Well, although the weather is about to start picking up, Covid-19 has certainly thrown a spanner in the works as far as the 2020 flying season is concerned. With so many events already off, and more cancellations occurring daily, we have reluctantly decided to cut Where to Go and our Landing Voucher columns, plus the list of events in Struts4U for this month, and will review the situation on a monthly basis.

Clearly there’s little point in advertising events that are almost certainly going to be cancelled as government advice seemingly speeds ever more quickly towards what they call ‘lockdown’. I know that for many of us it is going to be more like ‘lockup’, but I refuse to be uptight about it; there are events in life that simply can’t be helped, and this is one of them. We must all be sensible, pull together, and look out for each other.

What can be helped however, is the EU behaving like spoiled kids and blocking the renewal of the derogation that allows UK pilots to fly UK registered EASA aeroplanes in UK airspace on a Self-Declared Medical. That’s a totally avoidable paperwork exercise that is as easy to do as it is to undo. They ought to be ashamed of themselves. One can only hope that if they learn anything from Covid-19 it is that life is too short and too precious to be so damn petty.

Our cover feature this month is the e-Go, an aircraft that sprang from the Association’s 2007 SSDR design competition. Rather than a very basic minimalist machine, which is what many feel the SSDR category embraces, designer Giotto Castelli and

experienced homebuilder Tony Bishop envisaged a state-of-the-art machine capable of serious cross-country flying.

Their e-Go adventure sadly faltered just as the first production prototype was completed, but it may yet rise from the ashes, as Giotto looks to cut production costs and re-introduce the aircraft to the marketplace.

I’d like us all to welcome the winners of this year’s Armstrong Isaacs Bursaries, each of whom is featured this month (P28) as they not only receive £1,500 worth of flying training, they are also now members of the LAA. The fact that we had more than 60 applications for the bursaries highlights the fact that there’s a healthy number of youngsters currently learning to fly, and that has to be a positive situation as we look to the future of our hobby. Good luck to them all as their training progresses and we look forward to hearing how they get on.

Incidentally, if you are stuck at home why not consider submitting an article for the mag? I am always on the lookout for good copy. Ahh, that’s the doorbell, must go, could be my toilet paper delivery. I hope the driver’s got a forklift…

Be safe, be kind and be happy. Brian

By Brian Hope

By Brian Hope

Just when you thought that we were reaching the final stages of the truly ghastly winter weather we have been having, along comes this ‘other thing’ (I refuse to give any more exposure to that word than I have to…) set to test our patience and resilience right at the start of our flying season.

Steve tells me that we have had to cancel and postpone a number of events in accordance with government guidance, so we are all bitterly disappointed that we are not starting the season on the right foot. Despite this, I hope that you and your families are able to navigate your way through safely, and our collective best wishes go out to you all.

This current set of circumstances is unprecedented in modern memory for one reason, and that is that at a time when we should be able to rely on our community coming together, we are encouraged to split up and not meet, not even to share a glass or two. For civil aviation generally, this will go down as a seminal moment in our lifetime, with talk of airline collapses and even airport closures. And yet, there is something unarguably attractive in the resurgence that will surely come in our type of flying.

Fun, affordable flying never looked so good and, when you add in our separation from EASA and potential wider use of Permit aircraft, imagine the possibilities from a sector that could react swiftly to any uptick.

But then, I wonder if we sell our flying as well as we might. I’ve had conversations recently – you know BC –when quite sensible pilots more used to certificated aircraft, have expressed a jaw-dropping lack of appreciation for

what you can currently do in a Permit aircraft, including flying abroad –amazing. I think their concept of a Permit aircraft still involves wicker seats, so maybe we should put more effort into our publicity, eh Steve?

At the time of writing this article, there was ever more pressure from the Government to cut oneself off from the world and stay at home, most unlike are usual desire to mix with friends and fellow aviators and get out and about to enjoy our splendid isle from on high. What to do?

Well, here’s what I’m going to get stuck into:

■ I’m going to revisit my checklists and make sure that the sequence of checks makes sense, and accentuate the areas where important checks can easily be missed.

■ Read my POH (do you have one?) again and make sure all the vital bits of information are readily referenced.

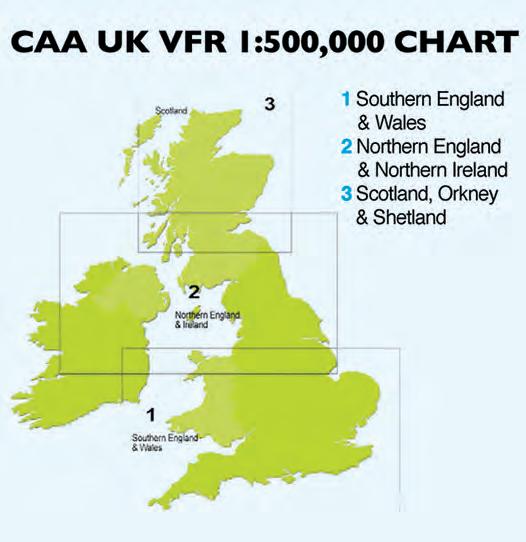

■ Plan my top 10 destinations and routings using manual charts, pilot logs etc., ‘the old-fashioned way’, to keep my skills fresh just in case someone turns off the GPS signal. And I’m going to do this through Farnborough’s new airspace to get an appreciation before I do it for real.

■ Get out to the aircraft if I can and at least keep it clean and well maintained, ready for the off when weather and the restrictions permit.

There’s bound to be more we can do, I think you might be hearing from Francis soon on that one.

Last but not least, don’t forget that LAA members can achieve satisfactory social distancing by engaging throttle and joystick – good luck.

06 NEWS

EASA flying with UK PPL, NPPL and Self-declaration. LAA/BMAA merger talks suspended

09 LETTERS

How can we deter Rotax engine thieves? Transponders must be on!

10 STARTER’S ORDERS

Prop swinging is a skill that demands great care and good technique, says Steve Slater…

14 PROJECT NEWS

Electric Zenith CH 750, Fairchild 24W-41A, New Projects and Cleared to Fly…

20 FLYING ADVENTURE

In a bid to recapture the thrill of flying for one pilot who had lost his ‘mojo’, Martin Ferid sets off with him to Kortrijk, Belgium

26 COACHING CORNER

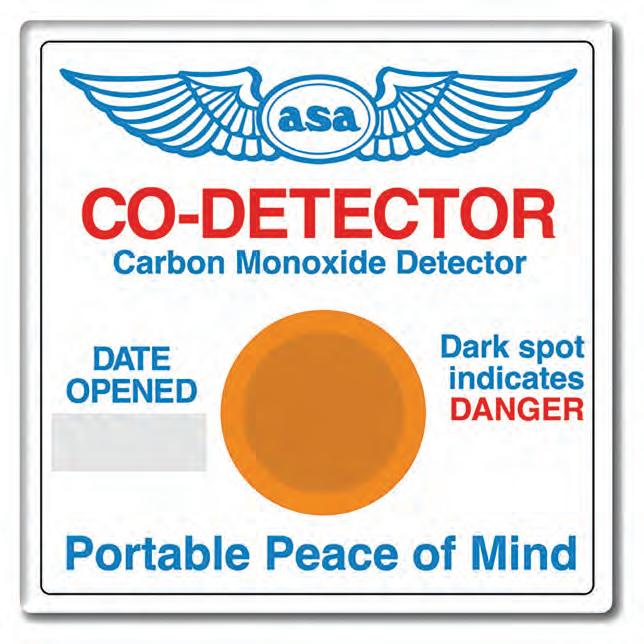

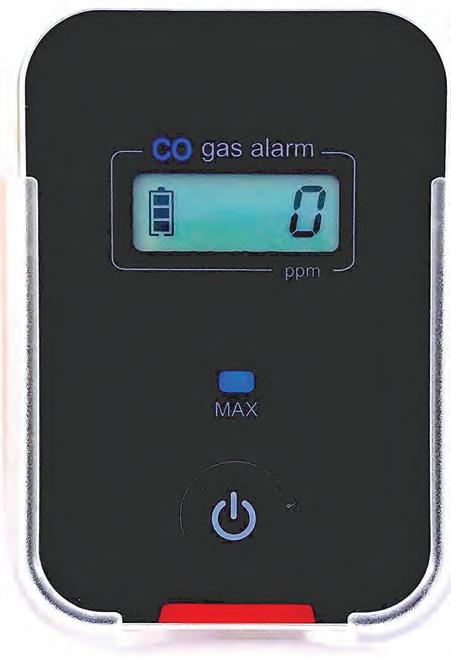

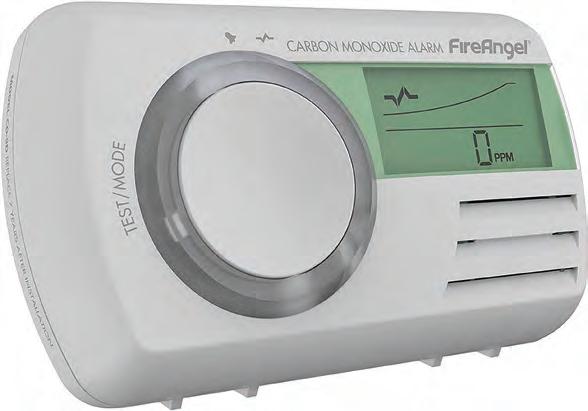

COVID-19 and the PCS. Beware of the cockpit ‘silent killer’, says David Cockburn, PCS Head of Training

28 AND THE WINNERS ARE…

LAA proudly introduces the winners of the 2020 Armstrong Isaacs Bursary awards

31 AIR COURTAGE

The future of aviation insurance

32 FLIGHT TEST

Francis Donaldson flies the eGo

38 FIBREGLASS REVISION

A trio of friends, who met at their local Strut many years ago, have a bonding experience, as Phil Hall reports

42 BLOOD, SWEAT AND TEARS

An update on the Mark Manwaring’s Flight of the Navigator Project

46 STRUTS4U

Anne Hughes profiles the activities of the Struts, plus a note on cancelled events

50 SAFETY SPOT

A flying wire failure during aeros, perished fuel hose and FOD. Plus be alert to Alerts

56 MEET THE MEMBERS

We meet Binder Smaragd co-owners and Bristol Strut stalwarts Mary Leader and Trevor Wilcock

60 CEO THOUGHTS

There are challenging times ahead with COVID-19 and EASA licences and self-declaration

On Friday 20 March, the LAA Board wrote to the BMAA to say that they had decided, regretfully, to suspend the merger discussions between the two associations. The LAA Board anticipates that there will be a continuation of collaborative effort underpinning the mutual passion for aviation and wishes to signal their readiness to enter into further

discussions as and when a unanimous BMAA Council position has been established on the subject.

