Dynorbital®

– Most consistent speed under load in the industry.

– 12 models available in non-vacuum and vacuum styles.

Dynorbital®

– For high-production work environments.

– 27 models available in non-vacuum and vacuum styles.

– 3/8", 3/16" and 3/32" dia. orbits.

Dynorbital-

– Lightweight – great for vertical applications.

– Small grip housing is ideal for operators with small hands.

Dynabrade_IMD_Feb2022.indd 1 1/18/22 3:21 PM

IndustrialMachineryDigest.com | Q3 2023 The Industrial Machinery Digest Robotics & Automation Quarterly Resource!

Versatility and Rapid Adaptation How WST Fab Maximized Efficiency with UR10e Cobots

Inc. A Transformative Journey in Industrial Welding

Motoman

Is a Master Production Schedule (MPS)? CONTACT US FOR A FREE NO-OBLIGATION DEMONSTRATION TODAY! Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | DYNABRADE RANDOM ORBITAL SANDERS

Embracing

Bystronic

Yaskawa

What

Supreme

Spirit®

– 36 models available in non-vacuum and vacuum styles; 3/8", 3/16" and 3/32" dia. orbits. Extreme

– 3/16" and 3/32" dia. orbits.

Sell us your unwanted industrial automation product. Radwell.com - 800.884.5500 - sellto@radwell.com UNWANTED INVENTORY TAKING UP VALUABLE SPACE?

WE

WE

WE AUTOMATION SOLUTIONS DYNABRADE ROBOT- ATTACHABLE AIR POWERED TOOLS

In additional to air tools, we offer accessories and abrasives for complete process solutions with the know-how to get the job done right.

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

Dynabrade manufacturers air tools for use with automation systems. Random Orbital Sanders, Finishing Tools, Grinders, Disc Sanders, and Abrasive Belt Tools are just a sample of our new product offering for robotics.

LISTEN.

OBSERVE.

Ask about a no-obligation demonstration on any product in our line. OPTIMIZE. ABRASIVE POWER TOOLS & PROCESS SOLUTIONS SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com |

4 | IMDQ | Q3 2023 6 EDITORIAL DIRECTION 10 INDUSTRY NEWS 14 CASE STUDY Embracing Versatility and Rapid Adaptation How WST Fab Maximized Efficiency with UR10e Cobots 16 COMPANY PROFILE Bystronic Inc. 20 INTEGRATIONS A Transformative Journey in Industrial Welding 24 MACHINES Yaskawa Motoman 26 SOFTWARE & CLOUDWARE What Is a Master Production Schedule (MPS)? 34 PRODUCT SHOWCASE 40 BUYER'S GUIDE FEATURED 45 SURPLUS GUIDE FEATURED 48 SURPLUS BUYING & SELLING 53 CLASSIFIEDS 54 ADVERTISER INDEX 12 16 18 22 24 QUARTER 3 2023 Table of ConTenTs

DIE GRINDERS & DISC SANDERS

DESIGNED FOR PEAK EFFICIENCY

– Durable, American made air tools are ideal for rapid material removal, deburring, finishing and polishing.

– Straight-Line, Right Angle and 7° Offset models offered in front and rear exhaust configurations.

– Tools available in horsepowers ranging from .3 hp to 3 hp, with speeds ranging from 3,200 RPM to 100,000 RPM.

Contact us for a Free Tool Demonstration!

PROUDLY DESIGNED, ENGINEERED AND BUILT IN AMERICA SINCE 1969 Dynabrade, Inc. | 1.800.828.7333 | dynabrade.com | WE LISTEN. WE OBSERVE. WE INNOVATE.

William C. Strickland III, Publisher william.strickland@indmacdig.com

800-366-0676 ext. 103 | Fax: 866-826-5918

Trey Bell, Editor-in-Chief trey@indmacdig.com

800-366-0676 ext. 104 | Fax: 866-826-5918

Brian Self, Associate Editor assoc.editor@indmacdig.com

Shane Bell, Creative Director sbell@indmacdig.com

SALES

Lisa Hanschu, Sr. Account Executive lisa@indmacdig.com 785-965-9159 | Fax: 785-965-7199

William C. Strickland III, National Sales 205-903-9178 | fax 866-826-5918

Adrienne Gallender, Media Adviser agallender@indmacdig.com 888-407-7737

Susan Strickland, Accounting susan@indmacdig.com 205-542-1098 | Fax: 866-826-5918

CIRCULATION & SUBSCRIPTIONS

IMD, 3590-B Hwy 31 South, Suite 233, Pelham, AL 35124 circulation@indmacdig.com | Fax: 866-826-5918

REPRINTS

To purchase article reprints please call 800-366-0676 ext. 103 or email wstrickland@indmacdig.com source media llc

6 | IMD Q3 2023

360

PUBLICATION OF:

Hwy 31 South PMB #233

AL 35124 INDUSTRIAL MACHINERY DIGEST (ISSN 1542-5223) is published 12x per year by Source 360 Media. POSTMASTER: Please send change of address to INDUSTRIAL MACHINERY DIGEST, 3590-B US Hwy 31 South, PMB 233, Pelham, AL 35124. Printed in the U.S.A. SUBSCRIPTION POLICY: Individual subscriptions are available without charge in the U.S. to qualified individuals. Publisher reserves the right to reject nonqualified subscribers. One-year subscription to nonqualified individuals in the United States: $96.00. Single copies available (prepaid only) $20.00 each. Alabama Automotive Manufacturers Association SERVING AMERICAN MANUFACTURERS FOR OVER 37 YEARS North America’s Manufacturing Resource for Industry Professionals Since 1986 ACTEKMFG.COM 200% PROOF LOAD TESTED INDIVIDUALLY SERIAL NUMBERED FOR BETTER TRACEABILITY ORDERS SHIPPED SAME DAY RATED LOAD 400 LBS - 250,000 LBS 800-752-7229 | SALES@ACTEKMFG.COM HOIST RINGS ACTEK Forged Street Plate™ Swivel Hoist Rings Side Load Hoist Rings Hoist Ring Kits Pivots180° Swivels 360° Drop Forged Hoist Rings Mold Handler™ Swivel & Pivot Hoist Rings Round Base Swivel & Pivot Hoist Rings Forged Swivel Hoist Rings ISO 9001

A

Source 360 Media LLC 3590-B

Pelham,

Welcome to the 3rd Quarter issue of IMDQ focusing on Automation and Robotics. This edition offers an in-depth look at the latest advancements and innovations in the field.

We start with an exploration of how WST Fab has increased efficiency and adapted quickly to market demands through the implementation of UR10e cobots. The article provides a detailed case study on WST Fab’s approach to combining business agility and technological innovation to overcome challenges and seize opportunities.

We also feature Bystronic Inc., a leader in high-quality laser cutting systems, automation, and software for sheet metal processing. This article gives a comprehensive overview of Bystronic's pioneering work in robotics and automation, focusing on its commitment to enhancing manufacturing efficiency and helping businesses navigate the fast-evolving landscape of Industry 4.0.

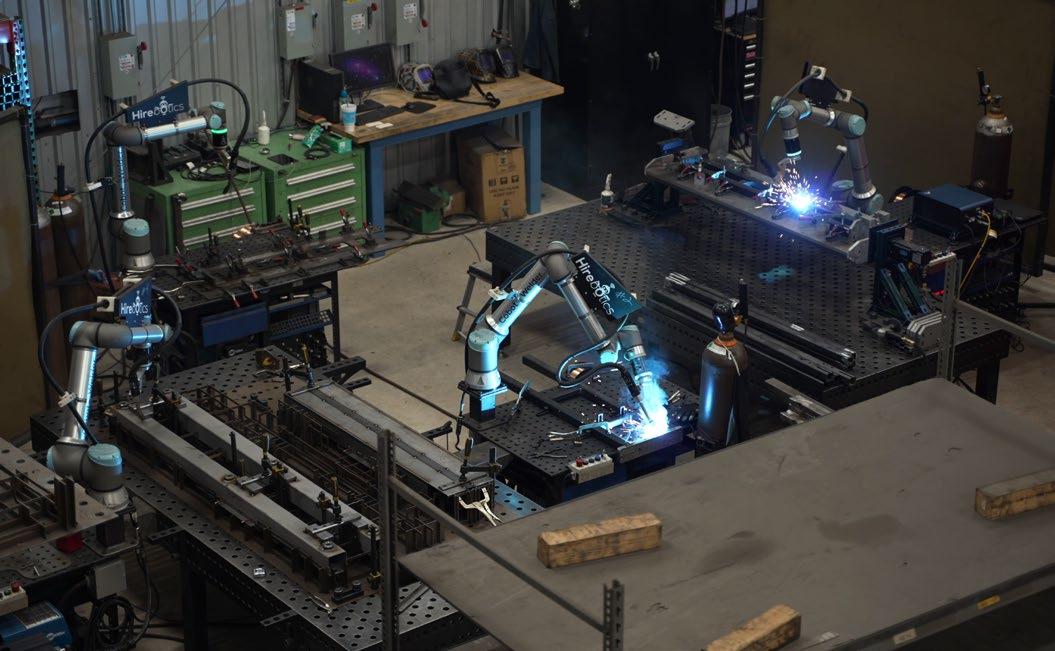

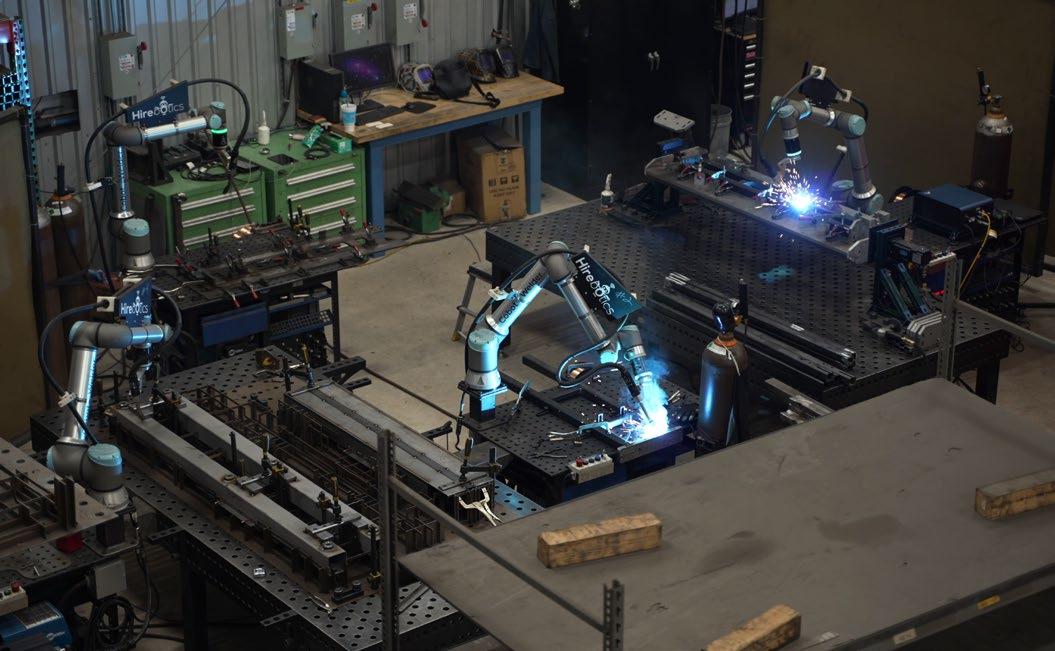

Next, we discuss the transformation journey of Advanta Southeast LLC in the field of industrial welding. Faced with labor shortages exacerbated by the COVID-19 pandemic, the integration of Hirebotics' Cobot Welder has proven to be a game-changing solution, reshaping the entire landscape of industrial welding for the company.

