HIGH PRODUCTION FLATBED LED UV PRINTER

Dscoop Edge Indy ‘fuels the future’

Highlights and key learnings from this year’s Dscoop Edge Indy

Embracing the intelligent revolution

Why the packaging industry is wellpositioned to adopt emerging technologies

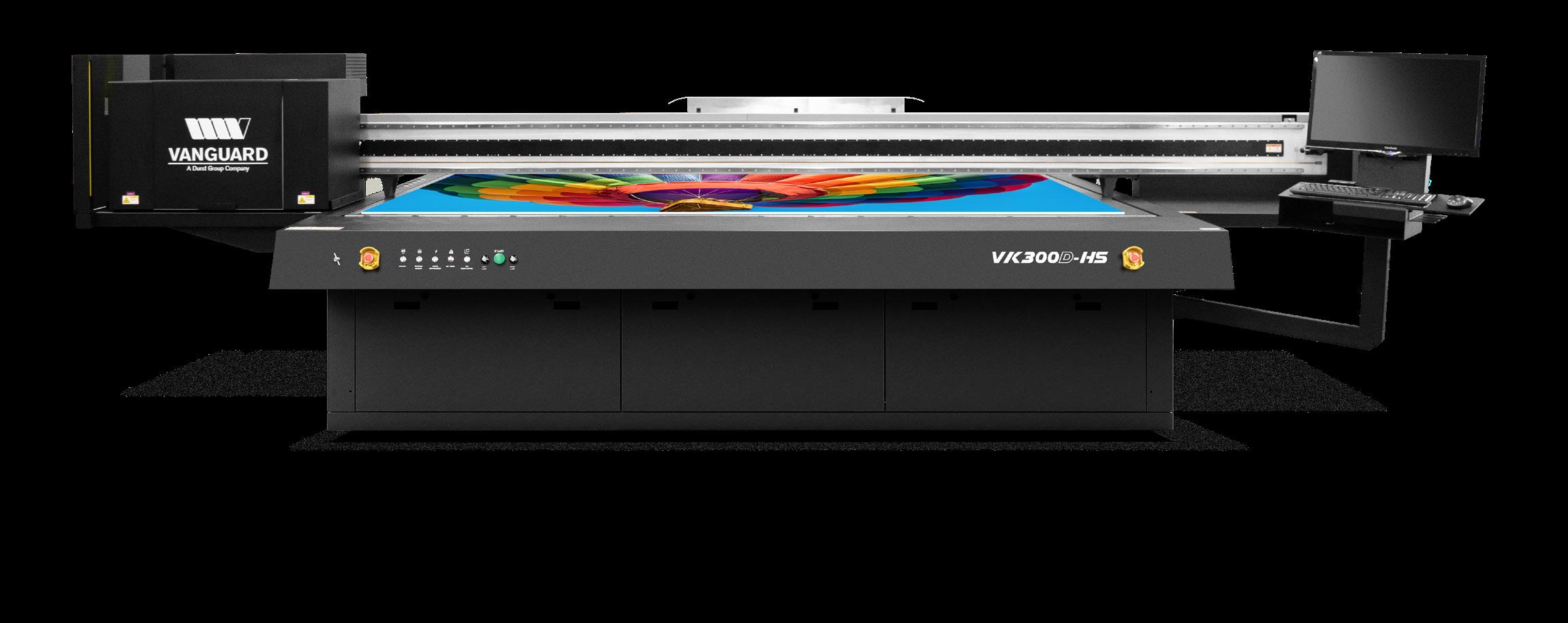

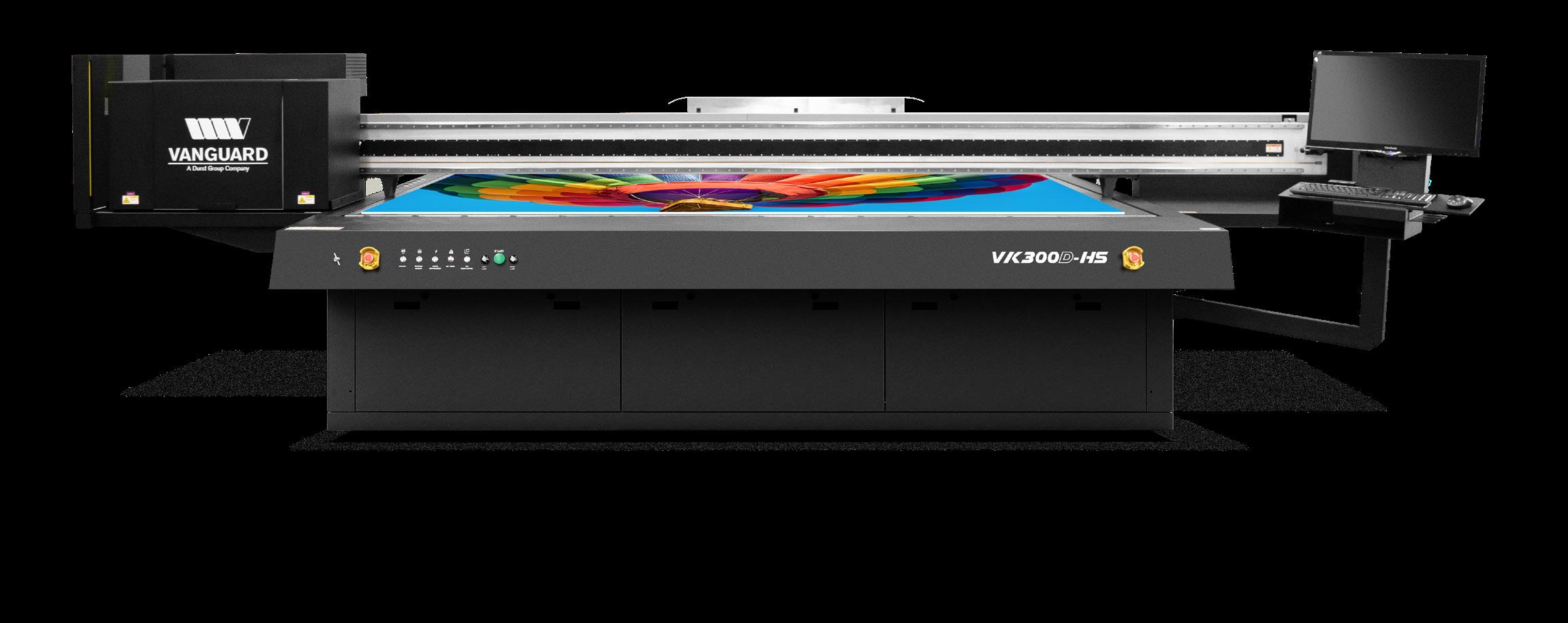

The Vanguard Digital VK300D-HS is the impressive high speed version of our six-time award winning VK300D series.

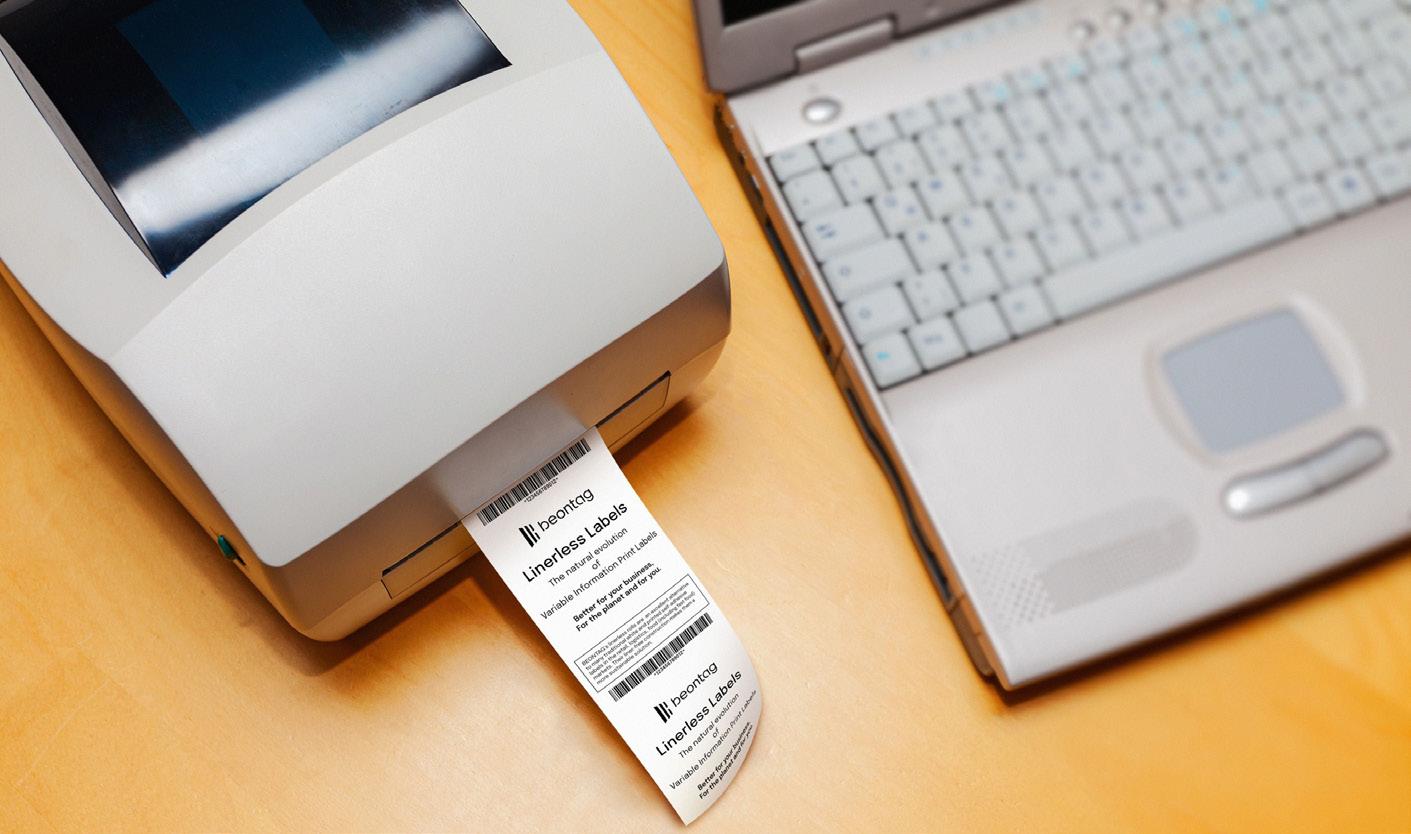

Linerless is more How linerless labels are reshaping the labels and packaging landscape

ALSO INSIDE...

A B Graphic International visit further strengthens ANZ ties

April 2024

Technology Business

ON:

www.propack.pro

People

A FOCUS

Great work, reliability and quality really help us look good to our customers, meaning you get more work.

Thank you for helping.

Ian - 12/12/23

Thanks for everything. The book is fantastic and is the cumulation of great graphic design and excellent printing!

Thanks to you for all your help which has been more than just doing the basic job.

Jeff - 4/12/23

Thanks also for all the hard work on the split delivery this week. They look great and I know you guys worked so hard to make that happen at your end.

Daniel - 22/11/23

Wow! Thank you for the amazing service! Got my order and the customer service and updates etc. Were all very much appreciated Love them.

Sophie - 21/11/23

Just wanted to send a huge thank you for all your quoting, recommendations, advice and assistance always – I know I throw you a few curve balls sometimes!

Thanks for the quick turnaround, high quality print and professional service.

Leeanne - 21/11/23

Calendars arrived safely yesterday. I wanted to just say thank you for such a seamless process.

The quality of the product is fantastic. I will definitely be recommending hero print!

Tim - 17/11/23

OF OUR NEW CLIENTS ARE REFERRALS YOU CAN SEE WHY...

AUSTRALIA’S BEST TRADE PRINTER

Innovation and collaboration: keys to the future

In March, more than 1250 industry professionals from 37 countries, including Australia, attended Dscoop’s annual event, Dscoop Edge Indy, in Indianapolis, the proclaimed home of racing, with the flagship event recording its highest number of attendees for the event post-pandemic.

With the theme, ‘fuel your future’, HP kicked off the three-day event unveiling its latest lineup of HP digital printing presses and intelligent solutions for the commercial printing and labels and packaging industries.

The pre-drupa portfolio reveal included two new generation B2 presses, the HP Indigo 120K Digital Press and the HP Indigo 18K Digital Press, in addition to the HP Indigo 7K Secure Digital Press and innovations across the intelligent production floor.

Speaking at Dscoop, Noam Zilbershtain, VP and GM, HP Indigo and Scitex, said the “portfolio defines the industry standard for automation and sustainability”, reflecting HP’s vision for the print production floor.

HP’s reveal was part of a 96,000 squarefoot education and exhibition area that was centred on collaboration and innovation, showcasing 70 Dscoop partners. Peter van Teeseling, Dscoop’s executive director, said the ever-increasing Dscoop community is a “testament to the partnerships and idea-sharing of members across the world”.

