Affordable fun – a single-seater can represent minimum purchase and operating costs.

Affordable fun – a single-seater can represent minimum purchase and operating costs.

The uncertainty of the times continues, which I know is a worry for many of our members, but I hope you are all well and able to enjoy life.

Flying-wise the ‘season’ is all but done and although at the moment we seem to be having something of an Indian summer in some regions, it won’t be long before owners may be advised to consider whether they might want to prepare their aircraft to avoid some of the problems of last winter. With the vagaries of mogas’ life over extended periods, it might be an idea to switch to avgas over the winter in case the weather or the coronavirus adversely impacts our ability to fly for months instead of weeks.

This issue sees something of a celebration of the single-seater, which can offer incredibly affordable flying and/or aerobatic or high performance. The flight test (P36) is of the Falconar F9, a Canadian variant of the Jodel D9, one of the first post-war homebuilt designs to become available. Clive Davidson discovers that it is great fun to fly, like many of the other single-seaters featured in Steve Slater’s article, and they also offer, in most cases, a low-cost entry into LAA flying, certainly well under £10K in some instances, with reduced operating costs to match.

Allied to the single-seaters is an interesting historic piece about Wilhelm Stark, a former WWII Luftwaffe pilot who went on to license build the Turbulent in Germany in the late 1950s (P48). His examples are cherished to this day and Wilhelm is alive and well and had his 100th birthday earlier this year.

We also feature one of our own pioneers,

Arthur W J G Ord Hume, one of the founding members of this Association and a pre-eminent historian of 20th century light aviation. His wonderfully atmospheric black and white photographs and charming story about the restoration of a Luton Minor is a pure joy (P16).

And coming bang up-to-date, Carl Parkinson has written a very informative piece about how he updated his Europa Tri-gear’s avionics and ancillaries to permit it to operate at night and in IMC. I hope it encourages others interested in extending the practicality of their aircraft to take a look at this aspect of operation (P52). It’s not for everybody of course, it is undeniably expensive, the complete antipathy of buying a VP1 or a Turbulent, but as I’ve said before, isn’t that the joy of the LAA?

We are a hugely diverse group who share a common passion. If only we could run society the same way – sharing a passion for equality among the diverse races and creeds – wouldn’t the world be a much better place? Not too much left rudder now, Brian!

Take care and be safe.

By Brian Hope

By Brian Hope

Ihope you are all safe and well and bearing up with the state of the nation… At least we are still able to fly and admire the stunning autumnal countryside.

If you have indeed been able to fly since the lockdown, I hope you will agree that the camaraderie among pilots and builders remains as strong as ever, enabling us to focus on some common interest away from the dreary daily commentary that seems to exude from every media pore.

I wonder if you have managed to stop yourself from discarding the all-important AGM proxy voting form on the reverse of the address sheet of this magazine? I’m afraid I stand guilty on at least three counts in the past, however, in my defence, m’lud, I’ve always managed to attend the meeting, so didn’t need it. But for this year, that defence won’t stand up because, as I mentioned last month, only Steve Slater and I will be attendees while the rest of the membership log in to Zoom. Please read all the instructions about proxy voting with care so we can have a successful, albeit brief, event.

Following the formal business of the AGM, we have a Members Forum where you will be able to ask questions of, and suggest ideas to, Board members. Please do not be slow in coming forward, this Association is run for to all of us and the more feedback you provide, the more likely that any improvements you seek can be made, or new initiatives you’d like to see can be adopted.

Hopefully this time next year we can bask in the glow of a maximum effort 75th Anniversary year and Rally, and I

am sure friends and colleagues will have much to catch up on.

I have at last been able to experience the new Farnborough airspace arrangements recently on a brilliant trip to the Isle of Wight.

I read all of the documentation about negotiating the airspace carefully, so that I would be well ahead of anything that might crop up. Managing to keep well below the London TMA, and talking to Farnborough as I flew, everything went well as there wasn’t much traffic, despite it being a glorious day.

As I approached the Farnborough CTR I was asked to descend, I thought there must be some Farnborough Airport traffic about, but there wasn’t and once past the runway centreline, I found that I could ask for a climb to my original cruising altitude – hmmmm, that’s strange. As I proceeded southbound, the controller had to make a number of calls to me confirming the service I was receiving, as my chosen route crossed a few CTA boundaries. The words ‘doing the hokey cokey’ did actually cross my mind!

The same thing happened on the way back, so I concluded that procedurally, all GA traffic is treated the same irrespective of whether Farnborough Airport is active or not. As it was a Sunday, the airport wasn’t very active at all and there were quite a few biz jets parked up, many more than I have seen on previous transits.

Going forward, my sincere expectation is that the CAA will enable far better airspace arrangements than this – there’s too much fragmentation, too much segregation, and not enough integration.

06 NEWS

HQ Covid closure, Channel Danger Areas

08 AGM

Due to COVID-19 the AGM of the LAA Ltd will be a ZOOM virtual meeting at 10am on Sunday18 October 2020

10 PROJECT NEWS

Stolp SA-500 Starlet, Sherwood Scout, Cleared to Fly and New Projects

16 POST-WAR RESTORERS

Arthur W J G Ord-Hume reveals the joys of the post-war aeroplane restorer…

21 AIR COURTAGE

The impact of COVID-19 on insurance

22 GPS JAMMING

Ian Fraser explains how to best protect against GPS signal jamming… but be prepared to revert to traditional navigational techniques

26 BOLT HEAD AIRFIELD

How determined flyers set about developing a former RAF landing ground into a new GA airfield…

28 FLYING ADVENTURE

Martin Ferid discusses the delights of Texel, in Holland, the most westerly of the Frisian Islands…

34 STRUTS4U

Anne Hughes profiles the activities of the Struts, making good use of social media

36 FLIGHT TEST

Clive Davidson has some fun with the quirky and smile-inducing Falconar…

43 SINGLE SEATER FUN

Single-seater enthusiast Steve Slater extols the virtues of… going it alone

48 STARK TURBULENT

Celebrating the achievements of German aircraft design pioneer Wilhelm Stark, who turned 100 earlier this year…

52 NIGHT/IFR

The process of modifying a Europa for Night/IFR flight

58 MEET THE MEMBERS

Meet John Wighton, stress engineer, aeromodeller and Europa owner…

65 CEO THOUGHTS

Steve Slater on reclosing HQ and the ongoing Brize/Oxford airspace debacle

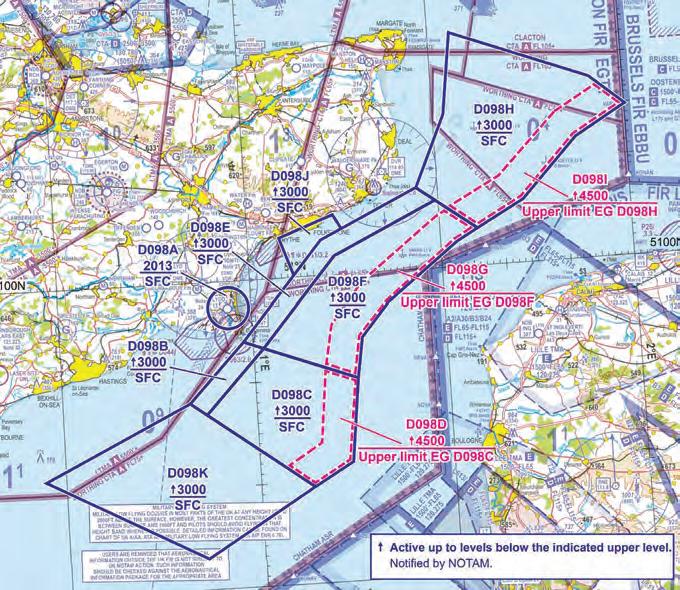

During the month of September, a substantial complex of 11 Temporary Danger Areas was extant in the English Channel to facilitate transiting and search operations by a number of Remotely Piloted Aircraft Systems operating, beyond visual line of sight, from Lydd. The activity was covered by Yellow AIC 074/2020. The complexity and extent of the complex, extending from the North Foreland to Eastbourne, and from sea level to 3,500ft throughout and up to 4,500ft along most of the Danger Area, means it had the potential to be a significant problem to recreational GA VFR pilots wishing to cross the Channel.

Although a number of VFR routes were specified, it isn’t clear whether those routes remained open, other than at certain levels, when the Danger Area was Notamed as active.

As we go to press it is unclear whether the Temporary Danger Areas are likely to be reactivated in the months ahead or, more worryingly, next summer. Covid has meant that the cross-Channel routes have been uncommonly quiet this year, and only time will tell if this develops into a major headache for touring pilots.

