadership, and education, including the Geoff Selig Scholarship, named in memory of the former IVE Group chairman. The LIA Graduate of the Year was also presented for the first time at the awards night.

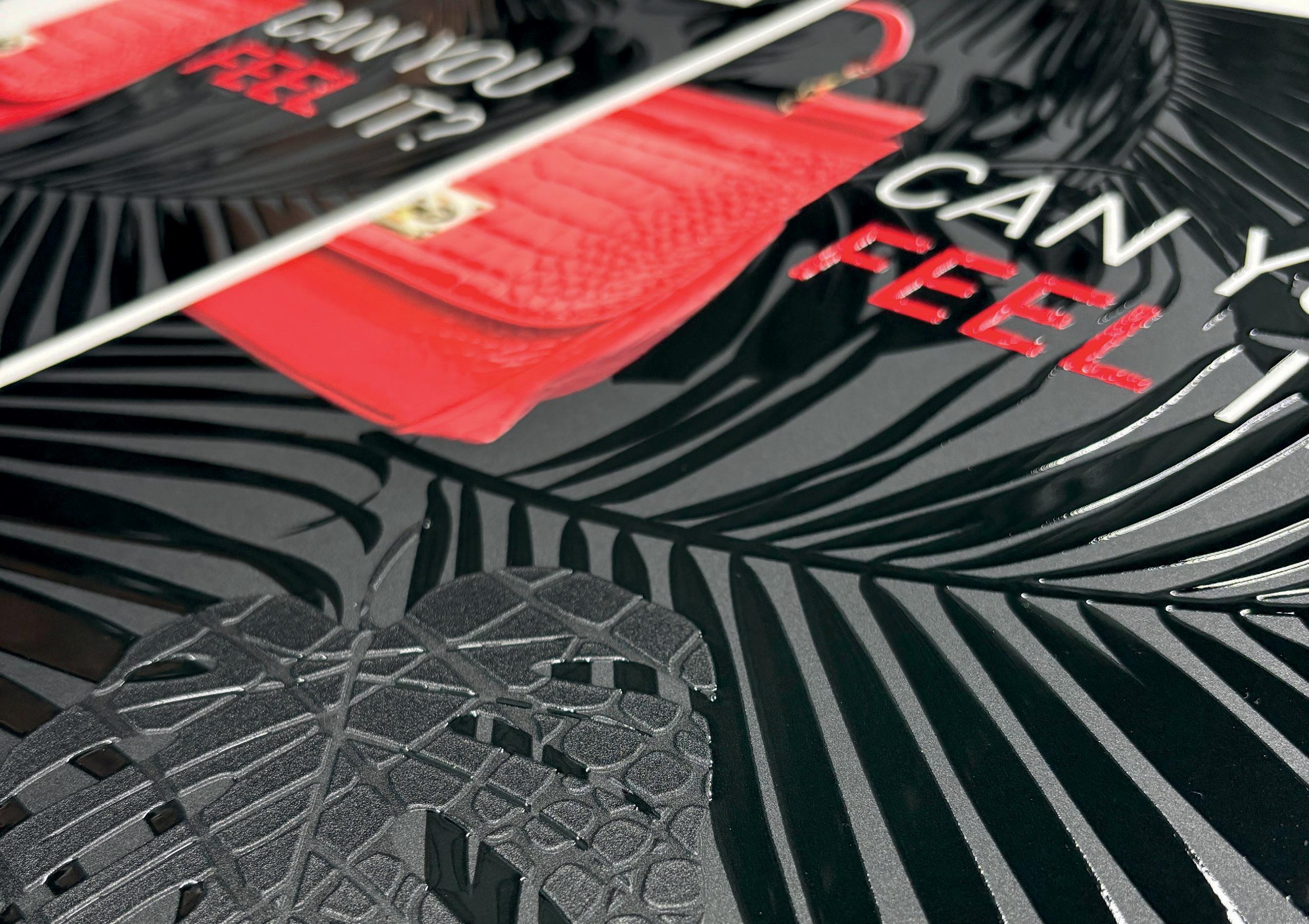

Next Printing was named winner of the Outstanding Achievement in Sustainability Award. Next Printing has long been a pioneer in eco-conscious printing. Nearly a decade ago, the company embraced Re-board technology – well ahead of the mainstream shift towards sustainable alternatives. Earlier this year, the company earned global recognition by winning the FESPA 2025 Gold Award for its Barbie@Grill’d display – a month-long Barbie-themed activation at Grill’d in The Galeries, Sydney. The campaign highlighted the creative potential of sustainable materials while significantly reducing environmental impact.

The 2025 Industry Achievement Award recognised Celmac CEO Wayne McIntyre

for his contributions to the printing industry over a career spanning more than 40 years. The Industry Achievement Award celebrates an industry veteran with more than 25 years of experience who has made a significant and lasting impact beyond the scope of their own business. McIntyre was selected for the honour by the Top 10 of the 2024 ProPrint Award’s Printer 50 and the 2025 Platinum sponsor Durst Oceania. McIntyre founded Celmac in 1987 and has since led the company to become a major force in Australia’s signage and wide format printing industry.

Kathy Doan from Corrective Services Industries was named the second recipient of the Geoff Selig Scholarship. The scholarship honours former IVE Group chairman Geoff Selig and reflects his passion for nurturing emerging talent

within the industry. It represents his lifelong commitment to nurturing talent, celebrating the growth and success of those he supported. The scholarship provides a financial value of up to $10,000 for personal and professional development and is funded jointly by ProPrint and IVE Group.