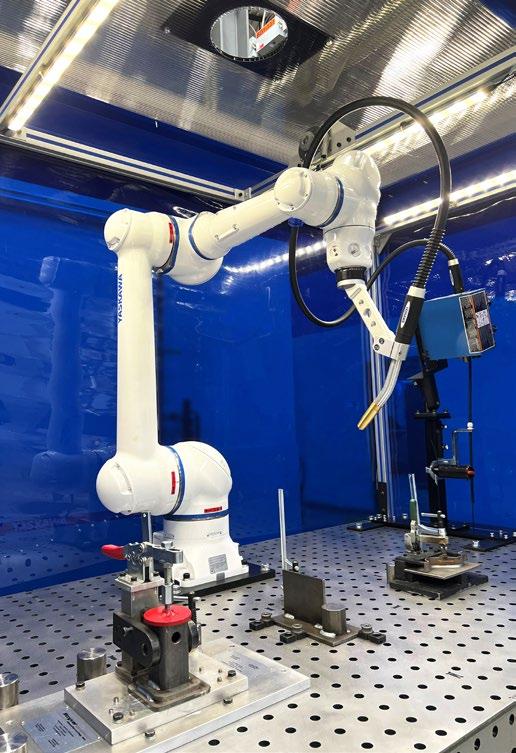

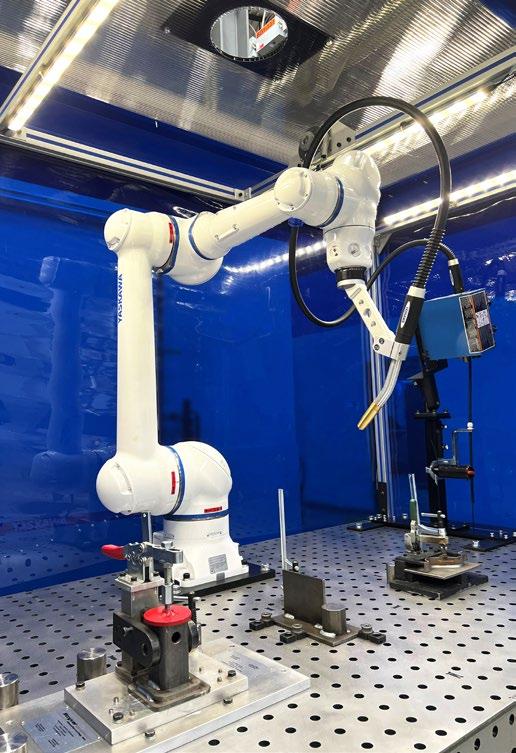

In this edition, we also spotlight Yaskawa Motoman, a prominent player in delivering innovative robotic solutions across various industrial sectors. The company is renowned for its focus on human-robot collaboration and its stateof-the-art controllers and powerful simulation software, ensuring seamless integration of robotics into existing enterprise operations.

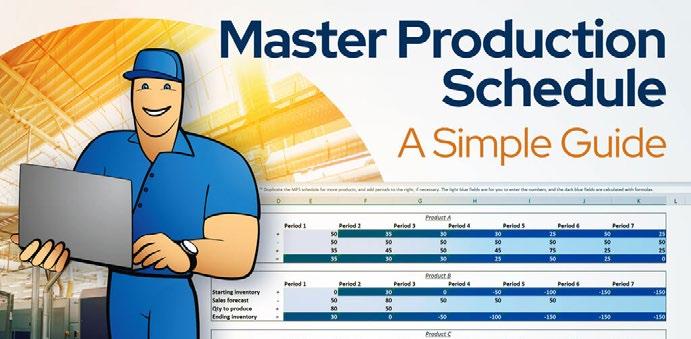

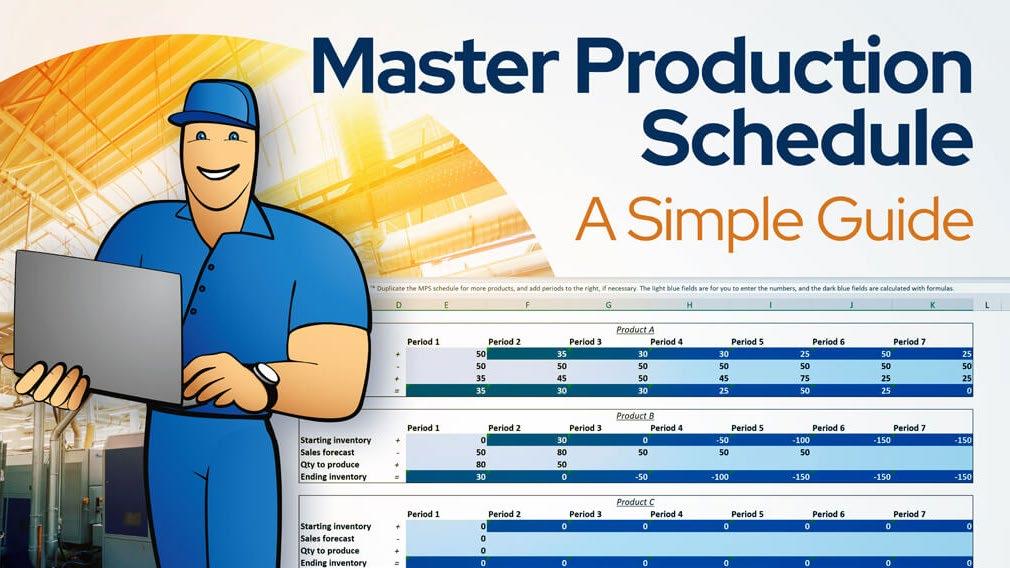

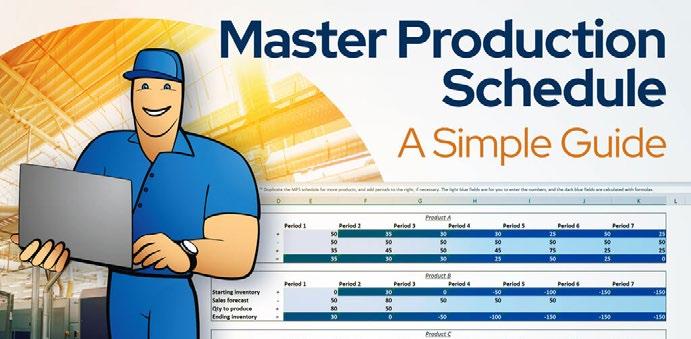

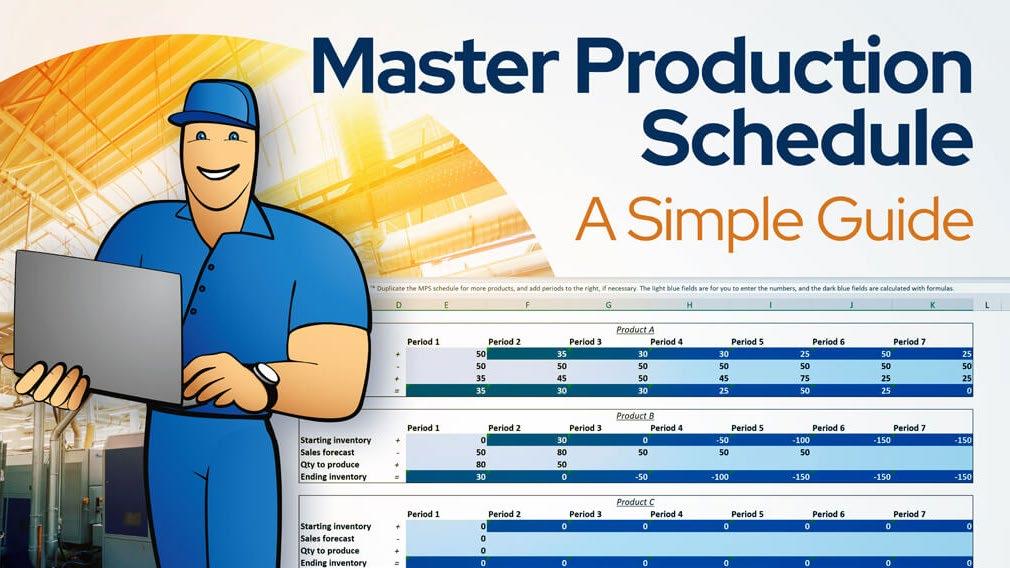

Lastly, our analysis of the Master Production Schedule (MPS) sheds light on its role as a vital production planning tool, bridging the gap between sales and manufacturing departments and driving production activity to optimize balance and profitability within diverse manufacturing setups.

I hope this issue provides you with valuable insights and understanding of the remarkable innovations in automation and robotics and fosters thoughtful discussions and inspiration for future developments in our field.

Regards,

William Strickland Publisher, IMDQ

8 | IMD Q3 2023

ediTorial direCTion

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! CABLE VS CHAIN With

Subscribe now to receive FREE news on upcoming auctions! YOUR COMPLETE AUCTION RESOURCE

Strickland

our user-friendly website, users can easily find the type of auction they are looking for, regardless of size or location. The site has the latest technology to make it simple for users to engage with an auction of interest.

