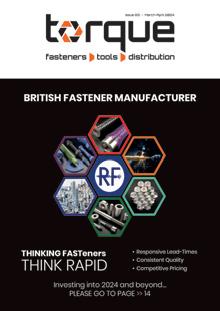

BRITISH FASTENER MANUFACTURER THINK RAPID Investing into 2024 and beyond... PLEASE GO TO PAGE >> 14 • Responsive Lead-Times • Consistent Quality • Competitive Pricing THINKING FASTeners

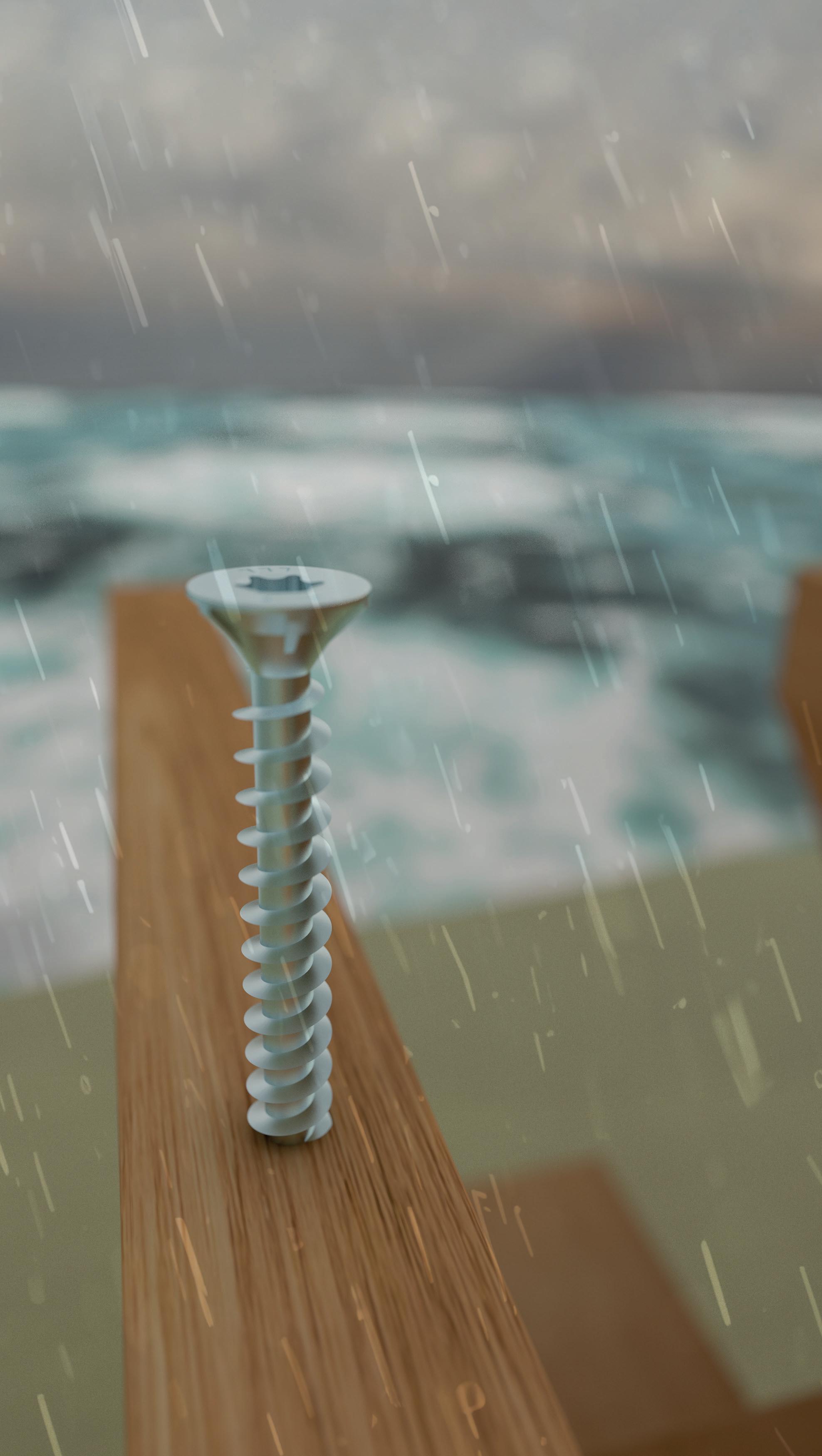

W E BREATHE FASTENERS ® M anufacturer & distributor Fasteners and Fixings. From small screws to ETA approved construction bolts. From nylon plugs to seismic tested anchors. These are the visible or invisible connections that keep building projects together. They are indispensable links. For pgb-Europe and pgb-Polska it is our daily aim to provide our customers with quality products and a matching service. We have been an established supplier and manufacturer of fasteners and fixingsformorethan60years. Your partner for all fasteners and fixings! More information: www.pgb-international.com

Publisher Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Sales Manager – UK Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

UK Sales Manager - Tools Lloyd Ramsdale lloyd@torque-expo.com

Circulation

Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers

Dan Bennett dan.bennett@torque-expo.com

Victoria Arellano victoria@torque-expo.com

Head of Marketing Shona Hayes shona@torque-expo.com

Published by

Stag Publications Ltd

18 Alban Park Hatfield Road

St Albans Herts AL4 0JJ

tel: +44 (0)1727 739160

fax: +44 (0)1727 739169

Email: info@torque-expo.com

Web: www.torque-expo.com

Disclaimer

Although

06 GUEST EDITOR

08 NEWS

14 COVER PROFILE > RAPID INDUSTRIAL PRODUCTS RICHARD WHITE TELLS TORQUE ABOUT RAPID’S EXPANSION PLANS AS ITS MANUFACTURING ARM GROWS

16 WOMEN IN FASTENERS & TOOLS > GLENDA ROBERTS, TR

22 NYLON & PLASTIC FIXINGS AND FASTENERS > FEATURING VOLT INDUSTRIAL PLASTICS, BÜLTE, FISCHER, JCP, NYFAST & BÄCKER

34 SHOW PREVIEW > FASTENER TAIWAN

36 TERRITORY FOCUS UK > TOOLFAIR

38 TERRITORY FOCUS UK > THE INSERT COMPANY

40 SHOW PREVIEW > TORQUE-EXPO 2024

56 FASTENER DISTRIBUTION > OWLETT-JATON, PEM, DRESSELHAUS & EXCELLENCE IN DISTRIBUTION

66 SPOTLIGHT > ARMA FIXING SYSTEMS

68 FOCUS > R&D CAS ON GRAPHENE IN BATTERIES, IP PROTECTION & EJOT

72 SHOW PREVIEW > WIRE 2024

82 FOCUS > DRILL & SCREWDRIVER BITS DRAPER TOOLS, WERA & HMT

88 FOCUS > HI TENSILE & BOLT ASSEMBLIES

94 SPOTLIGHT > TOOL THEFT

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code...

As part of our commitment to the environment, Torque Magazine is fully recyclable.

HAS THERE BEEN A BUSIER Q1?

If current experience tells me anything, I’m going to assume you’ve got a lot going on right now. Juggling multiple projects? Tick. Paddling frantically under the water while appearing to serenely glide along like the proverbial duck? Tick.

Has there ever been a Q1 as busy? I can’t speak for each of Torque Magazine’s thousands of readers, but anecdotal evidence and the volume of emails I’ve received apologising for slow replies and laying the blame on ‘having a lot on’ (many of which I am sure are true) seem to indicate that we’re all working pretty hard right now.

There’s a type of comfort in being busy – it’s always better than being quiet, they say. But the problem is that given the current middling economic climate, we’re probably all working pretty hard due to those conditions – battling tighter margins and increased costs and basically working harder to maintain previous levels. That’s not across the board, but I suspect there’s some truth in that view.

Perhaps you’re also busy because the show calendar is very much back to pre-Covid activity levels? This is a point that neatly brings me to our forthcoming Torque-Expo 2024, taking place in May in Telford. Is there a more ideal place to meet with your peers and shoot the breeze over the current state of the industry? OK, there will be if you’re based in the Far East (hello Taiwan International Fastener Show), but with much of the industry about to descend on Telford International Centre in the West Midlands, it’s surely a key place to spend a few hours to gauge the state of the market and make some new connections. We hope to see you there.

Jonathon Harker Editor jonathon@torque-expo.com

the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd. Copyright Entire contents copyright © 2024 Stag Publications. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher. INSIDE THIS ISSUE Proud member of:

14 MAY 2024 TUESDAY RESERVE YOUR STAND BY CONTACTING CLAIRE WARMAN Email: Claire@torque-expo.co.uk | Call: +44 (0)1727 739 160 EXHIBITION • NETWORKING • SEMINARS • AWARDS

Working with di erent brands?

All with just one CAS battery pack.

CAS. The multi-brand battery system.

More than 40 powerful manufacturers have joined forces so that tools, battery packs, and chargers are 100% compatible with each other. CAS battery packs are developed in Germany and perform well even in the most demanding applications thanks to leading battery pack technology.

40 brands. 400 tools. 1 battery pack. cordless-alliance-system.com

PINAR ÖZTÜRK SALES DIRECTOR OF NORM FASTENERS IS GUEST EDITOR OF THIS ISSUE OF TORQUE MAGAZINE

HIGHLIGHTING UNCERTAINTIES AND ADAPTING TO NEW TRENDS

Market research reports indicates that global sales of industrial fasteners, which were valued at approximately $94.4 billion in 2023, are projected to increase to $127.3 billion by the year 2030.

In an expanding market, the ability to rapidly adapt to new trends and embrace change is crucial and should be developed as a key strength by companies. While technology, customer expectations, and market dynamics change, companies that view these changes as opportunities and create strategies that transform the expectations into gains, position themselves as robust competitors in the market and ensures sustainable success.

As customer expectations evolve and increase, the importance of engineering and R&D capabilities becomes more critical from the customers' viewpoint. Within the scope of both sustainability and cost-reduction efforts, the added value offered by engineering teams to the customers is getting more crucial. This is clear in efforts to develop lightweight product, enhanced efficiency, functional improvements, and the creation of more durable and long-lasting products.

Similar to many sectors, the global economy is facing a significant challenge in 2024, with expectations of a slowdown in growth. This deceleration is attributed to factors such as high interest rates, rising energy prices, geopolitical uncertainties, and conflicts arising from the repercussions of war. These challenges are leading to disruptions in the supply chain, posing specific concerns for manufacturing customers. Presently; instability is the biggest challenge and is expected to continue throughout the year.

In the current business landscape, it is more important than ever to develop systems that can shed light on all these uncertainties. Meeting customer require-

ments comprehensively, precise planning and ensuring on-time delivery are critically important. particularly for customers in the manufacturing sector. Companies need to establish systems that are flexible enough to adapt to possible variations and achieve forecasts with minimal deviation.

The industry closely monitors sustainability as a top priority. The automotive industry's pursuit of a zero carbon footprint highlights its commitment to sustainability and combating climate change. Norm Fasteners is proactively addressing growing sustainability demands through measures such as minimising chemical usage. The company is transitioning to hybrid systems instead of fossil fuels and placing a strong emphasis on electrification and energy efficiency as part of its decarbonisation initiatives. Furthermore, we are allocating a $30 million investment towards renewable energy initiatives. As part of our digital transformation strategy, we have achieved significant gains and efficiency by automating repetitive and low valueadded tasks through the deployment of RPA robots and automation technology.

Within the "Human Life Matters" initiative, the sustainability committee has goals to enhance gender diversity within the company by promoting equal opportunities, aiming for an increased representation of female managers and employees. I believe maintaining a balanced gender ratio in all workplaces is a significant advantage for companies, to create a harmonious and diverse perspective. Norm Fasteners is aware of the significance of gender balance and ensures equal opportunities in internal promotions and new hires. I expect a further increase in this harmony within the sector.

www.normfasteners.com

06 torque-expo.com GUEST EDITOR COMMENT

www.king-inox.com vendite@king-inox.it WEB-SHOP +39 02 57606482 / +39 02 57604100 Via Abruzzo, 2, 20090 Opera MI - ITALY Discover the new SCAN HERE WEB-SHOP CUSTOMER CARE FAST DELIVERIES +20000 ITEMS Stainless steel fasteners leading master distributor

RECORD TURNOVERS + “ECONOMIC NORMALISATION”

Outgoing Liverpool FC Manager Jürgen Klopp may be leaving Anfield in a few months, but he’s still firmly attached to fischer, which recently revealed another recordbreaking turnover year.

