Francis

Francis

The CAA is offering a rebate of 50%, up to a maximum of £250, to pilots purchasing Electronic Conspicuity Devices including those listed below. Equipment purchased from 1st October 2020 until 28 February 2021 will be eligible for the rebate.

uAvionix SkyEcho 2 Electronic Conspicuity

• ADS-B Transceiver and FLARM Receiver

• TSO-C199 GPS (SIL=1)

• Barometric Altimeter

• Up To 12 Hour Battery Life

• Use With SkyDemon, ForeFlight and more

The AGM passed by almost unnoticed with only 70 members logging into the Zoom event, most of those being from the usual hard core of active members who show up on a regular basis. I had hoped that the ability to ‘attend’ without having to leave the comfort of your favourite armchair might elicit a rather healthier showing, but I suppose after more than three decades of attending PFA and LAA AGMs myself, I should have realised that unless there’s some sort of upset, interest in how the Association is managed scores pretty low on our personal agendas.

Don’t get me wrong, if as members you are satisfied with the LAA, and I think on the whole most of you are, it’s up to you if the preference is to leave it to that oft overworked ‘someone else’ to take responsibility for the direction the organisation travels. I just happen to believe that it would be healthier if a broader spread of ideas and critique were at play, after all, they do say that ‘together we are stronger’. We have a brief AGM report on page 9.

re-christened G-KIRB, has finally been completed and flown.

Another particularly interesting aeroplane was also completed and flown this year, although it was a rebuild rather than a new build. The prototype Beagle Pup, G-AVDF, only flew for a couple of years in the late 1960s before it was pensioned off, having served its purpose.

It had heralded a new dawn, a post-war dream that Britain could once again become a major player in the light aviation industry, able to take on and beat anything the rest of the world had to offer. Sadly, it came to nought, the enthusiasm not being supported by sound financial sense, and only 175 Pups being produced before the house of cards collapsed.

The prototype was fortunate to survive and commitment, hard work and good fortune have seen it finally brought back to flying condition, resplendent in the same red and white scheme it left the Shoreham factory with in 1967. Francis Donaldson, a former Pup flying group member as a young man, regales us with the Beagle Pup’s fascinating story.

Many will recall the A Plane is Born documentary series in which Mark Evans built and flew a Europa XS; believe it or not, that was 20 years ago. It was a not particularly well-kept secret that the aircraft that Mark flew at the end of the series was not the one that he was seen building –project timetables work out just as badly for television as they do for the rest of us! So, what happened to the actual build project? Well you can read about that in our Project News Special on page 46 where the star of the show, G-OIZI, subsequently

Take care and be safe, Brian.

Brian Hope

Meet the Members’ Frank Cox taxies in at Lundy in his superbly restored Fairchild Argus. Photo: Neil Wilson

Brian Hope

Meet the Members’ Frank Cox taxies in at Lundy in his superbly restored Fairchild Argus. Photo: Neil Wilson

Greetings all, and a special thank you to those who were able to join us for our e-AGM (is that an actual entity?). Procedurally, all went well, and we were able to inject some animation into the event but it’s clearly no substitute for the real thing, which we hope we will be able to deliver next year. I was also pleased to hear support for keeping a remote AGM function even if we are able to meet physically, I think this is most appropriate for such an extensive organisation as ours with members and Struts so widespread.

We received some positive reaction to the delivery of this year’s AGM on the day, however, in the spirit of openness, we would welcome any further comments and thoughts, regarding how we might be able to improve future meetings.

Now that the AGM is out of the way, the LAA team has much to focus on, apart from all of the considerations thrown up by renewed restrictions and new ways of working. For this forthcoming year we have the 75th Anniversary celebrations, working with the CAA on the new 600kg class and ab initio in permit aircraft and more –there’s so much to look forward to.

On the latter points, we have had some positive discussions recently with colleagues from the CAA’s General Aviation Unit (GAU) on how we might progress the development of our sector of GA, both from the perspective of a broader base of types, and how as an association we must step up to the challenges this development will bring.

Right now, we are starting a review process of our airworthiness oversight permissions with the GAU designed to help us with further privileges, such as initial permit issue, transfer of types to the permit scheme and, of course, the 600kg class and ab initio. We must take advantage from this process, and this will no doubt require some changes to the way we do things in future. We will keep you updated as we progress.

In the meantime, I hope you can get out and fly as much as possible, as the days get shorter and the weather unfortunately deteriorates. It seems we are ending the year in the same way we started it with heavy rain, but I noted in my logbook that in the last three years, I was still able to fly through until the New Year before the grass runways and taxiways gave up the unequal struggle and became waterlogged, so here’s hoping!

VAC member Dave Scott is seeking an unserviceable Hewland three-cylinder two-stroke engine (as used in the ARV) for use as an exhibit at the Museum of Berkshire Aviation at Woodley. If you can help please contact Dave at: davescott321@btinternet.com

06 NEWS & LETTERS

Electronic Conspicuity rebates, A/I Bursary recipient gains PPL

09 AGM REPORT

A report from the LAA Ltd virtual AGM

10 PROJECT NEWS

KFA Safari update, Eurofox 912iS, X’Air Hawk, Cleared to Fly and New Projects

16 EC: UPDATE

The state of play with EC in light of the new CAA/DfT equipment rebate scheme

20 HEATH PARASOL

We dive into the archives to look at a very early LAA type – the Heath Parasol…

24 MAKING A PASS – TWICE

A post-pandemic challenge to drive and fly Austria’s tallest mountain – with a Kitfox and a Morgan…

28 COACHING CORNER

COVID-19 concerns impact on everyone. David Cockburn, PCS Head of Training, looks at continuing to fly safely…

30 NEVER GIVE UP!

After a lifetime of longing to become a pilot, with numerous setbacks, Gillian Boston obtained her well-deserved PPL…

36 STRUTS4U

Anne Hughes profiles the activities of the Struts, making good use of social media

38 FLIGHT TEST

Francis Donaldson flies the recently rebuilt prototype Beagle Pup, bringing back memories aplenty

46 PROJECT NEWS SPECIAL

A TV ‘star’ languishing forgotten in a hangar for years, has finally been completed

50 REFUELLING CONUNDRUM: 2 More ideas from members about refuelling at private airstrips…

54 SAFETY SPOT

The importance of thorough inspection – it’s not just a tick box!

60 MEET THE MEMBERS

Frank Cox, former Fleet Air Arm, corporate jet pilot and restorer / owner of a Fairchild Argus

66 CEO THOUGHTS

Steve Slater on contingency planning…

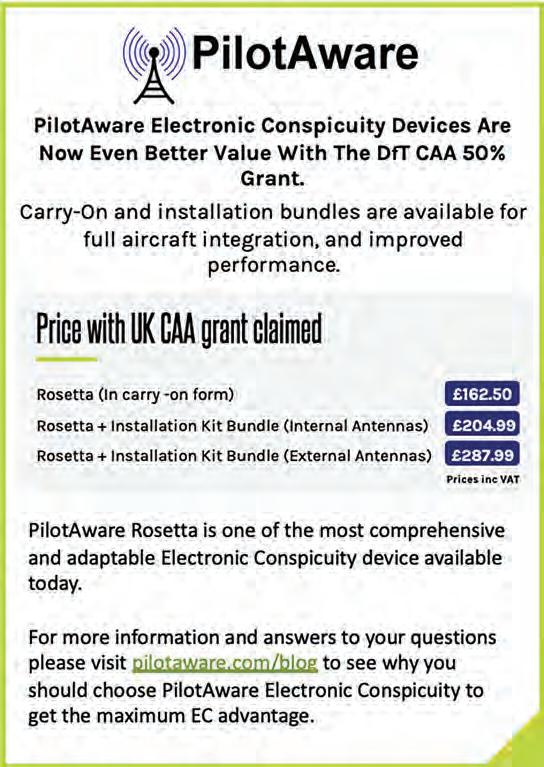

Electronic Conspicuity has become an increasingly important topic in recreational flying over the last few years. It is seen as a useful tool not only in the open FIR for collision avoidance, but also within controlled airspace as a means of accurate position identification of all traffic by all traffic as well as ground controllers. From the recreational pilot’s viewpoint, it is also hoped that it can more readily open up access to more of that airspace.

In order to encourage engagement with EC technologies, the DfT has made funding available in the form of a 50% rebate up to a total £250 (a £500 spend) on the purchase of EC equipment. This includes the Pilot Aware Rosetta, uAvionix SkyEcho, Power Flarm, ADSB Out capable transponders, and approved GNSS position sources such as Trig’s TN72.

The scheme is being managed by the CAA and opened on 5 October and will run till 31 March 2021, and

will cover purchases from 1 October until 28 February 2021. Conditions for application are:

■ The equipment must be carry-on or aircraft-fitted devices.

■ A single rebate of 50% – up to £250 per applicant.

■ Only equipment purchased from 1 October 2020 until 28 February 2021 will be eligible.

■ You must produce a proof of purchase receipt.

■ You must hold at least one of the following UK issued UK or EASA Part FCL pilot licences: Private Pilot’s Licence

In a recent update on licensing, the CAA offered the following advice to GA pilots.

We recognise that COVID-19 remains a significant challenge for the foreseeable future and we remain committed to continuing to provide as much support as possible to GA. For procedural, legal and safety reasons, we are not able to provide exemptions in perpetuity and the GA sector needs to prepare for an ending of certain exemptions soon as part of the return to a more normal operational and licensing framework.

GA organisations, operators, pilots and students are encouraged to review their own circumstances now in order to decide how they can best prepare themselves for the ending of exemptions which have extended the validity of some

pilot licences (which would otherwise have expired) to 22 November 2020 and some medical certificates (which would otherwise have expired) to 31 December 2020.

Noting the unpredictability of the British

(PPL), Commercial Pilot’s Licence (CPL), National PPL (NPPL), Sailplane Pilot’s Licence (SPL), Balloon Pilot’s Licence (BPL), Light Aircraft Pilot’s Licence (LAPL), or be a registered member of either the British Hang Gliding and Paragliding Association (BHPA) or the British Gliding Association (BGA). UAS/ UAV operators must hold an authorisation issued specifically to them by the CAA.

