Informing the electrical industry for 150 years

Listen to what your OLTC has to say

The vibro-acoustic measurement (VAM) method focuses on the mechanical integrity of the On Load Tap Changer. Therefore, the new VAM1 accessory for TESTRANO 600 records a detailed vibration pattern produced during the switching operation using piezoelectric sensors.

omicronenergy.com/testrano600

Instead of turning to coal power plants, we should stop wasting and store renewable energy

The grid connections process needs to get smoother if we hope to hit net zero

offered an alternative career path, instead of being pushed to

Energy Storage, Standby Power &

UPS

Power Generation, Transmission &

Distribution

Final Say It’s time for students to

university 20 24 28 March / April 2023 Volume 257 | No 1 www.electricalreview.co.uk

be

ME! AD23003-TESTRANO-600-VAM-184x198mm-ENU.indd 1 2023-01-30 11:06:39

SCAN

5YearWarranty

as standard on all UPS models up to and including 3kVA

Reliable power for a sustainable world

Contents 10 18 22 26 12 6 Regulars 4 • Editor’s Comment The final, final warning. 6 • News Stories from the sector. 8 • Gossage Gossip The latest from our industry insider. 26 • Talking Point Nathan Barwell from Seaward considers how PAT technology continues to evolve and its use for general safety management applications. 28 • Final Say Classrooms need to spark an interest in alternative career paths for students, such as electrical engineering, says Sarah Chapman, Senior Technical Manager at 3M EMEA. 30 • Product News All the products that you won’t want to miss. Features 10 • Cables & Cable Management Alex Smith, Technical Director at Flexicon, shares his advice on what to look out for when choosing your cable protection solution. 16 • Energy Storage, Backup Power & UPS The world’s tallest wooden building is a showcase for the importance of battery energy storage systems, as it relies on the tech for its incredibly important sprinkler system. 22 • Power Generation, Transmission & Distribution To achieve net zero, the UK needs a smoother grid connection process for clean energy projects, according to Estelle Limon, Policy Coordinator at Regen.

EDITOR

Jordan O’Brien

jordano@sjpbusinessmedia.com

CONTRIBUTING EDITOR

Kayleigh Hutchins

kayleigh@datacentrereview.com

DESIGN & PRODUCTION

Rob Castles

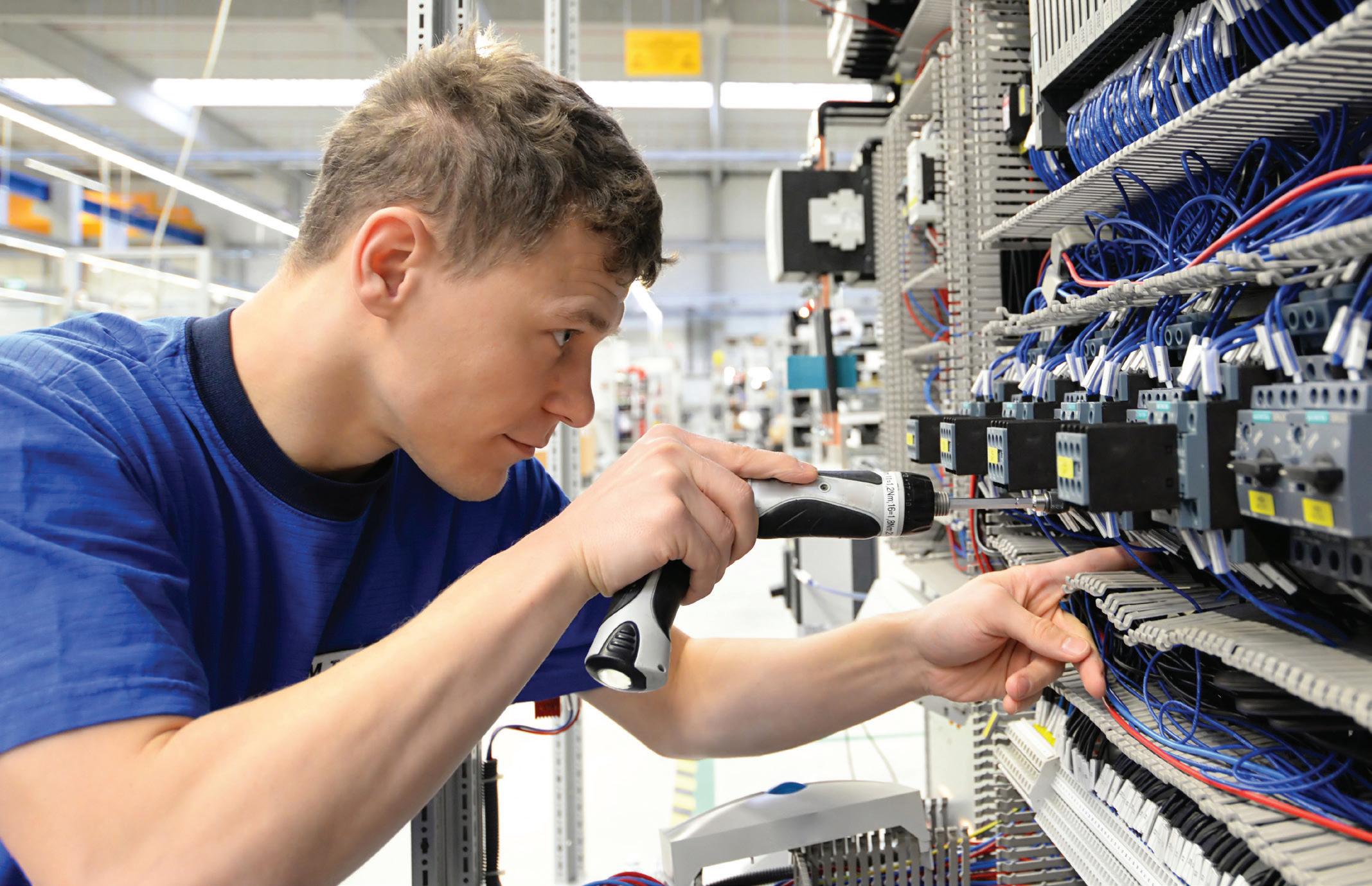

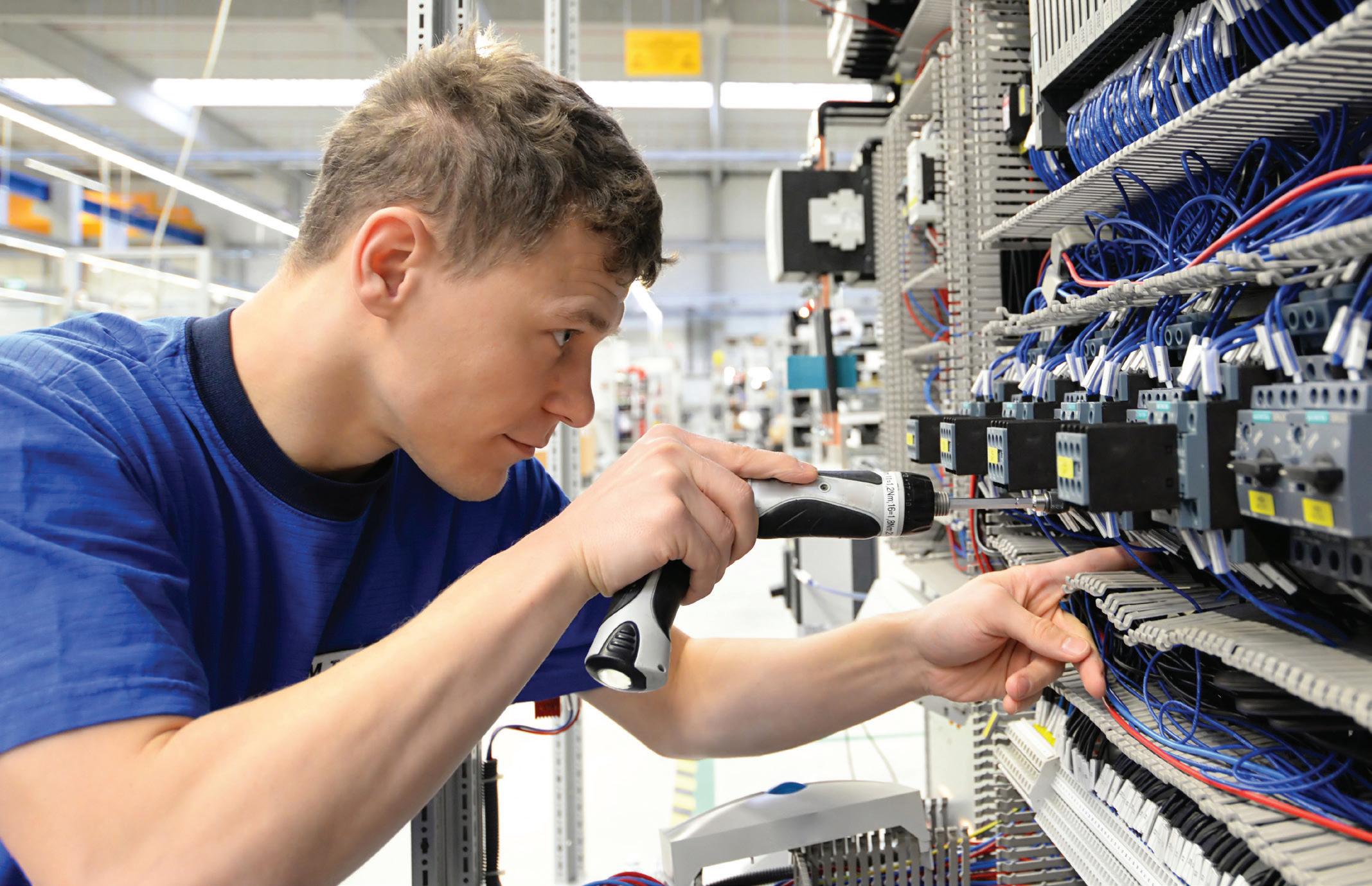

robc@sjpbusinessmedia.com

GROUP ACCOUNT DIRECTOR

Sunny Nehru

+44 (0) 207 062 2539 sunnyn@sjpbusinessmedia.com

SENIOR BUSINESS DEVELOPMENT MANAGER

Abdul Hayee

+44 (0)207 0622534 abdulh@sjpbusinessmedia.com

GROUP COMMERCIAL DIRECTOR

Fidi Neophytou

+44 (0) 7741 911302 fidin@sjpbusinessmedia.com

PUBLISHER

Wayne Darroch

Printing

Editor’s Comment

This is our final, final warning

It’s officially 2023, which means the clock is slowly ticking for the UK Government and Governments around the world to take urgent action to tackle climate change and put us on a path to net zero.