William

AMERICAN-MADE SHEARS & PRESS BRAKES

Hydraulic Shears: 1/8” (10GA), 3/16”, 1/4”, 3/8”, 1/2”, 5/8”, 3/4”, 1” and 1-1/4”

Press Brakes: 50-Ton to 550-Ton

C-Frame Presses: 40-Ton to 200-Ton

Custom Designs: for Custom Applications

Retrofit Backgauges: for Shears and Press Brakes. Made to fit most machines with minimum modifications.

Precision Knife Sharpening

For over 50 years! www.betenbender.com Call for a free catalog! Phone: 319-435-2378 | Fax: 319-435-2262 | sales@betenbender.com

Alphasense Core becomes Core Research

Sevensense Robotics has announced the rebranding of its advanced multi-camera visual-inertial sensor development kit, formerly known as Alphasense Core, to Core Research. The new name pays homage to its primary users— academics and researchers focused on computer vision and Visual AI. The kit is equipped with five high-sensitivity cameras and a synchronized Inertial Measurement Unit (IMU), offering capabilities like multi-camera support, synchronized visual-inertial data, high-sensitivity image sensors, and robotics-specific exposure algorithms.

Since its launch in 2019, Core Research has achieved significant milestones. It received the RBR50 Innovation Award in 2020, acknowledging its contribution to the field of robotics and computer vision. Furthermore, it was instrumental in the success of team CERBERUS in the 2021 DARPA Subterranean Challenge, providing a crucial broad field of view for object location tasks. Researchers from top institutions such as ETH Zurich, the Norwegian University of Science and Technology, and Oxford University comprised this winning team.

The development kit is also used by construction hardware manufacturer HILTI for their annual SLAM challenge. Michael Helmberger, a Robotics Engineer at HILTI, praised Core Research's high-class cameras and IMU, stating they are well-calibrated and synchronized, making the kit extremely effective in changing light conditions.

In conjunction with the rebranding, Sevensense has outsourced the sales

of Core Research to specialized resellers MYBOTSHOP and ARGO. MYBOTSHOP will focus on distributing the kit to universities and research institutes primarily in Europe but also offers worldwide shipments. ARGO will concentrate on the Japanese market, where it specializes in introducing innovative technology from outside Japan.

Through this rebranding and sales strategy, Sevensense Robotics aims to strengthen its foothold in the academic and research communities, offering a state-of-the-art platform for further innovation in vision-based solutions.

EMAG at the Motion + Power Technology Expo

EMAG will be exhibiting at the Motion + Power Technology Expo in Detroit, Michigan, from October 17-19, 2023, at booth 2813. The company's experts will be available to discuss machining solutions and editorial topics. EMAG will showcase its K 160 horizontal hobber, a multi-axis machine ideal for high-volume production of automotive pinions and gears. The machine features direct-driven performance drives, easy-to-program controls, and built-in automation.

The company is unique in offering a complete process chain for manufacturing various components, including gearbox, engine, and chassis parts, both in automotive and non-automotive sectors. Their technology solutions encompass a wide range of automated operations such as gear hobbing, grinding, shaping, power skiving, turning, drilling, milling, laser welding, ECM deburring, and PECM machining. The expo will be held at Huntington Place in Detroit, MI, USA.

10 | IMDQ | Q3 2023 indus Try news industrial Machinery digest's industry news features the latest news and press releases from some of the industries top companies. WANT TO BE FEATURED? Send your press releases to editorial@indmacdig.com www.IndustrialMachineryDigest.com Streamlining Credential Processes Bringing Global Technology to a Local Level Manufacturing IndustrialMachineryDigest.com October2021 MANUFACTURING SHOWCASE: FEATURED STORIES: Cincinnati, Inc. IMPACTING DROP ZONE Wildeck Provides Increased Safety for Moving Palletized Loads the » Empowering Employees » Surpassing Energy Savings Manufacturer in Oxnard, CA experiences the benefits of Green Hydraulic Power Units » Lifting Higher Combi-PPT - A High Capacity Powered Pallet Truck Streamlining Control Siemens Offers Optimized Control Panel Construction to Machine Tool Builders IndustrialMachineryDigest.com March 2019 IndustrialMachineryDigest.com June2021 ESTABLISHED IN 1986 AND IS THE INDUSTRY’S Most Extensive Industrial Publication. GETTING BACK TO WORK!! 2021 INDUSTRIAL MACHINERY DIGEST’S INDUSTRY NEWS

OSARO and FANUC America Collaborate to Enhance Capabilities of Robotic Warehouse Automation Solutions

OSARO, a leader in machine-learning-enabled robotics for e-commerce, is partnering with FANUC America, a leading supplier of robotics systems, to enhance robotic automation solutions for warehousing and e-commerce fulfillment. The collaboration merges FANUC's expertise in robotics with OSARO's advanced vision software, SightWorks™, enabling robots to automatically learn and execute complex pick-and-place tasks. The partnership kicks off with a piece-picking demonstration robot at FANUC's Innovation Center in Michigan.

The union aims to address the burgeoning needs of the e-commerce sector, offering solutions that feature machine learning for object identification and task execution.

OSARO CEO Derik Pridmore states that the collaboration will yield the industry's most advanced automation solutions for all stages of e-commerce fulfillment, from depalletizing incoming inventory to kitting and bagging outbound shipments.

FANUC and OSARO are also inviting authorized system integrators to join OSARO's partner program, which aims to offer a one-stop solution for businesses looking to automate their fulfillment operations. The collaboration promises numerous benefits for businesses, including increased throughput, reduced labor dependence, faster order processing, improved shipment accuracy, and scalable solutions that optimize floor space.

ISA Announces 2023 Automation and Leadership Conference

The International Society of Automation (ISA) has announced its 2023 Automation and Leadership Conference (ALC) to be held in October in Colorado Springs, Colorado. Described by ISA President Marty Bince as the "automation event of the year," the conference will offer a comprehensive program, featuring society meetings, technical presentations, career skills sessions, and networking events.

The conference aims to attract a global audience of automation professionals interested in topics like digital transformation, cybersecurity, and career development. Keynotes will be delivered by Mark Weatherford, CSO and SVP of Regulated Industries at AlertEnterprise, and Dr.

Lauren Goodwin, formerly CISO at NASA Houston White Sands Test Facility. The conference will use a hybrid format, allowing both in-person and virtual participation.

Last year, ALC won first place at the 2022 vFairs Eventeer Awards in two categories: Best in Class Hybrid Event and Best Use of Mobile App. Registration is currently open, with details on the ISA website. Space is limited for some events, so prompt registration is advised.

Mitsubishi Electric Automation, Inc. Launches Machine Tending Offering for LoadMate Plus Engineered Solution

Mitsubishi Electric Automation, Inc. has introduced a new product line, LoadMate Plus™, aimed at addressing labor shortages in the manufacturing sector by offering machine tending solutions. Machine tending involves the loading and unloading of parts or materials into machine tool centers like vertical machining mills and turning centers. The LoadMate Plus line is designed for easy setup and offers flexibility and mobility.

To accommodate manufacturers without experienced robot programmers, the LoadMate Plus line provides flexible connectivity through Ethernet and features easy programming via the Direct Robot Control (DRC) of Mitsubishi Electric's M8 Series. The system is compatible with almost any CNC machine, even those not from Mitsubishi Electric, and can be connected via discrete I/O. The company also offers expert engineering support and a 5-year robot maintenance and warranty program.

According to Dave Simak, service product manager at Mitsubishi Electric Automation, the LoadMate Plus solutions offer a cost-effective, turn-key approach to the labor shortages and productivity challenges facing many manufacturers.

MRPeasy Manufacturing ERP Delivers First AI Tool to Small Manufacturers

MRPeasy has introduced the first AI-powered chatbot, named Mr. Peasy, in its manufacturingoriented ERP (Enterprise Resource Planning) software aimed at small manufacturers. This innovative feature allows users to ask questions in natural language and receive comprehensive answers regarding the software's use. The chatbot is designed to improve user experience and make the software more accessible, addressing the industry's issue of complex ERP solutions.

INDUSTRIA L MACHINERY DIGEST COM IMD | 11 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

Mr. Peasy is trained on a large dataset of MRPeasy documentation, user manuals, and support data, and can assist with queries related to features, pricing, implementation, and troubleshooting. The chatbot also continually learns to provide up-to-date information and users can give feedback for further refinement. Traditional human support is still available through MRPeasy's support ticket system.

According to Karl Lauri, CMO at MRPeasy, this AI integration is part of the company's ongoing commitment to providing user-friendly, powerful, and affordable tools for small manufacturers. MRPeasy plans to introduce more AI tools to further streamline business processes for its customers.

Siemens, DMG MORI, Walter and TRAK Machine Tools collaborate on next-generation part manufacturing digital thread

Siemens, in collaboration with DMG MORI USA, Walter, and TRAK Machine Tools, announced a new project aimed at advancing next-generation part manufacturing, specifically for electric vehicle (EV) components. The project is built on Siemens' Xcelerator business platform and incorporates technologies from all partners.

The initial design of a critical suspension component for an EV is generated using Siemens NX™ software and features generative engineering tools. The design is then validated and optimized using structural simulation technologies, reducing the component's weight by 45% while improving its performance.

In the Process Planning phase, Teamcenter® and Opcenter™ software automate programming and create a unified data source for digital manufacturing. The Siemens eRod component is produced through a combination of additive and traditional manufacturing techniques, with automation reducing programming time by 60%. Advanced capabilities in NX CAM, DMG MORI's LASERTEC 30 DUAL SLM machine, and Walter's industry-leading tooling hardware are used to achieve required tolerances and meet various machining challenges.

For traditional subtractive processes, TRAK Machine Tools' TC820si turning center is integrated using a digital twin, enabling the virtual programming of the spindle component. Quality control is ensured through automated CMM processes and PMI (Product Manufacturing Information) leveraged within NX CMM Inspection Programming software. The end result is an optimized steering knuckle component that is integrated with the traditional spindle and ready for assembly in the Siemens eRod.