Homegrown innovation was also recognised, with Australian print technology company DFLOW named as the software system partner of the Dscoop Distributed Print Exchange platform, which aims to streamline the outsourcing of digital jobs to other members of the

Claire Hibbit

Claire Hibbit

Dscoop community. This issue of ProPack.Pro highlights the innovations showcased, learnings shared, as well as the key trends to watch in the labels and packaging market from Dscoop Edge Indy. Read our in-depth coverage of the event from page 30.

Also in this edition, read why Indigo founder Benny Landa and HP global executive Markus Weiss believe digital printing won’t ever kill offset, and we share what the market can expect from some of the industry’s leading brands including Hybrid Software, Canon, Miraclon, Bobst, Kongsberg, and Zünd after recently attending pre-drupa press conferences in Dusseldorf ahead of next month’s event. And finally, read how linerless labels are reshaping the landscape of packaging and labelling.

ProPack Industry Supporters

www.propack.pro EDITOR’S LETTER Stay informed… visit www.propack.pro and subscribe to receive the latest packaging industry news and views

Claire Hibbit Managing Editor 4 ProPack.pro April 2024 ProPack.pro is published by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication. Managing Director & Publisher: James Wells Editor: Claire Hibbit News Editor: Melissa Parker Production Manager: Jacqui Cooper Pre-Press Manager: Tony Willson Design: Sarah Vella Printed by: Hero Print, Alexandria, NSW 2015 Mailed by: D&D Mailing Services DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2024 — Charted Media Group Pty Ltd ProPack.pro National Sales Manager Carmen Ciappara +61 2 410 582 450 carmen@proprint.com.au

IN THIS ISSUE...

COVER STORY:

Durst Oceania launches

Vanguard in Australia P18

Durst Oceania has launched the entire range of Vanguard products in Australia and New Zealand.

Hybrid Software to launch MyPACKZ at drupa P22

Hybrid Software will launch MyPACKZ cloudbased software at drupa – complementing the existing MyCLOUDFLOW.

Miraclon to bring modern flexo to packaging printers at drupa P24

At drupa, Miraclon will focus on communicating the benefits of “gamechanging” modern flexo to packaging printers.

Zünd to unveil new cutting solutions to improve efficiency at drupa P26

Zünd will showcase new cutting tables and innovative UnderCam technology to improve efficiency at drupa in Düsseldorf.

Photo gallery: Highlights from APPEX 2024 P28

Highlights from the recent Australasian Processing and Packaging Expo (APPEX) at the Melbourne Convention and Exhibition Centre.

Dscoop Edge Indy ‘fuels the future’ P30

This year’s Dscoop Edgy Indy brought together more than 1200 delegates from 37 countries to explore the latest industry trends.

THIS ISSUE SUPPORTED BY

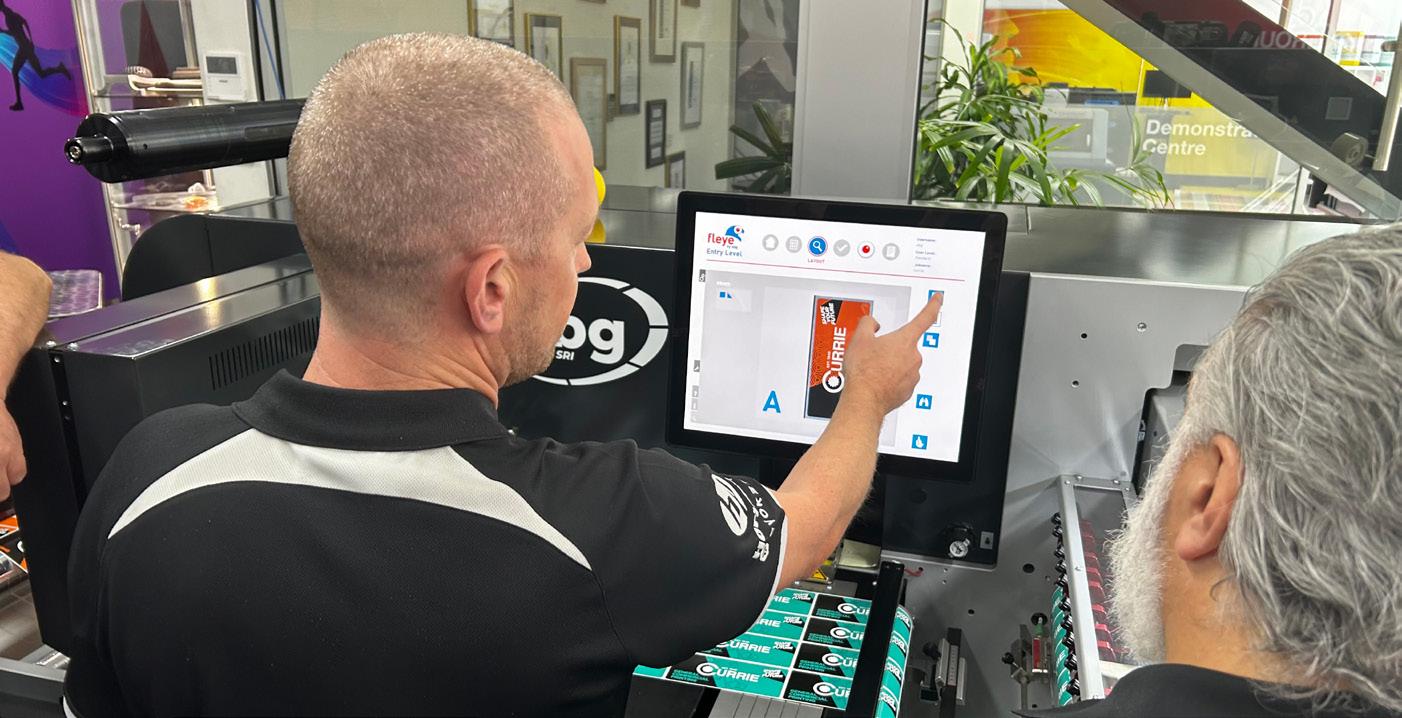

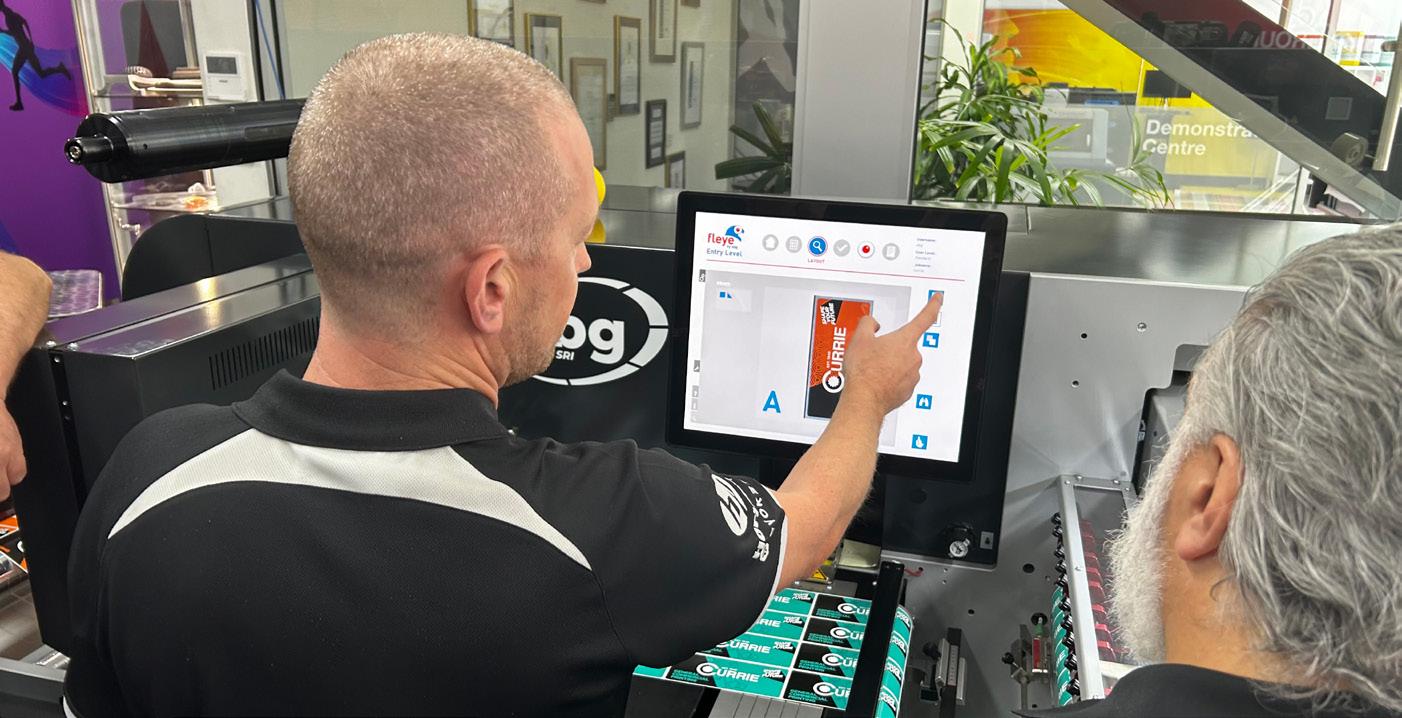

A B Graphic International visit further strengthens ties with ANZ customers P36

ABG By Appointment events at Currie Group’s Melbourne headquarters delivered expert insights to the fully subscribed sessions.

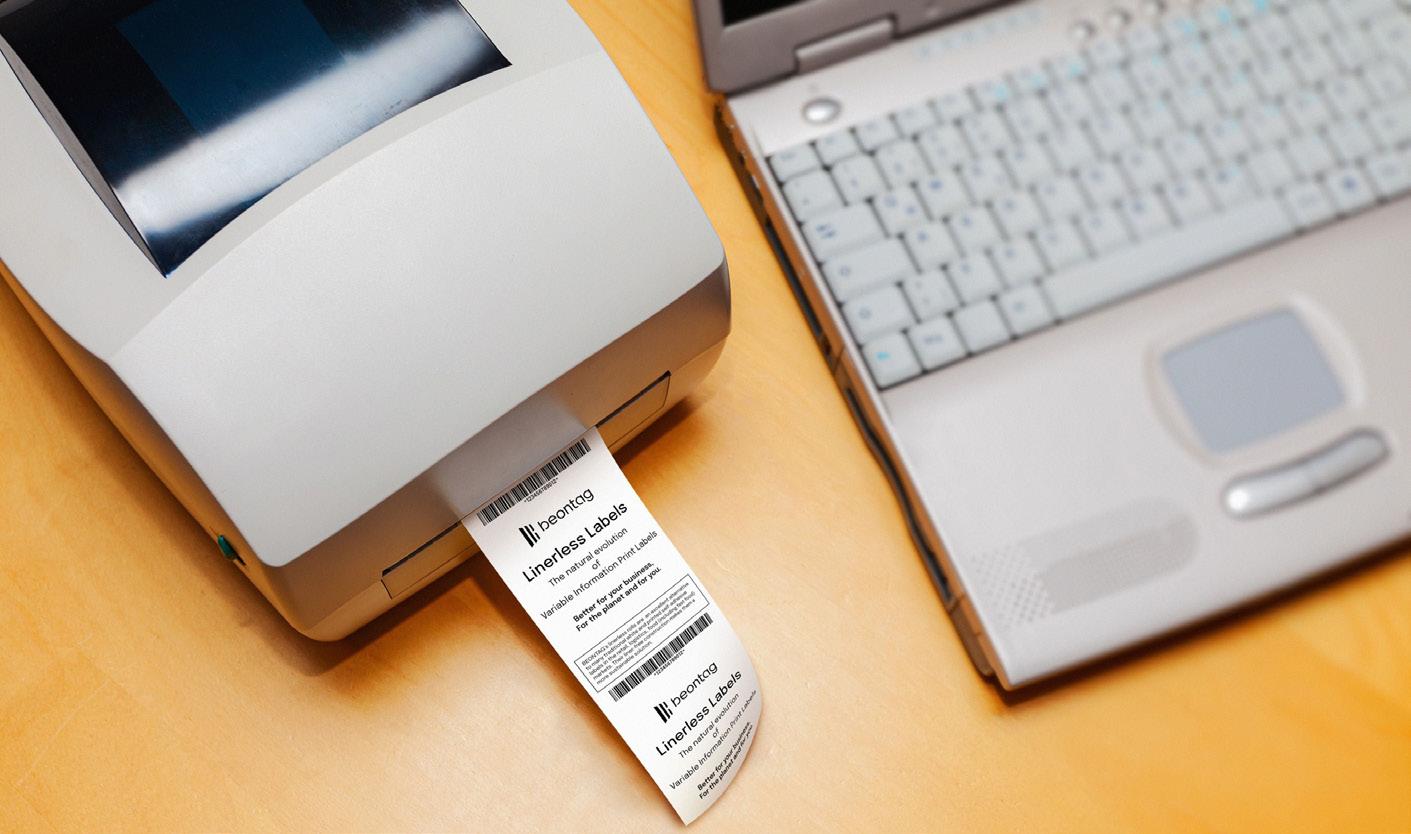

Linerless is more: Embracing a linerless label future P42

From reducing waste to streamlining labelling processes, linerless labels are reshaping the landscape of packaging and labelling.

