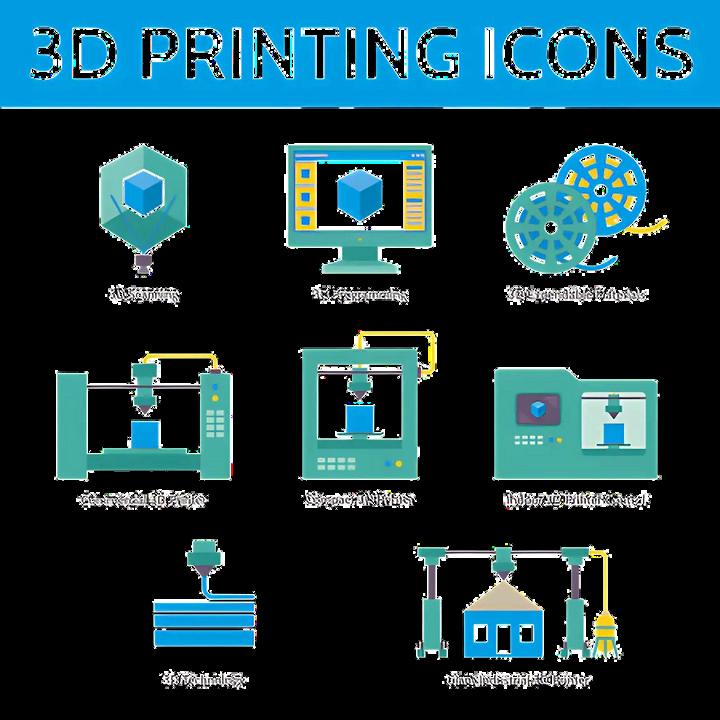

3D printing (additive manufacturing) creates objects by building them layer by layer from a digital file. Instead of molds or cutting, the product is built from the ground up using plastics, resin, or other materials. In simple terms: Your digital design → A product in your hands.

Customization – Add logos or unique branding to any design

Speed to Market – Samples in hours, no molds or tooling.

