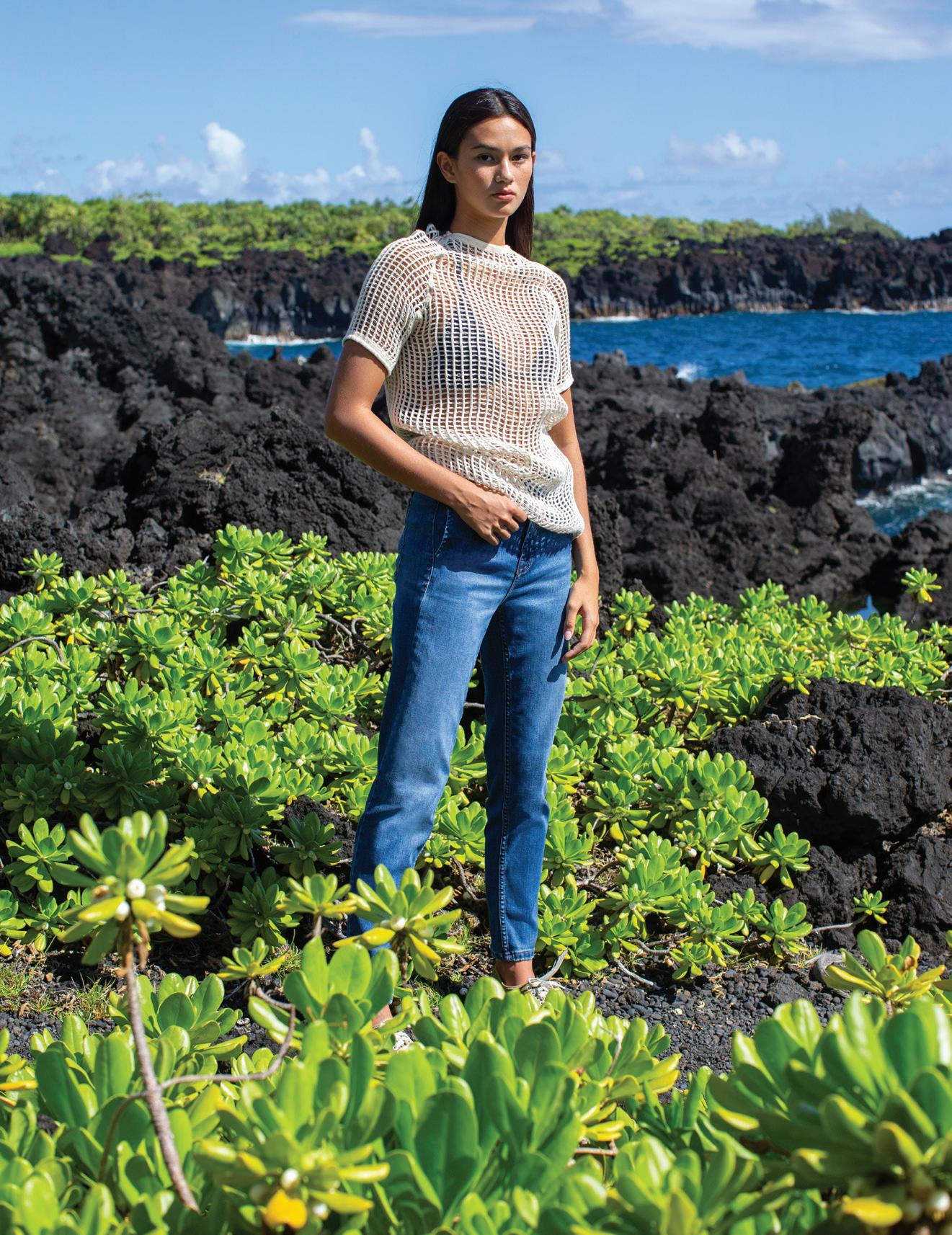

Blue Hour, Supima Field supima.com

beauty,

Chosen for

function and feel.

Survey Says: Shoppers Will Shell Out for More

Textile Recyclers and Clothing Resellers Weigh In On Fashion’s Circular Future

Reformation Pledges To Be Circular by 2030

Gap Inc.’s ESG Progress Report: Cotton, Worker Well-Being, PFAS and More

Everlane Updates Environmental Impact

Sorona Maker CovationBio Reinforces Sustainable Commitments

2023 SUSTAINABILITY REPORT Table of Contents 09 11 13 19 23 26 29 32 Executive Summary Green Shoots New Calif. Legislation Aims To Stem Textile Waste

is Set’ for Fashion’s Collective Climate Action Coalition

Circular Fashion As ‘Economic Empowerment’ Addressing the ‘S’ in ESG Higg MSI Controversy Cited in Sustainability Labeling Trends Embattled Higg Co Gets a New Name 05 05 35 38 41 47 50 53 56 59

‘Stage

Champions

Ellen MacArthur Foundation Rolls Out Circular Startup Database

Sustainable Stuff

to

Change’

Better Cotton 2030 Targets Look

‘Galvanize

Prescriptive supply chain planning. Balance Supply Chain Sustainability with Profitability. Logility is the supply chain leader entrusted by the world’s leading brands to deliver value through a digital, agile and sustainable supply chain that powers the resilient enterprise. To learn how Logility can help you make smarter decisions faster, visit www.logility.com. Worldwide Headquarters 800.762.5207 / United Kingdom +44 (0) 121 629 7866

62 63 65 67 70 72 74 77 79 81 84 86 88

SUSTAINABILITY SUMMIT

H&M Sustainability Lead Says Fashion Must Focus On ‘Circularity Now’

ESG Legal Experts on Regulatory Upheaval: ‘Know What Is Coming Your Way’

ThredUp CEO on Resale Economy: ‘Math Says This Stuff Is Super Hard’

How Three Firms are Putting Their Stamp on Circular Fashion

Exploring Cotton’s Role In a Sustainable Future

Taking a Top Down Approach to Sustainability

‘Regulatory Momentum’ Will Root Out Greenwashing

How FGX Approaches Product Development with A Sustainability Lens

Centric Software Delves Into The Mind of the Consumer

You Can’t Be Sustainable Without Traceability

Next-Gen Materials Show Promise Amid Obstacles

A Look Back: The Day Rana Plaza Changed the World

91 94 98

India’s Sustainability Road Show Crafting a More Sustainable Future in Bangladesh Experts Discuss Unions, Minimum Wage in Bangladesh

101 105 109 112

Regenerative Fashion: By the Book

Sustainable Ways to Achieve Y2K-Inspired Dirty Washes

Soles4Souls: Changing Lives With Footwear and Apparel

Patagonia, Levi’s and The North Face Top Kearney’s Circular Fashion Index

2023 SUSTAINABILITY REPORT

Table of Contents

07 07

Behind the Thread: Himatsingka’s journey towards sustainable practices

Reinventing strategies to reach new markets, categories and adjacencies

Consumers are increasingly seeking products and services that re ect the values of a caring economy. They are leaning towards healthier practices, balanced routines and planet-positive lifestyles that are inclusive and accessible. Himatsingka recognizes wellness, sustainability and the environment as key themes that consumers are consciously embracing. To ful l the expectation of our consumers and future needs, we are reinventing the wheel aesthetically, technologically and functionally.

The re ection of our commitment to sustainability, enhanced comfort, and responsible living are demonstrated with our expanding collection

Executive Summary

In 2015, all United Nations Member States adopted a blueprint to make the world more sustainable by 2030. Timewise, we’re a shade more than halfway there. On the ground, at the stores and in the factories the signposts of progress can be a little harder to quantify.

In this report we talk with Kerry Bannigan, executive director of the Fashion Impact Fund, who points out that just 12 of the 17 SDG targets are on track and that “we have stalled or gone into reverse on more than 30 percent of the SDGs.” The reasons for that shortfall are numerous and nuanced, and while some years lost to the pandemic didn’t help, it’s also become more appar-ent that the road to 2030 was a bit longer—with a bit tougher terrain to traverse—than many had expected.

In search of cohesion, the Ellen MacArthur Foundation and the Apparel Impact Institute are touting green initiatives, a circular startup database by the former, and the ongoing Clean by Design of the latter. We take a closer look at what they have to offer on pages 34 and 18.

We also check in with some select companies on their progress, Reformation and Everlane, which have made sustainability a part of their ethos, as well as two others, Gap Inc. and Cova-tionBio, to add some perspective and flush out the array of challenges and different paths to success businesses are taking.

True change needs to be an industrywide undertaking, and one example of this is the American Circular Textiles Group, whose aim is to

provide a “glue” for a fragmented and competitive market so it can come together and discuss what it needs to scale its solutions. Information about their latest report can be found on page 22.

