32 minute read

III The Golden Decade

III

The Golden Decade

Advertisement

At the end of World War 1, the block industry was still pretty much a backyard operation. Usually the owner of a block plant worked as a laborer 12 to 14 hours a day. He had no time for selling block because he was too busy making them. The lack of vision, imagination and sales ability on the part of most manufacturers was a major problem.

Industry pioneer J. L. Pitha recalls that "investment requirements were but a very small fraction of what they are today. With $5,000 in cash it was possible to go into the block business in 1918. Major equipment consisted of two block machines and a mixer. A 750-squarefoot building was large enough to provide space to stack the block for curing.

Block were made in most unusual places then. One small manufacturer in the East worked with his wife in the cellar of their home every night after he came home from work. They mixed cement and sand on the floor by hand and then molded the material in a small hand machine. He made about 50 block every night that way. The next night, when they were cured, he would lift the block out through the cellar window and his wife would stack them.

It was recognized, even in those days, that heat was needed for curing, and in most of these small plants the only heat they would have in cold weather was a big pot stove. It was normal for the block nearest the pot stove to be "cured" better than those which were too far away, even though the "curing" was mostly drying out. However, the cement content was greater than it is today, and because it was necessary for the block to be hard enough by the following morning to permit stacking, calcium chloride was frequently used.

But in the post-war economy, conditions for this tiny, scattered, uncertain concrete block industry to become a large, powerful and important element in the construction field were almost exactly right. An exhaustive market survey made by the Portland Cement Association in 1919 indicated that the U.S. was some two million houses short of requirements, especially in the central states where concrete block manufacturers were then concentrated. There was also a powerful need all over the country for stores, schools. theatres and other public and semipublic buildings, long delayed by the war. And, between 1917 and 1920, coal had skyrocketed in price from 9¢ to $2.40 per ton, driving up the price of block's principal competition — clay brick — since coal made up about 10 per cent of the production cost of brick.

How well prepared was the block industry to take advantage of this potential bonanza? According to the same PCA survey, about 50 million concrete masonry units were produced in 1919 by some 2,000 manufacturers, of whom about one-third were adjudged large enough and stable enough to rate first-class standing. The same study revealed about 3,000 favorable locations in the U.S. where there were no block plants.

Before block producers could spread into these areas and take advantage of the market potential, however, there were some serious problems that had to be solved. The industry was in a deplorable condition from the standpoint of personnel, manufacturing equipment, quality of product and merchandising methods. Power equipment was almost unknown. Not more than a dozen fairly well organized plants existed. No attempt was made at the grading of aggregates, proper mixing or adequate curing. Quality products were practically unknown because no standards of quality were available. Building codes in a few localities gave some recognition to concrete masonry but quality requirements varied widely, and little, if any, attempt was made at enforcement. The result was that concrete masonry units were in ill repute generally and condemned by building departments, architects and reputable builders. The product was too unattractive to compete with clay brick, terra cotta and lumber on anything like price equality. Insurance rates were outrageously high; quality fluctuated wildly; building methods had never been standardized or even defined; promotion was non-e xistent; and the industry was unorganized and generally chaotic in such crucial areas as manufacturing, selling, cost accounting and advertising.

Typical of the confusion of this period was the situation in Wisconsin, where 8 x 8 x 16" block were selling in Janesville for 32 cents, while a few miles away in Madison — where manufacturing costs were higher because materials had to be shipped in — the same block was selling for 16 cents. Much of this economic chaos grew out of an almost total lack of cost accounting in the industry. Producers often didn't know they were losing money until they found themselves out of business.

Faced with these problems and opportunities, the block industry was floundering rather badly when the Portland Cement Association — then less than five years old, itself — called a conference of block producers and block machinery manufacturers in Chicago in mid-1919. The conference chairman. A. J. R. Curtis, head of PCA's newly formed Farm and Cement Products Bureau, told the assembled producers:

"The present high cost of lumber and the relative saving of time and labor by using concrete block construction constitute two arguments which would be working powerfully in our favor right now if we were organized to take full advantage of them.”