For the first time, the 2025 ProPrint Awards hosted the biennial Lithographic Institute of Australia (LIA) Graduate of the Year Awards, which promote the vital role of apprentices and graduates in the printing and packaging industries. Jackson Young from Harden Packaging in Victoria was awarded the $10,000 LIA Visual Connections Scholarship Prize, and Kathy Doan from Corrective Services Industries in NSW received the $5,000 LIA Future Leader Award.

AUDITING PARTNER

SPIRITS PARTNER

INDUSTRY AWARD ACHIEVEMENT GEOFF SCHOLARSHIP SELIG

Several Printer 50, Emerging 50, and Supplier 50 winners who were unable to attend the 2025 ProPrint Awards event have since received their trophies, marking the completion of last year’s celebrations.

1. For Kirsty and Luke Woodhead, the ProPrint Awards have proven to be a bonanza in 2025. Not only were they jointly recognised with a Printer 50 Award, but three of their staff received recognition with Emerging 50 Awards.

2. David Walton is no stranger to Omnigraphics, having worked there for almost 18 years. He bought the business two-and-ahalf years ago, was CEO for six months before that, and was its operations manager earlier on. “The innovation of doing things with traditional print but outside the norm” is what excites Walton the most about his work at Omnigraphics.

3. Aninah Chua is tasked with improving the environmental impact of Note Printing Australia’s (NPA) operations by identifying environmental issues, developing solutions, and delivering outcomes. Chua is also currently working on a chemical management project to look for opportunities to align with and improve NPA’s sustainability targets. “Printing the products we make is very different to what’s produced in the broader printing industry,” she said. “Being exposed to banknote printing is fascinating.”

4. Meagan King is pre-production assistant manager at Note Printing Australia (NPA) and has worked with the Australian and international currency printer for more than two years. “I’m still learning a lot about the department, which manufactures a range of products that are critical to our printing operations, providing plenty of learning opportunities and ensuring that no two days are ever the same,” she said.

5. Arishma Maharaj has been part of the Hexis Australia team for almost three years, spending two years in Melbourne and the past year at the Yatala office on the Gold Coast.

“I came to Australia seeking better career opportunities as Fiji is a small island and when I had the chance to move, I decided that Australia was going to become my home,” she said. “Joining Hexis was a challenge for me at the very beginning as I was new to the industry and I did not know anything. The team has been so great to work with; they have made it very easy to understand the various product codes, and it has been a very smooth experience.”

6. Aaron Lusch of Platypus Print Packaging thanked the industry for the acknowledgement and said, “I’m proud to be part of an industry that continues to evolve, invests locally, and supports so many skilled people and businesses”.

7. Diana Nikolic from Ball & Doggett said she felt very humbled to have received a Supplier 50 award. “Starting in customer service and now working as the business development executive, it gives me great joy in connecting with the print community and to put my customer service skills to the test. What a great feeling it is to be recognised and celebrated – something we probably should do more of,” she said.

8. Evan Gill from Kwik Kopy Eagle Farm has won an Emerging 50 award for the third year running and he’s only been in the industry for three years. He said, “It’s very humbling to have my efforts recognised and I look forward to building on this momentum”.

9. Ashley Day from Ball & Doggett said this is her first industry award and so it’s very exciting for her. “It’s a huge win and I’m very proud of myself. I feel honoured to be recognised within the company and the industry,” she said, adding that working with customers in this industry has been very rewarding. “So, I’d love to be able to use my people skills to help them and Ball & Doggett grow within the wide format printing area,” she added.

10. Simon Pugh from QLM Label Makers Group said it has always been an honour to be recognised in the Printer 50. “I think it’s an important award that showcases the excellence in our industry, in an industry that continues to evolve and develop, and to lean into some of the changes and challenges we face. We have some amazing leadership in print and visual communications, and I think being part of that and being seen within the Printer 50 of our industry gives me a lot of joy in its recognition for QLM,” he said.

11. Samantha Bailey-Jensen from Bailey Print Group said that being named in the Printer 50 for the fourth year in a row was a significant milestone for the company, particularly as it coincided with Bailey Print Group’s 40th year in business. “It’s a strong endorsement of our team’s commitment to quality, innovation, and consistency over time,” she said. “Reaching this recognition while celebrating four decades in the industry reinforces that our focus on evolving with technology, investing in people, and delivering exceptional outcomes continues to resonate with our clients and the wider industry.”