Fashion, however, is a global affair, and good intentions in Europe or the United States must be mimicked in Southeast Asia, where the majority of garments are produced. Initiatives like a new textile recycling program in China (page 10), talking points at events in Bangladesh (page 90) or India’s “Sustainability Road Show,” (page 93) are evidence that the industry’s upstream el-ement is headed in the right direction.

It is also of paramount importance to have a united front. One way to achieve this is through mass gatherings of stakeholders up and down the supply chain. Sourcing Journal hosted one such event in April, the second annual “Sustainability Summit: The Road to 2030.” Catch up on full coverage of the day’s highlights on pages 61 to 89.

And where does the consumer fit in to all this? According to a recent survey, most shoppers say they would indeed pay more for sustainably made products all other things being equal. Learn more on their preferences on page 37.

All in all, as we inch toward the midpoint of this decade, there are plentiful signs that progress is being made, but these gains in many places are offset by the scope of the work left to be done.

Peter Sadera Editor in Chief Sourcing Journal

2023 SUSTAINABILITY REPORT

09 09

changing world calls for more sustainable solutions. So we created the first-ever plant-based non-fluorinated water repellent, with performance worthy of the Teflon brand. Teflon EcoElite finish from Chemours. © 2023 The Chemours Company FC, LLC. Teflon , Teflon EcoElite and any associated logos are trademarks or copyrights of The Chemours Company FC, LLC. Chemours and the Chemours Logo are trademarks of The Chemours Company.

From nature. For nature. Our

Green Shoots

Money Trees

Canopy, an environmental not-for-profit and past partner of brands like LVMH, H&M and Ikea, will receive $60 million in funding to advance low-carbon and circular supply chain solutions, it said. The funding comes from The Audacious Project, a collaborative funding initiative housed at TED, the nonprofit behind TED Talks.

China Takes On Textile Waste

China has taken a significant step toward a dual carbon strategy with the creation of a platform to identify sustainable textile products.

Called the “Reborn-China Fibre Zero Carbon Action 2023 – Sustainable Textiles Credible Platform,” its brief is to promote green products and get more consumers to buy them. It is jointly run by the China Chemical Fibres Association and the National Advanced Functional Fibre Innovation Centre.

The new platform is part of a move to establish China’s recycled fiber standard certification system. China is the world’s largest producer and consumer of chemical fibers, which are crucial to the international textile industry. At the launch, Duan Xiaoping, vice president of the China National Textile and Apparel Council, called for a comprehensive waste textiles recycling program to tackle waste-related issues while establishing a steady supply of raw materials for the production of green fibers.

Twenty-six companies have signed on to the platform. It is sponsored by the Department of Consumer Goods Industry under the Ministry of Industry and Information Technology and the Suzhou Market Supervision Administration. — Claire Wilson

“Innovative low-carbon solutions, such as regenerated cellulosic fibers from waste textiles or agricultural residues, are showing the potential to reduce our impact on climate and protect forests, so no ancient and endangered forests are put at risk to make fashion,” Leyla Ertur, head of sustainability at H&M Group, said in a statement. “Together with Canopy and other industry leaders, we want to use our size and scale to continue driving demand for low-carbon material solutions while building scalability faster.”

Canopy described the funding influx as a “massive capacity boost” that will accelerate the commercialscale production of low-impact and circular clothing, paper and packaging solutions that don’t rely on pulp from “Ancient and Endangered Forests.” These solutions are derived from what is usually landfilled or burned, including waste textile, waste food scraps and agricultural residues, to create new fabrics, paper, pulp and packaging. These “Next Gen” alternatives produce on average 95 percent to 130 percent less greenhouse gas emissions, 88 percent to 100 percent less land use impacts and five times less impact

on biodiversity, Canopy claimed. By 2033, the not-for-profit plans to “unlock” more than 60 million metric tons of low-carbon Next Gen fiber production, avoid more than 1.3 billion metric tons of emissions, divert nearly 800 million metric tons of agricultural residue and waste textiles from being burned or landfilled and completely eliminate the use of Ancient and Endangered Forests in the paper, packaging and fashion viscose supply chains.

Ancient and Endangered Forests, which Canopy says is a term defined by “leading” conservation and biodiversity scientists and environmental non-governmental organizations, includes forests of at least 50,000 hectares in size where industrial logging hasn’t taken place, rare forest types, forests with high numbers of plant and animal species, forests with high concentrations of rare and endangered species, forests with species which can only be found in very specific regions, forests with key focal species, forests with rare ecological and evolutionary phenomena and forests with high carbon stocks.

“We are very proud to be included in this year’s group of Audacious grantees and believe that Canopy’s creative, collaborative and transformative work will be key in driving supply chain change at scale and, in turn, provide a reprieve to critical forests that are under current and future threats, within the next decade and beyond,” Canopy’s founder and executive director, Nicole Rycroft, said in a statement.

— Chelsea Dobrosielski

11 | TKTKTKTKTK 2023 SUSTAINABILITY REPORT

_____Employees carry a bag of clothes at a waste sorting center in China.

11

Deng Yinming/VCG via Getty Images

New Calif. Legislation Aims To Stem Textile Waste

THE

Representing the fifth largest consumer market in the world, the Golden State is responsible for the bulk of America’s clothing consumption. In 2021 alone, Californians purchased 780,000 tons of apparel, according to McKinsey research. The vast majority of those items—740,000 tons, the group estimates—eventually end up in landfills. That’s enough pants, shirts, outerwear, dresses, intimates and swimwear to blanket a region more than five times the size of Los Angeles.

Lawmakers are now seeking to stem the tide of that waste. The Responsible Textile Recovery Act of 2023 (SB 707) would compel producers of clothing and fabric goods to fund the creation of an extended producer responsibility (EPR) program. Such a platform—which the state has implemented successfully with other waste streams, like mattresses, batteries, medical sharps and plastics—would redirect post-consumer waste into recycling and reuse projects developed and managed by the industry.

State Senator Josh Newman, who represents the 29th district including parts of Los Angeles, San Bernadino and Orange County, introduced the bill in February. “California has done some really good and groundbreaking programs using the EPR model,” he told Sourcing Journal, “and textiles seem like an obvious object of this kind of thing because they’re probably the fastest growing source of landfill in California.”

Newman acknowledged that because the industry is a “very variegated space” with a

By Kate Nishimura

wide range of products and producers, both in- and out-of-state and country, constructing a comprehensive program is no simple feat. CalRecycle, the state’s premier recycling agency, has taken the lead on the state’s previous programs, and is currently working to establish solutions for consumer plastics, from trash bags to food and beverage containers. But textile recycling is still largely the Wild West. Innovations are still in their infancy. And organizations working through ways to shred, melt down or chemically deconstruct old goods for use in new products have not yet managed to implement those solutions at scale.

“One of the reasons why there isn’t scale or efficiency within these recycling systems is that there aren’t incentives within the system to sort and segment and dispose of a particular type of textile one way or another— it’s so undifferentiated,” Newman added. One need only look to the intake facilities of the state’s thrifts, from Goodwill to Salvation Army, to comprehend the magnitude of the problem. Thousands of pounds of goods made from all kinds of fibers, from cotton to polyester, nylon, man-made cellulosics and most problematically, blends of all the above, enter the thrift system each day. A 2020 audit of a Goodwill in San Francisco revealed 44 fiber types and 275 unique blends were taken in during a two-day period.

“If you can create a system that makes sense end-to-end, where there’s somebody downstream that has the wherewithal and the economic incentives to sort different

RESPONSIBLE TEXTILE RECOVERY ACT OF 2023 IS A POTENTIALLY VAST UNDERTAKING THAT CURRENTLY LEAVES MORE QUESTIONS THAN ANSWERS.

13 13 2023 SUSTAINABILITY REPORT

types of textiles for recycling, the economics tend toward that happening,” the Senator believes. “That’s part of the premise of any EPR system in California—to create that market and then make it work efficiently.”

There are still a number of kinks to iron out before such solutions can be built, brought to scale and enacted, however. The bill’s text refers to textile and apparel “producers” as the responsible parties in the equation. “To the extent possible, everybody who’s involved the value chain should be invested in this,” he said.

Much of the product being consumed— and subsequently trashed—in California comes from overseas locales like China or Bangladesh. “These are these are such big systems,” Newman said of the global fashion industry and the corporations that comprise it, “and so the question is how to assign that value and cost, how to collect it, and then how to redistribute these funds so everybody in the system is incentivized to do their part.”