Qt Group study reveals growing connectivity in factories, yet divergent tech priorities persist among Industrial Automation

A study by Qt Group has revealed that manufacturers in the industrial automation sector are struggling to

find a technological advantage despite investing in various technologies. The study found that 39% of respondents believe connectivity has most impacted product development, followed by interoperability at 31%, and AI/ML at 33%. The technology preferences of respondents vary widely, with AR/VR lagging significantly behind at 6%.

A key focus for these manufacturers is enhancing the user interface (UI) and user experience (UX) of their devices. Although many are struggling to allocate budget for UI/UX improvements, the main drivers for prioritizing it include financial gains, technological advancement, increasing market share, and competitive innovation.

Macroeconomic factors have also impacted the industry; no company reported being unaffected by economic conditions. Reported effects include increased product prices, lower profit margins, and longer time-to-market. To combat these challenges, over 40% of companies are adopting cross-platform development tools and hiring new talent, while others are extending deadlines and streamlining product lines.

Patrick Dalez, Product Business Line Director at Qt, points out that the industry's hesitant nature in adopting rapid technological changes may explain the varied focus on different technologies. He notes that as AI gains traction in other sectors, industrial automation is likely to follow. Dalez also emphasizes the challenges companies face in improving UI/UX with limited resources, suggesting that the right software development framework could help mitigate these issues.

Pixelle Invests $1.4 Million in Mill Safety and Productivity with Industry First Robotics

Pixelle Specialty Solutions, a major manufacturer of specialty papers in North America, has enhanced safety and efficiency at its Spring Grove, Pennsylvania facility by installing a smelt spout cleaning robot made by Valmet. This is the first installation of its kind in North America. The robot automates the cleaning of recovery boiler smelt spouts, improving the liquor recovery cycle and eliminating the need for manual intervention.

Manual cleaning of smelt deposits in recovery boiler spouts can expose operators to hazardous conditions like molten smelt, hot gases, and ash. The robot performs this task safely and efficiently, following a programmed sequence. Operators maintain remote control and visibility, using the robot's camera for troubleshooting and assessment.

The robot was designed and installed by Valmet, a leader in technologies and services for the pulp, paper, and energy industries. The installation aims to change perceptions about what's possible in the pulp and paper industry while prioritizing safety and productivity. Ross Bushnell, President and CEO of Pixelle, highlighted that this innovation underscores Pixelle's commitment to operational excellence in specialty papers.

12 | IMDQ | Q3 2023

Lifting

Application

Lifts up to 500 lbs! Ergonomic Portable Lightweight Meets OSHA & ASME

Customized Safety

Devices For Any

SAFETY FIRST Prevent Lifting Injuries

Embracing Versatility and Rapid Adaptation

How ws T fab Maximized efficiency with ur10e Cobots

Since its inception in 2010, WST Fab has earned its stripes as a premier supplier of CNC machining and metal fabrication services in the United States. Adhering to a robust set of core values—Service, Accountability, Integrity, Innovation, and Dedication—the company has built a strong, small customer base across multiple sectors such as agriculture, lawn and garden, snow removal, and commercial packaging. The Wisconsin-based firm’s recent experience with its new UR10e cobot-based machine tending system serves as a remarkable case study in how business agility and technological innovation can transform challenges into opportunities.

The Challenge: Facing the Unexpected

WST Fab found itself in a unique predicament: A large customer order that the company had been preparing for fell through on the very day they received their newly configured UR10e cobot-based machine tending system. This particular system had been tailored to meet the specific requirements of that order. The cancellation posed a question: How could the new, specialized equipment be redeployed?

The Partner: PCC Robotics

WST Fab had collaborated with PCC Robotics, a UR Certified Systems Integrator, to design a complete machine

tending system that featured the UR10e cobot. This partnership was pivotal. PCC Robotics not only provided the cobot but also included end-of-arm tooling, a system base, and staging for both raw materials and finished parts. Furthermore, they ensured full integration with WST Fab's existing CNC machines. Importantly, they offered training both through the online UR Academy modules and with onsite instruction.

"Working with the UR, if you first look at the pendant and you don’t know anything about it, it’s a little scary," recounts Tyler Schuh, WST Fab’s Manufacturing Engineer. "But then you start playing with it, and it’s so easy to learn. I trained two other people how to do basic setups already, and they can make simple programs now."

The Turnaround: Reprogramming and Reconfiguring

With its engineers trained, WST Fab could rapidly reprogram the cobot, adjust its versatile fixturing, and 3D-print new grippers. Within days, the UR10e system was up and running, not just for one part but for a dozen different parts.

The quick pivot also involved 3D-printed grippers, which allowed WST Fab to adapt swiftly to new parts and processes. These dual grippers enhanced machine utilization by enabling the simultaneous unloading of a finished part and loading of a new raw part, embodying WST Fab's core value of 'Innovation.'

14 | IMDQ | Q3 2023 Case sTudy

Photo Credit: Universal Robots USA, Inc

The Business Transformation: Versatility Over Traditional Robots

WST Fab had considered investing in traditional automation, but the rigidities and higher costs associated with such systems were a deterrent. Charlie Lenn, General Manager at WST Fab, elucidates: "From a cost standpoint, to invest $550,000 into an industrial robot that’s in a fixed position versus probably a third of the cost for a heavier-duty cobot that we can then move somewhere else if we need to, it just feels a lot safer."

Timm Abel, Operations Manager, complements this by adding, "That’s how we’ll grow our business in the robot world—versatility. We can put a cobot in place, do this job, and pull everything out, and have the same machine we had before we started. And this is in a matter of hours, not days."

The Tangible Benefits and Lessons

Key Value Drivers:

» Quick Redeployment: The ability to swiftly reprogram and reconfigure the cobot system illustrates WST Fab's core value of 'Service,' enabling the firm to meet different demands effortlessly.

» Economic Efficiency: Achieving comparable results at about a third of the cost underscores the company's commitment to 'Accountability,' particularly in its stewardship of resources.

» Employee Safety and Skill Development: The cobot

system alleviates unergonomic, repetitive tasks, freeing up employees for more valuable roles. Easy programming, facilitated by PCC Robotics, supports WST Fab's hiring and mentorship programs, emphasizing the values of 'Integrity' and 'Dedication.'

Challenges Overcome:

» Versatility in the Face of Change: WST Fab demonstrated its adaptability by transitioning a specialized machine tending system into a versatile asset, reinforcing its core value of 'Innovation.'

» Ownership and Control: Full knowledge transfer from PCC Robotics to WST Fab gave the manufacturer ownership and control over the cobot, falling in line with their core value of 'Accountability.'

Conclusion

WST Fab’s experience with the UR10e cobot system offers compelling insights into the power of agility and innovation. These traits, combined with a focus on their core values, have positioned WST Fab as a leader in CNC machining and metal fabrication. The company's agile response to an unexpected challenge highlights their ability to turn such events into pathways for growth and excellence. This case study serves as a testament to WST Fab's unwavering commitment to improving themselves, their customers, their company, and their community.

DID YOU KNOW TORMACH SELLS PLASMA TABLES?

Premium features make better parts.

• Closed-loop servo motors for reliable accuracy

• Floating head with Digital Torch Height Control that help make cuts to uneven surfaces like corrugated metal

• Standard breakaway torch holder with collision detection to minimize machine damage if things go wrong

• Minimized run times with fast rapids (1,000 in./min., 400 in./min. cuts) and acceleration (30 in./sec.²)

• Integrated water table mounted on sliding rails, ideal for cutting pipes and larger parts

• The only plasma table built with PathPilot, Tormach’s award-winning CNC controller, and access to PathPilot HUB, Tormach’s browser-based version of PathPilot

INDUSTRIA L MACHINERY DIGEST COM IMD | 15 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

CNC MILLS | CNC LATHES | CNC PLASMA TABLES | CNC ROUTERS | INDUSTRIAL ROBOTS | AUTOMATIC FEED BANDSAWS

Learn more and build yours at tormach.com/1300PL/IMD

BYSTRONIC INC.

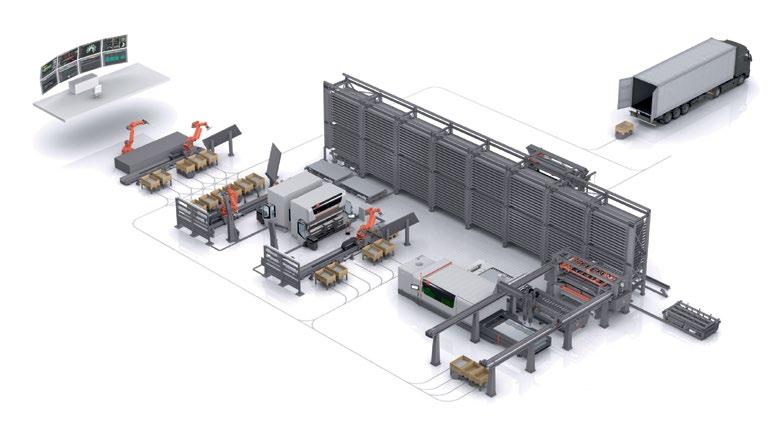

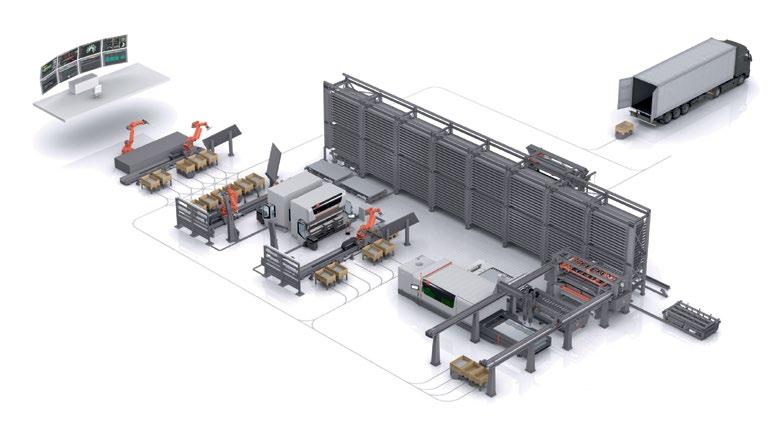

Bystronic Inc., a global leader in high-quality laser cutting systems, press brakes, automation, and software for sheet metal processing, has become synonymous with innovation in the fast-evolving landscape of Industry 4.0. Headquartered in Hoffman Estates, IL, the company's North American presence is complemented by offices in Canada, Mexico, and Brazil, underscoring its commitment to providing high-performance solutions across continents. As businesses struggle to adapt to volatile markets, shrinking batch sizes, and an ever-growing range of product diversity, Bystronic is ushering in a new era of manufacturing efficiency. This article aims to provide a comprehensive insight into the company's pioneering contributions to the world of robotics and automation.

