ANYONE CAN DO COLD CHAIN PACKAGING.

But there’s only one who can do climate-friendly, zero-waste, modular and payload-optimized pharmaceutical packaging that will save up to 1,000 kilograms of CO2* per 333-liter packaging box – and can do that in all temperature zones: eutecma!

Get ready for retecma!

It’s the one and only AI-supported reverse logistics system that fights to keep all resources in the lifecycle as long as possible.

4 FOREWORD GREEN VISION

6 Building a Healthier and More Environmentally Sustainable Future

Environment, Health, Safety and Sustainability (EHS&S) refers to the practices to protect the health and safety of employees and the public as well as the environment. Strong EHS&S management requires the implementation of systems and processes to assess and control the risks of environmental impacts and health and safety hazards. Besides assuring compliance with applicable legislation, EHS&S management systems drive continuous improvement and learning. EFPIA member companies strive to invent, produce, and distribute new medicines and vaccines in a safe and environmentally responsible manner. Furthermore, we are actively providing a safe and healthy workplace while reducing the environmental impact in our operations and those of our supply partners around the world. A risk management approach is employed to create transformational health innovations, while protecting our employees and employing practical aspects of environmental sustainability.

8 Pharmaceuticals in the Environment: A Threat to the Health of Ecosystems, Animals, and Humans

Pharmaceutical pollution can be found on all continents. Pharmaceuticals can enter the environment throughout their life cycle and cause serious damage to ecosystems and contribute to antimicrobial resistance (AMR). There are many actors across the pharmaceutical value chain, who with the support of improved regulation, must all take action to effectively reduce this environmental and health threat. Jean-Yves Stenuick, Safer Pharma Programme Manager at Health Care Without Harm (HCWH) Europe discusses the work, with the healthcare sector to minimise pharmaceutical pollution and its contribution to AMR through policy advocacy and upstream initiatives.

11 International Responses to the Emerging Threat of Antimicrobial Resistance

The problem of antimicrobial resistance is not confined to a few countries but rather is a challenge that affects the entire world. The extent and pattern in which antimicrobials are utilised can, however, have a significant impact on the degree of urgency or severity of the condition. The problem has gradually but steadily extended to every single country in the globe, posing a threat to the safety of human, animal, and plant health as well as the security of food production. The consistent rise in the consumption of antibiotics in both the human and animal sectors raises serious concerns about a future in which not a single antibiotic will be available for the treatment of even the most prevalent bacterial diseases. Hina Malik, Wasimuddin and Randhir Singh outline the international responses to the emerging threat of antimicrobial resistance.

14 The Green Discussion

In 2020, we decided that the theme for our year would be regenerating the veterinary world. I had been running The Webinar Vet for a decade and begun the online revolution for vets, which had taken millions of miles off the roads over the last decade. However, we wanted to do more to show leadership in the veterinary industry. As a digital educational business, it is arguably simpler to be sustainable than a large pharma company. However, we calculated our carbon footprint; offset double what we produced during the pandemic year; started a veterinary sustainability podcast and planted a wildflower meadow at the Liverpool Science Park along with encouraging our landlord to embrace renewable energy providers.

18 New Paper-based Security Seals Revolutionise Pharma Packaging

Since the 60s, the use of plastic has increased twentyfold. The EU is therefore focusing on a sustainable economy and is pulling the emergency brake on plastic packaging in particular. The Single-use Plastics Directive is only one measure to achieve this goal. The first step was the ban on plastic bags - products such as cotton swabs and drinking straws are also already adopting alternative packaging materials. In the future, there will be penalties for packaging that is not designed to be recyclable within the European Union. According to Securikett CEO, Werner Horn, "A switch to our new paper-based VOID seals and VOID tapes will therefore pay off for all businesses by eliminating the risk of non-compliance with material requirements of new regulations. The pulp material used by Securikett can be recycled together with folding cartons and complies with the new EU general circular economy package."

20 Meeting the World’s Evolving needs for a More Sustainable Future: How to Realise a Circular Approach to Drug-delivery-solutions

The world is looking for companies across all industries to take leadership positions that not only advance their traditional business metrics, but more importantly improve their impact on the environment and people’s lives around the world. When it comes to sustainability, there is not a single easy solution to solve all issues. Instead, taking a holistic view across various aspects of our business has led Aptar along the path to meeting its sustainability goals. Companies are increasingly adopting the principles of the circular economy where waste and pollution are eliminated or reduced as they are designed out of products throughout their lifecycle.

26 Inside Sustainability at Airnov: A Look at How Healthcare Packaging Solutions Expert Airnov Continues to Pioneer Sustainable Products and Develop Sustainable Working Practices Across its Business

Sustainability is a core priority for almost all packaging producers, including those which support the healthcare sector. As the world transitions towards a more circular way of operating, both in a personal and business sense, the ability to make sustainable enhancements down to the very last detail matters more and more. At Airnov, a pioneer of innovative solutions for the healthcare and medical packaging sectors, sustainability and circularity underpin all of its business activities. Here, we will explore some of the company’s latest products and initiatives that are helping to enhance its environmental credentials and those of its customers.

30 The Pharmaceutical Supply Chain in the Age of Sustainability

The drive for sustainability has impacted every business in recent years and continues to place new demands on all aspects of the pharmaceuticals supply chain. The team at Recipe Design, a London based consultancy who have worked in the industry for over 12 years, see positive developments coming both from legislative pressures and the shifts in values of the customers and end users its clients aim to serve.

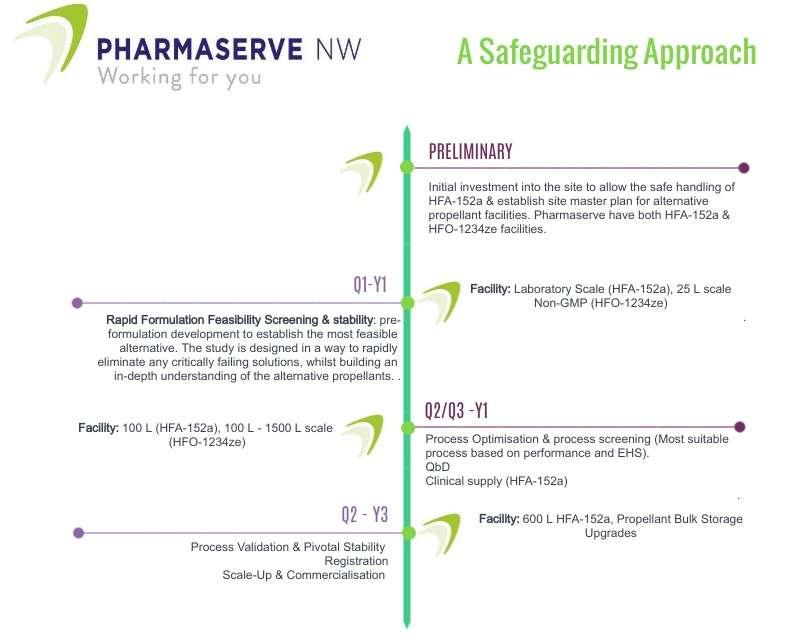

32 A Greener Future for the Inhalation Industry: A Critical Year for our Climate

This article explores the legislative and economic drivers of why the industry needs to adapt, and crucially why now is the time to act. It is also important to ground ourselves and remember why we develop medicines; to better the health of the public and save lives. Adam Kay at Pharmaserve North West discusses the challenge to produce sustainable products cannot compromise the safety, efficacy and patient adherence to inhaled medicines.

COLLABORATION

36 Understanding the Role of Energy-Efficiency in Achieving Pharmaceutical Sustainability Targets

The pharmaceutical industry is growing. A 2020 report valued the worldwide life science manufacturing market at $405bn USD, with an expected compound annual growth rate of 11.34% over the following 8 years. As the quantity and diversity of pharmaceutical product continues to rise, so too does the burden this place on our environment. While the pressure to operate sustainably is beginning to be applied by a variety of interested parties, just 42% of the pharmaceutical industry has established a clear carbon reduction. Keith Beattie and Jamie Young of EECO2, explains that to deliver a more sustainable future, the life science industry needs to align the ambition for a cleaner, healthier future with objectives and targets that will deliver this aspiration.