In line with the Prime Minister’s announcement on 22 September 2020 that ‘office workers should aim to work from home wherever possible’ the LAA is minimising the number of staff in attendance at HQ from 1 October, the remainder working from home. However, the switchboard will remain live and calls will be forwarded whenever possible.

LAA HQ will be closed to general visitors without a specific invitation from the CEO, CE or office manager. Documentation and other packages may be delivered and picked up by prior arrangement.

We will endeavour to maintain as high a level of normal service as possible and apologise for any inconvenience caused while these necessary actions to safeguard LAA staff and members remain in place.

The London TMA constitutes an enormous piece of airspace comprising 24 different areas extending approximately 100nm from West to East and, in some areas 90nm from North to South.

In 2019 there were 279 reported infringements of the LTMA, each one requiring an ATCO to achieve 3nm or 3,000ft separation from the unknown infringing aircraft, invariably requiring

‘safety intervention measures’ such as avoiding action to known traffic to achieve separation.

The CAA has identified four locations as specific infringement hotspots, some of which also result in infringements of CTAs adjacent to the LTMA.

A 5nm radius of the following areas is a general guide as to these identified hotspots.

Inspired by Picasso and her grandfather, Amy Whitewick wanted to show that aviation can be as creative as any artistic venture…

Ayoung Dorset pilot recently took to the skies of the South West to prove that aviation and navigation can be creative. Using SkyDemon, Amy Whitewick plotted a challenging route that depicted Picasso’s famous illustration Dove of Peace over the Dorset and Somerset countryside to ‘not only improve my terrible navigational skills, but to inspire other pilots that aviation is just as creative as any other artistic or sporting endeavour’.

“This year has been challenging for all of us,” said Amy. “My friends and I would often visit fly-ins and events at other airfields, including food festivals and meet-ups. This year Covid put a stop to that, and many of us are at a loose end on how to keep up our skills and focus our efforts on safety. I wanted a challenge that could be achieved within the local area, something that would sharpen my skills, and something that would give the flight a purpose and sense of achievement. This one has been the most challenging yet.

“Picasso had an enormous love of doves and pigeons – as did my grandfather who had a loft full of colourful, award-winning

birds. I chose the image not only to denote peace and friendship as intended by the artist, but as a reflection of my grandfather, whom I would have dearly loved to have taken flying. His pigeons never ceased to amaze me, navigating vast distances from France all the way home to their cosy loft.”

The 140nm-plus route consisted of a number of challenging curves. “The hardest part was checking for traffic while navigating. I’d normally take a fellow pilot as traffic spotter to lighten the load for a difficult

route such as this, but due to COVID-19 the passenger seat was empty, filled only by my stuffed mascot, Reggie, named after my grandfather. Mild turbulence, stubborn cloud patches, changing coastal winds, pockets of hang gliders and busy traffic routing to Dunkerswell made for an eventful flight,” commented Amy.

After completing the flight in her Cessna 150, G-JHAC, Amy said, “The task was mentally tiring. After two hours of flight, it was a relief to land back at Compton Abbas but the sense of achievement was brilliant. I hope it inspires others to go get creative with a mini-mission.” ■

Due to the COVID-19 restrictions the 2020 Annual General Meeting of the Light Aircraft Association Limited will take the form of a ZOOM virtual meeting commencing at 10am on Sunday 18 October 2020.

The link to the meeting will be https://bit.ly/31dE3nP (Zoom meeting ID: 854 0107 1535) with Passcode: 552713. Please commence log in from 0945 to avoid a delayed start.

The programme for the day will be:

■ Welcome

■ Apologies for Absence. Confirmation of establishment of quorum

■ CEO Overview

■ Minutes of the previous meeting for approval

■ Chairman’s Report

■ Treasurer’s Report and Adoption of 2019 Statutory Accounts

■ Re-election of Henson Rees Russell (formerly Phipps Henson McAllister) as Auditors of the Company

■ Re-Election of Will Garton-Jones as a director of the Company

■ Motion by Tim Hardy to amend Article 8 (Electronic Communication and Use of a Website)

■ Motion by Mike Hallam that the LAA pursues a joint BMAA, AOPA (etc) strategy to regain GA access to, or passages through, areas where we have lost airspace, or where an airfield’s traffic use no longer justifies retention of its enlarged ATZ

■ Close of AGM proceedings.

■ An opportunity for members to discuss issues and ideas with the Board.

The Minutes from the 2019 AGM, the Annual Report, the 2019 accounts, the Treasurer’s Report, the Chairman’s Report as well as the agenda and Motions contained herein, are available on the LAA website (www.laa.uk.com).

To vote at the AGM you must be a beneficial shareholder of the LAA. Unless you have specifically opted out, you will be a beneficial shareholder by default if you are a current member.

However, because the Articles of Association do not currently allow electronic voting, for this ‘virtual’ AGM the sole method of voting will be using the Proxy Voting Form which came printed on the reverse of the address sheet with this magazine. It must be completed and sent to LAA HQ in advance of the meeting.

One of this AGM’s Motions seeks to change the Articles so that in future electronic voting will be permitted.

1 .This year due to COVID-19 precluding a face-to-face AGM, we are requesting that all members respond using the proxy voting form, via the chairman of the meeting. To be valid, the proxy must be received at LAA HQ by Thursday 15 October 2020

2 .You may only appoint one proxy, this year the Chairman.

3 . Only those beneficial shareholders whose names appear on the register at 1400 on 16 October 2020 shall be entitled to vote at the meeting.

4 . In the case of joint holdings, the vote of the senior beneficial shareholder who tenders a vote shall be accepted to the exclusion of the vote of the other beneficial shareholder. For this purpose, seniority shall be determined by the order in which names stand in the register of beneficial shareholders.

5 . If this form is returned without any indication as to how the Chairman shall vote, he may exercise his discretion as to how he votes, or whether he abstains from voting.

6 . The proxy form must be signed and must show a membership number. ‘Signed’ must mean signed by hand and not signed electronically, bearing in mind that all proxy forms will be checked at the LAA office.

7 . We will accept an emailed legible scan of a properly signed and numbered proxy form. However, it has been noticed that scans emailed at low resolution can be almost illegible when they are received in the LAA office, so the wisest course may be to post the paper form.

David Mole, LAA Company Secretary

Mr Will Garton-Jones Membership No. 041479

Will is an experienced business executive in the UK and African tourism and global IT services markets covering all aspects of outsourcing, systems integration and consultancy. He is fascinated by the ability of technology to deliver innovative and far reaching change to society everywhere. His current areas of interest and knowledge are:

■ Transformation of the UK Rail industry through technology innovation

■ Cost effective marketing of distributed tourist infrastructure

■ Gyroplanes and their uses

■ Global payments and financial inclusion

He trained as a mechanical engineer and has had a longstanding interest in aircraft and flying, starting with aeromodelling before moving onto microlights and gyroplanes, In recent years his focus has been largely on gyroplanes. He also has 32 years of experience in the UK self-catering market, 25 years of experience in the IT services, outsourcing and business consulting markets, 22 years of experience in the African hotels market and 10 years as a Commissioned Officer (CO) in the British Army. He has an excellent understanding of business issues, technology and commercial disciplines and was trained as a consultant in accountancy by Price Waterhouse and KMPG.

Will has served as the Association Treasurer for the past three years.

Proposed by: David Mole, Membership No. 037969

Seconded by: Steven Slater, Membership No. 034052

1. That Article 8 be amended to read as follows: “ELECTRONIC COMMUNICATION AND USE OF A WEBSITE

8. (a) Subject to the provisions in the Companies Act 2006, the Company may hold a meeting, conduct a vote, supply a document or transmit information to its members by electronic means and by making it available on its website (b) A person in communication by electronic means with the chairman and with all other parties to a General or Board meeting shall be regarded for all purposes as personally attending such a meeting so long as at such meeting he / she has the ability to communicate interactively and simultaneously with all other parties attending the meeting including all persons attending by electronic means provided that a break or disruption in

communication with an attendee shall not invalidate the proceedings of the meeting .

(c) A meeting at which one or more members attend by electronic means is deemed to be held at the place at which the Chairman of the meeting is physically present.”

2. That the following passages be deleted:

i. In Article 18, the words “the meeting shall be adjourned for twenty minutes”

ii. In Article 25, paragraphs (c) and (d), And the paragraphs of Article 25 be renumbered accordingly.