Parsing roles and responsibilities will be one of the California Product Stewardship Council’s goals as the legislation moves forward over the coming months. The

primary sponsor on the bill, CPSC has helped CalRecycle to execute on all 14 of its EPR programs.

The group’s special project manager, Joanne Brasch, said that brands will be responsible for paying into the EPR program if they are importing goods from overseas. But when it comes to goods made in-state, like in Downtown, L.A.’s Fashion District, cut-and-sew operators, and potentially fabric mills, will be subject to the law. While brands are the ultimate sellers of the products, they will only be forced to pay into a Producer Responsibility Organization (PRO) managing recycling efforts if their supply chain does not. “Typically, what we see in reality is they split the fee [with suppliers], and it’s a part of their contract,” she said.

Producers will pay a fee for each garment, or other item, manufactured and brought to market, but notably, “it’s not the role of the state” to designate that unit cost. Instead, the fee will be determined by the average amount it costs to recycle each product through the EPR solutions that are developed. “California style EPR is not prescriptive,” Brasch said. “It gives the industry the driver’s seat to plan a

2023 SUSTAINABILITY REPORT 14 14

▲ Thrift organizations like Goodwill and Salvation Army, among others, will serve as a primary donation point for consumers disposing of used textiles.

Juanmonino/Getty Images

program and a budget that meets all performance requirements.”

The EPR will fully fund the most costly elements of the recycling process, including transportation to sortation hubs, sorting for recycling, and transportation to repair operations and recyclers. Those businesses will be bolstered, but not fully, through a combination of state subsidies and research and infrastructure grants, allowing them to scale different solutions for the multitude of materials and products being funneled into the program, Brasch said. “We know when this program starts there isn’t going to be a solution for all the fabrics,” she added. The EPR program’s sortation functionality will remain malleable as recycling capabilities across the state continue to evolve and grow in scale.

“Our plan is not to create new collection infrastructure, because we already have it,” Brasch added. Thrift organizations like Goodwill and Salvation Army, among others, will serve as a primary donation point for consumers disposing of used textiles. They will conduct some of the initial sorting, placing unsalable goods in a recycling bin for collection. “The public messaging will be, ‘Take your unusables to these eligible

participating thrifts,” where they will be either re-sold, or recycled.

Goodwill has been a pioneer in the circular textile ecosystem for over a century, the non-profit’s Orange County CEO and chair of the Association of California Goodwills, Nicole Suydam, told Sourcing Journal. With 420 collection points across the state, the organization diverted 266 million pounds of goods from being shipped off to landfills last year alone.

The thrift’s “deep commitment to sustainability and our role in waste diversion” is evidenced in its already robust recycling operations for electronic waste, bedding, metals and cardboard, Suydam said. The products are first processed through Goodwill’s internal systems, “and then recycled to well-vetted vendors that share in our commitment to furthering the life of these goods,” she explained.

When it comes to creating an analogous system for textiles, “The greatest challenge will be creating a solid infrastructure to roll this out in a meaningful way across the state,” she believes. “Statewide, about 174 million pounds of textiles are collected by Goodwills every year—that is about 50

percent of all our donation collection.” While the resale of clothing and other textiles is a “very important part of our nonprofit social enterprise model,” funding the group’s philanthropic goals and providing jobs for community members, the executive said the new EPR program will create new, yet unknown opportunities for unsalable goods.

“With the implementation of this new EPR program, we are ready to be at the table to understand how Goodwill can be further utilized as collection sites, sorting and recycling systems and much more,” she said. Moving forward, the group will have to work with stakeholders, including the Senator’s office and CPSC, to determine “what tasks will need to be completed by clothing and textile producers, and what will be asked of us as secondhand collectors and stewards.”

At this point in time, those roles remain nebulous—and industry insiders are both curious about the tasks they will be asked to undertake, and apprehensive about the potential impacts to their businesses.

Mateo Neri, a partner at Los Angeles apparel producer UStrive Manufacturing who specializes in apparel recycling, said brands should bear the largest share of the burden in funding new solutions for apparel waste. “The manufacturer is just making what the brand is asking to produce,” he said. “If a brand is saying, ‘We need a million units,’ and half of that gets sold and the other half gets landfilled, that’s not a manufacturer’s responsibility.”

On the other hand, mandated textile recycling could create new revenue streams for California textile and apparel producers that are able to devise solutions for waste. UStrive’s Repurpose pilot program aims to facilitate textile recycling by auto-sorting using AI technology. “For companies like ours that are trying to do this, there has to be more funding, because creating and scaling a plan is very costly,” he said. Machinery alone can cost millions.

“You want the supply chain to be working together,” said Andrew Schulenberg, marketing lead for L.A. textile mill Laguna

16 16 2023 SUSTAINABILITY REPORT STORYPLUS/Getty Images

▼ 740,000 tons of apparel eventually end up in California landfills annually according to McKinsey research.

Fabrics and materials science company Circular Systems. L.A.’s Fashion District is home to dozens of businesses poised to take on the challenge of making new goods out of discarded duds, he believes. “You want people to have a vested interest in this and commit to the offtake of the [inputs] that are the result of the recycling.”

That’s where a mill like Laguna could play a role. “Once the recycling facilities are up and running, there’s a need for support from a fabric standpoint,” he said. The company could take on recycled yarns to use in its fabrics, which are purchased by a multitude of California manufacturers and brands. The group prioritizes sustainable fibers, which are in high demand, working with organic cotton, Tencel and hemp. It is also engaged with Texloop, a subsidiary of Circular Systems, which creates recycled cotton fiber made from shredded pre-consumer textile waste.

Not all discarded textiles will be fit for textile-to-textile recycling, Schulenberg acknowledged. “If [waste] can’t be used for textiles, it could go into shoddy, which is a short staple fiber that’s used for insulation and other industrial purposes,” he said. But whether it’s recycled or downcyled, Schulenberg believes there’s ample opportunity to create productive—and lucrative—new business as a result of the legislation. “No one’s really been looking at the value of this waste,” he said.

Isaac Nichelson, founder of Circular Systems, the creator of Texloop, said the sector is in the midst of “the creation of a circular industry and a new textile economy” that stands to impact “the whole value chain.”

“It looks like a really interesting future for the apparel system,” he said. “It’s a big opportunity” that will create jobs and new

facets of business surrounding sortation, recycling, yarn spinning and textile production. But today, “there’s not even proper infrastructure, or even optimized technology, for the sorting” of textiles, and that will be the program’s biggest hurdle, he believes. Regional support and private-sector funding will be a “critical factor” in developing scalable solutions. “We want to be a part of that and are just now gearing up to start to investigate what is available in terms of forthcoming additional support,” he said.

Even for an established materials sciences company that isn’t starting from scratch, developing the domestic capability

740,000

to recycle tons of used garments will take time and considerable resources. “It could take years of development to move beyond pilot capacity,” he explained. But a number of emerging technologies show promise when it comes to effectively recycling used cotton garments, along with cotton-poly blends, and “Those are going to be two of the larger waste streams.”

Nichelson echoed sentiments that textile recycling isn’t just an environmental necessity, but an opening for solutionoriented innovators. “I think upcycling should always be a goal with as much of any waste stream as possible and getting more value out of it just makes sense,” he said.

17 17

2023 SUSTAINABILITY REPORT

TOTAL TONS OF APPAREL THAT END UP IN CALIFORNIA LANDFILLS ANNUALLY.

Source: McKinsey research.

IT’S ONE INSANE MEMBRANE

OUR FIRST NON-PFAS, EXPEDITION-GRADE WATERPROOF + BREATHABLE FABRIC TECHNOLOGY ENGINEERED FROM A PLANT-BASED* MEMBRANE. CRAZY, RIGHT?

©2023 POLARTEC, LLC. POLARTEC® POWER SHIELD® IS A REGISTERED TRADEMARK OF MMI-IPCO, LLC.

‘Stage is Set’ for Fashion’s Collective Climate Action

NOW COMES THE BRIDGING OF THE GAP BETWEEN ASPIRATION AND EXECUTION, ACCORDING TO THE APPAREL IMPACT INSTITUTE.

For the Apparel Impact Institute (Aii), everything boils down to numbers.

Certainly, the multistakeholder organization, whose tentpole initiative, Clean by Design, has transitioned hundreds of mills in countries worldwide to greener, more efficient practices, cannot function without them. It’s data, after all, that underpins the Sustainable Apparel Coalition spinoff’s ability to identify, fund and scale projects that reduce the fashion industry’s prodigious impact. And it’s data that demonstrates whether its efforts are headed with sufficient speed in the right direction.