The Comprehensive Automation Suite: Versatility and Efficiency

At the heart of Bystronic's value proposition is its diverse range of automated solutions targeting the complex challenges in the sheet metal processing industry. Take, for instance, the ByTrans Extended—a compact material handling system that perfectly integrates with any ByVision controlled machine. This powerful combination empowers manufacturing units to optimize material handling, offering a swift loading and unloading process that barely takes a minute. To further add versatility, Bystronic's ByTower material storage solution can be integrated into the ByTrans Extended, enhancing its capabilities and allowing for an even smoother, more organized material flow. The result? A dramatically reduced need for manual labor, increased throughput, and a more streamlined manufacturing process, allowing businesses to get closer to the dream of a 'lights-out' factory.

Revolutionary Bending Solutions: The Xpert Pro Series

In the realm of sheet metal bending, Bystronic’s Xpert Pro series is nothing short of revolutionary. This state-of-the-art machine, coupled with the fully automated Bending Cell component, has changed the way manufacturers perceive efficiency. The Xpert Pro features a 7-axis robot that can autonomously change grippers and bending tools. This

automation marvel is empowered by intelligent software that calculates the most optimal sequence for tool changes and bending operations. The outcome is a 30% reduction in processing time and an unprecedented level of repeatability and reliability in the bending process.

The BySort: A Seamless Extension to Laser Cutting

Another gem in Bystronic’s automation portfolio is the BySort—a material handling add-on that extends the capabilities of a laser cutting system. BySort automatically sorts the cut parts and removes them from the cutting table, facilitating a rapid workflow that ensures the laser cutting system is never idle. This feature is particularly beneficial for businesses that deal with a high mix of products, as it allows for seamless switching between different cutting tasks.

16 | IMDQ | Q3 2023 CoMpany profile

Robotic Welding and Collaborative Systems

Bystronic’s Robotic Welding Innovations

Bystronic has redefined the welding landscape through its collaboration with CLOOS, a Germany-based industry leader specializing in robotic welding technology. Together, they have released a series of robotic welding cells, including the Compact Cell, Compact System, Compact System FLEX, and the all-new CLOOS ArcBot Collaborative Welding Center. Each model is designed to accommodate different sizes and weights of workpieces, boasting two-station workpiece positioners and high-capacity welding power supplies of 450A.

Perhaps the most striking feature is the system’s integrated safety protocols. Bystronic and CLOOS have been meticulous in ensuring workplace safety by including features such as nozzle search and anti-collision sensors, interlocked doors, and safety enclosures. When necessary, safety fencing and light curtain barriers are also included. This attention to detail makes the welding cells not just efficient but also safe environments for workers.

Thru-Arc Seam Tracking and Mobility

The Compact Cell and Compact System models come equipped with automatic Thru-Arc Seam Tracking. This feature maintains the integrity of the weld seam, ensuring that the welding robot stays centered throughout the

process. The Micro Cell and Compact Cell also offer integrated forklift pockets, enabling quick installation and a rapid transition into a "ready-to-weld" state within a customer’s production environment.

Collaborative Welding: The CLOOS ArcBot

The CLOOS ArcBot Collaborative Welding Center represents a leap towards more human-robot collaboration. While traditional robotic cells are often secluded, requiring a separation between human workers and robots, the CLOOS ArcBot is designed for more integrative, cooperative workspaces. This is a significant

INDUSTRIA L MACHINERY DIGEST COM IMD | 17 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

move towards realizing the vision of a fully collaborative manufacturing environment, where robots and humans can coexist and complement each other's strengths.

A Leap into the Digital Realm: Bystronic Smart Factory

Navigating Industry 4.0

As Industry 4.0 changes the manufacturing landscape, Bystronic is leading the charge with its Smart Factory solutions. This suite of networked solutions for sheet metal processing is especially timely as manufacturers seek new approaches to manage volatility in markets, increased product diversity, and reduced lead times.

Software Prowess with Kurago

In a strategic alliance with software specialist Kurago, Bystronic aims to pioneer process solutions that will drive forward Smart Factory software solutions across different brand platforms. This collaboration has led to the development of a brand-new enterprise operational environment for sheet metal processing. By leveraging cloud technology, Bystronic offers scalable solutions that grow with a company's requirements while minimizing the total cost of ownership.

Your Transformation Journey

Bystronic encourages companies to embark on a transformation journey toward digital production. Their suite of scalable solutions grows with your requirements,

ensuring a smooth transition from a machine-centric environment to a fully integrated Smart Factory.

The Future of Sheet Metal Processing at Bystronic's Experience Center

Bystronic Experience Center: A Live Laboratory

The notion of the Smart Factory is no longer a concept relegated to the future; it's very much a present reality for Bystronic customers. Located near Chicago, Bystronic’s new Experience Center serves as a live laboratory where customers can witness firsthand the future of sheet metal processing. Here, Bystronic presents an extensive range of its latest technologies: from laser cutting and flexible bending systems to tube and profile processing solutions. The Experience Center is more than just a showcase; it's an educational hub where clients can partake in live demonstrations, tailored to their specific needs. This way, companies get a practical sense of how Bystronic’s cutting-edge solutions could integrate into their own production lines, giving them a head start in adopting Industry 4.0 technologies.

Software That Powers the Chain

In the era of digital transformation, software is as crucial as hardware. Bystronic understands this paradigm shift and offers a comprehensive software landscape that covers the entire sheet metal processing chain. Developed in partnership with software specialist Kurago, Bystronic's software solutions are geared towards achieving

18 | IMDQ | Q3 2023

operational excellence. Whether it's planning, interlinking, monitoring, or optimizing production processes, Bystronic has software solutions that bring transparency and efficiency to the table.

Bystronic – A Pioneer in Robotics and Automation Bystronic stands out as a frontrunner in the fields of robotics and automation for sheet metal processing. With its versatile offerings in laser cutting systems, press brakes, automation, and software, the company is well-positioned to address the complexities and challenges of the modern industrial landscape.

The company's partnership with CLOOS for robotic welding solutions has set new standards in efficiency, safety, and quality. Their push towards collaborative robotics signifies an understanding of the future of manufacturing— one where robots and humans work side-by-side.

Through their Smart Factory initiative, powered by software expertise from Kurago, Bystronic offers scalable

digital solutions that grow with a company's needs. Their Experience Center serves not just as a display of technological prowess but as an interactive playground for companies looking to step into the future.

In a rapidly evolving industry landscape, staying stagnant is not an option. Bystronic not only understands this but leads by example, constantly innovating and pushing the boundaries of what's possible in robotics and automation. For those looking to navigate the complexities of modern manufacturing, Bystronic appears to be a guiding light, illuminating the path towards a more efficient, transparent, and collaborative future.

INDUSTRIA L MACHINERY DIGEST COM IMD | 19

A Transformative Journey in Industrial Welding

In a world where technology is ceaselessly advancing, businesses must evolve to remain competitive. One such business, Advanta Southeast LLC, found itself at a crossroads. This South Carolina-based division of Advanta Industries provides industrial metal fabrication services to diverse sectors like automotive, defense, marine, and energy. Yet despite its wide-ranging influence, the company found itself grappling with a labor market made even more challenging by the COVID-19 pandemic. Labor shortages and the ever-increasing demand for skilled welders posed significant obstacles. Advanta needed a solution—and fast. Enter Hirebotics' Cobot Welder, a technological marvel that promised not just to fill gaps but redefine the entire welding landscape for Advanta Southeast.

The Dilemma: A Labor Market in Flux

Before we delve into the solution that would eventually increase Advanta Southeast’s output by a staggering 400%, it's important to understand the severity of the challenges they were facing. "Employees were concerned about losing their jobs to automation, and some of our managers were skeptical about how practical robots would be in a real-world scenario," said Mark Moye, the Plant Manager at Advanta Southeast.

These apprehensions were twofold. On one side was a global pandemic that had exacerbated an already dwindling supply of skilled welders. On the other side was a reluctant

management team worried about the steep learning curve involved in programming traditional welding robots, not to mention the long lead times for receiving such specialized equipment.

Breaking Barriers: Why Hirebotics?

Advanta Southeast decided to cast its lot with Hirebotics' Cobot Welder, which promised a departure from traditional robotics. "We had been running on technology that was decades old," Mark explained. "Robotics was new terrain for us, and that’s precisely why we needed a partner like Hirebotics. They offered something simple, effective, and radically different from what we were used to."

A Seamless Integration: Unpacking the 'Plug-and-Play' Experience

Within just two weeks of placing the order, Advanta Southeast had their first Cobot Welder unit on-site and operational. One of the standout features was the ease of implementation. “The unboxing to the operational stage was shockingly quick,” says Mark. Even for a team that had no prior experience with such sophisticated robotic technology, the learning curve was practically non-existent.

For the first unit, Mark did request support from a Hirebotics expert, but after seeing the speed and ease of installation, he was confident that subsequent setups could be managed in-house. “From unboxing to operational

20 | IMDQ | Q3 2023

inTegraTions

The Manufacturing Technology Series connects decision-makers from diverse industries with leading suppliers of advanced manufacturing technology, equipment and tooling. Don’t miss the most important manufacturing technology events in the U.S. in 2023. The Manufacturing Technology Series 2023: Four Regions . One Mission . Visit mtseries.com to learn more. Feb. 21-23, 2023 May 16-18, 2023 Oct. 24-26, 2023 Nov. 7-9, 2023

functionality, we're talking about a couple of hours. It was a stark contrast to what we had feared based on our assumptions around traditional welding robots.”

The Symbiotic Relationship: Man and Machine

Initial skepticism among the welding team quickly gave way to enthusiastic acceptance. "We ran the cobot for about a month to gauge its usability and ease of operation,” says Mark. Soon, the team was operating the Cobot Welder alongside manual welding setups. As the cobot handled one job autonomously, the human welders could concentrate on other complex tasks. “It was as if we suddenly had extra team members. The efficiency gains were immediate, and it allowed us to operate like a well-oiled machine,” Mark adds.

