FLY FOR UNDER 20K!

If you think that ownership is out of your league – then think again!The sky really is your limit…

DERRING-DO FATHER AND SONS ON AN AFRICAN ADVENTURE

MEET THE MEMBERS DAVE

If you think that ownership is out of your league – then think again!The sky really is your limit…

DERRING-DO FATHER AND SONS ON AN AFRICAN ADVENTURE

MEET THE MEMBERS DAVE

Halfway through the year. Can you believe that? I don’t seem to have managed to get much done at all, although now we can get back to the Jodel we are at least progressing reasonably well with that. I had initially hoped to have it flying by the end of May, do a couple of hours with a mate, get my licence revalidation and get some decent flying in during what is shaping up to be a pretty good summer. Realistically, that’s now out the window, but if we get back in the air and I sort the licence out by the end of the season I’ll count that as a good result. I do try to be a ‘glass half-full’ sort of guy.

Still, at least a number of sporting events have started to take place, albeit behind closed doors, something that unfortunately wouldn’t work with the LAA Rally. Sadly, we have had to take the decision to cancel the event because the health risks are simply too great. The Rally is a very important part of what we are as an association, so this was not an easy decision, but as somebody who has been heavily involved in the organisation of the Rally for a number of years, I am absolutely sure that this is the right thing to do. Next year will be the Association’s 75th Anniversary and we are already committed to doing all we can to have a bumper Rally to celebrate that and make up for this year’s disappointment.

Anyway, this month we have a feature on getting into aircraft ownership for under £20K, which includes a nice piece on group ownership from Duncan Campbell, who is one of five owners of a lovely old

Luscombe on a farm strip in Sussex.

Most of the sub £20K two-seaters are factory-built orphans, great aircraft for your first foray into ownership with plenty of expertise and owner clubs to fall back on.

If you are thinking about the bargain end of aviation, then I hope it gives you some ideas.

I doubt there are many of us who haven’t dreamt of an African adventure, the heroics of the likes of the Mollisons, Henshaw and Cobham firing the imagery of expansive landscapes and fiery sunsets.

Sling 4 builder, Ron Wheeler, and his two sons Chris and Nick, took time out for their own unique Boys’ Own tale of derring-do, joining a group of Sling owners to make a round trip from South Africa to Zanzibar to experience the ‘dark continent’ in all its glory. Part one starts on page 18.

All this and more – how do we do it for the money!

I hope you enjoy this issue and have been able to have some flying fun since the skies reopened for recreational activity.

Now… I’ve got to get back to it and finish my wooden wonder so I can come out to play too!

Take care. Brian.

Brian Hope

Brian Hope

The LAA summer is off to a delayed start this year but I hope you are all getting to enjoy some reasonable flying, even in the current restricted form. There will however, need to be some further lifting of restrictions if we are to make the most of this year and enjoy our pastime. It’s nice to be able to visit old and new airfields but such a pity that catering and atmosphere are two casualties of the pandemic – people were, and still are, vital ingredients to our enjoyment.

Flying training is, of course, the major ingredient that is missing from GA at the moment, however, I’m sure you have noticed that the approach varies wildly across the globe – from complete shutdown of airspace to pretty much business as usual. I hear that there are some products now being offered to prevent infection while we are airborne with someone from a different household, i.e. an instructor, but I wonder whether these will soon be discarded or become, as they say, the new normal?

The damage to commercial air transport seems to be continuing unabated, with recent announcements about severe retrenchment by airlines, and airports which are left trying to serve significantly diminished volumes of passengers and aircraft movements with too many resources.

Something has got to give I suppose, but developments like these will also have impacts on our community unfortunately, these being, for example, the curb on careers and less disposable income to go private flying.

One of the impacts that might seem a little counter intuitive, will be on airspace and its modernisation.

Even though traffic volumes are severely depressed, there remains a pressing need for changes of airspace design and structure that are well past their sell-by-date, having been introduced for 1970s

commercial aircraft and their operation.

In addition, we need to have a cross industry agreement upon the timing and implementation of the future roll out of electronic conspicuity, in whatever format enables both air-to-air and air-toground awareness. In fact, this current upheaval is probably the best time to modernise our airspace, rather than wait until everybody’s too busy to do it properly.

From a GA perspective, there is much to be concerned about and, bizarrely, perhaps even be pleased about. On the one hand, today’s commercial aircraft can perform better than their more aged counterparts, climbing quicker and faster and potentially allowing the base of controlled airspace to rise.

On the other hand they (the airline operators) say they need more space laterally to improve and increase routings, providing more system capacity and reducing delay… and even though we are leaving the EU and EASA, our regulators seem to be chasing down compliance with EU legislation. No, I can’t work that one out either. Nevertheless, it’s a delicate balance, but GA needs to be front and centre in the debates. If you haven’t already done so, please take a look at the Airspace4All.org website to learn more and get engaged.

Still on the subject of airspace, I’m told that within three hours of the return of GA flying in May, the CAA recorded their first post-lockdown airspace infringement and that overall numbers are starting to rise again.

I’ve asked for a breakdown of the infringements by aircraft type, so that we can see whether permit types are involved, however this information wasn’t available in time for me to complete this article and meet the editor’s deadlines. Hopefully I will have something to report next month.

In the meantime, stay safe!

06 NEWS

Thumbs up to 600kg microlights from CAA, Rally cancellation and Air League kit build plans

10 FINANCIAL REPORT

A look at our 2019 financial accounts

13 ROCC COURSE

Taking the Radio Operator’s Certificate of Competence Course at Popham Airfield 2020

14 PROJECT NEWS

KFA Explorer, Van’s RV-6A. Plus New Projects and Cleared to Fly

18 SLING AFRICA

Rod Wheeler relates a Boys’ Own flying adventure in Southern Africa. Part I

24 ELECTRIC AIRCRAFT

LAA engineers produce a primer to encourage electric aircraft activity

29 METAL SEAGULLS LIGHTS

Finding lights that tick all the boxes…

30 REFUELLING

When it comes to refuelling, you should find a system that offers you, the aircraft and the environment the safest solution

32 STRUTS4U

Anne Hughes profiles the activities of the Struts, making good use of social media

34 FLYING ADVENTURE

Pretty villages and spas – Freiburg has it all – and more, as Martin Ferid reports

40 OWN FOR UNDER £20K

Brian Hope looks at the options available which can make it possible to own and fly for less than 20K

46 NEW PANEL

Ruth Kelly installs a new panel using determination and skill…

52 SAFETY SPOT

Engine fires and problems highlighted through deep inspections

58 MEET THE MEMBERS

We chat with Dave Howell, an inveterate aircraft owner/repairer…

62 CEO THOUGHTS

Steve Slater looks to the future, and laments the LAA Rally cancellation…

63 LANDING VOUCHERS

Your free landings, discounts and offers

On 16 June, the CAA issued a statement confirming a move to bring many new light aircraft designs under national regulation. The statement and the accompanying paper, CAP1920, is the CAA’s response to the consultation they held in autumn 2019, in which 1,254 respondents from a total of 1,379 (91%), supported the adoption of regulation for aeroplanes and helicopters up to 600kg to ‘opt out’ of EASA control and come within national oversight. The LAA, which has worked with the BMAA, industry representatives, and the CAA since the start of last year to see this issue progressed, welcomes the move as the next step in the consultative process.

Why microlights?

The consultation asked if these 450-600kg aeroplanes should be defined as ‘microlights’ or as ‘light sport aircraft’, and the LAA Board agreed that an expansion of the microlight definition was more advantageous than LSA in the short term. In the consultation, 78% of respondents expressed a preference towards the microlight definition. As microlights they also very much simplify the pilot licencing requirements for both microlight and SEP/SSEA licenced pilots.

The new rules will mean that manufacturers currently limited to producing microlight aircraft certified to 450kg would, under future national regulation, be able to sell new machines without having to switch over to more onerous EASA regulations, so long as they have no more than two seats, a calibrated stall speed not exceeding 45kt and a maximum mass of no more than 600kg.