The Covid crisis has made it clear that the proper conduct of company business requires the ability to make comprehensive and flexible use of electronic means and, in particular, to make it clear that those ‘present’ electronically are to be treated as if present physically for the purpose of the Articles. The amendment simply applies the provisions already adopted for Board meetings to all meetings and it removes a provision that would cause unnecessary delay.

The Board supports this proposal.

Proposed by: Tim Hardy, Chairman. Membership No. 029407

Seconded by: David Mole, Company Secretary and Vice Chairman. Membership No. 037969

I move that the LAA pursues a joint BMAA, AOPA (etc.) strategy to regain GA access to, or passages through, areas where we have lost airspace, or where an Airfield’s traffic use no longer justifies retention of its enlarged ATZ.

One year ago, on 10 September, I wrote to the LAA concerning the progressive strangulation of airspace access to our kind of flying, specifically our loss of any feasible north/south route past Farnborough, and a free route between Heathrow and Farnborough at the hitherto gap by Bagshot.

Steve Slater kindly replied indicating he would try to introduce the subject at meetings he’s privy to, and limited correspondence between us followed.

Since then we learn that Brize Norton/Oxford airspace is likely to join up to form another country wide virtually no-go ATZ.

Similarly reduced free airspace access for Norwich and Southend has closely restricted where we can fly.

Once granted, such a zone appears to become permanent and apparently our CAA has no mechanism to rescind or modify things – even if in practice the actual traffic doesn’t warrant it. They are also reluctant or even appear ignorant of our desire to pursue the Corridor method as precedent for partially rectifying matters by actively taking GA flying needs into account.

In these circumstances I urge the LAA to actively pursue a strategy – if necessary jointly with other flying organisations – to find a way to roll back some of the effects of loss of GA access which has been the result of an absolute failure to consider our needs when granting exclusive controlled airspace to vested interests.

Proposed by: Mike Hallam, Membership No. 002398

Seconded by: Stephen Slater, Membership No. 034052 ■

Iwas recently minding my own business, stumbling toward the onsite facilities of a small grass strip, when I noticed a very shiny red and white tail section poking out of a shed/hangar –and ‘Poly-Fiber wet look gloss’ went through my head. On the way back, curiosity got the better of me and upon looking in, I found Barrie Towers with his fantastic Stolp Starlet. Happy to share his part complete build with us, Barrie was in fact ahead of the game, and his project report reached my inbox before I arrived home. It’s an interesting look at the traditional form of amateur aircraft construction – i.e. plans-built aircraft. His build approach and reasonings are very interesting and I rather hope we’ll have an update in late spring 2021, when I’m sure the bird will have flo wn!

In September’s Project News , we heard how Mike Clark upgraded his incomplete Reality Escapade into a completed TLAC Sherwood Scout. Below, David Bremner explains the rationale for vandalising his Escapade and treading a similar upgrade path.

Maybe this metamorphosis will become a trend for the type, as both owners cite handling improvements as one of the major driving factors. David is a former Chairman of the BMAA, and indeed edited its magazine for a number of years, and built and has owned his Escapade, G-IMNY, for 16 years. I took the opportunity to ask David an owner’s opinion of the type’s cavernous cockpit area and he confirmed that it is indeed possib le to, and he has, slept in the load area – once. Additionally, at 6ft 3inches, he commented that he may be too short for the type as when the seat is adjusted fully aft, he cannot reach the rudder pedals! Joking apart, it was one of the type’s original design goals to have wide doors and a large seat adjustment range so as to allow easier access for a paraplegic pilot.

Do please get in touch with Project News , and tell your story, report a milestone or just to send a picture. Email: projectnews@ laa-archive.org.uk . Please share your story!

Ithought I would update members on my plans-built project, at one time the only way we could build our own aircraft. Now of course, all manner of kit aircraft are available and although I’m unsure of the exact ratio between plans and kit built, I am sure kits are in, by far, the great majority. Building any type of aircraft is not for the faint-hearted, and not wishing to take anything away from kitplane builders, plans building is very different and can be far more daunting and time consuming, particularly if it’s a complicated design. Re-joining the Association after a break of over 20 years has shown a major change in what is being built, and a move away from ‘simplicity’ to more complicated designs. Just looking at some of the aircraft avionics, their cost alone must be more than the material cost of a simple plans-built aircraft!

There is undeniably much pleasure when an owner’s new kit arrives, checking the inventory of parts and trying to work out how they all fit together. In total contrast, as a plans builder, the starting point for the Starlet project is 24 sheets of A3 scale drawings, a

couple of larger full size sheets for the wing ribs, seven A4 sheets of notes and a three-inch thick Aircraft Spruce catalogue!

The other thing to consider is whether there is factory support, as although Stolp Aircraft were in business for over 30 years, they ceased trading around 15 years ago, so you are on your own to some extent.

Fortunately, however, there is information to be found on the internet, and past builders are helpful when / if they can be located. Aircraft Spruce sells the plans but does not provide technical support. Also be aware that while the plans were considered good in the 1960s, by today’s standards they do have areas that leave it to the builder to sort out, so I’m not sure that they would be suitable for the first timer!

My past light aircraft projects were a Kitfox Mk2 that took 18 months to complete, and a plans-built Murphy Renegade, G-BVAT, that took 2½ years to complete but that was over 25 years ago. I’ve also built five three-axis

‘bolt together’ microlights over a 35-year period, one of which I’m still flying to this day, G-MJTZ, a Phantom built new in 2012 as parts, and complete aircraft are still available today. A great aircraft, aerobatic in the US, it has a 60mph cruise and three-hour endurance, you do see a lot more of the country with this sort of flying. Try searching YouTube for Phantom Ultralight.

The Stolp SA-500 Starlet is a parasol wing design from a company more famous for its sport biplanes and first flown 52 years ago in 1968. Around 40 Starlets have been built in the US, one in Australia and one in the UK. I’ve always wanted to build an American single-seat open cockpit, steel, wood and fabric covered aircraft, and my choice was further reduced as it needed to be powered by a Rotax 912, be single wing and most definitely, on the LAA approved list.

Plans-built aircraft can have very long build times but there are some types that can be built quite quickly, and I believe the Stolp Starlet is one such example – but you do

Left Progress to date and what the pilot will see. Photo: Barrie Towers

have to be very committed. The aircraft is quite small at 17ft long with a 25ft wingspan, and it can be constructed in a single garage or, in my case, a 20ft x 8ft shed at the bottom of my garden. The fuselage is only 12ft long without engine mount or rudder and is light enough to be manoeuvred single-handedly. I obtained a copy of Air Pictorial from August 1974 that included a flight test article on the UK’s only example, G-AZTV, and that was started in August 1971, completed in June 1973 and first flown on 4 July 1973. Under two years from start to flying for a plans-built aircraft I believe is quite impressive.

Having the inspector a few steps from my hangar has also proved a bonus. Peter Montgomery only has to walk 100 yards from his aircraft maintenance business to inspect progress and give advice when required. I have also been fortunate to gain access to the only Stolp Starlet in the UK and I’m indebted to its owner, Graham Rowland, for his help.

Fuselage construction is fairly straightforward using 12ft x 2ft wooden frames covered in plywood, then drawing

out the plan detail with wooden blocks screwed down to hold the tubes in position for welding. I made the top and bottom fuselage sections first, then I made a third wooded jig that held the two sections together so that the side tubes could be cut and welded into place.

Many other jigs are required for the tail section, struts, jury struts, and engine mounts to name but a few. But it could have been a lot simpler as many things are neither square nor straight! The top fuselage is wider than the bottom, so the sides taper out, and there is also a change in depth of the fuselage in the cockpit area.

Then we have the wings which, although attractive, are semi-elliptical in shape with a nine degree sweep back and most of the ribs being of different lengths, which does complicate things, I built them on a vertical jig as the trailing edge components need to seamlessly flow from one to another and this does add a considerable amount of build time.

I now have the fuselage and tail section complete and painted, with the undercarriage and engine bolted on. The wings are built but not fabric covered as yet, and I have obtained most parts ready for the assembly stage. It also may be of interest that I applied for a number of modifications, the important ones being:

1. Grove Landing Gear: The original landing gear was found to be weak and has been known to collapse, although this problem was mostly caused by installing a Lycoming O-235 which increased the weight considerably. Stolp issued a strengthening modification but quite a few owners changed to a different main gear type, including the aluminium Grove one-piece that I’m going to install. Advantages are many, including

Below Progress to date, engine on, good view of the Grove undercarriage, and the custom baggage compartment in the head rest. Photo:

simplified installation and proven design. However, there are a few disadvantages, the cost is one but the biggest for me is the additional weight over the original design – something all builders must normally avoid if possible but I’m hoping to make up for this during the engine installation and by reducing the fuel capacity.