42 A Journey of Generations

Today more than ever, businesses are uniquely qualified to address the impacts of climate change and social inequality. PCI has formally established the Global ESG Program as the foundation for our sustainable business practices. We believe in creating the changes we want to see in the world. PCI’s ESG commitment has gained recognition from global sustainability agencies, having been awarded Bronze Medal status by leading environmental, social, and ethical performance evaluation platform EcoVadis, and Gold Medal status at its Philadelphia Headquarters and Biotech Centre of Excellence.

46 How to Save 1,000 kilos of CO2 per 333-litre Refrigerated Packaging – Thanks to the First-ever Circular Economy Pharmaceutical Packaging

The year of 2019 was a turning-point. It was the year when fears of palpable global climate change gripped society, including the worlds of business and industry. In 2020 the COVID-19 pandemic led to a second dramatic realisation. To increase the resilience of global supply chains there is a radical need for greater sustainability. Sven Rölle of Eutecma GmbH describes the enormous potential which climate-friendly, no-waste packaging can offer the temperaturecontrolled transportation of pharmaceuticals.

SHOWCASE

50 Medicines that Don’t Cost the Earth: New Awards Showcase Innovations

“We know that climate change is bad for our health. What is less well known is that healthcare is bad for the environment,” said Nazneen Rahman while chairing a panel discussion showcasing innovations in sustainable packaging. The session was held on 14 September in Geneva at Connect in Pharma, a new annual event connecting innovators in pharma and biopharma to the world’s leading suppliers and manufacturers. Rahman, a physician, scientist, and AstraZeneca Non-Executive Director, said she had this epiphany two years ago and was compelled to devote the next phase of her working life to making healthcare more sustainable.

YOUR SECURE SUPPLIER FOR TAMPER EVIDENT SEALING WITH SUSTAINABLE PRODUCTS

The PAPER-based security seal with VOID technology is now available!

• Works on almost all cardboard surfaces

• Underlying text and printed codes remain legible

• Compliant with FMD safety requirement

• Serialisation of each individual product

• 'One package - one material' - this way you improve the recycling process and make a positive contribution to the recycling management

• Paper seals are produced from renewable raw materials

Our seals are easy to understand multi functional security locks against tam pering and counterfeiting. They are used and tested on pharmaceutical packaging worldwide.

The entire world has heightened its focus on environmental sustainability. Driven to address the global threat of climate change and safeguard our planet, organisations across a variety of sectors are seeking new ways to operate more sustainably and reduce environmental impact. The pharmaceutical industry is no exception. For drug developers and manufacturers, embracing greener practices and processes has become a key strategic priority.

The pharmaceutical industry often involves significant processing for a relatively small amount of active ingredients. Industry-wide, efforts are focused on reducing the waste generated by processing and making sure waste product is used rather than disposed of. As biotechnology and pharmaceutical organisations turn to outsourced service providers, they are increasingly focused on identifying partners that take environmental sustainability seriously.

The development and production of drugs and devices inherently consume large quantities of natural, human, and economic resources. As such, it represents a risk to the environment and the sustainability of the pharmaceutical industry.

However, with these challenges comes opportunity –many key players in the pharmaceutical industry, have committed to environmental stewardship across their production lifecycle, from discovery right through to disposal.

By minimising the environmental impact of operations, the pharmaceutical industry is becoming a driver of positive change towards a sustainable future.

We are always looking for new ways to enhance environmental sustainability and better manage waste throughout the lifecycle of products. Key issues from on-site improvements like energy-efficient lighting and bulk nitrogen systems, to more significant investments like combined heat and power plants that drive progress toward energy self-sufficiency. The industry needs to commit to addressing a full range of pharmaceutical waste, treating waste waters at our on-site biological treatment plant, handling hybrid waste through anaerobic digestion, and finding ways to recover and reuse solvent waste.

Transparency is key to success on the journey towards a sustainable future, not only to ensure the industry sticks to its sustainability targets but also to help in gaining and maintaining stakeholder confidence.

Overall, the pharmaceutical industry has made great steps towards this by identifying realistic sustainability targets however, we need more pharmaceutical companies to be accountable and join the sustainability movement now.

It is extremely important that large, profitable organisations ‘give back’ to local communities and contribute to the economic, social, environmental, and cultural sustainability of the societies in which we live and work. Sustainability is not just about the environment or improving patient access to medicines, it is also about empowerment, using resources to support local causes and activating communities to take charge of their health and wellbeing.

We have some clarity over the desired end point of zero carbon within the next 30 years (or sooner for some pharma companies), but our industry is uncertain how we will achieve this objective. As pharma engineers, we will all play a role in delivering this endpoint through the continuous improvement of existing facilities and by designing, equipping, and building new facilities that will be operating in 2050. The zero-carbon scenario requires us to make radical changes while simultaneously improving supply chain quality and resilience.

As we undertake this “decarbonization” process of designing for a future with a “100% green grid,” the lack of clear timetables for the various breakpoints challenges all pharmaceutical engineers. Even when we achieve a green grid, there will be no “magic bullet” for zero carbon because pharma companies will remain significant users of heat and other energy-intensive products. Process intensification, continuous processing, and modular containment technologies promise to deliver future facilities that will consume less energy but remain complex. Vendors supplying equipment for these facilities need clear guidance (user requirement specifications) on the specific needs of the facility to achieve optimized equipment designs – and providing this specification requires a strategic vision for the site.

The pharmaceutical industry is making strides towards greater environmental sustainability, and the right partner can empower you to minimise your environmental footprint today.

Together, we can reduce our impact and make a meaningful change.

In this journal entitled “Pharma Nature Positive”, we have drawn on the term “Nature Net Positive” – Give more back to nature than what we take away from it.

The goal of this journal is to create a dedicated platform where all stakeholders of the pharmaceutical and healthcare industry can discuss, and share technologies and innovations which will enable the industry to attain the challenge of reaching zero carbon, and any engineer with the bandwidth to develop the breadth of technical know-how needed to clarify, evaluate, and implement energy-efficient strategies will be in a good position to add value in the years ahead.

Mark A. Barker Managing Director, Senglobal Ltd

Environment, Health, Safety and Sustainability Building a Healthier and More Environmentally Sustainable Future

Environment, Health, Safety and Sustainability (EHS&S) refers to the practices to protect the health and safety of employees and the public as well as the environment. Strong EHS&S management requires the implementation of systems and processes to assess and control the risks of environmental impacts and health and safety hazards. Besides assuring compliance with applicable legislation, EHS&S management systems drive continuous improvement and learning.

Equally important, the rapidly growing rate of resource consumption throughout the world is unsustainable. The pharmaceutical industry recognises that reversing the use of natural resources, the degradation of ecosystems and the disruption of the environmental systems that support human life, are critical for the benefit of current and future generations. Therefore, we believe that an increased focus on environmental sustainability is key for the future health of our planet.

EFPIA member companies strive to invent, produce, and distribute new medicines and vaccines in a safe and environmentally responsible manner. Furthermore, we are actively providing a safe and healthy workplace while reducing the environmental impact in our operations and those of our supply partners around the world. A risk management approach is employed to create transformational health innovations, while protecting our employees and employing practical aspects of environmental sustainability.

Building a Healthier and More Environmentally Sustainable Future

The pharmaceutical industry is committed to building a healthier and more environmentally sustainable future. We do this by driving an agile, innovative, evidence-based sustainability strategy to enable the pharmaceutical industry to embrace evolutions in science, technology & society and to integrate sustainability across our entire value chain to deliver quality-based, healthy, and green outcomes while positively impacting on the lives of patients.

EFPIA welcomes and embraces the Commission’s focus on the Green Agenda and a more sustainable Europe and looks forward to engaging constructively on the roll-out of their policy priorities.

