Beneke Wire Company is a supplier of aluminium wire and redraw rod to the cold heading fastener industry serving aerospace, automotive, marine, general construction, sporting goods and apparel industries to mention a few.

Beneke Wire Company is a family owned and operated third generation aluminium mill celebrating its 55th anniversary in 2023. Beneke takes pride in delivering a value package to their customers that combines quality, consistency, on-time delivery and unsurpassed customer service. Beneke has an exceptional team of metallurgists and engineers that offer excellent support to their customers.

It’s “Better By Beneke” for a reason, come experience it for yourself.

Specialty Aluminium Wire benekewire.com +1 502.367.6434 5540 National Turnpike, Louisville, KY 40214 USA

Redraw Rod Wire Bar

PROUD TO BUILD A NEW WAY TO LIVE TOGETHER

With our wood screws, available in a wide range of both sizes and finishes. The only thing we don’t know precisely is where all our screws are, but surely they are very close to you.

THE GROWTH OF OUR WAREHOUSES IS COMPLETE

Find out more on... ambrovit.it/en/x2

NEWS

WEARENOTNUMBERS.IT

Publisher

Jerry Ramsdale jerry@torque-expo.com

Editor Jonathon Harker jonathon@torque-expo.com

Deputy Editor Rachel King rachel@torque-expo.com

Sales Manager – UK

Claire Warman claire@torque-expo.co.uk

Sales Manager – International Harry Whyte harry.whyte@torque-expo.com

Circulation

Tracy Howell tracy@torque-expo.com

Head of Production Luke Wikner luke@torque-expo.com

Designers

Dan Bennett dan.bennett@torque-expo.com

Victoria Arellano victoria@torque-expo.com

Head of Marketing Shona Hayes shona@torque-expo.com

Published by Stag Publications Ltd 18 Alban Park Hatfield Road St Albans Herts AL4 0JJ tel: +44 (0)1727 739160 fax: +44 (0)1727 739169

Email: info@torque-expo.com Web: www.torque-expo.com

Disclaimer

Although the utmost care is taken to ensure that information contained herein is accurate and up to date, the Publisher cannot be held responsible or in any way liable for errors or omissions during input or printing of any material supplied or contained herein. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or of Stag Publications Ltd.

14

16

ALL HAIL THE MANUFACTURERS

Manufacturing is one of the big topics we look at in this issue of Torque Magazine and as you might expect there are tales of companies expanding ranges, enhancing their processes and providing their expertise for customers.

One of the big manufacturing-related questions right now is where do you source?

20

Pandemic-related disruption has highlighted the dangers of over reliance on one country. Are candidates like India or Eastern Europe becoming more attractive for your production requirements? We’ve got a lot more detail on manufacturing and shows in the Eastern Europe market starting page 58. And if you are looking at your options when it comes to sourcing product, then you could do a lot worse than start thumbing through our manufacturing special, starting page 20.

There are a few more recurring themes that crop up and are equally relevant to the broader industry; recruitment, sustainability and digitalisation. Getting the right people and retaining them is an enduring challenge and that’s probably why digitalisation is becoming an even bigger deal. Automation and increased efficiency are viable and maybe essential routes for companies.

Likewise, sustainability goes beyond manufacturing too. It’s possible to remember a time when the topic only came up when we remembered to ask about it – now interviewees bring it up without any prompting. As one of this issue’s interviewees puts it – ‘manufacturing businesses may have been guilty of pushing sustainability to the periphery in the past, but those days are gone’.

Jonathon Harker Editor jonathon@torque-expo.com

Jonathon Harker Editor jonathon@torque-expo.com

Copyright Entire contents copyright © 2023 Stag Publications. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

THIS ISSUE Proud member of:

INSIDE

part of our commitment to the environment, Torque Magazine is fully recyclable. 06 NEWS

OPINION >

SUPPLY CHAIN?

To subscribe to Torque Magazine visit: torque-expo.com/subscribe/ or scan this QR code... As

12

NEED HELP WITH YOUR

COVER PROFILE > PGB-POLSKA’S COMPETITIVE EDGE

INTERVIEW

> ACHILLES SEIBERT ON ITS NEW WAREHOUSE AND WORKFLOW REVAMP

FASTENER MANUFACTURING SPECIAL > FEATURING GROWERMETAL, ROTHOBLAAS, OPTIMAS, PERFORMANCE FASTENERS, SMITH BULLOUGH, NSSS, EUROTEC, GÜDE, NORM CIVATA AND MORE 46 FOCUS > TORQUE TOOLS, TECHNOLOGY AND BOLTING 58 TERRITORY FOCUS > EASTERN EUROPE 68 SHOW PREVIEW > STAFDA 2023 72 FOCUS > WIRE AND FASTENER COLD HEADING 76 BUILDING & CONSTRUCTION > ANCHORS 84 CASE STUDY > INVENTORY MANAGEMENT SOLUTIONS 86 SHOW PREVIEW > TAIWAN HARDWARE SHOW 14 MAY 2024 TUESDAY RESERVE YOUR STAND BY CONTACTING CLAIRE WARMAN (UK) Email: Claire@torque-expo.co.uk | Call: +44 (0)1727 739 160 EXHIBITION • NETWORKING • SEMINARS • AWARDS

LATEST WAVE OF REGULATIONS HIT FASTENER AND TOOL INDUSTRIES

Manufacturers, importers, wholesalers – and just about everyone else – have been preparing their businesses to deal with the latest wave of regulations to hit the fastener and tool industries.

CBAM, UKCA, enhanced Russiarelated sanctions and other soontoarrive or recently introduced regulations have heaped another level of complication on businesses at a time when many markets are sluggish.

While companies appear prepared for this latest wave of new rules – businesses spoken to by Torque Magazine have discussed the topics in detail (see elsewhere in this issue) – the fastener and tool markets are not alone in wishing for greater clarity and decision making that takes them into account.

In August, the UK government announced it would extend recognition of CE marking for most goods on the market in Great Britain indefinitely, effectively negating the need for the UKCA mark (devised due to Brexit) for many industries. Further clarification, however, revealed that rail and construction products would still need UKCA marking by a new deadline of June 2025 – a deadline that leaves “insufficient time” for the industry to comply, said the CPA.

Meanwhile, many nations including the EU group agreed to step up sanctions on Russia following its invasion of Ukraine. The scope of the new measures relates to the import of certain Russian iron or steel products processed in a third country or multiple country. For some time, there was a lack of clarity on what kind of proof would be accepted by customs officials and in the week before this magazine went to press, details finally emerged on what kind of proof would be

acceptable (eg Mill Certificates), less than three weeks before the regulations came into effect (on 30 September 2023).

Amidst these changes, the EU’s landmark Carbon Border Adjustment Mechanism (CBAM) is being implemented (1 October 2023) where importers of certain carbonintensive goods will have to pay a levy on their imports. Other laws related to the periphery of the industry could affect the supply chain too, including a Deforestation Regulation from the EU that will affect wood and rubber supplies.

In many cases the principle of the new regulations has not been a point of controversy – condemnation of Russia’s invasion and the need for more sustainable practices have a high level of consensus – but the implementation, clarity and timing of them has.

KELLER & KALMBACH TAKES OVER IEW

Backdated to 1 January 2023, Keller & Kalmbach group has acquired 100% of shares of IEW (Industrial Equipment Westendorff).

IEW, located in Erkrath, has specialised on drawing parts for the industry. As reliable partner for domestic and foreign industry companies, IEW delivers fasteners according to individual orders. Its owner Mr. Ewald Spleiter sold IEW for reasons of age.

Keller & Kalmbach plans to successively integrate the

company into its own group. With this takeover, Keller & Kalmbach said it is emphasising the importance of focussing on industry and drawing parts in the future in combination with the wide range of fastener and fixing technologies as well as industry and Cparts and Cparts logistic systems which are reliable and awardwinning for many decades.

www.keller-kalmbach.com

NEWS www.torque-expo.com Stainless steel fasteners. EdelstahlVerbindungselemente. Standard and non-standard items Norm- und Standardteile DIN, ISO, EN and others / und andere Special parts and special materials Sonderteile / Sonderwerkstoffe Lederer GmbH | Katzbachstraße 4 | 58256 Ennepetal | Germany | Fon +49(0)2333/8309-0 | info@lederer-online.com lederer-shop.com availability advice quickorder / file upload backlinked pdf pages Bestands-eMail Schnellbestellung / Datei-Upload verlinkte Katalogseiten News from the distribution industry…

Tel: +44 (0)121 4397329 Fax: +44 (0)121 4397346 Unit 4, Alma Industrial Estate, Stafford Road, Wednesbury, WS10 8SX, United Kingdon The Inser t Company (UK) Limited Specialists in Threaded Inserts for Wood, Plastic and Metal Zinc Alloy Inserts Steel Inserts Brass Inserts Furniture Connectors Headed Hex Drive Steel Knock-in Barbed Expansion Countersunk Caps

JPB Système unveils three new hires

JPB Système has announced three new management appointments to its team: Christophe Impinna as Purchasing Manager, Frédéric Duwicquet as Key Account Manager and Matthieu Loger as Industrialisation Manager.