Full details on those eligible to apply, EC devices and how to claim a rebate are available on the CAA website at www.caa.co.uk/ec

weather, particularly in the winter, and the potential for future COVID-19 measures to unexpectedly curtail planned flying, pilots whose ratings may lapse soon or over the winter months are advised to take early action to revalidate their ratings if they have the opportunity to do so.

Blessed relief to those flying EASA aircraft comes in the issue of an updated ORS4 No 1421 to replace No 1370. This effectively allows pilots with a UK issued PART-FCL PPL or LAPL to continue to exercise LAPL privileges (only) in G registered EASA aircraft in UK airspace without the appropriate Medical Certificate, provided they have made a valid Medical Declaration to the CAA and not withdrawn it. The exemption expires on 31 March 2021.

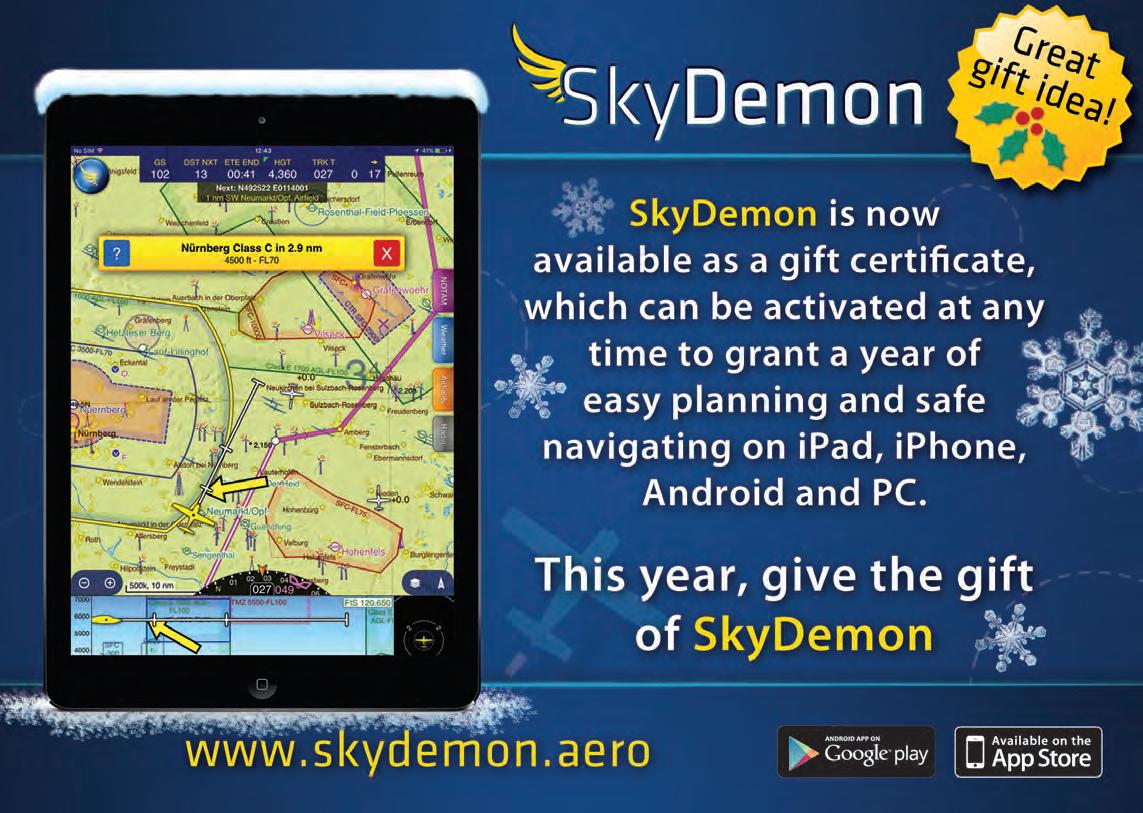

LAA members Keith Vinning (left), of PilotAware, and Tim Dawson of SkyDemon, received OBEs in the Queen’s Birthday Honours list for services to aviation safety.

Keith commented “It was a great honour and privilege to be able to accept this award not only for myself, for Lee Moore and

our small team at PilotAware, but also for the aviation communities who have supported the PilotAware infrastructure over the last five years.”

Tim said “It means a great deal to be recognised in this way by Queen and country. I could not have made the

Iwas awarded one of the 2019 Armstrong Isaacs Bursaries, to a value of £1,500, to help me through my PPL training. The bursary allowed me to complete all of my training towards the navigation phase of my PPL, including my qualifying cross-country. I completed my training at Bristol Aero Club (Gloucestershire Airport).

On 13 October I passed my skills test, and on the 16th I passed my RT practical exam. I have just finished the application for my licence, and I hope to receive it before my 18th birthday!

This bursary was an amazing help and gave me that final boost that I needed to get my PPL completed; I believe it would be incredibly beneficial to others to benefit from the same bursary in the future.

I can’t wait for the LAA Rally next year, and hope to fly myself (COVID-19 restrictions permitting). Thank you so much again, this bursary has helped set the foundations for an exciting future in aviation. Kind Regards, James Gunn

(The 2020 crop of Armstrong Isaacs Bursary applications will be assessed during November and five £1500 bursaries awarded. Recipients will be notified in December. Ed).

contribution I have to aviation safety without my wonderful team at SkyDemon.”

Heartiest congratulations from everybody at the LAA, not only for the awards, but for two excellent products that have made our pastime appreciably safer and more enjoyable.

Dear Editor The hand wringing over airspace busts continues (Letters, LA News, September 2020) with yet another study into the ever-upward trend of infringement underway – but even the researcher admits ‘there appears to be no simple explanation.’

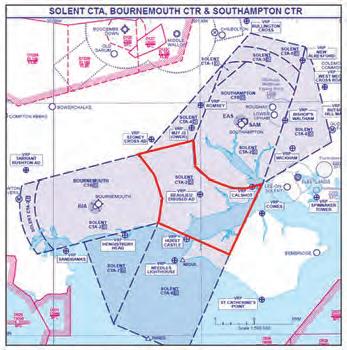

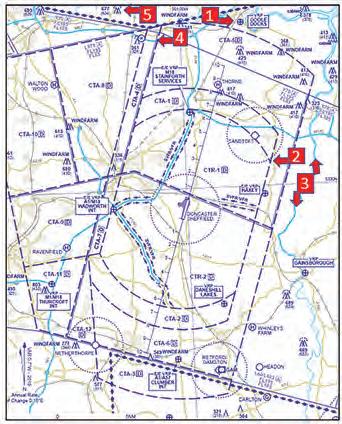

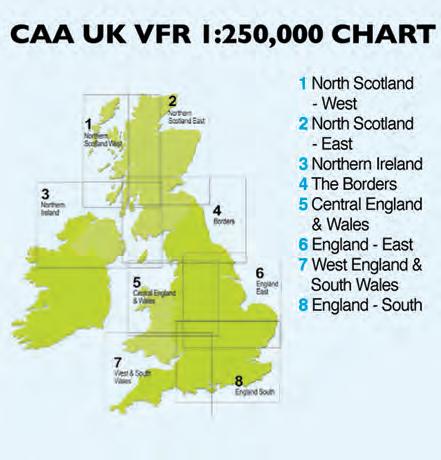

I’d suggest that there is at least one simple explanation – the absurdly complicated way in which UK controlled airspace is designed.

Take a look at Doncaster Sheffield’s airspace. The lucky controllers there preside over not one but two CTR segments and – if you can believe this – no less than 12 CTA segments of every imaginable shape and size. And they are far from being alone –Solent’s bizarrely-shaped airspace includes 10 CTA segments of assorted shapes and sizes. And don’t get me started on Farnborough…!

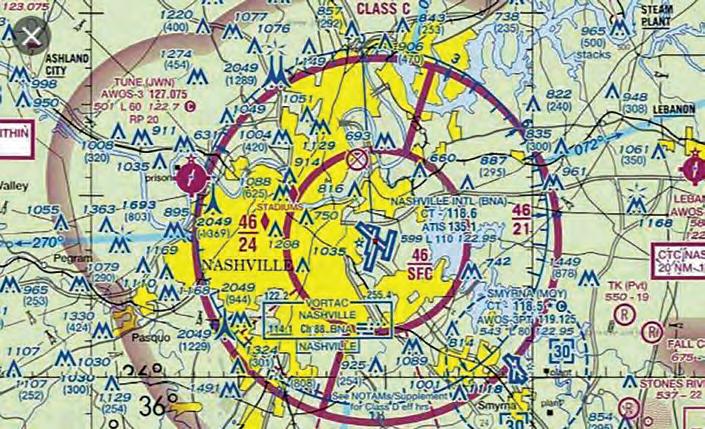

Now take a look at the chart for Nashville International’s controlled airspace, it’s blissfully simple – just three segments.

So, is it because Sheffield and Solent are so incredibly busy that they need all that super-complicated controlled airspace?

Hardly. Combined movements at Southampton and Bournemouth in 2019 were 76,359. At Sheffield Doncaster they had just 36,473 movements to justify hogging all those weird chunks of air. By comparison, Nashville International with its simple layout managed to cope with more than 230,000 movements.

Typically, airspace around airports in the US is designed based on an ‘upside-down wedding cake’ model – simple to read and understand, resulting in infringements being relatively rare.

We in the UK seem to have a knack of making everything more complicated than it need be. Those who design our airspace could do worse than look at the way they do things in the US. Until then, for as long as our controlled airspace resembles a collection of jigsaw puzzles, infringements by confused pilots will continue. Regards, Tim Watson.

Dear Brian, the article by Ian Fraser on GPS jamming trials and the potential effects for navigation in the October edition of Light Aviation was very interesting and thought provoking, especially raising the old debate about whether pilots should carry a paper chart on flights as a back-up.

The comment regarding the difficulty in obtaining information on these trials, or indeed many other things of interest to GA pilots, can more readily be delivered to electronic devices direct from the CAA by registering at http://skywise.caa.co.uk and as it states on the website: Aviation is a dynamic industry, and SkyWise allows you

to stay up-to-date with news, safety alerts, consultations, rule changes, airspace amendments and more from the CAA.