Pack diary P46

A guide to upcoming events globally.

www.propack.pro

CONTENTS

P30 P42 P18 April 2024 ProPack.pro 5

Durst and OMET announce KJet to be launched at drupa

Durst has announced the next stage of the relationship with OMET – the KJet – will be launched at drupa.

The launch of the KJet follows an announcement at Labelexpo in Brussels extending the hybrid development partnership between the two organisations beyond the XJet platform.

Durst sales director for labels and packaging, Thomas Macina, revealed the KJet will be the next product to be launched from the OMET partnership.

“The combination of digital with flexo offers an innovative hybrid solution that maximises productivity and flexibility, enabling printers to select between flexo or digital printing, thereby optimising efficiency and reducing costs while meeting evolving market demands such as personalisation and just-in-time deliveries in a single-pass,” Macina said.

HP and Landa predict digital printing won’t ever kill offset

Indigo founder Benny Landa and HP global executive Markus Weiss, have both predicted that digital printing will complement offset printing, and may not ever replace it.

The claims were made over two consecutives, yet separate, hour-long presentations on separate days during the pre-drupa press conference at Messe Düsseldorf in Germany by Indigo founder and current owner of Landa Digital Printing, Benny Landa, and HP General Manager of Industrial Print for EMEA, Markus Weiss.

In their presentations, Landa and Weiss both shared their future predictions for the ongoing digital vs analogue debate in the printing industry and despite both executives confirming they are continuing to focus on improving the speed and quality of their digital presses, they also believe that offset analogue printing technology will always have a place in a ‘hybrid’ environment.

In his presentation, Benny Landa announced two new machines with the ability to print over 11,200 sheets per hour which rivals the speed of offset printing.

“We have been leading the inkjet label printing market for many years and we provide solutions for all label converters around the world, starting with entry level solutions up to industrial needs with 100 metres per minute and 510 millimetres wide,” Macina said.

“We have been observing a clear market trend towards end-to-end production and

But rather than labelling the machine as an ‘offset killer’, Landa was more relaxed about the supposed ‘war’ between the two formats, and he believes both formats can live harmoniously.

“I think offset will be around for a very long time, and perhaps forever,” Landa told Propack in an exclusive interview.

“If you do an offset set up once and you create a printing plate once and your information doesn’t change – it can produce one million or two million or even three million times – in this instance there is no justification for a digital product. Offset will be the ‘niche’ in the future because the

this is why we’ve reinforced our partnership with OMET. At drupa, you will see we are launching a new machine – the KJet – which is the perfect combination of a dual-servo cylinder based flexo unit combined with the robustness, efficiency, and productivity of the Durst RSCi digital print engine. This provides a new experience to operators in terms of simplicity, minimal set-up time and low waste.”

Durst Oceania managing director, Matt Ashman, said he is looking forward to showing Australian and New Zealand converters the latest developments from the hybrid strategy at drupa.

“To have this OMET Hybrid solution with a Durst RSCi as its digital core is really the perfect solution for the busy label converter as they benefit from all of the advantages of our digital expertise as well as OMET’s analogue expertise. On behalf of Durst Oceania, we are very proud to be selling this solution.

“This is really beyond your standard label press,” said Ashman.

“It is customised to the needs of the converter, and it is a perfect synergy. We see the alliance with OMET as the best of both worlds. There is no need to invent everything by ourselves. We are the digital experts – this is where we are coming from and this is where we are going,” he said.

mainstream market now requires much shorter runs and variable information. Long jobs of the same image – that will be the niche and that’s where offset will continue to be strong,” Landa said.

“We have customers that have removed offset presses and installed our presses instead, but what happens is, not only do they become more profitable by using our press, but their offset press also becomes more profitable as well. This is because they have moved everything under 10,000 to our press and the offset press becomes much more reliable and profitable because there are now fewer changeovers and less wasted work.”

In his presentation, HP’s Weiss said he believes there will be a hybrid environment in the future where digital and offset operate in a complementary environment.

“When we envision the future – we would like to see an HP press next to every offset press. We see this hybrid environment as the future environment as customers need that. Customers require flexibility and they are likely to always need analogue printing. Of course, we are continuously improving the breakeven point, but let’s be realistic, we will not improve this breakeven point in the next four to five years to a level where you will completely replace offset or analogue technology. I am a very realistic person and not a dreamer, even though I work for a digital printing company. Hybrid production for me is definitely not just the future, it is starting now, and we have seen this very clearly in the market.”

Matt Ashman (Durst Oceania) and Claudio Piretta (OMET)

www.propack.pro 6 ProPack.pro April 2024 NEWS

Markus Weiss (HP) and Benny Landa (Landa Digital Printing)

The Jet Press FP790 digital press could be considered to be three presses in one, able to:

•Print digitally, with all the benefits of digital production

•Print mainstream flexo jobs

•Print rotogravure quality jobs

FUJIFILM and FUJIFILM Value for Innovation are trademarks of FUJIFILM Corporation. ©2024 FUJIFILM Corporation. All rights reserved.

discover more, scan below:

Jet Press FP790

To

Canon to become major player in corrugated and folding carton markets

Canon has announced plans to become a major player in the labels and packaging category announcing a strategy in the corrugated and folding carton markets.

In an announcement made at the pre-drupa global press conference held at Messe Düsseldorf, Canon confirmed its commitment to become “a significant, trusted partner to the label and packaging markets, and show a new digital press and product concepts that confirm its clear progress towards that goal. Indicating the importance of labels and packaging as strategic areas for growth, a dedicated zone on the Canon stand will feature live production of label, corrugated and folding carton applications”.

“As evidence of its commitment to expand into the corrugated printing market, Canon will introduce its concept for a sheetfed single-pass, industrial-scale digital corrugated press, targeting corrugated packaging converters and designed to combine offset-like print quality at a 1.7 m

CMYKhub sets up Amazon-like model with Graph-Pak’s Boxway Fitsize 2500

CMYKhub has furthered its business capability with its purchase of Graph-Pak’s Boxway Fitsize 2500, setting up an ‘Amazonlike’ business model.

The Boxway Fitsize 2500 produces customsize corrugated boxes. It allows CMYKhub to produce boxes when required, reducing box warehouse management by producing fitsized boxes at the touch of a screen.

“The Boxway FitSize 2500 is the way of the future for on-demand boxes. Companies can no longer afford to have tons and tons of pre-

Canon has announced the development of an unnamed sheetfed single-pass digital corrugated press

print width, productivity of up to 8,000 sqm/ hr and new levels of cost-efficiency. A 3D model, print samples and technology animations of the system will be shown on the stand at drupa,” the company said. “Visitors interested in digital printing on corrugated can see live production of packaging prototypes and short-run promotional packaging on Canon’s large format Arizona and Colorado printers. For packaging converters and print service providers, these solutions enable personalised, short-run, on-demand packaging production. The new Arizona 2380XTF FLXflow technology flatbed printer – also on display at drupa – will print a variety of display and packaging applications on a wide range of media.

“A UVgel Print Factory, comprising a Colorado M-series roll-to-roll printer and a Fotoba Jumbo Roll JRL 170 feeder and JRR 170 Rewinder, will be shown printing on a liner material for later lamination to a corrugated base to create a high-quality printed package, as a digital alternative to conventional litho lamination. Replicating the litho lamination process with digitally printed liner material offers short-run, highquality packaging that can be personalised or versioned, while the durability of UVgel prints means that additional top coat lamination is

purchased boxes sitting around on racks in a warehouse,” said Tom Ralph, MD Graph-Pak.

Ralph said a minimum order might be 2000 boxes, which ties up cash flow. He said with this product, people can enter a few numbers into a machine and out comes the box.

“The reinforced corners eliminate the need for other substrates and result in less damage. This machine is ideal for companies replicating the Amazon model of just-in-time shipping and is very affordable at around $160,000.

“It has many features available, including a

not always necessary. With the FLXfinish+ technology’s ability to achieve matte or gloss finish in one print without changing ink or media, customers can achieve a premium look and feel without any extra cost to the print service provider.

Since its acquisition of Edale in 2022, Canon has also started to establish a presence in the folding carton market. At drupa, an inline folding carton production process will be shown.

Folding carton print samples digitally printed on Canon presses, such as the toner-based imagePRESS V1350 and the varioPRINT iX3200 sheetfed inkjet press, will also be available on the stand.

Further demonstrating its intention to become a key supplier to the packaging market, Canon will provide its outlook on industrial-scale, digital sheetfed folding carton production, targeting converters who are interested in exploring the benefits of digital print.

Canon will also show the new LabelStream LS2000 digital label press, the first public preview outside Japan. Available in the EMEA region in 2025, the device prints CMYK plus white on self-adhesive substrates, with a new ink set designed to comply with food safety standards.

weigh scale, integrated printer, and automatic labeller—it can even scan a barcode and call a courier when the job is done.”

Alan Nankervis from CMYKhub said the team was excited about the positive impact the Boxway Fitsize 2500 will have on the business.

“Adding a box maker gives us more flexibility to package our print more safely and more efficiently. This eliminates wasted space and prevents damage in freight which has been a bit of an issue for us over the last few years.”

Nankervis said the Boxway FitSize 2500 will be an important piece of machinery for the company.

“We will install this into our wide format facility at Preston. Hopefully this is first of a few purchases and we can add more of these around the country.”

Ralph said Boxway FitSize 2500 is the way of the future for on-demand boxes.

“Companies can no longer afford to have tons of pre-purchased boxes sitting around on racks in a warehouse. A minimum order might be 2000 boxes and it ties up cashflow. With this product, people can enter a few numbers into a machine and out comes the box.”

www.propack.pro 8 ProPack.pro April 2024 NEWS

Tom Ralph (Graph-Pak) and Dayne Nankervis (CMKYhub)

Intelligent Finishing Solutions by Jet Technologies

Delivering a new level of Innovation, Performance & Reliability, the range from Polly Automatics is impressive, with a price you will appreciate. Explore

Jet Technologies is pleased to introduce a new option for finishing in the Australian and NZ print markets.

Slitter/Rewinder/Inspection

Die cutting & Sheeting

IML converting

Shrink Sleeve Seaming

Digital Print Finishing (inc. digital embellishments)