Quantifying Success: Beyond the Numbers

The benefits weren't just qualitative; they were profoundly measurable. Advanta Southeast saw a fourfold increase in production output, jumping from 25 to 100 parts per day within a few hours of the Cobot Welder's deployment. However, the advantages didn't stop at mere volume; the quality of the welds improved dramatically as well. "It was like having a master welder reproduce their best work, non-stop, without breaks," Mark explains.

The Data-Driven Edge

Another standout feature of Hirebotics' Cobot Welder was its accompanying app. This powerful tool enabled real-time monitoring of various metrics, including gas and

wire consumption, parts produced, and welder overtime. "Data-driven decisions are no longer a managerial buzzword for us; it's our daily reality," says Mark.

Scaling and Future Prospects

Emboldened by these successes, Advanta Southeast decided to scale up, acquiring three additional units for their South Carolina plant and two more for their Michiganbased parent company, Advanta Industries. "We are also considering further acquisitions in the near future,” Mark adds, hinting at the game-changing impact the cobots have had on their operations.

A Paradigm Shift in Industrial Operations

Mark Moye sums up the journey succinctly: “If you're hesitating about integrating cobots into your operations, don't. Take the plunge; the benefits far outweigh any potential challenges.” For Advanta Southeast, the introduction of Hirebotics' Cobot Welder was not just an operational enhancement; it was a paradigm shift. The company didn't merely adapt to new technology; it embraced a future where humans and robots work side-by-side, each amplifying the other’s strengths.

The experience of Advanta Southeast serves not just as a case study but as a playbook for any company grappling with labor shortages, quality control, and the need for rapid scaling. In this era of uncertainty and fast-paced technological advancements, taking the bold step to innovate could be the difference between stagnation and unprecedented growth.

22 | IMDQ | Q3 2023

OCTOBER 17–19, 2023

Huntington Place Convention Center

DETROIT, MI

Attending Motion + Power Technology Expo puts you right in the center of the power transmission supply chain.

• Keep up with the latest R&D and gearing innovation at the AGMA Fall Technical Meeting

• Network with leading professionals at the Opening Night Welcome Reception, free to all attendees

• Be empowered and connected at the Women in Manufacturing and Engineering Breakfast

• Gather with executives at the International Power Transmission Summit

• Advance your knowledge during one of the many in-depth education sessions

• See how AGMA is leading the way at the AGMA Electric Vehicle Technology Town Hall

is

Formerly Gear Expo

MOTIONPOWEREXPO.COM/IMD Register Today!

Yaskawa Motoman

In the world of robotics and automation, Yaskawa Motoman stands as a trailblazer, recognized for delivering cutting-edge solutions that drive efficiency, safety, and productivity across various industrial sectors.

Founded in 1989 and headquartered in Dayton, Ohio, the company has carved a niche for itself in the ever-evolving landscape of robotics. Specializing in a wide array of robotic applications, from welding and material handling to assembly and dispensing, Yaskawa Motoman has proven its mettle in offering robotic systems that not only meet but often exceed the industry standards.

The company's extensive portfolio is characterized by its focus on human-robot collaboration, state-ofthe-art controllers, and powerful simulation software that offers a seamless integration of robotics into the existing operations of any enterprise. As industries continue to strive for a perfect amalgamation of human skill and robotic precision, Yaskawa Motoman emerges as a preferred partner, leading the way with innovation, reliability, and an unwavering commitment to quality.

The Pioneering HC-Series Robots

In September 2023, Yaskawa Motoman has once again pushed the boundaries of what's possible with the launch of its new six-axis HC10 and HC20 human-collaborative robots. Designed with an acute emphasis on safety and adaptability, these robots can work in tandem with human operators or operate independently, adjusting to the varying demands of modern industrial settings.

Flexibility & Adaptability

The HC10 model offers a payload capacity of 10 kg and a reach of 1,379 mm, making it an ideal choice for supplementing manual welding tasks or managing large, heavy workpieces. Its greater flexibility allows for easy repurposing, enabling companies to meet fluctuating production requirements. On the other hand, the HC20 model provides an even greater reach at 1,900 mm and an increased payload capacity of 20 kg. These specifications

make it versatile enough to handle a wide array of industrial applications with ease.

Safety First

Safety is not just an afterthought but a cornerstone in the design of HC-series robots. These models have received TUV certification to ISO 13849-1 and also comply with ISO 10218-1 and ISO TS 15066 standards. They feature Power and Force Limiting (PFL) technology, where dual-channel torque sensors in each joint continuously monitor the force exerted, allowing for rapid adjustments to ensure safety. The pinch-less design of the HC10 and HC20 allows them to operate without additional protective measures like safety fences, saving both space and setup costs.

Smart Features & Communication

The HC-series robots come with through-arm utilities that neatly tuck away all cabling, including a Category 6 Ethernet cable, thereby minimizing the risk of any snagging or interference with other equipment. This feature ensures smooth communication with a variety of tooling options, enhancing the overall efficiency and functionality of these robotic arms.

Speed and Mode Flexibility

Both the HC10 and HC20 models are engineered for flexibility in terms of speed and operation mode. They can seamlessly shift between collaborative speed in Power and Force Limiting (PFL) mode and full speed in industrial mode. This adaptability is critical in optimizing cycle times based on risk assessments and specific process requirements. Programming these robots is a breeze, thanks to their

24 | IMDQ | Q3 2023 MaCHines

precision hand-guiding feature, making it easy for even those without extensive programming experience to implement a robotic system quickly.

Rugged and Reliable

Built with industrial durability in mind, the HC10 and HC20 robots are constructed with cast aluminum and feature a rugged IP67 rating. This makes them reliable choices for operating in harsh welding environments. Additionally, their easy-clean surfaces make them suitable for industries requiring sanitary conditions, providing a versatile option for a variety of application needs.

The Power of Simulation: MotoSim EG-VRC

Accompanying the HC-series robots is the MotoSim EG-VRC (Enhanced Graphics Virtual Robot Controller), a potent simulation software package offering 3D simulation for robot workcells. This tool enables manufacturers to accurately visualize their robotic systems in action before physical implementation, thereby minimizing errors and reducing setup time. This is particularly crucial for processes that involve complex systems and require high levels of precision.

Real-Feel Experience

One of the standout features of MotoSim EG-VRC is its ability to provide a "real" robot feel. The interface displayed is identical whether you're programming using a teach pendant or the software on a PC, creating a unified experience. This feature enables manufacturers to keep their actual robotic systems running while concurrently programming new parts to be processed.

Comprehensive Functionality

MotoSim EG-VRC isn’t just a visual tool; it's a functional powerhouse. The software supports reach analysis, cycle calculations, collision detection, and even complex offline programming. With support for up to 15 axes of motion, the software is well-equipped to simulate complex robotic maneuvers, making it an indispensable asset for any modern industrial setting.

Direct Teach, Plug and Play:

The HC10DTP and HC20DTP

Expanding its HC-series line, Yaskawa introduced the HC10DTP and HC20DTP models, designed with hand-guided programming and an ISO standard tool flange for a 'plug and play' approach. These models take humanrobot collaboration to the next level. They offer similar safety features as the original HC10 and HC20 but bring additional functionality that enhances human interaction with the robots.

Advanced Safety and Ease of Use

Like their predecessors, these new models employ Power and Force Limiting (PFL) technology to ensure that they can react quickly and safely to any contact with humans or objects. Their advanced pinchless geometry enhances

safety, making it easier than ever for humans to work in proximity to these robots.

A Range of Applications

With a payload capacity of 10 kg for HC10DTP and 20 kg for HC20DTP, and their respective reaches, these robots are ideal for a variety of applications—ranging from assembly and dispensing to machine tending and packaging. They can operate in damp or splash-prone environments, thanks to their IP67 rating, and come standard with NSF H1 certified food-grade grease, making them suitable for environments where there may be incidental food contact.

Conclusion

In the dynamic world of industrial automation, Yaskawa Motoman continues to set benchmarks with its innovative HC-series robots and simulation software. By marrying flexibility, safety, and advanced technology, the company is not just meeting the needs of modern industry but anticipating the future of human-robot collaboration. These solutions from Yaskawa Motoman underline the company's commitment to driving productivity, reducing operational costs, and ensuring workplace safety, proving yet again why they remain leaders in the field of robotics and automation.

INDUSTRIA L MACHINERY DIGEST COM IMD | 25 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

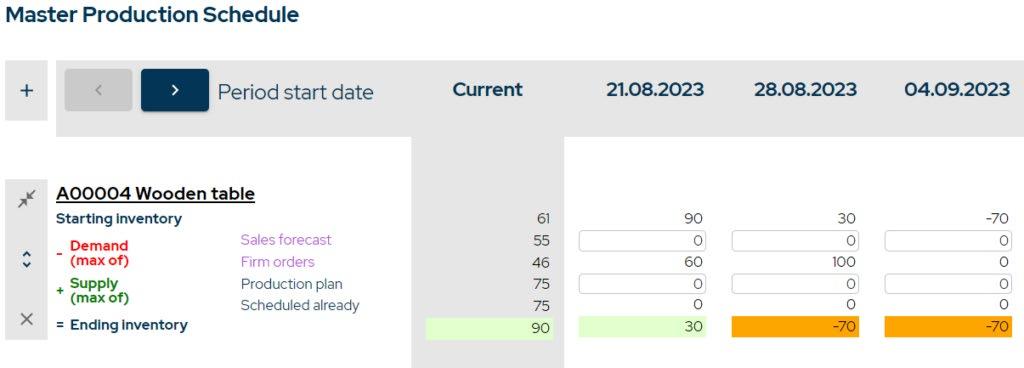

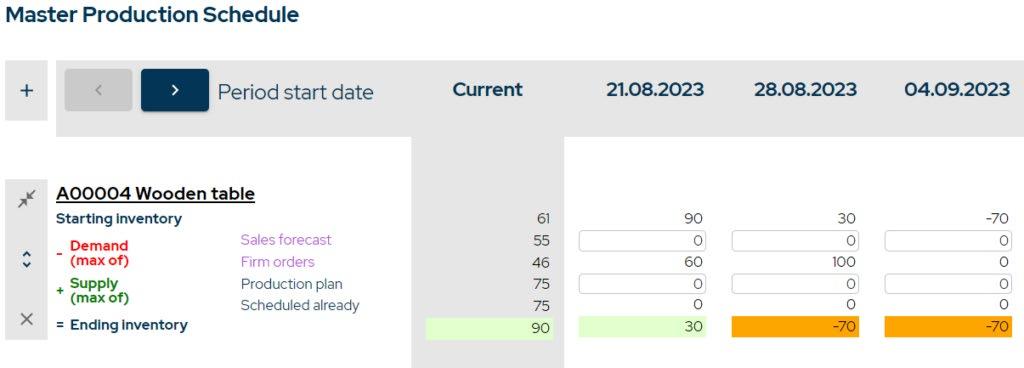

What Is a Master Production Schedule (MPS)?