The LAA’s vision of the future is that by working together, the CAA, BMAA and LAA could benefit the whole of the sport flying community by offering a new, more practical, economical and more environmentally-friendly fleet of GA aircraft.

The short answer is no, there will be no automatic transition, just as there wasn’t when the 390kg max allowable was moved up to 450kg. If an aircraft has been designed and built to meet the 450kg max weight, it may not be possible to increase the max allowable load without strengthening the structure. However, it may be possible to increase the limit on designs which were operated below their max design load in order to meet the microlight definition. We’ll be reviewing that as part of the implementation process.

To be issued a UK Permit to Fly, any design must be approved to an acceptable design code such as BCAR Section S. The next

stage of our work with the CAA is the implementation process, where the working group will develop options for appropriate design codes. It is also appropriate to look at an overhaul of the present requirements for microlight manufacturers to have CAA approval as manufacturers, which is currently a significant burden which has no equivalent among other European countries. It will be important to ensure commonality with codes and manufacturing approvals used in other countries, allowing the import and export of these aircraft to be simpler. Both the LAA and BMAA share the aim of creating a system to allow members to buy and fly aircraft from abroad, and for UK manufacturers to be able to sell outside the UK, with fewer regulatory obstacles.

Despite our best efforts, much of this is out of our hands and the CAA is, of course, also dealing with stepping more widely out of EASA as part of Brexit. Initially this was going to be a more isolated project, but now it appears we’ll need to wait for the

wider EASA opt-out at the end of December before this can go ahead. We hope though, that with the Associations and the CAA working together, we can get this programme into place in a matter of weeks thereafter.

CAP1920 can be found at: https:// tinyurl.com/CAA-consult

EASA allow fixed-wing microlight hours to validate EASA PPL or LAPL

Thanks in the main to the perseverance of Europe Air Sports, EASA has finally relented and will now allow fixed wing microlight hours to count toward the validation of an EASA PPL or LAPL rating. They cannot however be used for the hour’s flight with an Instructor or to gain a licence or rating.

A reminder that the CAA has published exemptions to allow those whose ratings or medicals expired between 16 March and 31 October to have them extended to 22 November 2020, subject to certain conditions (published as ORS4 nos 1385 and 1378 to cover both EASA and UK licences). For most Class 2 or LAPL medicals (there are additional requirements for those requiring additional checks), the pilot merely has to carry a copy of the relevant exemption with the original medical certificate.

For SEP, TMG, SSEA, and SLMG Ratings, any LAA Coach can authorise the rating extension by signing the licence rating page. To extend the 12-month period of LAPL currency, the Coach can sign the logbook.

There are CAA forms available if the Coach cannot sign the licence or logbook itself. However, by signing, the Coach is certifying that he or she has provided a formal briefing to the pilot covering the requirements listed in the relevant exemptions. The requirements and Powerpoint suggestions for the content of these briefings are available in the Coaching section of the LAA website.

It is with considerable regret that the Rally Working Group has had to take the decision to cancel this year’s LAA Rally. It joins a long list of aviation events that have had to be cancelled due to the impact of COVID-19.

Planning for the event had begun at the beginning of the year and continued despite the constraints of lockdown in the hope that, with the resumption of recreational flying and the prospect of further easing of lockdown restrictions, it might have been possible to hold an event of some sort at the beginning of September at Sywell.

In reaching its decision, the Working Group has had to consider the duty of care to members, the general public attending the event as well as the LAA staff, the many volunteers and the exhibitors, and our ability to ensure a safe and enjoyable event – all of this against a backdrop of uncertainty, evolving government guidelines and the spectre of a second spike in the virus.

Understandably, given the demographics of the membership, many members had expressed reservations as to the wisdom of holding and attending such a gathering. At the same time, there were many who wished to attend an event even if it had to be reduced in scope and format. A canvassing of exhibitors indicated a similar mixed response – how would it be possible to display aircraft or demonstrate electronic software safely?

As reported in the CEO’s chat, Sywell Aerodrome had indicated its willingness to support an event, albeit with reduced capacity in some of its hotel, restaurant and bar facilities. Like many airfields the FISO team had been furloughed and with staff requiring revalidation, there were also concerns of potential limitations on movement capacity.

As the Working Group continued its detailed planning, it became apparent that despite the ability to physically re-plan the event site to meet social distancing, many of the regular elements of the Rally would need to be scaled back or withdrawn. With many of the regular volunteers who set up and manage the Rally expressing reservations about attending, as well as the additional measures and resources needed to meet government requirements, we made the difficult decision to cancel the 2020 Rally.

Working Group Chairman, Eryl Smith said “The Rally is the highlight of the LAA year, bringing together the sport and recreational flying community and is greatly valued by our members and exhibitors alike. We are disappointed to have had to take the decision to cancel this year’s Rally but are committed to deliver a bigger and better event to mark the LAA’s 75th Anniversary in 2021. Make the 3, 4 and 5 September 2021, a date in your diaries right now.”

With major lessons learned from the 2016 build of a TL Sling 4 as part of the Centennial Wings programme, the Air League is planning a new aircraft building programme for young people, under the working title Project Slingshot.

Supported by the DfT, Project Slingshot aims to initially build an aircraft for cadet and youth flying training and delivery of Air League flying scholarships.

The programme will deliver significant long-term benefits as a STEM learning project through the participation of hundreds of young people in building the aircraft. It will also provide thousands more with the opportunity to learn to fly, as the aircraft is intended to be utilised for military cadet, and other youth

organisations’ ab initio flying, benefitting several thousand young people over its typical 25-year service life. This will all be made possible by drawing upon expertise within the RAF Sport Aircraft charitable organisation, the aviation and aerospace industries and the Light Aircraft Association.

The ambition is to launch a series of projects across the UK, each build project having the scope to involve a number of different groups of young people through the build being distributed in three elements – the fuselage, wings and empennage – to three locations, thus maximising the scale of the project’s impact, as well as reducing the time of each build.

On 3 June, one of the UK’s hang-gliding and microlight innovators, Brian Harrison (pictured), hang-glider pilot, microlight pilot, entrepreneur and jazz musician with the Clyde Valley Stompers, passed away. I first met Brian at Tinto in the mid-70s, where we were among the first hang-glider flyers in Scotland with Lanarkshire Soaring Club.

At the time, we were flying flappy Skyhook and Hawk gliders, but Brian quickly formed Scot Kites, where he produced the American-designed Electra Flyer hang-gliders which were sold as the Club Firefly, and was the first hang-glider which we had seen with battens in the sail.

Not being one to stand still, Brian was soon producing the Soarmaster engine and propeller drive unit, which he attached to one of his hang-gliders, and Jimmy Potts used it for the first microlight flight from Ireland to Scotland.

When the trike concept appeared on the scene, Brian manufactured his own and started operating a microlight flying school out of Cumbernauld Airfield, which was then just an empty grass field.

Not too much longer he was also

marketing the Paul Catto designed Goldwing Canard Microlight, an all-composite, three-axis machine which proved popular, a number of them being sold across the country.

When licensing and Permits for microlights appeared on the scene, Brian became an examiner, and those of us who had by then got into the microlight scene, had to get our licences. We found ourselves sitting in Brian’s house in Glasgow, taking the exams. Ironically, a few years later, Brian had let his licence lapse and the tables were turned. I was now the instructor and

Dear Brian, as a member, former pilot and engineer, I would like to offer up my past PhD research project as a contender for the ‘Future Flight Challenge’, mentioned in the last LA magazine. It is A VTOL fixed-wing project using an upper surface blown wing concept powered by a ducted fan.

I am now retired and not in a position to undertake this myself, but I would very much like to see it become a reality. I am happy to provide the existing research and ideas to another body to take it forward.

JohnRees (johnwrees@outlook.com)

Hello Brian. I have read with interest the articles about the theft of Rotax engines and the possible solutions. As a Chartered Loss Adjuster of some 40-plus years’ experience, I have seen many theft insurance claims, and advised on precautions. Maybe some of the following might be useful.