Klopp’s fischer ambassador deal, which started 2023 and lasts well into 2024, was noted as among the positive factors behind fischer’s groundbreaking year, where turnover breached €1.16 billion, up 2% on 2022. fischer said the sales figures were partly as a result of the company’s sustainable growth strategy, which has allowed fischer to continue to operate independently of negative global influences.

Largest division, fischer fixing systems, made a growing contribution to the success of the Group of Companies with a

2% yearonyear increase in turnover. Innovative new products and systems, consistent internationalisation and a comprehensive range of services for various customer groups had a positive effect on the company’s economic success.

Bossard: “Times of economic normalisation”

Meanwhile, Bossard said it achieved satisfactory results amid an environment of economic normalisation, strengthening its market position in its three regions.

Bossard saw stable demand in several of its growth industries and a strong performance for its Smart Factory services (designed in part to mitigate skilled labour shortages).

Sales in FY 2023 totalled CHF 1,069 million (2022: CHF 1,153.8 million). EBIT was CHF 113.1 million (2022: CHF 141.5 million), corresponding to an EBIT margin of 10.6% (2022: 12.3%). Net income decreased 27.2% to CHF 76.8 million (2022: CHD 105.6 million).

While 2023 was not flattering compared with 2022, Bossard Group said it achieved a net income in line with the average of the strong prior years as well as significantly reducing net debt with a strong cash flow of CHF 121.4 million.

Grafton: “Demand fundamentals” remain in place

International building materials distributor and DIY retailer Grafton Group plc, also announced its final results for 2023.

The group, owner of Selco Builders Warehouse, had a full year adjusted operating profit of £205.5 million which was above the top end of Analysts’ forecasts. There is also strong free cashflow of £205.6 million which is up from 2022 figures of £163.3 million.

Woodie’s DIY, Home and Garden retail business performed well while there was strong performance by UK Manufacturing businesses despite volume declines.

Chief Executive Officer, Eric Born, commented: “While trading conditions are expected to remain challenging, demand fundamentals are supported by a structural under supply of new homes and an aging housing stock that requires upgrading including energy conservation measures. With a somewhat improving economic backdrop, we are confident that Grafton is exceptionally well positioned to benefit as the cycle turns, markets normalise and consumer confidence improves.”

NEWS www.torque-expo.com Stainless steel fasteners. EdelstahlVerbindungselemente. Standard and non-standard items Norm- und Standardteile DIN, ISO, EN and others / und andere Special parts and special materials Sonderteile / Sonderwerkstoffe Lederer GmbH | Katzbachstraße 4 | 58256 Ennepetal | Germany | Fon +49(0)2333/8309-0 | info@lederer-online.com lederer-shop.com availability advice quickorder / file upload backlinked pdf pages Bestands-eMail Schnellbestellung / Datei-Upload verlinkte Katalogseiten News from the distribution industry…

A good result for fischer: Ambassador Jurgen Klopp with fischer Owner Professor Klaus Fischer

New Ops Director at INSTINCT HARDWARE

Instinct Hardware is boosting its senior team with the appointment of Scott Fowler to the role of Operations Director.

The new role will see Scott responsible for all operational aspects of the business, ensuring each department operates efficiently and achieves productivity targets. The main objective is to reduce customer lead times while ensuring Instinct’s highquality standards are never compromised.

Scott has been working with Instinct over the past six months in a consultant

New CEO for Dormole

Dcapacity, helping Instinct retain their ISO certification, so is already well versed with the workings of the business. He commented: “I have been lucky enough to work with the team in an advisory capacity already, so am familiar with the procedures in place and how these can be further enhanced to support the company’s growth objectives. It’s a fantastic time to join the Instinct team – the business is growing fast and I’m looking forward to getting stuck in and help Instinct achieve their goals.”

www.instincthardware.co.uk

ormole, the parent company of Toolbank, appointed Wayne Flory as its new CEO and Adrian Harris as a nonexecutive director. Wayne joined the Toolbank business in 1994 and has been CEO since 2015, more recently joining the Dormole Board as a director in 2020. Wayne’s commercial strengths, market knowledge and deep understanding of the Group’s culture, means he is the ideal person to lead the Group in the coming years.

Speaking about his appointment, Wayne said: “I am delighted to be given this opportunity. We have a great team ethos that runs throughout the business; one which has been built over the last 50 years. I very much look forward to working with our teams to grow our businesses, and supporting our customers and suppliers further, with new and enhanced products and services.”

www.dormole.net

lederer-world.com Stainless Steel Fasteners EXPLORE MORE: NEWS News from the distribution industry www.torque-expo.com PEOPLE NEWS

Selected news from the fasteners, fixings and tools industries around the world…

NORTH AMERICA 01

THE HOME DEPOT EXPANDS PRO ECOSYSTEM >

The Home Depot is expanding its pro ecosystem with four new distribution centres in Detroit, southern Los Angeles, San Antonio and Toronto in 2024. The new distribution centres will stock large, bulky merchandise so pros can order job lot quantities of the products they need and it’s delivered directly to their job sites.

NORTH AMERICA 02

OPTIMAS ANNOUNCES KEY HIRES FOR AMERICAS REGION >

Optimas Solutions has announced two strategic hires expected to help further support the Company's complementary direct manufacturing and distribution business strategy. Jim Heller is the new senior vice president of distribution, and Chris Martens is the new vice president of manufacturing for the Americas region.

UNITED KINGDOM 03

LAUNCHING PEM UK >

PEM® UK has opened offices in Burnley, signalling a renewed commitment to the UK market. The space introduces onsite warehouses featuring a comprehensive stock of fasteners and an expansion of its sales team. As part of the PennEngineering portfolio, PEM® UK offers the full line of Sherex Fastening Solutions®

UNITED KINGDOM 04

ATLAS COPCO GROUP OFFICIALLY OPENS NEW UK & IRELAND HEADQUARTERS >

Redeveloped from the ground up, Technology House in Hemel Hempstead was officially unveiled as the new Atlas Copco Group HQ for the UK & Ireland region. Distinguished guests joined customers, partners, neighbours, and employees to celebrate the special milestone together.

12 torque-expo.com GLOBAL NEWS ROUND-UP

01 02

EUROPE 05

ZAGO MANUFACTURING CO. LAUNCHES GERMAN AND ITALIAN WEBSITES >

ZAGO Manufacturing Co. has launched two new websites catering to the Italian and German markets. By launching dedicated websites in Italian and German, ZAGO aims to enhance accessibility and engagement for customers who prefer to interact with the company in their native languages. The websites feature ZAGO's product portfolio on its homepage.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

EUROPE 06

FISCHER INVOLVED IN EUROPE’S LARGEST AI ECOSYSTEM >

The Innovation Park Artificial Intelligence (IPAI) is currently being built in Heilbronn, Germany, and the fischer Group of Companies has become its latest member. As part of the IPAI project, laboratories, a data centre, a startup innovation centre, restaurants, daycare centres and apartments are being built on an area of 30 hectares by 2027. The aim is to become a new hub for trusted, applied AI in Europe and the world.

ASIA 07

LUBE FOCUS WEEK 2024 LAUNCHING IN SHANGHAI >

The 23rd Shanghai International Lubricants and Technology Exhibition (Inter Lubric China), and Shanghai International Metalworking Fluids and Surface Cleaning Technology Exhibition (MWF & SC) will be held from June 57, 2024, at Hall E7, Shanghai New International Expo Centre, China.

PACIFIC 08

BUNNINGS CROWNED AUSTRALIA’S MOST TRUSTED BRAND >

DIY, Garden and Hardware chain, Bunnings, has been crowned the most trusted brand in Australia. Bunnings lost its title in 2020, but Bunnings has shown a strong recovery since 2022, achieving the largest improvement in trust among all trusted brands.

13 torque-expo.com

08 04 03 05 06

07

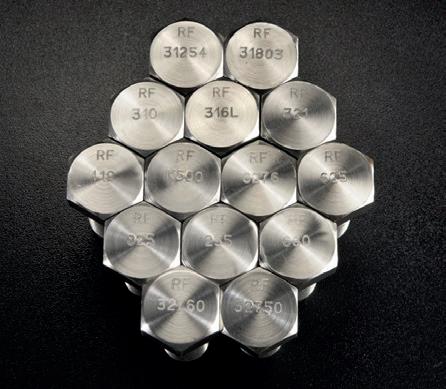

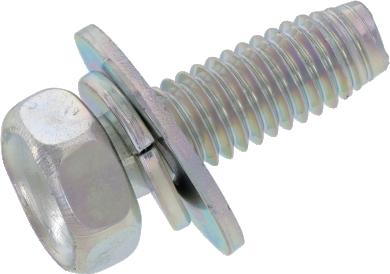

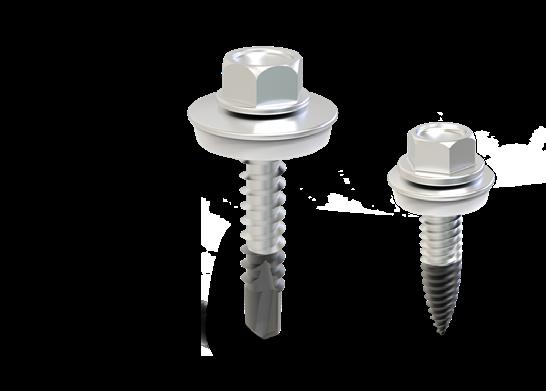

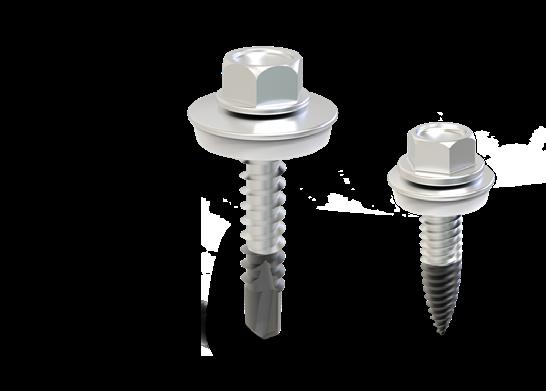

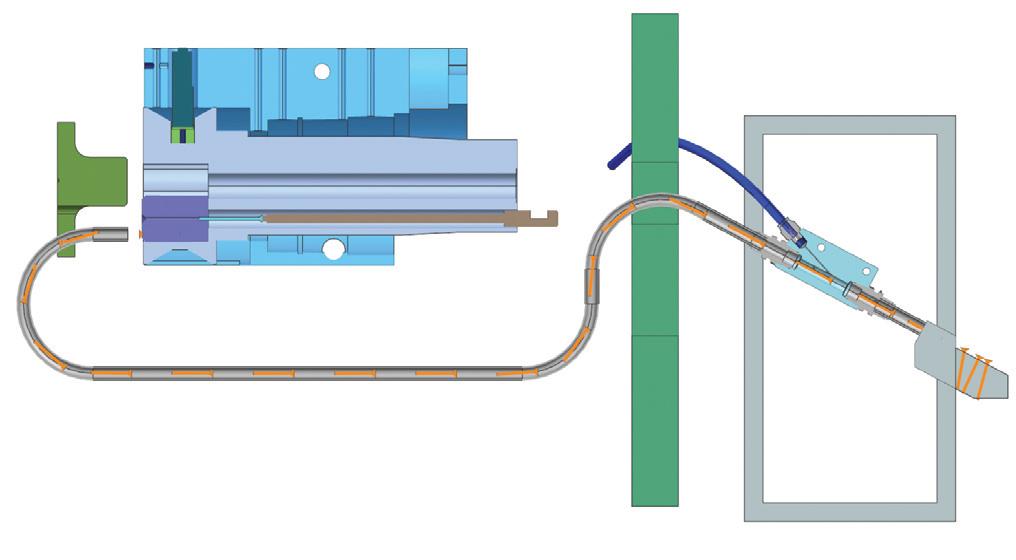

RAPID’S RISE

Rapid Industrial Fasteners are more than just distributors having made the move into manufacturing, with expansion plans set to increase capacity across multiple facets of the business. We talk to Managing Director Richard White about what is in store for the business over the coming months and into the future.

// Rapid’s facilities are set to grow by 65% and the new machinery will mean production capacity is set to initially increase by approximately 40%, with continued growth and development being the goal. //

After over 40 years in business, Rapid Industrial Fasteners success can’t be explained by any one reason but its current growth and expanded operations are largely due to the decision to continually invest in the business. With two distinct arms, distribution and manufacturing, it is the manufacturing capabilities that are responsible for recent investment and expansion.

Having reached maximum capacity in its current location and with the existing machinery, the company is now taking on additional unit space to fit another eleven machines. Located in close proximity to the current workshop, distribution centre and head office, the new facility is still being fitted out with the new machinery and the facilities expected to be up and running by May. “My philosophy has been that we need to continually invest, in manufacturing, particularly. Standing still is not an option for us,” explains Managing Director, Richard White. “We need to continually invest to modernise machinery, develop our capability and increase volume capacity. It is also imperative we invest in the development of our staff skills.”