At least, that’s according to the latest report from the UN’s Intergovernmental Panel on Climate Change, which has issued its final warning regarding the need for action, noting that the “window of opportunity to secure a liveable and sustainable future” is “rapidly closing.”

This isn’t the first time we’ve had what seems like a ‘final warning’, with the IPCC’s 2022 report commenting that it was ‘now or never’, while acclaimed nature broadcaster David Attenborough warned world leaders that 2021 was the last chance to prevent ‘runaway’ climate change.

However, despite the constant ‘final’ warnings, Governments continue to drag their feet and conspiracy theorists claim that hearing the same thing year on year out proves that climate change isn’t real. Unfortunately for those not heeding those warnings, climate change is very, very real.

According to the IPCC, average global temperatures have already increased 1.1°C from the late 19th century, and that increase alone is already causing widespread adverse impacts for the planet.

You just need to look at the climate-related damage done over the last few years to see the impact of climate change with your own eyes. In fact, you don’t even have to go back a few years. Just within the last month, Cyclone Freddy has become one of the longest-lived tropical cyclones on record, as well as one of Earth’s most energetic storms, and killed at least 400 people in both Malawi and Mozambique. It’s a fact that weather events are becoming stronger and far more unpredictable.

In fact, the strength of these weather events has even surprised the scientific community that has spent years warning about the potential impact of climate change. The IPCC report even notes that so much damage is already occurring with 1.1°C of warming, that it’s possible the harm caused by further climate change will be even greater than had been predicted.

So, with that in mind, now it really is the final warning. Electrical Review has stood witness to the amazing things this industry has done to reduce carbon emissions for 150 years, from its work on developing LEDs, renewable energy developments, cable management products that use less carbon, and so much more. From all of us at ER, thank you for all your hard work and dedication to this planet.

Jordan O’Brien, Editor

4 www.electricalreview.co.uk ???? Electrical Review | March / April 2023

27 Clements

EC4N 7AE

is a controlled circulation monthly magazine

free to selected personnel at the publisher’s discretion. If you wish to apply for regular free copies then please visit:

Electrical Review is published by Room 2.13, 27 Clements Lane London, EC4N 7AE Any article in this journal represents the opinions of the author. This does not necessarily reflect the views of Electrical Review or its publisher – SJP Business Media

0013-4384 – All editorial contents © SJP Business Media Follow us on Twitter @elecreviewmag Join us on LinkedIn

by Buxton Paid subscription enquiries: subscriptions@sjpbusinessmedia.com SJP Business Media Room 2.13,

Lane London,

Electrical Review

available

www.electricalreview.co.uk/register

ISSN

BECOME AN AICO EXPERT INSTALLER

Aico’s free, award-winning Expert Installer training scheme is FIA CPD accredited and is designed to make sure installers have all the information they need to correctly install domestic home life safety systems, including Fire and Carbon Monoxide alarms and Environmental Sensors.

Once you become an Expert Installer, you will be invited to join the Aico Installer Community – a connected online platform built to support Expert Installers.

Members of the community are eligible to participate in Aico’s free-of-charge City & Guilds Assured Training - Domestic Fire & CO Alarm Systems.

Visit

www.aico.co.uk | 01691 664100 | enquiries@aico.co.uk

The European Market Leader in Home Life Safety

our website to

sign-up.

News

National Grid ESO promises to speed up grid connections

National Grid ESO is reforming the process in which to request a grid connection, hoping that it will clear the bottleneck.

Recently it was revealed that many projects requesting a grid connection were being told that they had to wait until late 2030 before they would receive said connection, with industry experts concerned that such a delay would risk the UK achieving its net zero goal.

To speed up the process, National Grid ESO has revealed a five-point action plan, which includes:

1. National Grid ESO will be operating a transmission entry capacity amnesty until April 2023. This will allow developers to terminate their connection contracts without incurring liabilities. This should free up capacity in the queue, given as little as 30% of projects that apply for a grid application actually get built.

2. An update to ESO’s modelling assumptions should more accurately reflect current connection rates and reduce the assumption

that most projects in the queue will connect.

3. Energy storage will no longer be treated in the same way as other connection projects, allowing them to connect to the grid faster and free up capacity for other projects.

4. There will be new contractual terms for connection contracts to manage the queue more efficiently. It will allow projects that are going ahead to connect sooner, while those that are stalled will gain the ability to leave the queue.

5. Finally, energy storage projects will soon be

given the option to connect to the network sooner, although they may be required to turn off more frequently when the system is under stress without initially receiving any payment for downtime.

This five-point plan is the biggest reform to the connection rules in 20 years, which is when the process was first designed. At the time grid connection timelines were not a major issue, as National Grid ESO only had to deal with a few applications by a small number of large fossil fuel generators.

Energy bills could be £1,750 lower had UK transitioned to renewables faster

According to the Energy & Climate Intelligence Unit, if the UK had shifted away from oil and gas more quickly to technologies including renewables, home insulation, rooftop solar panels, heat pumps and electric vehicles, households could have been saving around £1,750 on energy bills in 2022.

On top of this, £400 has been added to food bills this year due to the impact of climate change and oil and gas prices on the food and farming system. The combined impact on a household’s bills could potentially be in the order of £2,150.

For the UK as a whole, the costs of slow deployments of net zero technologies, such as the ban on onshore wind, the cutting of insulation programmes and the slowdown in rooftop solar panel installations, could be in the region of £39 billion.

Signify taps former Schneider VP to lead its business in UK & Ireland

Signify has announced that Nico Van der Merwe has taken over as the CEO of its UK & Ireland business.

Van der Merwe is a veteran of the electrical industry, having spent the last 15 years at Schneider Electric, most recently as the company’s Vice President for Home & Distribution in the UK and Ireland.

EDF confirms plans to extend life of nuclear reactors at Heysham and Hartlepool

Nuclear reactors at Heysham and Hartlepool will continue operating until 2026, two years longer than operator EDF had initially planned.

Having taken on responsibility for the Heysham 1 and Hartlepool nuclear reactors back in 2009, EDF had expected to begin decommissioning the plants in 2014. However, following an extensive investment by the French energy giant, the company later announced that it would be able to continue generating electricity from the site until 2024. That date has now been pushed back yet again, with both generators expected to continue generating electricity for the UK grid until March 2026.

6 Electrical Review | March / April 2023

UK Power Networks spearheads world-first smart transformer trial

A world-first smart transformer trial is set to provide unparalleled network insights to help maintain reliable power supplies in the south of England.

UK Power Network’s Project Stratus will see smart electricity transformers installed within existing substations at Uckfield and New Romney in East Sussex which, if successful, will provide live data on electricity usage and demand, on a scale never-before achieved. This will help the company increase network resilience and lay the groundwork for a low carbon future.

Using state-of-the-art power electronic technologies, the smart transformers can flexibly adapt to make sure power is directed when and where it is needed, balancing load on the network, and protecting against multiple kinds of potential faults.

With greater visibility of the low voltage network, UK Power Networks will be able to release more energy on the network during times of peak electricity demand. Stratus’s optimisation algorithm can also seamlessly meet the changing needs of customers at different points of the day, without disrupting their energy supply.

UK’s lack of energy storage meant 1.35 TWh of renewable energy was lost

The UK wasted 1.35 TWh of renewable energy between October 2022 and January 2023 due to a lack of energy storage, new research has suggested.

That’s according to Stonehaven, an international strategy consultancy, which revealed that during the four-month period National Grid ESO asked for several wind turbines to be switched off to avoid overloading the grid, despite the fact that they would have generated enough electricity to power 1.2 million homes.

New European research project hopes to give new life to old EV batteries

A new £4.5 million research project is set to establish a process to recycle or reuse EV batteries to help prevent up to nine million tons of battery waste per year going to landfill. While some car manufacturers have announced their intention to give old batteries a new life as energy storage, the Europeanwide REBELION project will look at other ways to give used EV Lithium-ion batteries a second life, or whether they can be recycled in a more efficient way.