Our members are dedicated to making a positive impact on the lives of patients whilst operating in a sustainable manner. As we have a responsibility toward the health of the population, we are moving forward in making a beneficial impact by actively addressing climate change and the transition to a circular economy with changes throughout the value chain, as we continue to innovate.

What are we doing?

Environmental sustainability is a key value driver to accelerate delivery, improve efficiency and sustain transformational health innovation. Our industry encourages appropriate use of a risk-based approach to environmental challenges and undertakes initiatives to promote greater environmental responsibility.

The European pharmaceutical industry is committed to continue playing an active role in addressing concerns around risks associated with Pharmaceuticals in the Environment (PiE). Minimising the impact of medicines on the environment while safeguarding access to effective treatments for patients is a critical issue across all sectors of healthcare.

At EFPIA, we believe that a collaborative approach allows us to increase our mutual knowledge and understanding on how to proactively address any potential risks imposed by the presence of PiE. To this end, EFPIA, AESGP and Medicines for Europe have developed the Eco-Pharmaco-Stewardship (EPS) framework that applies the widely accepted principles of product stewardship and is implemented across the industry and with broader stakeholders in the healthcare and environmental sector.

The pharmaceutical sector is one of the most regulated in Europe and the world. Accordingly, the pre-approval of manufacturing plants, clinical trials and marketing authorisations should be given consideration when implementing and interpreting some elements of EU Chemicals legislation. The long development timelines and highly regulated nature of this industry are fundamental aspects of the ability to react to changes in legislation (e.g. restriction of chemicals). Chemical processes comprise a significant portion of a medicine’s environmental footprint, and responsible use of chemicals is a key environmental stewardship priority for the sector.

Our member companies lead projects and initiatives to minimise the impact of their manufacturing process, including reducing the generation of hazardous waste, and using greener solvents. Due to the global operation of our companies and increasing number of countries with

emerging chemical legislation, it is crucial that collaborations take place between industry and regulators globally. EFPIA supports the need to develop a sustainable chemicals strategy and to promote research & development for the transformation of the chemical industry and the creation of green and sustainable manufacturing.

Direct or indirect human activities have altered the composition of the global atmosphere and increased carbon dioxide emissions, driving up temperatures. This has led to what we often observe as more extreme weather conditions and is referred to as climate change.

The pharmaceutical industry contributes to a healthy environment while demonstrating leadership in mitigating climate change. Our activities support the ambition the European Commission expressed through their European Climate policies. EFPIA member companies are committed to:

• Establishing climate change policies and strategies based on materiality and impact for individual companies and addressing their entire value chains.

• Pursuing science based CO2e reduction targets.

• Contributing to reduced energy consumption and increased energy efficiency and seeking opportunities to use energy from renewable sources throughout the value chain.

• Annually and publicly disclosing CO2 performance calculated according to recognized methodologies such as e.g., the World Resources Institute Greenhouse Gas Protocol.

The Pharmaceutical Industry is supportive of a circular approach to its operations and products and is aligned with the European Commission's Circular Economy Action Plan.

We will achieve the goals of the Circular Economy Action Plan concurrent with our aspiration to safeguard the future supply of pharmaceuticals for patients and improve human health.

The pharmaceutical industry’s approach to circularity builds on our long experience in environmental sustainability, while recognising the constraints (e.g., speed of transition), from operating in a highly regulated industry. Circularity and regulation of pharmaceuticals should be carefully balanced. The innovation to enable circularity will drive new opportunities for growth, promote greater resource efficiency, create a more competitive economy and reduce pollutants.

Implementation of a circular economy is fundamental to help limit the global temperature increase to less than or equal to 1.5C, and we welcome the opportunity to be part of the solution by working collaboratively with the EU in shaping the legislative framework and within our organizations to mitigate our impacts.

EFPIA

The European Federation of Pharmaceutical Industries and Associations (EFPIA) represents the biopharmaceutical industry operating in Europe. Through its direct membership of 37 national associations, 38 leading pharmaceutical companies and a growing number of small and mediumsized enterprises (SMEs), EFPIA’s mission is to create a collaborative environment that enables our members to innovate, discover, develop and deliver new therapies and vaccines for people across Europe, as well as contribute to the European economy.

Pharmaceuticals in the Environment: A Threat to the Health of Ecosystems, Animals, and Humans

Pharmaceutical pollution can be found on all continents. Pharmaceuticals can enter the environment throughout their life cycle and cause serious damage to ecosystems and contribute to antimicrobial resistance (AMR). There are many actors across the pharmaceutical value chain, who with the support of improved regulation, must all take action to effectively reduce this environmental and health threat.

Pharmaceuticals have a Global Presence

More than 700 pharmaceutical agents or their metabolites have been detected in the environment1 across the world. These pharmaceutical residues are found in both soil and water systems, including surface and groundwater used for drinking water. In the environment, drugs can have harmful effects on animal and plant life threatening whole ecosystems. There are also questions about how humans can be affected by continuous, long-term exposure to low concentrations in drinking water.

In 2015, the potential adverse effects associated with exposure to environmentally persistent pharmaceutical pollutants2 (EPPPs) on human health and the environment were recognised within the Strategic Approach to International Chemicals Management (SAICM) global policy framework.

In 2020, UN Environment’s Assessment Report on Issues of Concern recommended to expand the scope of EPPPs to include pharmaceuticals in the environment.

Therapeutic classes of particular concern in the environment are anti-inflammatory drugs and sedatives consumed in large quantities, cytostatics that are cytotoxic by design, synthetic hormones that can act as endocrine disruptors, and antibiotics. Negative effects include renal failure in vulture populations, detrimental impact on the genetic material of aquatic organisms, reproductive failure in fish, and inhibition of the growth of certain aquatic species.

The Threat of Antimicrobial Resistance

The biggest concern of pharmaceuticals in the environment, however, is the contribution to the development and spread of antimicrobial resistance (AMR), a serious health and development threat that makes infections increasingly difficult or impossible to treat. It is estimated that AMR causes the direct deaths of 1.27 million people3 worldwide every year. Without effective action, AMR’s death toll could spiral up to 10 million people annually by 2050.4

Increasing AMR linked to the discharge of drugs and particular chemicals into the environment has been described by UN Environment as one of the most worrying health threats today.5 The main pollutant sources that exacerbate AMR6 include poor sanitation, sewage and waste effluent; effluent

and waste from pharmaceutical production, healthcare facilities, and animal production; as well as antimicrobial use and manure in crop production.

In 2022, the One Health Leaders Group on AMR, which brings together world leaders and experts to accelerate political action on AMR, called for a reduction in antimicrobial discharges from food systems,7 manufacturing facilities, and human health systems into the environment. Their recommendations include strengthening governance and oversight, improving surveillance and data availability, improving discharge management, and promoting research and development.

Main Pathways into the Environment

Pharmaceuticals can reach the environment throughout their life cycle, during manufacturing, excretion, and disposal. Wastewater treatment plants, which are primarily designed to eliminate biodegradable substances, have varying capacity to eliminate pharmaceutical substances in wastewater and even a low removal efficiency for most drugs. In addition, they do not capture diffuse sources of pharmaceutical solution such as surface run-off from agriculture.

Excretion after consumption is considered the most common entry pathway for pharmaceuticals into the environment with 30%–90% of orally administered drugs8 being excreted as active substance in the urine and faeces of animals and humans. Waste from unused medicine is another important problem, representing 10% of wastewater pollution9 with patients flushing medication down the toilets or sink.

Manufacturing pollution, however, has received growing attention in recent years with extremely high pharmaceutical concentrations found in water streams close to pharmaceutical plants, which is of serious concern for local ecosystems and the development of resistance. In Hyderabad, India, the concentration of the antibiotic Ciprofloxacin in the effluent from a wastewater treatment plant serving bulk drug manufacturing plants exceeded levels toxic to some bacteria by over 1000-fold.10

It is particularly concerning for antibiotics as the pharmaceutical industry has offshored the vast majority of its

production to countries with cheap labour and weak oversight and regulation. China currently produces 80%–90% of antibiotic active pharmaceutical ingredients (APIs)11 while India leads the production of ‘finished dose’ antibiotic products. Huge manufacturing pollution scandals have been reported in these countries.