Advance information on the jamming trials is also sent by this means, well in advance of the trials taking place and I recommend LAA members to use this facility.

The information comes as a short resumé and, if the recipient decides it is not relevant to them, they can just delete the email, but if useful, opening it will provide full details.

Another useful source of information is the CAA Airspace & Safety Initiative website at https://airspacesafety.com

Regards from John Broad.

(Useful info John, thanks, but if something is flight safety relevant, it should be Notamed! Ed)

Hi Brian. Always enjoyed the mag and still do. Just an idea – is it possible that the CHIRP GA edition could be published in the mag? I used to enjoy reading the CHIRPs when they came as hard copy inserts and

realise why they stopped around Credit Crunch time and money for anything ‘non-essential’ (since when is safety a luxury?) disappeared, but I still miss reading something REAL. I try to keep up with CHIRP electronically, but it just isn’t the same!

I don’t think I am a ‘flat-Earther’ or hopelessly behind the times – I am a software developer, albeit one in my 50s.

Like a lot of people, I stare at screens all day and it’s nice to have something on paper to read when it comes to reading for pleasure. It would probably increase CHIRP’s readership, which can only be a good thing. Regards, Rob Swain.

(I am sure many of us appreciate the tangibility of a paper magazine, so I do wonder whether the likes of CHIRP and the Airprox reports suffer from poor take-up. Though I am averse to simply publishing their content en masse, I wonder whether particularly relevant to LAA material might be usefully included. What do members think? Let me know. Ed)

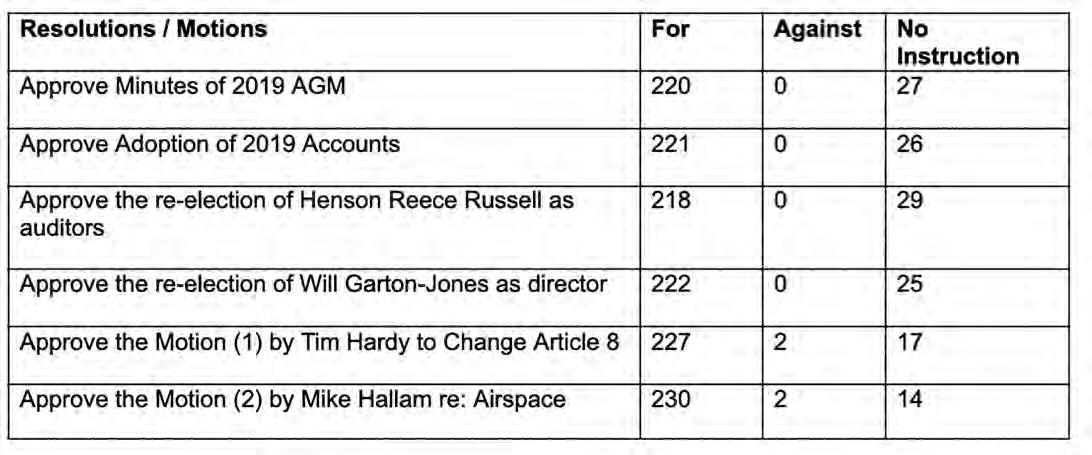

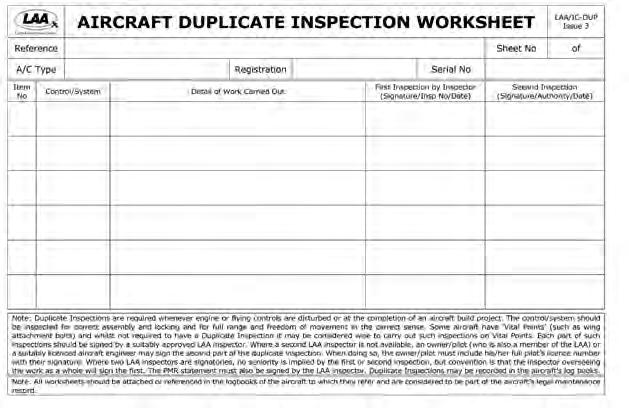

The pandemic forced the Association to take a new route to holding its 2020 AGM and for the first time it was held virtually, with attendees logging in to a Zoom conference from the comfort of their homes. Technically it worked very well, with Chairman Tim Hardy and CEO Steve Slater hosting the event from Turweston HQ.

The meeting started on time, 1000, and Tim announced that he had received one apology for non-attendance from John Mangham.

With only 68 members in attendance, less than the required 1% of the membership, it was not quorate and, in accordance with the Articles of Association, 20 minutes had to elapse before he was permitted to rule that the meeting could go ahead. The time was usefully taken up by Steve Slater presenting his CEO’s Report.

CEO Report: Steve congratulated the LAA staff on managing to maintain a good level of service to members despite having to work from home for two months during lockdown, and the subsequent COVID-19 safety requirements once back at HQ. The Association saw a significant drop in income over the first six months of 2020, but has recovered well latterly, with only 100 less aircraft being permitted (2,600 instead of 2,700) than in 2019. Membership has fallen by about 100 over the same period, almost certainly due to all the events where

we recruit new members unfortunately being cancelled.

Although sadly, this included the Rally, we are already forging ahead with plans for 2021, the Association’s 75th Anniversary, and events will include a special Anniversary Dinner, a Round Britain Flying Rally, and of course a bumper celebration Anniversary LAA Rally at Sywell.

The AGM was officially opened at approximately 1030.

Tim Hardy welcomed those in attendance and also commended the LAA staff on a job well done throughout a difficult year. He also passed on the thoughts and best wishes of the Association to all members and their families, some of whom will sadly have been adversely affected by COVID-19.

Voting this year was, of necessity, by proxy form only, sent in prior to the meeting and 247 completed forms had been received.

The vote to approve the Minutes for the 2019 AGM was announced, see the table (below) for details.

Treasurer’s Report: Will Garton-Jones reported that our finances remained in a strong and stable position, despite the fact that although COVID-19 followed on from a very wet winter, resulting in income being down 50% in the first half of the year, subsequently we had made a strong

recovery. We had also not had to furlough staff as previous investment in Cloud technology had enabled them to work effectively from home, and thus maintain member services.

Reporting on the 2019 financial performance we had made a planned deficit of £49,502 against an income of £1.3m after a number of very profitable years. The decision had been taken to invest in a succession plan – three additional engineering staff members – as several of our engineering team were nearing retirement. For 2020, our planned deficit will, as a result of COVID-19, be greater than planned which will mean a necessary change in plans for 2021, and an increase in subscriptions is being considered. For further details of the 2019 financial performance, please refer to the July 2020 issue of Light Aviation

The remaining votes were presented at this point – which completed the official business, and a members’ forum commenced, allowing an opportunity to raise a variety of topics.

Tim thanked those who had attended and commented that hopefully next year we could return to the AGM Day format with guest speakers etc., and the ability to fly in. A virtual element would, however, usefully be continued for those who were unable to attend in person.

The Meeting officially closed at 1130. ■

n the past, particularly with early scratch-built aircraft, the engine would be a project in its own right – adapting a car engine, maybe a VW Beetle, or perhaps rebuilding a tired existing aero engine and improving its electrical and ignition systems with after-market components. Coincident with the maturing of quick build, often high-performance aircraft kits, the Rotax 9-series four stroke engines really came of age, and itself matured into more sophisticated, higher power, more complex variants. Dare I say a little boring, a true Germanesque creation, an Audi of aero engines, fantastically dependable but perhaps a little dull. Costing maybe as much as a basic airframe kit, they are so reliable and expensive that they don’t seem to attract the bloke in a shed with an eye to making improvements.

In the UK, the only long-term tuning part available has been an alternate ignition module to tame the 912’s gruff starting habits. Of course, it goes without saying that most of us are more than happy with reliable uniformity, but some of us ‘old school’ engineering types do enjoy a bit of experimentation.

More recently Edge in Norway seems to have had more of a profile with their 912 aftermarket fuel injection and turbo kits . Their website proudly states that they have been interfering with Rotax engines since 2007, so clearly there is a tuning and modding world out there for the Rotax.

The build of my Safari is progressing well. There is a fair amount of work involved with the fitting of the butt ribs (the ones either side of the fuselage centre section), cockpit roof, windscreen, boot cowl and rear turtle deck. The design is rather clever, and a great deal of thought has been put into gaining access to the forward fuselage for maintenance.

Whilst the roof and butt ribs are painted prior to riveting to the fuselage, the rear turtle deck is removable, which is necessary for wing folding. The really clever thing though is that the boot cowl moulding, which covers the fuselage top and sides from the firewall to the door pillars, is removable, giving superb access to the rear of the instrument

Now, an Italian company, Vz Power, are also in the aftermarket Rotax business, producing a retrofit turbo kit. And it is a Vz engine that Dudley Pattison has chosen to hang on the front of his KFA Safari.

Thus far, Dudley has provided a couple of updates on his Safari, the first UK example to feature in Project News , and below he outlines how he is tackling the forward fuselage, wing covering, and preparing to hang that hot 912 lump up front.

We also hear from Peter Harvey, who provides an overview of his Eurofox project and the impact both Brexit and COVID-19 has had upon it. The very lucky chap now has a gorgeous Rotax 912iS powered Eurofox in which to fly around his local Cornish skies a nd the convenience of a workshop in his garden, sounds like flying heaven to me!

And finally, Dave Western and John White have built X’Air Hawk G-CLDR between them – and found it to be all they hoped for. I know from personal experience that these airframes come together at lightning speed and then take a little longer to commission with engine, instruments and paperwork. Bolted tube and fabric sock style, they are the Ikea of aircraft construction.

To get in touch with Project News , and tell your story, report a milestone or just to send a picture, email: projectnews@laaarchive.org.uk . Please share your story!

panel, fuel lines and valves, rudder pedals, header tank etc.

Once the firewall and engine mount have been fitted, the boot cowl is screwed to the preformed flange on the firewall and to lugs welded at strategic locations to the fuselage framework.