The average theft from both business

and commercial premises takes less than five minutes, but because airfields are often remote, thieves can work more easily for longer periods of time, so the best answer is to deter them from attacking their intended target in the first place. Perimeter security is the best solution, we need to keep them out in the first place.

Naturally, thieves would rather attack premises without an alarm – out of some 25,000 domestic burglaries I attended, only three were from alarmed houses, and there is a similar low rate from commercial properties, although it is a little higher because of the relative remoteness of trading estates.

Nevertheless, the fitting of an alarm significantly reduces the risk of an attack. Movement detectors are the preferred method, even with a unit looking at the entrance door. They can often be made to ignore small animals like foxes etc, so reducing false alarms. A monitored alarm is the very best solution, but requires mains

examiner – and Brian was my student.

A couple of years before SSDR was approved, Brian had purchased one of his old Goldwing aircraft and had set about restoring it. It needed a Permit and a check flight, both of which I had the pleasure of doing for him.

In 2016 the Vintage Hang-gliding Association organised their vintage gathering in the Lake District and Brian and I went, and we met up with many of the original flyers who immediately recognised him and were delighted to see him.

After we had walked around all of the assembled early hang-gliders, and watched the flying display, we attended a celebration where Brian received an award in recognition of his valued contribution to the world of hang-gliding and microlighting.

And so passes Brian, a valued friend and advisor to so many, one of the pioneers of hang-gliding and microlight aviation, whose contribution to and enthusiasm for our sports should never be forgotten.

So, next time you’re up flying, give him a wave. I’m sure that he’ll be watching.

Dave Whitelawelectricity, an underground phone line, and incurs a monthly cost to monitor.

As already mentioned, an alarm with a ringer is probably OK for most installations, the ‘bell’ being a klaxon horn with an output in excess of the threshold of pain for most thieves. They can be linked to a phone, or a PC to record the events via a camera, but the pictures aren’t wonderful.

Physical barriers are also good – metal or strong wooden doors, possibly lined with sheet steel, provide a good deterrent, and provided a closed shackle padlock is used the doors will be hard to open. A closed shackle padlock is one where the shackle (the moving bit) fits snugly to the body, so it’s not possible to get a crowbar or the like between the shackle and the body to force it open. Chubb or Banhams are the leading makers, available from good locksmiths or a local DIY or hardware store. New they can be £100 or more, but cheaper alternatives are available and are almost as good.

Best wishes, happy flying, Mike Farrer.

Aviation bears a certain degree of risk and the very purpose of insurance is to protect the pilots and their relatives in case of an unfortunate event. Accidents do occur, but fortunately they are not often tragic. The advances in technology, quality control and maintenance regimes over the years means there are now far fewer serious accidents caused by mechanical failures. Here at Air Courtage, we handle thousands of claims each year and human error tends to be the main causal issue of accidents. Some of them are tragic and will not be mentioned here, but some of them can give rise to a smile. What follows is a compilation of our latest rather unusual claims!

Improbable.

One of our clients had his aircraft stolen while it was on his trailer, but the guilty person was quickly identified and arrested. In fact, while towing the stolen trailer and aircraft, he decided to force his way through a police barricade. Unfortunately, the aircraft was damaged by the shock but is now repaired, and back flying.

Small scale.

One of our clients had his aircraft damaged by a model aircraft. Model flying was taking place on the airfield and though the ‘real’ aircraft was parked in the designated parking area, the pilot of the model aircraft unexpectedly decided to taxy his model towards the tail of the insured aircraft, damaging the aircraft’s trailing edge. He later said that he just wanted to see how it looked with the aircraft towing his model.

Not so inanimate.

Sometimes, perhaps to relieve feelings of guilt and responsibility, inanimate objects are blamed for accidents! “The lamp pole collided with my aircraft”. You must also beware the self-motivated hangar door, there are more around than you may think!

Danger - Animals!

Following an engine failure, our client made an excellent emergency landing in his microlight into a field. Unable to recover the aircraft straight away, it was left on site. The following day, when the insured went to remove the aircraft, he noticed further damage which had been caused by inquisitive horses.

Bully.

Similarly, we have recently handled a claim caused by a bull which escaped from its enclosure. It furiously charged and butted several gliders, damaging a number of fuselages and wings.

Falcon Jet!

A trained falcon died near the airport it was ‘working at’, presumably due to the engine start of a regional airliner at an unexpected location and time. The cause of the death was diagnosed as being a heart-attack, and the falcon’s owner claimed the cost of the bird, including loss of use, etc… The tricky part of this loss was that the loss adjuster had to determine whether the heart attack was caused by the air suction generated by the engine start, in which case it is fully covered, or by the aircraft noise, which is a standard exclusion of all aviation policies. At the end of the day, it was impossible to assess, and the third party suffered a loss due to the inappropriate position of the aircraft which had to be indemnified.

Cooling off.

Although not handled by Air Courtage, would you expect a passenger to open the emergency door ‘to get some fresh air’ just before the aircraft takes off? This occurred on an airliner in China and caused a significant delay to the flight.

Caught short.

Finally, and in rhythm with current events, let’s mention this recent claim which, although again not directly handled by Air Courtage, does make you wonder about some people. A gang of two armed robbers stole hundreds of toilet rolls from an airport due to the shortage in supermarkets because of panic buying over the coronavirus pandemic!

Insurance plays its part in these rather oddball scenarios just as it does in the normal run of unfortunate mishaps and your aviation insurance broker is here to assist you for any occurrence which happens. We take this opportunity to invite you to notify as soon as possible of any incident which happens to you, we are happy to assist even if it may not give rise to an actual claim.

If your aircraft is insured through us, you can report an event, or request any clarification on coverage or claim handling by calling: 03306 845 108 or e-mail: laa@air-assurances.com

Enjoy your return to flying and be safe!

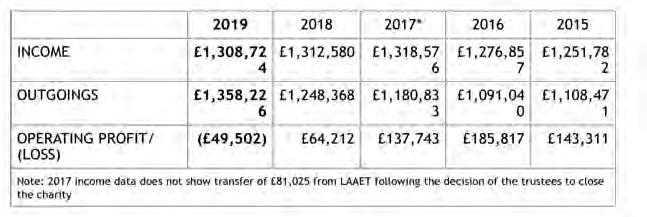

For the past six years, rather than wait until the Annual General Meeting in October, we produce an abbreviated form of our annual accounts in Light Aviation magazine. The full Financial Report for the year 2019 will be available shortly on the LAA website, and of course will be an agenda item at the AGM. However, this summary of the accounts, fresh from the auditors and following approval at the 29 May Board meeting, shows our income and expenditure, and some future planning for 2020 and beyond.

Why are these audited accounts only based on the figures to the end of 2019? Of course, the reason is that at the end of each calendar year we need to ensure all payments and deposits are completed before Henson Rees Russell LLP carry out their formal audit of the business. This took place in March, fortuitously just a week before the COVID-19 lockdown.

Their draft financial report was presented to our Directors for agreement and signature at the end of May, allowing this to get to you in time for this issue of LA

As I would expect, our auditors were happy to give a clean bill of health to both our accounts processes and our governance, even taking into account the exceptional circumstances in which we have found ourselves in recent months.

Although outside the timescale of these accounts, we cannot ignore the effects of the coronavirus on the wider environment, and on sport flying in early 2020. The suspension of general aviation for several weeks had a significant short-term effect on LAA revenues, but we elected not to furlough any staff, and our investment in remote, Cloud-based IT systems has meant that the LAA has been able to serve its members via home-working in an almost seamless manner.

The effective cessation of permit check flights and mod completion testing led to a 50% reduction in monthly Engineering incomes against the 2020 budget. Income for the first four months of 2020 was £305,375 versus a budget of £385,465 – a deficit of £80,090. Fortunately, we have the financial reserves to ride this dip and there are already signs, with around 400 permit renewal applications received in the weeks following the resumption of flying, that these revenues are recovering.

We owe a massive thank you to all the LAA HQ team for keeping things moving through the crisis.

