5 minute read

Upgraded Oil Recovery from Heavy Oil Sands

A case study is simply the study of the parti cularity and complexity of a single case, coming to understand its acti vity within important circumstances. Thus, identi fying appropriate strategies for the resoluti on of the ‘case’ while having the ability to weigh pros and cons of the remedial opti ons and strategies, enabling you to recommend and present a rati onale for the best resoluti on. Every engineer must have a tool as powerful as this one among their tool kit as they tackle the problems and challenges that they face, that is why we dedicated a secti on solely for presenti ng case studies that might be of great benefi t or interest to you.

Ahmed A. M. Algibaly Professor Faculty of Petroleum and Mining Engineering, Suez Canal University Petroleum Engineering Department

Advertisement

Introducti on

About nine heavy-oil sand reservoirs exist near Ras Gharib, in the western desert, Egypt. One of them is Assran oil fi eld which is currently under development by Scimitar Oil Company. These oil sand reservoirs are good candidates for thermal recovery methods.

In additi on, oil spills on land may be

another candidate for clean-up by ther

mal methods. Gulf war in 1991 resulted

in the fi ring of more than 600 oil wells in

Kuwait. The crude oil gushed from these

wells and accumulated in desert low

lands forming over 300 oil lakes of a total area of 49 km 2 . The amount of oil con

taminated soils in the oil lakes and their peripheries was esti mated in the range of 40 to 50 Million metric tons. Various oil extracti on and soil remediati on technologies were evaluated to fi nd the most suitable soluti on for treatment of the heavily oil-contaminated soil and sludge.

It appears that thermal desorpti on

by retorti ng process is one of the most

promising technologies to be suitable

for oil lakes soils. The retorti ng process is

based on heati ng the oil-sand mixture up to 500-600 O C in the vicinity of an inert

gas under atmospheric pressure. A great deal of laboratory and fi eld work has been done on oil extracti on from oil-shales and tar-sands by this process.

The objecti ves of the present study are: (a) To perform an experimental study that considers the process variables which govern the performance of the retorti ng process such as heati ng rates, operati ng pressures, specifi c properti es of the soil matrix, etc. (b) To develop a mathemati - cal model that can fi t the experimental data and characterizes the oil produced during the retorti ng process.

Pyrolysis Mechanisms

The quanti tati ve predicti on of the thermally recovered oil and its quality by a pyroIysis mechanism is directly related to the economic evaluati on of a retorti ng project. Three successive pyrolysis stages were identi fi ed for fuel formati on at the combusti on front during the in-situ combusti on process. These stages were classifi ed as oil volati lizati on, visbreaking, and coking.

Experimental program

The experimental apparatus used in this study is schemati cally illustrated in Fig. 1. Experimental runs were carried out on model oil-sands as well as genuine oil-sand samples collected at diff erent depths from bott om beds of the oil lakes.

Results

Fig. 1. Experimental Setup

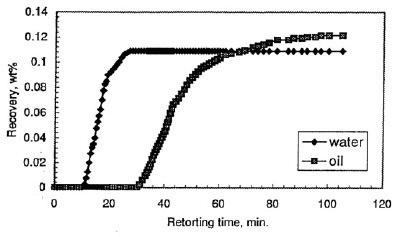

Fig. 2 shows the oil and water recovery results obtained from sample collected at the top sample of bed-137. It shows that connate water starts fl owing aft er about 10 minutes from the beginning of the experiment. All water was recovered before the start of oil producti on.

oil-sand samples the eff ect of heati ng rate is mainly refl ected through the less ti me of process durati on. Severe thermal cracking of crude oil during retorti ng process results in unwanted depositi on of coke in the porous medium. Further to oil consumpti on by coke, it may reduce the permeability of the porous medium.

Eff ect of surface area: The magnitudes of p and q refl ect the characteristi c eff ect of surface area on the retorti ng process. For instance, if the soil matrix consists of a large variety of fi ne parti cles and split agglomerates with a wide range of cracking rate, q is likely to be Large. This behavior is consistent with the previous experimental observati ons.

Conclusions

(1) Potenti al oil recovery has been obtained from the laboratory work with reasonably moderate ti me required for the retorti ng process.

(2) Four main transiti onal stages were observed under constant heati ng rate in an inert atmosphere.

(3) The kineti c model developed for the pyrolysis of oil sand samples fi tt ed well the experimental data.

(4) Results revealed that an opti mum heati ng rate of 10 to 12.5 °C/min could yield good process performance as low coke precipitati on and higher oil recovery were obtained.

(5) For oil sand sample of moderate values of oil content, an atmospheric operati ng pressure was found to be appropriate. For sludge and heavily oiI-contaminated samples, high operati ng pressure is recommended.

___________________________________________________ References 1. Puskas, K.; A1-Awadhi, N.; Balba, M. T.; A1-Daher, R.; Iwabuchi, M.; Kumamoto, S.; Kuwabara, M.; and Sueyoshi, M.: “Exploratory Work on Physical/Chemical Treatment of oil Sludge,” The Joint Kuwait-Japanese Symposium on Restoration and Rehabilitation of the Desert Environment, KISR, Kuwait, March 3-4, 1996. 2. Salib, P. F.; Barua, S. K.; and Furimsky, E.: “Retorting of Oil Shale from New Brunswick, Canada,” Canad. J. Chem. Engg., Vol. 64, Dec.1986, pp.1001-1007. 3. Li, S. and Qian, J.: “Study of the Pyrolysis of Maoming Oil Shale Lumps: FueI, VOI.70, Dec. 1991, pp.1371-1375. 4. Shu, W.R. and Hartman, kJ: “Thermal Visbreaking of Heavy Oil during Steam Recovery prosesses,” Paper SPE 12783 presented in California Regional Meeting, Long Beach, CA, April 11-13, 1984.

Fig. 2. Oil and Water Recovery from Top Sample of Bed-137

Eff ect of Operati ng Pressure: In the present study, it has been found that with relati vely high gravity oils (≈24 °API), an increase in the operati ng pressure caused rise in coke depositi on. Similar results were obtained for Athabasca bitumen being subjected to unstable burning at slightly higher pressures.

Experimental observati ons showed that when the operati ng pressure was increased the disti llati on peak was low in amplitude, and spread over a long ti me interval.