For more information, please contact us here or scan the QR Code

02 8399 4999 / dreece@jet-ap.com

David Reece

the world of Jet iQ intelligent finishing solutions

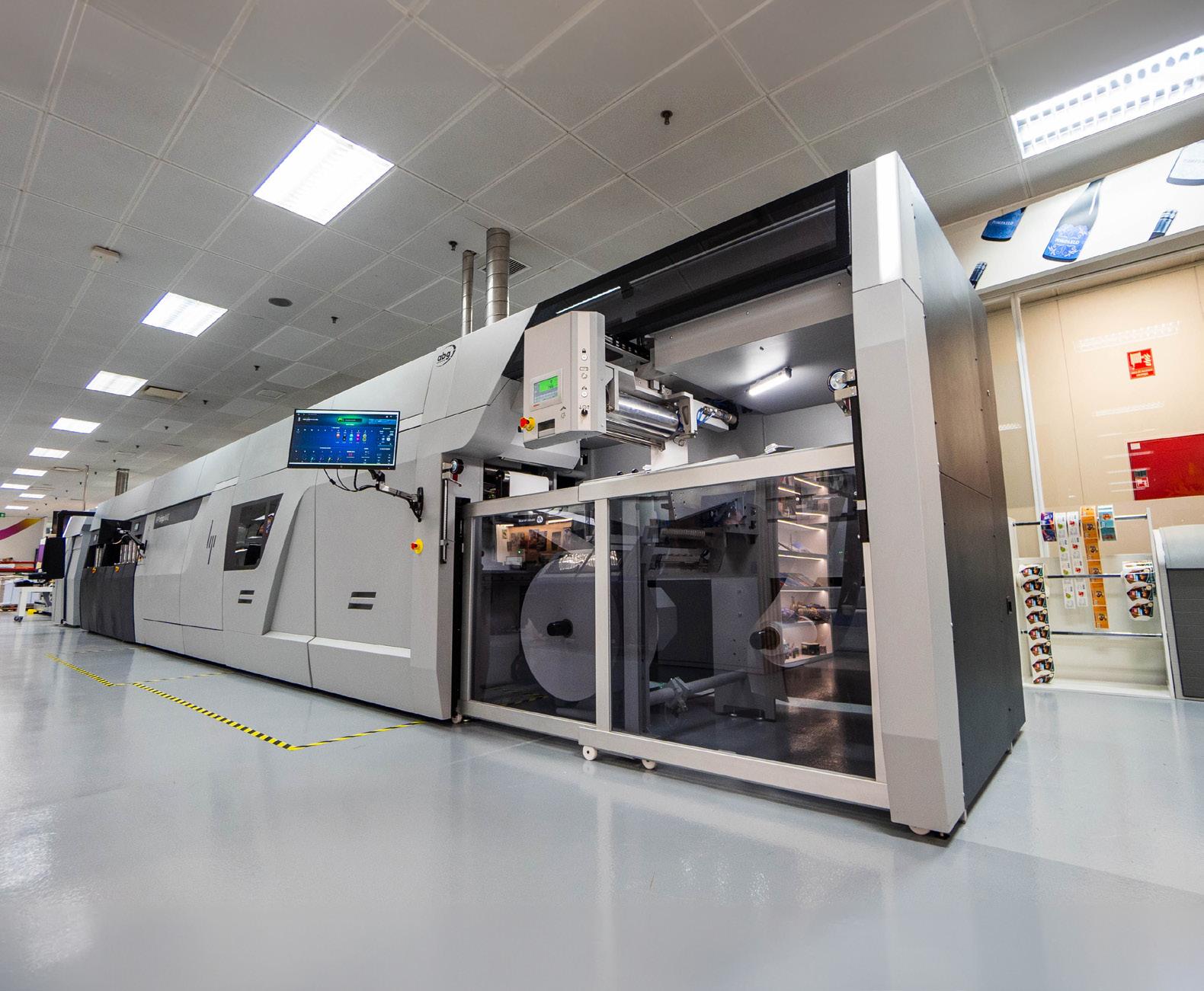

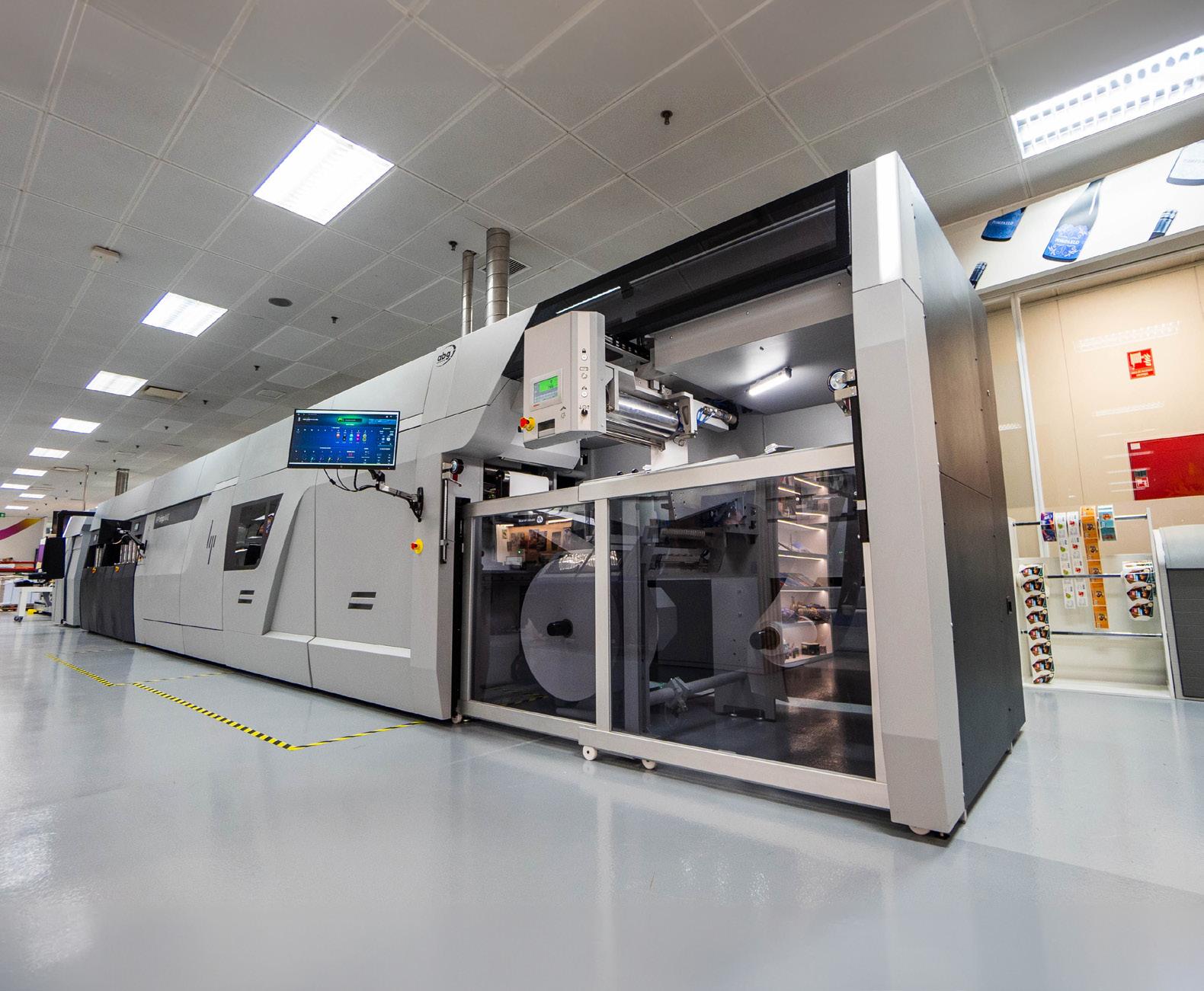

ABG and HP collaboration stimulates industry investment

The longstanding partnership between A B Graphic International (ABG) and HP continues to flourish. The recent integration of innovative nonstop winding (NSW) technology into HP’s flagship, the HP Indigo V12 Digital Press has attracted investment from leading label manufacturers, including All4Labels, Brook + Whittle, and Eshuis, who are all implementing the technology to enhance their printing and converting operations.

To build on this success ABG and HP have recently installed NSW technology to run in line with the HP Indigo V12 Digital Press at HP’s Graphic Arts Experience in Barcelona, Spain. This addition means that customers can now experience firsthand the efficiencies that combining the HP Indigo V12 Digital Press with NSW technology can generate. A further installation at the HP Center in Atlanta will follow later in 2024.

Currie Group is the distributor of both ABG and HP Indigo in Australia and New Zealand.

The newly introduced non-stop unwind and rewinding system from ABG is designed to integrate seamlessly with the HP Indigo V12 Digital Press, offering a unified platform that prioritises high productivity with comfort and operator safety. At a running speed of 120 metres per minute, it sets a new standard in performance. A standout feature of this system is its unparalleled tension control, ensuring reliability for a wide range of applications.

Elad Zmora, HP Indigo labels product manager, said: “The HP Indigo V12 Digital Press prints over 7000 metres an hour and requires 2-3 media rolls. Replacing the time-consuming manual operation of changing, unwinding and rewinding, ABG’s NSW solution increases press productivity by 10-20 minutes per hour, bringing digital value to every job.”

Matt Burton, ABG’s global sales director, said: “Key to ABG’s leadership in the print finishing market is our ability to evolve with the market. The addition of ABG’s NSW technology enables label printers to maximise the potential of the HP Indigo V12 Digital Press, reinforcing our commitment to delivering cutting-edge solutions and helping the transition to digital.”

NEWS www.propack.pro 10 ProPack.pro April 2024

Non-Stop Unwind Non-Stop Rewind

Highcon unveils drupa digital die cutting solutions innovations

Ahead of drupa, Highcon has launched a number of die cutting solutions innovations for the folding carton and corrugated packaging categories.

In Australia, Highcon is distributed by Kissel+Wolf.

In the folding carton category, the Highcon Beam 3 has been developed to digitally die-cut 10 folding carton jobs per shift with an average run length of 1000 sheets per shift.

“The Highcon Beam 3 is our gamechanging solution for digital die-cutting of folding cartons and micro-flute. This system offers a 50 per cent increase in productivity compared to the current solution, the Beam 2, when combined with the optional Beam Writer or about 25 per cent without it,” said Highcon CEO Shlomo Nimrodi at a pre-drupa press conference held at Messe Düsseldorf.

“The Beam 3 offers higher quality and workflow improvements and is incredibly user-friendly. Converters can now handle up to 10 jobs per shift, with an average run length of 1000 sheets, and achieve a rapid ROI of under two years.”

Highcon also announced a new product in development – The Vulcan – a next generation system for the corrugated packaging and display category with a 1.4 x 1.7m sheet size and can support boards up to 5mm, delivering the full

benefits of digital die cutting to mainstream corrugated production.

Highcon sees The Vulcan as addressing a painful gap in the current solutions available in the market. Vulcan will combine true physical creasing with laser cutting, and will have a maximum throughput of 3000 full-size per hour or up to 7000 sqm/hr. It will have a job changeover time of 5-10 minutes.

At drupa, Highcon will showcase its customers and their work as well as Highcon’s new solution portfolio, together with samples from the Vulcan prototype.

“In this challenging environment, Highcon’s customers are successfully using ‘the right tool for the right job’ to optimise their plant productivity, overcome capacity limitations, improve agility, costeffectiveness and efficiency, and better serve their customers – all while maximising their return on investment,” said Nimrodi.

“Inspired by our amazing customers, their feedback and how they’re using our solutions today – as well as inputs that we’ve received over several years –Highcon will be demonstrating how digital die cutting is becoming mainstream. The time to die cut digitally has arrived.”

Bruce Caldwell, sales manager ANZ for fibre-based packaging – Sign and Display at Kissel + Wolf Australia, was very excited about the Highcon announcements ahead of drupa next month.

“As the newly and proudly appointed distributor of Highcon Systems in Australia and New Zealand we are delighted but not surprised by the latest updates from Highcon,” Caldwell told ProPack.Pro.

“Highcon have always been at the forefront in the development of digital die-cutting technologies and solutions and have led the way in demonstrating the many benefits to converters worldwide. Their ability to listen and consult with customers is one of the key strengths in their product development.

“They focus on their customers’ challenges and needs and have an unmatched commitment to finding and delivering the solution. One of the key questions I am asked regularly is ‘what is the next big thing in digital?’ Well, at the top of the list is Highcon digital die-cutting systems. At times quotes can be overstated however the new technologies being launched at drupa really are a game changer,” Caldwell said.

Jamie Weller, managing director at Kissel + Wolf Australia, said Highcon is the leader in digital die cutting and with the announcement of the new solutions, they are going mainstream, addressing many of the challenges converters have.

“We at Kissel + Wolf Australia are excited to help converters transform into an agile finishing workflow. Allowing them to deliver their finished products faster, accurately and in a more sustainable way.”

www.propack.pro 12 ProPack.pro April 2024

NEWS

Highcon Beam 3

Highcon Vulcan

Highcon Vulcan applications

72 Grady Crescent, Erskine Park, NSW, 2759 Call us toll free: 1300 885 550 | www.graph-pak.com.au Supplier Profile Specialising in capital equipment sales, service, engineering solutions and consumables We offer a diverse selection of pre-owned equipment that is available for purchase. We also buy used equipment. and also sold to CMYKHub. As SEEN at Scan Here See BoxWay Fitsize 2500 in action

Kongsberg to show new robotics and digital cutting technology at drupa

Kongsberg Precision Cutting Systems (Kongsberg PCS) will demonstrate its new top-end cutting table and robotic handling system at drupa 2024.

According to Kongsberg PCS Vice President of EMEA and APAC, David Preskett, the game-changing new Kongsberg Ultimate will be viewed at an exhibition for the first time at drupa 2024 as well as a new sevenaxis robot cell that allows customers to increase throughput utilizing multiple pallets and multiple cutting systems, a further step towards ‘lights-out’ automation.

“This is our first drupa as a standalone business,” said David Preskett, Kongsberg PCS vice president of EMEA and APAC.

“We are incredibly proud of the significant advances we have made recently, and we are excited to showcase our very latest innovations. As well as having a first opportunity to see our new Kongsberg Ultimate that is transforming corrugated production, drupa visitors will also be the first to learn about our incredible new seven-axis, rail-mounted Robotic Material Handler (RMH) system. Seven axes provide significantly greater reach and flexibility, increasing the freedom to design the layout of a production cell to match customer needs. Multiple loading and unloading points can be located with greater flexibility within the cell and nested close to the cutting systems, and as the system is also modular it can grow to meet the evolving needs of a business.

“We are excited to demonstrate at drupa how both our market-leading Kongsberg cutting tables and MultiCam CNC solutions boost throughput, streamline production through automation and deliver optimum results – and all while maximizing sustainable production, user experience and safety,” he said.

“An array of innovative designs and samples made from a variety of materials will highlight the creative freedom that packaging, and sign and display manufacturers enjoy with Kongsberg PCS machines, while our latest technological advances in automation underline how we are committed to tackling the major pain point faced by businesses today –maximising throughput without compromising quality or creativity.”

Preskett said it was this customer-centric approach that made the launch of the new

Kongsberg Ultimate such a game changer for the corrugated production industry, adding it was exciting to have a large platform like drupa to demonstrate how this next generation Kongsberg technology redefines expectations.

“Through our customer centric research, exclusive preview events and feedback sessions during development, testing and beyond, we work closely with our customers and partners to ensure they benefit from maximum return on their investment in Kongsberg PCS technology,” Preskett said.

“It is important to us that we develop solutions that not only give our customers

the creative freedom they need to achieve their specific goals, but that also deliver the very best user experience while ensuring maximum operator safety. Likewise, using recycled materials in the manufacturing and assembly process, and incorporating materials that have less impact on the environment also demonstrates our focus on a sustainable, efficient, and forwardthinking approach to production. The Kongsberg Ultimate achieves all this, setting an incredible new benchmark in productivity and innovation.”

Speaking about the latest developments in automation on show at drupa 2024, Preskett said: “We are looking forward to demonstrating how we are harnessing the latest technology to enable businesses to unlock their potential, supercharge productivity and to maximize their return on investment. We will be giving a first look at our new generation seven-axis robot cell, with its innovative rail mounting and improved interfacing that delivers complete unattended production for a fully automated process, further maximising efficiency.”