2. Rotax 912UL engine installation: The Starlet was specifically designed for a VW 1500 engine, but unfortunately in the 1960s they only produced around 45hp and the first one built did not perform well. For the second example, they installed a Lycoming O-235 which, although powerful, was perhaps too heavy and gave a few weight and balance issues. Additionally, it increased the take-off and landing distances while raising the stall speed. For every 10% increase in weight the stall speed increases by 5% and the take-off/landing distance increases by 19%, so it’s important to keep weight down! The UK Starlet uses a C90-8F which, although lighter than an O-235, has no electrical system or starter. I’ve been able to obtain a few Lycoming O-235 Weight & Balance sheets and every one, without exception, shows that they operate on the forward CG limit due to the engine weight and, if a lightweight pilot was going to fly, they would be outside of the forward limit! Operating any aircraft like this will add to the stall speed when compared to a similar aircraft that is operating in the middle of the range.

It’s my belief installing a Rotax 912UL returns the aircraft to its design parameters and will benefit in many ways from this installation – lower weight, electrical system, electric starter and reduced fuel consumption to name a few, and with the benefit of a reduction in the stall / landing speed over the Lycoming powered examples.

3. Deleting the wing centre section fuel tank: The plans show two tanks, one in the fuselage forward of the instrument panel, and one in the wing centre section. Because of the lower fuel consumption of the 912UL, I decided to delete the centre section tank, not only to save weight but also to have a simpler set up with the hassle of refuelling when steps are not available. It’s no fun standing on the seat trying to empty a Jerry can into a top tank. I increased the depth of the fuselage tank to give 50 litres, which I’m hoping will give me a three hour plus duration, which I’m sure will be greater than mine!

Highs: Working with steel and building the fuselage was an enjoyable part, with the help of my welder Allen Hasseldine. You also need woodworking skills though, in order to make the steel assemblies wooden jigs are required.

I decided to use the Poly-Fiber covering system, as I had used it on both of my previous builds. I enjoyed the covering and everything up to applying the Poly Brush but left the painting to Aircraft Coverings Ltd (Chris and Alex) at Henstridge Airfield, Somerset, who did a great job for me.

Lows: I started making the wing ribs and most are different, requiring multiple jigs, and there are hundreds of parts to be made. If Stolp Aircraft still existed, I would have gladly paid a premium price to have had these made for me! Generally, the wings are not the easiest to build with a nine degree sweep back and a curving trailing edge, both of which took a lot of effort and time to sort out. The glass fibre turtle deck is another item that I would have gladly purchased, had I been able to, although in a day I had something made that looked the part, it took a further couple of weeks to shape, smooth and level it to an acceptable standard. While I was at Sun ‘n Fun last year I visited the Poly-Fiber stand every

day and tried my hand at rib stitching, something I had never had to do before and if my practice runs were anything to go on, this will take longer to do than to build the wings!

That’s it for now, you can see progress to date in the later pictures. So, will I complete the project in the two-year target that I set myself? I purchased the plans in November 2018, started to gather materials and received my LAA project number in early 2019. Thus far I’ve invested over 2,000 hours, so with a guidance of 1,400 hours, I should have completed it months ago!

In spite of quite a few holidays, a new bathroom installation and COVID-19, plus taking into account the fact that the building will slow a little in the colder months as I have moved the project to my unheated hangar, I believe that it should be finished by the end of this year. However, due to the wet conditions that normally prevail at my airfield, I don’t expect to be flying until spring 2021.

The first amateur-built Reality Escapade kit to be flown, G-IMNY, has operated as a microlight under the BMAA since 2005. In the autumn of 2019, there was increasing evidence of rust coming through the powder coating of the fuselage airframe, and I reluctantly took the decision to take a knife to the perfectly sound fuselage fabric.

It wasn’t just the rust that triggered this act of vandalism. The Escapade is now managed by The Light Aircraft Company (TLAC), which had renamed it the Sherwood Scout, and introduced modifications that improved its handling and allowed an increase in maximum all up weight to 499kg when classified as a light aircraft. So, I foresaw four benefits from the upcoming time, work and expense.

First, to preserve the airframe into the foreseeable future; second, to enable me to count my hours towards my PPL(A), instead of having to borrow other people’s aeroplanes; third, to get an increase of up to 50kg payload; and fourth to get an improvement in handling. Plus, while I was at it, I decided to give the 912UL the full zero hours treatment since it had been starting and running roughly for a good while. Only the wings survived untouched.

Stripping the airframe back to the original welded tubular structure took a long time, and all the peripheral bits had to be carefully labelled and stored. So, with the airframe on its bespoke trailer and the engine in the boot, I set off east, dropping the engine off with Kevin Dilks and stopping just before the North Sea to leave the airframe with TLAC at its delightfully named Little Snoring base.

Back home, I spent the winter rewiring the instrument panel and fitting a secondary flight instrument as back-up to the existing Enigma EFIS. A month or so later I picked up the engine, now looking brand new, and the airframe with its larger tail surfaces and one or two additional stiffening members. As soon as lockdown was eased enough to allow me to visit the hangar, I camped out there more or less permanently, taking the opportunity to tidy up the wiring in the rest of the

Right Corrosion that was showing through the fabric and started the whole rework process. Photo: David Bremner

Below The completely recovered fuselage and rebuilt tail, note the aft battery with easy access panel.

airframe and make one or two other improvements. I’d decided to recover the fuselage and tail surfaces with Oratex 600, which proved to be a major boon, as it involves no painting, and the wonderful glue at the heart of the process is water-based, so we were able to complete the tail surfaces in the living room with not a single complaint from my wife.

It was a huge relief to get to the test flight stage, of course, but a couple of things took the edge off the exercise a little. First, over the winter EASA had changed the rules so that I could count my microlight hours towards my PPL(A), which entirely wiped out one of the advantages. Second, I was anticipating an increase of empty weight of around five to eight kilos, and was therefore entirely flummoxed when, using identical, calibrated scales to the previous weighing five years ago, it came in no less than 27kg heavier, thus

halving the anticipated increase in payload. Neither I nor John Hamer, my very experienced inspector, can offer any rational explanation.

On the plus side, there is no doubt that the corrosion of the airframe was in urgent need of treatment, the new fabric on the fuselage has drawn admiring glances from everyone who’s seen it, the engine sounds and runs an order of magnitude better, and the handling is vastly improved. The larger elevator improves pitch authority and the larger rudder, with spring centring, has improved the directional stability so that you can now fly straight

and level with your feet off the pedals, and even make reasonably balanced turns with ailerons or rudder alone.

And the sealing strips fitted to the wing trailing edge in way of the flaps have entirely eliminated any changes in pitch trim with flap operation. A little part of me regrets the loss of the previous idiosyncrasies that took some getting used to, but there’s no doubt that it’s now a more mainstream product that would be ideal for training purposes – in particular for tailwheel training, and it should increase its resale value. I can’t wait to get the Permit to Fly and really start clocking up the hours again.

If your aircraft has been featured in the New Projects list, please let Project News know of your progress at: projectnews@laa-archive.org.uk

n Bristell NG5 Speed Wing (LAA 385-15716) 24/8/2020

Mr G Beale, 1 The Drive, Blackmore End, Wheathampstead, Hertfordshire, AL4 8LE

n Eurofox 914 (LAA 376-15715) 21/8/2020

If your aircraft has featured recently in the magazine and has subsequently completed its maiden flight, Project News would like to hear from you at: projectnews@laa-archive.org.uk

n G-CLBG Van’s RV-7 (LAA 323-15497) 3/8/2020

Ms Tracey Groves, 31 Russell Road, Lee-On-The-Solent, PO13 9HR

n G-UKRV Van’s RV-7A (LAA 323-15304) 3/7/2020

NETWASP.NET Ltd, 22 Boswell Gardens, Stevenage, SG1 4SB

n G-YOTS YAK-52 (s/n 9010308) 3/8/2020

Mr Jonathan Windover, Trustee Of: G-YOTS Group, 5 Childsbridge Lane, Kemsing, Sevenoaks, TN15 6TH

n G-BVZZ DHC-1 Chipmunk 22 (Lycoming) (s/n C1/0687) 7/8/2020

Bath, Wilts & North Dorset Gliding Club, The Park, Kingston Deverell, Wiltshire, BA12 7HF