Impinna’s role will be in developing the purchasing function and further solidifying partnerships with suppliers to ensure timely product to customers. Duwicquet will be responsible for overseeing contracts, identifying

new business opportunities to drive growth and promoting JPB Système’s products and innovations to enhance its market position. While Loger will lead the industrialisation department, acting as a crucial link between the R&D and production teams. His key objectives include automating inspection processes, optimising manufacturing processes, and successfully industrialising new products to improve productivity and quality.

Arctic Hayes reveals new additions

Plumbing products provider, Arctic Hayes, has announced the addition of two new members to its team: Richard Musgrave joins as Marketing Manager, while Emma Telfer takes on the role of Business Support Manager.

Musgrave’s role will be pivotal in creating innovative marketing campaigns, fortifying the company’s market presence and engaging with plumbing professionals nationwide.

Business Support Manager Emma Telfer’s primary focus will be on improving operations, enhancing customer experiences and streamlining internal processes to support Arctic Hayes’ ongoing growth.

Lee Parsons, CEO at Arctic Hayes, said: “These appointments enable us to better meet the needs of our customers while maintaining our commitment to delivering highquality products and exceptional service.”

EXPLORE MORE: lederer-world.com Stainless Steel Fasteners NEWS News from the distribution industry www.torque-expo.com PEOPLE NEWS

FOR STRONG CONNECTIONS! We invite you to the BlechExpo in Stuttgart from 7 to 10 November! HALL 7 / STAND 7419 More information on www.gesipa.com Follow us! Writing the history of socket set screws since 1966 6TH INTERNATIONAL TRADE FAIR FOR FASTENERS AND FIXING TECHNOLOGY 18th – 19th October 2023 – Krakow, Poland VISIT US AT OUR STAND – D74 – DUNAJ HALL www.arser.it

Selected news from the fasteners, fixings and tools industries around the world…

NORTH AMERICA 01

FASTENAL TEAMS WITH TREX >

Fastenal has entered into a scrap supply agreement with Trex Company, Inc., a manufacturer of outdoor building products made from recycled materials. Through the partnership, Fastenal is collecting used PE film and shipping it to Trex to use in the manufacture of its composite decking products.

UNITED KINGDOM 03

JERGENS INC. NEW UK APPOINTMENT >

Spencer Wills has joined Jergens Inc. as the Commercial Business Director for Europe. The move comes as the company, which has headquarters in Ohio, USA, looks to further expand its customer base and support in the UK and Europe.

NORTH AMERICA 02

SUR-SEAL ACQUIRES AMERITAPE >

Custom sealing solutions provider SurSeal has acquired Ameritape, a Floridabased company specialising in custom die cutting, slitting, laminating, and CNC cutting. The acquisition expands SurSeal's engineering capabilities, including performance materials expertise and enhanced manufacturing techniques.

UNITED KINGDOM 04

BHETA WELCOMES HULTAFORS >

Hand tools supplier, Hultafors has joined BHETA. The company offers a wide selection of professional hand tools for measuring, marking, cutting, striking and levelling. The company which is part of the Hultafors Group is committed to developing additional products such as workwear, scaffolds and ladders, under brands such as Snickers and Wibe.

10 torque-expo.com GLOBAL NEWS ROUND-UP

01 02

EUROPE 05

AHLSELL CONTINUES ACQUISITIONS >

Ahlsell, a distributor across the Nordic region of installation products, tools and supplies for installation, construction, real estate management, industrial and power companies and the public sector has entered agreements to acquire three businesses, Proffklær AS, Lindqvist AS and BMax Svets AB. The acquisitions are intended to broaden Ahlsell’s position in the market.

To subscribe to Torque Magazine and receive the newsletter visit: www.torque-expo.com/subscribe/ or scan this QR code...

ASIA 07

ATLAS COPCO TO EXPAND IN INDIA >

Atlas Copco Group has begun construction of a new manufacturing facility in Talegaon, Pune, India. The new factory is planned to be completed by Q2, 2024 and will manufacture air and gas compressor systems for the local market and for export.

EUROPE 06

FISCHER NAMED GERMAN BRAND ICON >

The fischer Group of Companies has been declared a German Brand Icon by the Plus X Award. The winners are selected by an international and independent panel of expert judges from over 80 industries. fischer was presented with the German Brand Icons award due to the company’s “relentless drive for excellence and its tireless innovative spirit,” the panel stated.

ASIA 08

CONDAT NEW SITE IN CHINA >

Already present in China for over 15 years with a local production unit in Shanghai, Condat is now expanding with a brandnew plant settled in the Shandong province with CONDAT Qingdao. The new facility sits on 33,000 m² of land with the surface area of the industrial buildings covering 12,800 m².

11 torque-expo.com

07 08 04 03 05 06

Building a resilient SUPPLY CHAIN

Planning, changing and adjusting – it’s as fluid as the water it sails on. Clive Daley of Daley Hub discusses resilience and supply chains…

your planning talent. Build a behaviour across your business so that both purchasing and sales arms are in harmony. Know exactly what you need, when you need it and in what volume. Critically, deal with the excess and obsolete stock. This frees up cash to spend on the stock that you are selling in volume. Third party businesses can make this easier for you. Engage with them.

GET CLOSER TO YOUR CUSTOMER

Disruptive times may have caused your customer relationships to become strained. Worse than that is when they have dwindled away, and you don’t even realise it.

Pick up the phone. Visit that customer you haven’t seen for a while. Understand their plans. Work together. It takes two to be successful.

Rebuild those relationships with a new energy, collaborate to ensure you help each other.

Recent events have demonstrated to us all that if there was ever a time for a resilient Supply Chain, it is now. If you think the after effects of the past three years are behind us, think again. Some challenges may well be here to stay.

What should we be looking at, or worried about? What should we be planning, changing, or adjusting?

We need to get our predicting heads on to anticipate issues and we must be agile.

Whilst it is tempting to breathe a deep sigh of relief, ensure you have your ducks in a row for a resilient supply chain.

“You can’t judge a good week by having no issues. You judge a good week by how you have dealt with them.”

OVER-RELIANCE

Prior to 2020, those purchasing from China planned for a Chinese New Year (CNY) that disrupted the supply chain for four to five weeks (OK, maybe a little longer with some factories I hear you say).

Some ordered ahead to anticipate it, but then 2020 landed and CNY lasted for nearly 20 weeks.

Those too reliant on China’s lowcost sourcing realised they had to change. When the entire world was engulfed with the pandemic, many forgot their over reliance. Let this be a prompt to remind you.

It is not just about China, though it still remains one of the largest lowcost manufacturing locations for volume, it’s about the learning we need to take from the overreliance.

Consider the regions that you purchase from and balance the risk. Act now, it can take up to 18 months to even move part of your sourcing to another region.

WORKING CAPITAL RIGHT-SIZED

Many businesses try to have everything available all the time. It can be done, but at what cost?

Cashflow running short has been the deathblow for many a business.

Where is your cash usually stored? A big draw on your funds is your stock. Invest in your planning systems and cultivate

BE AHEAD OF THE GAME

At last year’s Global DIY summit Rik Vera advised us to have a new KPI, the curiosity factor.

We have introduced this with several of our clients with great results. Get a feel for things about to happen. Be curious. Ask why something is happening. Connect the dots. Understand the picture that is being painted and react to it before it becomes a portrait of disaster. Anticipation will get you ahead of the game. If you are speaking to your factories, don’t just ask them about them and their production, ask about the economy, the factory view, their prediction of upcoming issues.

You will learn things that may well give you an edge on the market and propel you beyond your competition.

COST REDUCTION FOCUS

We are at a time of inflation. The cost of living has soared and might go even higher. There is no better time to deliver cost reductions, efficiencies and savings.

Everything from your logistics, to knowing where the main players are and what they should be charging will deliver immediate savings. Implement manufacturing efficiencies to deliver more in the same amount of production hours. Build the leverage you need to extract cost from the supply chain.

Additional costs are coming. Some are already here. Plastic and recycling taxes will only increase. The draw on resource to ensure you are doing the right thing for your eco credentials and CO2 footprint should not be misjudged.

The time to get busy is now. Prepare for the new challenges that will come. To be ready, implement your resilient supply chain.

REACH OUT IF YOU NEED SUPPORT

With so many areas to focus on, you may be overwhelmed and asking yourself where to start.