COVER PROFILE RAPID INDUSTRIAL FASTENERS 14 torque-expo.com

Stand A18

Rapid is increasing its manufacturing capacity with another 11 machines.

By adding more floor space, Rapid’s facilities are set to grow by 65% and the new machinery will mean production capacity is set to initially increase by approximately 40%, with continued growth and development being the goal. “We recognise there is more scope and more opportunity for increased business, more development, and more complicated parts that we can make. That’s why we’ve taken on additional space and will be adding more machines. We’re really excited for this next stage in our manufacturing journey and to see where it can take us,” adds Richard. But the team aren’t growing just for growth’s sake, it has been a deliberate process with attention paid to what, when, where and how the development has progressed. “It’s important to recognise what you are good at and don’t do things beyond your capabilities,” explains Richard.

// We recognise there is more scope and more opportunity for increased business, more development, and more complicated parts that we can make. //

The new machinery includes a Star SB16 sliding head CNC and a Citizen Cincom L32. The goal is to not only make complete parts but improve manufacturing efficiency by embracing the more complex technology. “It’s just making us more accessible to our existing client base and anyone else who want a diverse supplier. The new machinery will be doing some of the work we are already doing, but we can then do it quicker and faster in the right combinations,” he adds.

With the additional machinery Rapid will also be investing in personnel as well. “We’re undergoing training on the new machinery, and we are looking to add another couple of people over the coming months as well. We are not only reinvesting in plant and equipment, but we’re also investing in staff, and we are investing in training,” says Richard.

Throughout this entire process and with the added manufacturing and distribution capabilities, Rapid is keen to maintain their high levels of customer service. A focus on relationships and keeping customers informed are cornerstones of their operations. Regarding the move into manufacturing, Richard explains there was a desire to keep communication lines open: “The biggest learning curve in manufacturing for us has been to keep being transparent, open and honest. These things are massively important in life and in business anyway. When you are manufacturing items, it’s important to keep the customer fully updated. We’ve gone from taking boxes off shelves to actually producing and manufacturing. It’s managing expectations, keeping people updated and being proactive.”

In line with the expanded operations, the company’s exports are growing with new avenues beyond Europe being added to their customer base. “We’re exporting into France, Germany, The Netherlands, Spain, Denmark, Norway, Slovakia, Macedonia and others. But we’re now also shipping to Mexico, the operations are part of a large global group, and it is very exciting,” says Richard.

“This new era excites me,” he adds. “Not only the project of the new unit and the machinery but just expanding the business, expanding the business opportunities, the chance to engage with more people who we want to do business with. We’re very much relationship focused, and we like to focus on the people. We like for people to give us a fair opportunity to show what we can do. Hopefully, we give our customers a reason to keep coming back.”

Recognising how much things have changed at Rapid since its inception and especially in more recent years, the team are keen to keep moving and looking at the future with no set finish line. “We’re looking forward with optimism, we’re looking at attacking the year and not resting on our laurels. We want to be progressive and not complacent. The business needs to keep evolving and that’s what we will do,” concludes Richard.

www.rapidfast.co.uk

The new distribution hub has 972 pallet locations 15 torque-expo.com

GLENDA’S GOODBYE

After 34 years at TR Fastenings, Glenda Roberts has decided it is time to retire. As a well-known and muchadmired member of the fastener community for so many years, she speaks to Torque Magazine about her career and the industry she has helped shape and influence.

Congratulations on your retirement, how are you feeling?

I wanted to go gracefully into obscurity, and it didn’t happen. Instead, I’ve really been overwhelmed, and I feel humbled. Hundreds of people have contacted me, there has been lunches and other events. There was a fantastic photograph of me with all different pictures coming together, pixelated into my image, I was so choked up and it takes a lot to squeeze a tear out of me.

There hasn’t really been time for it all to sink in as we’ve been working on the new TR National Distribution Centre. We’ve had the joy of branding a new building completely, considering everything from the teaspoons to bespoke furniture, and artwork. Honestly, it’s looking pretty damn good. I’ve worked right up to the last minute, so that was a nice thing to finish on from a marketing perspective, probably one of our biggest projects.

You spent 34 years at TR Fastenings, what is it like to step down after all this time?

When you are on the board of a PLC, you get to a certain age, and you are considered a bit of a risk. So rather than somebody tell me I was past my sell by date, I said, I’m going to step down, but I wanted to have a key part in recruiting my replacements because I cover a number of roles. I wanted to be the architect of my own departure, which is really what I’ve done. I thought I would start to ease out the business, but it’s not been like that, it has been full on the whole time.

How did your fastener career begin?

I was in fast moving consumables, but I could see that computerisation was coming in and they wouldn’t need people like me out on the road. A lot could be done via automatic ordering, so I

started to cast my net and look around. I went for an interview with an agency and despite feeling like I was just a number; I fought hard and got the job. I was with that company for six years and ended up as their sales director.

At the time, many companies had good engineers who knew the product, but they didn’t have people who could sell. My problem was, I had no product knowledge. So, on my first day they sent me to their manufacturing site, and I turned up in my little black suit, lovely white blouse and high heels because that’s how life was – and they put me on the production floor! You could see I was an absolute danger, so they brought me into the offices. There were two guys, who I’ll be forever grateful to, who mentored me. And I was just so damn nosy about everything. If I didn’t understand electroplating, I’d go and work there for a day. If I didn’t understand different finishes or products then they let me work in the factory to show me how the product was made and then afterwards, I knew enough. And if I didn’t know, it was my practice to say I’ll find out for you.

I think the most important thing was then going back to people on time, even if you’ve gone back and said, I haven’t got you an answer yet, the very fact you go back was appreciated. I think that was helpful as a woman that you could admit that you didn’t know, but you’d find out. I think it’s easier for a woman to say, ‘explain that to me again’, and I’ve used that to my advantage my whole career. I like to follow the idea that “you never know what you know, till you meet someone else that doesn’t know it.”

Why did you stay with the same company for so many years?

TR gave me lots of opportunities. I was the first person recruited in as a director from the outside, and the first female director and it was very male dominated, but a great, fun place to work. You had to be able to stand your own ground because there were lots of characters.

I started in their factory in Telford and then I opened up a couple of TR locations where there were gaps in geography, then I went on from there to be the UK Sales Director. As the business started to migrate, with major customers going into lowcost countries, particularly in Asia, the then CEO Jim Barker, asked me to set up a global team to keep hold of the business wherever it went. I started to recruit a team and spent a lot of time in China. I got appointments, where probably other people wouldn’t but it was such a fantastic time to be out at the forefront working with companies.

16 torque-expo.com INTERVIEW WOMEN IN FASTENERS

I’ve built up the global team and we’ve developed global account strategies. So major customers have a global account director looking after them and we gave them the same level of service on three continents. They then have a strategic account manager team behind them and business development managers at a local level and that’s how we grew the business.

Have you enjoyed being a mentor and inspiring others in the industry during your career?

That’s one of the things I miss, helping to develop people or getting them to another level. I like encouraging anyone to flap their wings and to explore. I’ve liked to push the boundaries and give people that armour so that they can do a better job and could reach further.

// It was very male dominated, but a great, fun place to work. You had to be able to stand your own ground because there were lots of characters. //

COLLEAGUE VIEWPOINT

Maddy Webb

Head

of

Risk & Internal Audit

“I will never forget the adventures we had, or the battles we fought, or the times we laughed in the bar afterwards! You showed me how to be a woman in a man’s world, and the value of taking care of each other.”

What do you consider your greatest career achievement?

Is there anything you are particularly proud of?

Just being a key driver in the business. I do a lot on developing smarter systems, talking and going out to companies in India and China, teaching them the methodology that we used in the UK. Setting up a global enquiry portal so that we could track every enquiry globally and we weren’t competing against each other – that’s developed into a significant tool for the business. I’ve always seen myself as the ideas person and other people go and make it happen and do a better job of it.

Being on the main board for 10 years taught me a lot. I started to see the business in a different light, because your objectives are different when you’re on the main board. I think I helped influence the business in a certain way. Being seen as

17 torque-expo.com

INDUSTRY VIEWPOINT

Aneela Rose

Client Director, Rose Media Group

a global company with the TR brand, I’m very proud of that.

You do it with a team you’ve built around you, if they’ve got an achievement, I’m proud of their achievements. I’ve been looked after very well by TR, and I’ve had all the benefits, of my hard work. I was very lucky that I had a very tolerant husband, not many women would get away with being abroad as much as I was, but we all had the benefits out of it.

I’m quite happy and proud to tell you I actually love TR, I love my life there, and there aren’t many people that can say that after 34 years. It’s been an exciting ride, and my enthusiasm has never waned.

“An absolute pleasure working with you these past 13yrs. You’ve influenced so many people, and a role model for women in engineering across the globe.”

What’s the best piece of career advice you were ever given?

If you don’t know, ask. And I would also say sometimes if you don’t understand what somebody is trying to get over, get them to explain it again, and again, until it sinks in. People come up with plans and ideas but it’s important to ask what we are going to get out of it. It’s important to not be afraid to ask questions and also take a risk. Believing I can do that, so let me have a go.

After having worked across so many international markets throughout your career, what’s your perspective on the UK fastener industry compared with other markets? Has it changed over the years as well?

Definitely. I don’t think I could reel off all the names of companies that are no longer manufacturing in the UK. I think as more business moved abroad, with that, knowledge walks out the door,

because a lot of people that came into distribution previously worked in manufacturing. There’s a real shortage of knowledge, particularly product knowledge, in the distribution industry.

Our distributor sales are substantially more in Europe, and we find them very different to deal with. In the UK, there’s lots of smaller companies and I think they’re going to really struggle now with CBAM. It’s going to cost them and they’re going to need to recruit people, and a lot of them won’t know how to deal with it. So, I do see a decline in the UK distribution, although there are a few shining stars.

How are you adjusting to retirement?

What are you hoping to do?

I must admit, when I handed in my laptop and my mobile phone, I said that’s going to be hard for me. I’m used to having two phones and of a morning I’d make a coffee in my bedroom and then I start to look at my phone, and not having that now was difficult. What I’ve done was literally treat every day as a Sunday. I’m doing odd jobs and sorting things out.

I have had some nonexec directorships discussions with people and I’m to go do something new. At the moment, I’m freestyling and going with the flow. What worries me is how do I keep my brain active. I don’t think I’ll become a lady who lunches, but I’m going back and joining the gym, and swimming. All the things that you let slip, or struggle to find time for. But yes, I’m going to miss it enormously, no two ways about it.

www.trfastenings.com

18 torque-expo.com INTERVIEW WOMEN IN FASTENERS

The new TR National Distribution Centre warehouse

Head O ce: 9-28, 1-Chome, Itachibori, Nishi-Ku, Osaka JAPAN 550-0012 (World Trade Section) Tel: +81-6-6539-3560 Email: export@sunco.jp 3Qnet. Web Catalogue Website Company Information

Schäfer + Peters GmbH Compe t ence in St ainless St ee l Europe´s main distributor of stainless steel fasteners Over 37.000 items permanently in stock More than 40 years of experience Schäfer + Peters GmbH | Zeilbaumweg 32 | DE-74613 Öhringen | Germany Tel. +49 (0) 7941 6094-0 | Fax +49 (0) 7941 6094-700 | info@schaefer-peters.com | www.schaefer-peters.com C ompetence i n S tainless S tee l

AC-90 BIO MULTI-OIL

High performance biodegradable multifunctional oil for lubrication, release, corrosion protection, water displacement, cleaning and much more. AC90 BIO is a readily biodegradable formula (according OECD 301B >60%). Bio-based carbon content (based on ASTM-D6866-22): 63%.

AC-90 Displaces Moisture: AC-90 contains active ingredients which rapidly displace moisture and eliminate damp induced faults on ignition circuits.

AC-90 Lubricates: AC-90 keeps moving parts working smoothly and efficiently, eliminating stick-slip and improving operational efficiency. Does not contain silicone.

AC-90 Penetrates & Releases: AC-90 rapidly penetrates and releases seized, corroded and overtightened fasteners, leaving a fine lubricating film for ease of reassembly and future protection.

AC-90 Protects Against Rust: AC-90 provides excellent corrosion protection of metal parts and components, repelling atmospheric moisture and inhibiting flash-rusting.