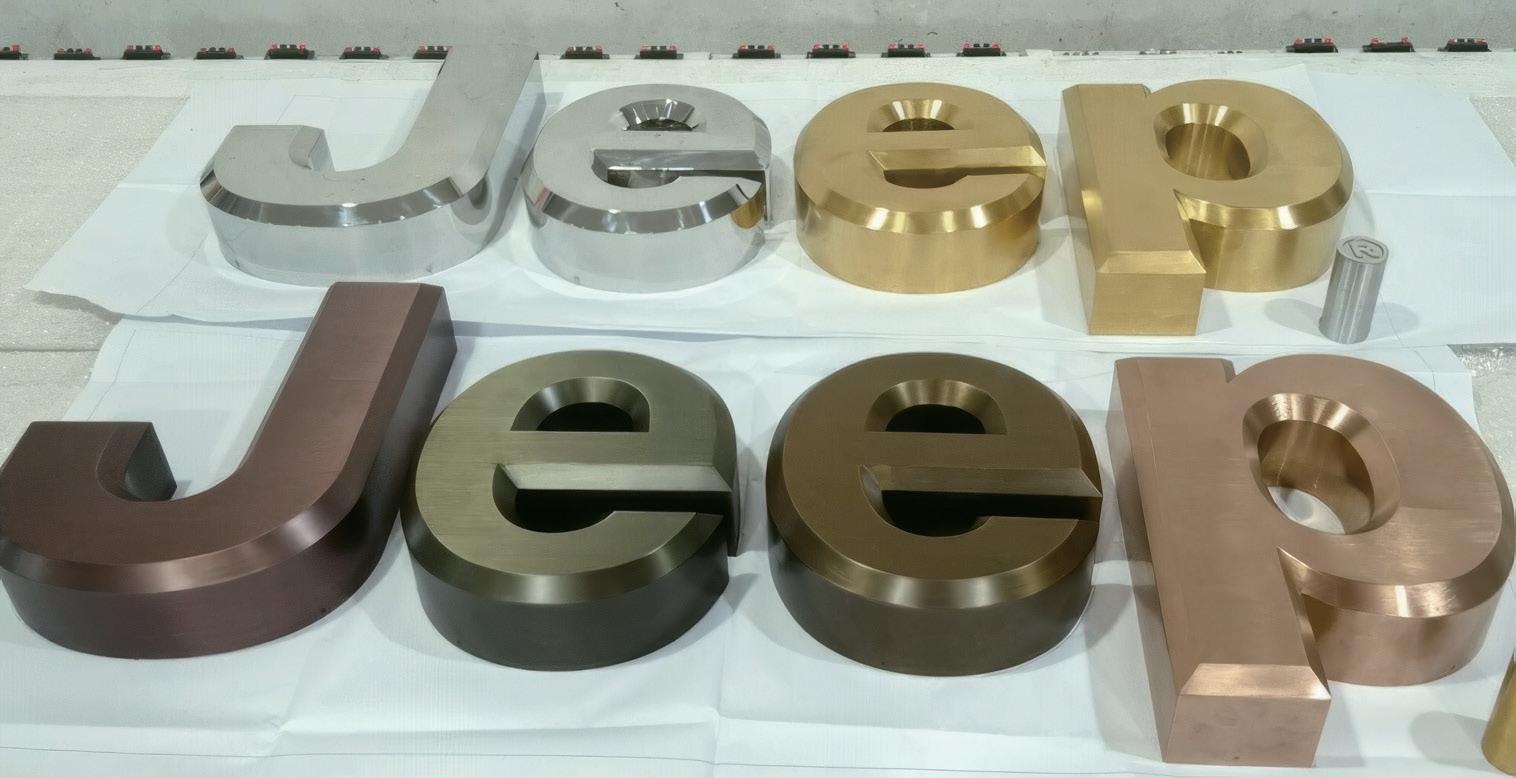

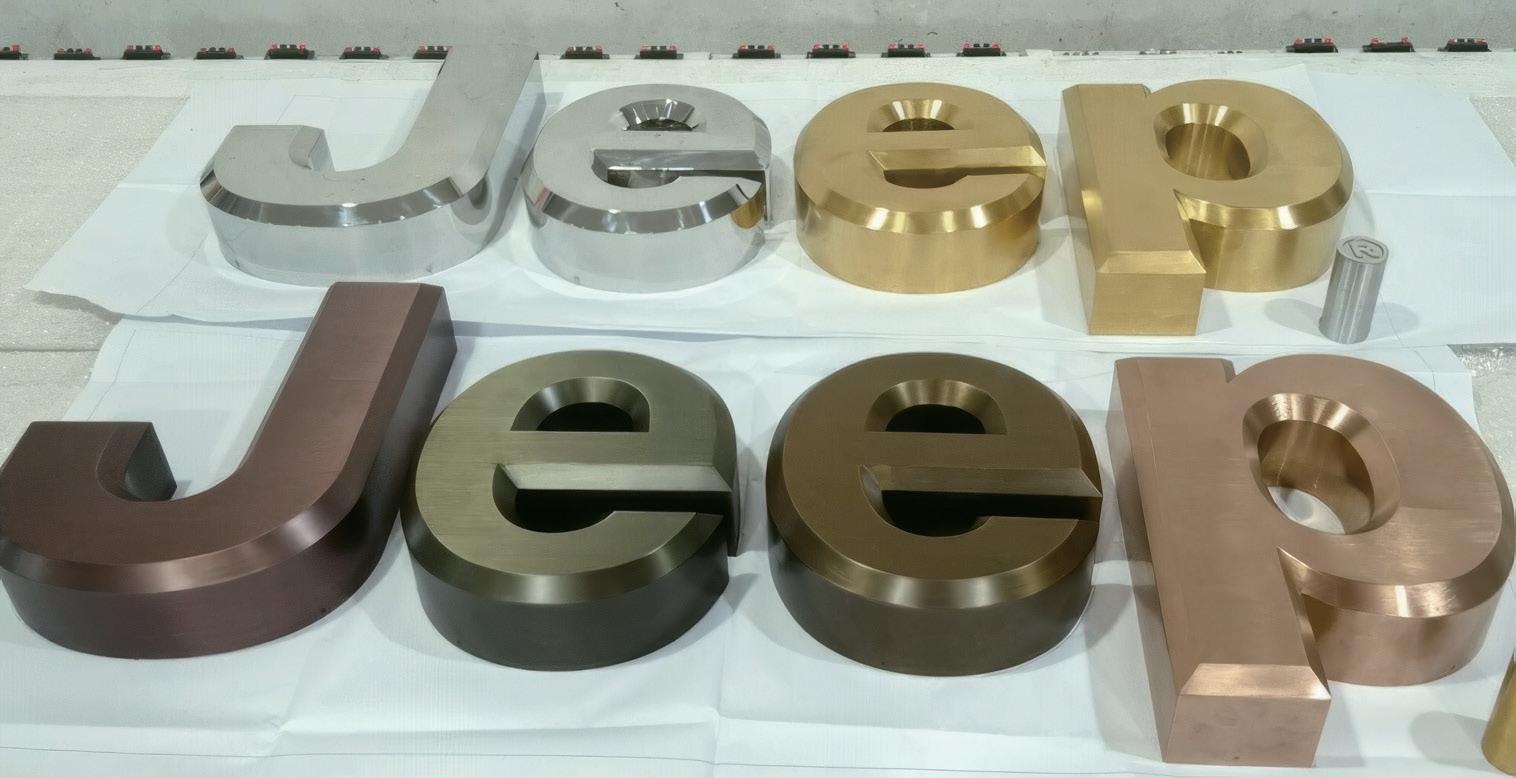

12. Lisa Michalanney from Signageworld 3D/SA thanked ProPrint, the sponsors and fellow nominees. “It’s great that South Australia can feature in the Printer 50, considering some of the eastern state heavyweights on the list,” she said.

13. Michael Nankervis, managing director of OnPack, said winning a Printer 50 Award has been a great experience for him because “printing has been a family tradition for many years”.

14. Since purchasing Kwik Kopy Ballarat in December 2023, co-owners Andrew Butcher and Katie Ammavuta have revelled in the communal involvement. “I always wanted to own my own business and the Kwik Kopy ‘brand’ and the support network behind the franchise system really appealed to us as a business model,” said Andrew. Katie and Andrew were individually recognised in the Emerging 50 category. “We’re still growing,” said Katie. “Eventually we’ll have plans to expand outside Ballarat, but still in this region,” she added.

15. As marketing and design manager for Spicers Australia, Cyndi Setia has a wide gamut of responsibility – handling everything from online and offline promotions, social media promotions and creating print samples as a resource for printer clients and advertising agencies. “I love the printing and paper side of design and I’m very lucky to be in this role where I get to promote not only to agencies, specifiers and designers, and inspire them to use our products, but it’s an exciting role to be in because we get to play with products, promote them and inspire other printers and designers to use our products,” she said.

16. In her role as marketing coordinator at Spicers Australia since 2022, Taylor O’Neill is thrilled to be working at the cutting edge of showcasing her company’s comprehensive range of papers, stocks and substrates to the industry. “It’s very diverse, covering anything from all-out promotions, to ecommerce, to social media,” she said. O’Neill has been at Spicers for nearly seven years. “I love the creative side of it – how it all evolves from concept to production.”

17. Bianca Martin, commercial manager at iconic print giant,

IVE Group, manages brand activations for wide-format print, as well as timber and acrylic, and fabric and aluminium extrusions. She also manages systems, tender responses, working with project managers and estimators. “What I’m focusing on now is making it easier for the users to get something into the system and produce. They just need to know what it will look like in the end, and then everything just gets built in behind it,” she said.

18. Lee Farrell has been with Hexis for over 18 months after a career in various parts of the printing industry for more than 30 years. At Hexis Australia, Farrell looks after a comprehensive range of consumables for wide-format, including selfadhesive vinyls for everything from window and wall graphics to vehicle wraps. “The company is family-owned, which is quite refreshing. They’re very well known on the world market for vehicle graphics and decorations, and for paint protection films. But we have a whole gamut of visual media for windows, walls, floors, you name it,” he said.

