25 minute read

Energy Storage, Backup Power & UPS

Why energy storage needs to be sustainable

Carlton Cummins, CTO and Co-Founder of clean tech firm Aceleron, discusses the importance of making energy storage more sustainable.

Advertisement

E

nergy storage will undoubtedly be powering our lives in the near future so, as we build a renewable energy infrastructure to meet today’s needs, it is vital that we create a sustainable, resilient system that will stand the test of time.

The transition to renewable energy is already underway, with increasing urgency and focus being placed upon this transition thanks to the serious and obvious signs of climate change, coupled with Russia’s invasion of Ukraine earlier this year.

A large part of this new renewable energy infrastructure will rely on energy storage. It is absolutely essential, therefore, that the technologies we use will be sustainable and built to last – first and foremost to reduce the impact on the environment but also, because replacing large-scale energy storage entirely will be an extremely costly and wasteful process.

Battery waste across the board is going to become an increasingly serious concern –if it isn’t already. The majority are made using raw materials that the Earth has a finite amount of, so making sure that we get maximum use before recycling or safely disposing of them is crucial from a sustainability point of view.

‘Layering up’ the power Large-scale installations – for grid deployment or data centres, for example – require a resilient, constant and vast power supply, which means that investing in several ‘layers’ of power source is unavoidable. Not only is the equipment and energy itself far from cheap, but using diesel-powered generators as a backup – although reliable – will not help us on the road to net zero and will eventually become obsolete.

The direct integration of solar panels combined with energy storage not only allows for backup power via renewable energy, but excess energy – on a sunny day for instance – can be sold onto the grid, transforming this operational expense into a revenue generator, and helping to decarbonise the grid at the same time.

Many of these larger facilities already use batteries as a form of backup power, but often buy the cheapest lead-acid batteries available. There are several drawbacks to these types of batteries. They do not last long, don’t store as much energy as other batteries, can be temperamental due to their chemistry and are highly toxic when being broken down at the end-of-life stage. For a facility that needs reliability and resilience, these batteries are far from ideal.

Now is the time to research more long-lasting, high-density and safe long-term energy storage solutions.

Finding a reliable, long-life energy storage solution Currently, the most widely referenced battery materials sit within the Lithium-ion family. Lithium iron phosphate (LFP) has no cobalt (which is costly and comes with geopolitical concerns), is amongst the least volatile, with the highest safety ratings, and benefits from one of the longest lifespans in the family, which makes it very popular for renewable energy storage – particularly for stationary applications. It has also become a serious contender for automotive batteries due to the lack of cobalt and long duration.

There has been a lot of interest in recent years in pushing the boundaries of LFP and this has resulted in a gradual improvement in energy density.

This gradual improvement in energy density is worth bearing in mind when searching for the right energy storage solution for a larger application. There are serviceable, repairable and upgradeable battery technologies available, where individual parts can be removed independently for repair or to be replaced with a newer, more energy-dense material as technology evolves over time. Replaced parts that still have use can be repurposed into second-life products, creating a circular economy – the gold standard of sustainability.

Meanwhile, the service and upgradability of such a system works to extend its lifespan which reduces its total cost of ownership and retains usefulness as energy storage technology improves. This combination of clean energy compatibility and future-proof longevity work together to make it a worthwhile investment.

This is what will provide the renewable energy infrastructures we build today with the ability to keep going for as long as possible, making the most use of the materials used to build the product in the first place.

Questions to ask when making the purchase decision Although cost will be a significant factor, there are longer-term risks in going for the least expensive. Taking the following into consideration will make all the difference to the legacy that our generation leaves behind: • How will the product be serviced and supported? Loss of power may well happen from time to time; making sure there is locally based support available will be key to safeguarding continuity. This includes access to replacement parts. Having to wait while they’re shipped in from overseas for instance is a headache we can all do without. • What are the safety standards? There are a number of internationally recognised safety standards that must be met. As a minimum, the product needs to meet the UL 1973 (standard testing for stationary applications) and IEC 62619 and/or IEC 62620 (which means that any secondary cells have been tested for industrial application.) • What is the overall environmental impact? It’s important to look at the entire life cycle of the product, starting with: how much carbon was produced during the build process, what materials were used and where it will be shipped from. This is also where the expected lifespan comes into consideration – the longer it lasts, the better for the environment and budget.