Phone:

+44 (0)1278 727200

Email: sales.uk@crcind.com

1755256

Action Can, Wylds Road,Bridgwater, Somerset, TA6 4DD

ACTIONCAN.COM

EMPOWER YOUR PERFORMANCE. EMBRACE THE FUTURE. Discover more at actioncan.com/ac-90-bio

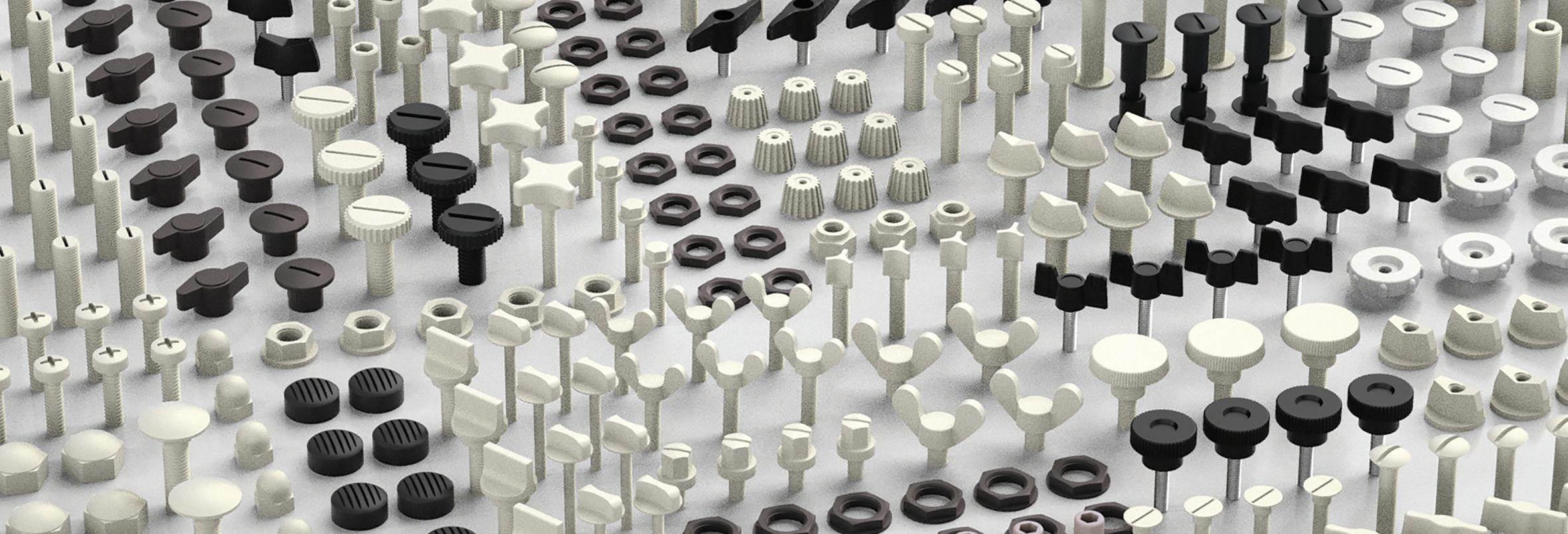

VOLT INDUSTRIAL PLASTICS EXPANSION

Growth plans for Volt Industrial Plastics mean not only increased operating space for new machinery but also larger warehouse capacity to boost the availability of parts for prompt shipping.

Volt Industrial Plastics, Inc. located in Yellville, Arkansas has raised the bar yet again. It has recently completed a very important part of its new 36,000 square foot expansion, giving it a total of just over 100,000 square feet of total operating space. 10,000 square feet of the new addition is primarily for the CNC/Tool Room. This new space will enable Volt to add more new and exciting products like the HeavyDuty Cable Clamps which will be completed later this year.

The architects and engineers that designed this new expanded space did it in such a way that allows Volt to grow but continue to remain efficient. Moving forward, Volt has always prided itself on keeping up with technology and will continue to do so. The new CNC/Tool Room space is and will continue to be housed with the most uptodate equipment so that Volt can continue making customer driven tools with a quick turnaround. Making the tooling is the first very important step in getting the product out the door and to customers.

Since Volt’s inception in 1992 it has had continuous growth, and several expansions along the way. The Tool Room is where the company’s founder, Joe Volltrauer began his career in the fastener industry many years ago. In 1952 Joe came to the United States from Vienna, Austria. Along with his few worldly possessions, he brought with him the European (German) work ethic that provided the foundation for the business that he eventually launched through becoming a tool and die maker himself in Chicago, Illinois. In 1973, he started his own company, JV Tool, and a couple of years later moved his family to Arkansas where he designed his functional, highquality moulds for manufacturers of plastic components, including plastic fasteners.

Volt has been a familyowned business from the beginning, and Joe’s daughter, Heidi Volltrauer, had already been intri

cately involved in the fastener industry and with Volt for over 32 years. Heidi has been there by Joe’s side from the very beginning, and now is taking the reins in overseeing everything, including this very exciting expansion. The next phase will be the warehouse expansion.

“We have now expanded our warehouse space by 16,000 square feet, and we are ready to fill it up,” says Heidi Volltrauer. Volt currently has over 100 million parts in stock and ready to ship, but with the recent expansion, they will now be able to keep many more products on hand. How many more? “We will let you know when we are at that part of the phase. With the additional space we’ve recently created for our production machines, we have the room to grow – and that is exactly what we intend to do. We will keep you posted,” says Volltrauer.

For more information give Volt Industrial Plastics a call toll free at 8008448024 or visit the website.

voltplastics.com

22 torque-expo.com TORQUE FOCUS NYLON + PLASTIC FIXINGS AND FASTENERS

The new CNC/Tool room

CHOOSING SMALL PARTS, MAKE A BIG DIFFERENCE

German family firm Bülte detail the benefits of using plastic fasteners over traditional metal counterparts.

Plastic fastener screws aren’t new and they have been widely used for a long time and for good reason. Plastic is exceptionally versatile.

HERE ARE 5 REASONS WHY PLASTIC SCREWS ARE ACTUALLY A GOOD CHOICE...

1. They are cost effective and good quality... which means also less expensive than metal screws. But above all they are complementary to metal fasteners.

2. Plastic screws won’t rust or corrode. If your project is exposed to diverse elements, particularly a wet environment, or corrosive atmospheres, you may want to consider plastic screws as they’re not affected by water (not even saltwater). Plastic screws may be ideal for marine projects.

Typically, metal fasteners corrode and develop rust over time, especially when exposed to moisture or salty conditions. Corrosion, of course, leads to degradation. If it’s corrosionresistant fasteners you need, you want plastic.

3. They have poor conductivity. Plastic screws offer superior insulation properties compared to their metal counterparts. Plastics are very poor conductors of electricity and heat. By mitigating the risk of short circuits and electrical hazards, plastic screws contribute to safer working environments and reduce the likelihood of costly downtime due to equipment failures.

4. Plastic screws are lightweight. It’s a huge advantage in terms of transport, handling and assembly. For assemblies that utilise lots of screws, plastic screws could shed a significant amount of weight, helping in projects that have weight requirements.

5. Plastic screws are also resistant to UV light. It turns out plastic screws and other plastic fasteners are perfect for outer space. Plastic is highly resistant to UV rays, which means sunlight won’t break down plastic screws as quickly. Additionally, plastic screws may not have the same temperature resistance as metal screws. It is important to consider the specific requirements of the application and the environment in which the screws will be used before making a decision.

Plastic screws are also recyclable and can be reused or repurposed, making them an environmentally friendly option, says Bülte. Bülte can also offer innovative plastics such as biodegradable plastic made from wood chips. A researcher has developed a bioplastic based on wood waste that degrades in just three months. This bioplastic material can replace HDPE, PP, PS, and PA.6. This is a biodegradable and compostable polylactic acid (PLA) grade. It is a biobased, rigid grade with 84% renewable content. It is suitable for processing by injection molding. The use of such recyclable plastic in industrial applications could represent a significant step towards sustainability in certain industrial activity.

With nearly 70 years of experience, Bülte is committed to providing excellent service in order to produce the finest products. We are aware that every project demands precision, reliability and versatility. Bülte has a wide range of plastic screws from M2 to M24 and are investing in new tools to be able to meet customers fastening needs.

Bülte has a range of diverse shape screws including Hex head standard screws, Cheese head screws, Flat head screws, Countersunk head screws, Pan head screws, Grub screws, Hex socket head screws, Knurled head screws, Wing screws, Violin head screws, Four stars screws and Binder posts.

The wide range of plastic screws is available in different types, from the most standard (normalised) screw models to the most specific screws, depending on the application.

Whether you’re working on complex electronics, heavy construction or delicate assemblies, the comprehensive range comes in a multitude of heads (DIN or Bülte specific heads, manual or tool tightening) to ensure you find the ideal screw size for every application. The screw range is available in a wide variety of materials (PA, PEEK, PE, PTFE, PP, PVDF) to meet the requirements of all the main sectors of industry.

Bülte’s core business is injection molding, offering advantages such as costeffectiveness, high efficiency and design flexibility. Bülte can advise customers on construction and material selection and have the potential to create specific custom samples using various prototyping processes. In addition to our standard programme, Bülte can also develop and produce customerspecific items made of diverse plastic materials.

As a pioneer in plastic fasteners, Bülte is continuing to drive forward the plastic fasteners revolution to unleash its full potential for the benefit of all industry players.

www.bulte.com

24 torque-expo.com

TORQUE FOCUS NYLON + PLASTIC FIXINGS AND FASTENERS

Choosing small parts, make a big difference

Need more sizes ?

We can work with you on your project to adapt the size of our standard DIN screws to your specifications.

Visit us on www.bulte.com

The widest range of Nylon screws! From M2 to M24

FASTENING INTELLIGENCE MEETS ENERGY EFFICIENCY

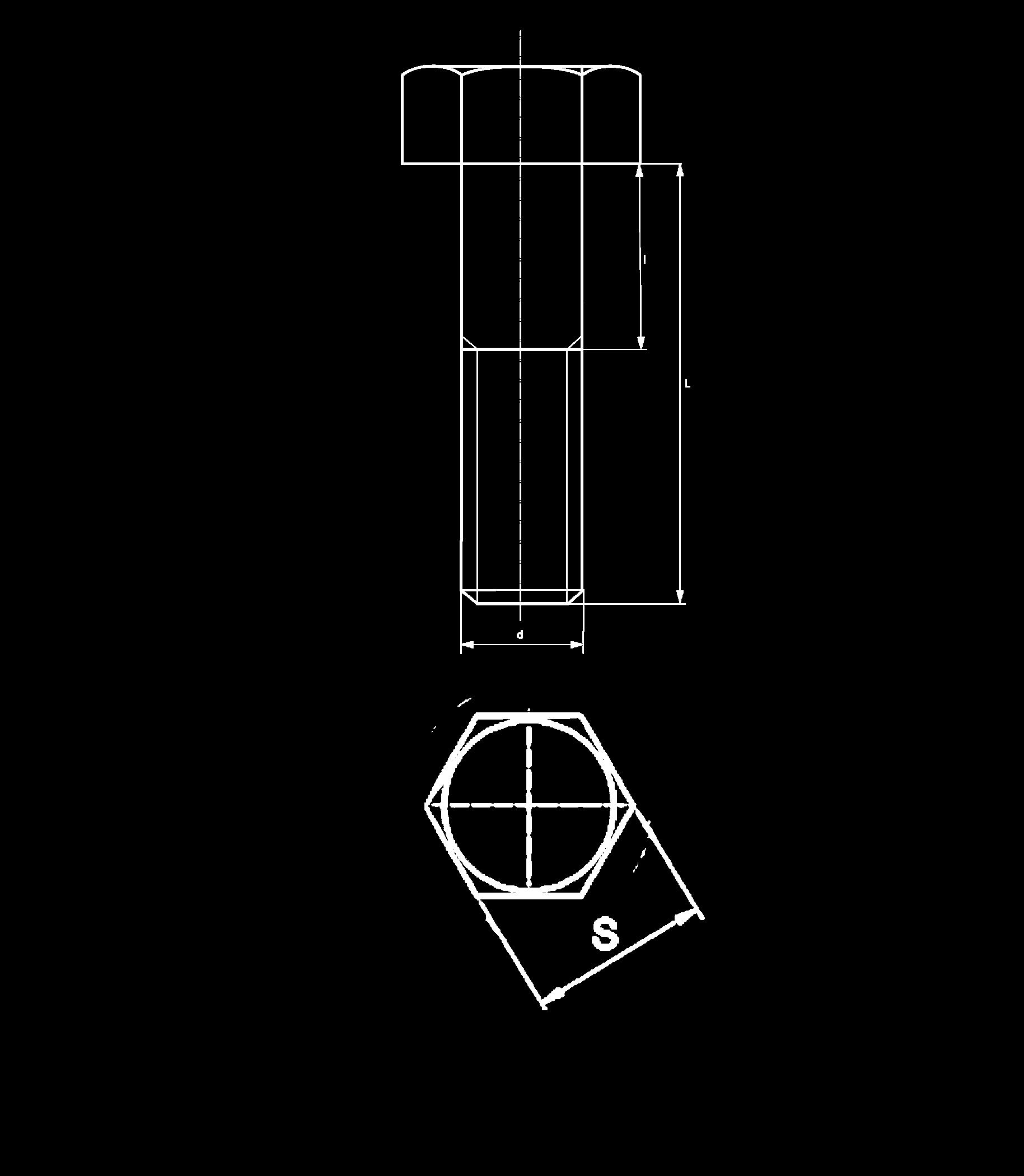

Glassfibre reinforced plastic is one of the materials used in the new products from fischer designed to ensure maximum stability in ETICS to avoid thermal bridges.