19. For Tia Savvas, it has been a good-news double. At Briner Signs, she was recently promoted to the position of real estate operations manager, which sees her looking after Briner’s customer service team and scheduling drivers to ensure the lightning-fast schedules and rapid turnarounds are smooth and efficient. Briner Signs general manager Robyn Scawen said, “Part of Tia’s role is to make sure that our workflows and our processes all fall into place. We don’t raise any manual orders here. Third-party artwork providers submit material for real estate work from templates. Once they submit their orders, they enter Briner’s workflow. Part of Tia’s role is to ensure that no links in the chain are broken”.

Series 3 430

20. Brett Matthews is the technical specialist at Graphic Art Mart and has worked there for two years, the latest chapter in a printing industry career spanning almost 20 years. “We basically offer everything a sign shop is going to need. We have wide-format, digital, self-adhesive, right up to rigid substrates for manufacturing and fabrication,” he said.

21. David Watt enjoys working for an established industry supplier that has a track record of almost 40 years. Watt has been in the industry for some 15 years and has been with Celmac for four years. “At Celmac, we’re very focused on hardware and consumables”, he said. “We have a range of all the consumables that go with the large-format machines. We’re a hardware, service and support business.”

22. Eliza Godwin is in Year 12 at school, but in her available time works as a production assistant and customer service manager – handling quotes and invoicing as well as operating the new Durst 340 RSC label printer. “I really enjoy the creative and textural aspects involved with printing labels as well as handing over the finished product to happy customers,” she said.

23. Matt Tangey leads Currie Group’s brand presence across all business segments, working closely with global technology partners, internal teams, media and industry bodies. With a collaborative and commercially focused approach, he drives engagement, supports customer success stories, and helps

position Currie Group and its partners as leaders across the print and graphics industry. “At the core of my work is a commitment to providing quality service and support that goes beyond simply supplying technology,” he said. “I believe success in this industry is about listening carefully, understanding each customer’s challenges, and working collaboratively to create solutions that deliver long-term value.”

24. “Everything we do is different – it never becomes boring,” reflects Justin Tout, production coordinator at Breen Printing. “I live up the road and walk to work.” Revelling in his production management role at Breen, Justin sees himself staying in the print industry for many years to come.

