Informing the electrical industry for over 140 years

July/August 2017 2016 Volume 250 | No 7/8 www.electricalreview.co.uk

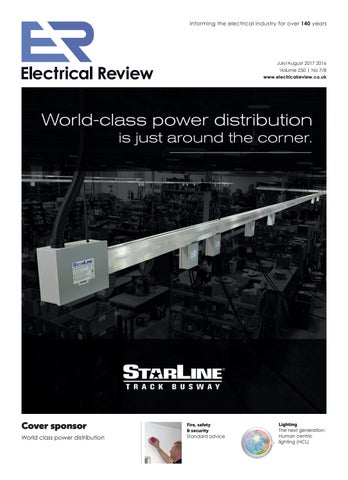

Cover sponsor World class power distribution

Fire, safety & security Standard advice

Lighting The next generation: Human centric lighting (HCL)