£1,308,724 £1,358,226

£1,318,576 £1,276,857 £1,251,782

£1,108,471 £1,091,040 £1,180,833

Last year I headed this section ‘Continuing Development and Growth’. Well, this year we haven’t shown fiscal growth, but we have certainly made some developments. As you’ll have noted from the table above, our overall income has fallen very slightly, but our expenses have increased, leading for the first time in recent years, to an operating loss.

This is part of a planned strategy to increase our spending in the short-term future. In recent years, the LAA has shown a surplus of anything up to £185,000, building reserves of more that £1.3 million and we felt that this was inappropriate for a not-for-profit members’ association. As a result, the Board agreed to a 2019 budget that, unlike previous years, did not require the Association to show a nominal two per cent surplus on turnover.

Rather than keeping money in the bank at low interest rates, instead we invested in member services, training, and the recruitment of new skilled staff. For some time, we have noted a shortfall in design engineering capability with all three design engineers working at full capacity, leading to delays in approval work. In addition, a number of key staff (including our CEO!), are approaching or are beyond their 60th birthdays. We therefore needed to plan a staged succession of skills and resources for the years ahead.

This was achieved by the recruitment of an additional design engineer and two graduate engineers to be able to take over from one or more of our existing staff engineers, as and when they elect to seek retirement in the coming years. Effectively, we are ‘carrying’ these additional staff above our existing planned establishment at a cost of around £80,000 per annum, meaning we will operate at a planned loss in the 2019, 2020 and 2021 financial years, funded by our current ample reserves.

This has therefore meant we have shown a planned deficit of £49,502, which is actually less than our

budgeted deficit of £104,000. The 2019 accounts show an increase in income in some areas such as training, thanks to more members taking advantage of courses at LAA HQ. We hope that when we can resume these, we’ll be able to continue to build on that success.

Even before the horrors of COVID-19 struck, we were already aware that we needed to plan for some challenges ahead. Our income, which had steadily increased year-on-year by about 1.7% since 2015, levelled off in 2019 to £1,308,724, in fact marginally down from £1,312,580 in 2018. The majority of this fall has been in membership revenues, which despite actual member numbers remaining stable, has seen more members being recruited in the ‘Full Member’ category as syndicate aircraft owners, rather than ‘Full Plus Members’ a sole operator of an aircraft.

Engineering incomes are the prime drivers of revenue, and the LAA ended 2019 with more than 2,700 aircraft on active Permits to Fly and, driven by permit renewal fees, Engineering revenues have increased to £637,471 (it was £615,137 in 2018). Made up of permit first issues, new project registrations and modifications fees, our engineering activities represent just under 50% of the revenues received.

Equally, our biggest area of expenditure is salaries and, due to the recent recruitment programme, overall staff costs increased to £643,231, or 47% of our expenditure. Our second largest area of expenditure is, well, …you are reading it! Light Aviation magazine cost the organisation a total of £157,000 to produce last year, an increase from £148,000 in 2018 as we also produced 10,000 copies of LAA Today, a special edition designed to introduce new members to the Association. Both Light Aviation and LAA Today are of course partially subsidised by advertising revenues, which last year totalled £112,000.

Another significant cost is our insurance coverage, which includes covers for Association and staff liabilities, as well Inspectors and Pilot Coaches when they are working on behalf of the LAA. It also includes liability cover of up to £20 million for Member Club and Strut events. As you might expect, this attracts a significant set of premiums – for the last three years we have paid annual premiums each totalling around £86,000.

However, the insurance market has hardened significantly in the past year and many insurers, having lost money in the GA sector, are pulling out. We expect that premiums in the coming year will increase significantly, perhaps as high as £100,000 per annum.

The LAA Rally continues to give great value for members. Last year the combination of record stand space sales, ticketing and event sponsorship generated revenues of £50,463, up from £47,774. Outgoings totalled £36,047, spent on marquees, servicing and support activities. The £14,000 surplus we generated from the 2019 event is held in a separate Rally fund and, may become useful if we elect to run a different, post-COVID event this year, which may have to be run at a budgeted loss.

While planning for a potential merger between the LAA and BMAA absorbed significant amounts of management and volunteer time, little of this is reflected in the Association’s ‘bottom line’. Expenditures associated with the planning, mainly accounting oversight, totalled £1,200.

The Association has, at £1,365,534, more than adequate reserves to protect our members from any short-term challenges. These reserves are held in a number of bank accounts and investment funds, ensuring that we remain below the Government threshold for compensation if a bank were to close. These investments have been affected by the coronavirus-related financial recession, which has led to declining interest returns. However, we regard these investments as long-term, and therefore expect that they will recover as the global economy gets back on its feet.

Within its reserves, the LAA also currently holds circa £230,000 in allocated accounts or ‘reserved funds’ such as an LAA HQ Buildings Fund, the Armstrong Isaacs Fund and Trophies Fund. These were created, in some cases many years ago, for specific purposes and there are restrictions on any future use. The Armstrong Isaacs fund was further boosted last year by a £50,000 legacy contribution from the estate of the late Dr Ian Brewster. Some of this was invested in areas including the

Top Fleet growth. Head of the CAA GA Unit, Rachel Gardner-Poole signs the authorisation for Yak 18A, 50 and 52’s and Nanchangs, to move onto the LAA register.

Above Training for the future. Chief Engineer Francis Donaldson, with LAA’s Graduate Engineers Mike Roberts (left) and Joe Hadley.

development of social media programmes, the creation of training videos – now rolled out on a dedicated LAA YouTube channel – as well as increasing the breadth of member training activities at LAA HQ.

Overall, even before factoring in the effects of COVID-19, we have noted a levelling of the previously rising trend in membership and we are also noting an increased move to syndicate ownership, along with fewer hours being flown each year. All this points to our all being more careful with our flying spending. This is reinforced by the findings of our member survey, which will be published in next month’s issue of Light Aviation. We’ll be developing future initiatives to recognise that.

We are continuing to invest in new developments, including working with the CAA to improve the scope and utility of the LAA aircraft fleet, including the transition of the Russian YAK fleet from CAA to LAA Permit status, and possible future expansion into the oversight of homebuilt helicopters.

We are also seeking approval to enable the use of LAA Permit aircraft for remunerated ab initio training, and in developing a strategy for the national oversight of factory-built sport aircraft up to 600kg (see NEWS, Ed). This has the potential to transform recreational flying in the UK by enabling microlight designs to operate at more realistic loads, and allowing a wider range of more modern, fuel – and environmentally efficient light aircraft to enter the GA market.

We’re also looking at other, more innovative ways to offer a wider service to existing members and to attract new ones. Despite all the challenges, we’ve got an exciting year ahead! ■

Initially resented, it slowly dawned that Continuing Professional Development (CPD) was an excellent method of keeping up to date. As a result, 50 years ago, I started introducing it into other areas of my life. April became the month for the annual driving lesson, a check flight, and for choosing which course to tackle next. And this year, a shiny new Radio Operator’s Certificate of Competence (ROCC) was ticked off my bucket list.

I learned about the ROCC Course from a round-robin LAA email in February. The ideal number of students is four or six (making two or three pairs) so candidates can work together, which makes the practice RT extremely interactive.

As instructed in the pre-course brief, I duly downloaded CAP413 and CAP452 and scanned thorough anything to do with the relevant sections of the Air Ground Communication Service (AGCS). I was completely ignorant of what it meant at the time and, although I was advised NOT to read everything, I was a little intimidated by the amount of material that seemed to be required.

A month later I set off to Popham on a miserable Friday evening in my campervan ‘Ernie’, and the following morning had a date with the famous Spitfire café all-day breakfast, which lived up to its well-earned reputation and certainly set me up for the day ahead.

We six students eyed each other nervously in the café, we were a diverse group from across the country, with little but aviation in common.

Chris Thompson, our instructor/examiner shepherded us into the Popham conference room, and explained that we had our work cut out if we were going to pass both exams, but that even if we were not successful, we would certainly learn a great deal about correct RT procedure.

One big problem was that the main CAA exam is ‘written’ and not ‘multiple choice’, so you don’t stand any chance of guessing one of the usual four possible answers! Not having done a written exam for 50 years, it was more than a little daunting!

