COVER STORY

BY LARA L. SOWINSKI

MAJOR BOX PORTS SUPPORT

REEFER CARGO A

At gateways along the East, West and Gulf coasts, improved infrastructure and handling are enhancing the integrated global cold chain.

s leading containerized carriers continue to grow their market share of refrigerated cargo, major box ports across the United States are likewise responding by improving their offerings to support imports and exports of chilled and frozen cargoes moving via container. We asked representatives at major box ports what they believe are the primary challenges facing beneficial cargo owners (BCOs) of reefer cargo right now, and how their port is tackling those challenges.

Port of Charleston www.scspa.com

Changes throughout the trucking industry are affecting all BCO shippers, especially those in the refrigerated food sector, notes Matt Pesavento, South Carolina Ports Authority regional manager, Atlanta office. Furthermore, now that the soft enforcement of electronic logging devices (ELDs) has moved into full enforcement as of April 1, the already critical driver shortage “may pose a challenge in trucking capacity, especially for cold chain BCOs who source drivers from a smaller, specialized pool within the trucking market,” he explains.

16

FOOD LOGISTICS | MAY 2018

FLOG0518_16-27_CoverStory.indd 16

Meanwhile, SCPA’s new inland facility, Inland Port Dillon, is coming online just in time to play a key role in alleviating that challenge for many of its reefer customers, says Pesavento, referring to the inland facility that opened April 16, which aims to convert approximately 45,000 container moves from truck to rail in the first year of operation. “A large concentration of our pork and poultry exporters located in North Carolina will benefit from the daily rail service between Inland Port Dillon and the Port of Charleston, as it allows their drivers to handle multiple container moves per day between their plants and Inland Port Dillon, rather than just a single container move per day to

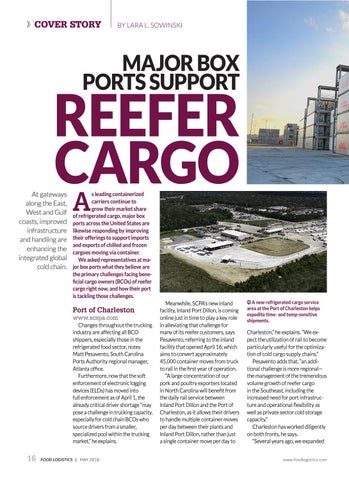

A new refrigerated cargo service area at the Port of Charleston helps expedite time- and temp-sensitive shipments.

Charleston,” he explains. “We expect the utilization of rail to become particularly useful for the optimization of cold cargo supply chains.” Pesavento adds that, “an additional challenge is more regional— the management of the tremendous volume growth of reefer cargo in the Southeast, including the increased need for port infrastructure and operational flexibility as well as private sector cold storage capacity.” Charleston has worked diligently on both fronts, he says. “Several years ago, we expanded www.foodlogistics.com

5/4/18 9:30 AM