We’re all under pressure to transition to 100% renewable energy, so it’s an exciting time for innovation. We now have a unique opportunity to create a clean and robust energy infrastructure for future generations to build on – so we have to get this right the first time. This means avoiding the temptation to source cheaper, short-term options based on current requirements – longevity will be the key to our success.

How to save money and reduce the environmental impact of a UPS

Louis McGarry, Sales and Marketing Director at CENTIEL UK, discusses improving the efficiency of an uninterruptible power supply to reduce its power consumption and its impact on the environment.

UPS systems are known for protecting critical loads in data centres. However, power protection is essential throughout most sectors. Examples can range from medical to banking and finance to defence applications. Whatever the use, if a UPS is ageing and/or incorrectly sized they can literally be ‘power hungry beasts’.

UPS and their associated infrastructure consume energy and if this is the case, the running costs alone can add up to hundreds of thousands of pounds over the years for some organisations.

A system working at its optimum efficiency will ensure it is cost effective and the impact on the environment will also be minimised with a reduction in power consumption. With energy costs at an all time high, now is the perfect opportunity to re-evaluate and review assets to reimagine and re-manage UPS installations to maximise efficiency.

Right sizing The biggest step change with iPhones was between the iPhone 8 and 10. Screen size and processing speed was improved dramatically, and facial

recognition added. We may not see enhancements on this scale again. It’s the same with UPS technology. In reality it is unlikely that a UPS will ever be 100% efficient, and with today’s technology offering <3% of losses, any enhancements will be minor. We have already reached the iPhone 10 stage. So, to continue to make advances in efficiency we need to consider other aspects of the whole set up.

The vast majority of UPS installations we are called to evaluate are oversized. There are many reasons for this including the need at the time of installation to ‘spend all the budget’. It could also be that the client wants to avoid the risk of under sizing, they may be asked to add headroom which can be anything from 10 – 50% to the design consideration ‘just in case’.

Have you ever looked into how much energy an oversized UPS can waste? It is standard practice for my team to compare the running costs of oversized, legacy systems with a replacement right-sized UPS. The Total Cost of Ownership (TCO) calculations can be impressive. Regularly I see new systems paying for themselves within three years through energy savings alone.

The key point to evaluating the efficiency of any existing UPS is to look at the loading. Below 25% load, a UPS is less efficient. Even with no load, a UPS consumes energy simply to stay on, so it pays to run a UPS at the sweet spot of its efficiency curve. This can vary between systems; this information should always be made available by the manufacturer.

Repair or replace Legacy kit will obviously be less efficient than a correctly sized new UPS. However, the cost of energy used to power a legacy UPS over five years is actually huge. It is generally more than the cost of a new system.

We are making TCO calculations on a daily basis to help clients understand how much they will save from day one, at what point in time the new system will have paid for itself, and the ongoing savings over the longer term. Making these calculations and choosing to replace legacy systems could save thousands of pounds on running costs, not to mention the associated benefits of increased availability of deploying true modular UPS technology.

Battery banks It is important to consider right-sizing of the entire UPS system including its associated battery bank. Larger battery banks will demand more energy from the grid to trickle charge and recharge, so be careful not to oversize or overspend on batteries that you don’t need.

Another consideration when re-evaluating batteries is their location in relation to the UPS and other heat sources. Lead-acid batteries need to be kept at 200C to optimise design life. Separating the batteries in a dedicated room, away from the UPS, means only the area housing the batteries needs environmental consideration. The batteries can now operate in an ambient room temperature, which on average is between 20-220C, needing very little or even zero environmental control. That’s another cost saving.

Future growth Don’t ever buy more UPS equipment than you need to. I’ll repeat that: don’t ever buy more UPS equipment than you need to! Whether that’s batteries or UPS. That may sound strange coming from a UPS manufacturer – however, our goal is to optimise system design and minimise the energy required to run the system for the best outcome for our valued clients. This means we nurture long-term relationships and work with organisations over many years as trusted advisors to design the best solutions for installations. We are experts at saving clients’ money.

The ‘what if’ question frequently comes up. What if the load changes? What if demand increases or decreases and the UPS system we’ve purchased becomes overloaded? The answer is that true modular technology is designed for a pay-as-you-grow approach, simply adding (or removing) more UPS modules ensures consistent rightsizing. This is achieved by ensuring there is sufficient physical infrastructure, or racks, to accommodate the changing nature of the organisation.

For clients to buy into this concept, UPS providers must work with clients to help them understand the facts and figures.