Chris has the air of a benevolent RSM with the confidence of a lifetime’s experience and

Above Course attendees have a lot to take in over the two-day ROCC course.

the urgency of a tight timetable. So, no prisoners here, and by lunchtime we were already exhausted from the quality and quantity of the information we had digested. We ate in silence, mulling it all over.

The afternoon consisted of a ‘mock’ written, followed by RT practice in pairs with one person playing controller and one playing different aircraft. It was continually emphasised that an Air Ground Communication Service operator is NOT a controller, and could not actually control anything. Getting the hang of the RT headsets was interesting practice for the coming ‘oral’ – we certainly all failed the no laughing rule.

This is a well-structured course which has obviously stood the test of time. Our only problem was going to be remembering everything in order to achieve the required 75% pass rate for the written exam before being allowed to take the oral practical, a hurdle I had seldom achieved even as a schoolboy. The questions covered the breadth of the syllabus, and having flown for more than 50 years, it was fascinating to experience RT from a ground station’s perspective. When you are in your own aircraft it is your world, you are only really interested in your call sign (and maybe the aircraft in front). It is very easy to rattle off your call sign and ‘inside leg measurement’ at high speed without realising the person receiving your (possibly distorted and low

volume) radio call has to make some sense out of it.

The following morning was exam day – a one-hour written paper, but happily no surprises with the format as we had done the mock the day before. After a full debrief I was relieved to find that I had exceeded the 75% by some margin and would therefore be allowed to take the formal one-to-one practical test.

The Oral started simply, based on a normal day’s flying in a fictitious circuit. The traffic gradually increased, with fire trucks, first solos and inbound emergencies. It was mesmerising. The 20 minutes passed in a flash, and I felt like I must have lost several pounds in weight! I was given a full debrief to find my many minor mistakes (every single one recorded by Chris!) and then learned that I had actually passed. There followed a couple of pages of the inevitable CAA paperwork and I was told to expect my ROCC Certificate from the ‘ivory tower’ in a few weeks. It took a couple of extra strong coffees in the Popham clubroom to calm me down afterwards, as it sunk in just how much I had learned, and felt that I had now achieved.

I am proud (and surprised) to have passed and as soon as lockdown is released in Wales I will be taking Chris’ advice and will sit in on a local airfield’s Saturday fly-ins RT to gain more experience.

I do certainly recommend the course, and now understand why some pilots (incorrectly) use ‘sir’ when talking to any ATC. ■

What a difference a month can make, the New Projects and Cleared to Fly lists are looking much healthier, having bounced back quickly now that flying is back on the menu, for most of the UK at least. There is an interesting variety of types making their first flights, two of which are detailed below.

I recently made a plea for contributions and, thanks to fellow members, my inbox has a healthy working backlog. Thank you.

Occasionally I’m aware that while keen to show progress, some wish to maintain anonymity so as not to risk potential theft, and we can certainly keep all names and places from any text if you wish.

Last month Dudley Pattison provided his second update on the KFA Safari, this month we here from Pete Marsden by way of a progress update on the KFA Explorer, the slightly smaller stabl e mate of the Safari. Progress is being made and I know that Pete is keen to get the airframe to Sywell this year, if we are fortuna te

enough to have any sort of gathering at all – fingers crossed, b ut as yet we do not know…

One of the aspects of the build reports in the Project News inbox that I always enjoy reading, is the human story behind a project. Occasionally, a member will say ‘you don’t want to hear about my aircraft, you’ve already covered one of those!’. But each of our circumstances is different and, intentional or otherwise, it is the human story that often reveals itself in a build report.

Many projects are not finished by the person or team that started it, and so it was with Malcolm Wright’s RV-6A. He took on the project following a bereavement and pledged that he would complete it to the original builder's high standard. Take a look below, I think you will agree that he’s done a terrific job.

To get in touch with Project News , and tell your story, report a milestone or just to send a picture or two, email: projectnews@ laa-archive.org.uk . Please share your story!

Funnily enough, I have found myself with a lot of time on my hands lately and, luckily for me, I had a KFA Explorer kit in my workshop that begged my attention… Much to the disgust of Stefan, the owner of KFA, I am building the first Explorer in the UK as a nosewheel, but that’s an argument for another day.

One of the great things about the Explorer and the Safari is that they may be built with the little wheel at either end. In fact, it would even be an easy job to subsequently change it to the other end, although I think most people will keep it how they built it, but it’s nice to have the option.

The kit arrives well packaged and labelled, giving even me a good chance to work out what is what. There are always bits in any kit you need to source yourself, however, the KFA kits are very complete, plus the instructions are good and have been steadily improved since my example arrived. One real boon has been a builders’ WhatsApp group. It has also been extremely helpful to message or even call the factory when you

get stuck, especially as they are in the same time zone as us. The UK builder group is growing as well, it can only become easier when you have more people to ask.

Being the first Explorer in the country, it has not been supplied as UK spec, and I have had to carry out some jobs that will be better performed by the factory. However, the build is not at all challenging, but I have had to make a handful of sheet metal folds, and the required equipment for this is the sort of equipment that the average builder will not have. So, in the future, this type of process will be carried out at the factory. Stefan has been very responsive to our constant whining… sorry, I mean constructive comments, and is improving the kits and instructions almost daily.

As the first in the country we were allowed to bring Graham Smith’s Safari and my Explorer in with more work done by the factory, so my fuselage is already covered, but I still have to cover the wings. This is something I have never done before and I have been unable to proceed with that particular task during lockdown, as I need to get some help from Graham.

Compared to some aircraft I have built, the access is great – and fitting out the wiring, fuel and brake lines has been a breeze. The access for the firewall and instrument panel is brilliant, no hanging upside down or inserting a small child. With hindsight, I should have plumbed in the brake lines at the pedals before installing the firewall, which will be my next task, and as the aft cowl comes off I will still have much better access than I had, say on my SportCruiser. The engine bay has plenty of space too, and I am finding that easy. The cowling took some fettling but again, nothing beyond the capabilities of mortal man. This is an area where we can, and will, make improvements to the instructions.

Apart from giving me a hard time because I need a training wheel at the front, Graham and Stefan are amused that I, as the ‘fuller-figured’ partner, have chosen to build the smaller of the two aircraft. At first, I thought this might be a problem, but the more I work inside of the Explorer the more comfortable I feel in it.

Right The BRS bay, aft of the standard luggage area, where Pete plans to add a small extra load space. Accessibility to the general structure can also be seen. Photo: Pete Marsden

As old and creaky as I am, I now feel confident that I will have ample space and will be able to hop in and out with ease. The Explorer already has reasonable luggage space, and at some stage I will look at putting a smaller luggage area (15kg including the shelf) where space is provided for a ballistic parachute. Almost all the outer panels are easily removable, so there will be no excuse not to check inside during maintenance.

All in all, I am enjoying the build very much and I look forward to flying it sometime this year.

Once we are given more freedom of movement, please feel free to drop by my workshop near Newbury and take a look. You can find my contact details on the Sprite Aviation website.

I’d had years of fun operating a Bolkow Junior, but for some time I had been harbouring the thought of building my own aeroplane, and favoured aluminium construction, so it would have to be an RV. It was pointed out to me that before I could order any kit, I would need somewhere to build it, so I spent the summer of 2015 building a workshop at home – I knew how important it would be to be able to work on my kit as often as possible and have tea and biscuits on tap!

In a seemingly timely fashion, on completion of my workshop, the very next edition of Light Aviation had an advertisement for a partially built RV-6A for sale, but having a leaning towards a tailwheel version I almost dismissed it. However, I went to have a look and was immediately taken by the level of workmanship and attention to detail that had gone into it. It was started back in 1993 by father and son, Ron and Simon Baxter, who both worked for British Aerospace, and it showed.

Following the loss of his father, Simon sadly had to let it go and, even though I had offered above the asking price, I

had to wait to see if I’d been successful. I was, and as a tribute to Ron I promised myself (and Simon) to finish the build in the same vein as it had originally been started.