External thermal insulation composite systems (ETICS) are now a standard feature in new buildings and are increasingly being used in renovations. To fasten fixtures without thermal bridges, fischer offers the FID II, FID II Plus, FIDR and FIDZ insulation fixings.

When attaching any fixtures on facades with ETICS the fastening must not cause any thermal bridges in the facade and be fastened to the anchor substrate behind the insulation, depending on the load.

fischer also offers innovative insulation fixings to fasten lightweight to medium fixtures directly in ETICS. Variants of the latest FID II /FID II Plus generation can be used in ETICS with all kinds of common insulation types and superstructures. Because the fixing is placed directly in the insulation through the plaster, no thermal bridges are created while attaching any fixtures. Parcel boxes, charging points for electric vehicles or window shutter holders – FID II Plus provides an added advantage with its loadbearing capacity and its ideal combination with a chemical additive component. Combined with the insulation fixings, fischer’s Fill&Fix liquid plug or fischer 1K PU foam increase load values by up to 100%.

Thanks to the combined centring, milling and cutting function of the plug tip, the plugs can be screwed in with precision before

providing a flush fit in the insulation without damaging the surface. Thanks to their special tip geometry, the plugs can be screwed into plaster with strengths of up to 10mm, making the process simpler and faster. Predrilling is recommended when working with thicker plaster layers. Using conventional screws with diameters of 4.5 to 6mm (FID II Plus) or 3.5 to 4.5mm (FID II) enables flexible processing. When using the FID II Plus as a system together with fischer Fill&Fix or fischer 1K PU foam, the curing time of the chemical component must be observed before the screw can be inserted. Following the prepositioned installation, the plugs can be additionally sealed with a sealing compound, protecting the fastening point against moisture.

The special geometry beneath the head of the plugs provides a clean setting result. With its low head diameter, the FID II also provides an optimised appearance, meaning the plug rim is not visible even when installing slim fixtures. Made of glassfibre reinforced plastic, the new products ensure maximum stability in ETICS, including pressureresistant insulation materials such as wood fibre.

FIDR is ideal for installing rainwater pipes to ETICS without thermal bridges. The plug can be installed with standard tools thanks to its TX drive. Its accompanying cover and nut are applied on its threaded pin to seal the FIDR and prevent rainwater from penetrating. The pipe bracket is then screwed onto this fixing, which the rainwater pipe can be attached to.

With the fischer zinc diecast FIDZ insulation fixing, thin metal sheets can be fastened to plastered ETICS facades made of polystyrene, mineral wool, softwood fibres and polyurethane. Its special tip geometry is inserted directly into the sheet in the facade without requiring any predrilling. Fixtures such as crosscutting strips or splash guards can be attached with speed and ease using the insulation screw. The sealing washer on the screw head seals the drill hole against weather influences.

The fischer TherMax variants with M12 and M16 threaded rods allow heavy loads to be fastened in a compliant manner to insulated external walls, front faces of ceilings or in rear ventilated curtain facades with insulation thicknesses of 62 to 290mm while ensuring thermal isolation. Marquees, French balcony rails, air conditioning units, satellite dishes and numerous other fixtures can therefore also be fitted to walls with ETICS. TherMax 8 and 10 variants are suitable for securely fastening mediumheavy objects such as lights, letter boxes and lightning conductors.

www.fischer.group

26 torque-expo.com TORQUE FOCUS NYLON + PLASTIC FIXINGS AND FASTENERS

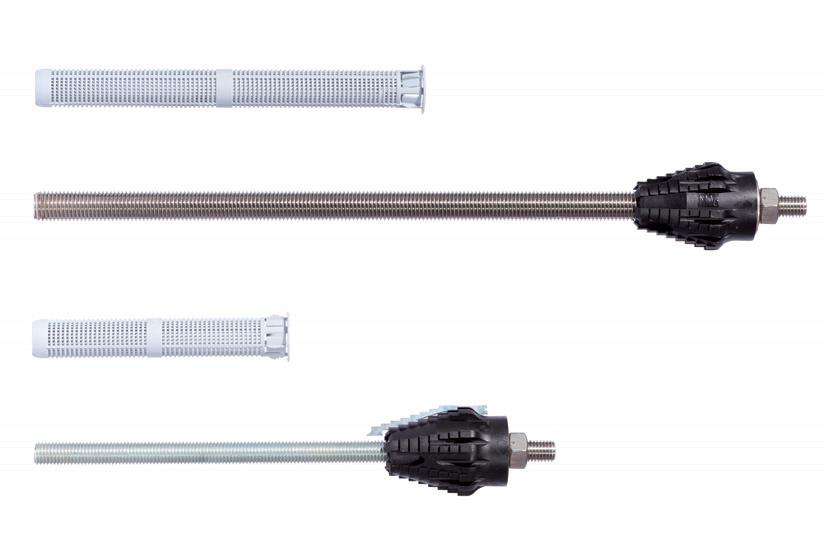

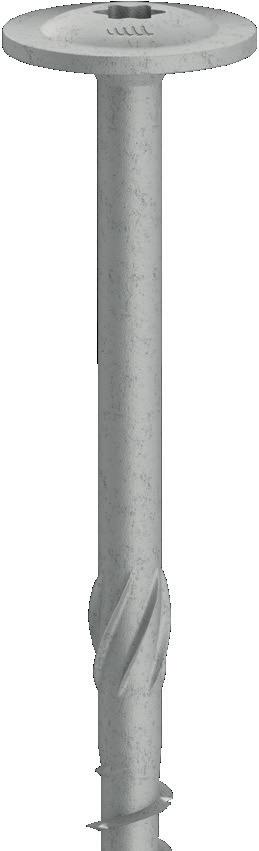

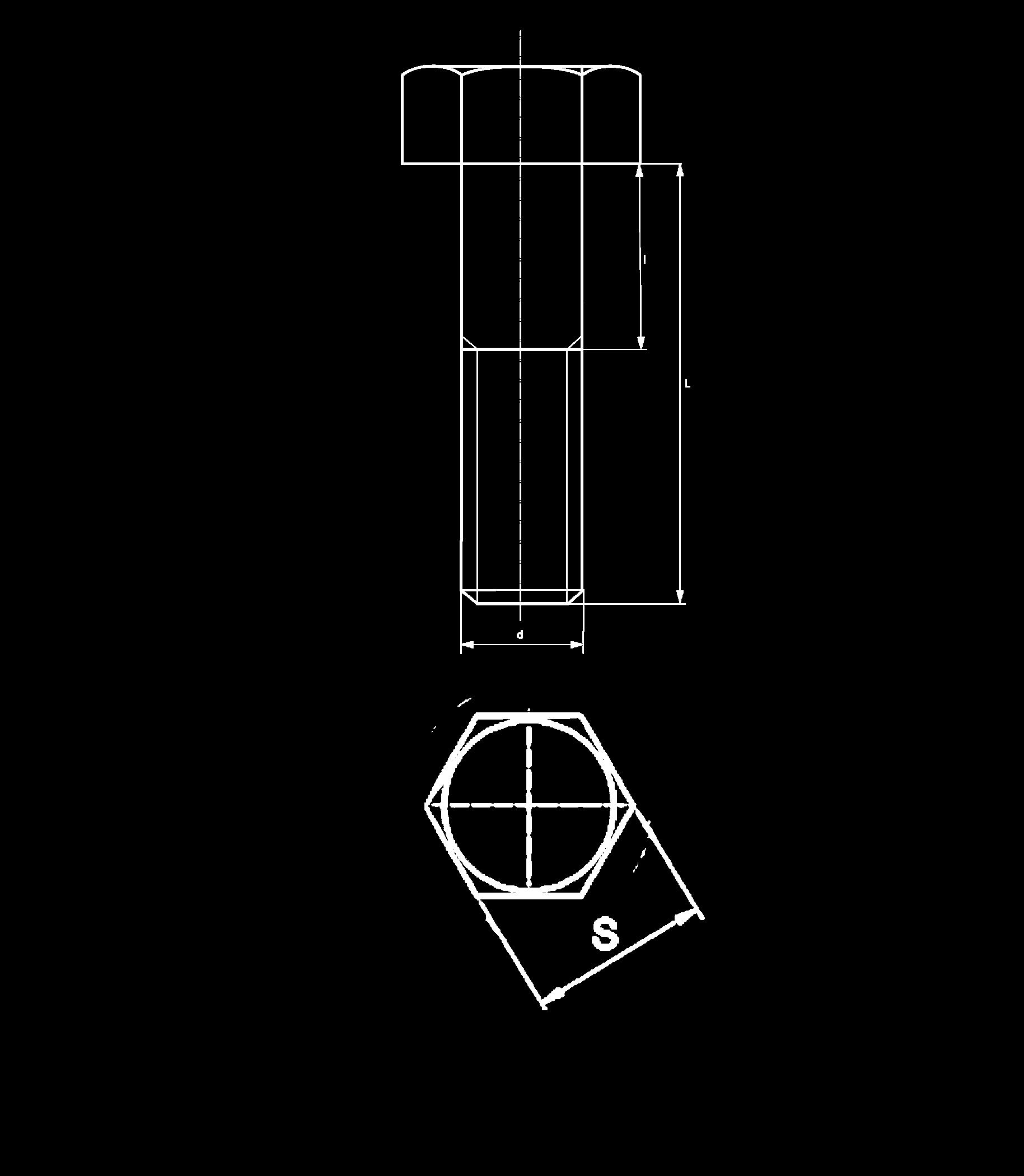

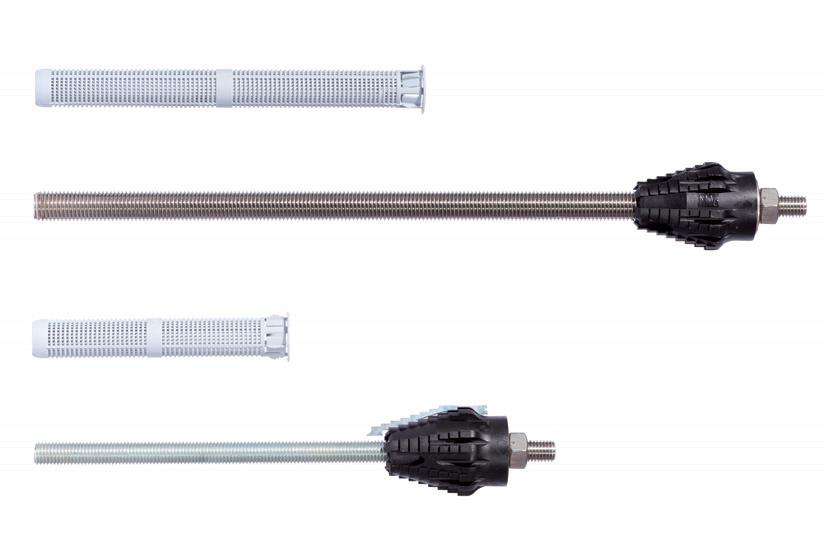

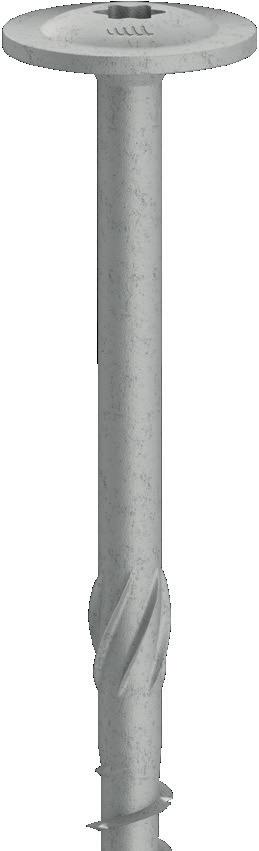

SPECIALIST FIXINGS FROM JCP

JCP has a wide range of nylon and cavity fixings in different styles, finishes, materials and sizes to cover multiple uses and applications.