The Master Production Schedule (MPS) is a production planning tool that outlines which products need to be manufactured, in which quantity, and when. A master production schedule does not go into detail regarding the production operations, sequencing, employees assigned to tasks, etc. Rather, it is like a contract between the sales department and the manufacturing department that balances supply and demand by defining the necessary quantities to produce within specific timeframes.

The master production schedule is a vital tool in make-to-stock manufacturing environments where a demand forecast drives production planning. As an MPS is often used as the main driver of production activity, it needs to be accurate and viable for it to have a positive effect on the profitability of a business.

The MPS can also be used in certain make-toorder environments and mixed-mode manufacturing operations where a business manufactures standard products. In this case, the sales forecast and master

production schedule are mostly used to plan the inventory needed for production. A standard master production schedule is a long-term plan made for each product separately. It is created with a planning horizon of a few months to several years, with a minimum time bucket (smallest timeframe specified) of 1 week.

Benefits of a Master Production Schedule

There are multiple benefits to introducing an MPS to a manufacturing business:

» It provides a solid base for building, improving, and tracking the sales forecast.

» It helps determine and achieve the desired inventory levels, thereby avoiding shortages and overstocking.

» It is an input for calculating the quantities of parts, subcomponents, or raw materials to purchase or produce, as part of the next stage of Material Requirements Planning.

» It enables the calculation of the required amount of

26 | IMDQ | Q3 2023 sof T ware/Cloudware

labor and shifts many months in advance.

» It allows for optimizing the installed capacity and balancing the load of the plant in advance, enabling companies to avoid bottlenecks.

» The manufacturing department can use the MPS to estimate production and maintenance costs associated with the work centers.

» The financial department of the company can derive expected revenues and expenses from the MPS and generate a cash flow forecast. Among other benefits, this will help build investment plans.

» The HR department can take advantage of the MPS to anticipate the requirements of hiring labor.

» Accurate MPS planning and execution can significantly improve customer service and satisfaction by ensuring the fulfillment of orders and maintaining the necessary service levels.

» The MPS defines visible, clear, and measurable objectives for the business operations, and a plan to achieve them.

The MPS should reflect the business plan as closely as possible. This requires constant updating by all departments of the company.

For example, if the marketing department plans a sales promotion, the increase in demand must be reflected in the MPS and the forecast. If the sales team discourages the sale of a product line in favor of another one, the MPS and the forecast need to be adjusted.

Where should MPS be used?

Although master production schedules are most often associated with make-to-stock manufacturing workflows, they can also support production planning in make-toorder, assemble-to-order, batch production, and mass customization environments. Here is a glimpse into where MPS can be most effectively applied:

1. Make-to-stock (MTS). In MTS environments, where products are manufactured for stock based on demand forecasts, MPS is used to align production plans with expected demand. By predicting the quantity of products needed, manufacturers can prevent overproduction or stockouts, optimizing inventory levels and reducing waste.

2. Make-to-order (MTO). Even in MTO situations, where products are manufactured once a customer order is received, MPS can be useful. It allows manufacturers to plan their capacity and resources efficiently, ensuring they can fulfill orders within promised lead times.

3. Assemble-to-order (ATO). ATO manufacturers, who

assemble products based on customer orders using pre-manufactured components, also benefit from MPS. The schedule helps plan for assembly operations, ensuring components are available when needed and final products are assembled in a timely manner.

4. Batch production. In environments where similar products are produced in groups or batches, MPS assists in determining the optimal batch size and sequencing the batches to maximize efficiency and minimize setup or changeover times.

5. Mass customization. Mass customization is a blend of MTS and MTO, where basic products are manufactured en masse and later customized according to customer needs. By coordinating the production of generic components with master production schedules and then customizing them according to specific orders, manufacturers can meet demand in a more efficient manner.

Inputs of a Master Production Schedule (MPS)

The basic inputs you need to create a viable master production schedule are the following:

» Starting inventory. How many units of the SKU are already available in stock?

» Sales forecast / demand plan. How many orders are expected for the period?

» Current order portfolio. How many orders are already planned for the time period?

» Quantity to produce. How many units need to be produced during the period to keep supply and demand in balance?

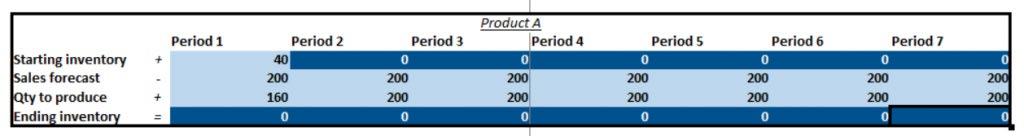

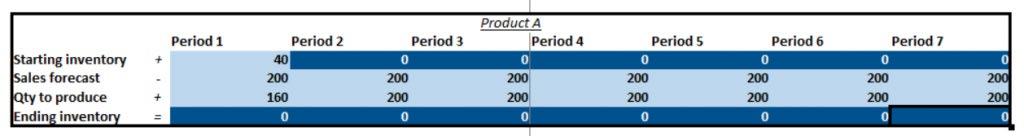

Example

Assume you produce wooden furniture such as chairs, dining tables, and coffee tables.

At the start of the period, you have 40 chairs in stock. Your sales forecast says that you will sell 200 of them. That means you will need to produce 160 chairs during that period in order to match the demand.

As a consequence, the beginning inventory of your next period will be 0. As business is steady, another 200 chair sales are forecasted. This means that now you will need to produce 200 chairs within a period in order to match demand.

Master Production Schedule and safety stock

Unless you have absolutely perfected the just-in-time manufacturing model, you would always want to keep a certain amount of units for backup in case there is an unforeseeable spike in demand. That is why we can

INDUSTRIA L MACHINERY DIGEST COM IMD | 27 IMD – North America’s Manufacturing Resource for Industry Professionals Since 1986

complement the master production schedule with:

» Safety stock. How many units do you want to keep in inventory in case there are spikes in demand?

In the master production schedule, safety stock will be expressed as part of the period’s ending inventory that will be transferred to the next time period as beginning inventory.

Example cont.

Now, continuing with the previous example imagine that you always want to keep 40 chairs as safety stock. Therefore, 160 chairs will not be enough to meet demand and replenish your safety stock during the first period. This means that you will need to produce 200 chairs altogether to satisfy your customers and maintain the required buffer.

Master Production Schedule and Rough-Cut Capacity Planning

When planning production, you always need to keep in mind how much exactly you are able to produce in a given period. If you take in orders that require you to produce a thousand chairs in a month, but you only have the means to produce 500, you will let down your customers and your company. That is why you would always want to account for:

» Production capacity. How many products would you be able to produce during the period, given that everything is running smoothly?

Rough-cut capacity planning is an important tool to use alongside the master production schedule. To calculate your production capacity, you will need to know your products’ throughput time and the total productive hours of your shop floor.

Once you have created your initial master production schedule, you can test its viability by creating a rough-cut capacity plan according to the MPS. If the capacity plan shows that your production capacity cannot accommodate the production levels in any period set in the MPS, you will need to find ways to increase capacity or modify the MPS.

Master production scheduling and rough-cut capacity planning is a back-and-forth process. That means any change in either of them requires reviewing the other.

Additional considerations regarding MPS

Master Production Schedule freezing

Freezing the MPS means locking the first couple of periods a certain amount of time, e.g. a week or two, before production starts according to the schedule. This is done to prevent last-minute changes that may slow down production and, ultimately, ruin your plans.

Available to Promise

Available to promise is the number of units that you can additionally promise to deliver to customers (as firm

orders) in the period at hand. It is calculated according to the master production schedule. It takes into account all the firm orders and the planned quantities across the MPS horizon. ATP plays an important role in supply chain management.

Batch criteria

When drawing up a master production schedule, you should always consider your batch sizes, i.e. how many products do you make in one run. That will determine the step of your quantities. For example, if you manufacture in batches of 25 products then your quantity to produce cannot be 240, it needs to be 250 or 225.

Maximum inventory

The MPS is a great tool for planning and preparing early for surges in demand. However, there are physical and practical limitations to the quantities you can store in stock. Even if you had the production capacity, it may not be possible to utilize it if your stock is full. Or beyond a certain inventory level, too much cash may be tied up in inventory.

6 tips for managing a Master Production Schedule

Mastering the Master Production Schedule is vital for efficient production planning and optimized manufacturing processes. Here are five key tips to help manage an MPS effectively:

1. Balance demand and supply. An effective MPS balances customer demand with production capacity. While it’s crucial to meet customer orders on time, overloading your production line can lead to increased costs and inefficiencies. On the other hand, underutilizing capacity can lead to lost sales and reduced profitability. Find the right balance based on your business strategy and market conditions.

2. Align MPS with business goals. Your MPS should align with your overall business objectives. If your goal is to reduce inventory holding costs, for instance, your MPS should be designed to produce just-in-time to meet demand. If your goal is high service levels, your MPS might need to include safety stock or be geared towards fast response times.

3. Regularly review and update. In the ever-changing landscape of supply and demand, a static MPS can quickly become obsolete. Regularly review and adjust your MPS based on real-time sales data, customer orders, inventory levels, and supply chain conditions to ensure its accuracy and effectiveness. A rule of thumb is that an MPS should be reviewed weekly.

4. Collaborate across departments. An MPS impacts multiple departments in a company, from production to sales to procurement. Ensure that all relevant parties are involved in its creation and review. This collaborative approach can improve forecast accuracy, resource allocation, and overall effectiveness of the MPS.

5. Use appropriate technology. Utilize a manufacturing ERP system that can automate much of the MPS and

28 | IMDQ | Q3 2023

manufacturing planning process. These systems can provide real-time data, helping to streamline the process, reduce errors, and improve responsiveness to changes in demand or supply.