UK joins EU in classifying nuclear energy as ‘green’

The UK has joined the European Union in officially classifying nuclear energy as ‘green’, which will have a big impact on the investment the industry will receive. The new classification means that nuclear energy will receive the same level of incentives that are currently available to other ‘green’ technologies, such as wind and solar farms.

Hornsea Four offshore wind farm on hold due to dispute with CCUS project

Ørsted has been forced to put the construction of its Hornsea Four offshore wind farm on hold due to an ongoing dispute with a carbon capture usage and storage (CCUS) project being led by oil giant BP.

For those of you wondering why these two projects sound familiar, that’s because they were the subject of a Gossage Gossip column in March last year. At the time our columnist explained that the competition between the two projects could lead to a reduction in the size of the Hornsea Four project by as much as 675 MW, which could make the project uncompetitive.

Now it seems that the Planning Inspectorate has sided with BP’s Endurance CCUS project, with it delaying Hornsea Four’s permitting decision until mid-July. Critics have argued that this would be short-sighted, given it would delay 2.6 GW of offshore wind being added to the grid at a time when the country is racing to achieve net zero.

All wind turbine blades could now be recyclable thanks to new breakthrough

Vestas has unveiled a brand-new chemical process that could lead to all wind turbine blades becoming recyclable.

While being able to recycle wind turbine blades is nothing new, it previously required blades to be engineered with specific materials. Take Siemens Gamesa’s RecyclableBlade: it was the first commercial blade to offer a comprehensive recyclable solution, but it was a specific product that businesses had to buy – it still meant existing blades and products from Siemens Gamesa’s competitors would end up in landfill.

That’s why Vestas’ revelation is a little more interesting, it removes the need to buy a specific product, or changes the design or composition of the materials used for wind turbine blades. Instead, through a special chemical process, all epoxy-based blades can be broken down into their raw material that can be reused to make new wind turbine blades, or for other purposes.

Vestas, as well as its partners Aarhus University, Danish Technological Institute, and epoxy maker Olin, discovered the chemical process as part of a coalition set up in May 2021, dubbed the CETEC project – Circular Economy for Thermosets Epoxy Composites. Having successfully demonstrated its abilities, the companies now plan to scale the process.

NEWS www.electricalreview.co.uk 7

Gossage Gossip

An unreliable reference

Caroline Lucas is the sole Green MP in the House of Commons. She is also one of its most diligent placers of written Parliamentary Questions. Such questions have two overt roles. The first, naturally, is to obtain formal answers on the record from Government ministers. Just occasionally, these do include genuinely useful information. The second, less obviously, is to draw the attention of the outside world, beginning with fellow MPs, to specific developments. Because the one publication every MP reads is the official parliamentary Order Paper, which contains these Questions. Earlier this year the Daily Mail published on its business pages a story which nobody in the Government will have relished being publicised. It concerned the Government’s struggles to fill the large gap in the money available to build the Sizewell C nuclear power station. With the Chinese government having been forced to withdraw, increasingly desperate attempts are being made to persuade any financial institution – especially pension funds – to contribute towards Sizewell’s anticipated horrendous £30 billion capital budget.

The Mail’s exclusive story stated that two of the largest pension funds, BT and NatWest, were both saying “thanks, but no thanks” to contributing to the White Elephant-manqué. Being deeply sceptical about the merits of nuclear power, Caroline Lucas thought she would ensure that her parliamentary colleagues got to hear about this. So she prepared a Parliamentary Question, asking what the Government thought might be the implications for Sizewell, of this Daily Mail story chronicling this big thumbs down from the key moneymen. She went along to the official parliamentary Table Office to place her question, but was told firmly that she would have to word it very differently. She could merely ask about how “discussions” with the two Pension Funds were proceeding. Not a word about the truth that they had ignominiously collapsed. Why did the parliamentary authorities refuse her original wording? The answer is simple. The news story she was seeking to cite was only from the Daily Mail. And that publication, she was told, is definitely not “a reliable newspaper of reference.” I believe that Wikipedia takes precisely the same view about Britain’s most read newspaper.

Go until they blow

It may have received considerable publicity, but frankly the announcement by Electricité de France that they intend to keep open until 2026 the (admittedly very elderly) nuclear power stations, Heysham 1 & Hartlepool PSR, was scarcely surprising. After all, as recently as 2019, the ONR (Office for Nuclear Regulation) had completed their 10-year periodic safety review covering both power stations. Subsequently the Regulator issued a Decision letter agreeing to the continued operation of the site through to 2029.

Those anxious to see such geriatric power stations closed for good have long argued that, as they are much the same vintage as both Torness and Heysham 2 power stations, they should be placed on the same closure trajectory. But the reason for the demise of those two were problems that emerged during 2021 regarding online refuelling. Certainly both Heysham 1 & Hartlepool were designed to enable online refuelling. But as in practice that facility was never used at either, that issue simply does not arise. Existing nuclear power stations become more and more costeffective in return-on-capital terms, the longer they run. There is no history of undue concerns about safety yet for either of these two. In that rather vulgar phrase, effectively they go until they blow. Or preferably, until immediately before doing so.

Here comes the sun

Hooray for Halifax

The venerable town of Halifax in West Yorkshire is entirely populated by scrupulously honest people. At least, that is what Northern Powergrid is fervently hoping.

Most unusually, the company had been seeking to reimburse customers who had been overpaying their fuel bills. They didn’t use BACS to do so, nor put the refund onto their customers’ credit cards. Instead they placed each of the requisite cheques into the post.

It was only when one customer, a Mr Gareth Hughes of Halifax, contacted them that they realised that this old-fashioned approach might be presenting them with quite a problem. Mr Hughes was querying why that morning’s post at his home had included a Northern Powergrid cheque, made out to him, for – wait for it – some £2,324,252,080,110. A bit more than the £110 he had anticipated.

Was there any explanation for this generosity? Subsequently, a distinctly red-faced spokesperson admitted they had investigated the matter and had established why this cheque was quite so enormous. The conclusion was, “A clerical error was caused by the electricity meter reference number being incorrectly quoted as the payment sum”.

The company stated they were confident that they had now identified no less than 74 of their customers, each with a Halifax postcode, and each of whom had also been sent a compensation cheque with an incorrectly generous payment amount. Somewhat plaintively, the company has very publicly thanked all those who were “honest” about the error. And presumably is praying that every other customer is just as honest as Mr Hughes.

Milestones may be arbitrary, but the morale boost they provide is not. The expectation is that the world has now installed enough solar panels to generate 1 TW of electricity directly from the sun.

The calculation that the world has now hit 1,000 GW of solar capacity is based on the confirmation that 183 GW was installed worldwide in 2022. There was already 788 GW of capacity in place at the end of 2021. These two values total 971 GW of installed solar. So the calculation can be confidently made that, three months into 2023, the world has almost certainly now also built the remaining 29 GW required to breach the 1 TW mark.

The largest contributor to this capacity is China. By 2016 the People’s Republic had installed 100 GW, and has expanded capacity at a rapid rate since. Meanwhile, the European Union hit 100 GW in 2015, and the US hit 100 GW in the first quarter of 2021. Collectively, these three regions alone represent the majority of the world’s installed solar capacity. The UK has 14GW, about 4.4% of renewables mix.