Although I am an engineer (having served my apprenticeship at Norton Villiers, the motorcycle manufacturer, and had worked for Dowty Boulton Paul) I signed myself up for the LAA Working in Aluminium course, which I would highly recommend to anyone thinking of building their own metal aircraft.

The build initially started with a steep learning curve, as the RV-6 has no pre-drilled holes, unlike the later models. They are not even marked out, so every hole had to be measured out and remeasured and checked again before committing to drill. However, I have thoroughly enjoyed almost every minute of it. I guess the only pressure I felt was whether I could keep the build quality to the same standard – Simon has since assured me that I have. I also took the opportunity to add any upgrades while finishing it, such as replacement nose leg and fork together with the ‘anti-splat’ bracket.

Above G-VANZ takes to the air in the hands of Pete Whitehead at Sleap.

Photo: Malcolm Wright

Left The encouraging sight that greeted Malcolm at the bottom of the garden and helped to maintain momentum.

Photo: Malcolm Wright

Right The brand new engine that came with the kit being lifted into place.

Photo: Malcolm Wright

Below A very tidy cockpit with traditional day VFR panel. Photo: Malcolm Wright

My workshop became a very pleasant place to spend most evenings and weekend mornings, and hardly failed to raise a smile on my face when I opened the door and saw what was in there.

I decided to keep the panel conventional instrument/ day VFR and did all the electrical wiring myself, together with the dreaded canopy cutting, which I also found enjoyable. I do think that I was able finish it with growing momentum because the workshop was so handy to just pop into, but boy did it feel strange when I moved the airframe to the airfield for painting.

Having spent so much collective time and effort in the construction, I didn't want to spoil it by cutting corners with the finishing, so I had the painting done by Shropshire Aircraft Spraying at Sleap.

I carefully chose what I thought was the right colour scheme for it and was greatly impressed by the effort that Keith at Shropshire went to in copying it, even down to the chequered under surface of the wings, all done without stencils.

Rigging has taken longer than expected, with the journey time proving much longer than just nipping out to my garden. It also meant that I had to ensure that I had the right tools with me for the job to be done. I was relieved to see no leaks from the fuel tanks when filled, and was amazed when the engine, which is a Van’s supplied factory new O-320 with Hartzell CS prop, started on the second blade.

Thanks to my inspector, Peter Claiden, for his full support, and had it not been for COVID-19 it would have taken to the air sooner, but on the evening of 27 May 2020, G-VANZ made a successful first flight in the hands of Pete Whitehead at Sleap.

Built by Phil Hooper

My thanks to Phil Hooper, who sent a couple of pictures of his Minicab. Scratch built and started 20 years ago, he has stuck at it but said that work just kept getting in the way. I’m sure many of us are all too familiar with the impossible balancing act of a growing family, work, and the attention required for a plans-built project. Alpha Bravo was at the ‘finished’ stage last May, and cleared to fly in November, but then we had that awful winter of floods and high winds and just as the weather turned, well, you know the rest… Let’s hope Phil can go ‘Minicabing’ very soon.

Left The first ‘passengers’ to sit in G-MCAB, both grown men now! Photo: Phil Hooper

Right Much farther down the track, the basic airframe nears completion. Photo: Phil Hooper

Below May 2019 and Alpha Bravo has her first engine run in the spring sunshine, Phil couldn’t resist the opportunity for a quick taxi up and down the strip.

If your aircraft has been featured in the New Projects list, please let Project News know of your progress at: projectnews@laa-archive.org.uk

If your aircraft has featured recently in the magazine and has subsequently completed its maiden flight, Project News would like to hear from you at: projectnews@laa-archive.org.uk

n G-CLDI Just Superstol (LAA 397-15465)

15/5/2020

Mr E Marsh, Paludis Ltd., George Hotel, Main Road, Hathersage, Hope Valley, S32 1BB

n G-GTWL Eurofox 912iS (LAA 376-15663)

14/5/2020

Mr Glenn Brown, The Old Mint House, 21 Park Street, Towcester, NN12 6DQ

n Van’s RV-7A (LAA 323-15701) 26/5/2020

Mr A Jenkins, 4 Willow Drive, Handforth, Wilmslow, Cheshire, SK9 3DR

n Evektor Sportstar SW (LAA 315C-15700) 21/2/2020

Mr R Cornwell, The Willows, Water Lane, Somerford Keynes, Cirencester, GL7 6DS

n Sequoia Falco F8L (LAA 100-15699)

4/5/2020

Name and address held by LAA Engineering

n G-OGZZ Van’s RV-8 (LAA 303-15536) 21/5/2020

Mr Edwin Fern, Point Quay House, Point, Devoran, Truro, TR3 6NL

n G-AVDF Beagle B121 Series 1 (s/n B121-001) 19/5/2020

Name and address held by LAA Engineering

n G-BVDG VPM M15 (s/n VPM15UK103) 28/5/2020

Name and address held by LAA Engineering

n G-EDFS Pietenpol Air Camper (PFA 047-13206) 20/5/2020

Name and address held by LAA Engineering

n G-JAAP Aeroprakt A32 Vixxen (LAA 411-15654) 21/5/2020

Name and address held by LAA Engineering

n G-JWNI Just Superstol (LAA 397-15478) 18/5/2020

Name and address held by LAA Engineering

n G-PULR Pitts S-2AE (LAA 009A-14904) 5/5/2020

Name and address held by LAA Engineering

n G-VANZ Van's RV-6A (PFA 181A-12531) 18/5/2020

Name and address held by LAA Engineering

It had all started back in February 2019, with an email from Tim Hardy, UK importer for The Airplane Factory (TAF), inviting me to join a gaggle of Sling aircraft on an African flying adventure, being arranged by the factory. It looked incongruous enough, but as we were only just two years into the build of our own Sling 4, my first reaction was no, let’s focus on getting our aeroplane finished. However, once the germ of an idea forms in my head about some crazy new project, I am usually pretty good at finding reasons why it would have been absolutely crazy to not jump right in. With a South African-born mother, and several family members living down there, I had a long-held ambition to recreate Cecil Lewis’ missionary flight recounted in his book Gemini to Joburg. Surely doing half the Continent in either direction would be just as exciting.

Having previously arranged some South Africanbased flying trips of my own in the distant pre-GPS and internet era, I had a vague idea of the requirements to get a valid SAA PPL, but Tim was quick to update me on the new rules. It seems the days of an ‘open book Air

Law exam, plus a quick once round the circuit in a Cessna 172’, were no more. A stringent pass/fail computer exam with no chance to retake before the ‘off’ awaited me and fellow UK aviators Lucien d’Sa and Colin Cleaver. The paperwork exchange with our UK CAA, preparation, actual exam and the subsequent flight test and excellent briefing provided by Wayne Jones of Eagle 1 Flight Academy at Rand Airport, is a story in itself. Suffice to say we all passed, and on a lovely sunny Sunday morning we gathered at Tedderfield Airport, home of the Sling factory. We were getting to know our rental Slings for the trip under the watchful gaze of Sean Russell, TAF chief pilot, who had worked tirelessly to prepare them.

It was hugely comforting to know that someone else was managing the enormous task of arranging local accommodation and flight clearances for our merry band – huge thanks to Essie Esterhuysen who took on this thankless task, as he has done for many similar air adventures in South Africa.

Several other reasons swayed my decision to join the

mad adventure. Tim made a convincing argument that getting 30-plus hours of Sling time in my logbook would mean I would be sufficiently acquainted with the Rotax and Garmin systems to undertake the test flying of our own example, G-SLNG, which we hoped to have completed by the end of 2019. He was absolutely right, and we did – I successfully undertook the wonderfully uneventful initial test flight on 30 December.

Another major reason was the chance to fly with my twin sons, Chris and Nick. Somehow, they had both managed to combine studying for numerous science A-levels with many hours in the shed riveting, as well as keeping my co-owner Richard and I on track with the build. The July timing would mean they would have completed the first year of their engineering courses, and as they had both just recently gone solo with their university Air Squadrons, my wife Sandy felt a lot more comfortable that at least there would be some sensible heads on board. She kindly blessed our Boys’ Own bonding session!