Aii’s most recent impact report summed up 2022 with some new figures. Over the past year, 380 facilities serving nearly 30 brands completed one of the San Francisco-based group’s programs, whether Clean by Design, its carbon tech benchmarking assessment or its carbon target setting. (Another 220 facilities were actively participating in at least one of these.) Together, graduates of its initiatives staved off 56,346 metric tons of greenhouse gas emissions, equivalent to taking 12,127 cars off the road. They also saved enough water to fill 714 Olympic-sized swimming pools and as much energy as would keep 3,504 washing machines chugging for a year.

Also expanding in 2022 was Aii’s reach, which increased from 19 regions worldwide to 28. Today, it covers a wide swath of the planet, including Bangladesh, mainland China, Guatemala, Egypt, India, Mexico, Pakistan, Sri Lanka, Taiwan, Turkey and Vietnam, all of

By Jasmin Malik Chua

which required localized tweaks to “activate” the organization’s solutions.

“We’ve always kind of known that it can’t be top-down; it almost has to be bringing the right resources to a region and letting them make them uniquely their own to solve for the problems,” said Aii president Lewis Perkins. “Because their problems are also slightly different.”

Overall, factories made more than $8 million in investments, reaping $4.8 million in savings in return. To put it another way, the average facility shelled out more than $501,000 to recoup nearly $300,000.

To be sure, decarbonization doesn’t come cheap, particularly at the outset. According to Aii’s research, it will cost the fashion industry $1 trillion to fully decarbonize its supply chain by 2030. In June, the organization announced the launch of the Fashion Climate Fund, a $250 million collaborative that is rallying funds from donors such as H&M Group, the H&M Foundation, Lululemon, PVH Corp., Target and The Schmidt Family Foundation to “unlock” $2 billion in blended capital to help the sector meet its goal of halving carbon emissions by 2030. As 2023 kicked into gear, Aii opened its inaugural call for submissions for the Climate Solutions Portfolio, which will dole out grants from the fund.

Things are only going to ramp up now that the “stage is set” for industry engagement and collective action, Perkins said. Now comes the bridging of the gap between aspiration and execution, something that watchdog groups, from Stand.earth to the

19 19 2023 SUSTAINABILITY REPORT

NewClimate Institute, say is stymying measurable progress. Aii and the World Resources Institute (WRI) estimate that the apparel industry generated 1 gigaton of CO₂ equivalent in 2019, or roughly 2 percent of that year’s global greenhouse gas emissions.

“The story of Aii, and the industry as a whole, is that 2022 was a big increase year in programmatic engagement, adoption and resourcing,” Perkins said. “From my perspective, the big story is there’s growth happening and actual climate action within Scope 3 of the supply chain.” It’s Scope 3, where a brand or retailer’s indirect operations reside, after all, where as much as 90 percent of a supply chain’s emissions are generated.

One point of pride is that the organization managed to expand its program coverage from two carbon-reduction interventions, as identified by Aii and WRI in their 2021 “Roadmap to Net Zero” report, to five, meaning that it’s tackling not only energy efficiency and energy but also maximizing material efficiency, scaling sustainable materials and practices, and eliminating coal in manufacturing.

Historically, Aii has homed in on lowhanging fruit to “whet the appetite” of users involved, said Kurt Kipka, its chief impact officer. Over time, however, it has seen manufacturers shift those efforts from an “almost purely cost-savings standpoint” to a “more strategic path,” which paved the way for other opportunities.

“The groundwork that we laid with a couple of interventions that we started with really did pay dividends for us as we look to expand that work, both with manufacturers and brands that we’ve worked with historically, but also new brands and manufacturers who are just getting started, [while] recognizing that everyone is coming at this challenge from a different perspective but can also benefit from aligned language consistent tools and resources,” he said.

But make no mistake, cost-effectiveness is still a key consideration for its initiatives, which ring up to $17 per metric ton of CO₂ equivalent reduced compared with an average of $67 per metric ton for alternative, external decarbonization strategies such as solar thermal and offshore wind.

“I don’t think that’s the only metric that you

2023 SUSTAINABILITY REPORT 20 20

▲ In 2022, 380 facilities serving nearly 30 brands completed one of the Apparel Impact Institute’s impact-reducing programs.

can look at when you’re thinking about a solution,” said Ryan Gaines, Aii’s chief financial officer. “But as we get into reviewing those other solutions that are out there, it’s an important benchmark to think about which ones are going to be the most cost-effective and at least to implement first. I think eventually you have to go deeper and deeper into the hard-to-reach and more expensive-to-reach carbon, but at least it helps us to start to prioritize with the limited funding that is available today.”

As 2023 barrels forward, Aii is in “build mode” around the financial unlock that it hopes the Fashion Climate Fund will accelerate.

“And so bringing more partners not just from the philanthropic or the brand engagement, but also the banks that we’re talking to and the other financial institutions that will participate in a lot of the loan models that we hoped to create,” Perkins said. “For us, it’s about building out that level of resource where we’re really starting to look at that sort of pre-seed pilot model scale approach that we’ve been pitching through our programs all along.”

For Kipka, this is the year Aii will be diversifying its projects and partners through the Climate Solutions Portfolio. So far, it has received more than 100 applications, which an advisory council

comprising experts such as environmental scientist Linda Greer, Textile Exchange Climate+ director Beth Jensen and Lululemon director of product sustainability and environment Crispin Wong is reviewing.

“I have a lot of hope, as I’m reaching the end of that review process that we’ve landed on a really strong subset of the

applications,” he said. “But there’s still so much room for growth, and if anything keeps me up at night, it’s that we might just miss something that might slip through the cracks. But those are the types of things that our advisory council is going to continue to dig into revisiting those criteria, making them more focused, and even framing our ask more succinctly based on key categories of filling that innovation gap.

From my perspective, the big story is there’s growth happening and actual climate action within Scope 3 of the supply chain.”

21 21 2023 SUSTAINABILITY REPORT

LEWIS PERKINS, Aii

Coalition Champions Circular Fashion As ‘Economic Empowerment’

RACHEL KIBBE, EXECUTIVE DIRECTOR OF THE AMERICAN CIRCULAR TEXTILES GROUP, EXPLAINS WHY FEDERAL POLICY IS CIRCULAR FASHION’S “BIGGEST GAP.”

Fashion in the United States is struggling to close the loop on itself. Strategic, bipartisan legislation that supports circular business models, according to a new report, can help.

Published last month, the white paper is the brainchild of Rachel Kibbe, founder and executive director of the American Circular Textiles Group, a.k.a. ACT, a coalition of reuse and recycling stakeholders that includes Arrive, Fashionphile, Recurate, Rent the Runway, The RealReal, Thrilling, SuperCircle and ThredUp. The goal of the platform, Kibbe said, is to provide a “glue” for a fragmented and competitive market so it can come together and discuss what it needs to scale its solutions. And one of the levers it’s settled on is public policy. If regulation can promote cleaner transportation, boost jobs and hone national competitiveness, she asks, why can’t it do the same to make clothing more sustainable?

“There is a long history of government action to curb pollutive industries,” said James Reinhart, CEO of ThredUp, the secondhand e-tailer that has inked partnerships with high rollers like Gap, Madewell and Kate Spade. “We have seen regulation and incentives for everything from plastic bags to electric vehicles. We also know that one company alone cannot solve all the world’s fashion problems, which are both humanitarian and environmental.”

Kibbe said that the only parts of circular

By Jasmin Malik Chua

fashion that can be deemed scaled or scalable are the ones that have existed for “hundreds of years,” meaning resale, repair and rental. These are well and good and should be encouraged, since, she said, it’s beautiful that “clothes can be reused.” End-of-life scenarios for a ratty pair of sneakers or a hole-riddled sweater, however, are more “nuanced,” she said. Garments can’t be recycled the way a yogurt container can, meaning that what you put in is what you get out. Right now, the types of fiber-to-fiber technologies that are bubbling up aren’t being underpinned by the types of policies that can spur their wider adoption. Fixing that will also help reuse, repair and rental in a “rising tides lifts all boats” kind of way, she said.

State and federal governments, according to ACT, which recently welcomed Debrand, H&M Group and Reformation into its fold, could dole out grants or subsidies, provide consumer and business tax incentives, create extended personal responsibility schemes— much like the one California is currently mulling—and increase oversight over waste polluters. There’s infrastructure to be shored up, consumers to be educated and startup costs to defray. The right type of policies will “kill a lot of birds with one stone,” said Kibbe, who is also the founder and CEO of the Circular Services Group, a sustainability consultancy based in New York City.