25. In his third year as an apprentice at Breen Printing, Liam Hyde-Brody is looking forward to the fourth and final year of his apprenticeship in 2026. He has specialised in commercial printing and especially enjoys the technology and what makes it click. “I see my future in printing, I enjoy it,” he said.

26. As a prepress operator at Breen Printing, Nic Benson prepares artwork and files that generate output on the Healesville, Victoria commercial print company’s Heidelberg Speedmaster. He also does prep work for jobs that go on its two Konica digital presses, a C6100 and a C7100. “Breen is a great opportunity for me. It’s expanded quite quickly in the time that I’ve been here. Luke and Kirsty’s vision for the company has also helped my career which is terrific,” he said.

Upgrading to a Ricoh Pro C9500 has enabled XPS Group to achieve superior digital print quality, greater flexibility across all job types, and dependable performance to support continued business growth.

Founded in 2016, Sydney-based XPS Group supports a broad network of print resellers across Australia, particularly those that sell printed materials but lack in-house production capabilities. Offering offset printing, digital printing, and signage, XPS Group is committed to delivering high quality output with fast turnaround times.

By mid-2024, the company’s Ricoh Pro C7200S was nearing end of its life. The team needed a new solution that could keep up with increasing demand while meeting its high standards for colour accuracy and image quality, ideally matching the output of an offset press.

After evaluating several options, XPS Group invested in the Ricoh Pro C9500 colour press. The upgrade has delivered significantly improved digital print quality, greater flexibility for short and long print runs, and consistent, reliable performance to support the team’s growing workload.

Meeting last-minute demands was becoming increasingly difficult for XPS Group with its existing setup, and expectations for quality were only rising. With XPS Group looking to replace its existing Ricoh Pro C7200S as it neared the end of its life, the team wanted a reliable alternative that would meet the company’s output needs and stringent high quality control standards.

“Previously, it was not possible to take a print job from the offset and run it on a digital machine,” said John Meoushy, director of XPS Group. “The noticeable drop in quality was simply not acceptable.”

With the Ricoh Pro C9500 colour press fully operational, XPS Group was quickly enjoying some significant benefits. Traditionally, the quality of output from offset printers has been higher than that of digital machines.

However, during the assessment process, the XPS Group team recognised the output

being delivered by the new Ricoh Pro C9500 colour press was indistinguishable from that of the offset printer. Print jobs that previously would have required the offset press could now be quickly and efficiently completed using the new digital printer.

“Our clients were very impressed with the quality of the outputs we were able to deliver. Often, the jobs were indistinguishable from offset outputs,” Meoushy said.

XPS Group found more flexibility when it came to scheduling and completing print runs. Rather than having to rely totally on the offset printer to ensure top quality results, jobs could now be shifted as needed to the digital machine.

“We are now able to turn small jobs around much more quickly which is proving to be a major business benefit.”

Meoushy said the company has been very impressed with the reliability and performance of the Ricoh Pro C9500 colour press. It consistently delivers highquality outputs with little to no downtime.

“Because the press is so reliable, we’ve

had very little need for service calls,” Meoushy said.

“The machine is designed in a way that allows us to handle small replacements ourselves, while knowing Ricoh support is always just a call away if required.”

While there were no immediate plans to add additional printers to the fleet, Meoushy said this option is being kept open. As demand continues to grow, the team sees Ricoh as a key partner in future capacity planning.

“We have a great working relationship with Ricoh, and I am sure they will continue to support our operations in the future,” Meoushy said.

“They have become a valuable print technology partner for us, and we are keen for this to continue.”

• Reliability meets quality: Impressed by the outstanding performance of the Ricoh Pro C7200, the XPS Group team chose to upgrade to the Ricoh Pro C9500 colour press, unlocking even greater capabilities and efficiency.

• Consistent high-quality results: XPS Group can now deliver digital outputs that match the quality of their offset press.

• Job flexibility: With the Ricoh Pro C9500 colour press, the business easily migrates jobs from offset to digital production

• Minimised downtime: Seamless operations with self-service parts, keeping the machines running smoothly, and reducing the need for extensive after-sales support.