Highest Concentrations of Active Pharmaceutical Ingredients

A large research project led by the University of York,12 United Kingdom, recently monitored over 1,000 sampling sites in 100+ countries for pharmaceutical pollution. It observed highest cumulative API concentrations in Sub-Saharan Africa, South Asia, and South America, particularly in areas associated with poor wastewater and waste management infrastructure and pharmaceutical manufacturing.

The most frequently detected APIs (found in more than half the sites monitored), were Carbamazepine, used to treat epilepsy and nerve pain, Metformin used to treat type-2 diabetes, and Caffeine used to treat tiredness and improve the effect of some pain relievers (in addition to lifestyle use). Overall, concentrations of at least one API were above levels considered safe for aquatic organisms or of concern in terms of selection for AMR at a quarter of all monitored sites.

The five most detected antibiotics in the study were Trimethoprim, Sulfamethoxazole, Ciprofloxacin, Metronidazole, and Clarithromycin. At one sampling site, close to a pharmaceutical manufacturing plant in Barisal, Bangladesh, the concentration of Metronidazole was more than 300 times higher than the safe target. However, even low concentrations are of concern as they can drive resistance and increase the likelihood that resistance genes transfer to human pathogens.

The EU Regulatory Framework

The European Union is the second market in the world13 in terms of pharmaceutical sales (25% for human consumption and 31% for veterinary consumption), behind the United States. However, there are no specific rules in the EU regulating the emissions from pharmaceutical production into the environment; active pharmaceutical ingredients (APIs) are not covered by the REACH regulation, which addresses the production and use of chemical substances.

Environmental Risk Assessments (ERAs), which aim to valuate and limit potential adverse effects of medicines on the environment, were introduced in 2005 for veterinary pharmaceuticals and in 2006 for human pharmaceuticals. However, ERA guidelines were not applied retroactively meaning that medicines that entered the EU market through the centralised procedure prior to these dates often lack an adequate ERA and for many there are is no data on potential environmental impact.

For human pharmaceuticals, environmental risks are not even criteria in the benefit-risk assessment in the marketing authorisation process. Environmental aspects are therefore not taken into account when the European Medicines Agency (EMA) makes a marketing recommendation for new human drugs. As a result, pharmaceutical companies tend not to prioritise ERAs during drug development14 and Member States tend not to develop appropriate resources for the evaluation of ERAs.15

There are also concerns that ERAs do not consider manufacturing risks, the risks of AMR development, nor the risks that degradation products, metabolites, and combination effects can pose – despite growing evidence that mixtures of pharmaceuticals can have a greater joint toxicity.16 ERA data is not fully publicly available, making environmental information on APIs difficult to research and leading to weak oversight.

The European Commission is currently revising the EU general legislation on human medicines17 with a proposal for a regulation expected later in 2022. This revision provides a unique opportunity to strengthen the EU regulatory framework to better mitigate the risks that pharmaceuticals in the environment can pose to ecosystems and human health through their contribution to the development and spread of AMR.

Need for a Multi-stakeholder Approach

There is no silver bullet to address pharmaceuticals in the environment. However, a number of stakeholders involved across the pharmaceutical value chain can take a series of measures, which together can significantly reduce the risks. These include the pharmaceutical industry, healthcare professionals and procurers, patients, veterinarians and food producers, wastewater treatment plant operators, drinking water utilities, and civil society.

Intergovernmental organisations, national government, and regulatory agencies and authorities also have a key role to play in building a strong regulatory framework with a life-cycle approach that includes a mix of source-directed, use-orientated, and end-of-pipe measures18 to protect the environment and safeguard public health. End-of-pipe measures alone are insufficient, as upgrading wastewater treatment plant is costly and energy-intensive.

The Role of the Healthcare Sector

Health Care Without Harm (HCWH) Europe19 works closely with the healthcare sector to minimise pharmaceutical pollution and its contribution to AMR through policy advocacy and upstream initiatives. Whilst healthcare facilities are only responsible for approximately 20% of APIs20 found in municipal sewage systems, they emit particularly high concentrations of pharmaceutically active compounds and administer specialised pharmaceuticals that are not commonly taken at home.

The healthcare sector is a key actor in the chain approach to reduce pharmaceutical pollution. It can enhance responsible pharmaceutical use, and strengthen green procurement, as well as raise awareness on the adverse effects of pharmaceuticals entering the environment and influence the purchasing, use and disposal of medicines. It can promote take-back schemes for household drugs and establish best management practices for collection and disposal schemes at healthcare facilities.

Medical doctors, in particular, as drug prescribers can take simple practices to reduce unnecessary emissions and waste21 and educate patients about pharmaceutical pollution to improve purchasing and disposal behaviour. By leveraging their trusted voice, they can also engage with healthcare leaders to change procurement and prescription practices and advocate environmental criteria when buying medicines and developing formularies.

REFERENCE

https://www.umweltbundesamt.de/en/databasepharmaceuticals-in-the-environment-0

http://www.saicm.org/Portals/12/documents/meetings/ ICCM4/doc/K1606013_e.pdf

https://www.thelancet.com/journals/lancet/article/ PIIS0140-6736(21)02724-0/fulltext

https://amr-review.org/sites/default/files/160525_Final paper_with cover.pdf

https://www.unep.org/pt-br/ node/20131#:~:text=Nairobi%2C%205%20December%20 2017%20%E2%80%93%20Growing,solutions%20in%20the%20 environmental%20space.

https://wedocs.unep.org/bitstream/ handle/20.500.11822/38373/antimicrobial_R.pdf

https://www.amrleaders.org/resources/m/item/ reducing-antimicrobial-discharges-from-food-systemsmanufacturing-facilities-and-human-health-systems-intothe-environment

https://ec.europa.eu/health/system/files/2016-11/study_ environment_0.pdf

https://saicmknowledge.org/sites/default/files/ publications/position_arzneimittel_englisch.pdf

https://www.researchgate.net/publication/6134174_ Effluent_From_Drug_Manufactures_Contains_Extremely_ High_Levels_of_Pharmaceuticals

https://changingmarket.wpengine.com/wp-content/ uploads/2016/12/BAD-MEDICINE-Report-FINAL.pdf

https://www.globalpharms.org/

https://op.europa.eu/en/publication-detail/-/ publication/5371e7bd-25db-11e9-8d04-01aa75ed71a1/ language-en

https://pubmed.ncbi.nlm.nih.gov/24447908/

https://ec.europa.eu/health/system/files/2016-11/study_ environment_0.pdf

https://www.oecd.org/environment/resources/ pharmaceutical-residues-in-freshwater-policy-highlights.pdf

https://ec.europa.eu/info/law/better-regulation/ have-your-say/initiatives/12963-Evaluation-and-revisionof-the-general-pharmaceutical-legislation_en

https://www.oecd.org/environment/resources/ pharmaceutical-residues-in-freshwater-policy-highlights. pdf

https://noharm-europe.org/

http://www.pills-project.eu/PILLS_summary_english.pdf

https://www.youtube.com/watch?v=9PTpylVotd8

Jean-Yves Stenuick

(HCWH)

International Responses to the Emerging Threat of Antimicrobial Resistance

The problem of antimicrobial resistance is not confined to a few countries but rather is a challenge that affects the entire world. The extent and pattern in which antimicrobials are utilised can, however, have a significant impact on the degree of urgency or severity of the condition. The problem has gradually but steadily extended to every single country in the globe, posing a threat to the safety of human, animal, and plant health as well as the security of food production. The consistent rise in the consumption of antibiotics in both the human and animal sectors raises serious concerns about a future in which not a single antibiotic will be available for the treatment of even the most prevalent bacterial diseases.