So, instead of saying ‘we need a like-for-like UPS replacement’, the question to ask is: ‘what is my actual load and do we really need a UPS that big? By looking at the alternatives, right sizing and managing room layout, it is possible to minimise energy and running costs and tame the power-hungry beast.

Why there’s never been a better time to invest in battery energy storage

Alastair Morris, Chief Commercial Officer at Powerstar, considers how Battery Energy Storage (BESS) technology can help companies to profitably manage energy security and net zero targets in volatile times.

Progress is lagging behind ambition, and it is a significant issue in the transition to net zero, as highlighted in the latest Progress Report from the Climate Change Committee (CCC). Couple these policy problems with an energy crisis, and the difficulty of balancing the agendas of energy security and sustainability is clear.

In his foreword to the CCC’s latest Progress Report, Lord Deben was explicit, observing that, despite the UK being a world leader for net zero ambitions, implementation is severely lacking across key themes and sectors. He pinpoints “sharply rising fuel costs (which) should have given added impetus to improving energy efficiency, yet the necessary programmes are not in place…” With targets of 95% low-carbon electricity generation by 2030 and a fully decarbonised sector by 2035, the CCC is now focused on scrutinising delivery of these legally binding goals.

While policy is vague on implementation, UK companies are increasingly taking it into their own hands to address the energy crisis – the spiralling costs and the insecurity of supply – through investment in Battery Energy Storage (BESS). And, alongside these commercially pressing imperatives, BESS technology is helping companies work towards their own net zero commitments, harnessing on-site renewable power generation and reducing carbon emissions.

Considering long-term energy management strategies, the current energy crisis is not a one-off, and energy prices and supplies will be volatile for the foreseeable future. The transition to renewables can’t be a simple switch from coal and gas to solar and wind. Rather, it means changing energy transmission, distribution and energy storage.

Given the infrastructure implications, capitalising on the opportunities of a shift to renewables while pre-empting supply issues will be a balancing act for many years to come. The CCC Progress Report points to some positives – namely, electric car sales and renewable electricity deployment. However, renewable energy is still inflexible and potentially unstable, while electricity demands are growing exponentially in a data-driven world, and with the significant demands of EV charging.

In this context, the energy security and storage capabilities of a BESS make it a compelling technology choice for companies needing to protect digital assets, maintain an undisrupted workflow, and work towards their own net zero targets.

Why opt for battery energy storage? In terms of power resilience, the benefits of a BESS in comparison to a traditional uninterruptible power supply are well-established. Although a UPS will protect specific equipment during any interruption to power supply, the unit remains idle most of the time, with a loss of capacity – generally between 10 and 15% – meaning continual costs and the associated unnecessary carbon emissions.

In comparison, a BESS offers site-wide protection, with an energy loss of around 1%. In commercial terms, the cheapest unit of energy is the one you don’t use. It’s also the greenest.

BESS technology offers the flexibility to use stored electricity as and when required. Using the appropriate control software this process can be automated, with AI determining what generation and usage to prioritise.

The commercial application of BESS for Behind the Meter (BtM) scenarios provides an integrated energy management and microgrid solution for the greater flexibility and control of energy usage that are vital during an energy crisis.

In addition to resilience for security of supply during any power disruption, energy storage allows companies to shift the times when grid-supplied electricity is used and provides the capability to buffer large loads so that these can be more easily and more cheaply connected. This is particularly pertinent while EV charging remains a significant issue, as highlighted by the CCC Report.

How policy is falling behind decarbonisation Security of supply and sustainability are two arms of the Energy Trilemma, and the UK ranks highly – currently fourth – on the World Energy Council’s latest Energy Trilemma Index. However, the third arm of the Trilemma – energy affordability – is the UK’s Achilles’ heel. It is also the aspect which brings together the agendas of security and sustainability in the current economic landscape, demonstrating what are, arguably, the greatest benefits

of BESS as a means for companies to balance competing priorities.

The UK’s Review of Electricity Markets Arrangements proposals, outlining plans to minimise exposure to wholesale natural gas prices, is highly relevant here. Linking power supply to gas prices is illogical and untenable in an increasingly decarbonised energy sector and decoupling the two – as tabled in the proposals – would be the biggest shakeup of the UK electricity market this century.

Policy falling behind ambition and implementation is problematic – but solving the UK’s baseload generation issues won’t be quickly resolved by nuclear technology, where the timeframe could span decades.