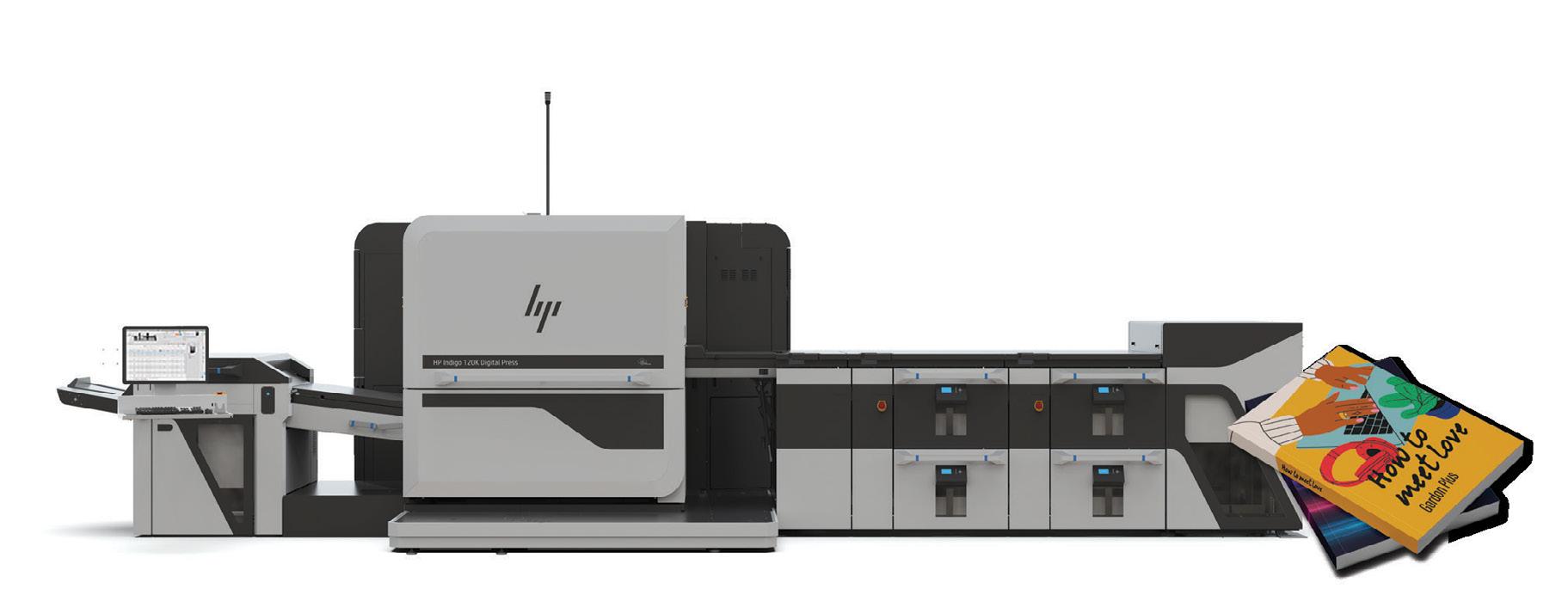

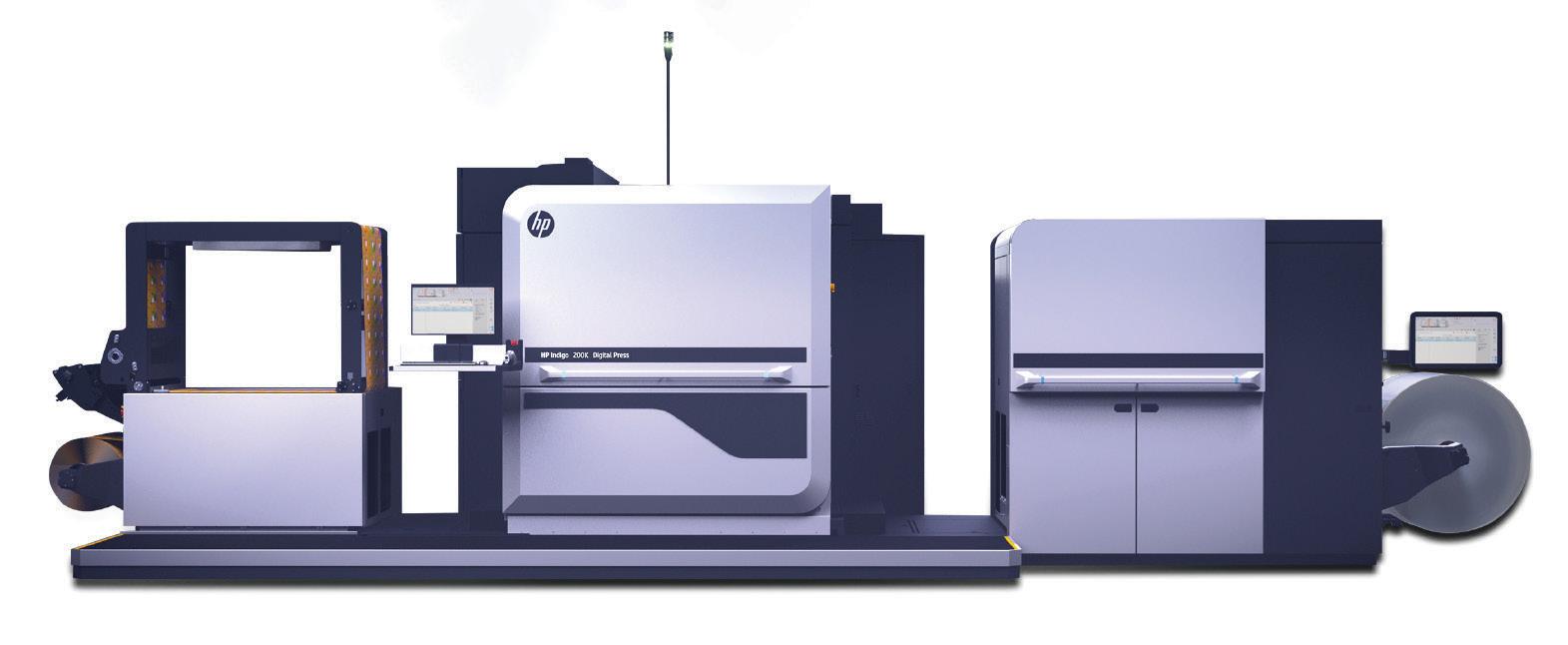

A strong partnership between HP Indigo and Currie Group, combines world leading digital print technology with deep local market expertise, addressing a range of industry challenges.

Across Australia and New Zealand, commercial print, labels, and packaging businesses are navigating a period of rapid change. Customer expectations continue to rise, run lengths are shrinking, speed to market is critical, and sustainability is no longer optional. At the same time, margin pressure, labour constraints and growing operational complexity are forcing businesses to rethink how they operate. At the centre of this shift sits the partnership between HP Indigo and Currie Group which provides solutions when addressing industry challenges.