The drivers of AMR are present in human health, animal production, environment, and plant production sectors. Therefore, the problem requires joint and global efforts to address the challenge. In this pursuit, the first and foremost step is to measure the extent of the problem in different sectors. There is a coordinated effort underway to address this potential calamity including a wide range of international organisations. In response to the impending socioeconomic concerns of AMR, the World Health Organization (WHO) in its 68th World Health Assembly (WHA) adopted the Global Action Plan (GAP) on antimicrobial resistance, which was jointly developed by WHO, the Food and Agriculture Organization (FAO) and the World Organization of Animal Health (OIE) (1). This action plan emphasizes the importance of a sustainable "one health" strategy for cooperation between multiple worldwide sectors and actors, including human and veterinary medicine, agriculture, the environment, finance, and informed consumers.

The global action plan on antibiotic resistance specifies the following five strategic goals:1

(1) To improve AMR awareness understanding among the general population

(2) To utilise effective surveillance for generating evidence

(3) To minimise the disease and infection events

(4) To regulate the usage of antimicrobial agents in the human and animal sector

(5) To invest in research and development to counter antimicrobial resistance

For as long as practicable, the action plan aims to maintain access to effective medicines for treating and preventing infectious diseases, with the availability and accessibility of safe and quality-assured drugs which are used responsibly by all those who require their usage.

All 194 WHO Member States are urged by the World Health Assembly decision to align their National Action Plan

on Antimicrobial Resistance (NAP) with GAP-AMR. The United Nations General Assembly's High-Level Meeting on AMR further reinforced the commitment of global leaders to address AMR.2 Many countries have operationalised NAP-AMR; however, a few underdeveloped nations are in the midst of developing effective and fully functionalised NAP.3

These international bodies have operationalised surveillance and monitoring of AMR and Antimicrobial usage (AMU) at regional and integrating information at global. WHO started Global Antimicrobial Surveillance System (GLASS) in 2016 to collect official data on AMR and AMU.4 As of May 2021, 109 countries are enrolled in this surveillance system and sharing data, however, there are limited countries contributing data on AMU.5 Antibiotic usage in the major driver for AMR, therefore information on its extent of usage can provide valuable insight on its influence on the problem.

In another surveillance program started in 2005 by WHO as WHO-Global Salmonella Surveillance system which was later renamed as Global Foodborne Infections Network (GFN).6 Surveillance was committed to enhancing the capacities of countries to detect respond and prevent foodborne and other enteric infections from farm to table. The network work with countries to build national capacities for integrated surveillance and promote collaboration among various sectors. The network has also developed manuals and protocols for detection of various pathogens, Antibiotic sensitivity testing (AST) protocol and molecular detection methods for implementation of surveillance system in and harmonised manner.7

WHO also established Advisory Group on Integrated Surveillance of Antimicrobial Resistance (AGISAR) to support and build national capacities on integrated surveillance of AMR & AMU.8 In its 6th review meeting it was agreed to develop and standardise protocols with One Health approach. ESBL E. coli Tricycle Surveillance, a model of integrated surveillance of AMR

with harmonises protocol with single key indicator was started to assess the frequency of ESBL producing E. coli in human, food chain and the environment.9

Food and Agriculture Organization (FAO) which looks after agriculture and food sector is also active in surveillance of AMR and has developed FAO Assessment Tool for Laboratories and AMR Surveillance System (FAO-ATLASS).10 For this they have developed platform, International FAO Antimicrobial Resistance Monitoring data (InFARM) for collection, analysis and reporting of AMR data from food and agriculture sector at national level, including AMU data in plants and crops.11

World Organization of animal health (OIE) has mandate to improve animal health, welfare and veterinary public health. The organisation has set standards related to AMR & AMU which are available in Terrestrial Animal Health code and Aquatic Health code.12 The standards and protocols are aimed to harmonise national, AMR surveillance and monitoring program. On antibiotic usage OIE collect data from member countries on usage of OIE listed antimicrobials of veterinary importance and is regularly publishing report. OIE in its ongoing efforts is working on an AMU database project for

the countries to have tailor made tool of their need, setup tool/software to help countries in annual collection of data on AMU.

Accepting the importance of AMR across different sectors and to retain the effectiveness of antimicrobials in treating diseases, promote health of the people and food safety, the three international organisations in its resolution in 68th WHA stressed upon the collaborative and multisectoral ‘One Health’ approach to address the problem. As a consequence of this, in May 2018 the three organisation signed a Memorandum of Understanding (MoU) as a Tripartite agreement for joint cooperation to address the issue of AMR.13 The Tripartite also involved United Nation Environmental Program (UNEP) to integrate environment as well in their efforts to combat AMR. They have developed Tripartite workplan to be implemented in 10 pilot countries where impact of AMR is likely to be greatest. The workplan will help in implementing multisectoral National Action Plan (NAP) on AMR across the human, animal, plant, food and environment. The Tripartite agreement has also advocated for a common platform Tripartite Integrated Surveillance System (TISSA) where harmonised surveillance data from different sectors will come through their respective

organisation and available at one point for analysis of trends and policies decisions.14

Whereas in 2019, due to the pandemic, the aggressive efforts employed to combat AMR were redirected to protect the world from the immediate threat. The lack of a solid public health system, which may contribute to the emergence of antibiotic resistance throughout healthcare institutions, nations, and the globe, was painfully obvious. In the year 2019, estimates for the number of deaths associated to bacterial AMR ranged between 3.62 million and 4.95 million.15

International leadership united with more comprehensive measures after fully comprehending the implications of AMR. The Global Leaders Group on Antimicrobial Resistance was created in January 2021 for the purpose of collaborating for long-term political action on AMR.16 In collaboration with UNEP, a Tripartite Strategic Framework on AMR for the years 2022–2026 was prepared. The "Call to Action" for the UN General Assembly High-Level Dialogue 2021, which was endorsed by 35 non-state entities and signed by 113 Member States, included AMR as a key component.17

REFERENCES

1. Global Action Plan on Antimicrobial Resistance. Microbe Mag. 10, 354-355 (2015).

2. www.un.org/pga/71/event-latest/high-level-meeting-onantimicrobial-resistance/, visited on August 22, 2022.

3. https://amrcountryprogress.org/#/map-view, visited on August 22, 2022.

4. World Health Organization. Global antimicrobial resistance surveillance system (GLASS): technical meeting on the early implementation phase. (2016).

5. https://www.who.int/publications/i/item/9789240027336, visited on August 22, 2022.

6. Arthur, R. R., LeDuc, J. W., Hughes J. M. Global Surveillance for Emerging Infectious Diseases. Tropical Infectious Diseases: Principles, Pathogens and Practice. 9. 105. (2011)

7. https://www.cdc.gov/ncezid/dfwed/pdfs/gfn.pdf, visited on August 22, 2022.

8. World Health Organization. Integrated surveillance of antimicrobial resistance in foodborne bacteria: application of a one health approach: guidance from the WHO Advisory Group on Integrated Surveillanec of Antimicrobial Resistance (AGISAR). (2017).

9. WHO. Global Tricycle Surveillance – ESBL E.Coli - Integrated Global Surveillance on ESBL-Producing E. Coli Using a “One Health” Approach: Implementation and Opportunities. (2021).

10. FAO. FAO Assessment Tool for Laboratories and AMR Surveillance Systems (ATLASS). Available online at: http:// www.fao.org/antimicrobial-resistance/resources/tools/ fao-atlass/en/ , visited on August 22, 2022.

11. https://www.fao.org/antimicrobial-resistance/resources/ database/infarm/en/, visited on August 22, 2022.

12. https://www.woah.org/en/what-we-do/standards/ codes-and-manuals/, visited on August 22, 2022.