Daley Hub – supporting leaders, customers and colleagues to drive business forward.

www.daleyhub.com

12 torque-expo.com OPINION

PGB-POLSKA’S COMPETITIVE EDGE

Investments have come thick and fast for pgb-Polska, including extending its ranges, making packaging more efficient and boosting its warehouse capacity, all aimed at improving the fastener company’s competitive edge…

pgbPolska is a leading supplier and manufacturer of fixings, anchors and tools. With an assortment of around 5,000 items constantly available from stock, the company offers a solution for almost every fastening challenge.

Since 2020, pgbPolska has expanded its product range, adding new sizes of frame anchors and insulation plugs according to market needs. The business has also introduced new types of fasteners for gutters and expanded the range for photovoltaic installations. From the foundations to the fastening of the panels; pgbPolska is continually expanding its offer, while simultaneously gaining new markets. In 2021, the business increased its storage capacity from 10,000 m2 to 14,000 m2 to ensure there’s room for its expanding ranges.

Investment in an automatic packaging line has allowed pgbPolska to increase its distribution capabilities.

The manufacturer is also continuing to expand the range of packaging: “We are able to pack the products in plastic bags, standard boxes and a range of plastic packaging such as boxes or buckets,” says the firm.

The system allows customers to choose the right packaging and labels tailored to their customer's requirements, in any size of package according to customer demands. Private label products and custom, tailored packages are available, suiting a brand’s specific needs.

The complete anchoring programme of pgbPolska is distributed under the brand name SMART. At the production unit in Zabrze, it produces highquality and Europeanapproved synthetic anchors such as window plugs, nail plugs, insulation plugs and universal plugs. For (structural) anchors, SMART offers a complete range of mechanical and chemical

COVER PROFILE pgb-POLSKA 14 torque-expo.com

ENERGY EFFICIENT: pgb Polska has an extensive photovoltaic panel system (550 of them) helping meet the energy needs of its plant

anchors. More than 25 product families have one or more extensive ETA ratings and offer a guarantee for safe and durable anchoring thanks to excellent technical aspects.

PgbPolska strives for highquality materials through a proper purchasing policy, ensuring compliance with industry standards (DIN, ISO, or customer specifications). It approves, provisionally approves, or rejects suppliers based on their past performance and quality system evaluations.

Random inspections of incoming goods are performed, with measurements taken and a standardised report made, depending on the product type. PgbPolska has a formidable arsenal of testing tools such as the Fischerscope, Thermo Scientific Xray, Pullout Tester, Go and NoGo gauges, Torque Tester, sliding gauge, micrometer, hardness meter, profile projector, and wire gauge for its inspections.

The firm says: “At pgbPolska, we keep our promises. ‘Sustainable business’ is not an empty statement. Our commitment to the environment is gradually taking shape. And we can prove it.

“What does sustainable business mean to us in concrete terms? Well, the sun is the basis of every green energy source we know: it makes the wind blow, makes trees and plants grow, keeps the watercourse going, and much more.”

pgbPolska has 550 photovoltaic panels with a total capacity of 250 kW, so the company can run on a high proportion of autonomous energy to keep its carbon footprint as small as possible. The recently integrated installation is working and bringing the first results – hence the motivation to continue this direction in the future and try to reduce energy costs – and thus the final cost of the product, customers will be pleased to hear.

Furthermore, while shipping its goods, pgbPolska tries to limit packaging material, and in addition, it uses packaging material (cardboard) that is already recycled or can be recycled.

Finally, pgbPolska also takes into account the different methods of galvanisation. For example, it ensures that its screws are galvanised ChromeVIfree and that they comply with RoHS guidelines.

pgbPolska is a European player strongly committed to digitisation and comprehensive service to its customers. It foresees that automation and smart manufacturing technologies are likely to play a significant role in fastener production. The implementation of Industry 4.0 concepts, such as IoT devices, robotics, and data analytics, can enhance production efficiency, quality control, and reduce downtime.

Another important element to consider is customisation and personalisation, says the firm: “Customers may increasingly seek customised or personalised fasteners to suit specific applications. Manufacturers that can offer a diverse range of options and quick turnaround times are likely to gain a competitive edge.”

PgbPolska concludes: “In today's fastpaced and dynamic business landscape, staying competitive is essential for survival and growth. Investing in new technologies and innovative solutions helps businesses keep up with or surpass their competitors. Innovation often leads to process improvements, automation and the development of more efficient systems. These enhancements can boost productivity, reduce costs and increase overall profitability.”

15 torque-expo.com

www.pgb-international.com

Packing a punch: Recent investments include an automatic packaging line – which has helped the business expand its distribution capabilities – as well as expanded packaging range options

// In 2021, the business increased its storage capacity from 10,000 m2 to 14,000 m2 to ensure there’s room for its expanding ranges. //

ACHILL ON ITS NEW WAREHOUSE AND WORKFLOW REVAMP

It’s little over a year since Timo Scholle took over sole ownership and management of Achilles Seibert GmbH. In that time, the distribution market has continued to produce new challenges meanwhile Achill itself has seen some sizeable investments. We asked the Managing Director to bring us up to date with the latest at the family company…

You took over sole responsibility for Achilles Seibert with a leadership transition just over a year ago. How’s it been going so far? All relatively stable?

It’s been relatively stable and of course, the first year was quite exciting. Not only as the sole owner, but business had been pretty good for the last couple of years too. On the other hand, in the second half of the year you could see some clouds on the horizon, with prices and inflation.

Nevertheless, we have been happy looking forward and most of the time have struggled to find enough staff to keep up with the work. That’s been one of the biggest points. We changed a lot internally, we brought in a lot of employee benefits and now we have a new warehouse construction.

Achill’s warehousing will be 50% larger by the time the new warehouse is complete, later this year

Can you tell us a bit more about the warehouse in Germany? We are expanding by around 50%. Our warehouse hopefully will be completed in time for Christmas – bad weather here put us behind schedule, but we will have everything finished by year end.

Presumably you’ll need more staff to run that as well, because you've already mentioned the staffing challenges? Those challenge are not because of this warehouse. We have the pallets outside, part of an external warehouse so basically our people are already handling the tonnage, but it will be made easier because they don't need to unload and load from a secondary warehouse. Nevertheless, regarding recruitment, our

16 torque-expo.com INTERVIEW ACHILLES SEIBERT

growth over the last few years was quite significant and we also increased our product range. So we have more product to move around. Over the last few years, we could basically cover that with existing staff, but everybody was working to the limit. So, to get back to a normal level we are trying to hire more people and use our existing space more efficiently. It has been very difficult to find people, although, recently it has felt that there are more people on the market. Employment agencies are sending through more candidates now.

In India we have finished our warehouse with a partner in India. We also have one staff member in India who is handling the whole Indian operation, purchasing, sourcing, taking care of quality before it leaves the Indian warehouse… it’s working pretty well especially with the political background to China, Taiwan and the European Union. The Indian market is becoming more and more interesting.

The next step is to set up this kind of operation in Vietnam, another big upcoming sourcing market.

We are definitely hearing more industry chatter about India and it’s interesting to hear you mention anti-dumping and other supply chain challenges in that context.

I think mainly it is the price and also China is not so willing anymore to offer a very low price on fastener work. You could argue that the fastener business is not their core interest with the support of the export companies maybe not as high as it used to be. China has its own market, other markets and, frankly speaking, they got punished twice by the European

// Our growth over the last few years was quite significant and we also increased our product range. //

Achill is broadening the scope of its sourcing to new geographical territories

Union over antidumping. So, let’s say we shouldn’t be surprised that Europe is not the first choice of business anymore. Also, the German government is pushing more economic connection with the Indian market. There are some difficulties with the time it takes to get visas, but in the longer term, I believe that the Indian market will be, in the next five to 10 years, the same as China was 15 or 20 years ago.

Going back to the new warehouse in Germany, has that been created because holding more and more stock is an increasingly important part of the business? Do you need a bigger range these days to sort of satisfy your customers?

Yes, there are basically two reasons. Of course we increased our product range which leads to a bigger warehouse. There’s also the price advantage you get if you buy in bigger quantities. Increasingly, manufacturers in Asia are more driven now by efficiency. Factories won’t produce a couple of kilos and then ship it to you. They also need to be efficient. It’s also easier for us to buy full pallets instead of mixed pallets because whole pallets can be handled in the warehouse much easier. Mixed pallets have to be completely unpacked and checked. Maybe you end up with a little too much stock, but from the handling side and the price advantage, it makes it up. Those are the two basic reasons.

Have you any insights you can share about which markets are doing well?

We supply only to distributors, so it is difficult for us to say which industry is booming. Countrywise, we see that East Europe, Italy, Spain and France are way more active than traditional business partners in Germany or Scandinavia. So, you listen to the news and see which countries are still growing economically and that’s also where we can see the business goes right now.