Steve Slater, LAA CEO commented: “It’s disappointing, because there has been a great deal of work done by volunteers from both organisations and I personally feel it is a huge opportunity being missed. Together, we have demonstrated that a future single

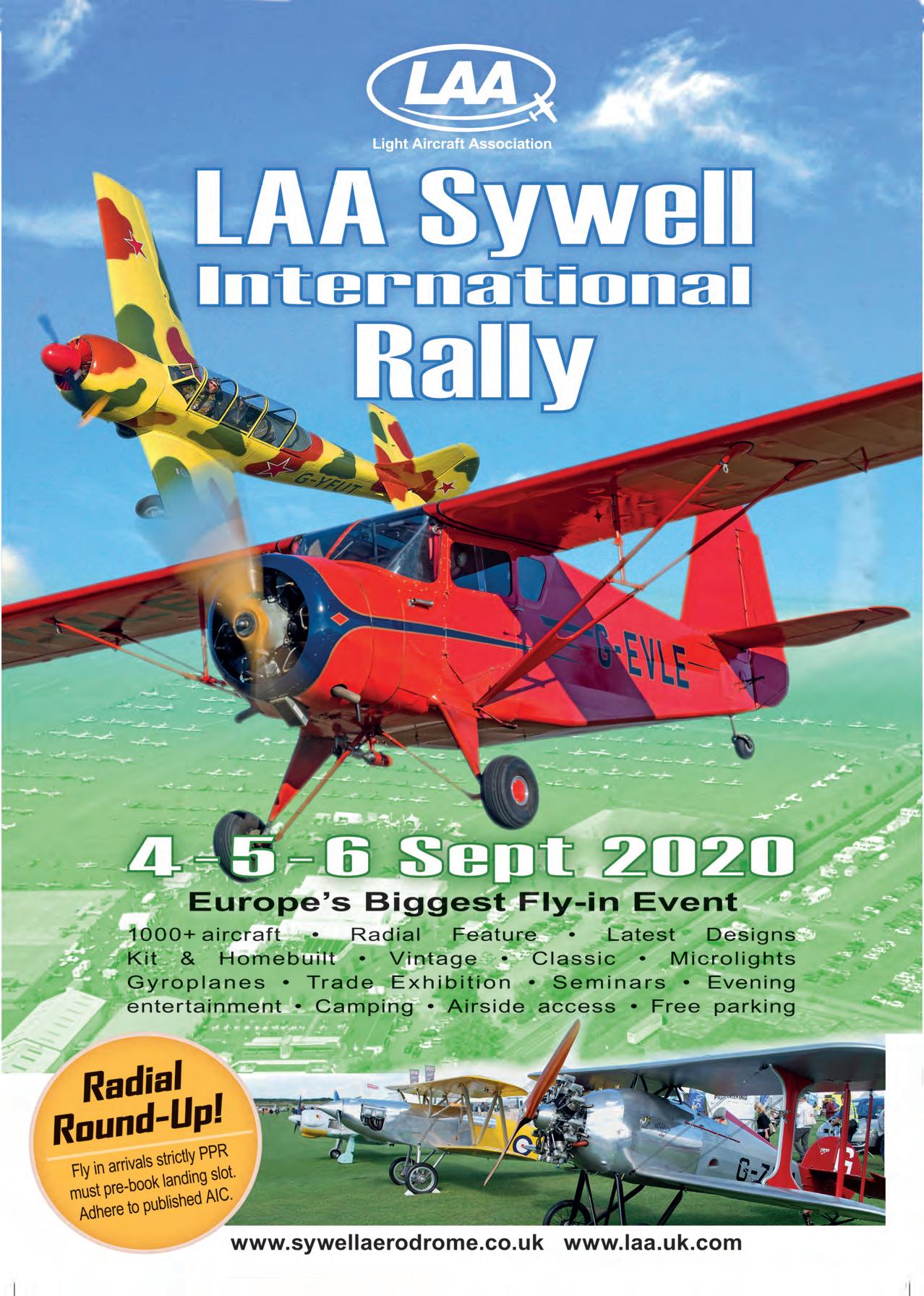

Amid so much gloomy news, let’s all look forward to later in the year when, hopefully, the world will have turned the corner and life will be returning to normality. With that in mind, planning for this year’s LAA Rally, due to be held at Sywell on 4-6 September, which has been underway for some time, is continuing.

The format will continue the successful partnership between the LAA and Sywell Aerodrome and bring together exhibitors, builders, flyers and enthusiasts to what is widely recognised as the pre-eminent fly-in event in Europe.

Our featured aircraft theme this year will be ‘Radial Roundup’, those aircraft with wonderful round engines, large and small – the Pratt and Whitney Wasp of the Harvard to the diminutive Pobjoy Cataract of the BA Swallow.

In addition to exhibitors’ stands, we aim to expand our programme of informative talks and presentations in Speaker’s Corner and hold another keynote presentation on the Saturday evening following the success of

organisation can be viable, would be a powerful voice for sport flying, and our Board and the wider LAA membership believe in principle it is a good thing. Sadly, we haven’t had similar reassurances from the BMAA Council and their members, so we’ll focus on the LAA’s future but keep working together in areas where BMAA and LAA can jointly promote our mutual passion for flying for fun.”

Ivan Shaw’s talk last year. There are also plans to enhance the members and Struts’ Pilots Lounge and repeat the evening social event for Strut members with a Hog Roast on the Campsite, together with the usual entertainment and bar in Hangar One.

We have been working closely with Sywell and the CAA to secure an increase in arrival slot numbers and the ability to offer ‘on the

Once the COVID ‘lockdown’ comes to an end, the LAA has come up with a new initiative to encourage younger visitors to airfields (not to mention their mums, dads and grandparents).

The An Airfield Adventure colouring book, produced by the LAA in association

with leading children’s illustrator Ursula Hurst, is aimed at ‘little aviators and big aviator helpers’ and its 16 pages are filled with puzzles, drawing and other activities covering all aspects of life

day’ slots arising from cancellations once again, and are optimistic that we will soon have good news on this front.

September may be a long way off, but we remain hopeful the Rally will be able to go ahead and offer some light at the end of what is going to be an extremely challenging summer for everyone. We will continue to provide updates as the summer progresses.

on an airfield – leading to an ‘LAA Airfield Adventurer’s Licence’. Copies of the book will be sold for £1 by LAA Struts to raise local funds, or copies can be bought from the LAA Shop for £2, including postage.

We cannot ignore the impact of the Coronavirus or COVID-19, on all our lives. In the past weeks we’ve been making sure that the LAA HQ team has resilient back-up systems to ensure we can handle permit administration, engineering support and enquiries, even if we have to reduce office staffing to the minimum.

You should have received in recent weeks, emails keeping you up to date on the situation; if you haven’t, it could be that we don’t hold your correct email address. If that is the case, simply drop us an e-mail to office@laa.uk.com with your name, preferred email address and membership number and we’ll make sure you receive any urgent messages from us.

Basically, we made plans based on three contingency levels: normal service, reduced staffing, and a full closure of our offices. In mid-March, in line with Government advice, we moved to ‘Level 2’, with fewer members of staff in the office and others working from home on rotation. We still have the option to activate ‘Level 3’, with the office effectively closed and all the HQ team working from their homes.

Fortunately, part of our IT investment in recent years has enabled our records and databases to be stored outside our offices ‘in

the Cloud’, which will allow members of staff to work from home and ‘self-isolate’ if required. Even if things escalate to a stage where we are forced to close the office completely, while there will inevitably be some disruption, we are still in a position to issue permit renewals and modification approvals online.

Clearly though, ‘home working’ or having a restricted office presence means we will not be as readily available by telephone. If you have an enquiry, please help us to help you by emailing rather than phoning; either to office@laa.uk.com or engineering@laa.uk. com. Please avoid using personal email addresses too, indirect messages will get logged into the system by the admin team –and in these coming months as the virus takes effect, it will be particularly important not to assume that individuals are at their usual desks.

At the time of going to press, there haven’t been any restrictions placed on private flying. We are in daily contact with the CAA and DfT on this and have made the case against any prevention of GA flying, unless

there is clear and pressing evidence of a health or safety case.