8 Electrical Review | March / April 2023

M *Subject to minimum quantities and fair use policy

Time saving cable protection

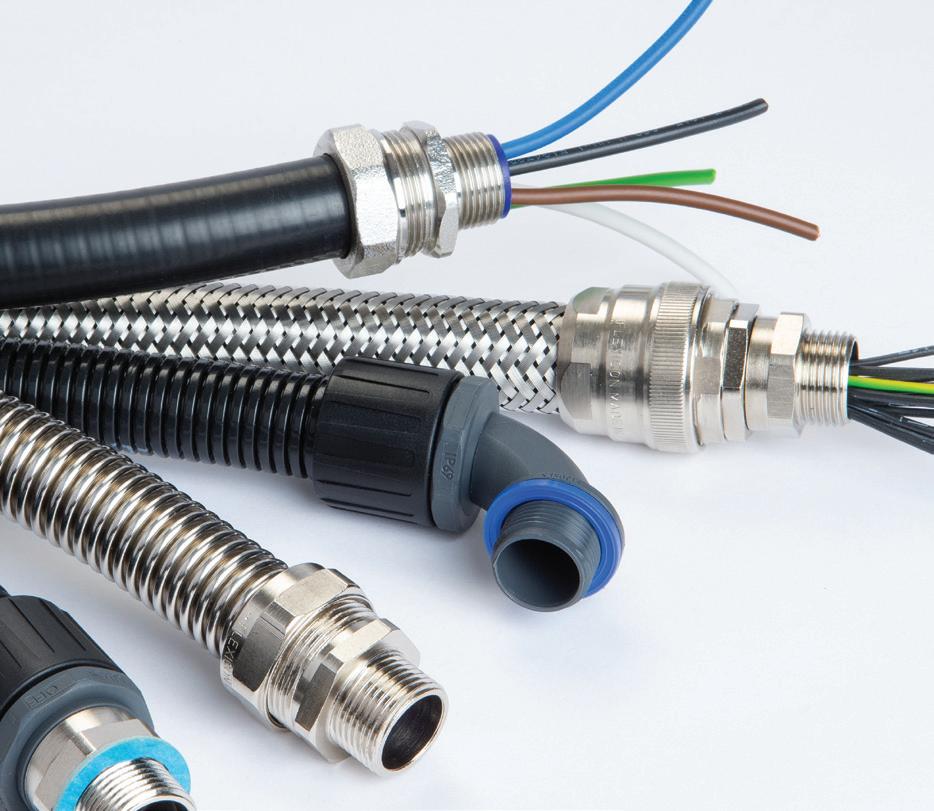

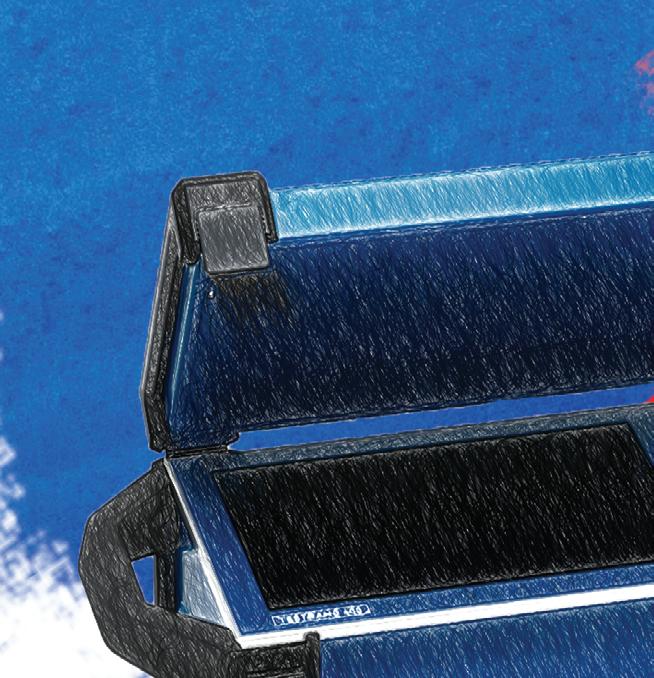

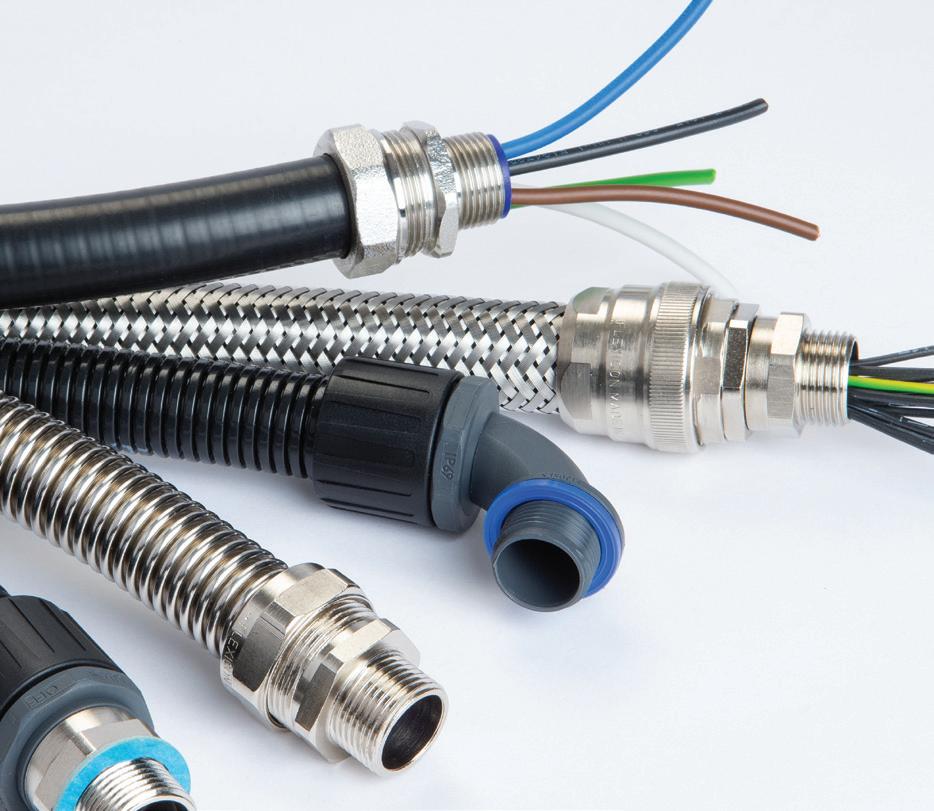

Choosing the wrong cable protection could result in potentially compromised cabling, lost time and higher expenses. Alex Smith, Technical Director at Flexicon, shares his advice on what to look out for when choosing your cable protection solution.

One of the biggest challenges for electrical installers and contractors is time. The requirement to move on to the next task quickly will often see electricians defaulting to products they know well and have used multiple times.

While it can be tempting to select based on previous installation experience or personal preference, when it comes to specifying cable protection systems, it is well worth considering all the available options, especially where time is an important factor.

A brief history

Historically, conduits and conduit fittings were only available in metal, but, over time, the development of engineered plastics saw more flexible, corrosion and water-resistant solutions enter the market.

These solutions could withstand large temperature ranges, offered improved fuel and oil resistance, and enjoyed a high level of mechanical strength.

As the market acceptance for these systems grew, nylon polyamide became an increasingly important material. However, metallic and

10 Electrical Review | March / April 2023 CABLES & CABLE MANAGEMENT

Metal

Composite

Nylon

composite systems also remain in demand because of their excellent mechanical strength and EMC screening possibilities.

Specification first

Specifying cable protection based on one property alone can be a costly mistake and the full range of environmental factors should be considered. These can include exposure to extremes of temperature, UV radiation, harsh chemicals and the likelihood of water or dust ingress. Additionally, fire performance, compression strength and impact or abrasion resistance, risk of explosion or even the resistance to the build up of bacteria should be considered.

Nylon, metal or composite?

Where fatigue life or impact resistance is important, installers should consider nylon polyamide corrugated flexible conduits, which can offer high impact strength and recovery if crushed, combined with excellent temperature performance.

Polypropylene and PVC conduit systems are available; however, both systems are inferior to nylon polyamide when it comes to fire performance, resistance to solvents and abrasion, as well as UV properties in external applications exposed to the damaging effects of the sun.

With no exposed metallic content, non-metallic conduits do not rust or corrode thus maintaining performance and appearance over time. In addition, it is worth considering labour and installation time – nonmetallic systems are often quicker to install than metallic options as they are easier and faster to cut. Non-metallic fittings will typically be one piece and simply push on and twist to secure. This makes them easier to handle as well as providing a lighter weight system.

For installations subject to increased UV exposure, it is important when specifying non-metallic and polymer-coated metal conduit to consider that UV radiation will naturally degrade any plastic materials. Failure could result in materials cracking, an increase in brittleness, reduced flexibility and lower impact strength.

Metallic flexible conduit typically has a higher level of crush resistance, high mechanical strength and can provide excellent EMC screening properties. Metallic systems are ideal for applications that require a very high compression or pull-off strength, or where there is the need to protect cables from exposure in hazardous environments. They also offer excellent performance for extremes of temperatures, both high and low – with uncoated options, such as stainless steel, offering a performance range from +600°C through to -100°C.

Composite products, such as plastic sheathing on metal conduits, metal over-braiding or metal threads on plastic fittings can also offer the ideal combination of light weight and high strength.

Retrofitting options

In existing applications, retrofitting cable protection has, traditionally, been a more complex task, with the installer required to pull existing cabling through the open end of a conduit system.

Conduit system manufacturers are therefore developing enhanced retrofit options to make it easier and quicker to install cable protection in existing applications, such as interlocking slit conduit. The construction allows existing cabling to be inserted laterally via a slit opening, enabling the installer to wrap a flexible conduit around the cables retrospectively with minimal disruption and without the cable being exposed.

It is also important to consider the cable routing. Traditional split conduit options can potentially expose cabling when bent or routed around corners, whereas newer options can maintain continuous protection of the cabling irrespective of orientation or routing.

Don’t forget the fittings

The specification process should also take into consideration the range of fittings available, especially where these can help reduce installation time. Conventional fittings can take time to assemble and install, whereas newer designs feature innovations such as simple push and twist conduit connection. These can offer significant time and cost benefits, particularly where there are numerous cables to terminate.

Elsewhere, design improvements to help simplify cable management and routing are available. Some junction boxes now feature easy-toconnect entry points which can be used with flexible conduit. These use push, twist and lock connectors to make a reliable connection in seconds, with the highest ingress protection of IP66, IP67, IP68 and IP69. This is without having to remove knockouts, drill holes, fit lock nuts or even torque tighten any components.

Bespoke-designed cable protection

For more complex application requirements, customers should speak to their supplier to discuss bespoke options.

These could include conduit supplied in non-standard or precut lengths, in larger or smaller diameters or with different thread termination or fitting options. Additionally, more complex requirements, such as altering performance characteristics to meet a certain temperature requirement, compression strength or abrasion resistance or to achieve a greater fatigue life may also be considered.

www.electricalreview.co.uk 11 CABLES & CABLE MANAGEMENT

The requirement to move on to the next task quickly will often see electricians defaulting to products they know well and have used multiple times

It’s time to reduce the embodied carbon on your project

Specifying cable management that uses recycled content can be a quick and effective ‘environmental win’, according to

Alan Goode, Business Development Manager (Specification)

at Marshall-Tufflex.