13. FAO, OIE, WHO. MoU Regarding cooperation to combat health risks at the animal-human-ecosystems interface in the context of the “One Health” approach and including AMR. (2018)

14. WHO, FAO, WOAH, UNEP. The Tripartite Workplan on

antimicrobial resistance. J Lang Relatsh. (2019)

15. Murray, C. J., Ikuta, K. S., Sharara, F., Swetschinski, L., Robles Aguilar, G., Gray, A., Han, C., Bisignano, C., Rao, P., Wool, E., Johnson, S. C., Browne, A. J., Chipeta, M. G., Fell, F., Hackett, S., Haines-Woodhouse, G., Kashef Hamadani, B. H., Kumaran, E. A. P., McManigal, B., Naghavi, M. Global burden of bacterial antimicrobial resistance in 2019: a systematic analysis. The Lancet, 399(10325), 629–655, (2022).

16. https://www.amrleaders.org/#tab=tab_1, visited on August 22, 2022.

17. WHO. WHO Strategic Priorities on Antimicrobial Resistance. (2022).

Hina Malik

The author holds a graduation degree in Veterinary Science and a master’s degree in Veterinary Public Health. She has been working as a veterinarian in the Uttarakhand Animal Husbandry Department for the past seven years. Currently she is pursuing a doctorate in veterinary public health and epidemiology at the Centre for One Health, Guru Angad Dev University of Veterinary and Animal Sciences in Ludhiana, India. Her study focuses on zoonotic diseases with emerging antibiotic resistance in one health framework.

Email: hinamalik.vet@gmail.com

Wasimuddin

Senior scientist at Centre for Cellular and Molecular Biology, Hyderabad, India. The focus area of research of the author is the One Health framework focusing mainly on human and environmental health in terms of shifts in microbiome and the emergence of antimicrobial resistance. The author has many research and review articles to his credit on host-pathogen interaction and microbiome dysbiosis in many international journals. Currently, he is working on the surveillance of antimicrobial resistance in human and the environment in India.

Email: wasim.bt@gmail.com

Randhir Singh

Professor at the Centre for One Health, Guru Angad Dev University of Veterinary and Animal Sciences in Ludhiana, India. The focus area of research of the auther include zoonoses, food safety and antimicrobial resistance in One Health framework. The author has many research and review papers and popular articles to his credit on zoonoses, food safety and antimicrobial resistance emergence published in various national and international journals.

Email: sainirandhir72@gmail.com

The Green Discussion Forum

In 2020, we decided that the theme for our year would be regenerating the veterinary world. I had been running The Webinar Vet for a decade and begun the online revolution for vets, which had taken millions of miles off the roads over the last decade. However, we wanted to do more to show leadership in the veterinary industry. As a digital educational business, it is arguably simpler to be sustainable than a large pharma company. However, we calculated our carbon footprint; offset double what we produced during the pandemic year; started a veterinary sustainability podcast and planted a wildflower meadow at the Liverpool Science Park along with encouraging our landlord to embrace renewable energy providers.

Part of beginning a sustainability journey is that the further you get down the road, the more you realise more can still be done. Many larger companies have not yet started, because they don’t know how to start. Small steps are enough at the start to build the company owner’s confidence.

Part of this year’s journey was to try to facilitate bringing the veterinary industry together to see how we can collaboratively move faster into a more sustainable future. I was at COP26 and I realised how government, industry and individuals need to work closely together to achieve the environmental targets that have been set for this decisive decade. Carbon seems to be the main focus that everyone concentrates on but it is not very holistic. When I decided to organise the forum, I wanted to look at resource use and biodiversity as well as climate change and carbon.

It's very hard to get a lot of big companies in the room initially. Companies want to know who else is turning up and, inevitably, there is some distrust in being too open in sharing where they are in their sustainability journey. From the start of the process, I made it clear that this would be a safe place to discuss topics and that Chatham House rules would apply. Sustainability and regeneration are such big topics and companies are learning as they go. Every company that is taking these topics seriously have strengths and weaknesses in its approaches and I believe we will learn quicker if we work together. Collegiality and collaboration are more important than competing against each other in the environmental arena.

This was the background that led me, as a vet in an independent business, to start bringing companies in the veterinary space together to collaborate in this essential area of veterinary regeneration and sustainability. This journey will not be finished next year. It is a long journey, but one with a clear goal of reducing carbon production by 50%; creating a

more circular, less wasteful economy and having 30% of the land of high biodiverse value by 2030 (30 by 30).

The Webinar Vet opened for business 12 years ago and is well-trusted in the industry. It is set apart from the pharmaceutical, feed and corporate veterinary practice groups and can, hopefully, act as a facilitator. It’s possible that an association can also take this role. At the inaugural forum, we were incredibly fortunate to have our regulator, the Royal College of Veterinary Surgeons, present as well as the British Veterinary Association, The British Small Animal Veterinary Association, The British Cattle Veterinary Association and VetSustain. This, obviously, enhanced the credibility of the forum.

The Webinar Vet has never held a physical conference. Indeed, during the pandemic, we helped over 50 associations and companies take their events online due to our decade-long experience of running online events. However, we decided that a green discussion forum had to take place at a physical venue and so we decided to hold it at Brockholes Nature Reserve just outside Preston. Holding it at a nature reserve would help to ground us and show clearly how protecting the environment was essential. The centre at Brockholes is an architectural masterpiece designed by the esteemed architect, Adam Khan. It floats on the lake and rises and falls as the lake depth varies due to floods and drought. As a result, its design has protected it from being inundated on several occasions There is much to learn from the design of the visitor centre which can help with the design of buildings on floodplains. It is a truly stunning creation using wood extensively to give it a natural, warm feeling.

We were keen to bring the representatives of the companies together to facilitate networking and discussion and the content of the forum was mainly created by the delegates. Although, we had a keynote speaker for every session of the two-day

forum which also included an afternoon working in the reserve to rake cuttings off one of the wildflower meadows or removing invasive Crassula helmsii or New Zealand pygmyweed from the main lake. This session was characterised by the number of breaks that delegates took to chew the cud with fellow delegates and carefully remove the myriads of small toads and frogs that we found on the meadow. Everybody clearly enjoyed working on the land!

After much planning and hard work, we managed to get 40 individuals in the room, representing 24 companies and associations. Inaugural meetings are always tricky. Some companies are more willing to take a risk on a new event in the calendar whilst others wait to see if it fails or not. All industries should be attempting these collaborations. It is better to attempt such an event that fails rather than not to try. I must admit that I was worried and a bit stressed before the event and decided that I would mainly walk to the event as well as using public transport so that I could immerse myself in the beautiful natural landscape and calm myself before the event. This was a very good move before the forum began.

Over the course of two days, we spent time listening to each other and the keynote speakers as well as discussing the important questions in small groups. Our keynote speakers were dialled in virtually to keep our carbon footprint as low as possible. We recorded everybody’s journey to the congress and offset the carbon emitted to make it a carbon-neutral event. It was also not for profit with several thousand pounds being donated to the Lancashire Wildlife Trust which own Brockholes.

Climate Change and Greenhouse Gases

Our first main keynote speaker was Juliet Davenport, the founder of Good Energy. Juliet spoke about the ongoing energy crisis which was partly due to the slow uptake of renewable energy. She also spoke about the journey she undertook to start Good Energy at the beginning of the millennium when no one else was really interested in the space. Insulation must also be a part of our journey towards net zero as this would massively reduce our energy needs. This must become a key part of every individual’s and company’s environmental commitment.

One of our delegates had done magnificent work moving their company’s car fleet away from diesel and petrol to hybrids and electric cars. Again, because of government tax reforms, this is not only good for the environment but also for employees’ pockets. She explained the benefit in kind advantages of these schemes. I am a committed environmentalist but if we can encourage a change of behaviour using money as the carrot this will guarantee greater uptake from people who do not understand the environmental issues.