Successful decoupling of gas and energy prices would require flexibility, and this approach is evident in policy terms, including National Grid’s proposals to incentivise end-users to minimise electricity demand during peak times, with new proposals from BEIS to offer cheaper electricity rates when demand is low and renewable generation is good.

Using BESS for financial gain For BESS users, there are opportunities – income generation through the UK’s Capacity Market, as well as potential financial savings for companies that can take advantage of fluctuating energy costs through storage. As the UK’s energy generation moves further to renewables, these are still inherently inflexible and even though electricity prices would seem likely to reduce if decoupled from gas prices, this inflexibility may well mean short-term variance in electricity costs.

BESS technology allows companies to mitigate against such volatility by purchasing and storing electricity when prices are lower to then be used at peak times when prices are higher – maintaining power resilience in cases of disruption and assisting with budgeting in times of great cost fluctuations.

Perhaps the most financially compelling opportunity for BESS users, though, is the ability to take advantage of income generation – where battery technology really comes into its own.

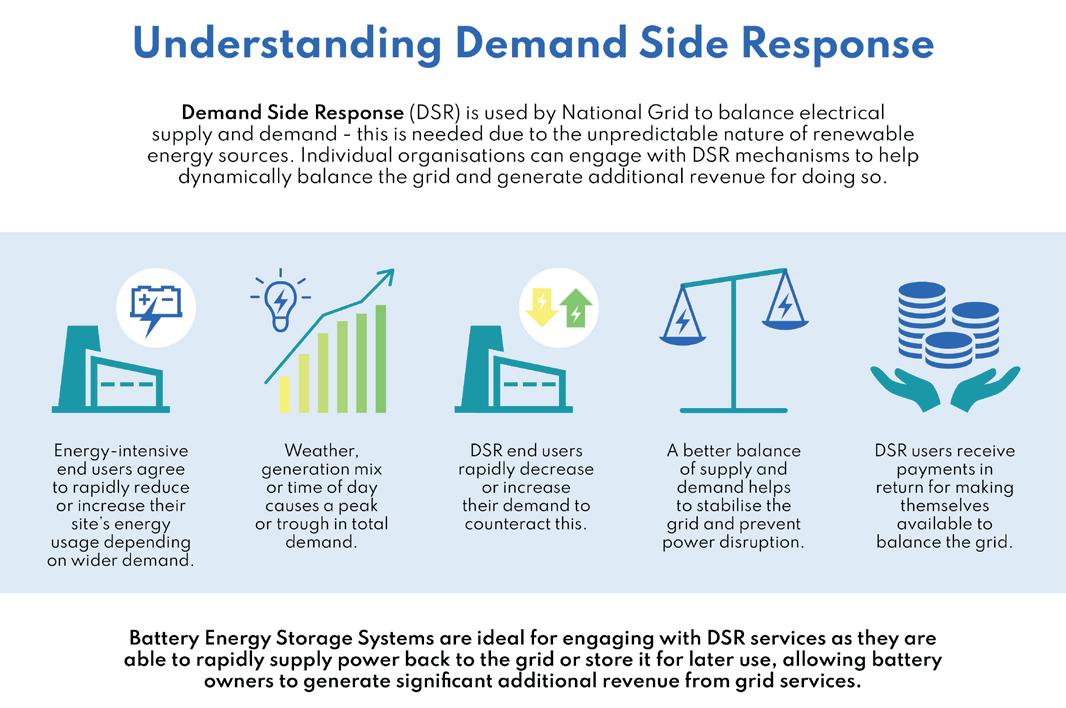

Businesses who can engage with National Grid on demand side response (DSR) are operating at the forefront of the shift away from the old model of centralised energy dispatch and towards more distributed power generation.

DSR works for the grid as a cost-effective mechanism to manage supply and demand. For BESS users, there are revenue-generating opportunities either through a direct contract with the grid, with the local distribution network operator or, at a smaller scale, via an aggregator service.

In essence, battery storage enables end-users to fulfil DSR contract obligations by turning up, turning down or offsetting their own demand in real-time, helping the grid to smooth out peaks and troughs in overall demand. With a BESS, companies can secure a better price for surplus power by storing and selling when demand peaks and prices are highest.

As a mechanism to ensure supply meets demand, the Capacity Market has many critics, not least because of its descending clock format which, effectively, has subsidised fossil fuel generation – the lowest bidders at auction – to stay on standby. However, the Electricity Market Review includes a proposal to use more low carbon flexibility technologies to provide for the Capacity Market, which may well see further incentives for BESS users and new opportunities as government policy develops.