We are living in an era where climate change is hard to ignore. Last year, the UK experienced some of the most extreme weather events – from scorching temperatures and torrential rainfalls – and watched as other parts of the world suffered from devastation caused by monsoons, flooding, prolonged droughts and hurricanes. These extreme weather cases are set to continue and putting measures in place to address these is now a responsibility for us all.

The impact of the built environment

As part of this, improving the sustainability of our buildings is a huge focus. The UK’s built environment is responsible for 25% of the UK’s greenhouse gas emissions and emits carbon in two ways: through the

12 Electrical Review | March / April 2023 CABLES & CABLE MANAGEMENT

energy consumed day-to-day (operational carbon); and the CO2 emitted in producing materials and products – from the extraction of raw materials, to manufacturing, to installation in the building, as well as their disposal at the end of their life (embodied carbon).

sustainable practices as a factor for selecting suppliers and contractors, with many looking for ways to include more low carbon and low waste materials.

How can cable management reduce embodied carbon?

With all of this in mind, it has never been more important to look closely at each element of a project and identify where simple improvements can be made. One such area is the use of responsibly-sourced plastic products, especially cable management systems.

Whilst often overlooked as a contributor to embodied carbon, cable management can in fact, represent a substantial component of an interior fit-out, especially for larger buildings and sizeable developments. As such, it is worth considering the level of recycled content used in the manufacture of any PVC-U cable management systems specified – as here there is a real opportunity to have a positive impact on a project. It really can be a simple, and often cost neutral, way to help reduce embodied carbon and divert materials away from landfill.

For some time, the emphasis has been placed on reducing the operational carbon with measures that improve energy efficiency and reducing the emissions associated with energy usage – such as lighting, heating, and ventilation. However, to truly achieve net zero by 2050 and tackle the climate emergency that is on the horizon, embodied carbon must also be considered – from the planning stages and design of a building through its life cycle and demolition – and every person in the supply chain has a role to play in reducing this.

As a result, building owners and developers are increasingly using

This approach is reinforced by research undertaken by the Sustainable Industrial Systems Group at the University of Manchester, which uncovered the scale of the carbon savings that can be made by utilising recycled PVC-U content. Its study determined, for example, that a PVC-U window manufactured using recycled content has between 17 and 20 times less embodied carbon than those manufactured from virgin plastic.

So, what should specifiers be looking for when it comes to cable management solutions that offer this environmental benefit?

The recycled content used in the production process for conduit and trunking can be sourced from either post-industrial PVC-U waste, such as discarded material and off-cuts from manufacturing, and postconsumer waste from products such as PVC-U windows removed from buildings.

For example, in 2022, PVC-U cable management products from Marshall-Tufflex were manufactured using 69% recycled material across the range, while the company’s all-white conduit, Mini and Maxi trunking lengths are currently manufactured using between 80 and 100% recycled material.

If other manufacturers took this stance, the benefits would be huge – which is why Marshall-Tufflex is calling on specifiers and everyone in the supply chain to choose products with a minimum of 50% recycled material, for it to become the industry norm by 2028.

Choosing products from a trusted manufacturer will help to ensure that the recycling process has not compromised the quality, durability or appearance of the products. Specifically, only selecting products from manufacturers which implement a rigorous quality testing regime to ensure products meet all quality expectations.

Sustainability is now a key consideration in the specification of building materials and products. Choosing PVC-U cable management solutions with recycled content from trusted manufacturers is a simple and cost neutral way of reducing embodied carbon and waste and contributing to a more sustainable future.

www.electricalreview.co.uk 13 CABLES & CABLE MANAGEMENT

Whilst often overlooked as a contributor to embodied carbon, cable management can in fact, represent a substantial component of an interior fit-out

A PVC-U window manufactured using recycled content has between 17 and 20 times less embodied carbon than those manufactured from virgin plastic

FIGURE 1

Top: Raw signal from OLTC operation (left) and detailed diverter switch operation (right).

Introduction

The on-load tap-changer (OLTC) is crucial for maintaining a stable voltage level in the electrical grid. With the help of the OLTC, the transformer turns ratio can be adjusted under load to account for voltage fluctuations. This mechanical switching process causes heating and arcing inside the OLTC. Consequently, various components will experience wear and tear over their lifetime. Increasingly advanced diagnostic tools have been developed that can reliably analyse and assess the condition of the OLTC.

1

The following example discusses a condition assessment based on combining a dynamic resistance measurement (DRM) and a vibroacoustic measurement (VAM). While the DRM concentrates on the electrical characteristics when the load current is switched, the VAM focuses on the vibration pattern that the OLTC produces during

the switching operation. The evaluation of the VAM results relies on comparing them with reference data, such as a fingerprint or with sister units.

Measurement Setup

Practical application for on-load tap changer vibro-acoustic fingerprinting and diagnostics 2

The mechanical movements and arcing during an OLTC switching operation produce a wide frequency range of vibrations. The VAM allows these vibration patterns to be analysed and compared with reference data and enables the mechanical condition of the tap-changer to be assessed. The signals are sampled at 250 kHz by the measurement system using integrated electronic piezo-electric (IEPE) acceleration sensors. This way, a non-invasive measurement can be performed on the transformer. This can even be done with the transformer in operation throughout the entire process.

14 Electrical Review | March / April 2023 SPONSORED FEATURE

FIGURE 2 Top: Envelope curve of

switch operation. Bottom: Corresponding DRM curve. Damping in dB 6.85 -50 0 6.90 6.95 7.00 7.05 7.10 7.15 7.20 Current in A 6.85 9.9 10.0 6.90 6.95 7.00 7.05 7.10 7.15 7.20 Envelope DRM

diverter

Bottom: Corresponding

curve. Voltage in V 0.0 0 -50 0 1 2 3 4 5 6 4.9 0 -50 5.0 5.1 5.2 4.9 5.0 5.1 5.2 0 1 2 3 4 5 6 2.5 -2.5 0.0 2.5 -2.5 Damping in dB Time in s Time in s Voltage in V Damping in dB Raw Signal Envelope

envelope

VAM Data Evaluation

3

The signal recording covers the entire tap switch operation from motor start to finish. The strongest signal is obtained during the diverter switch operation. As a first post-processing step a wavelet transformation is applied to the sensor signal. The so-called envelope curve is derived through integration in a typical frequency range from 10 kHz to 100 kHz and subsequent Gaussian filtering. The resulting curve reflects the energy of the raw signal in the defined frequency range. It can be used to compare reference data such as factory fingerprints or data from sister units. Figure 1 illustrates a sensor’s raw signal and the corresponding envelope curve in dB over time.

Figure 1 shows a detailed view of the diverter switch operation (highlighted). Attention should be paid to shifting peaks and less so to amplitude changes between the reference and the actual envelope curve to identify possible mechanical changes in the OLTC. The switching time analysis based on the envelope curve shows a considerably higher tolerance for external influences, making it much more suitable for comparisons.

Combining VAM and DRM

The VAM and DRM measurements of an OLTC represent mechanical and electrical time sequences, respectively, and provide an opportunity for a complementary evaluation. Using the vibro-acoustic measurement, all OLTC components that produce sufficient vibrations are picked up and can be considered for evaluation. In contrast, a dynamic resistance

measurement is only affected by operations that cause a change in the test current. Individual events in the DRM curve can typically be associated with the movement of diverter switch contacts. Thus, this information can map parts of the envelope curve to specific steps in the switching operation, such as opening or closing contacts.

Figure 2 shows the synchronous measurement result of an envelope curve and the corresponding DRM curve and illustrates which events are picked up by the VAM and DRM curve respectively.

4

Case Study – Comparison of Sister Units

The VAM results of two 410 kV / 27 kV transformers are discussed in the following example. Both units have MR Oiltap Type G diverter switch on-load tap changers.

Since fingerprints from the units under test aren’t available, comparing the two sister units is an effective approach for assessing the results. The following evaluation will only focus on the diverter switch operation.

The comparison of the envelope curves reveals that the vibration pattern of the two sister units matches almost perfectly, Figure 3.

Figure 3 depicts the tap switches from tap one to tap four. The markers indicate the start of the diverter switch operation. Ideally, each tap switch should be compared to its direct counterpart with the same parity and switching direction. Adding in the DRM data (Figure 4) helps map some of the VAM peaks to specific events like the operation of the main and auxiliary contacts.

www.electricalreview.co.uk 15 SPONSORED FEATURE

Time in s 4.9 5.0 5.1 5.2 5.3 OLTC #1 OLTC #2 Start odd Start even

FIGURE 3: Comparison of the envelope curves for a) odd and even and b) up and down traces.

FIGURE 4

Damping in dB -50 4.95 4.95 5.05 5.10 5.15 5.20 5.25 5.30 4.95 4.95 5.05 5.10 5.15 5.20 5.25 5.30 0 Current in A OLTC #1 OLTC #1 Time in s DRM based VAM based 4.95 5.00

Combination of VAM and DRM data from both OTLC units.

Goodbye to diesel generators; it’s time for clean backup power

Carlos Nieto, Global Product Line Manager for Energy Storage Solutions at ABB, explores the ever-mounting case for sustainable back-up power alternatives and explains how one of the world’s tallest wooden buildings is using such an innovation to drive its incredibly important sprinkler system.

As we move to national power systems which are increasingly run on renewable energy generation, the chance of regional blackouts is becoming more likely as wind, solar and hydro power are, by their nature, very changeable. While system operators work on ways to better balance supply and demand with more non-synchronous generators on the grid, the onus is shifting to commercial and industrial businesses to ensure they have strong, consistent back-up power systems to deliver continuity in the event of the lights going out – something which has historically been provided by a diesel generator.