JCP, the specialist fixing division of OwlettJaton, offers a wide range of nylon and cavity fixings, spanning over one hundred and thirty products.

The range includes a choice of nylon frame fixings, with options on head styles, finishes, materials, and sizes. But JCP does not stop there; it also offers a range of nylon frame fixings that are not only CE and ETA (European Technical Assessment) approved but R90 firerated (90 minutes resistance), too.

Tested to ETAG 020, plastic anchors for multiple uses for nonstructural applications, the ETA substantiates that they can be used for a range of solid and hollow base materials for multiple fixings in nonstructural applications.

Nylon frame fixings are a lightduty matched screw and plug. Typical applications include timber, uPVC, and metal framework to concrete and masonry. A strong grip in weaker materials is achieved by the use of a high expansion ratio, and heavy ribbing on the expander which digs into materials.

Nylon frame fixings offer many benefits. Being a multipurpose anchor, they are ideal for a wide variety of trades, offering supreme fixing. Preassembled, they are quick and easy to fit, resulting in time reduction, and ultimately cost. There is also no waiting time before loading. They can be removed and reinstated with ease making them ideal for maintenance and repair jobs. The countersunk lip on the plug helps with setting it to the correct depth, giving a flush finish. The antirotational lugs prevent the plug from spinning inside the hole.

The new JCP catalogue contains the entire nylon and cavity fixings range, in addition to the rest of their product lines.

2024’s catalogue includes a whole host of new product addi tions including bimetal ETA pan head ankerbolts, bimasonry screws, woodfix highthread selfdrilling screws for

// The new JCP catalogue contains the entire nylon and cavity fixings range.

timber, fibre cement screws for timber and plasticcoated fixing bands.

To provide fast and easy access to the technical data for JCP products, QR codes have been added to each of the ranges. A handy guide to JCP products suitable for use in cracked concrete has also been added.

For more information on the nylon range or a copy of the catalogue, visit the website or contact your local OwlettJaton sales office.

27 torque-expo.com

//

NYLON + PLASTIC FIXINGS AND FASTENERS

NYFAST FAST BY NAME AND NATURE

Nyfast (Nylon Fasteners Ltd) is celebrating its 15th anniversary and Directors Marcus Birkmyre and Jake Phillips are keen to recognise the company’s achievements as they reflect on the speed the business has grown in that time.

Starting out as a oneman operation from founder and Director, Marcus Birkmyre’s home, Nyfast has grown from strengthtostrength yearonyear in the 15 years it has been in operation. Recognising a gap in the industry and knowing there was a better way to do business, Marcus took the leap to go out on his own “Back in 2009, I started by myself, just working from my barn at home. We then bought our first unit that we occupied for six years, which we then suddenly outgrew really quickly before purchasing our current location in Basingstoke in 2018,” explained Marcus.

Nyfast’s facilities work well for the team as it has the floor

space and the flexibility to allow for when big orders come through. “With the mezzanine and layout, we can get nearly 6,000 square foot of stock out of this unit. So, it works really well for a small company where we can hold a lot of stock boxes, bins and pallets. It’s nice just having the space,” says Marcus. The space is perfectly suited for future growth, as this is very much the team’s focus. “Whatever the next project is, however many new product ranges we need to move in here or whatever the next step is, we are in the perfect position to do that,” adds Sales Director, Jake Phillips.

The location along with the range of products lines available

From l to r:

Brian, Connor, Jake and Marcus at Nyfast HQ

28 torque-expo.com

TORQUE FOCUS

NYFAST STANDS OUT WITH SEVERAL KEY UNIQUE SELLING POINTS THAT SET US APART IN THE FASTENING INDUSTRY...

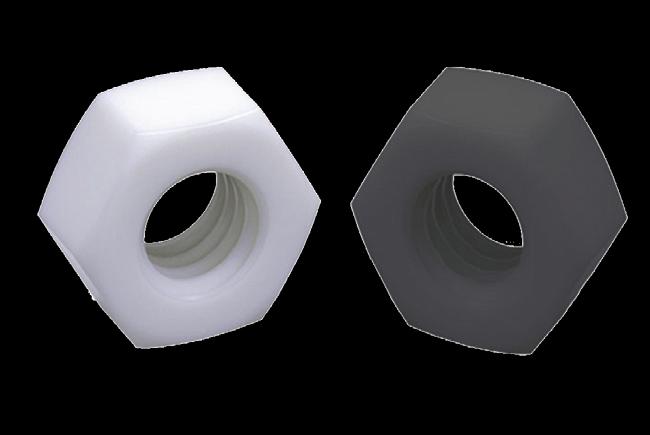

Firstly, we are specialists in nylon fasteners, operating within a niche area of expertise with a wealth of product and market knowledge.

By focusing solely on this field, we ensure extensive stock holdings and maintain the most competitive pricing in the market.

Our specialisation also enables us to cater to specific customer requirements and usage scenarios, offering tailored stock holdings to meet individual needs. A common unique requirement for customers is a black nylon solution as well as standard natural nylon, both colour variants are readily available with Nyfast.

We also offer a custom washer service –inviting customers to fill out our online form, stating desired OD, ID & thickness dimensions, quantity required and a drop down of 37 additional materials outside of Nylon 6 Natural, Nylon 6 Black, Nylon 66 Natural and Nylon 66 Black.

Moreover, Nyfast recognises the challenges faced by metal fastener suppliers when sourcing plastic components. We address this by regularly supporting the metal fastener industry with their plastic fastening requirements, leveraging our expertise to provide seamless solutions.

With Nyfast, customers can expect unparalleled support, a vast inventory of nylon fasteners and personalised service to meet their unique demands.

+44 (0) 1256 533 088 | sales@nyfast.co.uk | www.nyfast.com

// We have no intention of moving into the metal fastener space, we want to focus on nylon.

mean that the customers Nyfast work with are from diverse fields with all manner of problems to solve. Whether it’s a unique walk in request for fir tree clips going into polo helmets, to multi pallet MOD contracts, the team are happy to assist and help solve any of the fastening problems presented to them.

“We work with fastener distributors, but we also make a conscientious effort to focus on the end user across all industries,” says Marcus. “For example, what helped us through the Covid shutdown was our diverse customer base. We supplied basic PPE, elastic head banding, face shields and the nylon rivets to secure them together by the million. We weren’t relying on one particular market, so that when a number of sectors went down a bit, we had other sectors to fill the gap.”

Nyfast’s top product lines include Industry Standard Nylon Snap Rivets & Panel Fasteners, Nylon Washers & Spacers, Nylon Threaded Fasteners, PCB & LED Fasteners and Cable Clips & Clamps. Millions of these items are available in stock for next day UK dispatch from their Basingstoke location.

Both Marcus and Jake were keen to emphasise their aid to the metal fastener market, recognising Nyfast’s niche and focus within plastic fasteners. “We know that most fastener suppliers and distributors’ focus is on metal, but for the small requirement of nylon that these companies have, we are already trusted by many to source, supply and hold stock of exactly what they need to take the pain out of these requirements. This means that there are no worries or delays for them with import, customs, small order fees or lead times. We have no intention of moving into the metal fastener space, we want to focus on nylon and being the best in our field for service and price,” explains Jake. In addition to fastener suppliers, some notable industries that Nyfast supply include: Lighting, POS, Automotive, Electronics and many more.

Speed and efficiency are two company attributes that Marcus, Jake and the team take pride in, which they believe stems from the collaborative atmosphere they endeavour to have among the various members of staff. From enquiries, to fulfilling orders, invoicing, marketing and more, everyone understands what is going on and can step into the various roles as needed. All of the team get to have a say on new ideas or other aspects of the business, and everyone’s opinions count. This great team dynamic is helpful when decisions need to be

made. “We can pivot on a dime, we can make decisions very quickly and quite major decisions as well,” says Marcus.

The team are in the process of taking the company’s website to the next level by adding more 3D render videos of products in action so customers can clearly see how they work. “This continued investment is providing another level of customer service and professionalism,” explains Jake. “Sometimes it can be tricky to describe something in words, not so much for straightforward items like cable ties and washers, but for some of the weird and wonderful clips or PCB hardware, people can watch the videos and it is so much easier to understand and comprehend.”

Nyfast’s products are sourced globally from the US, Europe, China and elsewhere. They are consistently growing the product portfolio online and provide items in a number of materials, including natural nylon, black nylon and an array of different colours on request. Nyfast have also introduced their Custom Washer Service in recent times where customers can choose their desired OD, ID and thickness as well as a drop down of over 40 different materials.

There are no issues with shipping/lead times as they primarily use air freight due to the inherent lighter weights of nylon goods from their various factories worldwide. If something isn’t available from stock, it can generally be sourced quickly with minimal shipping delay, shipments leaving various factories generally on a weekly/bimonthly basis and the team keeping customers informed throughout and when necessary.

Customer service is another hallmark of Nyfast’s operations as they try to take the pain out of the process for customers –whether that’s a distributor or end user. They are happy to go above and beyond for customers as they recognise some products are so niche. Nyfast are experts in alternative sourcing and providing supply chain improvements – not only from a cost perspective, but on service and lead times too. As a small company with low overheads, great savings can be reflected to their customers. “We like taking that extra level of care whether that’s on the phone or when it is packing an order, it’s got to be done right to our self set high standards,” concludes Jake.

nyfast.com

30 torque-expo.com TORQUE FOCUS

+ PLASTIC FIXINGS

NYLON

AND FASTENERS

//

Solution Provider. Hall 004 | Stand: A34 Hannover Messe Hermesallee, 30521 Hannover, DE THE MOST POWERFUL LOCKBOLT PLB v2 System ものづくり補助金により作成 Supported by a special government Grant NISSEI CO., LTD. 2022 Torisawa, Tomihama-machi,Otsuki-shi, Yamanashi, Japan 409-0502 USA Office, 620 East Bigelow St.Upper Sandusky, Ohio 43351 Michael Shutt,shuttm@aol.com,419-460-1101 Scan the CODE to see“PLB v2”website ものづくり補助金により作成 Supported by a special government Grant

BÄCKER PRESENTS NEW PLACOLOCK® LATCHING SYSTEMS

BÄCKER is expanding its product portfolio with the new PlacoLock® brand which includes locks and fasteners, plus edge protection in materials such as EPDM and PVC.

The German standard parts manufacturer BÄCKER GmbH & Co. KG is adding innovative locking systems and security solutions to its product portfolio. Under the PlacoLock® brand, the company is now offering compression locks, twist locks, edge protection and sealing profiles as well as various other locking systems. The products are used in sectors such as mechanical and plant engineering, vehicle construction, IT and telecommunications and shipbuilding.

With this approach, BÄCKER is adapting to changing customer requirements and taking another decisive step towards futureorientated growth.

PlacoLock® compression fasteners

The compression latches with pressure locking are ideal for sealing cabinets, compartments or pullouts. They allow the clamping force to be adjusted when closing and tightening hinge parts. This eliminates vibrations from doors, lids and drawers during machine operation. In addition, the latches are also used when opening insulated and pressurised doors, thus ensuring safe decompression.

PlacoLock® Quarter-turn latches

The range of applications for quarterturn latches is virtually unlimited. With their simple rotary movement of 90° to 180°, they ensure secure locking of cabinets, gates or other locking mechanisms. There are locks with conventional key inserts as well as locks that are operated with a tool spanner.

PlacoLock® Edge protection and sealing profiles

Edge protection profiles are used to protect the unprocessed edges of sheets and panels. They prevent cavities at the edges of the material, cover sharp edges and protect against injuries. The edge protectors are also equipped with a sealing profile to insulate doors, flaps, lids and other hinged parts. Installation is straightforward and requires no tools and is carried out by pressing the profile onto the edge.

For further information or product enquiries, contact the sales team on +49 2753 59500 or info@baecker.eu.

www.baecker.eu/en

32 torque-expo.com TORQUE FOCUS NYLON + PLASTIC FIXINGS AND FASTENERS

TIME FOR TAIWAN TO SHINE

Fastener

Taiwan 2024: Navigating the future of green and innovative high-value fastening solutions.

The countdown to Fastener Taiwan 2024 has begun, inviting all industry players to the Kaohsiung Exhibition Centre from 57 June. In its seventh edition, this event stands as a beacon of innovation, spotlighting the pivotal themes of “Green Sustainability” and “HighValue Innovations.”

With over 300 firms confirming their participation and an extensive showcase of 1,000 booths, this global rendezvous is a celebration of innovation and progress. Industry professionals can confirm their attendance through online preregistration at www.fastenertaiwan.com.tw.