Bending the 3mm polycarbonate windscreen around to meet the fuselage members at each of its rear edges is a bit fright making, but it works, and with the aid of a few speed clamps it is possible to do this solo. The bonus is that if you wreck your screen by spilling fuel on it (how many times have you heard of that happening to someone?) the screen can be easily removed and used as a pattern for its replacement.

So, the fuselage is sitting in the garage ready for the Vz Rotax to be hoisted into position. This engine came from the Vz Power company in Italy, who take an 80hp 912, add their turbo to it and the 80hp becomes 115hp. The plan is to fit an FP propeller, which is a fully automatic variable pitch propeller which, I am told, will not allow the pilot to over boost the engine. Sounds like the one for me. This propeller is currently being flight tested with the aim of gaining LAA approval.

A few days ago I brought the first wing from the garage into the workshop for covering. This is another first for me as I have never covered an under cambered wing on a full-size aircraft before, models yes, but this wing panel is quite large at four metres. The under camber isn’t heavy though, and no difficulty has been encountered as yet (my fingers were crossed as I typed that, and that is difficult…).

As I have mentioned in a previous Project News , I am using the Poly-Fiber covering system with single pack Polytone paint. Polytone doesn't have a high gloss finish, more a subtle eggshell finish, which in my eyes better suits the types of aircraft I usually build (Van’s excluded).

This paint is very easy to apply and the chances are you won’t die spraying it. One problem that it does

Above The wing is covered in two pieces starting with the under cambered section of the underside. Here the spar position, ribs and trailing edge are pre-glued Polytak. The fabric is then laid on and a 50/50 mix of MEK and Polytak is brushed through the fabric to bond with the pre-glued areas. Photo:

Above right Vz Rotax lump ready to be lifted in. The roof is nearly finished, and the screen and boot cowl fitted. Access is given to the footwell and rear of the instrument panel by removing the boot cowl.

throw up is that it doesn’t stick to metal components very well. There is a way around this that is not too onerous, and worth doing in my opinion, to keep the other benefits of Polytone. The metal parts are prepared in the usual way, sanding, etch primer, grey primer etc. When at the stage that you would normally apply the topcoat, it is sprayed with Poly-Fiber EP-420 epoxy primer. While this primer is still tacky, a light coat of Polytone is sprayed onto it. It doesn't mean you need two spray guns though, as you have time to clean out the epoxy from the gun and refill with Polytone. It is all in the detailed Poly-Fiber manual.

So, when the two wings are covered and have the Polybrush applied, I will take them back to the garage and bring the fuselage into the workshop, after hoisting the engine into position. They will reside there during the winter as my spray shop is actually ‘the great outdoors’, meaning I will have to wait for warmer weather to Polyspray and Polytone them.

With the fuselage indoors, I can start on the instrument panel and finish the forward fuselage. I missed school the day electrics was taught, luckily Merv White attended, so he is going to help in that department. I have often said that I don’t know how it is possible to build aircraft without friends!

Building my own aircraft has been an ambition of mine for a number of years – but a passion not shared by my wife! But, by 2018, rather as water dripping on stone will eventually wear a hole, I won her over. Over previous years I had researched a number of options and knew that by this time I didn’t want to take many thousands of hours building essentially from scratch. A flight with Roger Cornwell convinced me of the merits of the Eurofox, as well as making my decision on colour scheme an easy one too; I simply copied his aircraft as I thought it looked stunning.

I have always been a fan of new technology, and I found the reviews of the 912iS very interesting, particularly the ability to abandon carb heat and mixture control. Additionally, the Eurofox team had very much led the way with introducing the 912iS into the UK, so I knew that I would be in good hands when the inevitable queries arose.

At one level the engine is extremely easy to install, no carb balancing, only a single (throttle) cable. Admittedly there’s a plethora of sensors and with everything controlled by the box of electronics, a distinct lack of user serviceable parts. I had to work quite hard to make sure the panel wiring didn’t become a nest of rats’ tails!

Below Always a benefit if our creation has room to spread its wings in the garden. Photo: Peter Harvey

On the advice of Eurofox, I combined the 912iS with Kanardia instrumentation, an EMSIS unit for all the engine parameters, and a HORIS which is linked into the same system and gives a DI, horizon, ASI and Altimeter. It additionally provides the GPS feed for the ADS-B out on the f.u.n.k.e. transponder.

Obviously it is still very early days, but to date the engine performance has been faultless. Starting is easy, it appears to be extremely economical, burning just nine litres/hour at 4,000 revs, which is enough to bimble around at 90mph. At around 4,500rpm that rises to 12 l/hr as the speed increases to 100mph. The Eurofox is a draggy machine and high top-end speed was never part of the design criteria.

Take-off performance and climb rate are both excellent, it’s no wonder that the aircraft has proved so popular with gliding clubs around the country as a tug.

So how exactly did Brexit and COVID-19 play a part? Those of us with long memories will recall we were originally set to leave the EU at the end of March 2019. It seems that the factory in Slovakia decided that UK buyers would change their minds about importing aircraft once that happened and put all UK orders on hold. Whilst this was sorted out quite quickly, it did mean that my kit didn’t arrive in the UK

in June, as originally planned, but in November. By that time, Rotax was having supply problems with the fuel pump units, so that didn’t appear until sometime later.

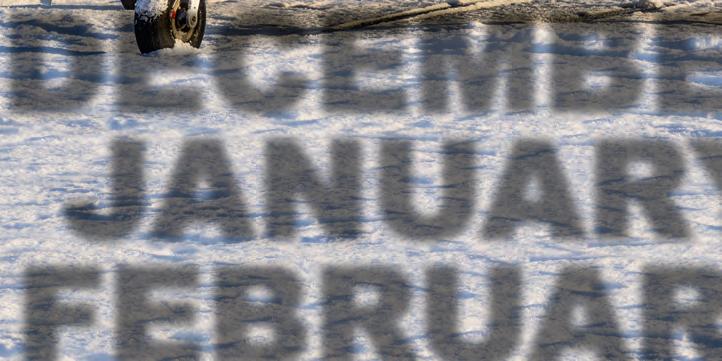

December, January and February were always going to be full of other commitments, so initial progress was quite slow. Then the nationwide lockdown was introduced, but luckily for me my build workshop is at the bottom of the garden, so I spent most of the lockdown happily building Foxtrot X-ray.

Then I had to hit the pause button as my Inspector wasn’t able to travel to sign off the work. Up to that point we had had numerous phone calls, swapped photos and managed to overcome all the problems/ queries I’d encountered. However, as any builder will know there can be no substitute when it comes to finally signing off the project.

By this time the LAA were back working in Turweston HQ but there was a further delay in issuing the Permit to test fly whilst one or two queries, mainly about whether I could test fly the aircraft myself, were sorted out.

Then the insurers seem to have their own COVID-19 ‘moment’, but thankfully all the pieces of paper did duly arrive and, despite Brexit, COVID-19, Rotax fuel pump problems and such, Foxtrot X-ray took to the sky, with me at the controls, on 4 September.

To anybody thinking of building, I would encourage you to take the plunge. I’m no engineer by training, although I

Above The panel as a work in progress.

Below The Kanardia EMSIS and HORIS, well-suited for teaming up with the Rotax 912iS. Photo: Peter Harvey

do like to think that I’m quite practical. There is a plethora of advice available out there, and the choice of kits seems to grow every year. I was looking for a taildragger that had good short strip performance and that, in truth, would probably spend most of its time bimbling around the superb Cornish coast, yet had sufficient load carrying capacity and range to take me further afield if I wanted. The Eurofox fits the bill perfectly…

We decided that we would, between us, construct an aircraft, and both leaned towards a rag and tube kit, of which there are many on the market. However, after a phone call to Gordon Salter of Wessex Light Aircraft Co, we went down to his strip, viewed an X’Air Hawk kit, and were taken up in his demonstrator. The decision was made. The kit comfortably beat all the competition on price, was easy to fly, and again compared well to other similar types. Of course, it also helped to know the importer was friendly and helpful, and perhaps more important, knowledgeable.

Due to his work involving a desk, PC, telephone and photocopier, it was decided that John would handle the paperwork, for which I am grateful. I, on the other hand, would do the bulk of the build, because as a small boy I had owned a Meccano set… I hasten to add that I also went into the Fleet Air Arm as an aircraft mechanic as my first post-school occupation.

If your aircraft has been featured in the New Projects list, please let Project News know of your progress at: projectnews@laa-archive.org.

uk

n Pitts Model 12 (LAA 349-15719) 28/09/2020

If your aircraft has featured recently in the magazine and has subsequently completed its maiden flight, Project News would like to hear from you at: projectnews@laa-archive.org.uk

n G-JOET Eurofox 912S (LAA 376-15691) 24/9/2020

Mr Joseph Thomas, Rose Haven, Bourne Lane, Hamstreet, Ashford, TN26 2HH

n G-LLYN Eurofox 912iS (LAA 376-15678) 29/9/2020

Mr Dewi Griffiths, Bryn Haul, Dinas, Pwllheli, LL53 8UB

Above The Hawk is almost ready to test fly.

Left The X’Air product line has always been blessed with a very roomy cockpit, and the Hawk is no different.

Photo: John White

The build itself was straightforward, as any builder will tell you, and after quite a short period the fuselage is up on its wheels and you feel the rest will follow very quickly. Sadly, this isn’t the case. For many weeks to follow, nothing seems to change, appearance-wise, as your time is taken up with engine installation, controls, wiring etc.

However, the time eventually comes when you start to build the wings, and then things develop more quickly, until all that is left to do is the paperwork. At this point don’t get too excited, the paperwork is a major task. Then there is the test flying, which we left to Gordon, since he has flown more X’Airs than I’ve had hot dinners. We have to say now that she’s complete, it’s probably the best flying experience we have ever had. She is fast enough to get us anywhere we are likely to go in decent time, fuel burn is very good, stability and manoeuvrability excellent, and she’s a good looker too.

Thanks to Gordon Salter, the importer, who must have answered the phone to me 100 times, yet always found time and patience to solve my problems, and to Miles our Inspector. Also thanks to all at Westonzoyland Flying Club, who followed the build with interest and encouragement.