“Our commitment to quality, productivity and efficiency is reinforced with the power and capabilities of our impressive MultiCam Apex3R CNC router, which sets the standard in routing with its perfect balance between performance and precision,” said Preskett.

“Already massively popular in the USA, drupa visitors will have the opportunity to see the impressive CNC router in action as we now increase its distribution across EMEA and APAC.”

The flagship in the MultiCam range of advanced routing and CNC cutting systems, the Apex3R is one of the most versatile CNC routers on the market. Its combination of power, flexibility and an extensive selection of innovative tools make handling materials such as metals, rubber, foam and textiles simple.

Summarising the company’s plans for drupa 2024, Preskett concluded: “We are more driven than ever to provide the innovative solutions that packaging, sign and display manufacturers need to meet today’s ever-changing demands, and those of tomorrow. With our new technology and a commitment to addressing customer pain points, we cannot wait to show our innovations at drupa.”

www.propack.pro 14 ProPack.pro April 2024

NEWS

David Preskett, Kongsberg PCS vice president of EMEA and APAC.

Kongsberg Ultimate with robotics

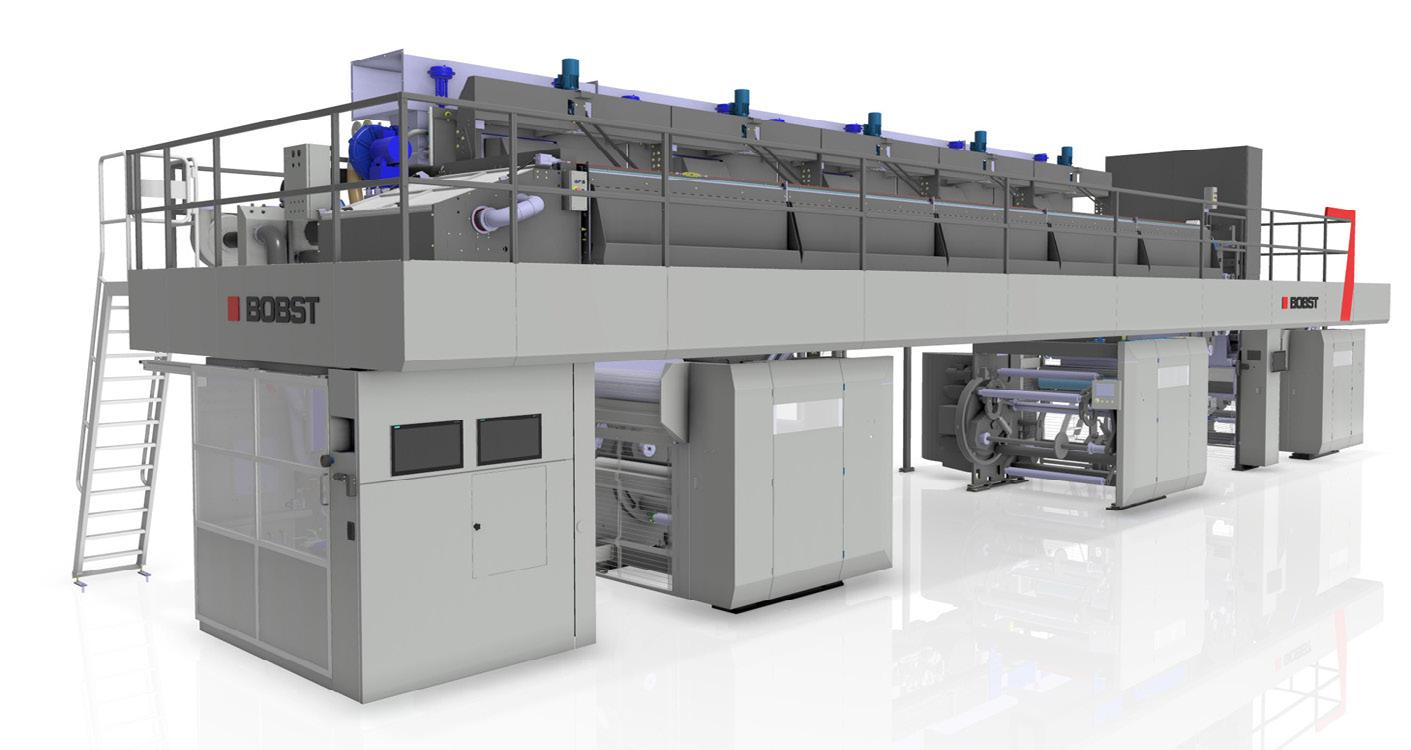

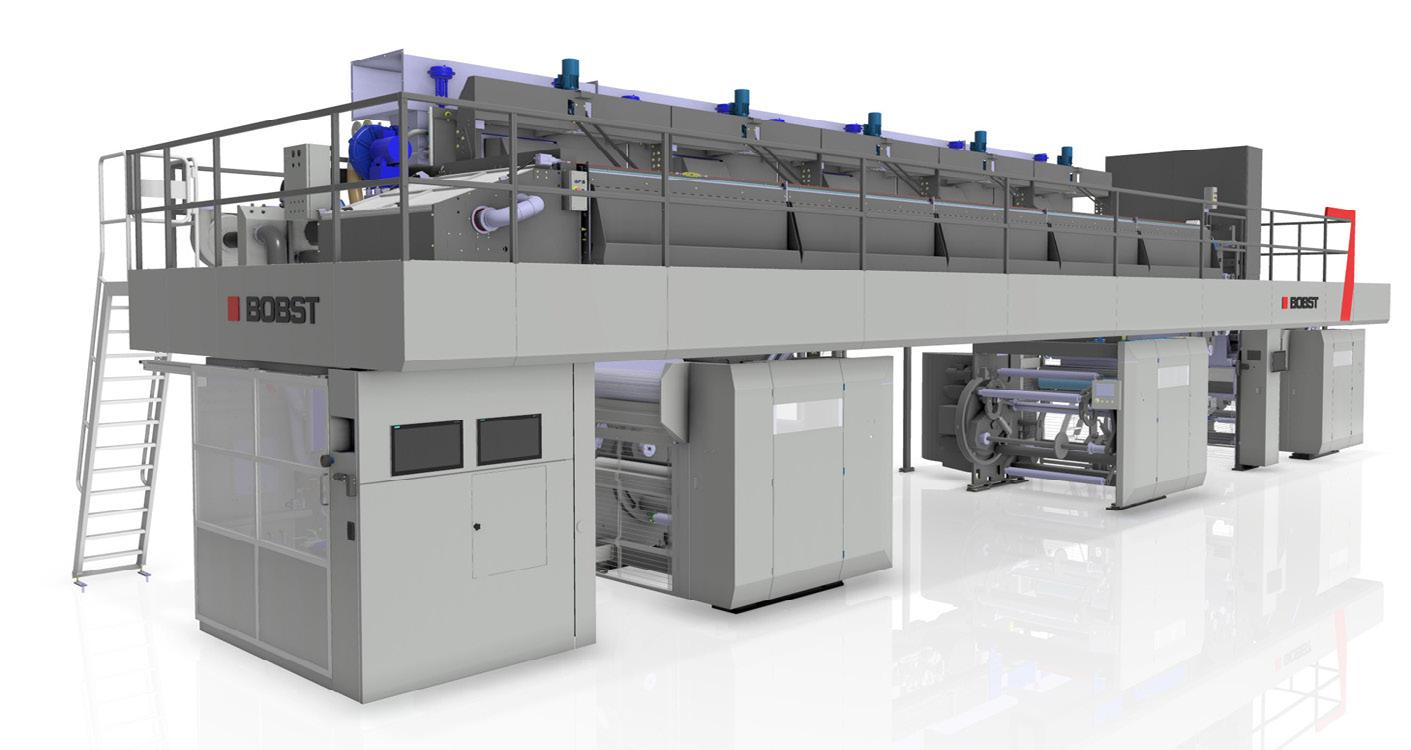

Bobst unveils innovations on the road to drupa 2024

Bobst has confirmed the products to be released at drupa 2024 across flexible packaging, labels, folding carton, corrugated board, and services.

Bobst CEO Jean-Pascal Bobst told more than 70 journalists at the pre-drupa press conference at Messe Düsseldorf that the company is looking to help its customers to thrive in the current and future packaging environment.

“We have made great progress with our vision to shape the future of the packaging world based on the pillars of connectivity, digitalisation, automation, and sustainability,” Bobst said.

“Now, with an extensive portfolio of solutions that answer our clients’ needs, we can tailor our offering to them based on their evolving requirements over the years to come. Our latest solutions announced today, embed machines and software with the aim to increase performance, complementing our global offering beyond machine operation, helping us all to build towards a more connected and sustainable future.”

New equipment and increased productivity through Bobst Connect

Bobst has announced the launch of two major new features for Bobst Connect, the company’s constantly evolving, cloudbased digital platform, which improves productivity. Workflow with Job and Recipe Management empowers customers to seamlessly integrate Bobst machines in their production and design workflows and benefit from bi-directional job and

recipe data synchronisation for fast set up and increased productivity.

The Energy Monitoring feature allows customers to measure their energy consumption and costs in real time. By collecting data across various jobs, settings, and connected machines, and together with our industry leading Workflow and Automation Partners, we help our customers to drive efficiency improvements and cost savings.

Reinforcing its credentials as a strategic partner, the company has also announced to develop Bobst Application Management across the four industries, a hands-on innovative consulting service focusing on workflow automation, colour and process optimisation, end-to-end converting improvements as well as regulatory compliance, addressing the needs of converters and brand owners.

Meanwhile, Bobst’s commitment to sustainability – both for its own operations and helping its customers to achieve their sustainability goals – is reflected across multiple streams and in all the new solutions announced today.

The company has stated that all new machines purchased in 2024 will benefit from at least between 10 per cent and 20 per cent efficiency and productivity improvements, from reductions in waste, substrate, and energy usage.

Below are the newly announced highlights from each industry sector to be featured at drupa 2024.

Flexible packaging

In the flexible packaging industry BOBST can help customers to innovate for a sustainable future.

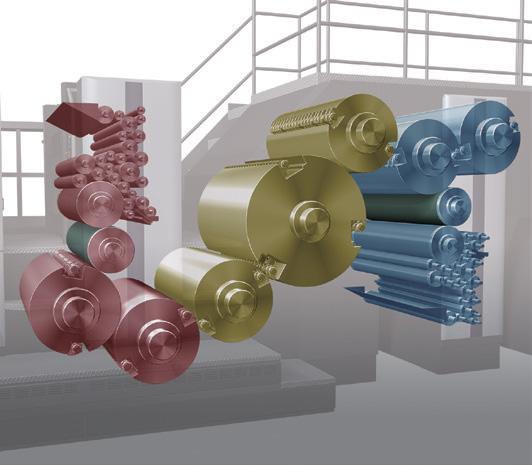

• New machine with new elements of digitalisation and automation: smartGRAVURE revolutionises the gravure printing process with elements of automation and digitalisation. This innovation will help to overcome the important set-up time and tuning

www.propack.pro 16 ProPack.pro April 2024

NEWS

Jean-Pascal Bobst CEO Bobst Group

Bobst EXPERTCUT 106 PER

required with gravure printing, which require high level operator skills. With automated colour management, digitalised set up and controls, and connectivity with BOBST Connect, smartGRAVURE will increase productivity and output consistency, reduce downtime and complexity, and offer considerable sustainability benefits.

• New Bobst intelligent Metallizing Assistant: The BOBST AI driven intelligent Metallizing Assistant represents a breakthrough in machine integrated process expertise for vacuum metallizing. BOBST intelligent Metallizing Assistant supports the machine operator by automating the deposition process, resulting in more output and consistency of the end product, and ensuring that customers always have the best operator on their machine.

• New machine with new elements of digitalisation: EXPERTLAM 900 is a multi-technology coater and laminator, which is configurable in different forms, making it highly flexible both as both a laminator and a coater.

Labels

In the labels industry, Bobst can help customers to simplify label production.

• Closed loop workflow from PDF to TWIN PDF: Bobst is taking connectivity and digitalisation to the next level by providing new solutions supporting closed-loop workflow ecosystem from pdf to twin pdf to boost productivity, ease of use and sustainability. The features will allow label converters to accelerate job preparation, with faster job completion less dependent on operator skills, and with a more connected production floor, thanks to a range of new Bobst Connect and pre-press features. More details to be announced at drupa 2024.

• OneECG – advanced colour consistency between flexo and digital: Bobst has optimised its workflow leveraging

oneECG, enabling digitalization of colour information to reach the highest colour consistency between digital and flexo. Customers can easily allocate orders to the most suitable technology, optimizing machine utilisation and profitability while reducing waste and increasing overall output.

• oneBarrier / FibreCycle on UV in-line flexo presses: Following the success of the oneBARRIER sustainable solutions developed by Bobst together with industry leading partners and first introduced on BOBST wide-web machines, converters with UV-based inline flexo machines can now experience all the benefits of oneBarrier substrates – dedicated to the production of high-barrier and recyclable applications – on narrowmid-web solutions.