n Van’s RV-8 (LAA 303-15714) 20/8/2020

Mr J Wood, 255 Kenton Lane, NewcastleOn-Tyne, NE3 3EA

n Van’s RV-14/14A (LAA 393-15713) 11/8/2020

Mr M Albery, 1 Bascote Chase, Bascote, Southam, CV47 2EZ

Name & Address held by LAA Engineering

n G-CLFK Eurofox 912(S) (LAA 376-15581) 27/8/2020

Name & Address held by LAA Engineering

n G-CLML Skystar Kitfox MK 7 (PFA 172D14391) 3/8/2020

Name & Address held by LAA Engineering

n G-EUFX Eurofox 912iS (LAA

Left A bit of a Tardis, modest dimensions on the outside, cavernous on the inside. Photo: David Bremner

n Bristell NG5 Speed Wing (LAA 385-15712) 3/8/2020

Mr A J Palmer, Palmers Farm, Boship Roundabout, Hailsham, Sussex, BN27 4AT

n Onex (LAA 401-15440) 27/8/2020

Mr M Wiseman, 32 Market Place, South Cave, Brough, East Yorkshire, HU15 2BP

376-15623) 21/8/2020

Name & Address held by LAA Engineering

n G-IMNY Escapade (s/n BMAA/HB/358) 12/8/2020

Name & Address held by LAA Engineering

n G-JJGI Stampe SV4A (s/n 199) 13/8/2020

Name & Address held by LAA Engineering

n G-RBFX Eurofox 912iS (LAA 376-15645) 3/8/2020

Name & Address held by LAA Engineering

IArthur W J G Ord-Hume reveals the joys of the post-war aeroplane restorer…

’ll bet many of you have heard all you want to hear from boring old people like me rambling on about the war – the austerity, poor food, the struggle with bad winters, clothing coupons, no petrol and Wellington boots that leaked. If so, read no further. Just consider yourself to have had a lucky escape! If not, the please continue…

When I look in my workshop today, I see a selection of tools that were quite unheard of in the amateur workshops of post-war Britain. Circular saw, table saw, power fret saw, belt sander, riveting tools, a choice of electric drills equipped with variable speeds and automatic chucks… Then there’s metal folders and shears, spray gun and straight edges, clamps and staple firers, portable gas cylinders for welding, brazing and normalising… Ah! Shame I’m simply too old to get down to creating my very own third-size Lancaster bomber…

At one time, virile young men used to have dreams about electric drills; while those with more fertile imaginations would wake up sobbing, having just had a vivid dream of possessing their own planer thicknesser.

So how did we manage? We just did. My tale begins here…

While wandering around the Croydon hangars one

Above A radiantly happy looking Paul Simpson stands by G-AEVT, the Aeronca 100, after assembly at Elstree. Notice the camouflaged hangar.

day, I found an old man in faded blue overalls standing on top of a pair of steps and assembling a Tiger Moth centre section – a little pile of streamlined steel struts and a handful of bracing wires. He was carefully consulting the bubble in a spirit level and making tiny adjustments to the wires with a small spanner. “The secret of rigging a Moth,” he cheerfully proffered, “is to get the centre section right and the rest is a doddle!” I had never thought about it before, but his words sank in. I made a mental note of finding out what a ‘doddle’ was and where one found one on a DH.82a.

“If it takes two days to get the centre section right, OK,” he said. “Rush this bit of the job and you’ll never ever get the wings right in a month of Tuesdays!”

His words sank in a bit deeper. And so, some while later, Paul Simpson and I had Aeronca G-AEFT, the purchase of which, you will recall from June’s article, we tried in vain to secrete from my parents, standing on the lawn in the back garden.

I recalled how, several years before, we had struggled to get the rigging right on the similarly titled G-AEVT. Just to refresh your memory of things before the age of sleek, low-wing cantilever monoplanes made of tin and Tupperware, the Aeronca had no struts, only wires – a great number of them.

The words of that Croydon ground engineer stirred around in the back of my mind. There must be a secret in this rigging business. And I would be the one to find it! Thinking it through, the task was very simple, and the complexities of the Tiger Moth centre section didn’t enter into it. All we had to do was connect the wings, support the tips at the right height, bolt the landing bracing wires to the centre section triangular pylon – and then connect up the lift wires. Dead easy. Finished by tea time…

The first problem emerged uncompromisingly quickly, however. The centre section pylon didn’t want to remain absolutely upright. Not even slightly vertical. Simple! Shove in some flying wires to keep the wings level, then bingo! The pylon would stand vertical – it didn’t, of course.

Spin forward some days when, with sore fingers and a modicum of spilled blood, we had succeeded in getting that wretched pylon upright. The port wing now displayed visibly more dihedral than the other, while the incidence varied between the wings by quite a lot. Two hours later we had the dihedral right, but the pylon lent over to one side. The incidence was also still well out. By the next morning we had the

incidence spot on, but the dihedral was wrong. The pylon was straight, though.

A stern rebuke from a passing vicar who overheard some words, the meaning of which he maintained he didn’t know, yet clearly knew sufficiently well enough to sense they were not nice, spurred us into action. It was a bright Wednesday morning some while later when, with the evenings getting longer as spring turned to summer, we succeeded in getting all three variables unvariable . The dihedral was right, the incidence was right and so was the pylon, which stood straight, upright and proud. We had done it!

There was only one problem. The aeroplane was now fully rigged in a relatively small back garden from which not even a fully qualified headcase would attempt flight. It needed to be taken apart to be transported to a place from where it might reasonably be encouraged to get air beneath its tyres – as well as in ’em.

Unwilling to risk facing a repeat of that rigging palaver, I gave some serious thought to this bracing wire business and came up with a perfect solution…

This sort of thing, I assured Paul, comes with having a well-honed brain like mine… We would unscrew each wire one full turn and relock the locking nut before pulling the pin out. It was simple, it was

Above Nearing completion, the new airframe of the Luton Minor in the front garden of my parents’ house in Hatch End.

Left The original pre-war airframe of my Luton Minor LA.4 assembled in the back garden. It was incomplete and rather broken, and, in the end, it was all scrapped. Registered G-AFIR on 7 July, 1938, it was the third LA.4 to be constructed from the article in Practical Mechanics magazine.

elegant, it was clever – and I had thought it all out by myself. Ah, the genius of youth…

The wings came off quite quickly once we had got the procedure with the locking nuts down to a precise art. Each bracing wire now carried a label indicating its precise position in the bracing loom that prevents the Aeronca’s wing from falling off. Very soon afterwards we had the whole aeroplane tied onto Paul’s car in the approved manner, as shown in my previous story. Off to Denham, where we were assigned the blister hangar. Only a few hours until becoming airborne, eh…?

The first problem was the blister hangar itself. It had a floor made of loose cinders, poorly crushed concrete and sundry, uneven lumps of very hard and unidentifiable stuff. In short, the floor was rough. It was so uneven that we quickly discovered even a tripod rocked unsteadily on two legs. We found the best bit of floor and prepared the aircraft for rigging. It took a long while to be able to get our specially made wing support stands to perform their standing and supporting roles. It took even longer to balance the wings on them, so hat they were vaguely level.

The real shock came with the bracing wires. They were now all different lengths and none of them fitted anywhere near as easily as they had done back on the lawn at home. Then I remembered the infamous Harefield Triangle, which we had driven through en route to Denham. It was said that ‘mysterious forces’ altered the length of bracing wires when you drove in this notorious part of Buckinghamshire…

Spin forward two weeks. Largely because it was 14 days of sheer purgatory trying to rig the aeroplane so it was more or less straight. Then came the final bits and pieces which mostly involved drilling 1/16in diameter split-pin holes in bolts – by hand. Remember what I said about electric drills? Well, a handoperated brace is not much good when you are kneeling on a rough, sharp pointy floor late at night trying by torchlight to drill a hole at an awkward angle. Holes became measured in terms of how many broken drill bits each took.

Hangars seldom had lighting in those days. Our old hangar at Elstree had two light fittings suspended

Top The completed LA.4 Luton Minor with its brand new JAP engine stands at Elstree. The wholly new airframe and different engine type upset the authorities.

Above The LA.4’s engine was a 30hp Moteur Mengin, originally fitted to the Avion SCAL Bassou, which had crashed before the war. It was a very neat, lightweight twin but the magnetos were missing. In the end, this was the reason I was forced, reluctantly, to scrap the Mengin for one of the PFA’s stock of brand new J.99s.

high in the roof, each with an opaque, green enamelled tin shade and a 25 watt bulb. You could tell when the lights were on because, once your eyes got used to the level of illumination, you could see other people as shadows when they passed you. But not recognise them, of course.

G-AEFT did take to the air soon afterwards and gave us both some hours of enjoyment until a combination of shortage of cash, my sick parents, and the cost of running the Luton Minor combined to make the hangarage charges something of a final straw. It was a sad day when we delivered the Aeronca to new owner Brian Collins at Southend.