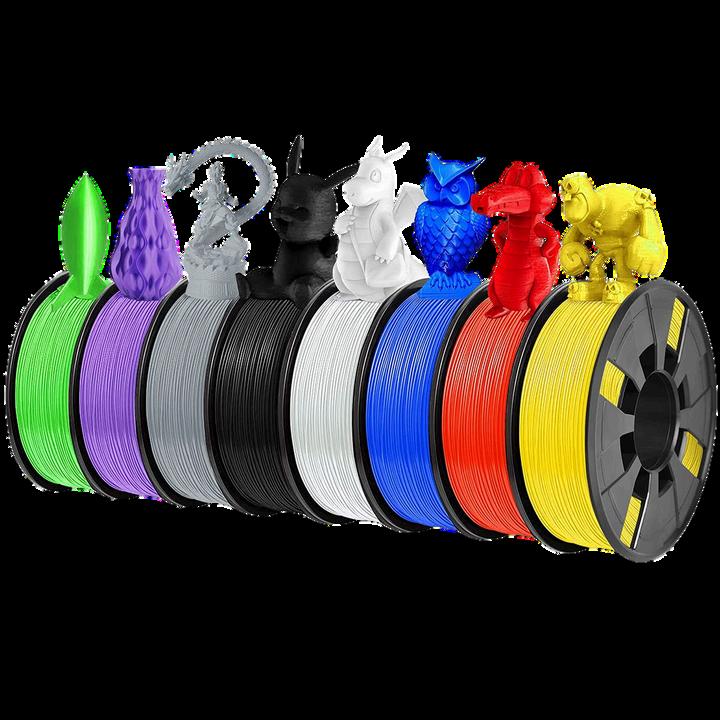

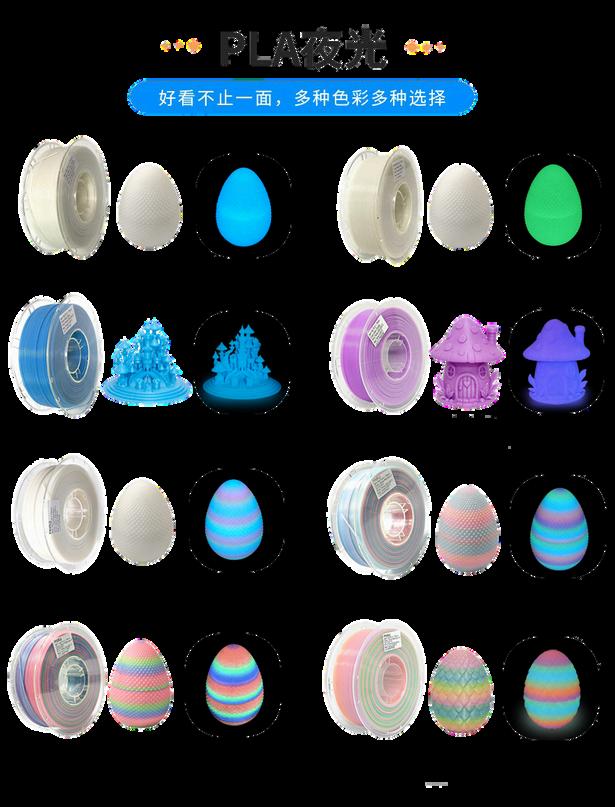

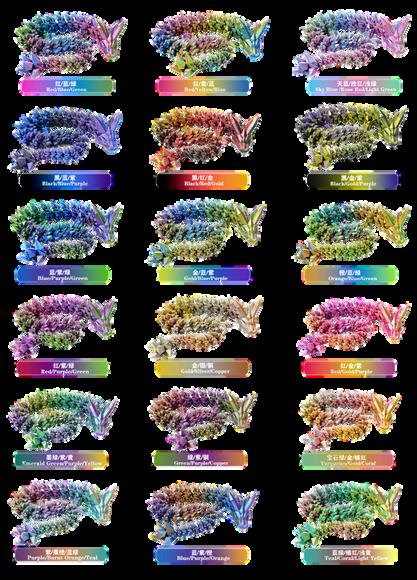

Creative Freedom – Create complex & detailed shapes with full control of colors, sizes, and branding.

Low Minimums (MOQs) – Cost-effective for short runs or exclusives Sustainable – Produce less material waste than traditional methods

Impress clients with innovative, made-to-order products Win more business with designs no one else offers Adapt quickly to market and trend demands