We do see that the automotive industry is in transition and undergoing uncertainty. It’s hard for repair shops, say, to know how many spare parts they should buy for traditional fuel cars.

Aside from the new warehouse, Achilles has also been investing in improved workflow? Is that still onging?

We have had a document management system since the middle of the year, which covers the whole workflow. Every document running through this company from customer inquiries, orders or whatever, is processed there. It's 100% traceable, nothing gets lost. So, we can push the workflow from purchasing to sales to the back office to the warehouse and this makes it far more efficient. And it’s easier, you can work basically anywhere now. It's very simple.

There is also continuous investment in new technologies. We're trying to provide our customers with barcodes on all documents, so they don't need to type their numbers when they receive the goods, they can just scan it. The second step

don’t need to scan each item. They just scan that QR code one time. We’re also talking with one or two customers about RFID identification. So, basically in the future our vision with customers is that goods pass the scanner at the entrance door and the system immediately recognises all the items and processes them, much more efficiently.

What else is coming up in the near future?

We invested a lot in the last one and a half years, so the second half of 2023 is about implementing all the investments and letting them run smoothly. So, by the end of the year or beginning of next you’re running with a fully smooth operation.

The

market

is adjusting to a lot of changes

at the

moment.

In the UK we were recently updated on UKCA marking, but it's still causing concern in the industry...

I talked with one UK customer about a similar problem, when from October onwards, if you import goods to the European Union, you need to have CBAM certification. We were aware of what CBAM means for us, but I wasn’t aware that my customer needs to do that when he sells to the European Union as well.

Another area of struggle is with Europe’s sanctions on Russia. We’re not selling to Russia and have no ties to that, but from 30 September we will need to have supporting documentation like Mill Test certificates to prove that our products have not been produced with any steel components made or touched in Russia.

It doesn’t seem to get any less complicated, there’s always something else. So, it’s not just that the UK’s regulations are confusing right now, I think they can be from the European Union too.

The next few months might be challenging, but I have nothing to complain about. It’s certainly not been boring!

www.achill-fasteners.com

18 torque-expo.com INTERVIEW

ACHILLES SEIBERT

// We see that East Europe, Italy, Spain and France are way more active than traditional business partners in Germany or Scandinavia. //

Efficiencies with barcoding, QR codes and RFID are underway with Achill

PIC CREDIT: @cmykstück, by Yvonne Eckert

FASTENER MANUFACTURING

HOW GROWERMETAL AIMS TO CREATE VALUE FOR CUSTOMERS

A long history alone is not enough to guarantee success. That’s why washer manufacturer Growermetal is constantly focused on delivering a wide range of parts, investing in cuttingedge technologies and strategic internal production.

The story of Growermetal began in the north of Italy in 1950, when the founder Virginio Cattaneo established the first settlement of the company in the area of Lecco. During the ‘60s the company moved to its current site in Calco where it lived the first stage of its expansion, paving the way to growth that saw one of its most fortunate phases at the beginning of the new millennium. Counting on its established history and long experience in washer manufacturing, today Growermetal is a reliable partner for some of the most demanding industries of the world, addressing European and international leaders in the automotive, aerospace, railway, power generation, electromechanics, construction and many other sectors.

“We are proud of our wellknown reputation in the fastener industry,” says Paolo Cattaneo, Growermetal CEO. “We are also well aware that a long heritage is something yet not enough to guarantee the creation of added value and bring a competitive advantage for our customers. To achieve these goals, we combine several strategic investments and a flexible service, aimed at improving the quality of our washers, creating the certified solutions according to the application needs and making them available to customers, wherever and whenever they need them.”

Among the factors contributing to the progression of the business, Growermetal’s structured portfolio is essential. Offering a range of 4,500 standard washers and more than 2,500 customised projects according to customers’ drawings, Growermetal is able to answer the needs of different markets. Together with the different types of washers, which include external and internal teethed washers, safety washers, flat

washers, conical elastic washers, spring washers, spherical washers, electric terminal washers and many others, the company produces also sealing pushin caps, metallic parts with EPDM inserts and special blanked and bended parts.

That variety is combined with a series of special treatments ranging from surface treatments to zinc flake coating and mechanical zinc plating, in order to make the performance of every piece longlasting and reliable. “Our completely inhouse production is with no doubt one of our most relevant strengths, as it gives us the opportunity to provide a number of coatings and heat treatments directly in our headquarters,” says Cattaneo. “Every department is linked together in a production chain that includes quality controls, research laboratories and a fully automatic warehouse, with the benefit of higher levels of efficiency, versatility and a constant control of the parts.”

PROJECTS AND PARTNERSHIPS

In facing future challenges, the commitment to the innovation of Growermetal is essential and there are several strategies in action, involving internal investments, product development, innovative projects and partnerships, as the recently entrance of Growermetal in the Lombardia Aerospace Cluster.

One of the main results of this approach was Growermetal’s entry into the Joint Research Center MATT – Metal And Transformation Technologies: a project born from the partnership between the Politecnico di Milano and other companies and based on the concept of open innovation, with the objective of developing researches through shared knowledge and tools.

20 torque-expo.com ITALY

// Offering a range of 4,500 standard washers and more than 2,500 customised projects according to customers’ drawings, Growermetal is able to answer the needs of different markets. //

Growermetal’s production capabilities include a vast range of different types of washers, as well as sealing push-in caps, metallic parts with EPDM inserts and special blanked and bended parts

The evolution of the company's approach is exhibited by the range of products launched by Growermetal in recent years. In addition to the production of standard washers, which still constitute the most important part of its portfolio, the inhouse research and development laboratory has contributed to the creation of exclusive projects, such as the flagship products Grower TenKeep and Grower SpheraTech. Products that express a tendency towards expansion, at service of the more and more demanding needs of the industries.

Furthermore, the digitalisation process represents a new opportunity for the brand, with the implementation of cuttingedge systems for data processing and the integration of digital technologies inside the products. An example of this tendency is the new Grower Detecto, a concept design launched in 2023 and characterised by an embedded smart sensor that allows live detection of bolt loosening.

Talking about the process, the necessity to improve the control of the various stages of production has led to the adoption of technologies aimed at the recording of process data. A system that allows Growermetal to monitor and improve the manufacturing stages, tracking each activity within the departments and preventing problems or nonconformities.

“Traceability is a key requirement to improve the performance

R&D investments have seen the firm launch new products like Grower TenKeep and Grower SpheraTech

of our washers and refine their management, maintaining the highest productivity standards,” says Cattaneo. “This is particularly true in demanding applications such as the automotive industry, where effectiveness and safety are crucial. The integration of software for data collection helps us in achieving new levels of efficiency at every stage, from production to storage and transportation. In this way, we are able to ensure the supply of highperforming and safe washers, enabling customers to get the best out of their business.”

These technologies also contributed in making the process more sustainable, both from the economical and environmental point of view, as underlined by Growermetal’s HSE manager Raffaele Motta: “When it comes to sustainability, the digitalization process opens up new opportunities that ranges from a more efficient production model to a remarkable reduction of resource and energy consumption. As a company focused on innovation, we can’t help ourselves but embrace the challenges linked to the use of these technologies, becoming more transparent, efficient and responsible. The results we are having are encouraging and will guide the next steps of our sustainable evolution.”

www.growermetal.com

21 torque-expo.com

Growermetal is expanding its project work and partnerships, including its recent entrance to the Lombardia Aerospace Cluster