Tools were rudimentary in those days and the availability of quality equipment was a rarity. Then Wolf Electric Tools introduced the Cub power drill at a cost of £4.12/6d – for the very young readers who don’t remember ‘real’ money, that’s about £4.65p. I remember going all the way to Liverpool to buy one, with its ¼in chuck and low amperage motor that wouldn’t quite put a 3/16in drill through a steel plate without perseverance and a lot of oil. The drill was also unsuppressed, which meant that each time you switched it on, surrounding houses could not watch their black and white TV for the ‘snowflake’ interference and the sonic stuttering caused by your appliance.

The measure of my personal aircraft restoration came with Comper Swift G-ABPE. This historic aircraft had survived the war and been beautifully restored.

New owner Adrian Golay was ready for his first flight from St Albans on 26 April, 1947. Youth and

bravura led him to attempt a steep climbing turn on his very first flight… The attempt was not a success and while the hedge recovered, the Swift didn’t. It ended up in a set of tea chests – in my shed…

Much as I cherished this aircraft, I never attempted a rebuild because I did not have a router, or even a suitable high-speed cutter. You see, every piece of spare wood on the Swift is routed away to save weight and an amateur router was unheard of. Of course, 70 years on, I’ve now got one!

Some time after this, I had an unusual episode with the Luton Minor. I had been based for a while at Panshanger, that beautiful large and unspoiled all-grass aerodrome between Welwyn Garden City and Hertford. Home of the North London Aero Club and numerous private owners, it suddenly closed, and not for the first time would this happen. It had happened several years before when the De Havilland School of Flying had moved out. During the war it had been a decoy aerodrome for Hatfield. However, this time was a bit different, most private owners, afraid of leaving their beloved aeroplanes on an unattended airfield, took their property away. The flying club had been the first to go and now the fuel pumps were locked, and the gates secured. Panshanger, for the foreseeable future, was shut…

There was a problem, and that was my small aeroplane sitting in a blister hangar (this one, thankfully, with a concrete floor) on the far side of the airfield. The snag was that there were only about four pints of fuel in the tank – not enough to take me to Denham where I could refuel, or even safely to Elstree where petrol was tuppence a gallon more expensive.

Now, I could run the JAP engine comfortably on motor spirit, and there was a garage and filling station just opposite the end of the aerodrome road on the Hatfield to Hertford main road. The downside was that it was a long walk carrying a couple of jerrycans.

On the other hand, immediately opposite the garage on the other side of that main road, was a largish field. There were trees, but there was plenty of room. I walked down and inspected the field. It felt OK

Above There was only one problem in owning and flying a small aeroplane. Whatever one parked near, the chances were that the other thing was larger than you!

underfoot. Then I had a capital idea. Why didn’t I simply fly the three-quarter mile or so from airfield to filling station and fill up?

I fired up the engine and took off from a totally deserted field and immediately lined up on final for that roadside field. It seemed to me to be a good deal smaller from up here… And there appeared to be rather a lot more trees than I had spotted from the ground. Never mind, I reckoned. It was do or die as I might not have enough fuel for a return flight.

Well, it all worked out OK. I landed between the trees, taxied up to the barbed wire fence, shouted across the road to the pump attendant who promptly crossed the road to see what I wanted. In minutes a couple of cans of petrol were being tipped into my tank through my chamois leather. Some cash changed hands, a warm thank you conveyed to the chap, and I was away.

Take-off was longer and more hairy, and the trees seemed to have moved closer in the 20 minutes since I landed, but they let me through and I flew straight to Denham, which was my turning point for the flight home to Sandown. In those days you could fly over Heathrow as long as you were above 4,000ft, or else you could fly around it, turning south at Langley.

Back on the Isle of Wight, I tucked G-AFIR into its hangar and set off to walk the half-mile over the fields, to what was my then home. Ah! Now I could relax and do other things. All was well for about four days until I received a letter. It was from the publicity department of a well-known motor spirit provider. “Dear Mr Worm-Hoard” it began. “We understand from our so-and-so service station manager that you landed your aeroplane at our premises recently to fill up with our best grade motor spirit.

“We would like to invite you to repeat the performance so that we can have a photographer present and interview you. Naturally, we will provide your petrol and pay all your expenses plus £20 for your time. We look forward… &c, &c.”

There’s an old adage about getting away with something once but avoiding any temptation to repeat it.

I had, and I didn’t… ■

The current health crisis is having numerous social and economic consequences worldwide, almost all sectors are struggling, although naturally some are more impacted than others. Industries such as tourism, culture, textile, automotive and aerospace of course, are being badly affected. The whole insurance industry is also going through a tough time!

Leaving aside the impact of low interest rates, the main impact on business insurance may be the significant reduction of premium earned due to the decrease of activity, jeopardising the necessary critical mass. As far as aerospace is concerned, many commercial aircraft have been grounded for months, as a result of an unprecedented decline in activity for the air transport industry – airline premiums are correlated to activity, therefore the premium earned for the insurers reduces more or less proportionally to the number of passengers carried.

Aircraft manufacturers too are reducing production and their workforces due to a sales slowdown, and we can easily foresee that it will take time for the industry to recover.

Additional to the downturn of premium volume, there is also a predictable peak of claims in some fields, such as business interruption, credit, directors and officers liability and so on.

Some private insurances on the other hand, especially motor, are experiencing stability or even positive growth due to the very small number of claims incurred during the lockdown. It is not the case of health insurance though, with a massively disproportionate impact depending on the structure of the healthcare system from one country to another. Nor is it the case for private aviation unfortunately, as the vast majority of annual claims occur each year during the first flights of the season after several months out of practice and

when withdrawal symptoms and adrenaline are reaching their highest levels! July was indeed quite loss-active this year, while such frequency is usually observed in May or early June in a ‘normal’ year.

Large risks in particular, which include aircraft, ships, ‘acts of God’, legal liabilities and financial losses among others, as fully defined by the Solvency II EC Directive (2009/138/EC), have given insurers bad results lately, leading to major changes in the underwriting strategy of most risk holders. Those of you who own an aircraft have suffered the consequences of this hardening market as all the premiums have gone up, and insurers are also less inclined to be flexible on coverage.

Large risk players have used all possible tools to improve loss ratios: reduction of capacity allocated to major risks, more rigorous underwriting, withdrawal from some lines of business… The poor technical results of the main major risk insurers in 2019 confirmed the poor health of these lines of business… and then came the COVID-19 crisis, aggravating its fragility and bringing a significant loss of income due to the reduced activity.

Despite the general premium increases, many insurance companies have announced loss ratios (incurred claims divided by earned premiums) between 115% and 125% for the first half of 2020, the COVID-19 effect having affected the technical result by approximately 20%, meaning that without the pandemic situation, the loss ratios would still have been close to 100%. A 100% loss ratio means that premium and claims amounts are balanced, but it doesn’t mean that they are breaking even. To be viable, a portfolio must have a maximum loss ratio of 70%, because additionally to the claims, insurers have to cover a set of other costs

such as human resources or an excess of loss reinsurance.

From a different perspective, the pandemic is boosting the adoption of new technologies in this otherwise traditional industry. The sight of insurance claim handlers walking across the City of London carrying enormous paper files to visit the insurers had already disappeared, along with the paper files, with computers starting to replace that personal touch. One could feel nostalgic for those times where interpersonal relationships played a major role, but a commercial approach and long-term partnerships have now had to make room for short term profit and greater efficiency. So, insurance had already turned to digitalisation before the COVID-19 crisis, but not to the same extent or at the same pace as other industries. Current circumstances have inevitably accelerated the zero paper working practices, extensive computer interface and artificial intelligence.

Most industries are currently facing difficult challenges, and they will all have to adopt changes in the way they operate, whether it is better preparation for the remote working of their employees or enhanced risk prevention, and many other specific adaptations of their processes.