Currie Group has supported the print and packaging industry across A/NZ for more than 75 years, and today represents HP Indigo across commercial print, labels, and packaging segments. This heritage brings a strong understanding of customer realities on the ground including commercial pressures, staffing challenges, workflow complexity, and the need for practical, sustainable solutions that deliver measurable business outcomes.

This is strengthened by Currie Group’s ability to deliver end-to-end solutions, bringing together HP Indigo technology with best of breed partners across workflow, finishing, materials and automation. As Currie Group CEO Rob Mesaros says: “It is this combination of advanced technology, integrated solutions and local partnership that’s helping customers move beyond the adoption of digital, towards true digital transformation.

“One of the most common challenges customers face today is balancing efficiency with flexibility,” Mesaros added. “Brand owners and buyers are demanding shorter runs, faster turnaround, greater versioning and more customisation, while still expecting premium quality. Traditional analogue workflows often struggle to meet these expectations economically. HP Indigo digital presses enable Currie Group customers to produce multiple SKUs, manage frequent changeovers, and deliver variable data applications without the time and cost penalties associated with conventional

production. For many businesses, this capability has become a genuine competitive advantage, opening doors to new clients, new applications, and new revenue opportunities.”

Mesaros said that automation is playing an increasingly critical role in delivering these outcomes on scale. “Currie Group works closely with customers to design production environments that extend beyond the press, incorporating workflow automation, colour management, and intelligent job orchestration.

“Solutions such as HP Site Flow, HP’s print production automation software, help streamline job onboarding, automate routing and reduce manual touchpoints across complex production environments. Platforms such as HP PrintOS provide real time visibility across operations, enabling businesses to monitor performance, optimise scheduling and improve decision making,” he added.

Mesaros said AI and machine-assisted technologies are also beginning to deliver real world value with capabilities such as intelligent quality monitoring, automated press optimisation, predictive maintenance, and HP Nio (AI powered assistant) all helping operators maintain consistency while reducing reliance on individual expertise. In a market where skilled labour is increasingly difficult to source, this is critical.

Across the region, there are many examples of customers using HP Indigo technology, supported by Currie Group, to evolve their business models. Commercial printers are expanding into higher value applications such as short run packaging, customised marketing collateral, and premium photo products. Label converters are building profitable digital divisions alongside flexo, supporting versioned SKUs, seasonal campaigns and rapid turnaround work. In flexible packaging, early adopters are working with Currie Group and HP Indigo to support brand owners with product testing and sustainability initiatives.

According to Mesaros, the measurable impact of these investments is clear: “Customers are reporting stronger productivity across complex job mixes, reduced waste and improved margins on short run and customised work. Digital production is also supporting sustainability outcomes, including reduced substrate waste, lower inventory obsolescence and more responsible manufacturing models. These are not theoretical benefits; they are commercial outcomes that Currie Group regularly reviews with customers as part of an ongoing partnership approach, rather than a one off installation.

“For businesses beginning or accelerating their digital transformation journey, the message is clear. Success depends as much on partnership as it does on technology. Define the outcomes you want to achieve, understand where digital can add the greatest value, and work with partners who bring both technical expertise and genuine market understanding. With the right strategy, support and tools, digital transformation becomes an opportunity for growth rather than a challenge to manage,” he said.

“Through its longstanding partnership with HP Indigo, and its deep commitment to the local industry, Currie Group continues to help commercial printers, label converters and packaging producers adapt with confidence, build resilience, and create operations designed for the future,” Mesaros added.