It is in this context – an energy crisis at the time when net zero targets are most pressing – that resilient power generation and storage capabilities provide a compelling case for companies to make profitable investment in BESS technology.

With a BESS, companies can secure a better price for surplus power by storing and selling when demand peaks and prices are highest.

How we can fuel the future

Morten Wierod, President of Electrification at ABB, looks at some of the key technologies which will fuel the energy transition.

Global demand for energy continues to increase exponentially, yet climate change demands lower emissions. As we look to COP27’s ambition to move from pledges to action in the context of an increasingly uncertain geopolitical landscape, there will be an even greater onus on how utilities and industry can tackle both challenges.

This will see an accelerated shift towards not just clean and renewable fuel sources but innovative solutions which enable decarbonisation strategies, as we continue to redefine how we produce, distribute, manage and consume electrical energy.

From heat waves and wildfires in the headlines, to longer term concerns about climate change putting greater pressure on ecosystems and communities, there is no doubt that sustainability is the defining issue of our times.

Add to the equation growing concerns about the cost and availability of energy which is exposing the vulnerability of economies that rely on global fossil fuel supplies – coupled with soaring energy demand – and it’s clear that the world needs a swift and broad transition to sustainable energy.

The wide consensus is that national and international focus on climate must take a definitive shift from optimism and ambition to decisive action. For many of the world’s biggest economies and carbon emitters it is time to take action to ensure promises made at last year’s COP26 are delivered at speed.

The good news is that we already have many of the tools we need to solve these challenges. The task now lies in deploying and scaling up the key technologies which could play a focal role in slashing emissions and realising a low-carbon society.

Why energy storage is a key enabler of the energy transition One of the most important climate change relevant innovations is one of the oldest – the humble battery. To understand why, we must first look at renewables. Science suggests solar and wind deployments are the cheapest ways to cut over a third of the required emissions reductions by 2030. But integrating these new energy producers to the existing mix is complex.

This is because most of the existing grid infrastructure is decades old and was only ever designed to manage a steady, reliable supply of energy under the assumption that the amount of energy fed into the grid is always roughly equal to the amount consumed. The inherent variability of wind, solar and hydroelectric, including potential imbalances in supply and demand and changes in transmission flow patterns, make balancing the grid more problematic. Without some form of backup, utilities run the risk of instability or even a blackout.

Battery energy storage systems (BESS) offer the obvious solution. Put simply, utility-scale BESS enables power generators to store excess energy and redeploy during periods of reduced energy generation, such as when the sun isn’t shining, or the wind isn’t blowing, to help balance the grid and ensure reliability. Amid increased pressure to deliver green energy at volume, this approach offers an economical route to renewable integration while using existing infrastructure in the space of grid modernisation programmes. When partnered with digital capabilities, BESS also makes it easier to manage growing demand – including the impact of transport electrification.

But it isn’t just about utility-scale BESS. As more industrial and commercial operators pivot to self-generation to reduce energy costs and emissions, and gain energy security, energy storage offers a more effective way to manage energy by leveraging peak shaving, load shifting and maximisation of self-consumption. It can also provide critical backup power, preventing revenue impact in the event of a grid failure.

In line with the wider rate of digitalisation, the emergence of Artificial Intelligence (AI) enabled BESS is shifting the decarbonisation dial further. By harnessing the power of data analytics and machine learning, AI-enabled BESS can provide an accurate prediction of future supply and demand requirements ahead of time.

Amid an unpredictable energy picture, the insight afforded by this technology is a game-changer. Through predictive analytics, it will allow energy generators at all levels to store and distribute resources far better to make sure that every single kilowatt of clean energy is used to maximum effect – genuine energy efficiency in operation. Further opportunities in predictive maintenance and asset optimisation also ensures each renewable investment offers the maximum performance.

SF6-free – preparing for a more certain future Alongside the adoption of clean energy sources, reaching climate neutrality, of course, also requires the reduction of greenhouse gases.

This was seen earlier this year as the European Commission announced progressive plans to tighten limits on human-made fluorinated greenhouse gases (F-gases) and ozone depleting substances (ODS). This includes proposals to ban SF6 – a synthetic, high-polluting gas widely used as an insulating medium in switchgear – from new MV electrical equipment up to 24 kV by 2026, and up to 52 kV by 2030.

This means power system operators will soon have little choice but to begin their migration to more eco-friendly alternatives.