Brainstorm product ideas

Use CAD software to design the item & add logos, branding, or event graphics

Send a digital proof for client review

Revise until the client approves

Convert the design into a printable file such as STL, OBJ, 3MF, or AMF

Use slicing software to set material, layer thickness, and print speed

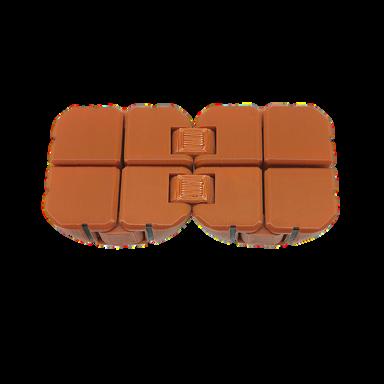

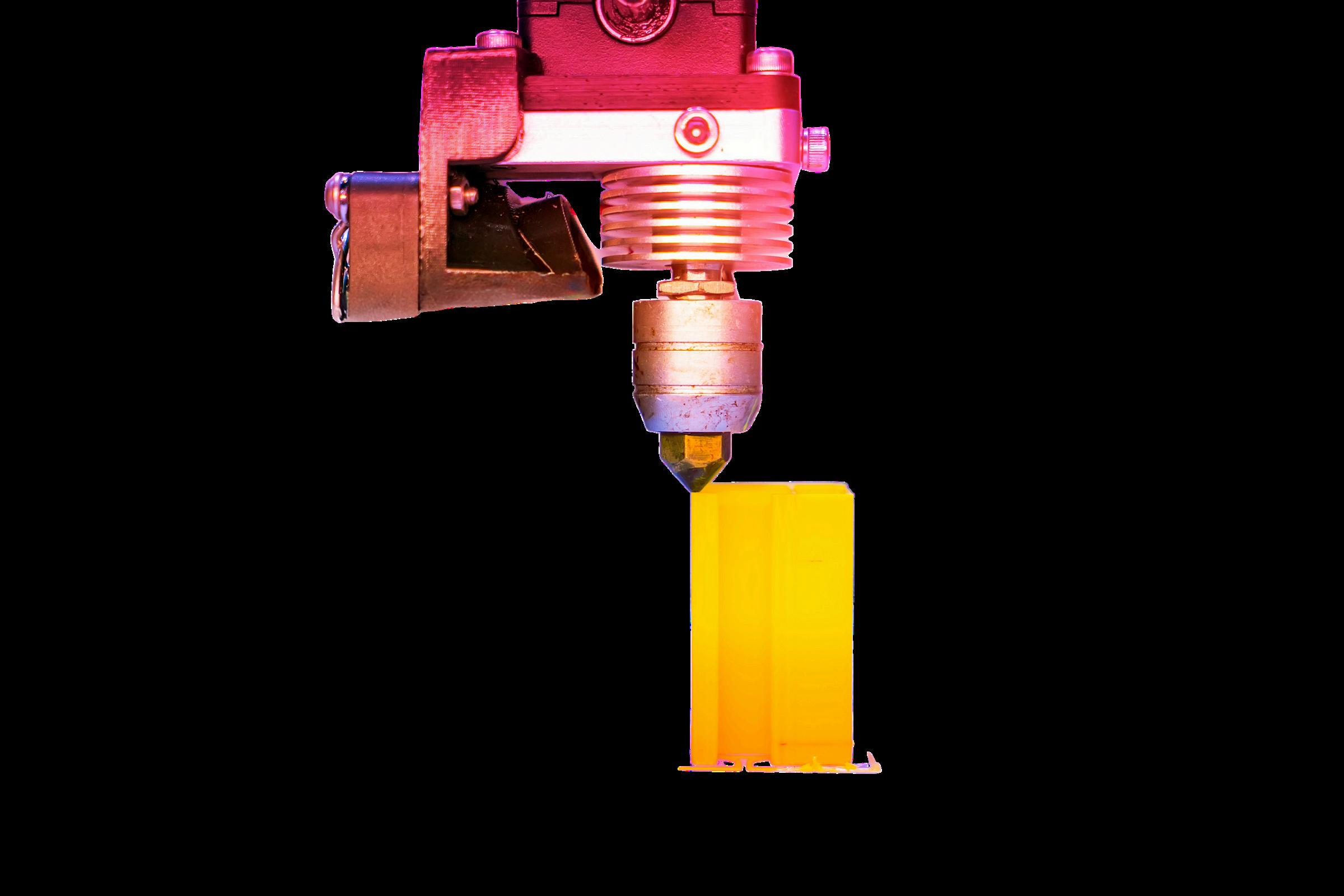

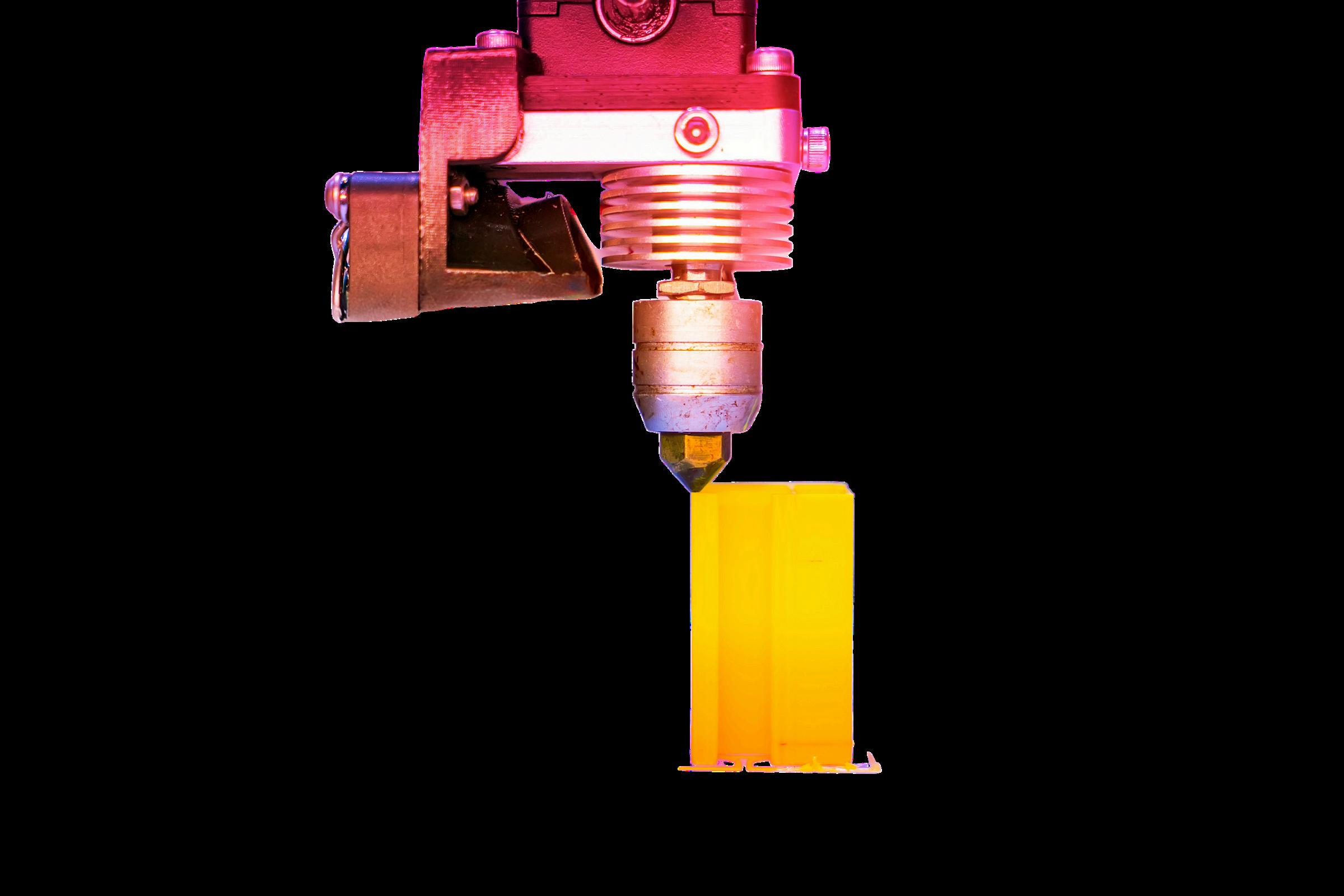

Printer builds the item layer by layer in plastic, resin, or other materials

Print time ranges from minutes to hours, depending on complexity

Remove supports, smooth surfaces, and add finishing touches like paint or coatings

Package the product & set for delivery