23 23 2023 SUSTAINABILITY REPORT

“I think policy is the biggest gap because there’s no framework laying out a way to make this economically viable to be able to compete with linear fashion,” she said. Encouraging brands, particularly those firmly entrenched in their ways, isn’t easy without supportive policies, she said. Kibbe isn’t so much advocating for “finger-pointing” scrutiny as she is for a “level playing field” where everyone is expected to participate and contribute. Reusing, reselling, renting and recycling clothing should be as easy as dropping an empty Coke can into a blue bin, she added.

“Fashion is complex, textile recovery is complex, and policy-making is complex,” said Amelia Eleiter, CEO and co-founder at Debrand, which specializes in reverse logistics and textile recycling. “ACT is led by passionate and experienced changemakers who are dedicated to developing the most effective and meaningful policy that will enable scalable systems change for textile recovery and end-of-life solutions.”

Kibbe sees ACT’s job as akin to turning an ocean liner around; it requires all hands on deck, whether brands, manufacturers, innovators, philanthropists, lawmakers or consumers.

“We want to engage with the whole industry and outside stakeholders—it’s not just fashion,” she said. “We have a seat at the table with transportation and energy because fashion takes transportation and it takes energy.”

Besides reducing virgin resource extraction and nipping waste in the bud, a circular economy that prioritizes the waste hierarchy also brings with it benefits such as job creation, supply chain protection and better product value and sustainability. The Ellen MacArthur Foundation estimates that circular fashion represents a $560 billion economic opportunity. If America “acts swiftly,” Kibbe said, public policy can usher in a “new era of productivity” for an array of skills, including clean chemistry and energy, technology, resale, logistics, sorting, repair, recycling and textile manufacturing while

keeping domestic resources in circulation and whittling clothing’s environmental impact. Similar efforts in the European Union can serve as an inspiration, she added.

“This is a huge problem—and it’s a huge opportunity,” Kibbe said. “And I think that the

biggest thing I want anyone who reads or skims the paper to take away is that we all want there to be more economic empowerment in this country. We all want customers to have more value. We all want there to be more jobs, and we all want to live on a planet that can sustain itself.”

24 24

▲ Reusing, reselling, renting and recycling clothing should be as easy as dropping an empty Coke can into a blue bin, says the American Circular Textiles Group.

2023 SUSTAINABILITY REPORT

Fashion is complex, textile recovery is complex, and policymaking is complex.”

AMELIA ELEITER, Debrand

Sustainable style, your way

Sustainable

belong to everyone.

Naia™ cellulosic fibers create possibilities for uncompromising, sustainable style. Learn more at naia.eastman.com eastman_naia eastman-naia © 2023 Eastman Chemical Company. Eastman brands referenced herein are trademarks of Eastman or one of its subsidiaries or are being used under license. TEX-WW-17168 5/23

textiles

Addressing the ‘S’ in ESG

THE FASHION IMPACT FUND’S KERRY BANNIGAN SAYS THE INDUSTRY IS FALLING BEHIND. By

Kate Nishimura

When it comes to ESG goals, too many fashion firms seem to believe the “S”—which stands for social—is silent.

That’s according to Kerry Bannigan, executive director of the Fashion Impact Fund, which supports women-led businesses and promotes equity and economic inclusion within the industry. The group’s partnership with the United Nations, dubbed the UN Conscious Fashion and Lifestyle Network, was formed in 2021 “to provide an impartial platform for the industry and the UN system, and to bridge the work of the sector’s changemakers to global leaders and governments,” she said. Today, the Network has brought together 199 members from 64 countries on a centralized online platform.

Guided by the UN’s Sustainable Development Goals (SDGs), the group’s key objective is to mobilize the industry’s collective expertise, innovative spirit and advanced technologies to drive sustainability and social change.

While brands have made progress since the 17 SDGs were officially established in 2015, “Balancing competing priorities” remains a “significant challenge for companies,” Bannigan said. Between juggling the pressures of pushing profitability with achieving environmental and human impact, certain key objectives are lagging behind.

“Some people believe that sustainability is only about environmental issues,” Bannigan said, but being truly sustainable involves taking a wholistic view of all business impacts, including “social and economic issues, such as fair labor practices and supply chain transparency.” The fashion industry was built on an “extremely

exploitive platform” that operates worlds away from the Park Avenue or Paris-based home offices of decision-markers. That extreme disconnect has inhibited both understanding and progress, she believes.

“When we look at people and planet, I feel like people is where it falls behind in most sustainability plans,” she said, “And the reality is, you can’t divide the two. We need social justice. We need fair labor practices. And this is a crucial thing that needs to happen.”

Brands have undoubtedly moved beyond “embracing ignorance” regarding their supply

what was happening,” Bannigan explained. Brands are facing questions from employees, from the models showcasing the clothes to “the person doing comms, social media marketing and branding,” she added. “They’re questioning, ‘Who are we? What are we doing?’—it’s a more comprehensive approach that cannot be ignored.”

This year marks a midpoint for the SDGs, which were adopted by UN member states in 2015. The call to action was to achieve all of the goals, which include eliminating poverty and hunger and reducing inequalities, promoting health and wellbeing, education, gender equality, clean water and sanitation, affordable clean energy, decent work and economic growth, by 2030. They also call for investments in innovation and infrastructure, sustainable cities and communities, responsible production and consumption, climate action, and partnerships.

chains, but there’s more work to be done. Just a few short years ago, it was not uncommon to find a global fashion firm embroiled in a worker rights crisis claiming it did not know about the conditions on the ground because of practices like subcontracting. The fashion supply chain is notoriously opaque, but organizations have been feeling the pressure—not just from consumers, but from their own employees—to shape up and become more transparent.

“There are more people rising up internally in this sector, whereas before that was not

“Whilst the United Nations Conscious Fashion and Lifestyle Network is seeing an increase in member commitments to achieve change, there is a critical need globally across all sectors to advance sustainable practices, supporting regulations and financial distribution to the solutions,” Bannigan said. Thus far, organizations haven’t come far enough.

In this critical moment in the global effort to achieve the 2030 Agenda for Sustainable Development, just 12 of the SDG targets are on track. What’s more, “we have stalled or gone into reverse on more than 30 percent of the SDGs.” The UN’s latest report also highlighted a financing gap of about $4.2 trillion—a deficit that highlights a key challenge for stakeholders across the globe. “Implementing sustainability initiatives can

26 26 2023 SUSTAINABILITY REPORT

When we look at people and planet, I feel like people is where it falls behind in most sustainability plans.”

KERRY BANNIGAN, Fashion Impact Fund

require significant investments in time and resources.” Those commitments are an even higher hurdle to jump for smaller companies with less financial wiggle-room.

Because companies can only focus their efforts on so many objectives at once, an imbalance in priorities has emerged in recent years. “I see the fashion industry aligning more so with a subset” of the SDGs, Bannigan added, including responsible consumption and production, climate action and partnerships. Many groups have honed in on developing portfolios of sustainable materials and are gravitating to business models that address waste, from resale to on-demand production. But “what the industry is lacking extreme progress on…. is gender equality,” she said, first and foremost, along with promoting safe working environments and opportunities for economic growth.

“These commitments were made at a time when people were inspired to drive action”—whether that purpose came from the will of consumers or pressure from the industry at large. But today, many organizations are struggling to advance because they did not engage in enough feasibility reporting in the early days. “There

was not enough due diligence to see what the reality was, and what it would take to make [their goals] happen,” Bannigan said. “Big companies have made bold statements and ambitious commitments, because the world needs it and people and planet are in dire and critical conditions,” she added. But the clock is ticking, and the industry isn’t meeting its benchmarks.

The process of assessing and reporting progress remains fraught with difficulty—an imperfect science. “Measuring progress can be complex and requires accurate data collection and analysis,” the executive director said, and that can require specialized expertise. Fashion brands have complex, multitiered supply chains comprised of multiple suppliers and distributors, sometimes spread across regions and time zones. Companies have invested in audits and certifications, along with traceability technology, to help gauge the impact of their efforts to create a more sustainable supply chain, but these technologies and programs can be cost-prohibitive to access. “In some cases, a lack of regulatory frameworks or incentives can make it harder for companies to prioritize sustainability initiatives,” she

added. “This can make it difficult for companies to justify the investment required to achieve sustainable outcomes.”

That’s where the UN Conscious Fashion and Lifestyle Network hopes to provide a sense of direction and community. “Given the significant impact of the fashion and lifestyle sectors on society and the environment, the Network is dedicated to fostering transparent, inclusive, and transformative engagement of global stakeholders to drive urgent action for sustainability,” Bannigan said. “The network works towards this goal by sharing knowledge and best practices, supporting research and development, facilitating collaborations among stakeholders and hosting convenings during high-level United Nations conferences.”