ROTHOBLAAS: IN STEEL WE (T)RUST

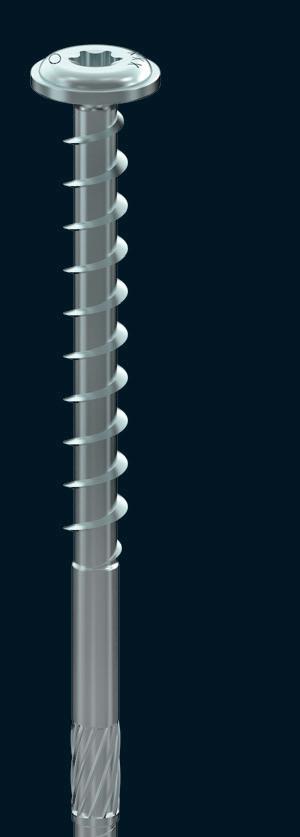

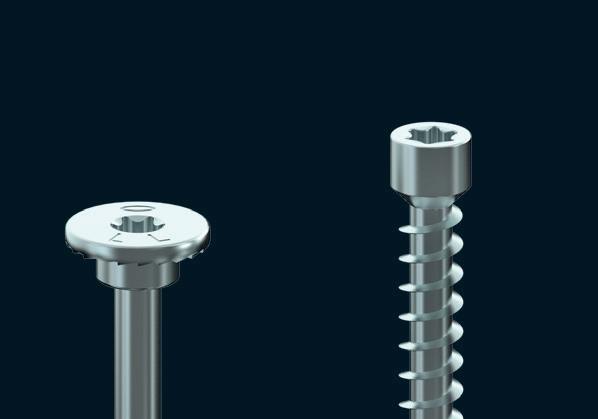

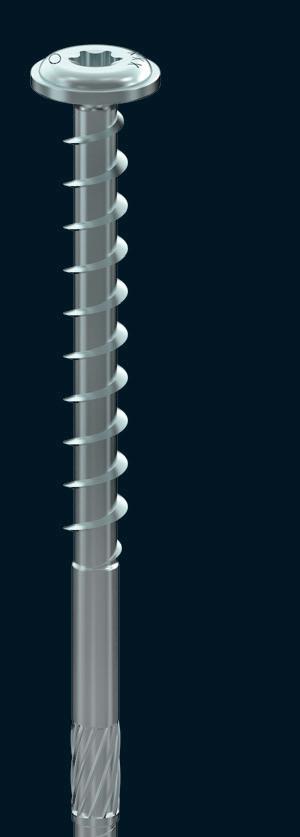

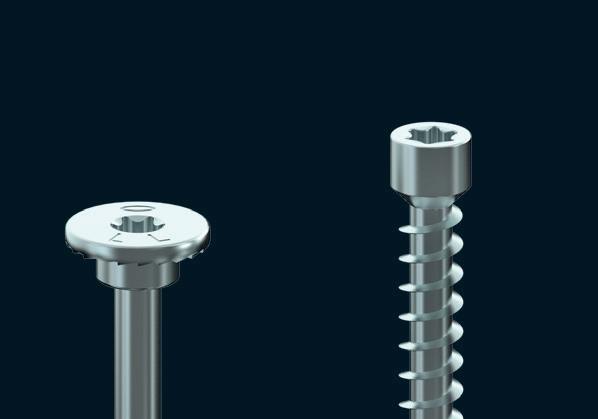

Choosing the right screw to account for weather conditions and corrosion is imperative in construction to ensure reliability and strength. Rothoblaas offers a range of products to meet the most challenging demands includes coated solutions and stainless-steel screws.

The corrosion of steel screws is a common issue in constructions exposed to weather conditions or in specific climatic zones. When screws corrode, they become brittle and lose the characteristics that ensure their effectiveness, leading to the failure of structures in which they are used. For this reason, knowing how to choose the right screws based on the context and the environment in which they will be used is crucial.

Naturally, to ensure proper behaviour and effectiveness of connections, their adequate strength and durability, the choice of screw must not only consider its corrosion resistance. In the case of wood applications, for example, the screw is subject to the impact of wood deformations on its mechanical strength, to its behaviour under fire conditions, and to the substrate on which it is installed.

The application of screws in a complex material like wood should also consider another key factor, the corrosivity class of the wood in which the screw is inserted. This is determined by the combination of several factors: primarily the service class (determined by the relative humidity of the environment in which the wooden element is placed) and the moisture content of the wood itself, the type of wood treatment and the specific acidity of the wood species.

Even in highly corrosive environments, using stainless steel screws is not always the best choice. There are many types of stainless steel, but in general, the higher the corrosion resistance of the alloy, the lower its mechanical strength.

Coated and resistant screws

The use of screws with certified coatings for corrosivity class is an ideal solution in many aspects. These carbon screws have extremely high mechanical strength, while the coating makes them highly resistant to atmospheric corrosion. Moreover, they are more competitively priced compared to equivalent stainlesssteel screws and are available in more sizes.

Class C4 screws are useful in constructions exposed to corrosive environments. For instance, they can be used for fastening wooden structures or for installing photovoltaic systems on several types of roofs. Their resistance to atmospheric corrosion makes them suitable for use in coastal or industrial areas as well.

Corrosivity classes and other factors

Atmospheric corrosivity classes represent the most common and standardised method for evaluating the aggressiveness of the environment in which screws are located. For instance, class C1 represents a lightly polluted and dry environment, while class C5 represents a highly corrosive and humid environment, such as coastal or industrial areas or environments highly exposed to chlorides or sulphur dioxide.

Choosing the right screws is essential to ensure the safety of weatherexposed constructions. Rothoblaas screws represent a reliable solution for corrosion in aggressive environments, offering a comprehensive range that includes coated solutions or stainlesssteel screws to withstand all types of weather conditions, ensuring longlasting stability of structures.

www.rothoblaas.com

22 torque-expo.com

FASTENER MANUFACTURING ITALY – CORTACCIA

// Rothoblaas screws represent a reliable solution for corrosion in aggressive environments. //

FASTENER MANUFACTURING

BARTON: BENEFITS OF COLD-FORMING

Optimas’ UK manufacturing division, Barton ColdForm, holds a rich 90year legacy of coldform fastener manufacturing.

Established in 1932 at the Barton Arms public house in Birmingham, Barton ColdForm has seen incredible technological advancements across industry since its inception. However, although coldforming is recorded to have been in use as early as the 19th century, the team at Barton have proved its suitability to many modern engineering requirements.

Coldforming’s production of durable and consistent fasteners on a largescale allows it to lend itself to many manufacturing applications of today. Coldform manufacturing is typically used to make fasteners with complex shapes and screw heads, and produces parts by forming metal into different shapes through force, and without heat. This process maximises a part’s metallurgical properties, prioritising strength and durability by ensuring its structural integrity. Working with partners from the EV, defence, power generation, automotive and offhighway industries, amongst many others, Barton’s coldform process has catered to a range of durable, bespoke fastening solutions.

Across its time, Barton has partnered with manufacturers with an incredibly high product output, but with 29 Nedschroef, Sacma and Nakashimada coldheading machines running 24 hours a day, Barton is more than wellsuited to largescale production. A single coldforming machine can produce hundreds of thousands of pieces a day, which is much higher than other forms of manufacturing, like hot forging or bar turning. However, Barton’s capability for largescale production hasn’t detracted from its environmental consciousness. The plant has recently attracted a wave of new customers with a heightened focus on sustainability. Not only does Barton’s central location in the UK allow for a lowered carbon footprint through onshoring and nearshoring, but its manufacturing process itself is highly reproducible.

Prioritising sustainability from the very beginning of the manufacturing process, Barton sources green steel, which is then formed in its nearnet state, ensuring very minimal waste of raw materials. Alongside running on 100% renewable energy, Barton also recycles 89% of its coldforming waste, with 0% of it sent to landfill.

With sustainability and localisation now key elements in the decisionmaking process for most manufacturers, Barton has only become a more attractive supply partner. In the face of increasingly advanced manufacturing technologies across industries, Barton is wellsuited to cater to even the most complex of fastening requirements.

www.optimas.com

24 torque-expo.com

A manufacturing process with plenty of history, cold-forming remains popular and suited to modern engineering requirements… and it has considerable sustainable advantages used in the way Optimas’ UK production unit, Barton Cold-Form, does…

UNITED KINGDOM

// A single cold-forming machine can produce hundreds of thousands of pieces a day, which is much higher than other forms of manufacturing, like hot forging or bar turning. //

Cold-form manufacturing is typically used to make fasteners with complex shapes and screw heads, producing parts by forming metal into different shapes through force and without heat

WE ARE EXHIBITING In-House Manufacturing Localise your fastener supply through our UK cold-form manufacturing facilities support@optimas.com www.international.optimas.com Reduce Your Total Cost of Ownership Consolidate your vendor base and partner with Optimas for all your fastener and component requirements Come and see us at our stand K110

MANUFACTURING ROUND-UP

Headlines, diary dates and statistics for the manufacturing sector

UK MANUFACTURING: THE STATISTICS

While the vast majority of fastener manufacturing goes on beyond the shores of Great Britain, with UK producers tending to be focused on special, custom and bespoke fasteners, the UK’s overall manufacturing scene is perhaps more sizeable than it usually gets credit for.

The UK’s fastener producers are part of a broader sector that employs a sizeable 2.6 million people in the UK and contributes a Gross Value Added (GVA) of £224 billion. 41% of all business R&D is via the manufacturing industry.

Where does it rank globally in the manufacturing stakes? Make UK reckons the UK manufacturing industry ranks 8th globally by value of output. Most UK manufacturing exports head to the US (£56.7bn), the Netherlands (£37bn), Germany (£33.3bn) and the Republic of Ireland (£30bn).

(Source: Make UK)

NEW PRESIDENT FOR MTA

NIKKEN CEO and President Tony Bowkett has become the Manufacturing Technologies Association’s (MTA) new President.