There is minimal likely risk to a pilot flying solo, providing pre- and post-flight social contact is minimised. There is clearly a greater risk of virus transmission if two or more people share a cockpit, but this risk is no greater than if they were sharing a car.

In contrast, there are a number of potentially adverse aviation safety implications of stopping flying. It would restrict pilot currency and continuity flying, creating risks which would outweigh any theoretical benefits to public health as things stand at the moment.

We’re currently discussing with the CAA, mitigating any difficulties which might arise from flying clubs, schools restricting dual instruction training, which may have a future impact on PPL revalidation and licence renewal flights. We would also advise owners whose aircraft may shortly require a CofV renewal check flight, to consider carrying out such a flight sooner rather than later, in case increased COVID precautions do restrict flying in the future.

In the meantime, please monitor our website on www.lightaircraftassociation. co.uk and our Facebook page for the latest information.

The Flying Yesterday and Tomorrow concept proved a challenge for many of our young artists, but over 70 imaginative entries for the UK national segment of the FAI International Art Competition were received at LAA headquarters by the end of January. This is the third year that the LAA, under the stewardship of Anne Hughes, has facilitated the contest for the UK.

In February we asked the editor of Pilot, Philip Whiteman, Chairman of the Guild of Aviation Artists Andrew Latham, and artist Eugenio Facci, to join Steve Slater (LAA CEO) to select the UK prize winners. After much discussion, three entries were chosen from each age group with a flight in a light aircraft, funded by the LAA, offered as the

first prize in each category. The winning entries will now be sent to the FAI in Switzerland for international judging.

Sincere thanks to all who spent time and energy at airshows, events, youth groups and schools encouraging young people to send entries for the competition. A new title for the 2021 competition will be announced in a few weeks’ time with details on our at www.lightaircraftassociation.co.uk/art

Congratulations to our winners, who are: Junior group: Henry Bean, Fleur Bouchaud and Daisy Harris

Intermediate group: Charlie Wilson, Bonnie Salter and Nathan Cox

Senior group: Callum Doak, Millie Bailey and Ben Berry.

It is sad, but perhaps inevitable in the current circumstances, that we have been forced to postpone the planned 2020 LAA Scottish Tour, which was scheduled for late May and which attracted more than 90 expressions of interest. We are so grateful to all parties engaged in the

organisation, including the Scottish Aero Club at Perth, the local Struts, airfields both north of the border and en route through England, NATS and so many more who have been so helpful and enthusiastic about the tour. They have already expressed their enthusiasm to help with

the event in spring of 2021, the Association’s 75th Anniversary year.

Sadly the ‘Meet the LAA Days’ at Eshott on 23 May and at Perth on 30 May, marking the start and completion of the tour, have also had to be cancelled at the request of both airfields.

Inevitably, as the Covid issues have intensified, more and more events have had to be cancelled – to the point where information that appears in the magazine will very likely have changed by the time you read it. As of 23 March, some of the more imminent events that have been cancelled are AERO Friedrichshafen (initially postponed but now cancelled), the Ernie Horsfall 102nd Birthday fly-in at Blackpool on 18/19 April, the one-day Duxford General Aviation Expo on 25 April, the Popham Microlight Fair on 2/3 May as well as the majority of Strut and Club meetings for April and May. Aero Expo at Booker on 11/13 June has also now been cancelled. As and when the situation improves, and we can once again mingle, it will be advisable to check any advertised event to ensure it is in fact still going ahead.

We have been planning a return of an Introduction To The Jabiru Engine course to be presented by Jabiru expert Roger Lewis, but the proposed dates in May have had to be cancelled. However, we would like to gauge demand, so if you are interested in attending such a course, drop an email to the office@laa.uk com address so we can contact you when new dates have been arranged.

This one-day introductory course has been crafted to meet the needs of the Jabiru 2200 and 3300 owner who’d like to understand their engine a little better.

Though centred around ownermaintenance, Roger will guide the attendee into the deeper recesses of the engine’s construction, right down to the crankshaft. If your aircraft is powered by a Jabiru engine then this course will definitely be useful to you. The proposed course fee will be £120.

Below right TLAC will soon be marketing the Comco C42C in the UK

UK Comco agent The Light Aircraft Company Ltd., based at Little Snoring Airfield in Norfolk, will take delivery of the UK’s first C42C model, to use as their demonstrator, in May 2020.

Since the launch of the Rotax 912 powered factory built C42A in the mid-90s, the type has been popular with training schools and private owners, moving on to the improved C42B variant in 2002. Although the C42C ha been available in Europe for several years, it is only now after significant testing that it makes its UK debit at the current 472.5kg microlight weight (includes ballistic chute), with a future MTOW of 560kg in readiness for any new regulation changes concerning increased MTOW weight in the UK.

The C42C is not merely a facelift model, it has undergone significant upgrades and comes with aerodynamic enhancements including wing profile changes, composite wing tips with winglets and aerodynamic spades on the ailerons to further enhance its great handling characteristics.

With a typical cruising speed of 115mph and an average fuel burn of 10 to 13 litres per hour, the C42C is a serious ‘go places’ aircraft. A wide range of exterior and interior options include personalised colour schemes and custom control panel layouts.

TLAC is able to offer a wide range of funding packages for both individuals, groups and flight training schools. Call to book your test flight. 01328 878809, email sales@g-tlac.com

Pilots with an EASA Light Aircraft Pilot’s Licence (LAPL) or Private Pilot’s Licence (PPL) who are using a self-declared medical to fly an EASA certificated aircraft in the UK, will no longer be able to do so after 8 April. They will have to get a LAPL Medical Certificate or a Class 2 Medical with an Aero-Medical Examiner (AME) or a LAPL Medical Certificate with their NHS General Practitioner (subject to certain criteria).

And pilots currently using an NPPL or a UK PPL to fly an EASA aircraft in the UK will also no longer be able to do so after 8 April, they will need to obtain an EASA LAPL or PPL.

The exemption from EASA regulation that allows both of these privileges in the UK expires on Wednesday 8 April 2020. It can only be renewed if EASA extends its own derogation that permits National pilot licence holders to operate EASA certified aircraft.

Left We will soon be holding Jabiru engine courses. Let us know if you are interested.

EASA has not yet published a decision on extending its derogation, despite the efforts of the CAA and the DfT to resolve the issue, and are advising pilots who are likely to be affected to consider booking and completing a LAPL or Class 2 Medical to enable them to continue flying. Information about obtaining a GP-issued LAPL can be found here: https://tinyurl.com/rsx97nx

■ Pilots flying non-EASA certificated aircraft, such as LAA Permit types, with a NPPLs, UK PPLs and/or medical self-declaration in the UK are not affected.

Thank you to those who have offered support and kind comments to myself and others who have recently had their engines stolen. I appreciate that the police have difficulty in resolving this issue as it would appear that they treat it as a local issue and perhaps fail to appreciate the value of the total losses incurred – the theft of Rotax 912 will cause an insurance claim in the order of £28,000!

Even before my loss, I was talking to another Europa owner, who had a similar loss late last year, about security in rural locations. He and I are now independently working towards anti-theft measures but have yet to find a solution. I have been looking at vehicle tracking devices but have not been able to find anything suitable.

My aircraft (at least what is left of it) is in

I think that our association is best placed to investigate preventative strategies, there must surely be some security expertise among our membership who can help identify solutions.

Steve Slater is happy to coordinate responses and host a working group if required, so in the spirit of self-help for which our members are noted, any ideas on how we can make life far more difficult for the perpetrators of these crimes will be most welcome. In the first instance, please write to office@laa.uk.com

Just to close, my only workable (maybe) idea so far is to put a form of car alarm on the aircraft to go off if the cowling is removed but of course, this will only work if you have people close enough to hear it.

Regards, Tim Houlihan, G-RIXS“Any ideas on how we can make life far more difficult for the perpetrators of these crimes will be most welcome”

just cause the thieves to scarper. Better to notify the police, who may be in a position to catch them red-handed.

Does anything like this exist? If not, do we have any techies among our members who would be up for putting something together?

Kind regards, Brian Mellor, LAA Coach.

Good Morning Brian. Just got my LAA mag and a line in your Weather Warning (Editor’s Desk) caught my eye. (see, you are read!)

“Please note that not using your correctly functioning transponder is illegal”. This is surely incorrect. Not using your transponder may be inadvisable, but I never thought it to be illegal. Kind Regards, John.

I’ll spare John his blushes by not using his surname but in case others are unaware, European Standardised European Rules of the Air (SERA) 13001: Operation of an SSR transponder came into force in the UK in 2017. It states

(a) When an aircraft carries a serviceable SSR transponder, the pilot shall operate the transponder at all times during flight, regardless of whether the aircraft is within or outside airspace where SSR is used for ATS purposes.

(b) Pilots shall not operate the IDENT feature unless requested by ATS.

a hangar that is part of a farm complex. It has several occupied houses within 50 or so metres, the nearest one owned by the airstrip operator. It has WiFi but the signal does not reach the hangar, and there is also electricity in parts of the hangar.

I am getting the feeling that working individually will lead to, at best, duplication of ideas and more likely, third rate partial solutions devised by pilots who are not security experts. I therefore contacted LAA HQ as I think a good number of LAA members are in the same situation as those who have joined the ‘stolen engine’ club in that most permit aircraft live in a rural location that is difficult to secure. As my friend found out, even a steel hangar and a sturdy lock is not sufficient. Apart from Rotax engine thefts, I know that members have suffered unwelcome intrusion, damage and fuel thefts, so these are by no means isolated incidents.