However, in a low carbon future, we need to find cleaner ways to deliver that back-up power.

The energy transition is bringing with it a whole raft of new challenges for us to resolve, particularly in applications where we have traditionally relied on fossil fuels. One challenge is finding an alternative to diesel generators. In the past, the answer to getting back-up power going in a commercial, industrial or residential building in the event of an outage was to run a diesel engine to power an electric generator.

In a low-carbon world, diesel and petrol generators are a no-no, and in the current project, hydrogen could not be used to run a generator. So, the answer lies in an innovative combination of renewables and Battery

16 Electrical Review | March / April 2023 ENERGY STORAGE, STANDBY POWER & UPS

Energy Storage Systems (BESS).

With BESS you can store energy generated from an on-site renewable resource – such as wind turbines or roof top solar panels – and use that energy stored in the batteries to feed an inverter running as a generator in the event of a blackout.

This technology is already in use at the Sara Kulturhus; a state-of-theart cultural venue and hotel in Skellefteå, Sweden. It is home to the city library, a museum and art gallery and a theatre.

At 75 metres tall, the 20-storey timber building is one of the world’s tallest wooden structures and is an international showcase for sustainable design and construction, with 100% of its electricity coming from renewable sources, including hydro and wind generation.

Its timber structure is so sophisticated that it removes more than twice the carbon emissions produced by the operational energy it uses, and the embodied carbon from the production and transport of the materials used to construct it.

In a timber construction like this, the sprinkler system is critical to keeping staff and visitors in the building safe. Traditionally, this fire protection system would have been powered by emergency diesel generators, which serve as an onsite power supply should the mains power not be available. But given the Sara Kulturhus’ commitment to sustainability, to avoid use of a diesel generator, an alternative solution was required.

Instead, the building received a bespoke energy storage solution to deliver maximum safety and reliability, while harnessing the building’s hydroelectric green electricity, received from the grid, which is used as the power supply. The bespoke BESS comprises six battery packs from a local supplier, as well as AC and DC switchgear, inverters and a distribution transformer.

With the unique wooden design of the building, the packaged solution was built, and factory tested off-site and then energised in the basement of the Sara Kulturhus. To make it easier to manage the BESS and to ensure a reliable 24/7 power supply for the building’s sprinkler system, the solution was supplied with a custom energy management system to provide next level energy monitoring, diagnostics, and data and analytics.

As well as optimising the building’s own energy use, this advanced autonomous AI technology interfaces with the building management system, which allows the centre to interact with nearby buildings so any excess renewable energy generated can be supplied to other parts of the city when required.

The team at the Sara Kulturhus is pleased that they have a reliable back-up power system for the sprinklers through a solution that embodies the region’s values of delivering ecological, economical, and social impact while supporting the green transition across North Sweden.

Anna Jirstrand Sandlund, CEO of Sara Kulturhus, noted, “With a wooden building of this scale, fire safety had to be one of our main considerations. By collaborating with ABB and Skellefteå Kraft, we have developed a unique solution that is now one of the highlights of our twice daily guided tours for visitors. With the building itself now a blueprint for sustainability, we continue to work towards equalling its impact on the inside and inspiring our visitors and residents to become more sustainable.”

The transition to renewable energy at every level is making us rethink everything we know about how we power our world. Yet, with innovative concepts, we can create new technologies that are equally as safe and reliable as those which came before, but with the added advantage of helping deliver a cleaner, more sustainable future.

What we’ve shown with the Sara Kulturhus project is a new blueprint for emergency power which can be used in endless applications in place of diesel gensets.

www.electricalreview.co.uk 17 ENERGY STORAGE, STANDBY POWER & UPS

With innovative concepts, we can create new technologies that are equally as safe and reliable as those which came before, but with the added advantage of helping deliver a cleaner, more sustainable future

Capacity to lengthen UPS lifespan

Capacitors play a crucial role by helping to smooth, filter, and store energy. A typical UPS contains dozens of capacitors ranging in size from a miniature drinks can through to a tube of Pringles. These aluminium or chromium-plated cylinders contain a pair of conducting surfaces, typically electrodes or metallic plates. A third element, known as the dielectric medium, separates and insulates these other elements.

The volume of charge that a capacitor can store is measured in farads – named after the renowned physicist Michael Faraday – and is determined by the thinness of the dielectric layer and the surface area of the aluminium plates.

You’ll find various types of capacitor in the power section of your UPS:

• AC input capacitors, which form part of the UPS input filter and/ or power factor correction stage. They are subjected to the incoming mains supply and have the crucial role of smoothing out input transients, reducing output-reflected switching noise and harmonic distortion.

• AC output capacitors, which form part of the UPS output filters. Their role is to connect to the critical load output, helping to control the waveform of the UPS output voltage and provide reactive power.

• DC capacitors, which form part of the rectification system and energy

ENERGY STORAGE, STANDBY POWER & UPS

18 Electrical Review | March / April 2023

Jason

Yates,

Technical Services

Manager at Riello UPS,

discusses the key role capacitors play by storing and filtering energy in uninterruptible power supplies and explains why proactive replacement can breathe new life into your power protection system.

storage. Their role is to help smooth out any fluctuations in voltage and provide short-term energy storage for mains to battery transitions to guarantee there’s no break in supply to your critical load.

Each UPS capacitor is subjected to potential high frequency switching, as well as all the stresses caused by the physical and electrical operational environment.

Such pressures explain why, along with batteries, capacitors are the UPS components most prone to failure. They age over time as the electrolyte, paper, and aluminium foil inside degrades physically and chemically.

The signs of a failing capacitor

Capacitor service life is shortened by any detrimental environmental extremes, for example, hot or cold operating temperatures, along with workload.

The harder a capacitor has to work (i.e. the more it has to filter unusual levels of voltage noise or transients), the faster it will deteriorate. Similarly, regularly exposing the capacitors to currents that exceed the manufacturer’s recommended rating will quickly cause damage.

Extreme heat, caused by either high ambient temperatures or potentially from blocked filters that limit airflow, will also start to evaporate the solution inside the capacitor. Over time, this builds up an unsafe amount of pressure.

There are several tell-tale signs of impending capacitor failure. Service engineers may notice some oil leakage or deformation caused by excess heat. They might also see a protrusion on the valve cap, which is a clear sign of stress probably caused by a short circuit inside the capacitor.

The use of thermal imaging cameras can also detect an increase in temperatures or any scorched wires connected to the capacitor, which tends to be the result of overcurrents.

Engineers can also use a capacitance meter, which are typically included in any quality digital multimeter, to measure the drop off in tolerance as the capacitor ages.

The

cost of capacitor failure

UPS capacitors fail in three distinct ways. Firstly, they can just gradually fall out of tolerance. Secondly, there are ‘open’ failures where they simply stop working but there’s actually little visible evidence that something’s gone wrong. Finally, there’s a ‘short’ failure, where there’s an obvious leak of the dielectric medium. Sometimes this is even accompanied by a loud popping sound like a firework.

Most modern power capacitors are fitted with pressure release valves or complete pressure release caps, which enables the capacitor to alleviate the internal pressure should a failure occur.

This does result in a rise in temperature, though, which in turn causes the internal pressure to increase. In certain instances, a sudden change in pressure leads to the capacitor releasing at an extremely high rate, discharging electrolyte across the surrounding area.

If a single capacitor fails, the rest of the set must pick up the slack. This has the knock-on effect of placing them all under greater stress. It downgrades the ability of the UPS to filter power, increasing the likelihood of problems with harmonics and noise. The energy storage volume reduces, while it can also potentially damage your battery strings.

In the worst-case scenario, a serious capacitor failure will trigger the UPS to switch to bypass mode, which leaves the critical load unprotected

and exposed to unstable power. If capacitors are left to completely dry out, they can even become a serious fire risk.

How to reduce the risk of capacitor failure

The areas most under your control are general good housekeeping and robust UPS maintenance. Try to stick to the recommended ambient temperature and humidity levels, as well as keeping air filters clean so air can flow freely and keep the UPS cool.

During regular preventive maintenance visits, field service engineers should visually inspect the capacitors and also scan with thermal imaging devices to highlight any potential problems. Analysis of maintenance field readings will also help to identify the capacitors most likely to fail.

There’s no standard age where a UPS capacitor will fail, and in favourable operating conditions they can reach a service life of up to 10 years. But it’s become accepted industry best practice to treat capacitors as consumables and proactively look to replace them between years four to eight of service life.

It often makes sense to combine swapping out UPS capacitors whilst replacing another key consumable, namely the fans that keep the inverter and rectifier cool enough to operate safely.

Commonly known as a UPS overhaul, proactively replacing ageing capacitors and fans before their end of service life can breathe new life into your UPS.

Naturally, the new parts will perform at a much higher level than the ageing ones. Not only does this reduce the likelihood of a major system failure, but it also makes sure that your unit runs more efficiently, which helps to cut your energy and operational costs.

The potential consequences – not to mention the cost – of a serious capacitor failure are simply far too high for you to ignore. An overhaul offers the most cost-effective way to safeguard the ongoing performance of your UPS at the same time as maximising your equipment’s lifespan and reducing the total cost of ownership.

www.electricalreview.co.uk 19 ENERGY STORAGE, STANDBY POWER & UPS

Regularly exposing the capacitors to currents that exceed the manufacturer’s recommended rating will quickly cause damage

Why battery storage is crucial to achieve our net zero goals

Renewable energy wastage is adding to energy bills and increasing CO2 emissions.

in innovative ways, it is possible to reduce these costs. If appropriately deployed, battery storage can help alleviate the impact of inadequate network capacity until the cavalry (i.e., the eastern links) arrive.