Now or never As we look ahead to COP27, there can be no question that it is ‘now or never’. Action has to overtake ambition if we are to achieve a low carbon future and the targets set. With many of the technologies already on hand to power the journey, governments, utilities and industry need to leverage these today, and commit to the necessary investments, to make the biggest impact to our future, where ‘survival of the greenest’ is the reality.

Mastering the art of UHF partial discharge measurements

OMICRON’s new UHF 800 offers you an optimal signalto-noise ratio Partial discharge (PD) testing is a highly effective tool for medium-voltage (MV) and high-voltage (HV) devices that assesses their insulation condition and detects critical defects in them.

Conventional on-site PD measurements, such as those specified by the IEC 60270 standard, are often affected by noise in the surrounding environment.

Measurement alternative for noisy environments Unconventional PD measurements performed in the ultra-high frequency (UHF) range of 100 to 2,000 MHz are a reliable measurement alternative. These measurements are especially useful for PD testing on gas-insulated switchgear and lines, oil-filled power transformers, and HV power cable terminations.

This is because numerous noise sources, such as mobile communications, radar signals, and corona discharges, predominantly transmit in lower or narrow frequency ranges. By comparison, measurements performed in the UHF range result in a very high signal-to-noise ratio. That means optimal PD measurement sensitivity is ensured with little or no interference from external noise.

Reliable UHF PD testing with UHF 800 The portable UHF 800 PD measurement system is our latest solution for performing off-line and on-line UHF PD measurements from 100 to 2,000 MHz on gas-insulated switchgear and lines, oil-filled power transformers, and high-voltage power cable terminations.

Tunable bandwidth filters ensure an optimal signal-to-noise ratio for reliable analysis, even in noisy onsite testing environments.

The system’s portable and flexible modular design enables fast and easy setup during type and routine testing in HV laboratories or test bays, onsite commissioning, and troubleshooting in the field.

Single-channel or multi-channel testing One UHF 800 measurement device is used to detect PD activity in the UHF range of each measurement channel. Up to 12 measurement devices can be connected via fibre optic cables in a daisy chain for simultaneous, multi-channel PD measurement and analysis.

Each UHF 800 measurement device is powered with our RPB1 rechargeable external battery for hours of uninterrupted testing.

Powerful software for PD measurements and analysis The UHF 800 is used with our MPD suite software and includes the latest, time-saving PD measurement and analysis features. These features include recording and replaying PD measurements, user-definable testing profiles, and customised reporting.

Use it with or without MPD 800 The UHF 800 can be used as a standalone UHF PD measurement and analysis system. It can also be easily used with our MPD 800 universal PD measurement and analysis system. This allows you to combine conventional PD measurements using the MPD 800 with UHF PD measurements when the UHF 800 is in the same measurement setup.

The combination of UHF 800 and MPD 800 PD measurement devices – up to 12 measurement devices in total – can be connected via fibre optic cables in a daisy chain for simultaneous, multi-channel PD measurement and analysis using the MPD suite software.

This November, Electrical Review is turning 150 years old!

To celebrate this renowned title and its past 150 years serving the electrical industry, we are publishing a special, one-off 150th Anniversary Commemorative Edition, and would like to offer you the unique opportunity to be part of it.

This publication, due in December 2022, will be unlike anything else you’ve seen before from Electrical Review, ever since its very first issue as The Telegraphic Journal and Electrical Review published on 15th November 1872.

A premium, 120-page, souvenir-style publication designed to be at home in any boardroom or executive lounge, it will focus on the milestones and highlights from our archive, tracing our coverage alongside the developments in the electrical industry across the decades. The content will be laid out in a timeline style, blending our early coverage of the invention

of the microphone, telephotography

(which eventually evolved into the fax machine) and the light bulb, that time when Nikola Tesla wrote for ER in 1888, through to developments in solar and nuclear power, energy storage and the creation of the National Grid, concluding in the present day and the future with features on offshore wind, electric vehicles, IoT and the Metaverse among others.

We will also bring back the best of iconic columns such as Gossage and Letters to the Editor, with a healthy dose of nostalgia which, we are sure, will be appreciated by our many long-time, loyal readers.

If you would like to explore this more with us, please contact: • Sunny Nehru on sunnyn@sjpbusinessmedia.com / (+44) 7741 911 296 • Kelly Baker on kellyb@electricalreview.co.uk / (+44) 7741 911 373