…and again

Just started to read the current LAA magazine, and like everyone else I was horrified to read about the Rotax engine thefts. It got me thinking that with today’s technology, surely there must be a way to help prevent or at least reduce these occurrences. Perhaps something along the following lines.

Nearly everyone has a smartphone, and probably at least one older phone that is no longer in use.

■ Use this old phone, with a cheap sim card (like giffgaff) and a bespoke app.

■ A microswitch (or other type of sensor) could detect the removal of the cowling, and signal the smartphone.

■ The phone would then call the owner’s phone (and/or send a text message) who would decide on what action to take.

Personally, I would prefer this notification rather than sounding an alarm, which could

(c) Except for flight in airspace designated by the competent authority for mandatory operation of transponder, aircraft without sufficient electrical power supply are exempted from the requirement to operate the transponder at all times. Ed.

Dear Brian, avidly reading like I do, your magazine, there appears to be a slight error in the Rotax course article (page 42, top right) where the author has, ironically, confused the terms slipper clutch and sprag clutch while stating these items should not be confused….! It should have read:

He explained that most Rotax engines have a slipper clutch which wears out over time and needs to be checked. This is done by locking the gearbox with a special Rotax locking pin…..

The slipper clutch should not be confused with the sprag clutch, which also wears over time and is much more complicated to replace and is attached to the starter motor.’

Regards, Jerry ■

Prop swinging is a skill that demands great care and good technique, says Steve Slater…

It’s the time of year when (we hope) the weather will allow airfields to dry out and aircraft to re-emerge, blinking, into the sunshine. Some of those aircraft may be a bit recalcitrant to instantly spring into life. A pilot’s starting techniques may also be a bit rusty and this is particularly important if the aircraft has to be handswung, or started by the ‘Armstrong method’.

There is, sadly, a steady stream of one or two incidents each year which continue to demonstrate that while prop-swinging can be carried out safely by following the right procedures, it is like many things in flying, inherently unforgiving of inattention or a lapse of the correct practices.

There has been no shortage of advice and information on prop-swinging down the years and I’m indebted in this article to among others LAA Safety Working Group colleagues Mark Wakem and John Marriott, Head of Coaching David Cockburn and Vintage Aircraft Club stalwart John Broad for their input and comments, which have allowed me to cover a wide range of different types, engines and techniques.

Main Starting the 230hp Bentley Rotary (BR-2) engined TVAL replica Sopwith Snipe ZK-SNI looks like it could be a bit of a challenge. Someone in the cockpit, a person on each wingtip and a fire extinguisher show that the Shuttleworth crew appreciate the potential risks.

Photo: Alan WilsonWe’re not even talking of the exotica of vintage rotaries and radials here. There is a world of difference for example, in swinging the propeller of a Gipsy Major on the front of a Tiger Moth or Auster, a Continental or Lycoming on say, a Cub or Pietenpol, or swinging a propeller attached to a VW-based aero-engine. I regard the latter as similar to baiting a Jack Russell terrier. It will go from silent indifference to attempting to bite you in a fraction of a second…

However, the most important thing is that anyone swinging a propeller, whether working in conjunction with a pilot in the cockpit or with the aeroplane suitably chocked, and in many cases with the tail tied down too, swinging solo you MUST have a standard set of procedures and stick to them – without interruption or distraction.

Position

Look at where the aircraft is parked before even considering trying to start the engine.

It should be located so that when it does start the propeller wash does not blow into an open hangar or

into the front of a building where the doors or windows may be open or opened. Also ensure that no other aircraft is parked behind which may be moved or damaged by the propeller wash on starting.

If the aircraft is parked on grass then consider the surface where the person starting will stand. Is it uneven or covered in stones or other loose material? That can be potentially damaging to the aircraft if it is caught in the propwash and if the surface is wet or damp, would that cause a slip hazard? It is not worth taking a chance, the risk of slipping, damage to the propeller, or injury to the prop-swinger is too great. Move the machine to a more suitable location.

Remember that if you are starting an aircraft on tarmac, the opportunity for the machine to roll forward is increased. Also, chocks may not grip the surface and should be checked for their ability to restrain the aircraft. Curved chocks will work better than triangular unless the base of the chock has some form of tooth to dig into the surface.

You’ll notice I’m not even mentioning brakes here. Many vintage types of course don’t have them anyway, relying on the chocks while starting and the drag of a tailskid for braking while taxying. However, even if an aircraft is fitted with a parking brake, I wouldn’t trust it, particularly if starting solo. I prefer to have chocks in place as an added insurance that the aircraft won’t move forward unexpectedly.

The person starting should check their own clothing to ensure that jackets are securely buttoned, zipped or removed, and scarves or any other loose items are either tucked securely in or removed to a safe

Above Thumbs up – Switches ON. Starting the BE2 replica. Having a knowledgeable occupant in the cockpit while prop swinging is always the best option.

distance. If wearing a cap ensure it is secure or again remove it and place it at a safe distance. A cap blowing off in the wind could distract the person just as the engine fires, putting them in a dangerous position.

Remove rings from fingers as these may not only cause injury but can damage the propeller, especially if it is wood or laminate. Footwear can be important as sandals, flip-flops or even shoes with loose laces can constitute a hazard. It is recommended that shoes should be worn which provide good support and grip and are securely attached to your feet.

It is also important to recognise the stature of the person willing to swing the propeller relative to the aircraft propeller. A machine such as the Tiger Moth may have the blade in a position too high for a shorter person to comfortably reach, which would put them off balance during the operation. Equally a tall person attempting to start something like a Jodel Bébé, may be off balance and, by leaning forward, could place their head in line with the prop blades as the engine starts. If you are in any doubt about your balance and ability to move clear at the end of the swing, do not even think of attempting it, your life is worth more than the risk.

If a person is to operate the controls from within the cockpit, the person starting the machine must remind them that as they are working at the dangerous end –the starter person is in charge.

When prop swinging was the norm, set procedures were developed, primarily by the military, to ensure the person in the cockpit and the person swinging the

propeller had complete understanding of who was doing what and when. Member Nick Radford recently sent us a note outlining the procedure from his late father’s training notes when he was a fitter in the Fleet Air Arm just after the war, and those procedures are as relevant today as they were then. Let’s call the person in the cockpit ‘Cockpit’ and the person swinging the prop ‘Swinger’. The recommended procedure is:

■ Cockpit turns on the fuel, closes the throttle and ensures the switches are OFF. He then gives a thumbs down signal to Swinger and calls out, ‘Switches off, fuel on, throttle closed, suck in’.

■ Swinger responds with a thumbs down and calls, ‘Switches off, fuel on, throttle closed, suck in’ and then turns the prop through to suck fuel through and stands clear. He then gives a thumbs up sign and calls, ‘Throttle set, switches on’.

■ Cockpit sets the throttle and turns the switches ON, makes a thumbs up sign and calls, ‘Switches on, throttle set Contact’.

■ Swinger steps forward and swings the propeller. If the engine fails to start and the prop has stopped against the next compression, Swinger will be able to approach again for another attempt. If the prop is in the wrong position, he will make a thumbs down sign and call, ‘Switches off’.

■ Cockpit will turn the switches OFF, make a thumbs down sign and call, ‘Switches off’.

■ Swinger will reposition the prop, stand back, make the thumbs up sign and call, ‘Switches on’.

“The risk of the propeller kicking back is one of the reasons you shouldn’t wrap your fingers over the trailing edge of the propeller”

Below A useful technique when extra grunt is required. Note the prop swingers’ trajectory is forward and away from the propeller.

If the engine fails to start and it becomes necessary to blow out excess fuel:

■ Swinger will make the thumbs down sign and call, ‘Switches off, throttle open, blow out’.

■ Cockpit will turn the switches OFF, open the throttle fully, make the thumbs down sign and call, ‘Switches off, throttle open, blow out’.

■ Swinger will turn the propeller backwards about six blades to clear the cylinders, and then the start procedure will begin again. It is vital that the throttle is closed and reset to the start position . This is one of the more common ‘gotchas’ so both parties should be absolutely sure that the throttle has been correctly set for starting.

Every type, and even individual aeroplanes, have their own starting techniques. For example, the process outlined in the Tiger Moth Pilots Notes, dates back to the 1930s when for a cold start, the Claudel Hobson carburettor requires a button to be pressed to ‘flood’ the float chamber and allow extra fuel to be introduced to the cylinders. The ubiquitous Continental and Lycoming engines usually use a primer or an accelerator pump on the throttle to pump the extra fuel into the cylinders, while automotivederived engines often use a choke to provide the rich mixture.

Setting the throttle of course is particularly critical. Too high a throttle setting will introduce excess air into the cylinders, increasing the risk of the propeller ‘kicking back’ due to a lean mixture. Of course, if it does fire, it will be at high revs, increasing the risk of

jumping the chocks, or even raising the tail on a taildragger, even if the stick is being held or tied back. Some pilots mark their preferred throttle setting on the quadrant or throttle control so they can have a smooth and stable start. Go beyond it, and things can get exciting very quickly!

The risk of the propeller kicking back is one of the reasons you shouldn’t wrap your fingers over the trailing edge of the propeller – if it kicks back you could receive severe bruising or worse. The military for many years briefed their prop-swingers to use just their right arm, holding their left arm behind their back. However, I find that this encourages me to loop my fingers over the prop.