“After having studied several of the past attempts aimed at the development of the block business, we are of the opinion nevertheless that a carefully planned cooperative effort by machinery

manufacturers, interlocked with a similar effort on the part of the block makers, may be expected to succeed in creating and maintaining enormous new markets for block. It goes without saying that to develop the block business to the utmost requires the broadest vision. The man who pictures block possibilities in terms of foundations or porch piers need hardly expect to get his block used in great commercial structures.”

“The concrete building block is a product that can be successfully advertised cooperatively. The exact kind of block and process of manufacture has but a secondary interest to the public if the impression is made and maintained that all block are good. Prospective owners can be interested in the superior advantages of high class concrete building units, promoted jointly by concerns of unquestioned business standing throughout the country.”

The PCA immediately put its staff to work organizing concrete products manufacturers in several dozen major cities to mount a concerted attack to improve the quality of concrete block. The motives of the PCA, of course, were scarcely philanthropic. Only one million barrels of portland cement—about one per cent of total cement production—were consumed by block manufacturers in 1919; the PCA saw a potential for ten times that amount.

PCA's concern was shared and its goals applauded by a group called the Concrete Products Association, which had been formally established on March 6, 1918 and held its first executive council in December of that year in the offices of the Hydrostone Company in Chicago. Much of the organizational impetus came from a former member of the PCA Cement Products Bureau named W. R. Harris (who later became editor of Concrete Products Magazine). Under the direction of Harris, the CPA held its first annual convention at the Congress Hotel in Chicago. On Feb. 9, 1920, the Committee on Constitution and By-Laws of the new organization worked through the night to complete a set of objectives to put before their fellow members the following day. Thus on Feb. 10, 1920, the Concrete Products Association dedicated itself to:

Facilitate the acquirement and interchange of practical knowledge among its members;

Encourage the development of the art of manufacturing concrete products;

Create a standard of excellence in manufacturing;

Promote the use of concrete products: encourage and provide for advertising the products of members;

Gather data and issue bulletins of promotional character;

Exercise a corrective influence on the quality of the product to the end that Association standards may be maintained; and

Secure mo re efficient cooperation with the government and agencies thereof, as related to the concrete products industry.

The convention then elected J. K. Harridge as the first official CPA president and adjourned to spend the final day in joint session with the National Conference on Concrete House Construction. While the convention didn't add much to concrete technology, it did have the salutary effect of giving the various elements of the concrete products industry a better idea of how they must organize their forces to get anything done.

Three PCA men served as Assistant Secretaries from 1918 until 1942. These were Roy Peck (editor of Modern Concrete magazine in 1970), Dr. R. “Spec” Collins and E. W. Dienhart. During this period, PCA offices served as headquarters.

One of the early block industry leaders, Ben Wilk, recalls that “the number of manufacturers who were willing to pay even a small annual amount for trade association participation was not large. Most of the early annual conventions were of a technical nature — and were scheduled for an extra day at the time of the annual convention of the American Concrete Institute. The active members were involved with both

groups.”

The PCA, however, took a dim view of the national concrete products group, feeling that local and regional cooperative efforts were more likely to prove fruitful. At the same time, machinery manufacturers — through the Concrete Block Machinery Association formed in July, 1919 — were encouraged to cooperate more closely with products producers while curtailing the sale of machinery to people who lacked the financing and technical expertise to make it successfully in the block industry.

Through all these organization activities, PCA agents were buzzing like a swarm of inspirational bees. By the end of 1920, thirty-four local and two state concrete block organizations were in operation in addition to the two new national associations. These groups were subjected to constant pep talks and ego-building reassurance of the social importance of their product. Jealousies within the associations and the narrow vision of many of the erst-while backyard producers often made cooperative effort difficult, but generally this nationwide forced-feeding of an industry was tremendously effective — to a large extent because block already had so many things going for it.