So, as far as insurance is concerned, if we want to look on the bright side, I would say that 2020 is definitely the year of a market metamorphosis through digitalisation! ■

Ian Fraser explains how to best protect against GPS signal jamming… but be prepared to revert to traditional navigational techniques

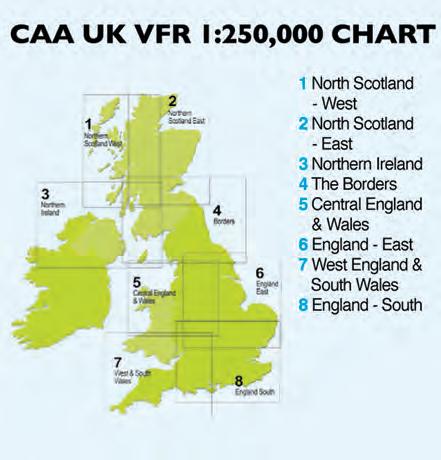

Radio jamming, in particular of the GPS civilian services, is very much in the news at the moment as new legislation is proposed that will provide the authorities more power to use it. Whether related or not, the military are currently conducting major trials of GPS jamming equipment, potentially impacting vast tracts of the country. Recent jamming activity lasted for 12 days in August centered around Hadrian’s Wall, with a potential service denial range (for GA) of up to 30nm. There was a second exercise for five days in September near the Brecon Beacons (https://tinyurl.com/y3nngrtn) with a potential service denial range of 60nm, and there are warnings for the Stranraer (Dumfries and Galloway) area for the rest of 2020.

How will this affect you? If you are in range of GPS jamming exercises, they will either stop your GPS dependent devices working entirely or cause them to report erroneous positions.

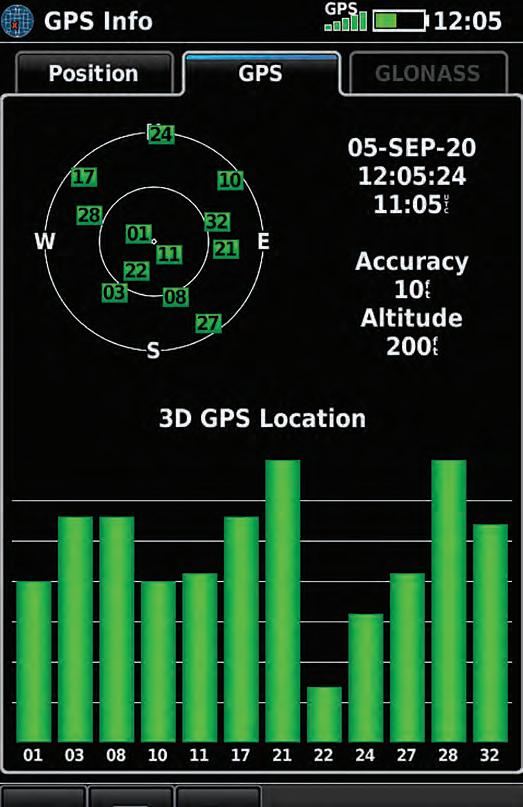

Many devices we have in our aircraft today rely on GPS. These include Electronic maps, EFIS (electronic) instruments, fuel range meters, smart phones, traffic warning devices (ADSB, FLARM and Pilot Aware) and Autopilots (picture 1). Who hasn’t got one or more of these, and if the GPS signal is jammed or corrupted, they will not work!

A GPS device is a very sensitive radio receiver detecting very low energy (weak) radio signals from satellites. These messages contain information defining exactly where the GPS satellite is and the precise time that its position message was transmitted, allowing your device to calculate the range. It requires concurrent information from at least three satellites to triangulate that information and calculate your position. A good signal-to-noise ratio (more signal than background noise) is fundamental to their operation and jamming is normally achieved by transmitting strong interfering signals on the same frequency, swamping the weak real satellite signals and thus preventing the GPS from receiving any data to calculate a position of any kind. A more sophisticated version is ‘spoofing’ where false satellite data is transmitted to the GPS, resulting in it calculating and reporting the wrong position.

Jamming is normally undertaken by military or government agencies testing equipment that they will probably use to deny the effective use of GPS guided weapons or drones. With the increased use of rogue devices (e.g. drones at Gatwick last year), such testing of countermeasures or rehearsal of their use will become more commonplace. However, our kind of aviation is becoming increasingly dependent on GPS to find our way around and to avoid conflict and restricted airspace. This is actively encouraged by the CAA.

For safety’s sake we need to understand the effect of jamming on our equipment, be informed when it is being done and have a contingency plan to deal with it. That is also dependent on the agency involved being aware of our need to know when and where they will be operating.

There is some evidence that this warning process does not yet fully work. Laudable though they are, the prime source of warnings should not be in obscure NATS or Ofcom papers. They must be Notamed well in advance, and of course, we must read the Notams.

But the military and other official bodies are not the only people jamming GPS. There is increasing use of jammers to corrupt truck tachographs for example, or prevent vehicle trackers reporting positions and other sinister activities. All highly illegal in the UK, but it is happening all the same, with some quite sophisticated devices readily available on the internet from £30. Although most of these are comparatively low power and unlikely to affect aviation, there are some available whose power is well beyond that needed to hide a truck from a tracker. The rogues using these are unlikely to Notam their use or tell Ofcom, however well the system works!

What, if any, precautions can we take to minimise the

risk of rogue jamming and limit the disruptive range of the military jammers? The military has its own encrypted GPS frequencies so are resilient to its own jamming but, at the moment, I am unaware of any sophisticated anti-jamming solutions in aviation GPS themselves. Indeed, if it was that simple the military wouldn’t be bothering with jamming anyway. We will probably have to wait for the self-driving car industry to sort out a palliative, and maybe another generation of GPS, but that does not mean we can’t reduce the risk with what we have today.

There is something you can do to minimise the range of disruption now – a good directional GPS antenna will reduce sensitivity to jamming, potentially reducing a worrying 30-60nm to a more tolerable and avoidable 10-20nm. Consider the geometry of what is happening when jamming occurs. Satellites transmitting the signals we want are always above us (generally greater than 30° above the horizon). Conversely, the majority of jamming comes from the ground, and normally below the horizon. GPS antennas can be very directional, and if correctly specified and fitted, reduce the range of unwanted jamming while retaining GPS performance. This is likely to become increasingly key to safe operation of our aircraft

The GPS antenna is fundamentally the same device in all receivers, a ceramic chip (picture 2) is a Garmin portable remote antenna without its lid. Generally, the larger the chip, the more sensitive to the satellites and the more directional. A portable device or phone is by its nature, deliberately not very directional. To work for everyone, they need to be small and equally sensitive to signals from below as above so you can hold them or mount them as you like. Unfortunately, this means they are just as likely to pick up the jammer as the satellite.

However, a GPS patch antenna has a much larger chip which can be a 10th less sensitive at 30° from the horizontal as it is toward the vertical (sky), and from below may only be 1,000th as sensitive (-20dB). Indeed, that is why the military (on the ground) have to resort to high power jammers to be effective toward an airborne target. Without directional antenna we are unlikely to receive a

GPS signal. So, to properly exploit the strengths of a GPS patch antenna it must be installed facing the sky as this optimises the reception of the satellite above and minimises the reception of the interference or jamming from below.

A good way to demonstrate this is to look at a GPS satellite monitoring page (or a satellite monitoring app as illustrated) on your navigation device. Pick an overhead satellite (04 in picture 3) and monitor its reported signal strength for all orientations. Pictures 4 and 5 (an internal antenna on a smartphone) show its extremes of strength as the device is rotated. For the internal antenna the signal strength is low and reduction is not much,

For a patch antenna you will see a much greater difference between up and down. Pictures 6 and 7 show the signal strength for a patch antenna. Picture 6 is the right away up and picture 7 upside-down, showing a significant reduction of sensitivity to signal from beneath. Patch antennas are available for most handheld navigators and all built in GPS devices.

For smartphones or tablets you can bypass the internal antenna with a Bluetooth GPS dongle mounted separately from your device. In a metal high-wing aircraft, the wings make very effective reflectors for jamming signals and good shields for the satellites. Its cockpit or coaming is not a good place for a GPS antenna of any kind. If you can, mount a remote patch antenna above the wings, that would be much more effective at reducing jamming and improve the GPS reception too.

Active antennas (picture 8) with an inbuilt signal amplifier are mandated for many certified GPS devices and jamming is an area where that may well actually be counterproductive. The reason for this certified mandate is to allow for the reliable receipt of the even weaker geostationary satellite signal necessary for SBAS (WAAS) operation, but of course, it may amplify the unwanted noise too. Do not install an amplified antenna unless you really need to, a modern small passive patch antenna will be more than adequate for normal GPS reception.

Finally, GPS jammers, like so many high frequency radio waves, are line of sight. The higher you fly the more likely you are to be ‘in view’ and thus within range of the jammer. If you lose GPS and it worries you, descend if you safely can.

But if all this fails and your GPS is jammed what are your options and indeed, what still works? Your eyes, paper map, watch and magnetic or gyro compasses are still fine. From a navigation instrument point of view VOR and ADF are all still good too, and mode C and S transponders still make you visible to ATC, TCAS and ACAS (but not FLARM or PAW). With the easing of procedures for use of jammers for the various enforcement agencies, and increased use of those in the hands of rogues, be prepared for it and to be able to navigate the old way.