Folding carton

In the folding carton industry, Bobst is empowering zero fault packaging.

• New machine with new elements of digitalisation: EXPERTCUT 106 PER: New generation die-cutter, which increases performance up to 20 per cent with increased throughput and positive sustainability impact. The EXPERTCUT 106 comes equipped with breakthrough new functions such as the ACCUPLATEN – a new system that will drastically reduce the patching effort during setting and increased running speed.

• TooLink on folder-gluers: TooLink brings converting into the digital world. It is a platform that connects machines and tooling and brings together the entire converting process to transform production flexibility, job turnaround times, and overall productivity. Soon available on foldergluers, TooLink will simplify and shorten the changeover by automating recipe management. In addition, it will check the quality of tools and ensure the quality of production.

Corrugated board

In the corrugated board industry, BOBST can help customers to boost end-to-end efficiency.

• Robotic solutions: An important milestone in bringing our vision to reality, BOBST now offers a wide range of robotic solutions for both loading and palletising, which will allow configuration of complete and seamless production lines for our customers.

• New machine FFG (flexo folder gluer) portfolio EXTENSION – machines with what matters for RSC (regular slotted carton) converting: Printing (1/2 colors) and die-cutting with flexibility in production, robust design and short set-up time with top printer. New JUMBO, from simple “printer-slotter” up to full line including stitching, taping and inline folder-gluer.

• MASTERFLEX HD+: New generation of the reference flexo printer, for unmatched productivity and highest quality. By incorporating a new feeder, upstream pre-feeder and stacker outlet, the MASTERFLEX HD+ achieves a staggering throughput of 15,000 sheets per hour, covering an impressive area of 53 million square meters per year.

Services and performance

Bobst offers a wide range of services and digital solutions to power performance with expertise and digitalisation. New additions include:

• The new, updated Bobst Connect: Providing digital solutions to prepare, produce, react to, maintain, and optimize the production workflow of a job. BOBST Connect is a one-stop shop for increasing productivity capability at every stage.

• Extended capacity of the EMEA Logistics Hub: Our Genk facility gives us the ability to serve our customers with speed and efficiency. We are extending its capacity by more than 60% this year to increase customer reach, increase service quality, while ensuring that our site meets the highest sustainability certifications.

• Remote Assistance with TeamViewer: Our Remote Assistance service, which includes video with augmented reality support using TeamViewer, allows fast, high-priority remote resolution of electrical and mechanical problems, and reduced downtime. The feature now includes live caption and chat translation.

• Operational Excellence Program: Through our Operational Excellence program, customers get support to drive continuous improvements with our combined data analysis, process expertise and proven consultancy.

www.propack.pro April 2024 ProPack.pro 17 NEWS

Bobst EXPERTLAM 900

Durst Oceania launches Vanguard

Durst Oceania has launched the entire range of Vanguard products in Australia and New Zealand, and has also confirmed its first sale in the region.

The first Vanguard product sold in Australia is the VK300D-HS

Durst Oceania has launched the entire range of Vanguard roll-toroll, flatbed and hybrid products in Australia and New Zealand.

“Durst acquired Vanguard back in 2019 and the Covid pandemic prevented us from launching it earlier into the local market. The benefit of waiting to launch has meant that the brand is now assimilated into the Durst business as well as the hardware and software ecosystem and this is fully backed by the Durst service network,” said Durst Oceania managing director, Matt Ashman.

“There are now over 1000 Vanguard installations globally and the brand continues to grow in the established market of North America as well as exponentially in the European market.

“Printers have been telling us that they are looking for an alternative to the other players in the market. There have been a number of manufacturers that have delivered some great innovation, but unfortunately this was a number of years ago. Now Vanguard is here delivering what Durst is famous for – innovation on a constant rolling basis. We will continue to be focused on what customers need and what customers want.

“Vanguard can deliver amazing quality at incredible speeds, while also providing a

very commercially attractive proposition. Vanguard sits within the Durst range as a more accessible entry point for the aspiring print business and we look forward to welcoming new customers to the ever-growing Durst family.”

“Vanguard is here delivering what Durst is famous for – innovation on a constant rolling basis. We will continue to be focused on what customers need and what customers want.”

– Matt Ashman, managing director, Durst Oceania

“I am pleased to confirm that Dan Mantel has come on board to develop the Vanguard business sector as business development manager and we will be reaching out to work with potential partners as well as existing customers in the near future,” Ashman said.

According to Mantel, there is a clear place in the market for dedicated flatbed printers that complement the remainder of the Durst product portfolio.

“Vanguard printers are known for their quality build and reliability. The good news for Vanguard customers is there are various machines to suit a number of applications. In-field upgrades are available with these machines and additional rows of printing heads can be added to double and even triple the speed without buying a new machine.

“We have plenty of options including a high velocity vacuum table with stronger pumps and additional perforations which enables the customer to work with challenging substrates such as printing single-sided or double-sided corrugated boards.

“There has been a lot of internal information shared within the Durst Group and we have now been able to upgrade the Vanguard platforms to the latest technology including Durst workflow software and Durst analytics,” Mantel said.

Durst Oceania confirms first Vanguard VK300D-HS sold in Australia

Durst Oceania has confirmed the first Vanguard product sold in Australia is the VK300D-HS.

“The VK300D-HS is a part of our 6-time award winning VK300D Series. It is a fully featured printer that has revolutionised

COVER STORY www.propack.pro 18 ProPack.pro April 2024

the industry with a high-speed electro-magnetic drive system that propels the carriage at speeds up to 1.8 metres per second for an incredible speed of up to 317 square metres an hour. These impressive advancements ensure your business will outperform any competitor,” Ashman said.

“The VK300D-HS comes equipped with industrial Kyocera KJ4A print heads that deliver print dots as small as 4 picolitre drop size ensuring tight dot placement for vivid output on virtually any substrate up to 10cm thick.

“Other features include auto height detection, one-touch pin registration, front-to-back and back-to-front printing, liquid cooled LED curing technology, static suppression bars, and reversible vacuum zones. Engineered to grow with your business, the VK300D-HS is available with multiple rows of print heads and can be expanded in the field.”

The new Vanguard VK3220T-HS

The new Vanguard VK3220T-HS ultra-high production UV-LED flatbed, on display at the recent FESPA Print Expo in Amsterdam and launched at Printing United in late 2023, redefines productivity and promises unparalleled quality at incredible speeds with phenomenal productivity.

The VK3220T-HS represents the apex of Vanguard’s evolution. It offers a larger bed size and up to three rows of industrial printheads for maximum productivity, an electro-magnetic carriage drive system for speed and precise drop placement delivering exceptionally high print quality, as well as field-upgradeability for peace of

mind, making this printer the ultimate option for any print service provider.

The new compact and user-friendly 3.2 x 2 metre size offers further throughput potential and enables the printer to operate on an industrial scale.

“Vanguard printers are known for their quality build and reliability. The good news for Vanguard customers is there are various machines to suit a number of applications. In-field upgrades are available and additional rows of printing heads can be added to double and even triple the speed without buying a new machine.”

– Dan Mantel, technical sales, Durst Oceania

Kyocera KJ4A printheads are equipped with variable drop technology and four picolitre drop sizes for remarkable print quality with better colour gradients and smoothing capability.

Vanguard VK 3220T-HS

The printer has been engineered to grow with any business, offering options for single, dual and triple row print heads, with optional white ink and varnish channels that can be added after installation.

The new machine can produce 1,800 dpi print resolution and speeds of up to 360 square metres per hour.

Vanguard global CEO, Jim Peterson said: “The VK3220T-HS is the culmination of years of technological advancements and our response to the demands of the market.

“We are dedicated to delivering the best printers available, and through our innovation and commitment to our customers, we have created the new benchmark for speed and quality, with a focus on productivity and efficiency. The VK3220T-HS symbolises the start of a new chapter for Vanguard globally, and we are so proud to share it with our friends in Australia and New Zealand.”

The VK3220T-HS can print on nearly any substrate up to 10cm thick and is driven by an electro-magnetic drive, ensuring tight dot placement for remarkable print quality and speeds.

Combined with a seven-zone, userselectable vacuum system, this printer ensures efficient hold-down for no unintended media movement and easy transitions between jobs.

Other strategic features include auto height detection, one-touch pin registration, front-to-back and back-tofront printing, water-cooled LED curing technology, and ionization bars.

The VK3220T-HS Ultra-Productive Flatbed UV-LED Printer redefines the meaning of productivity on a 3.2 x 2 metre UV-LED flatbed. With up to three rows of Kyocera printheads, print speeds can reach up to 360 square metres per hour. Utilizing 4 picolitre drop size Kyocera heads and a high-speed magnetic drive, there’s no compromise on speed to achieve remarkable quality. With the ability to print up to 10cm thick, the only limitation is your imagination.

COVER STORY www.propack.pro April 2024 ProPack.pro 19

Vanguard VR6D-HS

The VR6D-HS Flatbed UV-LED Printer is the most advanced 2.5 metre x 1.2 metre flatbed on the market today. It combines the latest state-of-the-art Ricoh Gen 6 print head technology and high-speed magnetic drive unparalleled speed, resolution, and quality.

The VR6D-HS can be configured in a number of ways to fit your needs as your business grows. The option to be field upgradeable with up to 10 heads (5 x 2) rows allows you to expand your capabilities and never slows you down. The VR6D-HS sets a new standard for all UV flatbeds.

Vanguard VR5D-E

The VR5D-E is the most revolutionary flatbed UV-LED printer on the market. It is field upgradeable, with up to 10 print heads in 2 rows (2x5), for increased production. While pricing is entry level, the VR5D-E is an industrial printer engineered for worry-free maintenance and ease of operation. High production workflow at a low operating cost is at your fingertips. The VR5D-E supports CMYK + W + V + Lc + Lm printing while utilizing 7 pL dots for vivid colour output on substrates up to 10cm thick. Other features include auto height detection, one-touch pin registration, front-to-back and back-to-front printing and 4 reversible vacuum zones. The end result is a versatile printer that helps you expand your job applications and grows with your business.

Vanguard VKR3200-HS

The robust VKR3200-HS 3.2 metre true roll-to-roll UV-LED can produce up to 269 square metres an hour utilising Kyocera’s 11cm wide KJ4A print heads and high-speed electromagnetic drive system. The KJ4A is a dual channel print head design that supports two colours at a time. The small 4 picolitre drop size ensures tight dot placement for a vividly printed output on flexible substrates up to 2.5cm thick. These advanced features make it the fastest and most accurate printer in its class. The VKR3200-HS is field expandable up to two rows of heads for a total of 8 and supports CMYK + W + V + Lc + Lm. The VKR3200-HS also comes standard with liquid cooled LED curing lamps, dual-roll printing capability and an ink-catch for mesh banner, window film, edge-to-edge printing, textile materials and other porous materials.

www.propack.pro 20 ProPack.pro April 2024

COVER STORY

The Vanguard Digital VK300D-HS is the impressive high speed version of our six-time award winning VK300D series.

For more information, please contact info@durst-group.com

VOC FREE HEAV Y METAL FREE REACH COMPLIANT

HIGH

PRODUCTION FLATBED LED UV PRINTER

Hybrid Software to launch MyPACKZ cloud-based software at drupa

MyPACKZ is a cloud-based software-as-a-service (SaaS) based pre-press application for any printing process, digital or conventional, derived from Hybrid Software’s highly successful PACKZ software.

Hybrid Software will launch MyPACKZ cloud-based software at drupa – complementing the existing MyCLOUDFLOW launched last year.

The announcement was made by Hybrid Software executives at the 2024 pre-drupa press conference at Messe Düsseldorf where the company also described itself as the ‘heartbeat of industrial printing and packaging’.

MyPACKZ is a cloud-based software-as-aservice (SaaS) based pre-press application for any printing process, digital or conventional, derived from Hybrid Software’s highly successful PACKZ software. PACKZ, with more than 5,000 copies sold, provides a full set of packaging prepress tools from preflight to step and repeat and trapping.

MyPACKZ offers the same functionality in a hosted SaaS business model for increased production efficiency, quality improvements and reduced error rates. It’s the ideal editing solution for MyCLOUDFLOW customers, since it allows their files to remain in the cloud at all times, even when editing is required.

CLOUDFLOW is Hybrid’s popular enterprise production workflow. The highly configurable enterprise production workflow system provides fast and

effective automation of prepress tasks for more than 1,000 customers worldwide.

All demos at drupa will be run using MyCLOUDFLOW, a 100 per cent cloud-based SaaS solution running in a dedicated Amazon Web Services (AWS) cluster. The No-IT solution offers quick access to CLOUDFLOW through a private and secure environment for each customer with strong data protection and immutable backups. Like any SaaS solution, there is no hardware purchase, and easy scalability without requiring local IT support. The installed base of MyCLOUDFLOW users grew steadily through 2023 as print providers accepted the power of SaaS and the advantages it can bring to their businesses.

“We are a unified Hybrid Software built from six distinct operating companies with one common mission – we are the heartbeat of industrial printing and packaging,” said Hybrid Software executive chairman, Guido Van der Schueren.