One of the most important was a very real cost advantage. A good grade of washed sand, delivered to the plant, would cost the block producer about one dollar per cubic yard. (The coarser material, called grit, was delivered at the same price.) Plenty of labor was available at 30 cents per hour. Portland cement — discounted and credited for the return of the cloth bags in which it was then delivered — cost about $1.50 per barrel. Despite these low costs of material and labor, block was selling for about three times as much as it brought 15 years later, and the demand was accelerating steadily.

Although this was due in part early in the decade of the 1920s to the shortage of other materials, there was the additional important factor that concrete block could be laid in a wall more quickly and at a much lower labor cost than could an equivalent volume of brick wall. For example, a common size of cinderblock that cost 20¢ in 1923 was equivalent in both size and cost to 11 clay brick. But the cost of laying up concrete block was more than 10¢ less than the cost of laying up the equivalent in brick.

The growing demand for block was also inspiring new and broader explorations by research and development specialists. For example, the first important broad-scale study of aggregates, mixtures, methods of curing and other factors entering into the manufacture of concrete brick was carried on during 1923 at Philadelphia in cooperation with Drexel Institute and the products manufacturers of that vicinity. Seventy different kinds of brick were made, varying in cement content, grading, and type of aggregates and consistency. The results of these tests conclusively proved the applicability of laboratory principles to manufacturing problems and pointed the way for improvements in quality and reduction of costs in products manufacture.

About the same time, several other important technological developments appeared on the concrete masonry scene. The use of washed sand became prevalent in the early 1920's, soon after Duff Abrams at Lewis Institute's Structural Materials Laboratory had come up with the water-cement ratio that converted the design of concrete mixes from a fortuitous accident to an exact science. Although the water cement ratio was supposed to apply only to the usual wet mixed concrete, it was found that it applied equally well to the semiwet mix used in making block. But dubious block producers had to prove this to their own satisfaction—and did. Ben Wilk recalls working "on some tests where we took the amount of water needed to give the right consistency for block and we called that 100 per cent. Then we used 5 % and 10% more water, then 5% and 10% less water. We found that the excess water put us on the wet side of the Abrams curve and the smaller amount of water put us on the dry side, while the right consistency followed the Abrams curve for ratios of cement to aggregate almost exactly."

The work year for the block industry was also expanding with the technology. Before 1920, most of the concrete block plants in the northern part of the United States closed from three to four months during the winter. Thus when Spring came, the small stocks which had been accumulated disappeared quickly, and the producer had to play catchup all summer. Cold weather involved several difficult problems for concrete block manufacturers. Since it was

impossible to work the banks or pits for sand, gravel, and stone, sufficient aggregate had to be stored to run the plant for the entire winter—and for a plant producing 3,000 block a day, this meant some 4,500 cubic yds. of storage space. In the few plants that attempted winter production, small reserves of raw material were kept from freezing by a steam coil installed underneath the pile, but major reserves had to be stored in large outside piles and the aggregate thawed as needed by several perforated pipes, five or six feet long, attached to the steam line. These pipes were driven into a portion of the pile, the area covered up with tarpaulins, and the steam turned on.

The principal drawback to winter operations, however, continued to involve the storing of large quantities of block, which meant tying up considerable working capital in finished goods inventory. But slowly the advantage of winter operations began to overcome the drawbacks. A growing number of contractors who poured foundations during the summer began using concrete block—when it was available—for winter construction. Materials such as cement were often cheaper in the winter, and it was also possible to provide continuous employment which made for more contented workers, lower personnel turnover and greater plant efficiency. When construction opened with a rush in the Spring, those block plants that had worked over the winter had a large supply of well cured block on hand and could give their customers good service. As a result of all these advantages, the stable, well financed members of the block industry began to operate year-round in the early 1920's.

During the same period, an immigrant bricklayer named Sigurd Bo was using his Scandinavian thrift to add to the technology of cinder concrete. Bo watched private scows dumping cinders into New York harbor under the cover of night while the city was paying out large sums of money to keep the harbor dredged. Bo suspected that most of the cinders could still be used as fuel. When he analyzed them, he found from 5 to 50 per cent of the fuel potential remained. He also knew that cinder aggregate was better with all the impurities burned out. So Bo developed a process for recovering the fuel and eliminating the impurities from cinder aggregate. It was patented in 1923 and assigned to the Cinder Products Corp. in Lockport. N.Y. five years later.