Bowkett has more than 30 years of experience as MD and Founder of NIKKEN Kosakusho Europe Ltd – a specialist in highaccuracy CNC Rotary Tables and NE Tooling solutions for manufacturing applications.

He is responsible for the success and triumphs of NIKKEN’s

activities across Europe and beyond, which includes multiple subsidiary companies within the NIKKEN Europe Group, together operating in excess of 23 countries.

NIKKEN, under Bowkett’s leadership, is also a Founding Industrial Partner and NonExecutive Industrial Board member of Sheffield’s Advanced Manufacturing Research Centre (AMRC) and firmly believes in UK manufacturing and knowledge transfer as a vital wealth creator, focusing on developing and training the next generation of engineers. With his experience in similar roles, such as a financial director and Vice president of the MTA, Bowkett is equipped to support the MTA to the highest level and aspires to promote and develop the association to engage and network with its members and associates, ensuring that UK manufacturing technologies are recognised as critical parts of government economic strategy.

DIARY DATE: MACH 2024

Pitched as the national exhibition for inspiring, innovating and connecting engineeringbased manufacturing, MACH 2024 will next run over 1519 April 2024. It expects to attract 26,000 visitors and in excess of 600 exhibitors at the NEC, Birmingham. MACH is owned and organised by the Manufacturing Technologies Association.

www.machexhibition.com

26 torque-expo.com

FASTENER MANUFACTURING

RapidIndustrialIndustrialFastenersareaproudBritishManufacturerof fastenersandturnedparts.

Operatingfromaseparatefacilitylessthan¼mileawayfromourdistribution centre,wemanufactureallstandardthreadedfastenersinawiderangeof steel,stainlesssteel,brassandexoticalloysincludingINCONEL,DUPLEXand SUPERDUPLEX.Additionally,ourfastenerengineersareabletoproduce complexbespokepartstodrawingandcustomerspecification.

Rapidhavebeenabletoapplyahighlyresponsiveandservicedrivenculture toourmanufacturingphilosophythathasbeengainedfromsupplyinghighly demandingendusersforover40years.

Itisoftotalimportancethatwedowhatwesaywhenwesay.Tothatend,we operateaTcardsystemtoplanandmanageourmanufacturingordersso wecanbetransparentwithourcustomersandcommunicateregular progressupdates.

HeadOffice Unit2, StourValeRoad, Stourbridge, DY98PP 01215013903 sales@rapidfast.co.uk www.rapidfast.co.uk ManufacturingHub Unit27, LyeValleyIndustrialEstate Stourbridge, DY98PP

BRITISHFASTENER MANUFACTURER THINKFASTENERS THINKRAPID

FASTENER MANUFACTURING

UNITED KINGDOM – MIDLANDS

PERFORMANCE FASTENERS –SETTING STANDARDS IN SERVICE

As an industrial hub in the UK, the Midlands has its share of fastener manufacturers. To stand out in the crowd, West Bromwichbased Performance Fasteners doesn’t try to be everything for everybody, instead choosing to focus on a niche area of the supply in the manufacture of specialist high performing fasteners. Believing service is king and manufacturing is the foundation of the supply chain, the team take pride in what they do, working hard to solve problems. “People have to be able to rely on you,” says Director Sally Matthews. “We break backs to get things done.”

Established in 2010, Performance Fasteners work across many sectors including aerospace, oil & gas, pharmaceutical, R&D, motorsport and automotive. Sally and fellow Director, Cliff Roberts, called on their collective many decades in the industry to carve a space for themselves on the market, working on things not everyone else can do. Whether it is prototype work, to enable proof of concept or working with more specialised materials, the team offer peace of mind. “We feel we are proficient with fasteners made from highgrade

performing stainless steel working with proven higher tensile,” explains Sally.

With 99% RFT and on time delivery as just some of the benchmarks the company aims for, it’s no surprise they have won awards for service in the region and from some of their customers. “We’ve achieved consistent Gold Awards for service on RFT (Right first time) OTIG (On time in full) and Response,” says Sally. All of this is in addition to the UKAS and ISO 9001:2015 accreditation you would expect from a manufacturer.

Taking service to the next level, Performance Fasteners also offer a handy Fastener Technical Guide for engineers. “Cliff designed, wrote, and developed the tech guide. It gives not just ISO and Din dimensions for a fastener range that includes hexagon head bolts nuts and sets, comprehensive sockes crew products and plugs. The contents include dimensional comparison tables, raw material weights, conversion charts for tensile strength ranges, fraction to inch and fraction to millimetre and most things you need to know,” adds Sally. Currently on its third edition, the comprehensive booklet has been a hit with customers and is regularly recommended to newcomers in the industry.

With a personable approach and attentive problemsolvers, Performance Fasteners are a trusted reliable manufacturer of fasteners, socket screws, turned parts and engineering components for specific requirements.

www.PFLUK.com

28 torque-expo.com

The fastener market is a competitive field but Performance Fasteners draw on their decades of experience to provide excellent service and solve problems for their clients.

Director Cliff Roberts

A LEADING MANUFACTURER OF ‘SPECIAL’ FASTENERS, SOCKET SCREWS, TURNED PARTS AND ENGINEERING COMPONENTS FOR SPECIFIC REQUIREMENTS NICHE & SPECIALISED FOR THE FOLLOWING SECTORS Aerospace | Automotive | Electronics Oil & Gas | Pharmaceutical | + More Tel. +44 (0) 121 525 1137 | Email sales@pfluk.com Unit 7, Interlux Business Park | 204 Oldbury Road | West Bromwich | West Midlands | B70 9DE | UK www.pfluk.com Performance Fasteners Ltd Manufacturing Fasteners that Perform in Industry Award-winning quality service to all customers Performance Fasteners Ltd are registered ISO 9001:2015 with UKAS accreditation Personable approach and problem-solvers, your trusted reliable manufacturer Technical experts with 60+ years combined industry experience and knowledge Contact us for a FREE comprehensive Fastener Technical Guide

“YOUR NON-STANDARD IS OUR STANDARD”

Pitched as a one stop shop for non-standard and special fasteners, Smith Bullough’s experienced team is hungry to convert more business in the UK and in Europe. Torque Magazine caught up with Director Tim Garton and Manager Richard Garton

IIn the heart of the manufacturing world in Greater Manchester, Smith Bullough is a fullblown fastener manufacturing operation.

With a history that can be traced back to the 19th century, the business knows a thing or two about making bolts. Today, Smith Bullough is fully focused on producing specials and nonstandards, bolts that are specific to customer drawings with a huge variation available.

Buying in steel bar from UK and Europe suppliers, Smith Bullough can forge and CNC machine bolts.

Director Tim Garton explains: “We have all types of material; All standard carbon steels, alloy steels and then a whole range of nonferrous and exotic materials.

“The majority of the stuff that we make is bespoke to customer drawings. We don’t tend to make much in a standard shape. We do all the thread forms from standard coarse pitch, fine pitches, all the different denominations of threads. You’ve got metric, unified, obsolete thread forms like BSF and BSW… we do the whole gambit.

“We can forge, we can then grind shank and we can get a real close tolerance on the shank if required. We machine threads, we can roll threads… If someone wants, for example, a bolt with flats on shank, we can do that. We’ve got CNC milling. We can also do a lot of drilling, so we can cross drill through threads. We can drill through the heads… we can drill anywhere you like within reason.

“Our standard drilling holes is from about 1.5 millimetre diameter, but we actually can drill holes down to 0.8 millime

tre, which is quite small. Yeah, but it’s inverse of the smaller the size, the higher the price. When you go below one point, it’s quite a complicated procedure.

“Diameterwise, we typically can start at about five millimetre, up to 800 millimetre long and if you push it, but to around 100mm diameter, but there isn’t much of a demand for that. Those are our standard working ranges. The machines don’t care what we throw at them!”

“We’ve got spark erosion inhouse and we make the majority of the tooling but if somebody wanted their own bespoke logo on the head, and we do a few of those, then we’ll get that contracted out but we basically control the whole operation.”

In addition to what is considered traditional bolt making equipment, the firm has the aforementioned CNC and manual turning machines, capable of sophisticated procedures: “We do manual drilling, CNC drilling, we’ve got quite a range of emimec sprints, they tend to be popular for threads. On finishes, we treat any form of heat treatment that’s required. It’s subcontracted. But through approved suppliers. Surface treatments, finishes, plating, all the standard stuff, anything that can be reasonably required, we can get done.”

And while the firm naturally likes to deal with large quantities, more modest amounts are welcome too, Tim Garton says: “Not everything needs to be 10s of 1,000s, hundreds of 1,000s. Sometimes we’ll do 10 bolts or even less. We can cover demand that most people want.”