“It communicates our DNA to our customers and the industry; one of long-term mutual partnerships and a commitment to expert local support. We will continue to deliver leadership in software and electronics for industrial printing and packaging, driven by the intelligence and passion of our people, speaking the language of our customers, and sharing their heartbeat.”

Hybrid Software also announced a number of projects with key cooperating partners. They include:

• Fujifilm: A workflow and SmartDFE front end for the new FP790 flexible packaging press (Hall 8b/A02–A02-6)

• AB Graphic International: Label finishing automation with FleyeVision integration

• Weigang: Printhead electronics and digital front end for its new high-end label press (Hall 4/D10)

• Koenig & Bauer AG: PrintFusion software for fast press setup (Hall 3/B31)

Hybrid Software is the only company that can drive any digital printing press with its own technology developed 100 per cent in-house.

“More than 100 Hybrid Software engineers have worked together to build the broadest product line in the industry. The result is a full stack solution for digital printing,” said Hybrid Software CEO Mike Rottenborn.

“This represents all of the tasks required to manufacture print, from file pre-flighting and ink estimation to prepress workflow and layout, to all facets of colour management, RIPping files to the digital printer, overseeing inkjet printhead performance, to analysing and reporting to networked MIS/ERP solutions. Yet, just as important as the technology is that we care, on a very local level, about the successes of all of our customers. We look forward to meeting visitors at drupa and helping them achieve exceptional print accomplishments.”

Hybrid Software is eager to welcome drupa visitors at their stand from May 28-June 7 in Hall 7A, Stand D03. Anyone who would like to schedule a meeting or product demonstration in advance can visit https://www.hybridsoftware.com/ eventhub-event/drupa-2024/.

Scan the QR code to view an invitation from Hybrid Software CEO Mike Rottenborn for local visitors to drupa 2024 in May and June.

DRUPA 2024 www.propack.pro 22 ProPack.pro April 2024

Christopher Graf, Guido Van der Schueren, and Mike Rottenborn from Hybrid Software

www.gd90.de

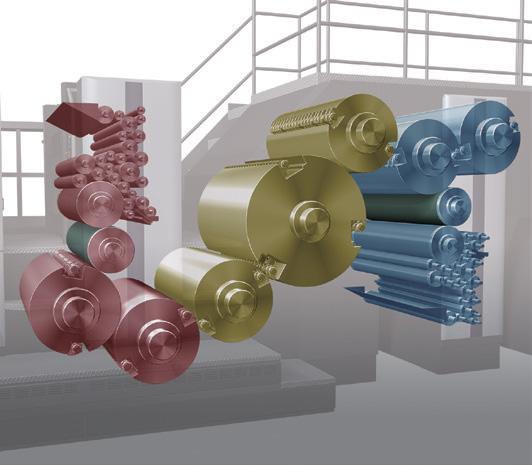

Miraclon to bring modern flexo to packaging printers at drupa

At drupa, Miraclon will focus on communicating the benefits of “game-changing” modern flexo to packaging printers.

Miraclon is looking forward to exhibiting at drupa for the first time this year.

Through its FLEXCEL NX technology, Miraclon is bringing benefits to pressrooms globally through the application of modern flexo.

According to Miraclon CEO Chris Payne, the drupa exhibition will focus on communicating the benefits of “gamechanging” modern flexo to packaging printers by enabling them to achieve their efficiency, sustainability and quality goals as well as maximise returns on flexo press investments.

“We are so confident in our technology, we will guarantee that we can demonstrate the benefits to anyone that visits our stand,” Payne said.

Exhibiting in Hall 15, Booth 50, visitors to the booth will learn how Miraclon, through the delivery of critical technology and knowledge, is a key enabler of the transformation to modern flexo; facilitating consistent, highly capable, efficient, sustainable printing.

Leading with real-world examples, the booth will showcase 12 case studies of commercial success, highlight nine new product innovations that build on the strength of core FLEXCEL NX technology, and provide access to Miraclon technical and commercial experts that can demonstrate the Miraclon difference and leverage firsthand experience to help customers navigate to business success.

“Flexo is an attractive and growing segment of the packaging printing industry,” Payne said.

“Flexo is evolving from its traditional capabilities, practices, and processes to a new era of modern flexo that is a standardised, sustainable manufacturing process. And, with printers under increasing pressure from brands to be more efficient and sustainable in their production, we invite them to visit the Miraclon booth to see, learn and experience how Miraclon, together with our network of valued partners including prepress providers, technology suppliers

Miraclon is bringing benefits to pressrooms globally through the application of modern flexo

and channel partners, can help them develop a practical plan for success. We guarantee it will be worth their time.”

“Visitors to our booth during drupa will see how FLEXCEL NX Technology, together with our team’s knowledge and expertise, can optimise the flexo print production process and help maximise the return on press investments. We look forward to showing them why partnering with Miraclon should be the first step in their journey to modern flexo success.”

“Miraclon is the home of FLEXCEL Solutions, which have helped transform flexographic printing for more than a decade. The technology, including the industry-leading FLEXCEL NX and FLEXCEL NX Ultra Systems, and FLEXCEL NX Print Suite that enables PureFlexo Printing, maximises on-press efficiency, delivers

higher quality and overall best-in-class results. With a focus on pioneering image science, innovation, and collaboration with industry partners and customers, Miraclon is committed to the future of flexo and continues to be positioned to lead the charge.”

Highlights of the Miraclon booth at drupa will include the Champions of Modern Flexo – 12 real life case studies of printers that have met challenging brand client needs and achieved dramatic financial and sustainability goals after successfully implementing FLEXCEL NX technology, aided by the technical expertise of Miraclon and its valued prepress partners.

Visitors will also have the opportunity to access expert knowledge-based services including consultancy, savings calculations, as well as technical and applications support to enable printers to maximise their returns in the press room.

Miraclon will also showcasing nine of its newest product innovations that build on and strengthen the core FLEXCEL NX Technology to put printers on a clear path towards modern flexo, including:

The FLEXCEL NX Ultra 42 Processor: Miraclon is the leader in high-performing, water washable plate technology. Building on the success of the FLEXCEL NX Ultra 35 processor for narrow-web applications, the new FLEXCEL NX Ultra 42 Processor offers a key proof point for achieving this in a high-volume, low maintenance plate production environment. Its water washable plates offer the same benefits as its solvent processed plates in the transition to Modern Flexo.

Also on display will be the Shine LED Lamp Kits, innovated by Miraclon, the Shine LED Lamp Kits are a simple and cost-effective path to UV LED plate exposure that makes an even more consistent flexo plate. Increased plate consistency leads to even greater efficiencies in printing.

A preview of next generation FLEXCEL NX Plate and FLEXCEL NX Ultra Plate Technologies: LED optimized plate technology that offers even cleaner printing for greater efficiency and sustainability benefits.

DRUPA 2024 www.propack.pro 24 ProPack.pro April 2024

Miraclon CEO Chris Payne

FLEXCEL NX Ultra Solution

Simplified Plate Processing

Meet us at Drupa 2024 to learn more about FLEXCEL NX Ultra Solution and discover modern flexo.

Hall 15 | Stand 50

Simply High Performing

Built off the same consistent, high quality, on-press efficiency characteristics of FLEXCEL NX Solutions

Simply Fast

Create a press-ready plate in less than an hour

Simply Clean

Use water-based platemaking that’s easy to manage and maintains consistency

LEARN MORE

Zünd to unveil new cutting solutions and UnderCam technology at drupa

Zünd will showcase new cutting tables and innovative UnderCam technology to improve efficiency at drupa in Düsseldorf.

Exhibiting under the motto – ‘Performance across the board’ – Zünd will launch the new Q-Line with BHS180 board handling system at drupa for the first time.

According to Zünd executive Lars Bendixen, the new cutting solution sets new standards in industrial, non-stop production and represents the highest level of automated digital cutting.

The concept behind the Q-Line with BHS180 has redefined performance limits in multiple respects and significantly improved production efficiency when compared to traditional die cutting.

The new Q-line substructure is made from a highly stable mineral casting. It ensures incredibly smooth operation and optimum cutting precision even when working at high speeds. The beams are made from carbon fiber-reinforced plastic, which makes them lightweight but exceedingly strong. This enables very precise cutting even of challenging materials at maximum speeds. With Q-Line, the Zünd portfolio of productive cutting solutions has been rounded out at the top level and now covers all performance classes and customer requirements.

“We have systematically expanded our portfolio to optimise the cutting workflow every step of the way,” Bendixen said.

“At drupa 2024, we will be presenting innovative and highly productive solutions to help our customers digitalise their production on an individual basis according to their needs. During our conversations with customers, we take the time to really get to know their specific requirements, right down to the smallest details. This way, we can put together exactly the right combination of solutions they will need to ensure a successful and competitive production workflow. We actively support them in their transformation to the digitalised future.”

Zünd’s top priority is to digitalise and automate the value chains of its customers, thus increasing their competitiveness. To this end, Zünd’s cutting solutions are increasingly capable of producing independently and autonomously.

At drupa, Zünd will show how productivity and cost-effectiveness can be optimised with innovative solutions such as the new board-loading extension with optional UnderCam now available for its third generation cutting systems. In a

technology transfer from Q-Line with BHS180, this solution has been adapted and will be presented at drupa 2024 together with a Zünd G3 cutter.

Combined with the UnderCam optical capture system, the board-loading extension enables semi-automatic board feeding, job identification via QR code, and registration during the production process. This significantly increases productivity, particularly in cases where cutting and creasing are done on the reverse side of the board.

Visitors to the Zünd booth at drupa will have the opportunity to experience in live demonstrations how they can control robots and pick and sort finished parts automatically. Zünd is demonstrating this process with the Robot PortaTable 130. The Robot PortaTable consists of a mobile off-load table equipped with a robotic arm, which can be quickly and easily set up and moved from one Zünd cutter to another. The Visualizing Option ensures efficient job logistics, providing the operator with visual assistance when removing cut parts. Functions such as optical identification of cut parts and printed QR codes simplify order tracking, facilitate cutting and kitting, and ensure smooth, efficient logistics.

Zünd is also putting its digital expertise on display with its growing software portfolio and range of workflow-automation solutions designed for all requirements and applications. The ZCC (Zünd Cut Center) operating software has been fully re-engineered and now features an impressive, state-of-the-art, intuitive, user interface based on touch. The ZCC helps the user optimise the production process before, during, and after cutting. Users only purchase the software components they need – no more, no less. More options can be added anytime as their need for automation continues to grow.

Also on display will be the Caldera PrimeCenter, the software for simple and automated print and cut file preparation. This prepress control centre ensures high performance and efficiency in the data workflow. Fully nested, ready-to-go print and cut layouts can be created in just a few clicks.

Lars Bendixen provided a preview of the new UnderCam technology at FESPA in Amsterdam

DRUPA 2024 www.propack.pro 26 ProPack.pro April 2024

Q-Line Concrete Performance

Q-Line with BHS180 delivers rock solid performance. Discover the latest innovation in digital cutting automation, designed for industrial production of packaging and displays. Perfect precision at unprecedented speeds — digital cutting at the next level.

Visit us @ Drupa Hall 9 Stand B03

Discover the Q-line and more at Drupa 2024!

Book your appointment by emailing infoau@zund.com or calling Dale Hawkins at +61 409 024 994