Flt Lt C Altass, 31 Herrick Road, RAF Brize Norton, Carterton, Oxfordshire, OX18 3FF

n Sling 2 (LAA 399-15717) 01/09/2020

Mr P G Hooper, 44 Lynford Avenue, Weeke, Winchester, Hants, SO22 6BN

n G-PLJR Pietenpol Aircamper (PFA 047-13426) 29/9/2020

Mr Patrick Taylor, 6 Swan Lane Marsh, Gibbon, Bicester, OX27 0HH

n G-SEKR ISA 180 Pocket Rocket (LAA 408-15535) 11/9/2020

Northern Aircraft Company Ltd., Sunnyside House, Hutton-LeHole, York, YO62 6UD

n Van’s RV-14 (LAA 393-15720) 30/09/2020

Name & Address held by LAA Engineering

n Van’s RV-7 (LAA 323-15718) 15/09/2020

Name & Address held by LAA Engineering

n G-CKCF Scintex CP301-C1 (s/n 557) 11/9/2020

Name & Address held by LAA Engineering

n G-CLKN Supermarine Spitfire MK26 (PFA 324-14634) 9/9/2020

Name & Address held by LAA Engineering

n G-REVV Van’s RV-7 (LAA 323-15588) 7/9/2020

Name & Address held by LAA Engineering

n G-VXXY Aeroprakt A32 Vixxen (LAA 411-15702) 29/9/2020

Name & Address held by LAA Engineering

n G-YELA Van’s RV-8 (s/n 2002509) 24/9/2020

Name & Address held by LAA Engineering

Following on from my previous articles I continue to monitor Electronic Conspicuity (EC) as it evolves in today’s aviation environment. As an engineer, I like to make decisions for my aircraft’s equipment based on an understanding of what is actually going on, rather than sales literature and blogs. In this article I focus on some key aspects of ADSB.

Recently there have been a couple of announcements on EC, the most headline grabbing one being the CAA / DfT announcement of a subsidy of up to £250 to help equip you with EC. This will cover 50% of EC-related purchases, up to the maximum £250 subsidy (https://tinyurl.com/ CAA-EC-offer). The other, announced in last month’s LA magazine, is a revised procedure for the LAA on installation of EC equipment on your aircraft (TL 3.03 section 9). For details see https://tinyurl.com/LAA-TL-3-03

Electronic Conspicuity is a concept in which radio beacons in our aircraft send out information about our current position, and radio beacon receivers in other aircraft, or on the ground, tell their crews where we are relative to them and display this information on a traffic radar display, an electronic map or via an audio warning device. ‘EC Utopia’ is when all beacons and receivers work together, everyone has one, they all work properly, and everyone can detect a collision risk if there is one. At the moment however, there are at least three competing standards which are not visible to one another.

EC is a dystopian world full of jargon, acronyms and confusion, and is a long way from being able to achieve the high standards expected of it. The CAA’s initiative can help improve EC by encouraging purchase or upgrade of either a beacon, receiver or both, but before you spend your share of the money, make sure you understand what the gadgets will do for you.

There are lots of dialogues on the aviation forums on the subject of EC equipment and which is best. The RV forum is just one example, and has recently been dominated by a ‘my solution is the best thing since sliced bread’ ping pong about FLARM, PilotAware and ADSB. They all have their strengths and weaknesses, so I won’t repeat the numerous articles written in this and other mags.

However, a significant issue which is increasingly being discussed, and is indeed important, is an obscure setting in the ADSB messages called, ‘SIL’. So, what is SIL all about? And what is its significance to EC, and indeed you, in the decision-making process of getting on board with EC?

Above The Trig TN72 is a certified GPS position source that will enable your ADSB ready transponder to transmit on SIL 1.

SIL

SIL (Surveillance Integrity Level) and its associated SDA (System Design Approval) are terms you will see referred to constantly almost everywhere ADSB is mentioned. They are simple numbers that define how reliable your transmitted position information is, and hence what it can be used for. They are determined by the approval standards TSO (Technical Standard Order [FAA]) or ETSO (European [EASA] TSO) of your GPS and Transponder, broadcast in the ADSB radio data message, and tell the recipient how reliable the GPS derived position information is that you are sending them. That in turn is used by the recipient’s equipment to decide what it can do with it, e.g. just provide awareness via a map or radar display, generate an alert, or form the basis of formal collision avoidance advice.

In some parts of the world where EC has become mandatory, SIL also determines if you are allowed to enter restricted airspace. Plus, keep this in mind for our future too, SIL is, in most cases, operator settable on your transponder, but there are rules governing what you can set. SDA, the other mysterious acronym, is an automatically generated value based on your SIL setting and a hardware value for your transponder. It is not operator settable, so while it forms part of ADSB jargon, we can ignore it and just concentrate on SIL.

Your SIL setting is key to being universally conspicuous and it has just four values, and they equate to a statistical probability of the position you transmit achieving a level of consistent accuracy. In other words, are you actually where you say you are? SIL 1 for example, indicates that there is less than a 1x10 3 per hour chance of your position report being outside a predetermined radius of your real position.

SIL 0, however, is the basic level output by a device with an uncertified GPS and implies that the position information you are transmitting has no known pedigree, so it cannot be totally relied upon by the other parties to make safe traffic avoidance decisions. In other words, your position message is only good enough to tell the recipient crew that you are close, but not necessarily (or accurately), where to look for you. Despite your portable GPS’s position accuracy display (it is just a theoretical calculation), you could be several hundred metres from where you report that you are, which could be due to satellite problems, reception problems, weather, interference – or more worryingly – jamming. This could result in an avoidance manoeuvre by another party, based solely on your reported position, actually causing rather than avoiding a collision.

It has long been said by various aviation safety agencies that awareness of traffic presence could make a valuable contribution to safety, and through CAP 1391 the CAA permitted the use of non-certified GPS’s to be connected to a Mode S transponder to affordably achieve this traffic awareness aim.

To identify such systems, the CAA mandated that a message reporting their status be transmitted with the position information – and they used GPS integrity indicators SIL 0 and SDA 0. They were previously a fault condition but have now become a valid status. However, most certified (and some uncertified) ADSB-In devices (receivers) still treat it as a fault status and completely

Top left The PAW is a rightfully popular device but it lacks ADSB-Out capability.

Top right No transponder? The UAvionix Sky Echo 2 beacon with a certified GPS is a lower cost alternative for ADSB-Out.

Above The long established FLARM and Power FLARM are also not ADSB-Out compatible.

ignore a SIL 0 message so, despite transmitting ADSB, you remain invisible to them.

To overcome these weaknesses, a process of constantly checking a GPS’s reported position was developed called Satellite Based Augmentation System, or SBAS. The US version of this, WAAS, is the best known but there are several other versions. SBAS predicts and refines the

accuracy and consistency of your position by using the same GPS satellites you are using to measure the position of a ground station. Any errors seen in its GPS position in comparison to its real surveyed position are processed and routinely transmitted to your GPS / SBAS device via one of the telecoms satellites. These reports are used by your GPS to correct the satellite error or prevent the output of an incorrect position.

If your source GPS has certified satellite augmentation its position reports are given a higher status of SIL 1 or above. The first level of this is defined by TSO (or ETSO) C199, and any device approved to this standard (or above) can be set to report a position integrity of SIL 1.

SIL 1 transmissions are used by ALL certified receiver equipment to produce traffic information or warnings, but not collision avoidance advisories, and are not legal for use in USA 2020 ADSB mandatory airspace. The latter requires a higher standard, typically defined on TSO C145 or above, and are allowed to transmit SIL 3. These higher standards are not really relevant to GA in Europe and afford you no more benefits or rights than those achieved by a SIL 1 transmission. TSO C145 devices are normally much more expensive to buy and require installation and maintenance by a certified avionics engineer.

Meanwhile, whether we like it or not, the CAA’s future airspace strategy and policies propose electronic conspicuity as a major contributor to future aviation safety. ADSB is their preferred solution (see AIC 141/2019) and, while not compulsory yet anywhere in the UK, some of their recent papers intimate that mandatory EC will be in place as early as 2023 for certain choke points. Add to that the current commercial pressures on NATS due to the lower levels of passenger revenue, we can expect an acceleration of EC as a replacement for their expensive to own and operate radar systems. Such EC will almost certainly have to be certified if used in controlled airspace. I expect this to be a mode S ES transponder with ETSO C 199 GPS (outputting SIL 1).

Don’t just look at Class D airspace when determining the impact of this on your flying; consider also the upcoming airspace grabs, expanding Class E, TMZs and TRAs, and possibly military airspace. Airspace modernisation won’t go away just because of COVID-19, and they are all potential candidates for mandatory EC in the next two or three years. While the CAA sits firmly on the fence on the matter of solutions, it is unlikely that a PilotAware or FLARM beacon in their current formats will be adopted as a standard due to regulatory constraints outside their control.

So, to enable and to futureproof your conspicuity, you need an ADSB-Out device capable of operating on SIL 1. You will then be visible to all who need to see you, and where you can go will not be constrained by a lack of equipment.

So, to be clear, if you currently have no ADSB beacon (FLARM and PilotAware are not Transponders or ADSB beacons) or have a SIL 0 transponder, you are invisible to certified traffic and their collision avoidance systems. You are also vulnerable to potential exclusion from our ever-expanding restricted airspace in the near future. TSO C199 approved devices e.g. Trig’s TN72 GPS (£400) to connect to your existing Mode S ‘ADSB ready’ transponder, or a freestanding UAvionix Sky Echo 2 TABS beacon (£500) that meets this standard, are now available and, with the CAA subsidy, are a very low-cost solution to

this vulnerability. I recommend that, before you plan anything else with this subsidy, you ensure that you can output ADSB SIL 1. That is where your future freedom lies.

In view of all this, the LAA has revised its procedures for approval of installed EC equipment in section 9 of TL 3.03. EC devices transmitting SIL 0 and 1 remain similar to the LAA’s normal transponder installation and approval process. They require a modification application, inspector approval of the installation, flight tests for transponder functions and for ADSB-Out, they require an additional ground test that you can do. The ground test requires either a software package (which my PC’s antivirus program rejects) or a PilotAware device (another item for the CAA’s £250). The additional check is simply to demonstrate and record that the transmitted position is roughly correct and SIL / SDA data is appropriate for the standard of GPS used. In other words, the data can’t be mistakenly used for a TCAS advisory.