The UN is a critical player in global sustainability efforts, and its active participation in discussions related to sustainability and the SDGs is essential, she believes. With 193 member countries, its reach and influence are as significant as any global organization, facilitating cooperation and collaboration across different sectors and countries. “The UN provides a platform for multilateral cooperation and dialogue on sustainability issues, allowing for the exchange of ideas,” Bannigan said.

Moreover, the organization is uniquely positioned to assist not only in the development, but the implementation of global policies related to sustainability. “The organization can provide guidance and support to governments, businesses, and other stakeholders in implementing sustainable practices and policies,” from technical assistance to capacity building. “The UN’s active participation in discussions related to sustainability and the SDGs is crucial for achieving a more sustainable and equitable future for all,” Bannigan said. “Its efforts can ultimately lead to a more sustainable world where all individuals have equal access to opportunities and resources.”

27 27 2023 SUSTAINABILITY REPORT

▼ Kerry Bannigan

Higg MSI Controversy Cited in Sustainability Labeling Trends

APPAREL BRANDS MAY BE SHIFTING THEIR ECO EFFORTS AND GROWING MORE SENSITIVE TO GREENWASHING ACCUSATIONS, CENTRIC PRICING DATA SUGGESTS.

By Chelsea Dobrosielski

Flagging growth in sustainable labeling indicates apparel brands might be shifting their environmental efforts and growing more sensitive to greenwashing accusations, recent Centric Pricing data suggests.

Each of the three countries in the market intelligence platform’s survey—the U.K., U.S. and Germany—saw product counts of generically labeled sustainable goods increase from January 2022 to January of this year. This growth, however, came in slower than in previous years, Centric Pricing, formerly known as StyleSage, reported, with counts peaking in October and since declining. The U.S. saw the largest year-over-year increase, 15 percent, while Germany experienced the smallest, 6 percent.

Product counts of certified sustainable products plummeted, meanwhile. In the U.S., these numbers peaked in April, but ultimately fell 34 percent year over year in 2022. In the U.K. and Germany, counts fell consistently throughout the year, falling 48 percent and 54 percent, respectively, by January 1.

Centric Pricing attributed the drops “in part” to last year’s Higg Materials Sustainability Index controversy. Though counts of certified sustainable products were already on the decline in the first half of the year, this downward trend accelerated in the second half, after the Sustainable

Apparel Coalition removed the published Higg Index seal and scorecard from participating online retail platforms. The move came weeks after the Norwegian Consumer Authority warned H&M Group and outerwear brand Norrøna that using Higg MSI data in sustainability claims would

be considered “misleading” and a breach of greenwashing laws.

The next month, H&M found itself at the center of a class-action lawsuit in the U.S. over what the plaintiffs called “false and misleading” environmental scorecards and advertising. Across the pond, Britain’s Competition and Markets Authority revealed that it was investigating Asos, Boohoo and

29 29 2023 SUSTAINABILITY REPORT

Even as regulatory pressures increase, it raises questions as to whether brands may be deprioritizing some of the tougher sustainability challenges as other financial pressures are faced.”

CENTRIC PRICING SURVEY

George at Asda over concerns their sustainability claims misled consumers. Months later, H&M stripped its “Conscious Choice” indicator from its online store worldwide. Zalando followed suit soon after.

On the consumer side, demand for sustainable goods grew in 2022, with sold-out rates rising 23 percent for certified sustainable products, Centric Pricing found. These rates grew just 12 percent for generically labeled sustainable products and 9 percent for everything else.

“Even as regulatory pressures increase, it raises questions as to whether brands may be deprioritizing some of the tougher sustainability challenges as other financial pressures are faced,” Centric Pricing wrote in the report’s conclusion.

The analytics platform also observed a

shift in the type of categories in which recycled materials were most used. Across the U.S., U.K. and Germany, shirts and outerwear led the way, outstripping sweaters and sweatshirts, the report’s previous leader.

As inflation drove up prices around the globe last year, certified sustainable products grew substantially more expensive for the consumer. In Germany, the average original price of certified sustainable products jumped 31 percent year over year, significantly faster than the 19 percent increase generic sustainable products experienced and above the 17 percent bump of all other products. In the U.S. and U.K., inflation proved much more dramatic, with prices of certified sustainable products up 75 percent and 116 percent year over year, respectively.

2023 SUSTAINABILITY REPORT 30 30

▲ An H&M store in London.

Mike Kemp/In Pictures via Getty Images

September 19-21, 2023

IT STARTS HERE >>

You’re invited to discover the latest in manufacturing, textiles, trims, suppliers, and services at SOURCING at MAGIC New York. Flexibility and agility are key to success in today’s fast-paced fashion and we’re bringing together the best to help you stay ahead of the curve. You’ll find manufacturers who specialize in on-demand production, low minimum order quantities, and quick turnaround times.

We’re committed to bringing awareness and finding solutions to the most pressing supply chain and buying challenges facing the industry. That’s why we’re bringing together a team of experts for panel sessions and educational programming that will inspire, educate, and empower you to take your business to the next level.

REGISTER NOW >>

Embattled Higg Co Gets a New Name

THE TECHNOLOGY PLATFORM THAT HOSTS THE POPULAR HIGG INDEX SUITE IS REBRANDING. By

Jasmin Malik Chua

Higg Co is no more.

The technology platform that hosts the popular Higg Index suite of social and environmental measurement tools is rebranding to Worldly, a move that it said it made, in part, to cut the confusion over who the organization is and what it does.

The Higg Index, which is owned by the Sustainable Apparel Coalition (SAC), the trade group from which Higg Co spun off in 2019, will retain its name. The SAC will also retain a shareholder stake in the new company.

Riffing off a reporter’s analogy, Jason Kibbey, Worldly’s CEO, compared the SAC to a movie studio and Worldly to Netflix. Worldly will continue to “broadcast” the SAC’s “films,” i.e. the Higg Index, to which it holds an exclusive license, but it might also do the same for a different “studio.” And, should it spy a gap in the market, it will create “films” of its own.

The latter point, fueled by heated conversations over the past year about the Higg Materials Sustainability Index’s ability to accurately capture a material’s footprint, is another reason for the identity change, Kibbey said. Higg Co, he said, realized it needed to be more of an intelligence hub, one with the flexibility to evolve in line with changing market and regulatory demands.

“Like where is the world going in terms of data and claims and making [them] actionable?” he asked. “And I think what we recognized is that we actually needed to be building some new tools that would allow a lot of the parts of the value chain that have just not been touched yet.”

These include what Kibbey described as the “huge percentage” of Tier 2 production, which includes yarn spinning and fabric milling, that’s never been measured in terms of carbon, water and even social impact. That’s data that needs to be freed, he said.

“We started hearing requests from our customers and hearing from some of the factories that they wanted something really light and easy that could get carbon and water data quickly,” he said. “And so we

knew that we actually needed to launch this as a new product and launch other new products to meet the challenges of due diligence as well as other things that are going to be outside of the Higg index [but] still very complementary.”

Worldly’s “All Quiet on the Western Front,” to continue the Netflix analogy, is the Factory Data Solution, which it says is an “industryfirst” effort to capture and share real-time

32 32 2023 SUSTAINABILITY REPORT

If we can really show where investment and changes are making a difference, we hope that that unlocks more capital to create more change...”

JASON KIBBEY, Worldly

utility bill data from factories across the supply chain. It has tapped inspection and certification giant SGS to help it determine the accuracy of the data at scale, though it may recruit others as the scheme grows.

As Higg Co, Worldly had been collecting utility bill data for many years, only “in summary,” Kibbey said. Factories, he added, were telling the organization that they wanted a simple way to validate and share that data that takes a few minutes a month rather than a “large annual reporting process.” Brands were also looking for ways to understand their supply chain—what’s getting better, what’s getting worse and where they can target investments to drive the biggest improvements, he said.

“One of the things is that the reporting burden on the factories is pretty heavy and often really complicated,” Kibbey said. “And we just wanted to make this as absolutely simple as possible so that they can be demonstrating their impact really quickly without hundreds of hours of work. We just want them to be able to do it in a few minutes.”

Kibbey said he expects several thousand factories to get on board with the tool over the next year. In time, however, he hopes it will become “ubiquitous” and “reach a lot of the corners of the fashion industry that just haven’t been touched.”

“[A question like] how many factories are there is even hard to [answer],” he said. “A lot of that is because there are a lot of these smaller upstream suppliers that are doing the knitting or the spinning for the thread or they’re doing the dyeing or the finishing that are kind of off-grid. And they can often be invisible in the value chain and that is who we really want to target with this.”