I prefer to use both hands with the fingers on the front face of the prop only. It does of course mean that you are placing your head and body closer to the prop as you swing, but I mitigate that by taking a step backwards as I swing. The important thing is to, initially, have some instruction by someone with experience, and to listen to their advice.

Some people with aircraft such as Cubs and Tiger Moths, swing the propellers from behind, allowing them to quickly reach the mag switches or throttle if something untoward happens. Again, it is all about developing the best and safest procedure, then sticking to it.

This specifically applies when things are not going to plan, such as a recalcitrant engine. As anyone who has tried to start an engine, whether a Gipsy Major, Continental, Lycoming or VW, when they are in that ‘not quite hot, but not quite cold’ scenario, one is never entirely sure whether you have got the starting mixture too rich or too lean. The important thing here is again, to stick to a standard procedure. Decide in advance that after so many swings of the propeller, you will turn off the magnetos, open the throttle and

turn the propeller backwards to blow out excess fuel. And having done so, you will of course remember to close the throttle won’t you?

Top left A runaway at Barton in 2006 –the aircraft was unmanned and was started without chocks after the engine stopped at the runway hold. The consequences could have been much worse. Photo: Alan Mosiezny

Top right Though switches are off when pulling through to prime the engine, the prop should always be treated as live. It would be better not to wrap one’s hand around the prop. Some pilots wear gloves when prop swinging for added protection.

Above A lovely period shot taken at Panshanger in 1948. Surprisingly no chocks are in place, but it does appear that the tailskid may be tied down – a recommended action if the aircraft has no brakes or is unmanned.

If you are getting hot and bothered after swinging the propeller fruitlessly for a while, stop. Turn off the switches, close the throttle and walk away for a few minutes. Even have a cuppa, to let the engine get sufficiently cool to allow you to return refreshed and use your proven cold-start procedure.

The chances are that any excess fuel that has pooled in the inlet system will have by then turned into a nice cloud of vapour that will give you just the right mixture to start anyway. Equally important, you might just break the potentially dangerous cycle of swinging the propeller expecting it not to start, then being taken by surprise when it suddenly bursts into life in front of you!

Another important thing is to not be afraid to ask for help. If there is someone suitably qualified around, don’t be afraid to ask them to ‘cover the throttle for you’ or assist in a suitable manner. Do, of course, ensure that they are properly briefed and know where the magneto switches are. I know of at least one quirky French aeroplane where the magneto switch operation (and placarding) took a group of us some time to translate!

I would be very cautious of trying to ‘swing’ an engine which is not normally hand started. It’s almost certain that the propeller is not in the right position for safely swinging, and when it comes to geared propellers, such as on a Rotax, just say no.

My final comment on propellers is, whether they are hand swung or electrically started, always regard them as potentially live. I was certainly glad that I did a couple of years ago when, after checking ‘switches off’ with a pilot in the cockpit, I was pulling through the propeller to suck mixture into cylinders when the engine suddenly fired. It turned out the pilot had accidentally flicked the switches on with his elbow while he was adjusting his seat belts. I certainly learned about flying from that… ■

Isuppose I should consider myself very lucky that in early March I was able to take the mower out of hibernation, fill it with dinosaur juice, pull it through a dozen times and coax it into life and cut the lawn. Following the record rainfall of February, there must be many grass strip flyers that would have loved that chore, along with the possibility of flying.

Only two projects this month received their Permit to Test, but a very healthy number have been commenced. I was surprised to see two Sling 4 TSi builds listed, but on looking back through last year, there are at least six ahead of them. It’s an impressive aircraft with its very capable Rotax 915iS, have a look on the internet if you have a spare browsing moment, African aviation does seem to be blossoming.

Andy Best has been working upon his own design ‘Blue Two’ for a few years now and I think it’s fair to say that he is approaching the home straight. I know that many readers are following this project, and I’m always keen to see how he is getting on. A warning though, one of his pictures does contain sunshine and a blue sky, remember those?

Tony Whitehead, who you may recall restored a beautiful and rare Morane Saulnier MS.317, has recently imported his latest project, a lovely radial powered Fairchild, which has been permitted to come onto the LAA register – he makes the process sound straightforward but I’m sure its smooth success is down to his experience and diligence. As I’m sometimes reminded, we make our own good luck!

When it comes to a stimulating topic of conversation now that the ‘B’ word is out of the way, then the death of the internal combustion engine and the electrification of transport is guaranteed to provide opinionated debate.

I imagine that when Orville and Wilbur made their first flight of some 120ft at Kitty Hawk, the detractors ‘poo pooed’ such an invention as worthless, perhaps claiming a bicycle would travel further and more cheaply. Still, less than 66 years later, mankind flew a quarter-of-a-million miles and set foot upon the moon. Relatively speaking, electric flight within our sport is probably only a little further down the road than the Wright Flyer, but things are changing quickly with technology migrating from that ever so very slightly less conservative industry, the automobile engineering.

Our sized electric flight does exist, but is still in the margin s

with the forthcoming Air Race E competition, Red Bull style competitive sprints and the likes of Rolls-Royce trying to take the electric flight speed record from Siemens with a custom-built airframe and powertrain.

Commercially, Wright Electric (imaginative name) has partnered with easyJet and is developing a pure electric A320 sized, 1,000 mile range passenger aircraft with proposed entry into service this decade.

More down to Earth and practical is Pipistrel, with their Alpha Electro training aircraft that has been in production for a while now, in fact they have recently increased their production from four to six aircraft per month – so someone is buying these six-figure microlights.

With the increasingly vocal ‘green’ agenda, I can imagine that in the near future, a flying school utilising electric training aircraft could attract more new students because of its perceived environmentally friendly credentials, even if those students still drive to their lessons in their internal combustion engined car!

Interestingly, some of the above electrified examples employ modular battery swap out as a means of rapid refuelling, which the Wright Electric passenger aircraft also proposes. However, I recently heard through casual but informed conversation that Pipistrel were considering moving away from this model as a result of damage to the storage modules from the repeated handling.

I can think of only one electrically powered LAA aircraft that has been featured in Project News in the last three or four years, so I was excited to learn of Tim Bridge’s current Zenith CH 750 build. Tim, an engineer working on large solar farm projects for many years, has set about building a CH 750 with a difference – it will be purely electric powered – but that’s not the whole story, see what he is up to below.

So, am I off to purchase a Lithium Iron powered lawn mower? I guess so when the current Victorian tech one decided to pack up, especially as I can use my current range of monster power tool batteries in one – but what will I then do with the stale fuel drained from my aircraft…?

To get in touch with Project News , and tell your story, report a milestone or just to send a picture, email: projectnews@laaarchive.org.uk

Please share your story!

Nuncats is a registered Community Interest Company (CIC) established to change the shape of E-Mobility in developing countries. They have the blessing of, and indeed have partnered with, the Zenith Aircraft Company to develop an electric power system for an otherwise almost standard Zenith CH 750, plus an off-grid charging station to suit. Their goal is that the whole system could be used to provide really useful rural transport and medical supplies in areas where fuel, roads and infrastructure are a problem in general. The airframe is under construction now and they have just started on the first of the power system elements.

The key aim of the project is to demonstrate the viability and utility of electric powered flight, using cost effective and existing technology. Subsequently, supplying the home market on a commercial basis would then allow charitable organisations to be supplied at cost.

There are NGOs in Africa working on health and conservation projects on tight budgets and in very remote locations, using light aircraft as flying jeeps. Totally ‘off grid’, the supply of fuel can be a challenge, and these aircraft need to be cheap, rugged and easily maintainable. In this environment, some of our Permit to Fly types could be made perfectly suitable.

Rural solar generation is not uncommon in much of Africa and, by tapping into that existing infrastructure, an energy source is potentially available to fuel such an aircraft – after all, sunshine is far more widely available than avgas in the bush.

There are many projects underway by big names in the aerospace world to produce fast, efficient, loadcarrying prototype electric aircraft, stretching the limits of current knowhow to eke out that last little bit of performance. Nuncats’ approach is different. Why design a new aircraft when they can work with what currently exists, sacrificing leading edge performance for economy and quickly bringing it to market. We know it takes a long time for a new type to be developed, so what’s the point for a small gain in efficiency? Its premise is to use what’s already out there and that includes the airframe. As an aside, consider any airfield, many of the aircraft are decidedly vintage, these older craft are unlikely to be scrapped any time soon, so even some of these could be electrified.

For bush operation, an aircraft needs to be rugged and repairable, a delicate composite tadpole would probably not last past the first inevitable mishap – nuts, bolts, pop rivets, aluminium and straight lines make for a much more maintainable structure. The Zenith CH 750 and similar models are just the sort of ‘jeep’ that are needed, and there are a number in the theatre already.

The creative focus in this project is almost purely firewall forward, where an electric motor with sufficient power to replace a Rotax 912 is a tiny affair – imagine a stack of six to eight dinner plates and you just about have the shape and size. So, a new motor mount will be required, and this may well be longer than the original item, and as a result, new cowlings will need to be moulded. All of that space between the firewall and motor can then be filled with power electronics and some of the battery storage.

Meeting 100-hour services in the middle of nowhere also presents its challenges, so the almost total lack of a frequent maintenance requirement upon an electric motor, with perhaps two moving parts as opposed to hundreds within an internal combustion engine, also benefits remote aircraft operation.