However, for SIL / SDA greater than 1 they have an added requirement that a test must be conducted by a licensed avionics engineer with the correct certified test equipment. This is enshrined in EASA Acceptable Means of Compliance procedures and cannot be changed. This requirement has caused some concern among several builders planning to use a certified device, such as the Garmin GTX 335, which can have an internal certified GPS. If it does, Garmin recommends it be set to SIL 3 / SDA 2.

I asked a licensed engineer what was involved and it appears they will do a very similar ADSB test to that the LAA specify for SIL 0/1 devices. It will probably take about an hour and cost under £100. However, he also said that he would set SIL back to 1, which I suspect is because equipment with higher value settings for ADSB in Permit aircraft will not have fully complied with EASA AMC 20-24, so he can’t approve it at SIL 3 anyway. I checked with Garmin to see if I could set SIL 1 on a GTX 335 and they eventually conceded that it can be done. The picture below shows the configuration page of a GTX335 with internal GPS set to SIL 1. With such a setting it can follow the normal home install and test procedure.

This begs the question ‘are we really allowed to transmit greater than SIL 1 from a Permit aircraft?’ If you really think you need a SIL 3 capability, talk to your equipment supplier and CAA engineer first, it’s actually their call.

I firmly believe that the key to affordable near future conspicuity for GA is an ADSB SIL 1 beacon or transponder. SIL 0 ADSB, FLARM or PAW as beacons don’t enable all traffic to see you, while SIL 3 adds unnecessary complication, process and cost.(See Steve Slater’s comments re interoperability for an alternative view: p66. Ed.)

Sorry about the jargon, it is a complex, but nevertheless important, subject to those of us who like to understand what is actually going on and make decisions based on that concept, rather than sales literature. As usual, I’ll start a thread on the forum for members to air their views. ■

SkyEcho II ADS-B transmitter at Sil 1. ADS-B, Flarm, UAT receiver. Carry on and connect with Wi-FI to display traffic on SkyDemon, Runway HD, EASY VFR, Foreflight, Airmate. From £479.00 Inc. VAT. £239.50 with CAA claim!

ADS-B, Mode C/S, Flarm receive and Flarm transmit. Needs display. £1500.00 £1362.00 Inc. VAT. £1112.00 with CAA claim!

Save 10% off PowerFlarm Core and Portable in addition to CAA contribution on orders placed by 30th November 2020.

TN72 TABS certified GPS for Sil 1 ADS-B out from your Trig Mode S Transponder.

£348.00 Inc. VAT, £174.00 with CAA claim!

ADS-B, Mode C/S, Flarm receive and Flarm transmit, with inbuilt display. £2220.00 £2016.00 Inc. VAT. £1766.00 with CAA claim! Trig

Garmin GTX335* £2754.00 Inc. VAT £2504.00 with CAA Claim!

*GTX335 is currently under promotion, and includes GA35 WAAS antenna for ADS-B out, worth £280.00.

Very few people in the UK will have heard of a Heath Parasol, let alone seen one.

There have been two registered in the UK, but since they ceased flying many years ago even LAA’s files on them are contained in buff folders with carbon copy flimsy paper now brown-tinged with age. The aircraft is a single-seat parasol monoplane similar to the Luton Minor and Corben Baby Ace, but its construction has a steel fuselage of bolted tube, rather than the more usual welded construction and a wooden wing.

This US design goes back to 1926, although Ed Heath set up his first aviation company in Chicago in 1913. The Parasol was designed by Heath and Claire Linstead and the prototype used a set of lower wings from a ThomasMorse Scout. This technique of borrowing bits and pieces from existing aircraft was used by many amateur aircraft builders in the 1920s and 1930s, not only in the USA but also in the UK, for example, the Blake Bluetit and the Martin Monoplane. The engine for the original Heath Parasol was a converted Henderson motorcycle unit.

It became a great success due to publicity in various magazines, and a series of articles on how to build one in Popular Aviation (now Flying), which started in December 1930. The aircraft could be bought complete or as a set of drawings, and Heath also turned it into the first kit-built

aircraft in the world – without an engine it sold for just under $200. You could also buy various sections piecemeal, meaning the cost could be spread over time.

There are a few examples in existence in the USA, though it has never had the following that Bernie Pietenpol’s Aircamper has had in the post-WWII period. For more information about the Heath visit http:// jimforeman.com/Stories/heath.htm. The Heath company name still exists in the DIY area with Heathkits, who have for decades sold electronics kits.

The aircraft featured in this article became G-AFZE and was first registered to Robert Parker on the 23 August 1939 – unfortunate timing for any new project as it would not fly before all civil flying ceased at the outbreak of WWII.

The correspondence we hold at LAA on this aircraft gives an insight into the emergence of our Association as a body that has been intimately involved in the airworthiness of the UKs fleet of amateur constructed aircraft from very humble beginnings. It must be remembered that over the time covered by this article, the Engineering function was a task taken on by qualified individuals working as volunteers in their spare time.

This aircraft’s origins are not exactly clear but it came to light at the time that the Flea era of the 1930s was drawing to an end as a result of its widely publicised fatal

accidents. A company called Puttnam Aircraft was formed in March 1936 in Hornsey, North London with Stephen Appleby as its Technical Director. Stephen was a leading figure in the Flea movement and flew Flea G-ADMH across the Channel in December 1935. One of the first projects of Puttnam Aircraft was to offer their factory premises for amateurs to build their own Flying Flea.

The company did not last long and was put up for sale in August 1936, due to the ill health of Stephen Appleby, who returned to live in France but came back to the UK in 1938, when he joined De Havillands. The advertised sale of the factory for £1,000 included: ‘A practically complete new design, strut braced orthodox control monoplane and five Fleas, plus staff and equipment’. It is thought that this ‘new design’ was Robert Parker’s Heath, with the construction number P.A. 1. It is this construction number that has led to the link between ‘FZE and Puttnam Aircraft, though the Fleas they built had serials PAC 1 to PAC 5. However, it could have been a new project and the P.A. in the construction number could have been for Parker Aircraft, but at this time we have no further information, so the link is a little tenuous.

After the outbreak of war, nothing is known about ‘FZE until the registration was cancelled in December 1946 by the Secretary of State in the clear out of lots of dead wood registrations in the immediate post-war period. At the time, the Ultra-Light Aircraft Association was being formed by Ron Clegg, eventually becoming the PFA and now LAA. Robert’s project was revived through the embryonic association, and a letter was sent by Ron Clegg to the Air Registration Board (ARB, now the CAA) requesting clarification on what evidence was required to allow the Heath to fly in the UK.

At the time, the authorities seemed determined to kill off any repeat of the Flying Flea mania, and decided that new homebuilt aircraft were not going to be allowed post-war. The only concession was an allowance that aircraft having flown pre-war could be given permission to fly – thus the only route initially to fly ultra-light aircraft was to buy a Comper Swift, Aeronca 100 or, as Arthur Ord-Hume explained in his articles in Light Aviation and his delightful book On Home Made Wings, to buy a pre-war Luton Minor and rebuild it, often with very little surviving of the original.

Heath ‘Parasol’ was not issued with a Permit to Fly by the Air Ministry and therefore is outside of the terms and reference, and in any case what little knowledge we have of the Heath ‘Parasol’ leads us to think that it was not a satisfactory type of aeroplane in that the stall characteristic left very much to be desired, and you will no doubt recall that the designer, Mr Heath, was killed when one of his aircraft broke in the air, but it may well be that the one he was killed on was of a type other than the ‘Parasol’. In the circumstances I regret I cannot agree to recommend the issue of a Permit to Fly.

Yours faithfully…

Not to be put off, Robert Parker re-registered his project as G-AFZE in November 1948, and at the same time, the ULAA received a letter from the ARB noting that there were two Heaths in existence in the UK, G-AJCK being the other one. They state that as the ULAA are presumably keen on assisting both aircraft to fly, are they satisfied that the current engine / airframe combinations are satisfactory, and are they prepared to take responsibility to nominate a test pilot.

It thus appears that negotiations had gone on since the original letter to give some hope that they could after all be cleared for flight.

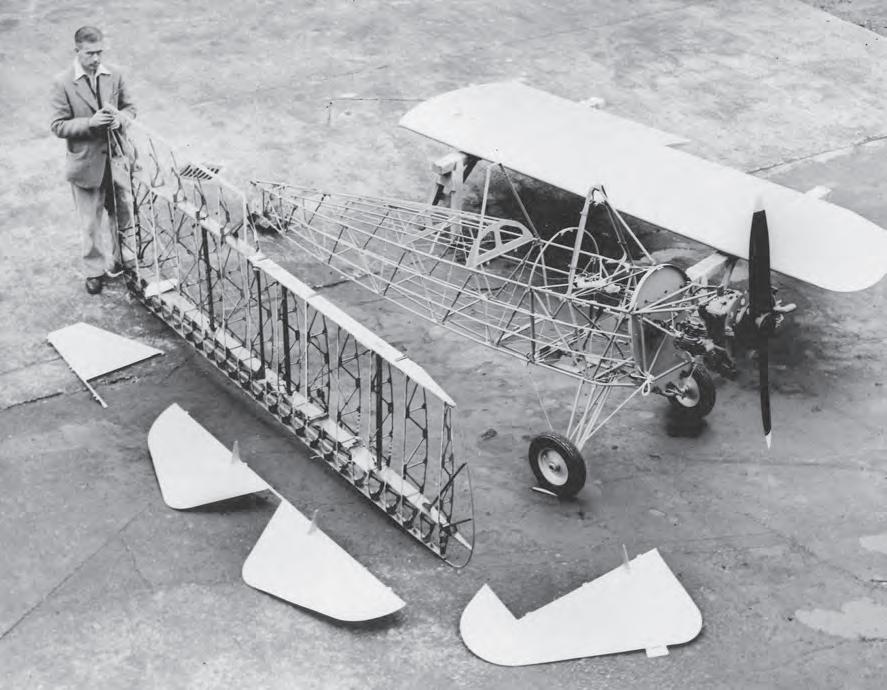

Built from scratch

G-AJCK, this second Parasol, was being built from scratch by the South Hants Ultra-Light Aircraft Club at Christchurch, whose members were in the industry, i.e. Airspeed and BOAC

Airspeed was at this time effectively controlled by De Havillands, though it was not fully integrated until June 1951. It is possible that Sir Geoffrey De Havilland, who was a member of the ULAA, put in a good word with the authorities and, as it was being built by ‘professionals’ they let it through, which was fortuitous for Robert Parker and the ULAA. At this time, ‘JCK was not that advanced and seems ultimately to have eventually been cleared directly with the ARB rather than via the ULAA.