To be sure, the Factory Data Solution isn’t a means to an end in itself, Kibbey said. What Wordly hopes for is that it spurs more and faster investment.

“If we can really show where essentially investment and where changes are making a difference, we really hope that that unlocks more capital to create more change because

the need for vast decarbonization across the value chain is really critical,” he said.

The “pressure for change” from stakeholders, customers and even internally from within a company has “never been stronger,” Kibbey said.

“What we really need now is help in figuring out how do you accelerate that change,” he said. “Where do you make investments? How do you actually know that when you’re you’re putting money and time into changing your value chain, that it’s moving the needle?”

So why “Worldly”?

“One of the reasons for the relaunch is I think we’re walking into a world where regulations such as mandatory human rights and environmental due diligence value chains [are] going to become a norm, and so brands who may have just been thinking that sustainability is nice to have, are now going to integrate this with into their business practices,” Kibbey said. “They need essentially systems and platforms that allow them to do that.”

It’s “no secret” that brands are coming up short on their carbon ambitions, he said.

“Ultimately we want to support the whole fashion sector and other consumer goods sectors in actually catching up with the science-based targets that they’re falling behind on because we need to see acceleration right now,” Kibbey said. “I want to continue to be an optimist.”

33 33 2023 SUSTAINABILITY REPORT

▲ The Higg Co is now Worldly.

At Cone Denim, we’re committed to 25% water savings by 2025. Our Zero Liquid Discharge wastewater treatment system in Parras, Mexico plays a key role in our water conservation efforts by recycling 90% of the wastewater used in denim manufacturing. The recovered water is treated and recycled back into the manufacturing process, saving up to 100 million gallons of water per year. Visit conedenim.com/new-wave/ for more information

Ellen MacArthur Foundation Rolls Out Circular Startup Database

THE LIST INCLUDES COMPANIES FROM NEIMAN MARCUS AND CHLOÉ TO THREDUP, VESTIAIRE COLLECTIVE AND YKK.

By Claire Wilson

The Ellen MacArthur Foundation has rolled out the list of textiles and fashion companies on its Circular Startup Index, that puts together Neiman Marcus, Tapestry and Chloé with seamstresses, tailors and resale platforms like Vestiaire Collective.

New names bring the number to 500 and represent the full version of the foundation’s current searchable circular startup database, designed to give businesses leads to pursue in their own transition to a circular economy. Those 500 companies come from a range of sectors, industries and centers around the globe, and is said to be the most comprehensive listing of the world’s existing circular business players.

Textile startups on the database include Sojo, a London-based app that hooks people up with seamstresses and tailors to alter pre-worn or vintage garments, By Rotation, a wardrobe lending platform, and Recurate, a resale-as-a-service platform that struck deals for secondhand sales with 7 For All Mankind, Michael Kors and Mara Hoffman. Resale platforms alone continue to grow in leaps and bounds, and will be worth an estimated $42 billion globally by 2027, according to the 2022 report by thredUp resale platform. The report also said the whole global second hand market would hit $350 billion that year.

ThredUP, Neiman Marcus, Vestiaire Collective, Chloé, and YKK, the Japanese

maker of fasteners, were added to the circular list last year. Most companies in the database were already part of the foundation’s community and were selected for incorporating one or more of the

principles of the circular economy into their business models. They include eliminating waste and pollution, circulate products and materials, and regenerate nature.

The index is designed to pair innovation with capital, which is the biggest hurdle for startups aiming to scale circular businesses.

James Repenning, CEO of Denver-based Again & Again which is about to launch a

35 35 2023 SUSTAINABILITY REPORT

We have already started working with one of the businesses we found on the Index and are inspired by the ongoing opportunity to engage some of the most forward-thinking businesses in the circularity space.”

HUGH MCCANN, D.S. Smith

men’s clothing line, has been part of the foundation since 2021. He signed onto a webinar where, he said, he found businessrelated things he never knew existed despite a career spent in recycling. “We found a very major textiles supplier that had a circularity idea with no one to pilot it,” he said, but wouldn’t give the supplier’s name. “The apparel is going into our first new shop that opens in July.”

That location in Denver will be a barbershop staffed by ex-convicts who will wear the clothing line as they work. The clothes will be made from organic fabric at the outset and sold in the store-cumbarbershop, which will also have a recycling repository. Called R&R Head Labs, two more units will open later this year in Boston and

Chicago. Repenning is also CEO of the barbershop startup.

D.S. Smith, a UK-based multinational packaging business, also found a partner on the database, according to Hugh McCann, senior circular growth manager for the company.

“We have already started working with one of the businesses we found on the Index and are inspired by the ongoing opportunity to engage some of the most forward-thinking businesses in the circularity space,” he said.

Thousands of business owners are already innovating for a future without waste and where products and materials are reused. Foundation executives hope more circular startups will become part of the Index and find their ideal collaborators.

2023 SUSTAINABILITY REPORT 36 36

▲ ThredUP is one of the companies to be named to the Ellen MacArthur Foundation’s Circular Startup Index database.

Survey Says: Shoppers Will Shell Out for More Sustainable Stuff

DATA FROM THE SHOPPING REWARDS APP SHOPKICK SHOWS CONSUMERS’ AWARENESS AND AFFINITY FOR ECO-FRIENDLY PRODUCTS IS GROWING.

By Kate Nishimura

Consumer awareness surrounding sustainability has been on an upward trajectory for some time, and data shows that the appetite for eco-friendly products persists even in an inflationary economic environment.

Shopping rewards app Shopkick, which surveyed more than10,000 individuals across the U.S. from March 24 through March 30, found that 63 percent consider a product’s sustainability profile as much as its affordability when making a purchase.

The majority of American shoppers have been privy to conversations surrounding climate change, and have been inundated with messaging from brands, media outlets and environmental groups about the importance of conscious consumption. Seventy-two percent said they are familiar with the sustainable product alternatives available at retail, and more than half (55 percent) said they consider a brand’s sustainability practices when they make a purchase. Most consumers (86 percent) said they want companies to offer more environmentally-friendly options across their product lines.

Consumers have become willing to vote with their wallets for brands that align with their values, and sustainability has become a sales-driver, rather than a perk, in recent seasons. Nearly two-fifths of Shopkick respondents said they were willing to pay

more for sustainable products, and of that contingent, 70 percent said they would pay up to $5 more than unsustainable market alternatives.

What’s more, a lack of focus on environmental impact could come back to bite brands in the long run. Only about half of those surveyed said they would still buy from a brand that wasn’t committed to sustainability, and 23 percent said they’d

SHARE OF RESPONDENTS THAT SAID THEY WOULD HOLD OFF ON A PURCHASE UNTIL THE SELLER PRODUCES A GREENER ALTERNATIVE.

hold off on purchasing until the label produces a greener alternative. Nearly one-fifth said they would abandon a brand that didn’t share their environmental outlook and switch to one that aligns more closely.

The shift could be taking place quicker than many companies anticipated. Two out of every five shoppers surveyed said they

38 38 2023 SUSTAINABILITY REPORT

23%

purchase more sustainable products now than they did just one year ago. They also said they plan to ramp up conscious consumption over the course of the next 12 months.

While those attitudes persist across retail channels, from e-commerce to malls and big box stores, a sizable majority (78 percent) of those surveyed said groceries were the “most important” product category to consider when it comes to sustainable consumption. Over half of the respondents said they’re attempting to offset their single-use plastic intake by purchasing durable, recyclable solutions like steel straws and glass Tupperware, along with products with less wasteful packaging.

Across the e-commerce sector, brands are turning to recyclable and biodegradable packaging options, from compostable poly-bags made from biopolymers to fully recyclable mailers.

Shoppers are also keen to support brands that they believe are responsible producers, with three-fifths citing a desire to reduce production waste through their purchasing decisions. Globally, shoppers are displaying a greater affinity for semi-personalized, made-to-order products that eliminate overproduction. Apparel brands are increasingly looking to on-demand strategies to cut down on waste, manufacturing only what they’ve already sold.

2023 SUSTAINABILITY REPORT 39 39

▲ A new survey from Shopkick reveals that consumers are invested in shopping sustainably.

Textile Recyclers and Clothing Resellers Weigh In On Fashion’s Circular Future

SECONDHAND CLOTHING AND RECYCLED TEXTILES WILL BE A $9 BILLION SECTOR BY 2027, AND RECORD SMART CONFERENCE TURNOUT SIGNALS STRONG INTEREST.

By Matt Hickman

When most people think about recycled clothing, they think of charity, Goodwill, Salvation Army, secondhand donations—dot-org, not dot-com.