30 torque-expo.com FASTENER MANUFACTURING UNITED KINGDOM – MIDLANDS

INVESTMENT IN PEOPLE

“We’ve been investing quite a lot recently in more skilled people and also the upskilling of staff,” Richard Garton explains. “With higher skilled people they can filter down knowledge though training, so we’re bringing existing staff training to a higher level as well. We’ve also employed additional high skilled personnel on the CNC area.”

The firm is also planning a return to apprenticeships, bringing them back after Covid disrupted its training schemes. Smith Bullough has recently signed up with local colleges to bring in fresh new talent.

Onshoring and reshoring have been recurring themes, particularly since the pandemic disrupted the supply chain. Has Smith Bullough benefitted? “I would say so,” Manager Richard Garton tells Torque Magazine. “We’re growing yearonyear. People haven’t actually said that is why they’re coming to us, but I assume part of that will be from those looking to source in the UK. The business is growing – that is a positive sign.

The firm continues to invest in systems to improve traceability too: “We recently invested in a bespoke temperature readout system for our hot forging facility. So, it won’t only just read out every single bolt, it’s also going to record the temperature of every bolt going through the production. So then, you know, we will have the controls locked. It’s part of our ongoing improvement in systems and procedures. Especially for the more exotic materials, if people are spending a lot of money on their bolt, then you need to ensure that you’ve got all the controls in place. And temperature is a critical function.”

CHALLENGES

Manufacturers are always keenly eyeing raw material prices, which Smith Bullough feels have been stablising over recent months, but other challenges are – as observed elsewhere in this magazine – new regulations regarding imports, particularly those which will prevent Russia origin materials.

Almost coincidentally, Smith Bullough has a solution in the works: “We used to buy quite a lot from distributors, wholesalers, but we’re actually going to buy more from the mills. It will mean we are investing more money, because you have to have tonnes at a time, but it’s an opportune time. It’s going to be far easier for us to get the data of origin and also in terms of going green and the CBAM regulations.”

Sustainability has been, the manufacturer honestly admits, something that many have kept to the sidelines in past years: “It’s been left out on the periphery too much in manufacturing.

That is something we are now paying a lot more attention to, as a producer and also as an SME.”

Exports are also a point of focus: “We’re endeavouring to increase our export sales, yes. We exhibited at Fastener Fair Global and we have had a team out in EU territory this year. We already do a reasonable amount, but we see it is a big opportunity – we believe we can be doing a lot more, especially in bespoke parts.”

THE VALUE OF THE FASTENER ECOSYSTEM

Too often, industries undervalue themselves and their impact on the broader economy and, in the view of Torque Magazine, that sometimes includes the fastener business. Businesses do not work in isolation, and their contribution to local employment and business goes far beyond their own profit and loss sheets, something that governments could well be reminded about. With that in mind, Torque asks Smith Bullough for a ballpark figure on the number of suppliers it uses. Straight off the bat, Richard Garton has the numbers. “It’s just over 300 suppliers, that includes everything from actual materials to things like stationery.”

ONE STOP SHOP FOR NON-STANDARD FASTENERS

“You can sum up our offering up with saying that ‘Your nonstandard is our standard’,” explains Richard Garton. “We have the facilities for every single process really within what you could want within the fastener industry. And we have subcontractors for all your plating, heat treatment, patch locking… so anything you can’t get from your standard suppliers, we will be able to help. We have the facilities and the personnel to machine it. We can back it all up with all the quality documentation that’s required.”

Smith Bullough is keen to get across its capabilities: “We’ve got all this specialist equipment and talented people that we employ – we want companies to know what we can do.

“We’re happy for people to turn up and we will be holding open manufacturing days, like we did preCovid, where we invited people to come and see what we do and all that happens in fastener manufacturing. With fewer people making bolts, especially in the UK, people don’t really understand everything that’s involved. It’s not just like waving a magic wand and it falls into a box. There’s quite a lot of disciplines and procedures required to get the product to that state.”

“There isn’t much within a bolting range that people can throw at us that we can’t actually come back with.”

www.smithbullough.com

32 torque-expo.com FASTENER MANUFACTURING UNITED KINGDOM – MIDLANDS

ASK FOR THEM BY NAME...

When choosing industrial fasteners, genuine quality means safety and performance. Billions of installations in millions of applications worldwide are Nord-Lock’s mark of authority, reinforced by meticulous production tolerances, thorough certification, and an industry-first lifetime warranty.

Engineers ask for them by name, and they’re are a standard-bearer for safety in construction and industry.

Choose lasting bolted connections. Choose reduced maintenance, cost-effective solutions and first-class engineering support. Choose reliable worldwide supply.

Ask for Nord-Lock.

© Copyright 2023 Nord-Lock Group. NORD-LOCK, SUPERBOLT, BOLTIGHT and EXPANDER SYSTEM are trademarks owned by different companies within the Nord-Lock Group. All other logos, trademarks, registered trademarks or service marks used herein are the property of the Nord-Lock Group. All rights reserved. nord-lock.com

NON STANDARD SOCKET SCREW MORE THAN YOU IMAGINE

Non Standard Socket Screw is more than its name implies. The company has grown significantly since it was established over 52 years ago, not only expanding physically on its current site, but also in the products being manufactured and the different markets it works in. The company manufactures goods that are supplied into a vast range of industries including automotive, aerospace, defence, rail, recycling and oil & gas to name just a few. Exports are largely to Europe but stretch as far afield as Australia, South Africa and the USA as well.

While the company name might suggest it only supplies and manufactures socket screws, it’s not the case, as NSSS manufacture all socket screw head types ranging from caps, countersunk, button, flange, shoulder screws but also hexagon heads, flanged hex, ferry & 12 point head, tee bolts and special bespoke items. The team work with a variety of raw materials including Alloys Steel in all tensile grades, Stainless Steel, Duplex and Super Duplex, Ali Bronze and Phos bronze, Aluminium and Titanium, plus Inconels and Hastelloy. A wide range of finishes are available including Zinc, Galvanising, Geomet®, Delta Protekt®, Xylan Coated® and cadmium plating to aerospace standards. There is also a spectrum of locking services on offer such as Patlok® (Blue), Tuflok® (Blue), Precote® (Pink), Eslok® (Red), Anulok® (Yellow), Wedgelok® (Nylon Pellet) and Nylon dog points.

With a range from M1.6 up to M64, and the imperial equivalent diameters, NSSS aim to provide an unparalleled range and service. The production facility is backed by a team of highly skilled staff, many of whom have been with the company for decades. Over a third of the 90plus members of staff working for the company have been there for over 25 years, and 13 for more than 35 years. “We see the low turnover of staff as a great achievement,” says Mark Wolsey, NSSS senior sales manager. “Most of the team have been home grown within and when looking to recruit we have been very successful internally offering promotion opportunities for further career development.”

Working in manufacturing requires a specific skill set by the employees and NSSS like to develop those skills internally where possible. “Fastener and technical training is given continually onsite. This knowledge is enhanced due to us being a manufacturer here in Birmingham and having that opportunity to visualise the production is a great assistance. This all helps when we are assisting our customers with their special enquiries and technical support,” explains Mark.

NSSS has seen continual investments over the years with new technology. The facility boasts an array of advanced machinery including Double Blow Hot Forging Presses and Multi Axis CNC Turning and Milling apparatus. Complementing this are Centreless Grinding and Thread Rolling machines for a comprehensive manufacturing process. After successfully introducing its first 7 Axis Cincom CNC Automatic Lathe over five years ago, the company now has eight Cincoms at its disposal to offer more capacity than ever. Internal heat treatment facilities further ensure that quality is maintained throughout the production process.

“We are committed to providing products and services of the highest quality, which meet international standards and/or specific customer requirements. It is the company’s aim to enhance customer satisfaction through effective planning and implementation of management system BS EN ISO 9001:2015, including the process for continual improvement and the assurance of compliance with statutory and regulatory requirements,” says Mark. Quality is checked at every stage and the company currently employ four full time inspectors and use specialised tools such as Keyence Optical Measuring equipment.

“As we are the UK’s leading manufacturer of bespoke fasteners and wholesaler of standard socket screws including Unbrako, supplying the network of Fastener Distributors throughout the UK and Europe we aim to fulfil your requirements first time every time,” adds Mark. www.nssocketscrews.com

34 torque-expo.com

FASTENER MANUFACTURING

KINGDOM – MIDLANDS

UNITED

The name Non Standard Socket Screw doesn’t come close to describing the full capabilities of the Birmingham-based manufacturer as the business continues to expand its offerings and expertise.