Meanwhile a revolution was taking place in the development of a wide range of other lightweight aggregates (described in detail in Chapter X).

The National Bureau of Standards had been assigned the task of research and experimentation on lightweight aggregate for use in Navy vessels in World War I. The first NBS working plant was a down-draft bee-hive kiln near Birmingham, Alabama, where enough aggregate was produced to supply the 3,000-ton "USS Atlantus," launched the following December at Brunswick, Georgia. The successful performance of this first vessel resulted in arrangements for letting two contracts for quantity production for other concrete ships then underway.

The fact that a lightweight concrete containing a cellular aggregate could be successfully employed in the building of oceangoing ships with 5" thick hulls and remain completely impermeable to moisture intrigued

designers and builders, and later established confidence among engineers and architects alike in the long-time performance of lightweight concrete. In 1923, Dan F. Servey, a graduate engineer and later president of the Haydite Company of Kansas City, produced the first block of expanded shale concrete masonry. The major block plants of the nation turned quickly in this direction, for it gave them a lightweight block with a high degree of insulation, and a uniform compressive strength equal to a heavy weight block.

Exhaustive physical tests confirmed the fact that expanded shale aggregate would adequately meet all concrete block specifications, and from that day on, the development of lightweight aggregate enhanced the esteem of the concrete masonry industry in the construction world. Haydite, the lightweight burned shale or clay aggregate, patented in 1918, was used increasingly by block producers during this period until by 1927, more than a hundred block plants were turning out Haydite block-30 to 35 per cent lighter than ordinary sand and gravel units.

But the real excitement of the golden decade of concrete block was not generated by technical developments. It came from one of the most effective promotional campaigns ever designed for a building product. The element—besides consistency of quality—most lacking in the early days of concrete masonry was imaginative promotion. Francis J. Straub took a giant step in the right direction, but he was one man—and an industry approach was badly needed. That approach was finally provided in the early 1920's under the leadership of a group of aggressive and imaginative young men in the Cement Products Bureau of the Portland Cement Association.

Their most remarkable single accomplishment actually penetrated the White House in Washington and enlisted the implied endorsement of the President of the United States for concrete block. It was the sort of corny, zany adventure that couldn't happen in the sophisticated society of 1970. But in 1923—in the days of Prohibition and simple verities and a total lack of social complexities—it could happen. And did.

In 1920 and '21, the PCA conducted a series of 31 home builders' short courses. Attendance varied from ten to 200 and included mostly block manufacturers, contractors and architects. Although the courses were designed primarily to furnish block producers with the information and inspiration to go out and sell their product, it was soon discovered that architects and contractors were equally interested in the possibilities of residential construction with concrete block. Because architects weren't familiar with detailing concrete masonry, the PCA published 25,000 copies of a house plan book that had to be reprinted twice in three years to keep up with the demand.

Encouraged by this show of interest, the promoters raised their sights and actually zeroed in successfully on the most visible target in America: the White House. The rationale for the promotion was the 100th anniversary of the writing of the song H o m e S w e e t H o m e , a bit of Americana dear to the hearts of farmers,

merchants and presidents alike. Why not, reasoned the concrete promoters, rebuild the home that inspired the song—by an odd coincidence built of white stuccoed concrete masonry—and make it the center-piece for the observance of a "Better Homes Week?" And where, they asked, would it attract the most attention? On the White House lawn, of course. And so they took this outrageous proposal to Washington—as part of a nationwide program of 36 widely scattered demonstration homes—and ended up with the active participation of three U.S. presidents.