But the fact is, recycling clothes and textiles is already a big business and one that’s only going to grow bigger for years to come.

According to a study by Markets and Markets, the textile recycling market was valued in 2022 at $6.9 billion and expected to reach $9.4 billion by 2027, and by 2050 apparel will account for a quarter of the world’s carbon production, potentially raising demand for recycling.

It’s a trend Adam Baruchowitz saw coming back in 2004 when he started Wearable Collections, by putting bins inside of New York-area apartment buildings that he’d pick up and sell as secondhand or as recyclable textiles. A decade later, he was setting up a collection table shop at farmers markets and by the eve of Covid, he was collecting and re-selling 2.5 million pounds of material each year and hosting 31 greenmarket events each week.

The value proposition Baruchowitz identified early on came from the sorting end of the chain.

“You’re getting paid for 50 percent of the stuff [secondhand clothing], which the sorters will make money from. The other 50 percent from the rags and stuff, they lose money on, so I’ve been more obsessed with

this 50 percent [of textiles], thinking that when you change the economic value proposition of that 50 percent, now you’re changing the incentive base to collect,” he told Sourcing Journal. “And when you change the incentive base to collect, you’re

likely going to divert more from landfills and there’s going to be more reason for more people to get into the game.”

But finding that quality second-run clothing gets harder and harder as the gospel of sustainability spreads and more and more consumers sell their best used items through online channels like Poshmark.

Out in western New York, St. Pauly Textiles has been profitable in the recycled

41 41 2023 SUSTAINABILITY REPORT

When you change the incentive base to collect, you’re likely going to divert more from landfills and there’s going to be more reason for more people to get into the game.”

ADAM BARUCHOWITZ, Wearable Collections

clothing business, but second-generation owner Joe Howlett has never seen it as busy as it is now.

“A lot of that comes down to people being more cognizant of their finances and wanting to get something at a much more reasonable price, but in addition to that, people are becoming more conscientious of the environment,” Howlett told Sourcing Journal. “Educating the general public that we don’t want this stuff going into the landfill is just a matter of getting that mindset.”

St. Pauly Textiles in Farmington, N.Y. was started by Howlett’s father in 1996 and has little trouble filling up its donation sheds.

“Basically, what we do is set up relationships with different non-profit groups collecting clothing, usually using it as a fund-raiser,” Howlett said. “We’re purchasing the product that comes in and we’re able to sell it.”

Whereas Baruchowitz seeks out quality secondhand clothing to maximize his profit on the recycled rest, Howlett puts his focus on resale first and recycled textiles a distant second. Howlett believes that as momentum for recycling mounts it will eventually run afoul of the fashion industry, which relies on consumers regularly buying new products to maintain profits.

“Our biggest focus is trying to get the highest quality clothing to go around the world; that’s one of the biggest pushes we need to have across the board,” he said. “I know it’s not a popular thing for people who manufacture clothing to make it at a higher quality—which essentially means it’s lasting longer, which means people aren’t buying new. But for sustainability in the future, we have to have higher quality clothing in the second market. Fast fashion is a detriment.”

Earlier this year in Dubai, Howlett was one of a record 204 attendees for the annual convention for SMART, the trade organization representing recycling in the clothing and textiles industries since 1932.

“What the companies have always done in the industry is to look for a way to make some money for their waste, or at least get rid of the cost of waste,” Steve Rees, SMART president and founder of his own textile

recycling company Wipeco, told Sourcing Journal. “More and more municipalities and more and more governments are trying to figure out landfill issues and textiles are one of the last behemoth things… It’s at a point where it’s gone from companies to a real focus on communities.”

Wipeco Industries is an industrial supply company which produces wiping rags from a mix of secondhand clothing, reclaimed linens from hospitals and hotels and other businesses, as well as unused partial rolls of fabric. He said pushes for labeling on clothing that will allow a garment to be tracked through a QR code would be especially helpful for recyclers needing to separate certain fabrics before they can be mashed into a pulp and repurposed.

“Right now we can break down 95 to 100 percent cotton goods, only some polyesters and for any blended materials—unless it’s being chopped into fiber, it doesn’t work,” Rees said. “So any info on a garment that can be scanned quickly can definitely help stream textiles into higher value.”

Ninety companies and 14 nations were represented at SMART, including India and Pakistan, where Rees said a majority of the

42 42

▲ Recycling Banks for clothes and shoes.

2023 SUSTAINABILITY REPORT

Future to Nature

• One of a Kind Eco-Conscious Innovation

• >99% Biodegradable*

• Effective for Synthetic Fibers

• No Textile Waste Any More

• No Limit for Elasticity Level

• After Biodegration, There is No Toxicity Problem for Planting in the Soil**

* Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under High-Solids Anaerobic-Digestion Conditions (ASTM D5511-18)

** Testing Under the Standard OECD 208

recycling workforce exists now. This makes Dubai a strategic site for a conference because of its geographic location and its relatively easy visa protocols.

“A lot of our conversation right now is based on closing the loop,” Rees said. “The talk was about how, as an industry, we need to have a seat at the table.” Governments and municipalities have to “get the message out” that people shouldn’t just throw their clothes and textiles in the garbage, Rees said.

Howlett, a regular at these conferences, said there was a “buzz” in Dubai he hadn’t felt before.

“I think there was an energy that’s difficult to quantify,” he said, adding, “The buzz was, ‘hey, we all need to work together and get better.’”

Howlett said the push to make recycling the norm will take a combination effort from for-profit and non-profit organizations alike.

“The need is so strong that everyone wants to be part of it,” he said. “I’ve always been taught that you don’t have to be a nonprofit to do the right thing.”

The collection bins inside of buildings that Baruchowitz helped pioneer nearly 20 years ago, is being taken to the next level of technology by Dallas-based CheckSammy, which earlier this month presented its novel approach to recycling of not just clothing but electronics and plastic devices too at the Aspen Ideas Summit.

Operating since 2018, CheckSammy has programmed its bins from coast to coast to signal when they are more than 75 percent full. That triggers a fleet of more than 5,000 gig economy drivers to come get the haul and deliver it to hubs, called “sustainability centers,” where advanced technology is used to separate and bundle and bale each product type, providing statistics of how much of each type was present in each load.

“We’re aggregating on mass specific commodities and it’s in one door and out the other,” CheckSammy co-founder and CEO Sam Scoten told Sourcing Journal. “We’re basically collecting the product, putting them into bailing machines where

we get 1,000-pound bricks, then they’re on a 53-foot [truck], like a Jenga, and they’re on to the next destination.”

Scoten said the process of hiring thousands of drivers is not so different from a ride-sharing service.

“Our typical hauler will have a 20-foot box truck, but it could also be a 53-foot rig, or a semi,” Scoten said. “The onboarding process makes sure that they’re fully insured, fully compliant and they’re permitted in the jurisdiction that they’re working.”

Scoten said placing bins inside of residential settings proves to be the best for getting the coveted secondhand clothes of quality.

“You have to control the source and the source is typically going to be from the individual’s closet, i.e., their residence,” Scoten said. “The benefit of a multifamily structure is you could have 100 residents or 500 to 600 and you have to have a mechanism to come back to collect, and that’s been the beauty of the bin-and-bag process is that process starts by educating not only the property management, but by educating the suppliers of the textiles, which would be the residents.”

When the QR coded bins and bags

44 44

▲ Wearable Collections table at a greenmarket event in New York City.

2023 SUSTAINABILITY REPORT

Courtesy of Wearable Collections

are brought to the center, they are weighed immediately.

“We actually narrow it right down to exactly what is inside the bag,” Scoten said. “Is it men’s wear? Women’s wear? What’s the seasonality? Are there children’s products in there? We can get very granular on the data and then we hand those items off to either institutional buyers or charitable entities.”

Scoten said today CheckSammy is the largest sustainability operator in North America, a superlative they claim thanks to vertical integration.

“We’re a for-profit entity…We’re about maximizing shareholder returns, but we’re also about doing the right thing,” Scoten said. “We found the system was broken where you have one company doing the operations, another is doing the data collection, a third is going to do the de-branding and so on. But we’re a one-stop shop… We can come to our clients and say when we collect, we will show you the data right down to the poundage, what it is we’re taking off the property, the cadence, and customize that process over a period of time by cutting costs and then coming back to them with their sustainability [figures].”

That process has allowed CheckSammy to remain profitable every year it’s been in operation, even through the pandemic.

“It’s a very powerful marketplace that we built and it is a profitable way of approaching [recycling] but at the same time mitigating the waste to landfill and nobody has done what