Mid-winter (our summer) in South Africa generally

Above Rod with twin sons, Chris, in front, and Nick taking a nap in the rear. Both are learning to fly with their university Air Squadrons.

“We were about to embark on an epic adventure where a forced landing in any one of the wild and exotic terrains we were planning to navigate over would be challenging at best”

provides good flying weather, with no thunderstorms, so on the Tuesday morning we gathered in the TAF offices to meet half our fellow ‘Slingers’ and brief for the first leg.

We had been allocated ZU-TAD, an identical Sling 4 to one that James Pitman and Mike Blyth had flown on one of their global circumnavigations. A standard factory build, with the 914UL engine but with additional long-range wing tanks and a couple of ¼in holes drilled in the floor beside each joystick. What on Earth could they be for?

Lucien and Colin had a bright orange Sling 4, and we were introduced to Natal-born Morne and Amanda, who had arrived in their own Sling 2. Also joining from the UK were Trevor and Lizzie, who were in the middle of building one of the first UK Sling TSi (the new 141hp Rotax 915 TSi powered Sling 4) aircraft in a TAF owned hangar at Tedderfield taking another TAF Sling 2. Tim Hardy and James Pitman teamed up in the factory demonstrator TSi to make us a group of five.

My initial impression was how relaxed everyone else was. We were about to embark on an epic adventure where a forced landing in any one of the wild and exotic terrains we were planning to navigate over would be challenging at best. Then it dawned on me that for pilots and adventurers who had themselves flown round the world several times, covering huge distances across oceans and the harshest of terrain, this trip was really just the equivalent of a weekend run to Le Touquet. But behind the ‘pommie joshing’, there was very careful attention to detail, and the professional guidance of those that have the deepest respect for the many ‘gotchas’ that aviation can throw up.

The 10-day flying safari was planned to route initially due

Below Refuelling Malawi style, from drums at Club Makakola.

north to Club Makokola on the southern edge of Lake Malawi. After two nights we would then head east into Mozambique to stay another couple of nights in Pemba, an old Portuguese trading town on the Indian Ocean. From there our route followed the sandy beaches and coastal savannah north, entering Tanzanian airspace as we crossed the estuary of the Rovuma River, before dipping down under the Dar Es Salaam TMA to transit the 45-odd miles to the spice island itself. It didn’t help that Lucien, who had grown up in Stonetown, mentioned he had never learned to swim. Apparently, there were ‘too many sharks around’…

James had wisely counselled against the original plan to overfly Zimbabwe, and utilise Harare International as an onward refuelling stop, due to the likely paperwork burden and the high cost of fuel. A decision that we understood all too clearly as the trip progressed… However, with a predicted flight time of nearly six hours this would put many of the standard build aircraft right on the limit of their range.

For us in TAD with more than 280 litres on board, even with an average cruise consumption of 24 Lph, we had the possibility of 11 hours’ endurance, or more. Well beyond the limits of my bladder, bottom and sanity, however! Ah, so that’s what the holes were for…

For the others, TAF had installed additional temporary fuel tanks that would prove their worth both on this leg and others to come.

Our first overnight stop was planned for Polokwane International, in the north-east region of South Africa,

where we would meet the rest of the group. This had the customs clearance necessary to allow us to depart even further north into the darker parts of Africa, but could not supply avgas. We would need to drop into Petersburg first, which was just a hop and skip across the N1 highway in order to top off our tanks.

Steeds mounted, it just required us to depart Tedderfield’s 10m wide and 1,000m long tarmac runway. Three of us, plus bags and full fuel, put us at MAUW, and with an OAT pushing 25° and 5,200ft above sea level, this would be a perfect first test. A loose formation departure was planned with James’ instructions to ‘keep up’ ringing in our ears. ZU-TAD accelerated quickly through 40kt and I engaged the ‘after-burner’ (115% turbo boost). We lifted off with little fuss at 55kt, and as the runway disappeared below I gently eased the nose up to maintain 75kt, climbing easily into the midday sky, while turning north to attain our initial transit altitude of 7,500ft at a very respectable 450fpm – and immediately we lost sight of everyone else. So much for the plan!

I felt confident of finding my way thanks to the purple line drawn on our Garmin G3X, but James had been clear: we stick together, which was wise counsel indeed. As we squeezed north between the Class C airspace of O R Tambo Airport (JNB) and Grand Central on the right, and Lanseria CTR on the left, the views of downtown Johannesburg sliding under the right wing were superb.

With some clever radio work on the chat frequency (123.45), and judicious jockeying of our throttles, James managed to re-group our colourful five ship formation as we passed the Hartbeespoort Dam. Gaining confidence in a slighter tighter formation, he settled us into a further climb to clear the Magaliesberg ridge just north of Pretoria. Taking the first leg in the P2 position, Chris felt right at home as he was used to piloting his RAF Grob Tutor from the right-hand seat with left hand for the throttle.

Johannesburg.

Above Excursion on Lake Malawi where fish eagles swoop down to feed on fish thrown from the boat.

With our northerly heading it was slightly disconcerting to realise that the sun was tracking right to left overhead, but soon we could begin to make out the Waterberg mountain range, blue and purple below the light haze layer.

As the sun finally dipped below the horizon, marking the end of day one, we were introduced to the other half of our gang – a group of five Sling 2s and their excited owners who were waiting patiently for us in the Polokwane terminal.

Beers in hand, after a bus ride to the hotel that took only marginally less time than our flight up, the group sat down to discuss the next leg.

The next morning an early bus ride got us back to the airport at sunrise. The cold, clear sky overhead belied

the rapidly disintegrating weather that had been forecast and a hurried consultation ensued. Balancing the risk of encountering poor weather en route against the disappointment of getting stuck in Polokwane for another night, the decision was taken to set off.

Eschewing a ‘big wing’ and knowing that some of the Sling 2s had the smaller 912 engine and would thus be a few knots slower, James grouped us into three formations. We departed within 15 minutes of each other and despite an initial layer of thin scattered stratus cloud we were soon able to climb between the layers to a comfortable FL95 with the somewhat rugged terrain always in sight.

It soon became apparent that having experienced South African pilots 20 minutes up ahead who were

able to relay weather information to the following groups was a real boon. Suvone and her husband Bernard, provided a continuous stream of positive news, alternating between their native Afrikaans and English.

Not having ADS-B in or out, each group radioed GPS distance and track information to the next waypoint, and we were thus able to monitor each other’s progress in virtual mode on our Garmin G3Xs, aided with the occasional call of ‘just passing the dirt road running to the lake’. Our little group of five brought up the rear and settled into a diamond four formation with James and Tim in the TSi buzzing around, ostensibly to keep the flock together and snap some spectacular photos of the scenery and aircraft, but mainly I think to demonstrate just how much faster the TSi was!

Nick managed to hand-fly in close formation with Sling 4 ZU-YAY in left echelon for long periods, and we only switched to the Garmin autopilot when he required sustenance. Having recently watched the series on the Red Arrows, we had already figured out the perspective angle of the Sling 4 left step and the gap required between the bottom of the wing to maintain station – it really works!

The long-range tanks in our Sling 4 were located outboard on each wing and held an additional 60 litres in each. TAF had installed an additional pump and a set of very neat crossover feed valves on the throttle pedestal, and Sean had advised that the pump was able to transfer up to 50 L per hour. This meant that it was important to only operate the transfer for half the time the tank on the same side had been used,

Left En route from Club Makakola to Pemba at FL95, the trusty Garmin G3X being our primary navigation aid.

otherwise unnecessary dumping of fuel would occur via the vent pipe. He also stressed the wing would fare better if it did not have all the weight out at the tips when landing, so I operated a simple system of running one main tank for an hour, then switching to the other tank, and at the same time starting off the feed to replenish the first tank from its outboard tank and starting the stopwatch. It was an odd but very welcome sight to see the fuel gauge going up, confirming that all was working. And even better to later find on landing that the outboard tanks required their full capacity when filling up.

