Informing the electrical industry for over 140 years

September 2016 Volume 249 | No 9 www.electricalreview.co.uk

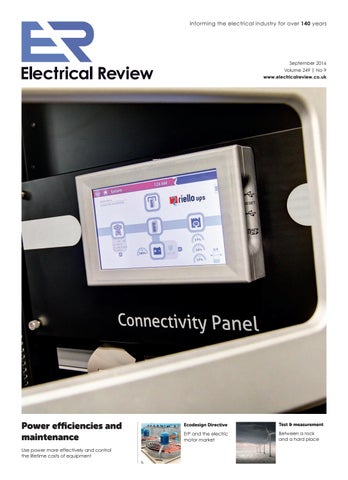

Power efficiencies and maintenance Use power more effectively and control the lifetime costs of equipment

Ecodesign Directive

Test & measurement

ErP and the electric motor market

Between a rock and a hard place