What are network constraints and what is renewable energy curtailment?

The numbers around UK wind power continue to balloon: a record 20 GW of wind generation in December 2022, CfD auctions doubled in frequency, and a national target of 50 GW of wind by 2030. But generating enough renewable power is just one part of the challenge. We also need to build infrastructure that lets us use that energy when and where we need it.

To update our power system for the age of renewable energy we need new transmission infrastructure such as the ‘eastern links’, scheduled to start operating from around 2030 onwards. These high-voltage cables will transport power down the east coast from Scotland, where there is a surplus of renewable energy, to sources of demand further south.

But until these cables start working, bottlenecks on the transmission network will continue to cause problems, including additional costs and delays to decarbonisation. By using new technologies such as batteries

Because the UK is not upgrading its grid as quickly as it is building wind farms, clean power is regularly wasted. On especially windy days, renewable generation exceeds network capacity – or to put it in industry jargon, the network is ‘constrained’. At these times, to ensure that Scottish wind farms do not overburden cables with electricity, overheating them, National Grid ESO pays generators to switch off their turbines. This process is known as ‘curtailment’. Meanwhile, to satisfy electricity demand further south, it buys electricity from generators in England, most often turning to gas-fired plants.

From 2020-2022, the ESO spent an average of £205 million per year on curtailing wind energy. The public ultimately paid for these costs through energy bills. These figures don’t take into account the money the ESO spent on procuring expensive gas-fired electricity to replace lost wind power (also paid for by the public): £196 million in 2020, £429 million in 2021, and £717 million in 2022. Curtailment takes a toll on the climate, as well as energy bills: when substituting for wind turbines, those fossil-

ENERGY STORAGE, STANDBY POWER & UPS

James Basden, Co-Founder and Director of Zenobe, believes battery energy storage can help solve both of those issues.

20 Electrical Review | March / April 2023

fuelled power stations emitted circa 3.5 million tonnes of carbon dioxide. But there is another way. Instead of paying to squander cheap, clean power, we can store it for future use.

The promise of battery storage

Batteries connected to the transmission system could help to resolve curtailment, reducing energy bills and cutting carbon emissions. Batteries have the potential to import power during peak generation, and then to export it back onto the grid when needed. In short, batteries offer ‘flexibility’ – the ability to balance shifts in renewable generation by sending electricity to where it is needed, or by storing it for later use. Using transmission-connected battery storage in this way would reduce the need for the ESO to pay to switch off wind farms. It would also cut the need for the ESO to spend money on climate-polluting gas. This would result in lower energy bills and lower greenhouse gas emissions.

So, what’s holding us back?

Firstly, storage operators face ill-fitting regulations designed for the age of fossil fuel generation. This disincentives them from locating assets where they would be most useful for the UK’s energy needs. For example, transmission charges treat storage like gas or coal generation – they do

not take into account how storage can import, as well as export, power. As a result, storage operators face unduly high charges that discourage them from building assets where they would have the most positive impact.

Secondly, National Grid ESO has historically been hesitant to dispatch storage assets via the Balancing Mechanism. This is because the ESO’s current IT systems do not allow it to see a battery asset’s state of charge at any given time. As a result, control room operators lack trust in battery storage and turn instead to fossil-fuel assets to balance the system. As National Grid ESO updates its IT systems and drives forward its decarbonisation programme, this situation should shift.

Finally, the UK’s current electricity market design dates from 2013 and does not always incentivise participants to behave in ways that benefit the overall operation of our fast-changing system. The Department for Energy Security and Net Zero (DESNZ) is considering these operability challenges as part of the ongoing Review of Electricity Market Arrangements (REMA).

Utility-scale battery storage is increasingly being recognised as an essential component to the UK’s energy transition. The transition doesn’t just mean developing wind farms – it also requires the redesign of our network infrastructure to harness the full potential of clean power and ensure electricity is cheaper, more secure, and more sustainable.

Where next?

The energy storage sector is growing rapidly, with 4GW of batteries set to connect to the grid by 2025-6. Previously storage operators found it difficult to raise equity or debt because of high upfront costs and a perceived lack of reliable revenue streams – but that perception is changing. Investment in storage is now expanding as operators develop new business models, stacking revenues from multiple services.

For example, in February this year Zenobē secured a £235 million long-term project finance debt facility to develop two grid-scale transmission connected battery storage assets in Scotland. The debt facility is the largest of its kind ever secured in Europe and is another indicator of the increased confidence in battery storage as an attractive investment opportunity. The sector is also benefiting from new contracts that are specifically designed to stabilise non-synchronous power systems.

Even so, this growth is not keeping up with renewable energy deployment. Curtailment costs are predicted to rise by up to 500% over the next 10 years. As the National Audit Office recently observed, the public will continue to face cost and decarbonisation risks ‘if network capacity does not keep pace with electricity generation expansion’. These risks can be linked not only to inadequate network capacity, but also to the fact that wind farm construction is outstripping storage installation.

The UK risks falling behind on power system decarbonisation due in no small part to the Inflation Reduction Act, which is seeing talent and money diverted to the US. While the EU has announced how it plans to respond to this landmark piece of legislation, we are yet to hear how the UK intends to continue to attract investment in clean power in an increasingly competitive international context. We also need to see significant change at Ofgem to put decarbonisation at the top of its agenda. With ambitious renewables targets set, policymakers now need to turn their attention to updating our outdated electricity network infrastructure.

www.electricalreview.co.uk 21 ENERGY STORAGE, STANDBY POWER & UPS

Overcoming gridlock in Great Britain’s electricity network

To achieve a net zero future, the UK will need to make the grid connection process much smoother for clean energy projects, as Estelle Limon, Policy Coordinator at Regen, explains.

Transforming Great Britain’s electricity system to achieve net zero emissions means massive and accelerated deployment of new wind, solar, electricity storage, heat pumps, and electric vehicle chargers across the country. What each of these technologies share is the need to connect to the electricity network.

However, ask anyone in the clean power sector about the biggest issue they face right now and chances are they will cite challenges with connecting to the grid.

With the UK government setting its sights on 2035 as the date by which to have fully decarbonised the power system, key questions emerge around being able to connect new projects quickly enough and having enough capacity in the wires at the local level to cope with increased demand from electrification of heat and transport.

Concerns about network capacity have materialised over the past few

POWER GENERATION, TRANSMISSION & DISTRIBUTION

years in that lengthy connection delays are now seriously clogging up the project pipeline. Astonishingly, almost all developers of new clean energy projects over 1 MW are being quoted a connection date 15 years into the future.

Speedy connections are key not only to enable new low carbon electricity generation and storage capacity to contribute to clean energy targets. They are also necessary to unlock a range of social and economic activities, from new housing developments, data centres, schools, hospitals and much more. The current gridlock in connections, therefore, poses a risk for both decarbonisation and economic goals.

The rules and codes that govern how the electricity network works are complex and detailed, but there are underlying systemic issues that mean network capacity and processes are failing to keep pace with a rapidly changing energy system.

network capacity is not there when it is needed. Investment in network infrastructure is regulated by Ofgem through periodic budget allocations, but the level of investment allocated in the most recent period falls well short of what is needed for energy targets. It also fails to encourage network infrastructure to be built in anticipation of future need. Ramping up the level of investment and moving towards a more strategic, anticipatory approach will be crucial to ensure sufficient capacity is made available – and done so in a timely manner.

Part of the problem also relates to the volume of applications from new projects seeking to connect to the network and how this queue of projects is being managed. National Grid would historically receive 4050 new applications to connect per year, but this has surged to around 400 as the system becomes more decentralised and many more projects seek to connect at the distribution level. The first-come, first-served basis by which these projects are allocated a position in the connection queue means projects further along in development get stuck behind projects that might be highly speculative, for example, they are yet to secure land rights. With the pipeline of prospective low carbon projects set only to increase, avoiding further gridlock means finding innovative ways to more effectively manage the queue and enable the shovel-ready projects to progress.

In particular, the current reactive approach to upgrading the network to facilitate new sources of generation and demand means

The good news is that there are several positive initiatives underway to get Great Britain’s electricity network infrastructure and processes net zero ready. The Electricity System Operator has launched a ‘GB Connections Reform’ which encompasses a range of actions to improve the connections process, such as freeing up space in the queue by allowing projects to exit at no cost or a reduced fee.

The transmission and distribution network companies have also stepped up to the challenge and are working hard to find tactical solutions to some of the key problems. In particular, some of the Distribution Network Operators (DNOs) are looking at how they can make much better use of electricity storage and flexibility to unblock capacity in constrained areas of the grid.

The question is whether these incremental industry steps are enough. Given the stakes and the scale of the challenge, attracting political attention to the issue could be the necessary catalyst for a faster and more joined-up approach.

Regen kickstarted this process by writing to the Energy Secretary calling for his personal leadership to address electricity network barriers. If everyone in the electricity sector followed suit in writing to their local MP to explain the impact of grid connection delays on delivering cheaper homegrown power – and investment and jobs in their constituency – that could help put this issue at the top of the new Department for Energy Security and Net Zero’s to-do list.