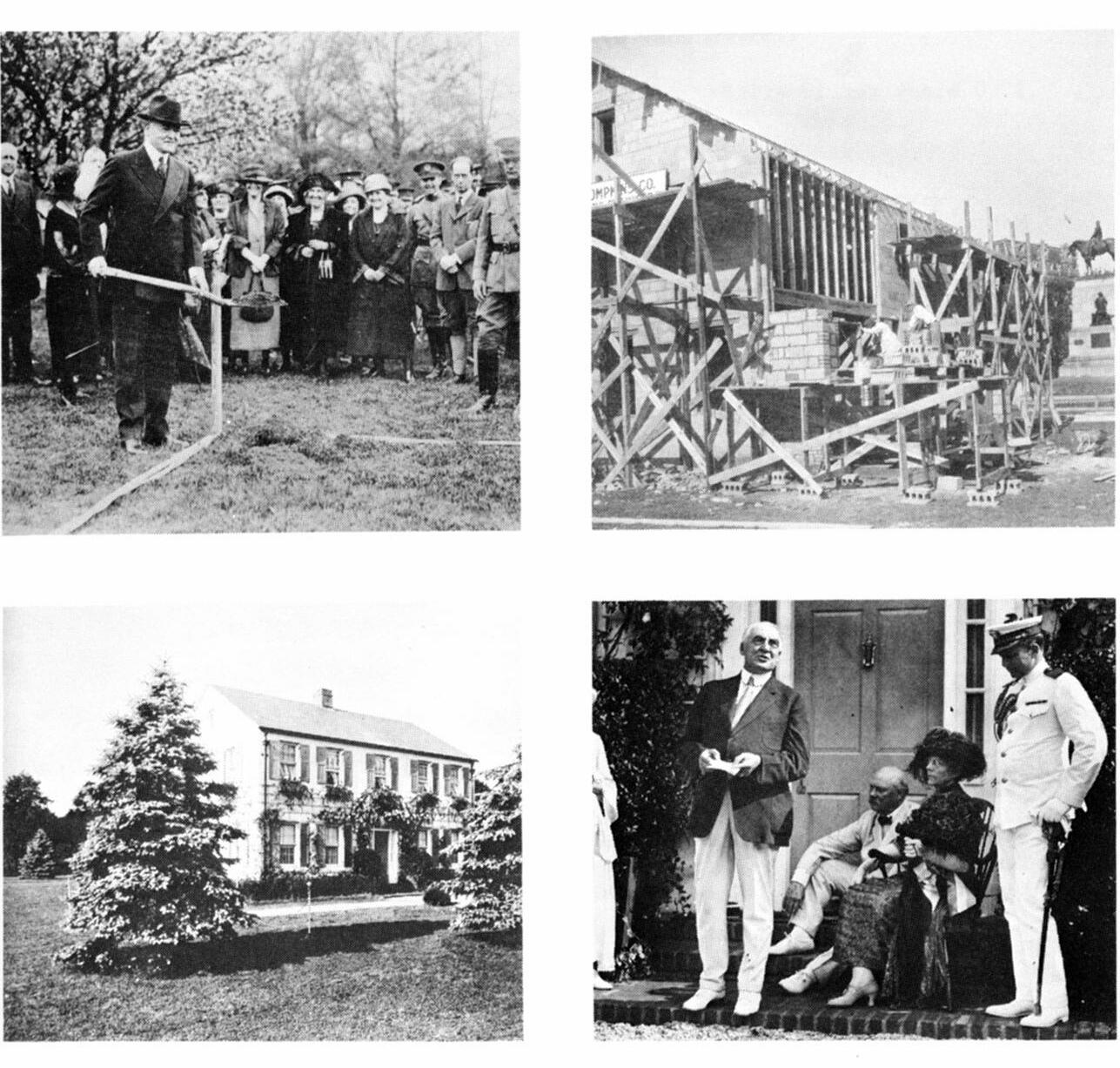

Secretary of Commerce Herbert Hoover broke ground for the house co-sponsored by the General Federation of Women's Clubs and the Better Homes in America League—in mid-1922. It was officially dedicated by Pres. Warren G. Harding on June 4, 1923. During the months it stood on the White House grounds, it was inspected by hundreds of thousands of visitors, including the new President Calvin Coolidge, who toured it just before it was given to the Girl Scouts of America as a headquarters building, opposite the Corcoran Art Gallery in Washington.