6. Track metrics and improve continuously. There are many KPIs you can keep an eye on in order to assess the accuracy and usefulness of an MPS. These include schedule adherence and attainment, inventory levels, capacity utilization rate, OTIF, etc. Measuring your MPS performance and comparing against historical data allows you to understand when some aspect of the planning process needs to be improved. Remember, an MPS is not a set-it-andforget-it tool. It requires continuous management and adjustment to reflect current realities and drive optimal production performance.

Master Production Scheduling vs. Manufacturing Resource Planning

The master production schedule is one of the jumping-off points for material requirements planning (MRP I) and manufacturing resource planning (MRP II). In addition to the MPS, however, MRP uses inputs such as inventory statuses, BOMs, routings, material requirements and costs, financial records, staffing and machine capacity, etc. to create a highly detailed plan for all of the different resources related to production and provide you with a real-time overview of your business, enhancing overall operations management rather than just production planning.

Unlike creating a master production schedule, the complexity of manufacturing resource planning makes it impossible to do manually. Today, there are many different software providers offering MRP systems, but many of them have grown out of accounting or inventory management software and are limited in their manufacturing resource planning capabilities. Using proper MRP software, however, is becoming more and more important when it comes to staying competitive in the manufacturing business.

MRPeasy is one of the few cloud-based solutions that bring together both production planning and production scheduling software functionality, meaning that the system supports both MPS-based long-term planning as well as short-term scheduling.

Master scheduling process within an MRP system

Although you can use Excel to create a simple master production schedule, modern manufacturing MRP/ERP

INDUSTRIA L MACHINERY DIGEST COM IMD | 29

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money! VICE HOOK ACCESSORY

MRPeasy automatically fills out the fields representing starting inventory, firm sales orders, and already scheduled MO quantities.

systems (or at least the ones with an MPS functionality) make using the master production schedule as a basis for more advanced planning and scheduling exceedingly simple. Here’s how an MRP system uses the MPS:

1. Automated data input. MRP software automatically fills several inputs based on the data it has: firm sales orders, already scheduled manufacturing orders, purchase orders, and starting inventory. When any of these values changes, the MPS is automatically updated, giving the sales, production, and procurement

teams real-time information and enabling them to take the necessary action, e.g. by changing the MPS, increasing capacity, or ordering extra materials.

2. Demand planning. The sales team uses historical data and trends to forecast demand for the coming periods. After putting in the firm sales orders and forecasted demand, the system compares it to current inventory levels to determine the quantities required to produce during the period. This is the basic master production schedule.

It is important to note that the demand forecast is only valid until firm order quantities do not exceed the forecasted demand.

Capacity planning. After the basic MPS has been created, the production planner steps in. The MRP system uses the MPS to perform Rough Cut Capacity Planning (RCCP). This involves checking whether there is sufficient capacity available (in terms of machinery and labor) to meet the production schedule outlined in the MPS. If the available capacity does not meet the capacity requirements, the production planner needs to adjust the MPS or increase production capacity, e.g. by adding a shift.

Procurement planning. Once the MPS is established, the system uses it as an input for calculating the material requirements for each period. MRP software takes the master production schedule and the bill of materials (BOM) for each product, as well as the current raw material inventory, and calculates the quantities of each material or component required and when they are needed. The procurement team can then use this plan to ensure that the necessary materials are procured in time for production and inventory levels are optimized.

5. Production scheduling. An MRP system can be used to convert customer orders into manufacturing orders and automatically schedule them according to available resources or the order’s due date. Alternatively, production planners can manually create

30 | IMDQ | Q3 2023

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com

WHY SKY HOOK?

The Sky Hook is your personal safety lifting solution, preventing lifting injuries while saving you both time and money!

MRPeasy automatically calculates the ending inventory by subtracting demand from supply.

manufacturing orders (which are then scheduled automatically) to align production with the MPS.

6. Real-time adjustments. As mentioned above, MRP/ERP systems can be used to adjust the MPS and subsequent plans in real time as conditions change, such as a surge in demand or a delay in receiving raw materials. This agility allows manufacturers to respond quickly to changes in the business environment, reducing risks and potential losses, and keeping each party informed and involved in the process. It also facilitates what-if scenario analysis, enabling manufacturers to be better prepared for a variety of possible situations.

By integrating the MPS into an MRP system, manufacturers can automate and optimize their production planning process, improving efficiency, reducing costs, and enhancing their ability to meet customer demand.

Key takeaways

» Master production schedule (MPS) is a production planning tool that aligns production with demand, detailing products, quantities, and timelines with a planning horizon of several months to years.

» The benefits of master scheduling include inventory optimization, forecast accuracy benchmarking, accurate capacity, labor, and financial planning, and potential increased customer satisfaction.

» Although MPS is mostly associated with make-to-stock environments, it can be used in make-to-order as well as mixed-mode manufacturing.

» Key inputs of MPS include current inventory, demand forecast, firm sales orders, and production quantities. In addition, companies can account for safety stock and production capacity.

» Proper management of master production schedules

entails balancing demand and supply, aligning the plans with business goals, regularly updating the MPS, collaborating across departments, using MPS-enabled ERP software, and tracking key metrics.

INDUSTRIA L MACHINERY DIGEST COM IMD | 31

800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com CLICK TO WATCH VIDEO 800-4-SKYHOOK 800-475-9466 • 208-365-5770 www.skyhookmfr.com The

saving

time and money! ERGONOMICS & SAFETY

Sky Hook is your personal safety lifting solution, preventing lifting injuries while

you both

MRPeasy uses color-coded fields to show users sufficient, possibly insufficient, and insufficient production capacity.

MRPeasy allows you to use the MPS for effortless purchase planning.

Frequently asked questions

What does a master production schedule tell you?

A master production schedule tells you the quantity of each product to be manufactured period-by-period.

CHAR-LYNN HYDRAULIC PRODUCTS

LOW SPEED

HIGH-TORQUE

MOTORS… The Char-Lynn motor range consists of three major types based on the valving used to distribute fluid through the Orbit gear set (geroler or gerotor), Spool Valve, Disc Valve and VIS (Valve-in-Star). A variety of displacement sizes are available in each of the three motor types to provide a wide range of speeds and torques.

STEERING CONTROL UNITS… offer these advantages:

• Minimal steering linkage reduces cost, provides design flexibility.

• Complete isolation of load forces from the control station.

• Continuous, unlimited control action with low output torque.

• Wide selection of control circuits and meter sizes.

• Works with many kinds of power steering pumps or fluid supply.

GEAR PUMPS… Eaton Series 26 gear pumps with 13-tooth gears minimizes flow ripple to reduce noise and vibration. Bearing lubrication system uses inlet oil rather than high pressure oil, improving volumetric efficiency and power output. The 13 available displacements and many mounting configurations provide for an easy retrofit. Other series available.

What is an example of master production scheduling?

An example of master production scheduling would be if a furniture manufacturer would have 40 chairs in stock. Their sales forecast says that they will sell 200 of them during the period, meaning that they will need to produce 160 chairs during that period in order to match the demand.

What is the difference between MRP and master production schedule?

The difference between MRP and master production schedule is that MPS focuses on when and how much to produce, while MRP determines the materials and resources required to fulfill the MPS.

What is master production schedule in lean?

In lean, the master production schedule is a streamlined plan that drives production based on actual demand while minimizing waste and inventory.

Read More Online! Links Below!

32 | IMDQ | Q3 2023

WWW.MACMHYDRAULIC.COM 7355 N. Lawndale Ave., PO Box 6, Skokie, IL 60076 PHONE: 847-676-2910 FAX: 847-676-0365

Industrial Machinery Digest's Monthly Product Showcase features the latest from some of the manufacturing industry's top suppliers.

Marty the Robot Gets an Upgrade: Enhanced Customer Experience at Stop & Shop Stores

Badger Technologies, a leading name in retail automation and a product division of Jabil, has joined forces with Stop & Shop to enhance the capabilities of Marty the Robot at over 300 locations. Originally introduced in January 2019, Marty was among the first autonomous robots to be implemented at a large scale in the retail industry. Designed to keep stores clean and safe, Marty is stepping up its game with new features aimed at inventory management and customer interaction.

The upgraded Marty now excels in real-time product monitoring. This robot not only identifies out-of-stock items but also notifies store staff about misplaced products, thus ensuring better on-shelf availability. Gordon Reid, president of Stop & Shop, emphasizes that Marty's ability to improve in-store efficiency will allow staff to devote more time to customer service.

But Marty's influence extends beyond store aisles. The robot is becoming an active participant in Stop & Shop's “Feed it Forward” community outreach initiatives. Recently, Marty visited a young cancer patient as part of a pediatric cancer fundraising campaign. On September 22, Marty will also appear at Fenway Park alongside the Boston Red Sox for Hunger Action Month, focusing on tackling food insecurity among students.

Incorporating advanced technologies like computer vision and cloud-based analytics, Marty provides real-time inventory tracking that facilitates quicker restocking and price adjustments. These upgrades are in line with Stop & Shop’s strategy to create a more connected customer experience, blending in-store and online shopping seamlessly.

According to William "BJ" Santiago, CEO of Badger Technologies, this new iteration of Marty underscores Stop

& Shop’s ongoing commitment to boosting store efficiency while adding value for shoppers. The updated robot helps in refining various aspects of the retail ecosystem, including order fulfillment, inventory management, and even e-commerce.

By focusing on both customer-centric and community-building functionalities, the new Marty represents a meaningful evolution in retail automation, offering a win-win scenario for both Stop & Shop and its customer base.

Beckhoff Vision Unveils Integrated, AwardWinning Image Processing Solution

Beckhoff Vision has launched a groundbreaking product line that merges machine vision hardware and automation software into a singular focus. This comprehensive offering includes EtherCAT-enabled industrial cameras, lighting, and lensing components, all supported by the TwinCAT Vision software, providing an all-in-one solution for diverse industrial requirements.

The hardware line-up features area scan cameras with IP65/67 protection, capable of delivering high-quality images via Sony CMOS sensors. These cameras offer up to 24-megapixel resolution and impressive GigE Vision transfer

34 | IMDQ | Q3 2023 produCT sHowCase

PRODUCT SHOWCASE

WANT TO BE FEATURED? Send your latest product information to editorial@indmacdig.com