Meanwhile, make sure you have the best type of and position for your GPS antenna… and a contingency plan which does not depend on it. ■

These days Bolt Head Airfield is a thriving coastal airstrip in South Devon, but it has a rich in history dating back to 1940, when The Air Ministry was looking for a location for an advanced landing ground. It chose this uniquely large area of flat land high on a hill close to Salcombe.

The diggers were sent in to clear the hedges and they built two runways one east / west and the other north-east / south-west, upon which they laid coconut matting and Sommerfeld tracking – a steel mesh strong enough to support heavy aircraft use.

The first aircraft to arrive at RAF Bolt Head were Lysanders of 16 Squadron during 1941, followed by 316 Polish Squadron flying Spitfires. Radar was also established on the site during 1941, close to the main runway, and this became RAF Hope Cove.

Above The airfield today, the car park lower centre is where the wartime tarmac intersection of the two runways was, the 11/29 original running parallel to the current strip, but just to the right of the road. Photo: Mike Mold

During the war, more than 40 different types flew from RAF Bolt Head including, Spitfires, Westland Whirlwinds, Typhoons, Mosquitoes, Hurricanes, Austers, Piper Cubs, Tiger Moths, Beaufighters, even Lancasters and B17 Superfortresses. However, most of the flying activity had ended by early in 1945 and the airfield ceased to be operational in 1946.

The tracking was removed and slowly farming recommenced until, in 1949, the Home Office returned and took back more land to build a new radar station, which became operational by 1954 and closed in 1958. The site remained in use by the government until 1994, when the bunker was sold.

The Squire family own much of the land in the area and in the early 1980s a family friend, Chris Millward, persuaded Malcolm Squire to fence off a 400 metre section so he could land his aircraft. Chris established regular flying from

the land, and when he passed away another local pilot, John Cummings, took over the running of the landing ground. He was joined by John Kempton and together they established a lawful certificate to use the ground for flying aircraft. A 200m extension was added, making 600m in total, but within a few years that extension was ploughed up as the land belonged to Malcolm Squire’s uncle. However, Malcolm Squire did eventually buy his uncle’s field, so the 200m section of the runway could be reinstated, which also brought the site under a single landlord.

During all this time there had been no hangarage facility, meaning aircraft using the field were parked in the open.

The dynamic impetus for the airfield you see today started 10 years ago when Simon Evans, a very keen and active pilot, retired and moved to Salcombe. Simon was a powerhouse of energy and with a small group, consisting of John Kempton, John Cummings, Keith Wingate and myself embarked on an ambitious plan to gain planning permission for a permanent hangar.

Bolt Head Airfield is surrounded by an Area of Outstanding Natural Beauty (ANOB) and is bordered by National Trust Land, so gaining planning consent to build a hangar was never going to be easy.

Simon and the group persevered for five years, spending £10,000 and eventually planning consent was given for a 34m x 15m hangar.

Malcolm Squire engaged Richard Triggs Construction to build the hangar in 2014 and, six months later, after one of the worst winters in many a year, the hangar was completed, and we moved in in spring 2015. Over that winter we had also prepared a new taxiway and closed the old one and gradually the new grass took hold and the ground returned to its lawn-like condition.

Simon never rested and embarked on many improvements. He persuaded Malcolm to give us the land to widen the runway by 10m – making it 24m in total – and, during this time, runway numbers were added. Sadly, Simon passed away last year following a battle with cancer. His passing has been a massive loss, we miss his acidic humour and his incredible energy and drive. He was a dear friend who has left an amazing legacy – and an airfield of which we are very proud.

Below TA wartime shot of RAF Bolt Head. Visible are two B17s parked alongside the runway. They were two of three that landed on the way home from a bombing mission to Germany, low on fuel, with engine problems and wounded crew.

Over the 2019/20 winter we have undertaken further improvements, one of which was replacing the chalk numbers with concrete. We manage to keep all works in-house, thanks to John Kempton our chief engineer, and to new chairman Keith Wingate for his building skills.

Bolt Head Airfield has a very comprehensive website (www.boltheadairfield.co.uk), with a full brief including two YouTube videos illustrating the joining procedures for both runways. Sky Demon also displays our airfield details and our no-fly zone.

Albeit that it was delayed of course, we have enjoyed an amazing 2020 season and our thanks go out to all our visitors.

We welcome visitors until the end of October and, if you see the hangar doors open, by all means come down to say hello and have a look around. ■

After this mixed-up, insane, crazy period, I must admit that it’s a bit of a task selling the concept of getting ‘out and about’.

Staycation has become a buzzword, but trying to remain optimistic we either need to look to the future or accept Private Frazer’s view, as epitomised in Dad’s Army in that ‘we’re doomed’!

While reading a fairly recent back issue of FLYER I came across one of Ian Seager’s articles where he questioned the complexity and lack of sense regarding some of our rules and regulations. It is eminently arguable as to whether pilots should be considered culpable when some rules are so complex and appear sequestered with the clarity of an insurance company’s small print.

The other, not insignificant issue, is that in our egalitarian society, apart from those among us who have clearly been shown to be ‘more equal than others’, should the rest of us mere mortals be subjected to the ‘letter’ or the ‘moral’ of the law? Some rules are pretty clear cut, ‘keep left’, nice and simple, no ambiguity and everyone knows where they stand in helping to create a safe environment. But with others…? Try an hour or two of light

Above Texel Airfield gets very busy during the annual Fly-in when all manner of additional attractions are provided.

reading with CAP 804 (Flight Crew Licensing) or negotiate certain bits of airspace when things get busy.

A recently appointed police commissioner saw his new role as implementing all laws literally and called for prosecutions for anyone caught, for example, doing 31mph in a 30mph zone. Using his judgement after years in the force, he decided that society was best served by such flagrant disregard for the law by strict enforcement.

It’s not just in aviation or the labyrinths that make up our inner-city roads; there are bad and outdated rules in every walk of life. Did you know that you can be penalised for being drunk in a pub? Well-intentioned – very likely – illconceived, most definitely, but it theoretically makes criminals out of huge swathes of society, including the lawmakers themselves. According to Section 12 of the Licensing Act 1872, which is still on the statute books, ‘every person found drunk in any highway or other public place, whether a building or not, or on any licensed premises’ is breaking the law. So anyone who has ever had one too many anywhere other than a private dwelling has unwittingly broken the law. For a bit of levity, you can look at more crazy laws that still apply, at www.thefactsite.com

In case you think the UK is the greatest proponent of ‘ridicalia’ (the word doesn’t exist, but maybe it should), you’d be wrong. Yes, we’re pretty good at it, but not quite as good as the Dutch. Their authorities appear to suffer from a degree of achromatopsia without being burdened by any shades of grey. For such a forward-thinking and liberal country, it is astounding to think that they have a dedicated aviation police force, and by ‘dedicated’ I mean in both senses of the word. They operate much like traffic cops, but possibly with the added desire to justify their existence.

That being said, the people and airfields are pretty chilled, and you can’t get much more laid back than a visit to the Dutch Wadden Islands. (If you are ever planning to go, don’t be put off, drop me a line for the usual ‘gotcha’s’).

The Wadden Isles are actually part of the Frisian Isles, stretching from the North of Holland across to Germany and up the Danish coastline. The five Dutch ones are Texel, Vlieland, Terschelling, Ameland and Schiermonnikoog, two of which – Texel and Ameland –conveniently have airports. And the most popular of these for British pilots is Texel, this month’s adventure destination.

Above The Fly-in attracts many interesting visitors, such as this Norwegian registered DHC Beaver floatplane.

Left ‘Down at the Fly-in’ takes on a whole new meaning when they set up the big screen in the air park

The two main routes for getting there are, the direct route, which takes you straight across the North Sea, or tracking the French/Belgian coastline before passing Rotterdam and Amsterdam. I take the long way around and leave the direct route for those who can ‘talk the talk’ in the bar or clubhouse as I am far happier having terra firma underneath me whenever possible. If the airspace en route appears a little daunting, try breaking it down into smaller segments and identify the areas that require more attention around Rotterdam, Amsterdam and De Kooy CTR’s. It’s best not to get a brain overload without having a ‘get me out of here’ plan and even though GPS is great, a little time spent on the ‘what if’s?’ beforehand should help avoid added stress later on. Throughout the country, if you’re not talking to a specific unit, a FIS can be had with Dutch Mil on 132.35.