One of our delegates was a chief sustainability officer at a leading insurance company. Scope 3 is a challenge for a lot of bigger companies. What are their suppliers doing on their sustainability journey? This will affect the emissions that another company is indirectly responsible for. If they did not need their materials, then they wouldn’t be produced and lower concentrations or fewer greenhouse gases would be emitted. Many companies have not truly grasped the importance of scope 3 to calculate their own carbon footprint but also to encourage their suppliers to begin the journey to net zero. The general consensus was that Scope 3 can be ignored until the

company’s own emissions are quantified and can be lowered and offset. The next stage of the journey to deal with scope 3 is more complicated but many important skills will have been learnt dealing with scope 1 and 2 emissions that will make dealing with scope 3 easier. The veterinary industry’s journey to a net zero future will be a series of stepping stones and we need to move from one stone to the next to reach our net zero destination.

The delegates then broke into small groups and discussed some circulated questions:

• What is your company doing to reduce its carbon usage in the next decade? What is the target?

• Is it time for the industry to follow the World Veterinary Association’s lead and declare a climate emergency or do we need to work closely together to create a set of standards?

• What are your thoughts about offsetting against carbon?

• How can we produce our own energy as businesses?

• The Amazon rainforest is now emitting carbon. How does that make you feel?

• How can we as an industry lobby government to move faster?

• Are practice groups discussing Scope 3 with you?

The discussion was so important to allow people to get to know each other as sustainability leads in their business but also to listen deeply and learn from each other. To facilitate the listening the symbol for listening in Chinese was displayed. This shows that listening involves the ears but also the eyes, heart and indeed the whole being. Delegates were encouraged not to interrupt other delegates who were speaking. A stone was used which every person speaking had to hold and only relinquish when they had finished speaking. This system was not abused by dominant personalities refusing to give the stone away!

The rest of the first day was spent networking and working on conservation projects on the nature reserve. At the end of the day, we returned to our hotel which was only 1 mile away to get spruced up. Many of the delegates walked through the reserve to get back to the hotel. We returned to the nature reserve in the evening to enjoy some fine food which had been locally sourced and was of good provenance along with some fine Italian organic wines from Vintage Roots which everyone enjoyed. Tom Burditt was our guest of honour and the CEO of the Lancashire Wildlife Trust. I’d asked him to speak about natural capital for about 10–15 minutes but he spoke for 55 minutes and had everybody spellbound. So many people spoke favourably about his passion for the topic. If we obsess too much about carbon, we forget about the inherent value of habitats already there which are biodiverse and have no carbon value but natural capital.

Many of the delegates walked to the reserve on the second day to see lovely views of deer and waterbirds by the River Ribble and on Brockholes Lake.

Our second keynote speaker was Professor David Goulson, author of The Silent Earth which bemoans the massive reduction of insect life which also affects their predators like spotted flycatchers whose populations have crashed in the UK. There are many causes for this precipitous loss, however, the

advent of very potent insecticides since the banning of DDT has certainly been a factor and the profession now worried that some of those insecticides used to kill fleas and other problematic insects may also be getting washed into streams and affecting aquatic life.

The day continued with talks on large and small animal parasiticide usage. A veterinary parasitologist described his work on a group of farms where reduced parasiticide usage and increased lungworm vaccine usage had led to healthier, more productive cattle. Justine Shotton, BVA president, spoke about the need to reduce preventive parasiticide usage in dogs and cats to prevent contamination of the environment with medicines. This is a problem across all medicine types including antibiotics and also across the various medical professions.

Sue Paterson from the Royal College of Veterinary Surgeons moved away from this topic to explain that the practice standards scheme run by the college now included an award for sustainability to encourage more practices to think positively about environmental concerns.

Some of the questions discussed in the small groups were as follows:

Biodiversity

• How much do you think the veterinary industry is part of the solution or part of the problem?

• How can we encourage practices to make their spaces more biodiverse?

• Should vets be the only one to prescribe anthelmintics?

• How can we make sure that products are safe in the environment?

• Are accreditations like Investors in the Environment and Bcorp worthwhile?

We then broke for questions followed by lunch.

The final afternoon we discussed resource use in the profession. Jen Gale was our keynote speaker discussing resource use and the circular economy. She is a veterinary surgeon and famous as the author of “Sustainable-ish Living Guide.” She spent a year not buying anything new and also is famous for emptying her bin for the first time this year in August. The circular economy was discussed. There is so much work needing to be done in this area to improve individual, corporate and government responsibility. During this session, other veterinary businesses discussed some of the work they were doing with biodegradable packaging and targets to reduce the rubbish going to landfill. Having a well-thoughtthrough sustainable plan was also deemed to be essential.

The forum finished with a discussion amongst the small groups around resource use.

Resource Use

• What are your targets for recycling and using recycled material in packaging?

• Any new innovations we can talk about?

• Could the industry come together to encourage recycling in practices?

• Which areas should the profession be concentrating on?

• Does the industry need to develop take-back schemes for packaging?

What Should We Be Copying from Other Industries?

The forum was very well received, and we are intending to run this at nature reserves until 2030 to act as encouragers for the various veterinary companies attending to work towards targets around carbon, biodiversity and resource use. This is the decisive decade and it is so important that we work together as industries to tackle the ongoing environmental challenges.

Anthony Chadwick

Anthony Chadwick BVSc CertVD MRCVS qualified from Liverpool University in 1990 and received his certificate in Veterinary Dermatology in 1995 from the Royal College of Veterinary Surgeons. Anthony was involved in first opinion practice and dermatology referrals until 2016. In 2010 Anthony set up The Webinar Vet, the first online training platform for veterinarians and nurses, in an attempt to make veterinary education more accessible and affordable across the world. Since that time tens of thousands of veterinarians and nurses have accessed the platform from all over the world. The Webinar Vet’s first virtual conference took place in 2013. During the pandemic, The Webinar Vet helped to take over 40 veterinary meetings and conferences online including WVAC2020 and WCVD9. In 2021, Anthony took the business carbon negative, helping to stand by The Webinar Vet’s principles of being as sustainable as possible and delivering exceptional quality training, internationally via remote means. The Webinar Vet is an Investor in the Environment Green Accredited business.

Web: www.thewebinarvet.com

IPI

Peer Reviewed, IPI looks into the best practice in outsourcing management for the Pharmaceutical and BioPharmaceutical industry.

www.international-pharma.com

INSIGHT / KNOWLEDGE / FORESIGHT SUPER PUBLICATIONS FOR SUPER PHARMACEUTICALS

JCS

Peer Reviewed, JCS provides you with the best practice guidelines for conducting global Clinical Trials. JCS is the specialist journal providing you with relevant articles which will help you to navigate emerging markets. www.journalforclinicalstudies.com

PHARMA’S DNA

Listen to industry experts on the latest in drug discovery, development, research, industry regulations and much more at Pharma,s DNA, the podcast channel by Senglobal Ltd., available on Sound Cloud, Spotify, iTunes and YouTube.

IAHJ

Peer Reviewed, IAHJ looks into the entire outsourcing management of the Veterinary Drug, Veterinary Devices & Animal Food Development Industry. www.international-animalhealth.com

IBI

Peer reviewed, IBI provides the biopharmaceutical industry with practical advice on managing bioprocessing and technology, upstream and downstream processing, manufacturing, regulations, formulation, scale-up/technology transfer, drug delivery, analytical testing and more. www.international-biopharma.com

New Paper-based Security Seals Revolutionise Pharma Packaging

EU-wide Amendment of the Packaging Law & Plastic Reduction

Since the 60s, the use of plastic has increased twentyfold. The EU is therefore focusing on a sustainable economy and is pulling the emergency brake on plastic packaging in particular. The Single-use Plastics Directive is only one measure to achieve this goal. The first step was the ban on plastic bags – products such as cotton swabs and drinking straws are also already adopting alternative packaging materials. In the future, there will be penalties for packaging that is not designed to be recyclable within the European Union. Further bans on plastics for certain applications are not ruled out. According to Securikett CEO, Werner Horn, "A switch to our new paper-based VOID seals and VOID tapes will therefore pay off for all businesses by eliminating the risk of non-compliance with material requirements of new regulations. The pulp material used by Securikett can be recycled together with folding cartons and complies with the new EU general circular economy package."

The trend toward use of recyclable and renewable materials is not just a European issue: recycling-friendly packaging based on renewable resources is in demand worldwide!