We manufacture special fasteners www.nssocketscrews.com NON STANDARD SOCKET SCREW LTD

FASTENER MANUFACTURING

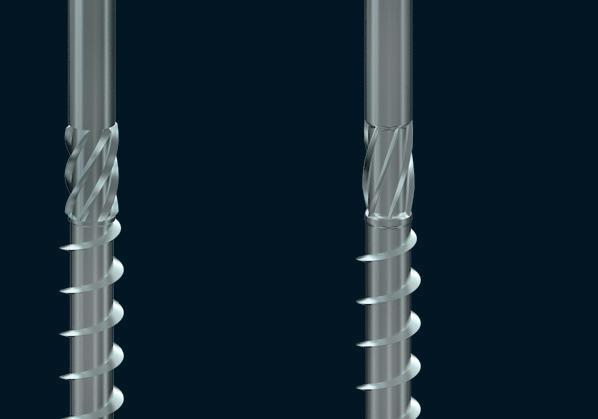

EFFICIENT CONNECTION SOLUTIONS FOR TIMBER CONSTRUCTION

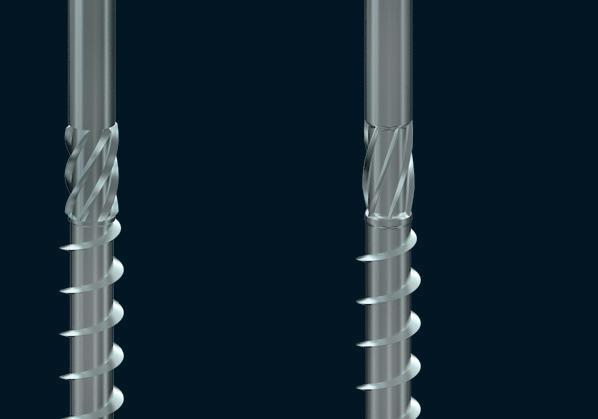

Eurotec has brought more wood screw production to its facility in Hagen, following a sizeable investment in 2022…

Eurotec GmbH has been producing a select part of its wood construction screw range in its own production facility in Hagen, Germany, since 2013. That manufacturing facility underwent a significant revamp last year, enlarged to around 7,000 m² with investments made in the machine part.

The decision to expand its machine shop was to not just create more space, but also to set futureoriented goals –including becoming independent of the world market as a local manufacturer and supplying innovative highperformance connectors for sustainable prefabricated timber construction and timber construction in general. Now, the company can react quickly and flexibly to increasing market requirements and increase production capacity accordingly. More local production also brings big opportunities to effectively reduce CO2 emissions in freight transport and bulk transport from alternative procurement sources.

An everincreasing proportion of wood construction screws is currently produced and will continue to be primarily produced in the future. The manufacturing processes for wood construction screws range from thread forming to head and tip geometry to screw length. The wide range includes inhouse produced screws from 5 x 40 mm to 13 x 1400 mm. The production of fullthread screws reflects Eurotec’s greatest production strength. This knowhow forms the basis for further entrepreneurial development. In addition, the company also covers the areas of injection moulding technology, stamping and bending technology and aluminium extrusion technology.

Quality assurance at Eurotec

By subjecting to regular test procedures and monitoring of production steps according to the high quality requirements according to DIN EN ISO 9001, customers can be assured of reliable and durable products. As part of internal quality assurance, the batches produced daily are strictly checked for standards such as conformity to drawings, functionality, appearance and compliance with customerspecific specifications. Eurotec’s ultimate goal is to provide customers with professional products and services and to ensure 100% ontime delivery. A large part of the fasteners in the range, especially in the wood, façade and concrete segments, have an ETA and CE certification and are suitable for loadbearing functions in various construction projects.

Sustainability in manufacturing

The goal of all company processes is a climate and environmentallyfriendly way of working: One focus is put on the sustainable production concept. For example, ecofriendly raw materials and auxiliary materials are used for production processes, energy is generated by solar systems and energy consumption is minimised by the use of LED lamps throughout the hall. Green steel is used in cold forming, which can lead to savings of up to 1.5 tons of CO2 per ton of steel.

What’s next?

Eurotec GmbH continues to strive for the development of innovative highperformance fasteners to outperform simple wood construction screws. Climatefriendly building with wood remains an important topic, as wood offers a clear advantage in terms of CO2 reduction compared to cement and concrete. This can be clearly seen in the everincreasing demand for professional fasteners in order to accomplish largescale projects. Eurotec works continuously on the development of reliable and innovative fastening technology to meet these requirements.

Eurotec GmbH is an established company that specialises in fastening technology for demanding construction projects in timber as well as in deck and garden construction and has been contributing to quality and innovation for more than 20 years.

www.eurotec.team

36 torque-expo.com

GERMANY

HAGEN

–

Customers can be assured of reliable and durable products and a large part of the range have ETA certifications

FASTENING IS OUR PASSION

TIMBER DECK AND GARDEN ROOF FAÇADE CONCRETE

Whatever your requirements are, we provide you with everything from a single source. We produce in various processes such as stamping and stamping-bending technology, cold forming, injection moulding and extrusion technology.

Production possibilities

• Screws with 40 mm to 3000 mm, with a diameter of 3 – 14 mm are produced on fully automatic machines

• Simple thread

• Double thread

• Reduced thread

• Milling tips

• Different materials

• Different coating

• Different tip geometries

• Individual customer requirements

Surface process

From zinc to blue galvanized for long-term resistance in weathered areas (C4 – C5)

www.eurotec.team/en

E.u.r.o.Tec GmbH · Unter dem Hofe 5 58099 Hagen · Germany Tel. +49 2331 62 45-0 · Fax +49 2331 62 45-200 · E-Mail info@eurotec.team

GERMANY – PLETTENBERG

75 YEARS OF EMBRACING CHANGE

The product may not change much but Plettenberg’s Güde takes pride in being ready to adapt its business, whether that’s adding a production site in Poland, adapting to the challenges of finding skilled labour or producing 50% of the energy it needs in-house. Torque Magazine speaks with CEO Lutz Güde about the milestones of Güde’s first 75 years...

How’s business?

I think the atmosphere in the market is worse than the actual situation is. We are hearing from many of our customers that August 2023 was one of the worst months in the last two to three years for them. August usually is a bad month in terms of sales, because all of Europe is on vacation, but this one does seem to be uniquely poor.

But we are doing OK. Business is down around 18%. Some of it is because of price, but of course it’s demand too. If you look at 20212022, I doubt that we will see this again. We can’t compare it to other years because it was so unique. There were high prices and high volumes. Now things are normalising. I would rather have had a weaker 2022 and a better 2023, but that’s the way it is, you have to get along with it!

That’s what we are hearing from a lot of the market. Would you define that as something primarily happening in the German market or more broadly?

We operate internationally, but Germany is our biggest market. We export to Europe of course, like Italy, France, Spain, Scandinavia, etc. We’ve been acting in North America for around 10 years now, which gave us a really solid foundation – in the hard times of 2020, the US market helped us out a lot. Now it’s not so strong and I think the US economy has the same problems as the rest of the worldwide economy.

Sometimes we receive these unusually large orders and we don’t know how the people have come to us. We are shipping products to India, we are shipping products in huge volumes to Australia. We just finished a shipment for a very interesting project in Japan… So, we are very internationalised. We believe that somewhere in the world, there’s always an opportunity to increase in business.

Güde has been investing alot lately, including a new logistics building?

We are constantly investing and always invest our money into the company. We keep adapting and investing our headquarters, we keep investing into our branches in Eastern Germany and Poland.

We believe that you don’t need to change every day, but you have to adapt every day. Everything around the product changes, so we have to adapt.

The demand for lockwashers is there and we invest where we see the need. There is a danger in the amount of skilled labour, so we are automating our logistics to keep it lean and less dependent on people. You hear it in every conversation you have, that skilled and unskilled labour is hard to come by. That’s the reason we’re investing huge money in optimisation. This is also the reason why we invested in Poland and the people are doing a great job there.

Güde moved to its current location in 1990 and has since expanded its buildings in 2012, 2017 and now again in 2023

38 torque-expo.com

FASTENER

MANUFACTURING

High-quality solutions for fastening technology

Fasteners always comes into its own when it comes to demanding and complex tasks in fastening technology. Fastener engineers and technicians work together with developers on the customer‘s side to develop efficient solutions, particularly in the area of application technology consulting before the actual launch of a series product. The specialists benefit from the fact that they are familiar with all common production processes and can therefore also recommend the most favourable and efficient production variant.

Turned parts

Cold formed parts

Welding nuts/ Welding screws

Stamped parts

Hönnestr. 22 58809 Neuenrade Germany Tel. +49 2394 619-0 info@kohlhage.de www.kohlhage.de

Inserts WE ARE

FASTENER MANUFACTURING

GERMANY – PLETTENBERG

the company was always one of the first things talked about over dinner. I used part of the yard as my football pitch and was upset whenever there were machines or pallets standing on my soccer pitch!