Apart from building the airframe, they will create a total system where a practical and useful electric aircraft is the outcome of the project. It is a fact that today the energy density of petroleum spirit cannot be matched by batteries, and it possibly never will. Equally, the simplicity of refuelling by pouring that energy dense liquid into an aeroplane’s fuel tank will be hard to match.

So, their solution is for multiple yet manageable battery packs that are rapidly swapped at turnaround to provide a reasonable range. They even envisage the possibility of a partial battery load so that fuel can be traded for luggage as we would consider in current aircraft.

Solar powered charging stations will hold spare battery packs at the various stop off points along the regular route, with future plans to develop automatic reporting of their charge and availability status by radio or over the internet. Consequently, a modest range of 50 to 70 miles is perfectly adequate to fly a route that is effectively several hundred miles, but made up of multiple legs, as are the existing missions flown by charities. These outlying charging stations, a mesh network, can then take days or perhaps all week to replenish the packs deposited there. This might not be flight as we currently know it but it would enable off grid operations that can both save and improve lives. Closer to home, the endurance would be very suited to flying school one-hour training slots.

While the technology is being sourced and developed, Tim is getting on with the build of the airframe at a good rate of knots.

Started only in January, the fuselage has progressed to a rolling shell, ready for the work to commence firewall forward. He already has three airfields, two grass and one hard, who have agreed to site remote charging stations. Subject to maintaining progress, they hope to be doing ground power and taxi testing later this year, with a view to being on a permit next spring, flying short hops about the county proving that it can be done cheaply and in a way that is robust and sustainable.

You can follow Nuncats’ progress on Facebook, just search for Nuncats.

Ido feel a little embarrassed to admit that progress on building Blue Two has been rather slow of late. Like many things in life, the main problem is in your head – subconsciously, I was afraid of breaking the wings during load testing. It sounds a bit pathetic but when you’ve spent countless hours designing, calculating, foam cutting, assembling and doing lay-ups, trimming, sanding, filling, and yet more sanding, you just don’t want to risk wrecking it all. However, reading a few stories of in-flight break-ups puts things into perspective. It has to be done, so I must get on with it.

As a reminder, Blue Two is a 450kg microlight built to BCAR section ‘S’ but also uses some of the load requirements from CS VLA for good measure. Their control surface loading graphs are particularly useful and, as Francis says, they save endless amounts of ‘discussion’ about load levels.

The wing area is 113 sq ft and a Rotax 912S provides the power. The structure is from blue foam (Dow Chemical’s Floormate @ 34 kg/m³) sandwiched between

layers of carbon fibre, mainly 160 and 200 gm/sq m twill from R-G.de in Germany. The only fibreglass used is the UNI cloth in the main undercarriage legs, which gives them about three times the flexibility of equivalent carbon fibre parts.

The picture of the overall assembly shows where I have got to. All that’s required is to finish the wings, seats, canopy and the wiring, which unless I have a failure of the wings under test, should be completed by the end of the summer (I hope).

The engine bay is quite compact and was challenging to complete, but with the world’s most complicated engine installation ever invented by mankind, this was to be expected. In an attempt to reduce cooling drag, the radiator, which has a seven-row oil cooler fastened behind it, has its own airflow ducting. Time will tell whether I have got the duct sizes right. The stainless exhaust was bought as a kit of parts from Aeroweld Ltd., in the Czech Republic for €478. After cutting the tubes and clamping them together (with jubilee clips and metal

strips) the pipe assemblies were TIG welded by a local rally prep shop.

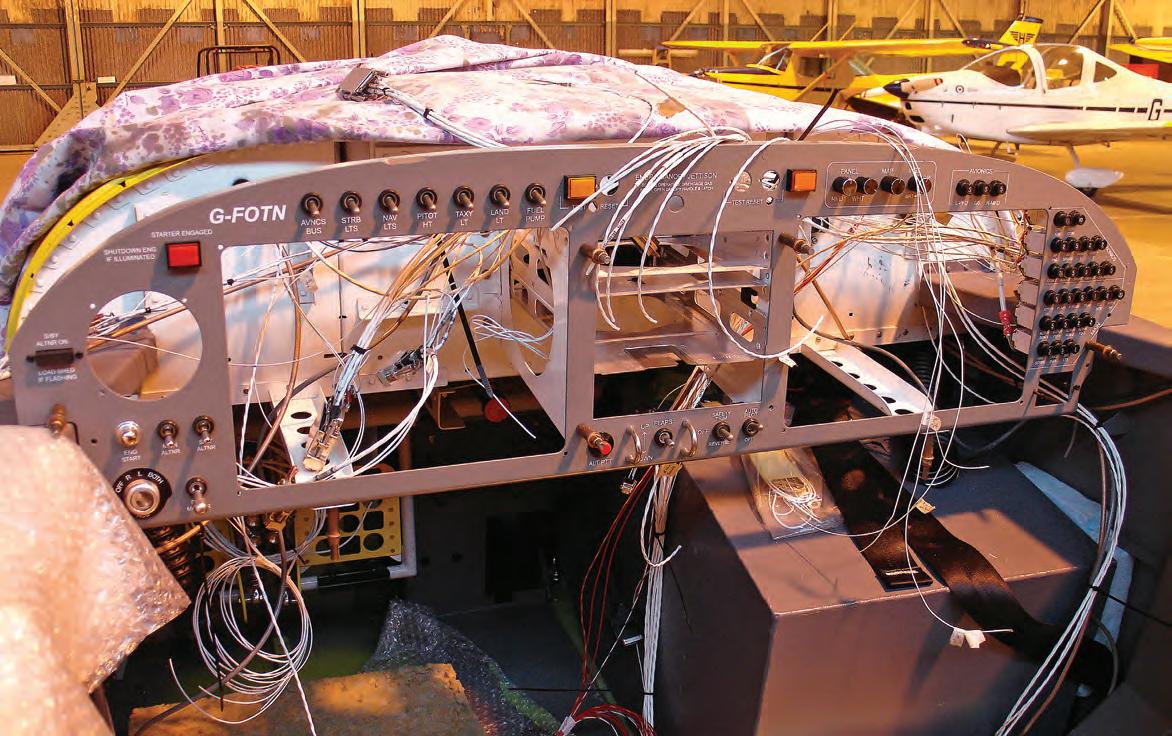

And so, onto the wiring. Solder or crimp, that is the question. I found convincing arguments for both, so in the end I decided to do both, initially soldering, then crimping over the soldered joint and the insulation and finally covering the connection with heat shrink sleeving.

After what seemed like years of sanding, it was quite a pleasure to do the wiring, but it does require some concentration and constant checking. As can be seen from the picture, it rapidly becomes chaotic looking. My advice now would be label everything and buy two to three times the amount of wire that you first think you need. The coloured aviation cable (not PVC) came from Parts4Aircraft. I have tried to keep all the electrical items which are normally found in the engine bay, inside the relatively cool and clean cockpit area. This is not normally a sensible thing to do, as access can be difficult, but because the instrument panel is integral with the canopy surround (like most gliders) and moves out of the way when the canopy opens, access here is OK.

The final picture shows the dreaded wing test rig. The wing is mounted upside down so that it can be loaded in the +ve ‘g’ sense. Loading it to just the limit load of 4g (i.e. the maximum load it would normally see in service) requires approximately 1.4 tonnes to be applied, so you can see why the test structure, which simulates the fuselage, is fairly hefty (and why I am nervous). I live in hope and vow to keep going.

Right This will be a tightly cowled engine, very neat. Photo:

Andy Best

Below right

Unusually, most electrical components are mounted on the ‘cool’ side of the firewall, but the panel has hinged up out of shot with the open canopy. Photo:

Andy BestBelow The wings mounted off aircraft so that they can be tested to maximum flight load. Photo:

Andy Best

So, with my much loved and enjoyed Morane Saulnier MS.317 moving on to new owners, I had a think about what’s next, the restoration project in the workshop would be a while yet so I casually started looking with a small budget. Nothing much sparked my interest in Europe so the USA beckoned, also, it was going to be hard giving up that glorious Radial engine growl!

I had been keeping an eye on the Fairchild for a while and was surprised it had not sold. It turned out there was an interested party, who was dragging his heels. I left it for a while and conducted more research, finally getting the go ahead for an inspection some weeks later. This I had carried out for me by a local Florida firm, as it was much cheaper than flying out there myself. The inspection was encouraging and after much soul searching and acceptance by the LAA for this Fairchild, I negotiated a deal. Later that day the owner got in touch asking if I had second thoughts! Turns out the previously interested party made an offer

20 minutes after we agreed a deal! My offer and acceptance were honoured, thankfully.

Then the fun began. I had previously obtained quotes from Neel Aviation for shipping from his Lakeland base, but unfortunately the owner cancelled his insurance and was unable to deliver. Meanwhile, Hurricane Dorian threatened Florida and the owner was pushing for payment, needless to say that was delayed.

The ferry job from Indiantown to Lakeland was very kindly sorted by Charles Stence, the aircraft’s maintenance engineer. The price being fuel only, a welcome gesture, plus an insurance contribution. He used an EAA scheme, UK insurers wouldn’t touch it!

Dismantling and shipping went without a hitch. I requested delivery to Barton, my home field, with a crane equipped lorry, which added several hundred pounds to the cost but helped make the unloading relatively easy. The UK handling agents, Ligentia, were very helpful, including arranging the pre-payment of VAT etc. There is no duty to pay and only five per cent VAT

on an Antique. UK registration was straightforward, insurance cover from the LAA scheme very reasonable, and re-assembly was made straight forward by careful labelling of parts at the time of packing.