Fastener Taiwan 2024 beats to the rhythm of “Green Sustainability,” a commitment echoing throughout the industry. It also embraces “HighValue Innovations,” showcasing advanced technologies and applications that redefine the sector’s future. A standout feature of the exhibition is the introduction of the “HighValue Fastener Gallery.” Here, visitors step into a realm of innovation, exploring cuttingedge solutions that promise to revolutionise the industry. Complementing this visionary space is the “Sustainability Zone,” offering a glimpse into a future where the fastener industry leads in green manufacturing and sustainable development.

Nestled in the bustling fastener industry hub of Kaohsiung, this exhibition offers more than a showcase – it’s an opportunity. Explore manufacturing facilities after immersing yourself in the exhibition, solidifying Fastener Taiwan 2024 as the goto procurement platform for global buyers.

As the global industry gears up for the European Union’s Carbon Border Adjustment Mechanism (CBAM) implementation in 2026, Fastener Taiwan 2024 positions itself as a hub for proactive discussion. “The Fastener Industry Professional Forum,” will have topics like international carbon rights, carbon trading, and carbon offsetting take centre stage. Venture beyond traditional discussions as the forum explores the applications of emerging technologies like AI and smart manufacturing, shedding light on their roles in optimising industries through visual inspection and robotic assistance.

Beyond the exhibition booths, the event provides a rich variety of experiences for visitors. From the glamour of the gala dinner opening ceremony to interactive procurement meetings, specialised thematic guided tours, and insightful procurement policy briefings from industry leaders – be ready for an immersive and enriching experience.

Diverse main theme sectors, including “Nuts, Bolts, and Screws,” “Machinery and Manufacturing Equipment,” and “Materials, Moulds, Tools,” promise not only a comprehensive representation but a glimpse into the future of the industry’s upstream, midstream, and downstream segments.

Fastener Taiwan 2024 invites industry enthusiasts to be part of this event, where sustainability, high value, and global cooperation take centre stage. Secure your spot now and be a trailblazer in the fastener industry’s journey into the future. Visit the website to register today.

www.fastenertaiwan.com.tw

34 torque-expo.com SHOW PREVIEW FASTENER

TAIWAN 2024

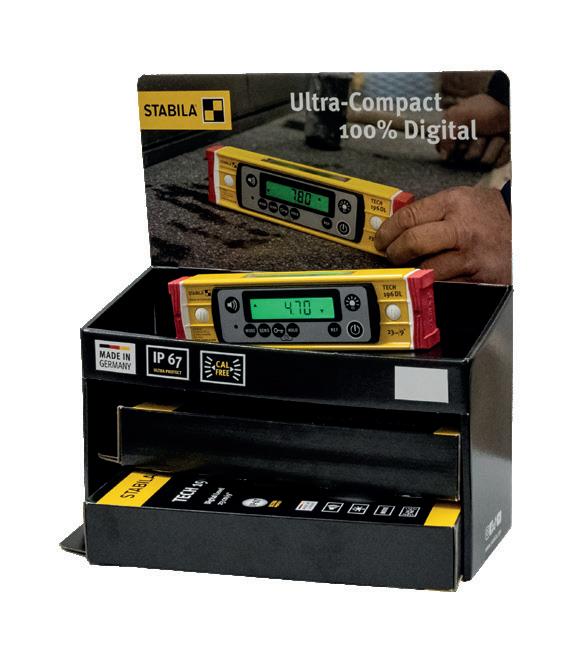

Spring TOOLFAIR at the Ally Pally in London: BIGGER AND BETTER?

Peter Brett heads to Alexandra Palace to take in the trends, opinions and products at TOOLFAIR…

TNEW RANGES AND INCREASED STOCK LEVELS

ool shows are an endangered species these days. Even the most prestigious (Cologne springs to mind) are not as well attended nor as cutting edge as they used to be. Well – no time for nostalgia – the trades are well able to take opportunities when they see them, and remain largely optimistic. And they still buy tools and accessories – especially ones that will help them work more efficiently and cost effectively. And there were many cheerful ‘Tradeys’ taking advantage of show deals at the Alexandra Palace event. Perhaps the only stressed faces were those who found the trek up the hill from the wellmarshalled carpark a little bit of an exertion. At least the walk back to the van will be downhill – especially if you are loaded with bargainpriced tools!

// Kevin Mcloud of Grand Designs told me that his most important tool was his mobile phone. Increasingly, trades can use their phones to do a range of tasks. //

We Were Promised a 60% Bigger Show

I heard quite a few comments from trades who had attended this TOOLFAIR last year that they were able to see who they wanted to see in half an hour, then grab a coffee and then get back to work.

The message must have got through to the organisers, because the show was definitely bigger and busier. Exhibitors I spoke to were happy that there was a steady stream of visitors over the two days of the show, who were

taking advantage of more major power tool manufacturers exhibiting. Nothing attracts other exhibitors and punters like a few major power tool brands. People gather and watch as the tools are demo’d – and they chat amongst themselves too, once they have tried the tools themselves. Ancillary manufacturers like work clothing, fasteners and fixings, adhesives, wipes can take advantage of the power tool bandwagon to pitch and demo their products too.

The TOOLFAIR is also linked to the ELEX and Professional Builder Show exhibiting at the same time. This makes sense, because so many home owners, along with the fashionable new kitchen extension with obligatory bifold doors, now expect to upgrade their electrical systems into a fully networked house that can easily accommodate the need to work from home, as well as streaming all the latest TV entertainment to suit. And builders will increasingly need to be on top of the latest developments, materials and gadgets in order to land the jobs that are still happening out there.

Things That Caught My Eye

It’s not always the big things that I notice –often they are small things that will make certain jobs quick and easy.

Enter the Olympic Fixings natty little adjustable wall and joist bracket. It allows users to mount an electrical plug back box between two wall or joists using two telescopic supports. They are fixed to the timbers that it is easy to cover the front of the box with plasterboard and make good. Simple, effective, time saving and neat. Should save loads of time and effort.

Marking tools have come a long way from a simple pencil behind the ear that would do most things. Pencils are still useful, but the increasing range of materials and situations needing specialist marking are growing. The range of marking implements from Pica, who advertise themselves as the Masters of Marking, are contained in a slick 70page cata

36 torque-expo.com

UK TERRITORY FOCUS

BRIGHTON-BEST INTERNATIONAL BRIGHTON-BEST INTERNATIONAL

Stainless

T: +44 (0)1384 568144 E: sales@brightonbest.org W: www.brightonbest.co.uk

BEST for

Steel

Stand E2

Like a Bosch: Big power tool names helped draw the crowds to a re-invigorated TOOLFAIR

logue. It seems to me that a close reading will allow users to find exactly the right solution for them. Do you need a long reach marker making white indelible marks on a black plastic substrate? No problem, Pica has that, and a lot of other bases, covered.

I was given a ‘simple’ pencil to experiment with. It was beautifully made and featured a green HiVis body and cap that contained the pencil itself. The pencil has a thin graphite that is easily advanced by pushing on the top. The top also holds the sharpener. The pencil end is slim and long enough to mark through holes up to approximately 30mm deep and 6mm diameter. The pencil holder quiver can be clipped onto a holster pocket or breast pocket and it gripped nicely – thus avoid

ing the loss of the quiver and ensuring the protection of the pencil point. Making things easier is always a hit with me – and you can bet it will work better than the freebie carpenters’ pencils that are the common staple these days.

Name dropping again – Kevin Mcloud of Grand Designs told me that his most important tool was his mobile phone. Increasingly, trades can use their phones to do a range of tasks using downloaded apps. Tracking your tools? No problem!

A new application from Moasure brings a new level of sophistication. With the Moasure app, sensor and stick, users can measure, lay out, calculate area, perimeter and levels almost as quickly as I can write this description. It takes a bit of learning

(not much to be honest) to follow correct sequences and apply the app but the Moasure app brings surveyorstyle capability to simpler layout and measuring tasks. It even works on curves – it doesn’t have to be a straight line.

The lesson from this is that the digital world is going to advance probably faster than tradespeople can keep up with. All the more reason for toolshows to become more like forums where learning and buying bargains are done in the same space – Professional Builder live seminars and lectures featured at the Ally Pally Show, so it is spreading the message. The future beckons.