creasing pressure

2.1 g acceleration 50 kg

2.8 m/s speed

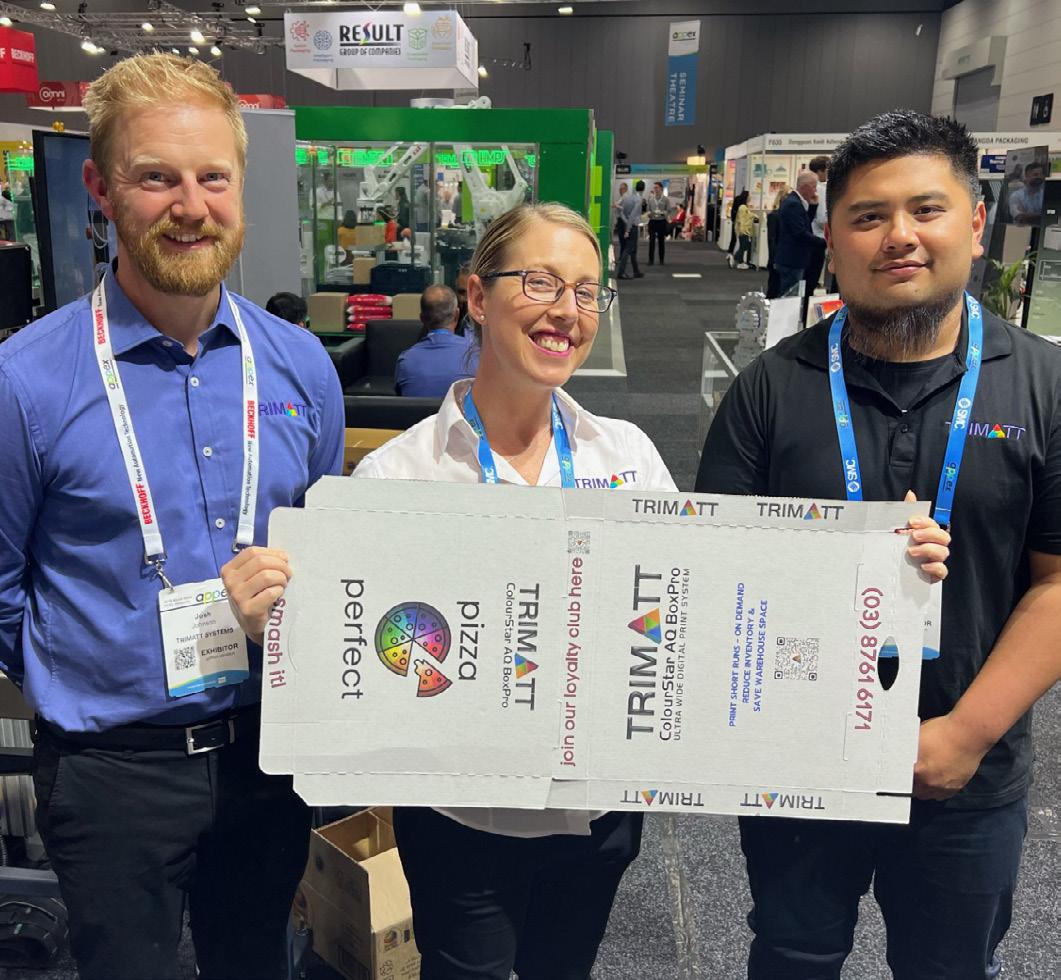

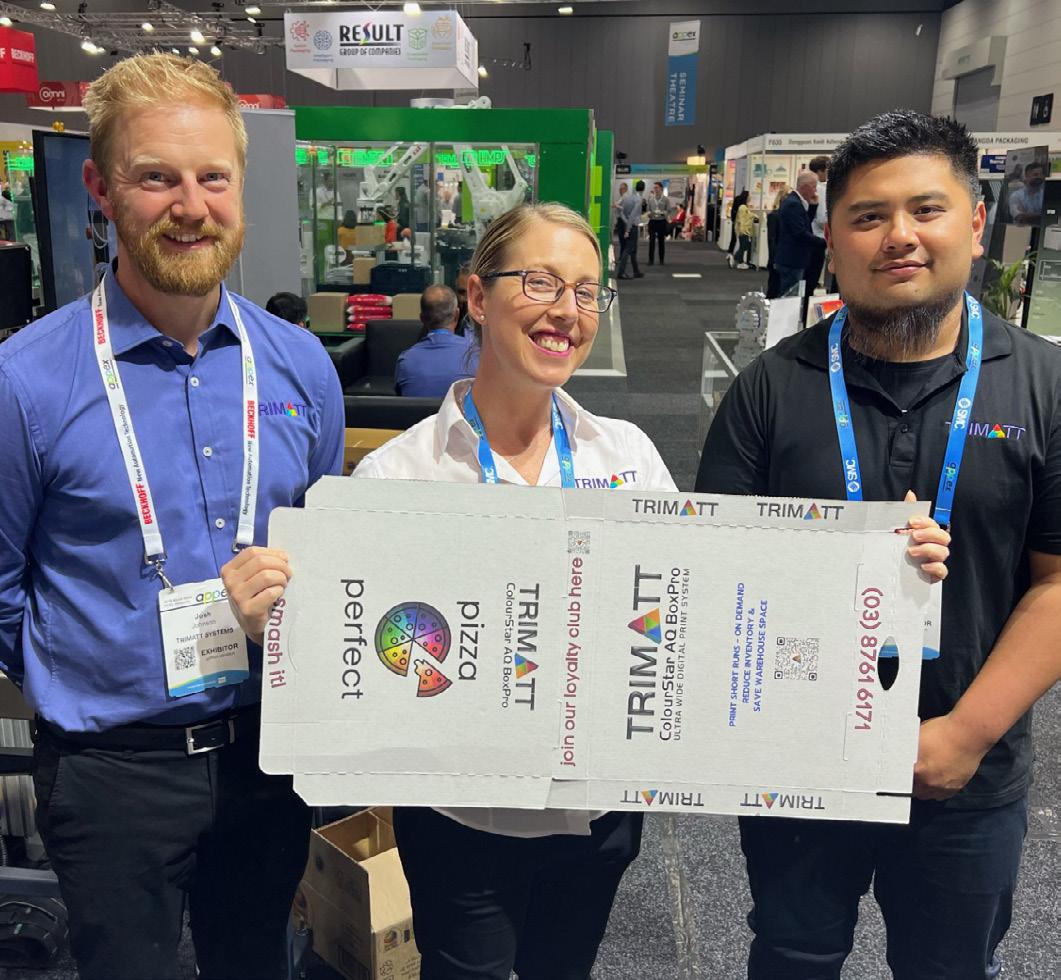

Highlights from APPEX 2024

The Australasian Processing and Packaging Expo (APPEX) was recently held at the Melbourne Convention and Exhibition Centre.

The processing and packaging industry recently gathered for the Australasian Processing and Packaging Expo (APPEX) in Melbourne.

Held at the Melbourne Convention and Exhibition Centre and incorporating the previous Auspack exhibition, APPEX brought together more than 400 industry exhibitors over the four-day

event representing machinery, ancillary equipment, materials and packaging, food processing, and industry services.

Informative seminars were led by industry experts at the Ecoporium from Ball & Doggett and the Seminar Theatre. Also held during the event was the Australian Packaging and Processing Machinery Association (AAPMA) Awards for Excellence.

www.propack.pro 28 ProPack.pro April 2024

APPEX 2024

Albert and Dan Malki (Jet Technologies)

Alan Nankervis (CMYKhub) and Tom Ralph (Graph-Pak)

Matt Ashman and Dan Mantel (Durst)

Mel Parker (Printer Media Group), Robyn Frampton (Visual Connections) and Stephanie Gaddin (Rocking Horse)

APPEX 2024 www.propack.pro April 2024 ProPack.pro 29

London Mills, Kellie Northwood and George Tzintzis (Visual Media Association)

Kellie Northwood from VMA presenting on the Ball & Doggett ecoporium stand

Nicolas Contoleon (Moda Packaging)

Robyn Frampton and Peter Harper (Visual Connections)

Martin Baker, Matthew Dorhauer, Jonathan Baker from Lite Corp

Josh Johnson, Mel McFarlane, Von Zeller (Trimatt Systems)

Dscoop Edge Indy ‘fuels the future’

Dscoop Edge Indy brought together more than 1200 delegates from 37 countries to explore the latest industry trends and showcase new cutting-edge technologies, including HP’s drupa portfolio reveal.

More than 1250 industry professionals from 37 countries, including Australia, attended Dscoop’s annual event in Indianapolis, the proclaimed home of racing, with the flagship event recording its highest number of attendees for the event post-pandemic.

“The Dscoop global community keeps growing, and it’s a testament to the amazing partnerships and idea-sharing of our members across the world,” said Peter van Teeseling, Dscoop’s executive director.

“Dscoop is a true community in every sense of the word, and it’s always incredible to watch and feel what happens when print mavericks come together at this event.”

Kicking off this year’s Dscoop, HP unveiled its worldwide pre-drupa portfolio, which included six on-site HP Indigo Digital Presses for commercial printing, label converting and flexible packaging.

HP’s reveal was part of a 96,000 squarefoot education and exhibition area that also included live equipment, press and software demonstrations from 70 Dscoop partners, with many showcasing equipment, hosting demonstrations, and introducing new products and services.

“We wanted attendees to walk away each year from Dscoop feeling good about themselves, their company, our community, and the industry,” said van Teeseling.

“We’re all facing the same challenges and a forum like Dscoop allows members to share their problems and share solutions. An important aspect of Dscoop is collaboration and that’s what the Dscoop community excels at.”

The event’s education program featured more than 45 presentations and panel discussions led by Dscoop community members as well as outside experts in sales, marketing, and technology. Role-based sessions were designed for

company owners/executives, production managers, IT managers, sales and marketing teams and operators.

Keynote speakers included former baseballer and chairman and CEO of investment firm A-Rod Corp, Alex Rodriguez, and author and gathering expert, Priya Parker.

Rodriguez shared his approach to building his post-baseball business empire, including real estate and various company holdings. A-Rod commented on building his $5 billion real-estate portfolio beginning 20 years ago with a humble duplex apartment.

“We started really small with a big vision and a big dream. And we started one step at a time,” he said.

Parker, an international leader in helping create effective and meaningful meetings and gatherings, lamented at the current state of how groups and companies are meeting. She recounted how experts in

DSCOOP EDGE INDY 2024 www.propack.pro 30 ProPack.pro April 2024

Dscoop’s flagship event was held in Indianapolis, the proclaimed home of racing

their fields have successfully created transformative experiences in their interactions and meetings with others.

“They started every single time with purpose,” she said, “asking questions like, ‘What is the need here?’ and ‘Why are we doing this ?’.” Parker led the audience through interactive exercises to help them understand how to refine how they conduct meetings to make them more effective and engaging.

“Dscoop has something for everyone depending on the business that you are in and what your objectives are while at Dscoop,” said Peter Barr, general manager - sales and marketing, Photo Create, and member of the Dscoop Asia Pacific and Japan (APJ) board.

“For us, it is about the connections that are formed, and conversations that are had with like-minded people and businesses,

whether that be the sharing of problems or problem solving. Our biggest takeaway is always the engagement and collaboration that we have here.”

HP unveils pre-drupa portfolio

HP’s pre-drupa portfolio reveal at Dscoop Edge Indy included two new generation B2 presses, the HP Indigo 120K Digital Press and the HP Indigo 18K Digital Press, in addition to the HP Indigo 7K Secure Digital Press and innovations across the intelligent production floor.

“Twenty years ago, we started our digital transformation, making a significant impact on the industry,” said Haim Levit, senior vice president & general manager, HP Industrial Print, in his opening address. “While there is more to come, you can be sure we are committed to pushing those boundaries further.”

The HP Indigo 120K reduces human touchpoints and enables multi-press operation by a single operator. The new press delivers offset-matching image quality, flexible job routing between offset and digital, and an ECO mode option that reduces the press’s carbon footprint by 11 per cent.

The HP Indigo 18K Digital Press, which handles the widest range of print applications ever produced with a single B2 digital press, accommodating diverse substrates and job types. Advanced AI features such as auto recovery and proactive alerts enhance productivity and simplify the entire production process, achieving up to 80 per cent press availability within a single shift. Aligning with HP’s sustainability commitment, the HP Indigo 18K supports Enhanced Productivity Mode (EPM), delivering 24 per cent energy savings per sheet.

DSCOOP EDGE INDY 2024 www.propack.pro April 2024 ProPack.pro 31

Dscoop Edge Indy brought together more than 1200 delegates from 37 countries

Dscoop concluded with the Edge Celebration Party

Peter van Teeseling (Dscoop)

Haim Levit (HP)

Noam Zilbershtain (HP)

Benn Murphy (Clarke Murphy Print), Anthony Jackson (Currie Group), Peter Barr (Photo Create), and Kelvin Gage (Hyble)

Also announced was the HP Indigo 7K Secure Digital Press. Collaborating with Jura JSP, this sheet-fed press enables workflows tailor-made for security production lines, so customers can diversify their offerings, cater to a comprehensive range of security needs, and acquire new customers to grow their business.

HP also announced the launch of a comprehensive print production automation ecosystem. According to HP, based on internal studies, customers who leverage automated processes achieve 51 per cent higher volume and 80 per cent more jobs per press compared to less automated customers. These customers also grow at an average of 27 per cent yearover-year which is higher than the industry average. HP’s holistic approach combines effective presses with intelligent features from job submission to delivery.

As the industry moves towards a more productive production floor, HP has launched Autonomous Mobile Robots (AMRs) in collaboration with Movigo to automate media transfer, saving up to two hours per day, per press.

A digital-first mindset

During his presentation, Noam Zilbershtain, VP and GM of HP Indigo, said HP plans to disrupt the packaging market all while emphasising HP’s five core focus areas: quality, versatility, productivity, sustainability, and economics.

“The opportunity is huge – only 10 per cent of the entire market is digital print volume. Looking at labels, in the past seven years, HP Indigo customers grew seven times faster. HP has led the digital labels market for more

than 20 years, holding more than 60 per cent of the market share and we are going to push the boundaries even further with the new LEPx and with the V12,” he said.

Zilbershtain announced at Dscoop Edge Indy that HP will roll out general commercial availability of the HP Indigo V12 Digital Press. Commercial availability comes after successful beta site installations including Brook + Whittle, a leader in sustainable packaging and digital printing in the US.

“We are officially eliminating the crossover point and shifting to a digital first mindset – a HP Indigo first mindset. At drupa, the HP Indigo V12 will be commercially available to everyone, enabling digital printing for almost every job,” he said.

Zilbershtain said flexible packaging is HP Indigo’s fastest growing segment. As he explained: “In 2023, we grew by 27 per cent, while the overall market great about

4.5 per cent. In this segment, LEP is the only proven technology for digital, flexible packaging and with our HP Indigo 25K and the new HP Indigo 200K, we are revolutionising this industry and leading the market with more than 350 presses installed. Our goal for this market is that we are aiming to double the HP Indigo flexible packaging volume every three years – double our footprint and double our volume every three years.”