Passing Blantyre to our right, the final approach into Club Makokola required a hurried last minute descent to clear a final ridge of hills, and with the dirt runway running parallel with the sparkling waters of the lake, our little formation slowed and separated downwind.

Nick executed a perfect touch down, despite a slightly blustery crosswind, and we taxied in to join the earlier arrivals. Much chatter and a general buzz of achievement bonded our merry band as we went through our first taste of the African immigration ritual.

Similar in principle to our European Shengen zone, our South African colleagues were able to pass through customs fairly quickly, while us Brits had to endure some additional form filling for visas. Once the requisite number of Malawian Kwacha had changed hands, we were able to gather in the beach front bar for a celebratory Kuche Kuche – never has a cold beer tasted so good. We were thus introduced to a way of life specific to this part of Africa with which we were to become well acquainted, beautifully translated in Swahili as pole pole (pronounced polay polay) – slowly slowly.

The accommodation throughout the trip was varied, alternating between hotel style rooms to thatched rondavels, depending on the location. All were first-class, and being the only group of three we were generally allocated ‘family’ accommodation. This often meant a nice sizeable arrangement of two bedrooms and a living room. Following a briefing session, each night we congregated for dinner grouped around two or three tables, giving everyone a chance to get to know each other and relive that day’s experience.

Lizzie had mentioned that she was a yoga teacher and I jokingly suggested that she should hold an early morning class to help straighten us out. She sportingly agreed, and as the sun rose at 7am, Suvone, James, Trevor and I were put through our paces on the beach front, watched in bemused silence by the Malawian fisherman heading out onto the lake in their mokoros. Within minutes I was discovering parts of my body that, while I knew they existed, had never been in such close proximity to each other.

Later in the day a well-stocked boat took us out to a nearby island on the lake. It is usually rare to hear the

piercing call of the majestic fish eagle, let alone catch a glimpse of one high in a tree overlooking a river. But this island was home to an entire convocation, and we were treated to the sight of them up close, soaring and diving down to catch small fish thrown from the boat.

After two nights, and fully fuelled for the next leg of only 4.5 hours, we departed out across the tip of the lake, the deep blue water shimmering in the early morning sun.

Climbing steadily to clear the hills that rose to 3,000ft on the eastern shore, we soon crossed back into Mozambique. The terrain below morphed into a strange mix of dense forests and great granite outcrops. These small mountains, called inselbergs, are scattered widely across central and northern Mozambique as if a mythical family of giants had tired of a game of boules. They are crowned by rainforests, which are home to species that have evolved in isolation for millennia and, fortunately, remain undisturbed.

Since we had become more adept at maintaining tight formations and precise navigation, thanks to our onboard avionic trickery, the poor controller at Pemba International must have rued the schedule that meant he had to handle our 10 aircraft arriving within minutes of each other, as well as the only scheduled airliner of the day. With all of us happily lined up on long final, he had no option but to waive off the Air Mozambique Embraer 190 until we were all safely down.

It appeared this was just a foretaste of the fun we would have to endure at Pemba Airport. Tackling visas, immigration and landing card forms took our little group of 20 pilots and crew over three hours. ‘Pole pole’ just did not do it justice. We all wondered aloud how they coped with an airliner full of foreign tourists and steeled ourselves for the return leg when we would have to go through the whole process again.

The town and port of Pemba were bustling and busy, with little sign of the troubles that had wracked Mozambique over the last 30 years. We were lucky to be staying in the oasis of calm that was the recently opened luxury Hotel Kirimizi on the beach front. So recent in fact, I had to install the handle for the cistern on my toilet, but this was a small price to pay for the otherwise luxuriant surroundings. James, Morne and Chris took the opportunity to rent motorbikes to explore the town, while we earned ourselves a delicious fish lunch, having walked some distance up the beach. ■

• Next month we spend time in Zanzibar before heading back to SA.

Mike Roberts and Joe Hadley take a look at electric propulsion and what it means within GA…

In recent years, there has been a steady increase in interest in electric power for aircraft, partly driven by the developments in the automotive sector. It’s a fast-developing area and while we have acquired a large knowledge base on operating internal combustion engine aircraft over the years, the knowledge base for electric power is inevitably very much smaller.

In an attempt to answer that, a new LAA Technical Leaflet has been produced. TL 3.28 can be found via our website at https://tinyurl.com/32wj2ra. The purpose of this document is to serve as a starting point for those LAA members considering converting aircraft to electric propulsion, and for anyone considering designing an electric-powered aircraft or propulsion system.

The document isn’t a ‘how to’ on building electric aircraft, but has been written to provoke thought about the various elements that make up electric propulsion systems – what a sensible setup may require and possible pitfalls that might be encountered. It is also a repository of references and information to help members ensure that their proposals are both safe and successful for future electric LAA aircraft.

LAA engineering staff began looking at electric aircraft projects back in 2016, and at one point we even considered building a proof of concept aircraft of our own, using an electric motorcycle power unit mated to a Rans S-6 airframe. However, we found that the weight versus

power, and cost, of the technology available at the time just did not add up. Since then, technologies have continued to develop, and several LAA members are now exploring exciting new projects.

LAA engineers Mike Roberts and Joe Hadley have been closely involved in these projects and are the authors of the Technical Leaflet and the content in this article. LAA Engineering is ideally placed to assist any member who wishes to pursue some form of electrically powered aircraft, so please do come forward with project ideas you have.

There are a growing number of electric aeroplane projects around the world. We’ve chosen six to demonstrate the range of activity:

The electric equipped Earthstar E-Gull is capable of flight times in excess of one hour with a powertrain removed from a commercially available Zero Motorcycles road bike. This system offers a 40kW motor powered by a battery of 11.4kWh capacity. Pilots who have flown the aircraft have said its performance exceeds that of the originally Rotax 447-equipped aircraft.

The Electraflyer-C is a development of a Moni motor glider. The aircraft is fully electric with amateur-developed electrical components. The 13.5kW motor can fly the Electraflyer-C for 90 minutes on a 5.6kWh battery pack, thus an average draw of just 3.73kW per hour. The power system is now offered as a package for homebuilt aircraft conversions using the same 13.5kW motor and its accessories.

The Elektra One is a purpose-built electric aircraft, which has been designed from the onset, with electric propulsion in mind. The all-composite airframe is powered by a 32kW motor though only requires 3kW to sustain flight. The aircraft’s battery has a capacity of 11.4kWh and is aided by the use of 280 solar cells embedded into the composite structure, providing a claimed four-hour endurance. The Elektra One was designed to be able to be charged with hangar roof mounted solar cells, with any residual power going into the grid for low cost operations. The company developing the aircraft is also developing a pilotless variant capable of an endurance of up to seven hours.

The Silent Electro sailplane is an electric self-launching motor glider. The aircraft is designed to be a competitive

left

Top right The Elektra Flyer-C is a development of the Konig-powered Moni motor glider

Above left The Silent Electro 2. Minimal power requirements, perhaps just to take-off and climb in to lift make electric power particularly viable for gliders.

Above right The Electric Cri-Cri has two electric motors, again on a wellproven ‘traditional’ ultralight design.

glider that can achieve a glide ratio of 40:1. The aircraft is unusual in that the power system is mounted in the nose and uses a radio-controlled (RC) glider style folding propeller rather than a retracting engine and propeller system. The batteries have a capacity of 4.3kWh and, due to the aircraft’s very low drag coefficient, it can fly for 50 minutes of sustained flight following a self-launch. The 22kW motor, controller, battery, battery management system (BMS) and instrument unit used for monitoring the electric propulsion system and throttle control, were all custom built for the Silent Electro. The battery consists of 16 off-the-shelf Kokam battery pouch cells assembled into a custom-built container with integrated BMS and cooling fans.

The famous Colomban design was adapted for electric propulsion and used to fly across the English Channel in mid-2015, just hours before the Airbus E-Fan completed its cross Channel flight. The modified Cri-Cri used two 35bhp electric motors, built by Electravia, in place of the original two-stroke engines. The electric Cri Cri used a lithium ion battery of an unknown capacity, although has been documented to give a 30-minute endurance.