www.toolfair.info

37 torque-expo.com

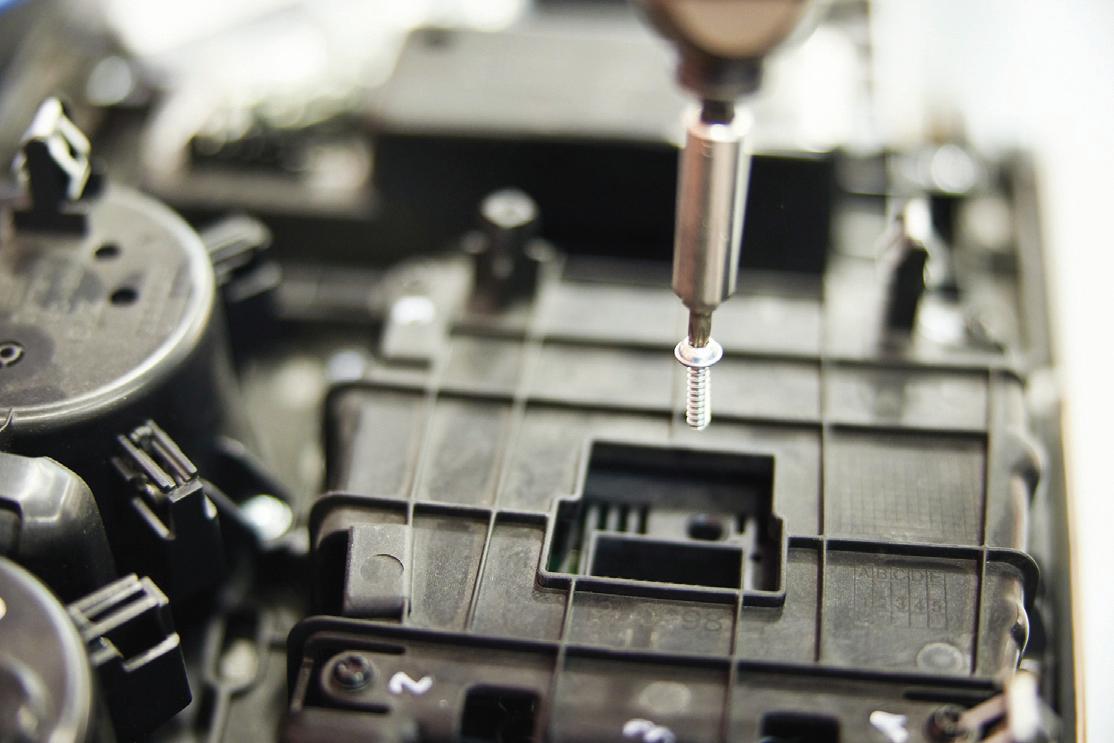

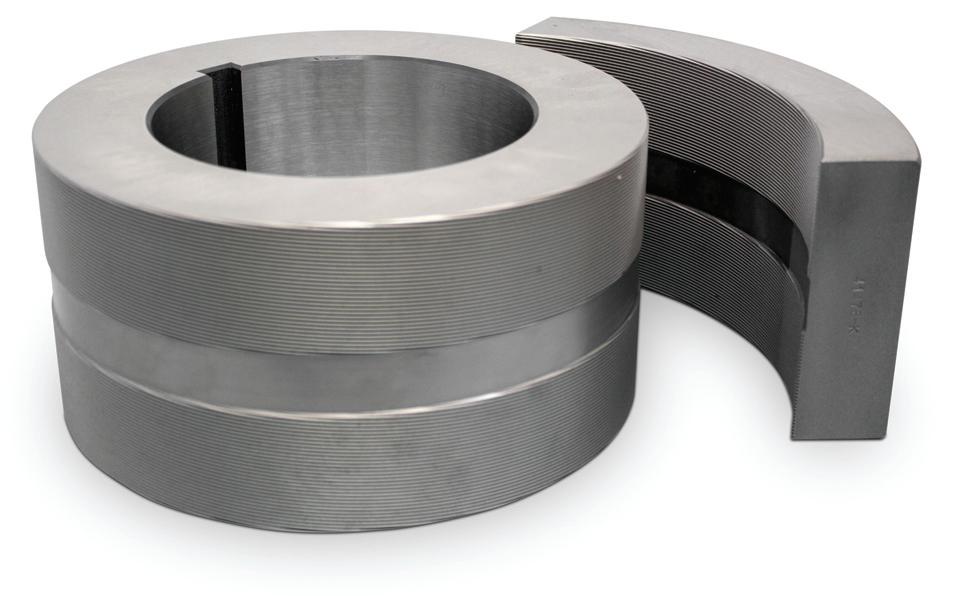

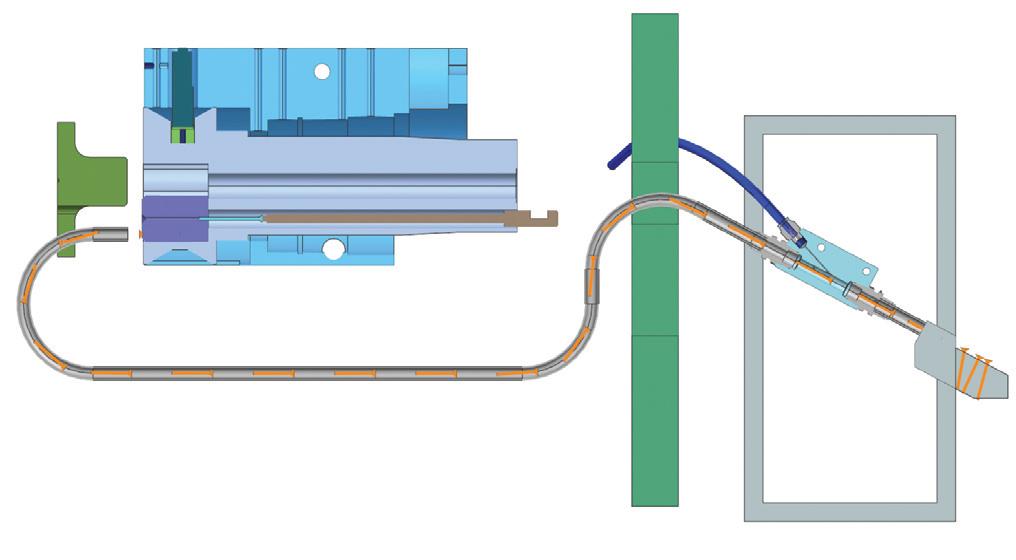

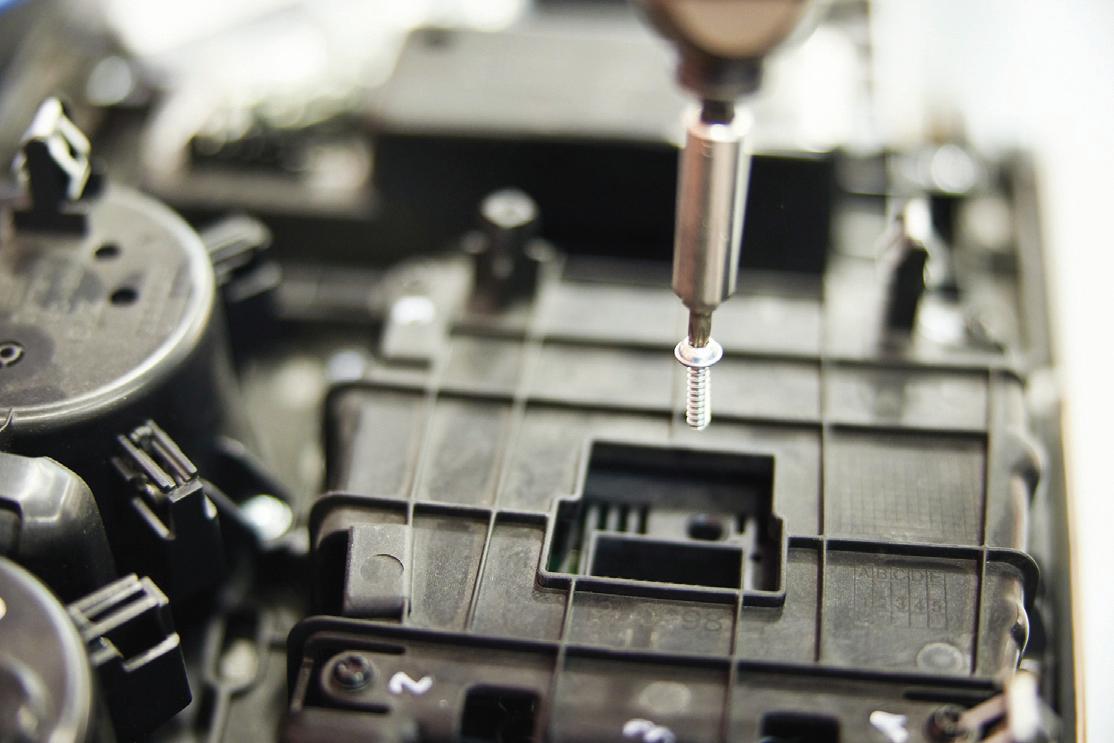

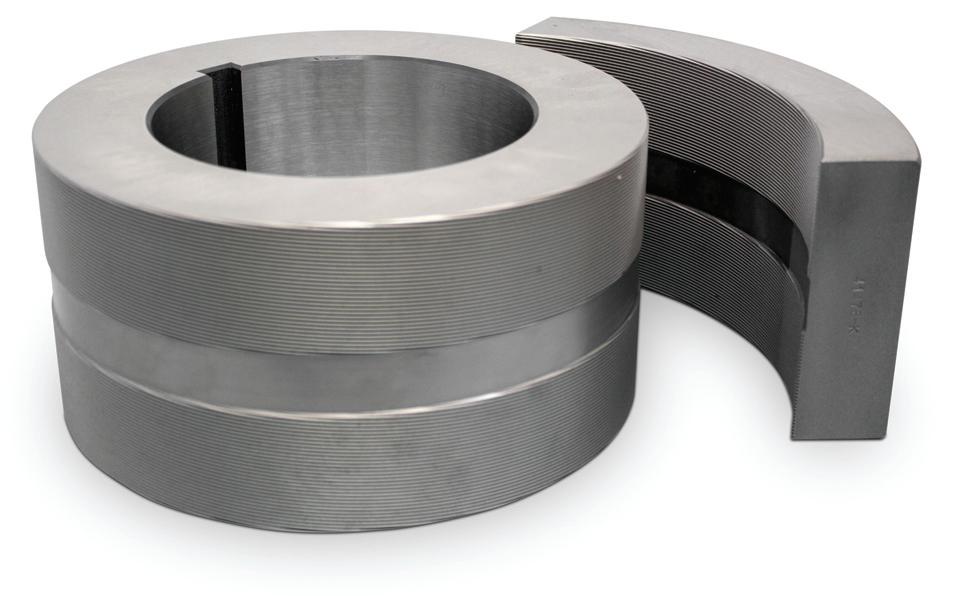

DRIVING FORWARD WITH NEW DEALS

The fastener industry may be under pressure from a variety of forces but The Insert Company is continuing to move forward with new product ranges, distribution deals and an eye on the end-user market.

Established in 2003, The Insert Company has been supplying high quality components to thousands of customers worldwide across numerous sectors for years. Based in the West Midlands, the team pride themselves on being able to supply any part at a competitive price, whether that is any of the zinc alloy, steel or brass inserts they have in stock or something from their extensive furniture connector range. The company can also supply custom parts that can be specially made for your application, including turned metal parts, metal presswork and plated finishes.

As specialists in threaded inserts for wood, plastic and metal, The Insert Company work with both distributors and end users to supply customers with what they need. “We aim to have short turnaround times on products to get to

// We are expanding and presenting new lines and looking to grow the business another 10 to 20% this year. //

customers,” explains Sales Director, Kevin Broome. By maintaining stock levels and sourcing from a variety of locations, The Insert Company are able to minimise issues such as shipping delays and freight pricing fluctuations which have plagued the industry in recent times, enabling them to pass these benefits on to customers in a range of locations. “Beyond the UK, we are heavily involved in the European market, selling to places such as Sweden, The Netherlands, Austria, Ireland and others. We have regular monthly sales with a large distributor in Austria, which is nice,” he adds.

With a diverse portfolio of products, and a keen desire to continue offering more highend goods to customers, sustainable growth and development is a priority. “We are expanding and presenting new lines and looking to grow the business another 10 to 20% this year.

That's a nice goal for us,” says Kevin. The Insert Company have recently started working with Hafren, and a range of FIXI fasteners is the latest collection to be added to the company’s catalogue of goods. The inserts are specially designed to work with stone and granite worktops, opening up more opportunities for the firm. “I would say the furniture side had been a big part of the business for many years, but we are looking in other areas too,” adds Kevin.

Keen to keep things simple, the website is straightforward with plenty of images to aid customers in making their selections. The team may be small, but they operate efficiently and want to help, with the knowledge and expertise to back up what they offer.

www.theinsertcompany.com

38 torque-expo.com

UK TERRITORY FOCUS

The newly added self-anchoring insert from Fixi

Tel: +44 (0)121 4397329 Fax: +44 (0)121 4397346 Unit 4, Alma Industrial Estate, Stafford Road, Wednesbury, WS10 8SX, United Kingdon The Inser t Company (UK) Limited Specialists in Threaded Inserts for Wood, Plastic and Metal Zinc Alloy Inserts Steel Inserts Brass Inserts Furniture Connectors Headed Hex Drive Steel Knock-in Barbed Expansion Countersunk Caps

EXHIBITION • NETWORKING • SEMINARS • AWARDS 14 MAY 2024

INDUSTRY INTELLIGENCE

An exhibitor list stacked with big names and up-and-coming innovators, a bunch of useful insights from a compelling seminar programme and networking opportunities that don’t come along every day. The list of reasons to attend Torque-Expo 2024 is pretty impressive, if we do say so ourslves…

The pace of change in the industry is quickening. Product innovation, supply chain challenges, customer expectations… there’s a lot to tackle. B2B shows are an excellent way to gather industry intelligence to ensure you’re up to date on all of the above.

Handily, there is just such a show for the fastener, tool, fixing and related industries in a short while: TorqueExpo 2024 will run onedayonly at Telford International Centre, on 14 May 2024.

Will there be a smattering of brands I am familiar with, you may ask? Absolutely, the (still growing) exhibitor list has some of the biggest UK and international players in the fastener and

tool business, take a look on page 52 to see the full list.

Not only that, but there is a significant seminar programme with talks tackling some of the burning issues of the day as well as uncovering recent product innovations you need to know about.

On top of all that, there’s a return of the networking evening, mixing an informal industry awards event with live music, food, drink and plenty of opportunity to catch up with colleagues, peers and meet important new contacts.

Incredibly, all that is available through TorqueExpo 2024. Read on for a fuller idea of what the show entails or get even more info and register at the site: www.torque-expo.com

SHOW PREVIEW TORQUE-EXPO UK TELFORD 2024 40 torque-expo.com

TUESDAY

Minimize Your Supply Chain Risk

We use a centralised global platform, supported by predictive analytics, to ensure your stock levels match product demand.

Our extensive network of suppliers aids seamless stock access, along with inventory management from manufacturer to point of use.

Our extensive logistics experience, customs requirements, and carrier relationships ensures reliable delivery.

Increase profitability with a streamlined supply chain, global sourcing, and readily available inventory.

optimas.com support@optimas.com Stand A12

TORQUE-EXPO 2024: THE EXHIBITORS

The key reason to come along to Torque-Expo 2024 is, of course, to have chance to speak and network with some of the most important fastener, fixing and tool suppliers in UK and international market. Read on for a taster of some of the names that will be well worth your time…

AEROTIGHT MANUFACTURING & APEX STAINLESS FASTENERS STAND: C8/C4

Apex Stainless Fasteners is excited to be attending TorqueExpo this year, ever keen to meet both new and existing customers to talk about its range of products and services. The firm said: “Above all, delivering customer service excellence is key for Apex and this is a good opportunity for customers to meet various members of the sales team, as well as hear more about what we have coming up to deliver service improvements for customers in 202425. We also have a very exciting competition prize draw for the Belfry Golf & Spa Resort, to enter all you need to do is come to Stand C4 and we will sign you up for entry.”

For the first time, Aerotight Manufacturing will have its own stand at TorqueExpo. In 2023, the Aerotight stainless steel selflocking nut had a recordbreaking year in terms of revenue. This has brought its own unique set of challenges, and following investments in robotic turning machinery, as

BOLLHOFF

Böllhoff is bringing its extensive range of fasteners and brands to TorqueExpo 2024.

Böllhoff is exhibiting as a joint venture between its General Industry Division, and its Standards Division.

Bollhoff UK General Industries will be promoting ONSERT, HELICOIL and RIVNUT with tooling available for demonstration.

ONSERT – The fastest and simplest solution for bonding fasteners and fixings to all surfaces.