‘One Package – One Material‘

If the packaging and label are made of the same material, the cost, efficiency, and effectiveness of the recycling process is significantly enhanced. Thus, paper security seals optimise the recyclability of all cardboard or paper packaging.

"By using the latest paper-based security seals, pharma companies can not only package their products in a tamper-proof way that complies with all international standards, but also make a sustainable contribution to environmental protection and avoid plastic," says the CEO of Securikett, Werner Horn, who is committed to producing high performance security products in an effective, efficient and sustainable manner. Securikett’s PaperVOIDs therefore combine all benefits from FMD-compliant closure seals with sustainability and environment protection.

Sustainable Packaging and Product Digitalisation in One Step

Securikett was the first in the market to launch paper-based tamper evident security labels with an integrated QR code. These labels provide distinct proof of opening, the so-called VOID effect, and give the manufacturer the ability to communicate further information about the product directly to the customer via a simple scan of the label. In this way, product digitalisation is simple and sustainable. The unique codes are created

A Superlabel Made from Renewable Raw Material that Can Do it All

The new PaperVOID labels can be fully customised to the customer's corporate design. When it comes to product properties such as sustainability, origin, authenticity, supply chain integrity, ethics, etc., digital Securikett technology enables this information to be linked directly to each individual sales unit of product. In this way, the properties can be communicated to the customer in a trustworthy, transparent and personal way and increase the integrity and perception of the product.

Innovation Comes from Austria

Securikett, an Austrian company specialising in digital and physical security systems for a broad spectrum of product sectors, is attracting attention with its invention of the new paper security seal. The company has been a key supplier to major industrial companies around the globe for years and is a global leader in the development and supply of transparent and opaque security closure seals.

"Our VOID labels turn all types of packaging into safes," says Werner Horn, the company's CEO, explaining how they work. "We are pleased that we can now offer this special paper-based

From left to right: 1. label applied on box, 2. peeling off the

VOID technology solution. Paper is one of the most renewable raw materials and recycling of paper is well established. Pulp fibers can be recycled up to 8 times."

The security closure seals are characterised by the fact that an irreversible effect remains on the packaging when it is peeled off. Opening and tampering of the packaging is thus immediately and clearly obvious. The company produces these new paper VOID seals in various designs, sizes and colors.

3.

on

After opening or peeling off the

such as “VOID” or “OPEN” become visible due to a color change.

Paper-based Security Seals

Securikett's research department has been working for a long time on the goal of being able to produce paper-based security seals with equivalent performance and security as the plasticbased security seals that have been more commonly produced up to now. The goal included development of both opaque and transparent security seals, in which the special security VOID effect is displayed when the seal is peeled off.

Vanessa Mitterer, Msc. Head of the Research Department, says: "Thanks to technical innovations, we have succeeded in producing a seal from the renewable and recyclable raw material paper that is superior to the plastic seal in many aspects. PaperVOID deforms when peeled off and is particularly resistant to manipulation with water and liquids."

business

one-stop SMART

integrating manipulation evidence, security and IoT services. The company was founded 2001 and engages 90 employees. Applications by Securikett are used on luxury goods, spirits, medicines, spare parts and shipping boxes. Based in Austria, Securikett currently distributes products to 45 countries around the world.

Meeting the World’s Evolving needs for a More Sustainable Future: How to Realise a Circular Approach to Drug-delivery-solutions

The world is looking for companies across all industries to take leadership positions that not only advance their traditional business metrics, but more importantly improve their impact on the environment and people’s lives around the world. When it comes to sustainability, there is not a single easy solution to solve all issues. Instead, taking a holistic view across various aspects of our business has led Aptar along the path to meeting its sustainability goals. Companies are increasingly adopting the principles of the circular economy where waste and pollution are eliminated or reduced as they are designed out of products throughout their lifecycle.

And it’s not just manufacturers who are supporting these potential solutions. Consumers are also demanding higher recyclability of products and are willing to pay more for them. In a recent Aptar Pharma survey conducted in 2022 with German, French and American participants, 77% of in total 840 respondents indicated that it was important or very important that the products they buy can be recycled. Further, 60% of respondents consider the recyclability of products when making purchasing decisions and 70% said they were willing to pay more for a product that they could recycle. Participants also voiced that they were willing to adapt their consumption habits to contribute to a reduced environmental impact, with six of ten respondents willing to use a refill/reload system to reduce environmental impact. These survey results confirm that consumer demand for increased sustainability, recycling and circular economy initiatives will be reflected in their buying decisions moving forward.

At Aptar, we’ve strategically assessed our businesses, which encompass pharmaceuticals, beauty, personal care, home care, food, and beverages, and have worked to embed sustainability throughout our business and within our product offerings. As the pharmaceutical industry is subject to very strict regulations, the introduction of such sustainability initiatives within our Pharma business must achieve not only the sustainability objectives but also maintain adherence to all regulatory, GMP (Good Manufacturing Practice) and quality requirements. We have categorised our sustainability programs into the three main action areas: Care, Collaboration and Circularity.

Care

As a company we show care to our employees, communities, and environment by continuously improving our impact and reducing our footprint. Our focus on care – for people and for our shared environment – as a key element of how we shape our future and achieve our objectives. Last year, Aptar named a Global Top 10 Female-Friendly Company

by Forbes for its progress on leading the way to support women inside and outside of their workforce. Notably, at Aptar in 2021, women accounted for 20 percent of leaders at the Vice President level and above. We have also grown our Employee Resource Groups (ERGs) to include the ALIGN Women’s Network, BOLD (Black/African American or African Descent) and ARC (LGBTQ+ community and their allies). We support these people focused initiatives, as Aptar firmly believes in the diversity and importance of every employee and the potential benefit they bring to Aptar, our customers and the world.

A second aspect of our care action area is reducing our footprint on the environment. We established a science-based target for the reduction of our Scope 1 and Scope 2 emissions by 28% by 2030 from a 2019 baseline. By the end of 2021, Aptar proudly achieved 74% of the goal, well in advance of the original target date. Aptar remained on track to achieve goals to source more renewable energy. In 2021, renewables accounted for 96% of electricity purchased, with the goal of 100% targeted by 2030. Also of note, 63% of Aptar’s facilities had achieved Landfill

Free site certification at year-end of 2021 through our dedication to our internal waste reduction certification programs. We have additional sustainability targets related to both people and the planet and we remain committed to building a better future. (see table 1).

Our care action area demonstrates that through care for both people and the environment, Aptar can achieve broader objectives benefitting the company, customers and the planet.

Collaborate

We collaborate with customers, suppliers, industry coalitions and nonprofits to progress towards goals and better outcomes for people and the planet. These collaborations are important as they allow Aptar to gain and share knowledge and develop innovations that deliver economic, performance and environmental value.

Table 1: Aptar defined corporate targets that aim at bringing forward our sustainability efforts. The group is on track and even surpassed some of the goals at year-end 2021.

Examples of Aptar’s collaborations across segments and industries include:

• Partnering with PureCycle Technologies as its preferred technical partner to test and transform their Ultra-Pure Recycled plastic for food, beverage and cosmetics applications

• Active participation with the Ellen MacArthur Foundation (Cowe’s, UK) as a signatory of the “New Plastics Economy Global Commitment”, within a recyclability working group through the CE100 Network, and piloting their “Circulytics” circular economy assessment tool

• Expansion of domestic North American production of Activ-Film™ technology to ensure COVID-19 test kit integrity and accuracy through the support of a $19 million U.S. Government contract

• Dedicated supplier engagement on sustainability objectives. By the end of 2021 Aptar had engaged approximately 40% of its supply base to manage their emission reduction efforts through a collaboration with EcoVadis

As system thinkers and change-makers, Aptar is committed to working alongside, and often leading, others by identifying solutions, processes and products that enable us all to move forward together.

Circularity

We are helping the industry advance system-scale changes that will benefit people today and generations to come by addressing climate change and waste crisis through Circularity.