Without greater focus on ensuring new clean energy projects are able to connect to the network, the country’s energy and economic goals are in jeopardy. The importance of the challenge cannot be overstated.

www.electricalreview.co.uk 23 POWER GENERATION, TRANSMISSION & DISTRIBUTION

Almost all developers of new clean energy projects over 1 MW are being quoted a connection date 15 years into the future

Without greater focus on ensuring new clean energy projects are able to connect to the network, the country’s energy and economic goals are in jeopardy

Is it make or break time for the UK’s energy transformation?

Could the lagging investment in the energy grid be one of the greatest problems facing the UK’s infrastructure today?

Suzanna Lashford from Vattenfall Networks shares her thoughts.

POWER GENERATION, TRANSMISSION & DISTRIBUTION

24 Electrical Review | March / April 2023

nce, Britain was a forerunner in electrical energy developments. London’s Holborn Viaduct power station, built circa 1882, was the world’s first and marked a revolutionary moment in the generation of electricity for public use. But in 2023, after decades of underinvestment into the electrical backbone that carries power to homes and businesses, things aren’t looking so bright. With electrical demand set to soar and the world aiming for net zero carbon emissions by 2050, the need for grid modernisation has never been greater.

A functioning grid is also the key for achieving the UK’s goal of a carbon neutral electricity system by 2035. Renewable energy is central to this aim, and enormous wind farms are being built off the coast of Scotland and in the North Sea. However, some of these initiatives are being told they will only be able to access a grid connection to the mainland in 2034 due to underfunded services and large connection backlogs. This is just one of the examples of connection delays and capacity constraints that may rein in the UK’s energy transformation.

The current state of the grid

In January this year, the National Grid introduced its ‘demand flexibility’ service where households and businesses are paid to reduce their electricity consumption during ‘peak’ times when the electricity grid is under the most demand. Despite the positives of offsetting household energy bill prices, this initiative shows the extent to which the grid is struggling to cope with the electric use already required – let alone future renewable projects.

Indeed, during the extreme cold snap of January the National Grid instructed three coal-fired units to be ready as a backup if the grid failed. These plants were due to be permanently closed in September 2022 as part of the environmental goal to phase out coal in the UK, and yet the current unreliability of our grid means they are still being depended upon, further endangering the UK’s net zero ambitions.

revolution targets the installation of 600,0000 heats pumps per year by 2028, which rely heavily on electricity. Bloomberg NEF predicts that heat pumps could add 14 TWh to electricity demand by 2030 – a 5% increase in electricity demand in seven years.

Energy security – macro and micro

Recent shifts in energy geopolitics have also highlighted the fragility of our energy markets, sending fuel prices soaring and bringing our national energy security into sharp focus. If the UK is to maintain secure supplies of (hopefully clean) electricity, significant reinforcements and upgrades will be required throughout the transmission and distribution networks, as will businesses’ own private wire networks.

At a local electrical distribution level the process for requesting and pricing grid reinforcements via District Network Operators (DNOs) is set to change in April 2023. The result of this is that grid connections will be far cheaper for the applicant as the grid reinforcement costs won’t be borne by the developer but socialised across the DNO’s network costs. While this is good for the customer, the inevitable backlog in demands for new grid connections will place unprecedented demand on the DNOs, resulting in bottlenecks and further delays.

Alternative solutions

But demand for clean power won’t slow down just because our grid isn’t equipped to handle it: the electrification revolution has just begun. In fact, demand for electricity is expected to double, or possibly triple, by 2050; partly being driven by uptake of electric vehicles, with the UK having committed to end the sale of all new petrol and diesel cars and vans by 2030. In addition, the UK’s Ten Point Plan for a green industrial

By partnering with an Independent Distribution Network Operator (IDNO), businesses have an alternative route to connect to the electricity grid. IDNOs contribute to the costs of network upgrades by investing their own funds and can reserve grid capacity for free on behalf of their clients. By forging a relationship with an IDNO energy partner, clients are supported along the energy transition process. IDNOs can take control of difficulties and work with the local DNOs on their client’s behalf, helping client’s map out the smoothest and most time-effective energy transition.

Private Wire Networks are another fundamental aspect that business owners need to consider when mapping out their electric transition. Being privately owned, their maintenance and upgrade requirements are the remit of UK businesses, and most will need significant upgrades to keep up with new power demands. For those concerned about the responsibility of upgrading ageing infrastructure or lacking the required funds, there are new models for energy infrastructure management, such as Power-as-a-Service, which can provide capital funding for upgrades, renewable energy systems, and energy efficiency improvements, as well as removing the risks associated with the ongoing maintenance and operation of complex private wire networks.

The challenges facing the UK grid are far reaching, yet seldom spoken about. In order to guarantee energy security, there needs to be a significant push to fill this investment gap and modernise this outdated and overstretched system. By failing to do so, we risk leaving our emission targets in jeopardy, and leaving the UK in the dark.

www.electricalreview.co.uk 25 POWER GENERATION, TRANSMISSION & DISTRIBUTION

O

Demand for electricity is expected to double, or possibly triple, by 2050

If the UK is to maintain secure supplies of (hopefully clean) electricity, significant reinforcements and upgrades will be required throughout the transmission and distribution networks

The common-sense approach to appliance safety testing

Nathan Barwell from electrical safety test equipment manufacturer Seaward considers how PAT technology continues to evolve and its use for general safety management applications.

There’s little doubt periodic inspection and testing of portable electrical equipment saves lives and prevents fires that may otherwise have caused injuries, loss of life and serious damage to business premises and workplaces. In this respect, the Electricity At Work Regulations 1989, along with the HSE Memorandum of Guidance, IET Codes of Practice, and most recently British Standards have consistently provided sound advice based on industry experience and the electrical safety needs of the business community.

Although nowhere in the EAWR 1989 is there a specific requirement for the testing of electrical equipment, there is an onus on the duty holder to ensure that equipment in the workplace is maintained so as to prevent danger. It is this requirement that has introduced the implied need for periodic inspection and testing – without such actions, the inference is that the duty holder will be unable to establish the potential dangers posed by faulty or unsafe equipment.

Planned and proactive safety measures must therefore be capable of detecting potential problems with appliances before they occur and this is the role of preventative maintenance programmes.

As a result, in the event of electrical accidents, property damage or personal injury occurring, portable appliance testing can demonstrate a responsible and diligent approach towards safety that may subsequently be required by the HSE, employers, insurance companies and other interested parties.

A proportionate response

Clearly, combined inspection and testing measures should be appropriate to the particular risk posed by the equipment and its environment. For example, smaller offices or workplaces with only a few electrical appliances, and a staff of limited technical ability, might be regarded as relatively low risk environments. Here a responsible attitude might be regarded as a regular process of formal user checks and visual inspection, combined with some limited periodic testing.

A different view, however, might need to be taken by a large organisation, with different departments having many different types of electrical equipment used by staff. In this case, ensuring the safety of appliances may not only be a matter of ensuring the correct test

26 Electrical Review | March / April 2023 TALKING POINT

equipment is available, but also having the ability to show that the right tests have been performed at the right time, in the correct sequence –with records of test levels and results.

To meet this need, continuous technical innovation has ensured that portable appliance test instrumentation has kept pace with the changing demands of the workplace to meet the needs of everyone who has a responsibility for ensuring the safe use of electrical equipment.

Over the years, electrical safety test instrumentation has evolved to make testing faster, more efficient and cost effective for those involved –and all of this has been achieved without any compromise to the integrity of the testing being undertaken. The broad distinctions between manual and automatic testers have also remained, but the obvious differentiation between the two continues to close. All portable appliance testers now have much greater functionality with remote download of results and the ability to link to specialist accessories for more comprehensive testing.

Also, as successive IET Codes of Practice have highlighted the benefits of different types of electrical tests, PAT manufacturers have responded by including, for example, the necessary technology to test fixed appliances and three-phase equipment, test RCD trip times, provide different options for insulation test voltages, and utilise specialist test currents for earth continuity testing, among many more.

Alongside these changing technical demands, recognition of the growing maturity of the PAT market has also been the driver of innovation. For the modern PAT tester, time is money and competitive pressures mean that tests must be undertaken quickly and efficiently, but without affecting the accuracy and reliability of the test results.

To meet the need to be efficient, a whole host of special features and accessories have been introduced. The introduction of barcode labelling of products with automatic recognition of test protocols by the test instrument was an early development, and this was followed by the introduction of Bluetooth connectivity with test accessories such as label printers to speed up the test process. More recently, remote download to mobile devices has allowed the modern tester to quickly send test data back to the office for processing.

Lightweight, battery-powered testers have further improved portability

factors and reduced the downtime between tests. Improvements in test management software have allowed records to be updated automatically, reports and certificates to be produced and advanced test schedules to be generated.

All round safety management

With developments such as these, the versatility of modern testing technology is increasingly being used as part of more general health and safety inspections and assessments. As well as comprehensive electrical test functions, the most advanced multi-purpose PAT tester is now equipped with an onboard risk management tool to help determine retest intervals. This feature is included alongside a built-in digital camera to enable high quality images to be tagged against appliance records for completely traceable record keeping.

These advances mean that visual evidence of all workplace health and safety equipment can be recorded and tagged against inspection records. In addition, the built-in risk assessment capability allows the consideration of a variety of different workplace hazards and corrective actions to be planned and documented easily.