A major service and very detailed inspection were carried out, plus many small improvements and a general tidying up, and the task was pretty much complete. There were a couple of horrible jobs thrown in, the rubber fuel pipes connecting the fuselage to the wings were rock hard and required replacing. These had been removed for shipping and were labelled appropriately with the additional comment of ‘good luck’! It was a tortuous job.

Below Gently does it, modern containers are a great way to transport an aircraft.

Photo: Steve Grimshaw

Bottom The Fairchild in the hangar and ready for inspection and re-assembly.

Photo: Steve Grimshaw

A couple of flap cables were not up to scratch, again a time consuming and fiddly job. But overall, the aircraft and engine were found to be in extremely good condition, in fact better than expected condition if not cosmetically perfect, but I love the used original look.

Paperwork forms from engineering for the application were provided, then more forms for jobs done, history etc., enough to fill a small book. The Permit to Test arrived and was very welcome, and having flown now for a couple of hours, I am happy to report no snags and lots of fun. The Fairchild is showing huge potential, vintage aircraft really are incredible value for money.

So, importing from the USA – having gone through the process twice now, I’d suggest that it’s not for the fainthearted. Reliable shippers etc. are very important, and Neel Aviation’s work was superb, absolutely no damage and very thorough. The advantages are vintage aircraft at a fair price.

In the UK, obviously early contact with LAA Engineering is critical, thank you Francis, and most important I think is your LAA Inspector. Those who know Nigel Jones will be aware as to why he is so highly respected, he was a huge help. Completion of testing is now at the whim of the weather.

For a little background, Fairchild Model UC-61, Serial No. 41-38806 W41A-252 was manufactured by the Fairchild

Engine and Airplane Corporation and delivered to the USAAF on 20 December, 1941.

Military service was mainly in Florida until September 1944, when it was dropped from the USAAF inventory and turned over to the Reconstruction Finance Corporation for disposition.

Accepted by the FAA for civilian use, the aircraft has had many subsequent owners in the US. In 1969 the Warner Scarab engine was removed, and the Jacobs R-755 engine and Hamilton Standard constant speed propeller installed. The total hours for the airframe are very low at less than 1,150.n

If your aircraft has been featured in the New Projects list, please let Project News know of your progress at: projectnews@laa-archive.org.uk

n Sling 4 TSi (LAA 400A-15693) 25/2/2020

Mr S A Lamb, Nettlestead Lodge, Maidstone Road, Paddock Wood, Kent, TN12 6DA

n Van's RV-8A (LAA 303-15692) 19/2/2020

Mr K Wingate, 16 Buckwell Road, Kingsbridge,

Below Back in her correct environment, the Fairchild on her first flight in the UK. A great looking aircraft now on the LAA register. Photo: Craig Duffy Cleared

If your aircraft has featured recently in the magazine and has subsequently completed its maiden flight, Project News would like to hear from you at: projectnews@laa-archive.org.uk

G-CLMZ Fairchild 24W-41A (s/n 252) 20/2/2020

Peter Whitehead. Address held by the LAA.

South Devon, TQ7 1NQ

n Eurofox 912(S) (LAA 376-15691) 18/2/2020

Mr J A Thomas, Rose Haven, Bourne Lane, Ham Street, Kent, TN26 2HH

n Bristell NG5 Speed Wing (LAA 38515690) 17/2/2020

Mr J C Simpson, Badgers, Bower Lane, West Chiltington, West Sussex, RH20 2RH

n Sling 4 TSi (LAA 400A-15689) 14/2/2020

Mr A Aliseril Thamarakshan, 6 Beverley Rise, Essex, Billericay, Essex, CM11 2HU

n Eurofox 912(S) (LAA 376-15688) 4/2/2020

Dr S Ledingham, Rose Cottage, Temple Sowerby, Penrith, Cumbria, CA10 1SD

n Van's RV-10 (LAA 339-15694) 27/2/2020

Name & Address held by LAA Engineering

n G-ERMN Staaken Z-21 Flitzer (PFA 223-14314) 19/2/2020

Name & Address held by LAA Engineering.

While the technology is being sourced and developed, Tim is getting on with the build of the airframe at a good rate of knots.

Started only in January, the fuselage has progressed to a rolling shell, ready for the work to commence frewall forward. He already has three airfelds, two grass and one hard, who have agreed to site remote charging stations. Subject to maintaining progress, they hope to be doing ground power and taxi testing later this year, with a view to being on a permit next spring, fying short hops about the county proving that it can be done cheaply and in a way that is robust and sustainable.

You can follow Nuncats’ progress on Facebook, just search for Nuncats.

Ido feel a little embarrassed to admit that progress on building Blue Two has been rather slow of late. Like many things in life, the main problem is in your head – subconsciously, I was afraid of breaking the wings during load testing. It sounds a bit pathetic but when you’ve spent countless hours designing, calculating, foam cutting, assembling and doing lay-ups, trimming, sanding, flling, and yet more sanding, you just don’t want to risk wrecking it all. However, reading a few stories of in-fight break-ups puts things into perspective. It has to be done, so I must get on with it.

As a reminder, Blue Two is a 450kg microlight built to BCAR section ‘S’ but also uses some of the load requirements from CS VLA for good measure. Their control surface loading graphs are particularly useful and, as Francis says, they save endless amounts of ‘discussion’ about load levels.

The wing area is 113 sq ft and a Rotax 912S provides the power. The structure is from blue foam (Dow Chemical’s Floormate @ 34 kg/m³) sandwiched between

Photo: Andy Bestlayers of carbon fbre, mainly 160 and 200 gm/sq m twill from R-G.de in Germany. The only fbreglass used is the UNI cloth in the main undercarriage legs, which gives them about three times the fexibility of equivalent carbon fbre parts.

The picture of the overall assembly shows where I have got to. All that’s required is to fnish the wings, seats, canopy and the wiring, which unless I have a failure of the wings under test, should be completed by the end of the summer (I hope).

The engine bay is quite compact and was challenging to complete, but with the world’s most complicated engine installation ever invented by mankind, this was to be expected. In an attempt to reduce cooling drag, the radiator, which has a seven-row oil cooler fastened behind it, has its own airfow ducting. Time will tell whether I have got the duct sizes right. The stainless exhaust was bought as a kit of parts from Aeroweld Ltd., in the Czech Republic for €478. After cutting the tubes and clamping them together (with jubilee clips and metal

In a bid to recapture the thrill of flying for one pilot who had lost his ‘mojo’, Martin Ferid sets off with him to Kortrijk, Belgium…

Reading the Hilaire Belloc quote ‘I have wandered all my life, and I have also travelled; the difference between the two being this, that we wander for distraction, but we travel for fulfilment’ – I’m not exactly sure if either of the depictions are apt for our little jaunts, or if indeed they fit into any particular category.

A ‘wander’ suggests something without a predetermined destination and ‘travel’ intimates a much longer journey. It may be facultative, but I consider them ‘jaunts’, conjuring up images of a short visitation with an indulgence of some kind. Assuming the aeroplane is running well, runways are drying out and with the prospect of better weather ahead, it’s time to start spreading our wings and take our little machines into their natural environment.

The likelihood is that during the brumal conditions of the last few months, bits and pieces will have been taken off the aircraft, inspected, and repaired or replaced in preparation for the coming season. On occasions, it will have been possible for a local flight here or a lunch stop there, but to go international for a few days with a reasonable expectation of getting back is a touch optimistic for the basic VFR pilot.

People rave about the splendours of winter flying and how some of the best days are found when the axis of the Earth is oriented away from the sun. With, short days, low sun and soggy underfoot, unless it’s from a tarmac runway, give me mid-summer, a period of high

Main One of those perfect days when the Channel visibility is simply superb. Here we are approaching the French coast near Cap Gris Nez.

pressure and a destination 400nm or 500nm away every time.

A friend was telling me about a recent trip to Spain, IMC nearly all the way down and most of the way back. How exciting? If you haven’t flown in IMC for any length of time, it’s extremely tiring and well… very grey! And, of course, all the things we usually delight in looking at can’t be seen, and you are totally reliant on the instruments for navigation. Each to his own I suppose.

My first introduction to Kortrijk, Belgium – or to the airport at least – was fraught, dodging thunderstorms en route to the vintage fly-in at Schaffen-Diest, sneaking in as best I could.

Compared to today it was not an easy time, navigation was without GPS, weather forecasts were a form of educated guesswork, and added to the mix was a nervous, low-hours pilot filled with a desire. As time went by, GPS came along, the internet revolutionised weather access and the pilot gradually gained that hard-earned experience. And what of the desire? Well, that was further enhanced by every trip. In fact, it grew at a rate that could easily compete with that of the fastest-growing 45 genera bamboo.

Originally known as the airfield of Bissegem, Kortrijk airport was created by the Germans in 1916, with Jasta 6 moving in under the command of Staffelführer Oberleutnant Eduard Dostler a year later. By 1918 it had been taken over by the RFC, flying an array of aircraft from DH.9s, F.K.8s, RE.8s, Sopwith Camels and Snipes to S.E.5.As.

“People rave about the splendours of winter flying and how some of the best days are found when the axis of the Earth is oriented away from the sun”

Being one of only six Belgian Customs airfields, over the years it has been a transiting point, a lunch destination, as well a weekend stopover. My first weekend away with Sian included a night in Kortrijk.