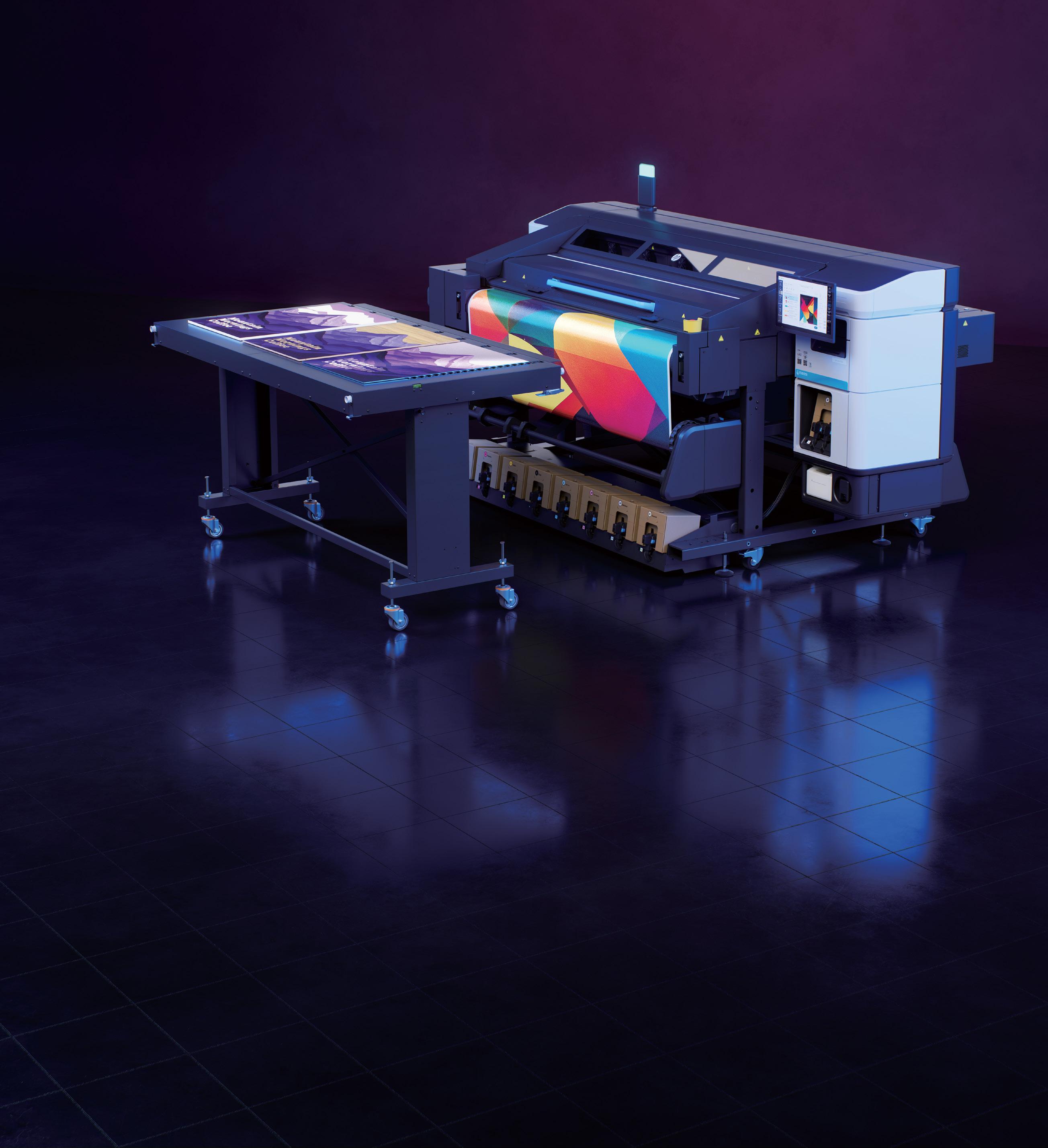

HP’s Craig Hardman explains how HP’s technology helps businesses stay ahead in a constantly changing market.

In an exclusive interview with ProPrint, ANZ country manager HP large format printing, Craig Hardman explained the current challenges in the market and how HP’s technology addresses these pressures.

“HP is helping PSPs embrace the future of work, where automation, intelligent software and hybrid production environments are becoming the new norm. Our goal is to give businesses the tools they need to run smarter, leaner and more predictably, no matter how the market evolves,” said Hardman.

“We find HP Latex can help enable customers to stand out from the crowd –whether it be in the flexible or rigid space. HP is focussed on solutions out of Print OS suite, with tools such as HP Production Hub, HP Learn and HP Ecommerce and Design.”

Hardman added: “When we look at workflow and reducing the manual touchpoints within a business, we see the immediate improvements with the HP Production Hub solution. When using the HP Jobs functionality, customers are removing whiteboards, job bags or baskets and allowing everyone in the printing process to understand where the business is – whether you’re in sales, production or finishing.”

“As well, solutions like the HP Latex R530 give them the flexibility to handle both rigid and flexible work on a single platform, making it easier to take on a wider range of jobs without adding complexity. For higher volume production, the HP Latex 730 and HP Latex 830 focus on speed and productivity, helping teams run more jobs faster,” he said.

When we look at machine-assisted technology, Hardman said print quality is a good place to start. “HP Pixel Control works at the pixel level to manage colour and ink placement with a high level of precision, improving consistency and image quality across different print modes and speeds. It’s a technology that we’ve brought across from our aqueous photo line of printers in HP DesignJet. For customers, this translates into smoother gradients, better colour transitions, and

reliable quality without the need for constant manual adjustment,” he added.

As an example of where HP technology has helped customers adapt to shorter runs or faster turnaround times, Hardman said: “A great example is Signart, a signage provider that integrated the HP Latex R530 into its workflow to address rising demand and limited production space. By bringing more work in-house, Signart significantly cut turnaround times and took on larger, more complex projects with confidence. The R530’s hybrid capability, white ink support and direct-to-rigid printing saved hours of manual work on jobs like backlit acrylic displays, allowing them to deliver customised jobs faster.”

Hardman agreed that technology needs to help businesses future-proof their operations, adding: “The print landscape is changing fast, and PSPs need to be ready for whatever comes next. With the HP Latex R530, customers have seen huge gains from an all-in-one solution that can switch from flexible to rigid in a quick and

easy manner – without losing anything they love about printing with HP Latex.

“HP PrintOS Production Hub gives full visibility across jobs, reduces manual work, and keeps workflows predictable, so teams can respond quickly to each customer’s demands. Our water-based HP Latex inks help PSPs meet growing sustainability expectations from brands and government customers, without compromising on quality or speed.

“Apart from all of the innovation around our HP Latex Printers and water-based inks, I think the tools and software we are providing to the market is something that sets us apart – and it’s applicable from our largest to our smallest customer,” he said.

Hardman added that because the largeformat market is evolving so quickly, digital transformation is driving customers to reduce manual work, introduce automation, and make smarter, datadriven decisions: “At the same time, there’s a strong push to grow online operations and make the most of digital channels.”

Regarding sustainability, Hardman said this is a key focus, with more customers looking for solutions that lower environmental impact: “We respond to these trends through a comprehensive ecosystem built around our innovation pillars, delivering stunning output with versatile applications and design with the environment in mind.”

For those print service providers who’re beginning or accelerating their digital transformation journey, Hardman advised: “Build a connected workflow that supports online channels without adding unnecessary complexity. Focus on where you can add value, whether through new applications or more responsible practices, so you’re shaping your own future rather than just reacting to change.

“The businesses that thrive will combine great output with efficient, adaptable processes and a mindset to innovate as the market evolves – from automation, AI integration and workflow software through to next-generation digital print technology and materials,” he said.

With digital cutting now a necessity in today’s sign and print industry, Zünd Australia’s