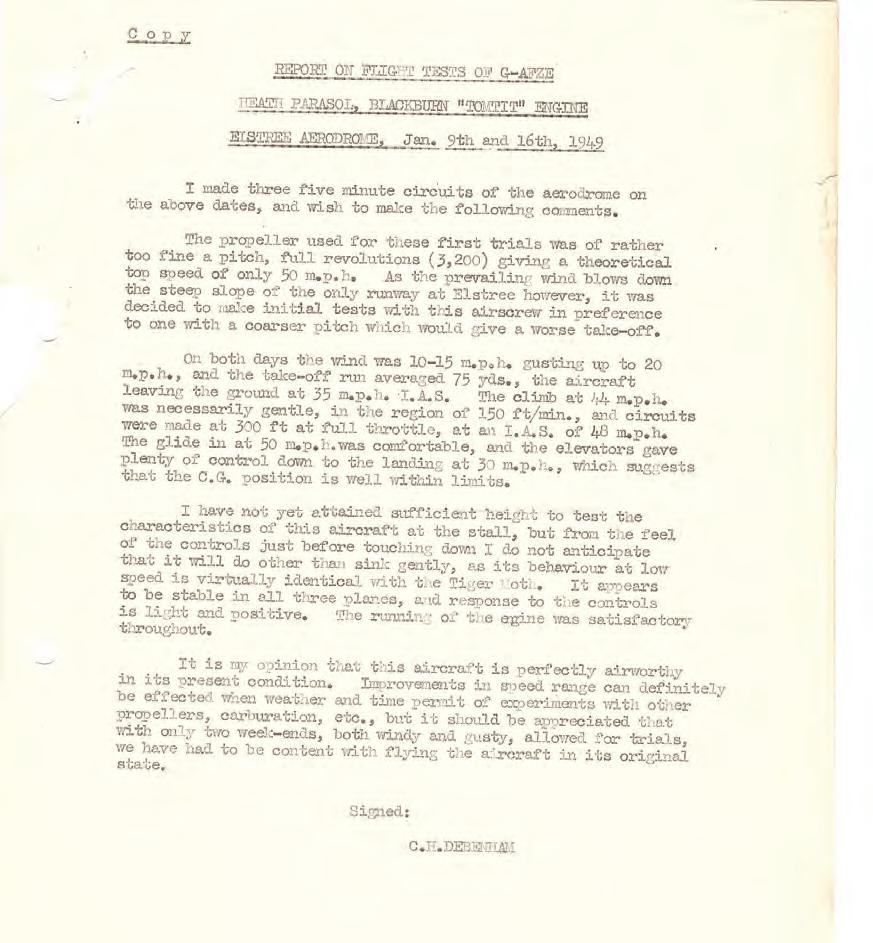

Maurice Imray, the Hon. Sec of ULAA, confirmed to the ARB that the centre of gravity of Robert Parker’s ‘FZE had been checked and that Mr C Debenham had been nominated as its test pilot. At the time, the aircraft was fitted with a Blackburn Tomtit inverted V-twin engine.

It was most important to have this pre-war link, however tenuous, but the problem with the Heath was that whilst registered, it had never flown pre-war, nor had any of the type in the UK. However, ULAA decided it should be considered, given that the design had been successful pre-war in the USA, and a letter was duly sent to the ARB.

Four days later, a letter came from the ARB quoting their letter of the 5 May and stating: As you know, the

A subsequent visit by the ARB surveyor to inspect the aircraft at Elstree noted four defects and stated that they were not completely satisfied with the centre of gravity position, and thus it was suggested that Robert Parker should bring the required calculations with him to a further meeting, which Robert suggested to be the following Saturday.

The ARB curtly replied that they did not do inspections at a weekend, and they were greatly concerned over the mud on the floor of the hangar that prevented a proper inspection! However, eventually, on 7 January 1949, a letter was received from the Ministry of Civil Aviation (MCA) enclosing permission for test flights to verify the engine/ airframe combination. The first flight took place

on the 9 January, followed by a second on the 16th. Pictures

Left is the flight test report submitted by Mr C Debenham on 20 January 1949.

An eye witness view of these flights, from Arthur’s book On Home made Wings, gives an idea of the precarious nature of these flights, which may well have ended up in the reservoir at the end of the runway at Elstree today, but fortunately it had not then been constructed.

The test pilot’s report is not so negative, but the ARB, in a letter, had uncomplimentary observations on its performance and stated that the aircraft should not fly or be sponsored by ULAA. They did, however, allow the ULAA to continue if they were prepared to make a firm recommendation for a further Test Permit.

A further letter from ARB on 24 January 1949 relating to the other Heath Parasol, G-AJCK, stated that its construction was a ‘first class job’. Its original engine, a twocylinder ABC Scorpion, had proved unsatisfactory when test flown by Airspeed’s Chief Test Pilot, Ron Clear and the ARB letter stated that the South Hants group were proposing to re-engine it with a JAP J99. The ARB further confirmed that ‘FZE was unsatisfactory with its Tomtit engine but that if trials with the JAP J99 in ‘JCK proved satisfactory, then that might be a way forward for ‘FZE. They advised waiting for the outcome of the ‘JCK trials. Maurice Imray for the ULAA, accepted their conclusions and stated that ULAA sponsorship of the design would be discussed at a forthcoming meeting in the light of the test pilot’s report.

We’ll conclude this vintage tale next

Kerry Skyring reports on the post-pandemic challenge – to drive and fly Austria’s tallest mountain – with a Kitfox and a Morgan…

Readers may recall the tale of Australian Kerry Skyring, resident in Austria, who flew his Kitfox to the 2019 Rally and won the Most Meritorious Flight award (November 2019). So, seeking a challenge in these most of unusual of circumstances, he decided to fly, and drive, Austria’s tallest mountain – the Großglockner. Kerry takes up his story.

A spring of cancelled trips and fly-ins due to COVID-19, led firstly to a bout of frustration, followed by obsessive hiking in the Vienna Woods. As lockdown dragged on towards summer those walks went deeper and deeper into the green hills, but creative inspiration eluded me. Each day I returned without a waltz or even a single tale from those woods. Another COVID-19 escape strategy was needed.

In mid-May Austrian aviators were again allowed to exercise their wings, and at the same time travel by ground-bound vehicles was also given the green light. But HOW to make the most of these freedoms was the conundrum. Around that time my flying buddy, Martin Hirczy, mentioned his failed attempt to fly over the Großglockner. His choice of aeroplane was probably not ideal – the not very powerful Motorfalke. A lack of thrust,

along with cloud obscuring the pass, forced his retreat from the snowy heights.

Martin has flown many hours with me in the Kitfox including a test flight to establish the service ceiling, so he knew running out of puff before the summit would not be an issue. We agreed to tackle the ‘Big Bell’ in the Kitfox as soon as work and weather provided the necessary window.

The following week, during a conversation with motoring mates, isolation-busting plan number two was born. Why not drive Austria’s highest Alpine pass as well as fly it? There were four of us, all Morgan owners, whose plans to drive to the Le Mans Classic race meeting in France this summer had been stymied by COVID-19 restrictions.

To drive the route of the historic GrossglocknerHochalpenstrasse would provide some compensation.

Maps were consulted, cars were serviced, and partners pacified. As with the flying attempt, weather would determine the dates – there’s no point viewing dramatic Alpine scenery from the inside of a cloud. Our first ground assault, scheduled for early July, coincided with poor conditions and so was abandoned, leaving the aerial reconnaissance in pole position.

The Grossglockner, literally Big Bell, at 12,461ft (3,798 metres) is Austria’s highest mountain. By comparison, Europe’s tallest mountain, Mont Blanc in France, is 4,810m. The historic ‘high Alpine road’ passes to the east of the peak, climbing to 8,215 ft (2,504m) via the Hochtor Pass, linking the provinces of Salzburg and Carinthia. Proposed in the 1920s as a scenic toll road and job creation project, the idea was ridiculed by many. However, completed in 1935 it was an immediate success and traffic, mostly motorcycles at first, began rolling over those cobblestones, which had been laid with such care and toil. Today the road attracts tourists from all over the world who pay a hefty toll to drive its sweeping curves.

Perfect weather window

Sunday 5 July brought perfect flying weather to all of central Europe, so we seized the opportunity and at 0930 the Kitfox lifted off from our base at Stockerau, 30km north-west of Vienna.

With full fuel (100L) we were about 30kg under MTOM with nearly 2.5 hours flying ahead of us to reach the start of the historic Hochalpenstrasse. At about 7,000ft we followed the east-west passes through the main Alpine range, the peaks in this area varying from around 6,000 to 8,000ft. The higher terrain, including the Grossglockner, lies further to the west so we delayed our climb to 10,000ft until approaching Zell am Zee. Some of you will be familiar with this lakeside tourist town and its popular airfield.

The original plan had been to land at Zell, drink coffee, breathe deeply of the mountain air, then we would take off, climbing in the valley to attain 10,000ft before heading south into the pass, which would take us past the peak.

However, approaching Zell we were already at 10,000ft, and quite comfortable, and could see no point in throwing away 7,500ft only to scale those heights again. A call to Wien Information advised them we were changing the flight plan and would now land at Lienz-Nickelsdorf (LOKL) on the southern side of the Alps, about 20km from the Italian border. This was accepted as a diversion and we began to focus on finding the correct valley to enter. It was important to get this right as there are two north-south routes across the Alps in this area, a modern one to the west of the Grossglockner peak and the historic route, the one we wanted to follow, to the east. There are also several valleys which, like the sirens of Greek mythology, will lure aviators into their beautiful interiors but fail to provide an exit.