However, my latest outing was with Dave Workman, a paramedic and all-round nice guy, in his Eurostar EV97. With the build finished four years previously, Dave had taken up friends and family, done all the usual stuff and, like many pilots, his flying had reached a plateau and become immotile. In joining our fly-out list he hoped to find new challenges, get across the Channel and maybe rediscover his mojo. Once a person’s flying stagnates, the excitement and thrills tend to diminish and can develop into a self-perpetuating downward spiral, often accompanied by insecurities that get swept ‘under the carpet’. At this stage, without some positive action and some restorative confidence-building, another pilot is at risk heading for a more ‘sedate’ pastime. Well, having met numerous pilots in his current predicament, I felt pretty sure that not only was the antidote close at hand, but we could also add a dimension to his flying that every pilot should try at least once.

Being based in the Midlands at Pound Green Airstrip, if Dave could get to Kent, we could pop to Belgium for a night and then nip into France for lunch before a leisurely return the following day. And by that, I don’t mean just a visit to the airfields, but into the towns themselves.

One of the pedagogical perks of instructing is being able to issue tasks for the ‘student’, such as checkingout the aeroplane or refuelling, while finishing off a cup of tea and biscuits. Well, on occasions, that complacency can backfire! Being very familiar with our

route to Kortrijk, I had tasked Dave to plan our trip and present it to me for checking. Unfortunately, or maybe fortunately, he discovered a problem I wasn’t aware of. Since my last visit, they had created a TMZ around the airfield and with us being ‘sans-transponder’ it created an issue. The despondency in Dave’s voice was hard to conceal and rather reminiscent of a youngster given a toy at Christmas without the batteries that were needed…

Trying my best to retain some semblance of professionalism and with the kind of quick thinking any politician would have been proud of, I suggested a call to ATC +32 56 36 20 40, as the red tape could be bypassed on their say so. Luckily, they were pretty chilled, unlike their counterparts at nearby Oostende, where you need a flight plan, 8.33 kHz radio, a transponder and a note from your mum – and that’s just for a local flight. The problem was averted, with nothing more than a little dented pride on my part.

Listening out on Headcorn’s frequency, I heard my ride call-up for landing and after a quick turnaround, an hour or so later we were mid-Channel with the White Cliffs behind us, en route to Belgium. From Dave’s perspective, it would be easy to think that the customs official and I were old pals by the greeting we got. Ivan Vanparys was the man on duty, and what a great advocate for the airport, Kortrijk and Belgium itself. When I explained that it was Dave’s first trip, he couldn’t have been more enthusiastic or helpful, much more like a welcoming host than an officious border guard. All I could say was a big thank you for the friendly manner, as opposed to the phlegmatic approach of so many people who are given a bit of authority.

I’m not sure how well it is known, but during WWII the Germans had built a bunker below the control tower that

has since been converted into a small museum. It was a place I had got to know quite intimately on a previous visit when weather had stopped play. Once mentioning that it would have been nice for Dave to have seen it, Ivan told us to wait while he went in search of the keys for our own private viewing. (http://fasinfo.be/)

Booking-in is a self-service affair in the main foyer these days, and fuel can be uplifted with a credit card, although oddly the landing fee still can’t be paid at the time and gets posted on.

If you go for lunch and plan to stay at the airfield, there are three options. Biggles is the formal restaurant (www.restaurantbiggles.be), the bar under the control tower serves simple things like croque Monsieur, and the bar/restaurant just before the exit offers a variety of fast-food type meals. For technophobes, this could well be interesting as meals are ordered on iPads and just appear at your table a while later, very likely the shape of the future. Sitting at the bar, the realisation was

beginning to dawn on Dave as he tried to comprehend just how the pile of bits he had assembled in his garage came to be parked in Belgium, having crossed the Channel and flown through France to get there. To say the man’s demeanour had changed does not do it justice as the ebullience which was effusing from one very happy paramedic, was refreshingly pleasing and infectious.

Getting into town couldn’t be easier. You can, of course, get a taxi, but once out of the airport, about 50 metres away on the other side of the road is the bus stop where the number 40 will get you into town in about 15 minutes.

To add to the day’s excitement our accommodation for the night could best be described using a vernacular from times gone by, when flares, kaftans and drooping moustaches were fashionable. Bootel Ahoi is a converted cargo ship moored on the River Leie that serves as a hotel/bar, not far from the centre of town. Although the rooms/cabins are small and functional, there is a certain fascination about lying on a bed, with

the water level lapping at a porthole above your head. They cost around €70 per night and the captain/owner, Stephan, is a larger than life character who could never be classified as one of life’s ‘also-rans’! Handelskaai 1, 8500 Kortrijk. (www.ahoi.be/kortrijk/ahoi).

Starting life as Cortoriacum this Gallo-Roman town was built on the River Leie (Lys) at the crossroads of two Roman roads and has known its fair share of conflict over the centuries. It has been fought over by the Vikings, Romans, Flemish, French, Portuguese, Spanish, Austrians and Germans, and was liberated in two World Wars by the Allies.

Philip, Count of Flanders, granted the town its city charter in 1190 and, due to good communications from both river and roads, the flax, wool, linen and the textile industry in general flourished.

Although once a walled city, the ongoing fisticuffs mean that the Broel Towers are all that remain of the fortifications today. As definitive symbols of the city, they sit either side of the river and, in spite of seeming identical in appearance, the ‘Speytorre’ was built in 1385, 20 years before the ‘Inghelburghtorre’ in 1415. The walk along the riverbank is particularly pleasant, especially if you have a bit of time on your hands and some sunshine to warm you. Perched in the middle of the bridge connecting the towers is a statue of John of Nepomuk, the Saint of drowning and floods, who oddly enough has ended up at the bottom of the river each time there has been a fracas of any kind.

Once in the centre of town, whatever you do you’re going end up at Grote Market Square, either for an evening stroll, a drink at one of the outside cafés, or even for something to eat or somewhere to sleep.

The Béguinage is a halidom village within the old town consisting of 41 alms-houses and is said to have been founded in 1238 by Countess Johanna of Constantinople for religiously devout women. Visits are permitted throughout the day. (www2.kortrijk.be)

Broel Museum offers an insight into the town’s history, as well as an audio guide to talk you through both the classical and new artwork exhibits. Broelkaai 6, Kortrijk 8500.

Kortrijk 1302 is a small museum that has particular significance in Flemish history, highlighting the battle of the Golden Spurs which took place on 11 July 1302. Begijnhof-Houtmarkt, Kortrijk 8500 (www.kortrijk1302.be)

There are also two linen and textile museums, which are naturally interwoven into the development of the town’s past prosperity.

For those with an interest in WWI, which likely encompasses most pilots, a look around the battlefields of Ypres is probably easier from here than anywhere else. The 1C train takes about 30 minutes, although if you want the flexibility of a car, Avis delivers to the airfield, or for better prices in town, with cars from around £75 FridayMonday. Try the comparison site (www.rentalcars.com).

Top This trip was Dave Workman’s first foray into mainland Europe in his Eurostar, and he thoroughly enjoyed the experience.

Above The busy main square in Kortrijk, plenty of ‘frites with everything’ restaurants where you can eat al fresco and watch the world go by.

Right John of Nepomuk, saint of drowning and floods, we can only hope he served the Belgians better that he did the UK in recent months!

For food, well the French border may only be a few miles away but although the Belgians have their specialities – they are good with chips, chocolate and beer – they can’t cook like the French. Most of the restaurants you’re likely to encounter in and around the central square are very similar, they are dearer than they should be and most serve some variation of steak and chips. Of course, that is where we ended up having our evening meal, watching the world go by as Kortrijk society went about their business and the sun dropped below the horizon.

For the foodies, if money is no issue go to Oud Walle, not far from the station and one of Kortrijk’s best. Koning Albertstraat 4 +32 56 22 65 53. (www.oudwalle.be/nl)

A 20 minute walk away, but more affordable, is the Bistro Bordo, a cosy little restaurant where you can expect a friendly welcome. Sint-Rochuslaan 10, +32 56 32 09 68 (www.facebook.com/Bistro-Bordo).

For those using the airfield as a bolthole, who just want to overnight with an early getaway the next day, the Hotel Bell-X is about 100 metres away with rooms around €85 – and I’ve found booking direct cheaper than the comparison sites. +32 56 37 17 71. For details visit www.cubilis.com/en/

In general, hotels are going to be over £100 per night anywhere near the centre. A nice 4-star in that price band with its own sauna and pool is Hotel Wu Wei Kongoweg 23, +32 56 29 01 00 https://wuwei.be/nl. At the other end of the spectrum at about half the price, is the no-frills Hostel Groeninghe Passionistenlaan 1A, 8500 Kortrijk +32 56 98 06 92. For more information visit: www.jeugdherbergen.be/

The following morning, skipping breakfast and with our flight plan filed, it was not long before we had crossed the border and were on short final for Calais. Just outside the terminal is the No 1 bus stop that will get you into town in about 20 minutes, where we rounded off the weekend with a very pleasant lunch.

The entire trip was an apotheosis of what is possible – and couldn’t have gone any better. After dropping me off later that afternoon, the flight home for Dave must have been like that of a conquering hero. I’m also guessing that he harboured hopes that the other pilots based at the strip had not yet gone home and were there to witness his triumphant return and maybe chat a bit about ‘mojo’.