Martin was an aircraft accident investigator in a previous life and reckoned that Greek sailors could blame

their shipwrecks on sirens. However this excuse would not read well for us if we became an ‘accident report’. After a little probing we found the siren-free valley, stoked the Rotax fire, and began a steady climb towards the peak.

The weather was as suitable as it could be, little wind, quite warm on the ground but pleasant at altitude, with downy clouds draped across the higher peaks. Bliss. But as the altimeter edged past 12,000ft the atmosphere in the cockpit lacked not just oxygen but composure as well. There were several reasons. About 15 minutes earlier, before turning south, the Rotax had given a little cough. Not a dry, virus-style cough,

more like a polite little attention grabbing ‘ahem’. Martin raised an eyebrow. I raised my best sangfroid. A few minutes later there was another little clearing of the Rotax throat. I explained to Martin that the motor had done this on a previous trip to the mountains and this was ‘just a little ice’ being swallowed… We talked about it. The 912 ULS installation in the Kitfox keeps the motor nice and cool in the summer but just a little too cool in winter. The carburettors at the rear of the motor rely on warm air gathering there to keep ice at bay – there is no separate carburettor heat system. In winter, I partially cover the oil cooler and coolant radiator with aluminium tape, raising

the under-cowl temps sufficiently for carb ice not to have been a problem in 300 hours of flying. But on this summer day at 10,000ft, with clouds forming over the peaks, we experienced excellent icing conditions while providing insufficient heat under the cowls. The solution was to climb harder using lower airspeeds and a higher power setting to generate sufficient heat to melt the ice. Obviously, this has its limitations as sooner or later one has to descend, but it solved the problem on this flight. A better solution is being investigated…

Also introducing edginess into the cockpit was the confined route we were forced to fly. Austria created a special bird sanctuary (within the High Tauern National Park) around the peak in 1986 and, although we had wings, the Kitfox does not appear on any list of protected species. Only in a narrow corridor of airspace above the winding 1930s-built road could we mix it with bearded vultures and golden eagles.

But where was the road? Raising the nose and power levels to keep temperatures elevated meant limiting

forward visibility. Can you see it? You must be able to see it! Of course, it was right there directly under us and some gentle turns revealed those looping curves, like a draper’s carefully folded cloth, a legacy left by men from our great-grandfathers’ era who, with picks and shovels and sticks of dynamite, laboured through searing summers and withering winters. It took them five years to build Europe’s highest alpine road and, when they were done, well, they weren’t! In the winter of 1935, the first after the opening of the road, 350 men picked up their shovels and tossed aside 350,000 cubic metres of snow to keep one lane open. Talk about bleeding blisters.

Last year around 900,000 people crossed the Alps via this employment project of the depression era.

Nature’s grand cathedral

Meanwhile, back in the Kitfox, euphoria replaced edginess. Who could fly through nature’s grand cathedral and not experience some sort of tingling? Hang on, could we be confusing religious ecstasy with hypoxia? Actually, we were both quite

cool – and not just because the Kitfox has no heater. As best as we could judge, we’d not experienced any oxygen deficiency symptoms. We’d been at 10,000ft for about 30 minutes, climbed to a maximum altitude of 12,216ft for an unrecorded number of minutes – maybe five – and then begun our descent into the valley of the Drau on the southern side of the Grossglockner, enjoying the long gradual descending turns between steep valley walls to achieve a circuit height of 2,000ft. I plonked the aeroplane down without finesse (OK, I bounced) on Lienz’ short tarmac strip and we broke out the stale sandwiches and warm ‘iced’ coffee. After filling the tanks and taking a short rest, we were off again, debating, and finally agreeing, on the best alpine passes to take us home to Stockerau. At the end of the day our flying time was had logged at 5.5 hours, but our living and learning time was immeasurable.

Ten days later, four old Morgans drove the Hochalpenstrasse over the Grossglockner. Starting in Vienna, the trip took three days and covered 1,000 non-autobahn km. But that’s another story!

The first to flight over the Alps took place on 28 September 1910 by French-Peruvian pilot Jorge Chávez Dartnell, who launched his Bleriot from

Brig in Switzerland and crash landed at Dormodossola in Italy, 51 minutes later.

He collected the large cash prize, for which he was competing, but sadly died

four days later from injuries suffered in the crash.

It’s reported his last words were ‘higher, ever higher’…

provides

The FLYER Club was created by pilots for pilots and its goal is to bring like-minded people closer together.

For many members, it's a social thing, others enjoy the free landing fee vouchers, some like the advice and info webinars we've started organising, and some like the exclusive discounts. As the FLYER Club community grows, it will become more useful, more valuable, more fun and have more opportunities to join in.

Whatever your reason might be for joining The FLYER Club, we would love to have you on board!

Ed Hicks Editor - FLYER Magazine

Ed Hicks Editor - FLYER Magazine

COVID-19 concerns are all encompassing for everyone. David Cockburn, PCS Head of Training, looks at continuing to fly safely…

However much I’d like to avoid the subject, it seems that COVID-19, with its consequent Government restrictions, is going to be with us for some time yet. Not only have many projected relaxations been discarded, we are seeing a growing number of localities being given additional restrictions, and have been warned that similar, or more stringent, restrictions may be implemented nationally.

I fear that, even though we can hope to avoid the return to the lockdown which prevented all but absolute essential flying in the spring, we ought to be prepared for the possibility, and I hope most of you were able to take advantage of the good weather in the past few months to reach an adequate level of currency.

The CAA has produced exemptions to allow pilots to maintain their licence rating privileges during the restrictions, and I hope these have allowed you to keep flying.

However, I know of several pilots who were approaching the end of their rating validities and were planning on obtaining the necessary hours and flights with instructors at just the time that became impossible. While being a few hours short has been assisted by ORS4 Nos 16 and 18, that has not helped everyone.

Not that that ought to be a massive hindrance to maintaining licence privileges; a proficiency check with an examiner is not something to be feared, and if a pilot feels he isn’t ready for such a check, our Coaches are able and willing to brush up one’s skills beforehand.

I should also point out that, even though one can fly legally, that does not mean one can necessarily fly safely! For example, it is quite possible for a PPL holder to fly legally when he or she has not handled the controls for the previous 35 months. And after three successful (?) take-offs and landings on their own, they can carry passengers!

Sadly, the late summer has seen several minor accidents, and not a few airspace infringements. Were these the result of pilots being less able to cope with demanding situations than they thought they were?

Although I do not have definitive investigation reports to hand, I certainly believe that to have been the cause of several of these incidents and accidents. When we are less current than usual, not only do our handling skills fade, but our reactions slow and our inflight decision-making process becomes less efficient. If pilots are getting less flying than usual, and this applies to instructors as well, safety margins reduce.

Can we increase these safety margins, even though we are less current than usual? Well, probably not. However, if we avoid flying in challenging situations when we are less current than usual, we stand a chance of maintaining an adequate level of safety. Be more ready to avoid potential trouble, whether it be a forecast of a marginal cloudbase, a crosswind close to our own perceived limits, a fuel load close to minimum required, or any of the thousand and one possible ‘gotchas’ which we routinely cope with as pilots. It is better to be ‘down here’ wishing one were ‘up there’, than the other way around!

And why not use the services of a Coach to brush up your skills and knowledge before you challenge yourself? We should not think of a ‘flight with an instructor’ as an unfortunate necessity, but as an opportunity to hone our skills and either learn something new or refresh what we may have forgotten. Look on the LAA website under ‘Find a Coach’ and take advantage of the experience available. However, in these troubled times some Coaches may be unwilling or unable to travel or fly, so keep trying.

Unfortunately, not everyone believes that a flight with an instructor can be of benefit. I quote from an email I received concerning the required flight with an instructor for rating revalidation. “I will never understand why this nonsense was ever brought in as it isn’t in any way instructional, but life is full of having to live with pointless regulations.”

That pilot is probably speaking from experience, and that really concerns me. If pilots want to use the services of an instructor, whether a LAA Coach or otherwise, they are entitled to value for money. While items are recommended for inclusion in revalidation flights, the instruction should be tailored to the pilot’s needs, and Instructors should try to identify what these are, brief accordingly, and provide guidance during the flight and post-flight debrief.

Mind you, it may not always be the instructor’s fault if

Above This is the time you realise that perhaps you should have had a refresher on your crosswind landing technique…

a flight offers little value. The pilot is paying for the service (even if only the fuel for the flight) so should offer some guidance to the instructor. You may be confident you can carry out the exercises listed in the CAA’s TrainingCom (see https://skywise.caa.co.uk/), but what skill, manoeuvre or radio procedure do you not usually practice on your own? What problem do you hope you never encounter, and what skill do you hope you will never need to exercise for real? The instructor is not there to assess your capabilities but to help you improve, so talk beforehand and give him or her the chance to prepare a suitable flight and brief you on the items you want to include.

Members are frequently confused by the various different regulations to which our variety of pilot licences are subject. Despite the expertise which I am rumoured to possess, I must admit to misunderstanding them myself on several occasions. I discovered one such case recently, so to avoid others being under the same misapprehension, I thought I should clarify that particular situation.

The LAA arranges with the CAA to give all Coaches ‘R examiner’ privileges in order to sign rating revalidation pages on licences. However, those privileges are confined to ratings on UK licences such as the UK PPL and NPPL. The privileges arranged by the LAA do not apply to EASA licences, so our R examiners are not able to use that qualification to sign rating revalidation pages on EU licences.

Nevertheless, many Coaches have their own privileges as listed monthly in the relevant sections of CAP 1585. In addition, all Coaches should also have ‘FCL.945 privileges’, which allows them to sign rating revalidations on EU licences if they have just completed the mandatory instructional flying for revalidation by experience as the final requirement for that revalidation.

Of course, if all UK issued EU licences become UK licences on 31 December, the situation should become a lot simpler!

Not everyone may be aware that the CAA recently issued and updated ORS4 No 1421 to replace No 1370.