In addition to the people who saw it in person, the house was pictured and written about in hundreds of newspapers and magazines, and a motion picture — ostensibly from the General Federation of Women's Clubs but bearing the fine promotional imprint of the concrete people — was shown in thousands of motion picture theaters throughout the country. The film had an added impact because it was the last public appearance of Pres. Harding before he departed Washington on the lengthy trip during which he contracted pneumonia and died.

Such promotions played a major role in the golden decade of concrete masonry during the 1920s, a period when all America was spending, and a large part of the money was going into building. The cement and concrete block industries were determined to move massively into this market, and they managed during the 1920's to knock down one-by-one the principal obstacles — unfavorable fire insurance rates, punitive building codes, total lack of product standardization — that stood in their way.

Probably the most stubborn roadblock in the early promotion of concrete masonry was the refusal of fire insurance companies to grant this product a competitive and realistic rate. The problem became a primary order of business at the first convention of the Concrete Products Association, where it was determined to set up an immediate program of fire tests with the Underwriters Laboratories to prove to a dubious insurance industry the firesafety of concrete block. The units to be tested were manufactured under the direction of the PCA's Cement Products Bureau in Sept., 1922. (The Straub cinderblock had been firetested six months earlier.) The fire endurance tests-conducted on six 10 x 11' panels of 8 x 8 x 16" block and twelve smaller panels-began in December, 1922 and lasted for eighteen months. A final report was published by the Underwriters' Laboratories on May l, 1924. The performance under fire of the sand and gravel block was almost identical with that of the Straub block, and both received a classification of 2½ hours as a fire retardant.

But this was only a first step. High fire ratings were of no value unless the construction world knew about them, so block producers all over the country began sponsoring a series of demonstration fires in small test houses built of concrete masonry. The first demonstration was held in Lancaster, Pa. where the test building was 13 feet high and composed of two equal compartments. Oil soaked wood was piled in each compartment and a load of ten tons of pig iron was placed on the roof. A maximum temperature of 2,200 degrees F. was reached in one half hour, and at the end of an hour, the fire department turned a hose on the walls with no visible damage. The test was so effective in improving the local market for concrete block that the show went on the road, first to Chicago (for the fiftieth anniversary of the Chicago fire) then to Providence. R.I., Pittsburgh, Pa., New Kensington, Pa., Columbus, Ohio and points West. These demonstrations were planned to interest city officials, architects, engineers, builders, and prospective home owners in concrete block. And if they weren't interested, they were certainly aware something was going on. On the day of each test. the local fire department would go tearing through the streets of the city, attracting an audience to the burning. The show played to SRO crowds in Phoenix, Springfield, Cicero, Topeka, Birmingham, Indianapolis, and Los Angeles. In Minneapolis, the burn-out was staged on a main thoroughfare in the downtown area, and in Joplin, the fire was permitted to rage for 3 ½ hours.

What did all this heated activity accomplish? When the first block home was set afire in 1921, practically all states rated concrete masonry on a par with or below frame construction in fire resistance. By 1924, the National Fire Council was giving concrete block walls a two-hour fire retardant rating, and this classification was improved to 2 ½ hours in 1926 and three hours a year later. These ratings were printed and given wide distribution by the Concrete Products Association. Result: local and state insurance rating bodies began revising their schedules to reflect more favorable rates for concrete block, and by 1927, block was receiving the same rate as clay brick in 34 states.

Building codes were also getting concentrated attention during the same period. Until the mid-1920's, there were many building code provisions all across the country that unjustly restricted the use of concrete block. The 33 per cent maximum air space, for example, was outrageously unfair if a block with a greater percentage of air space could meet the gross area crushing strength test. Similarly, regulations calling for filling of hollow concrete block with concrete when the block were used in foundations increased the cost of the building unnecessarily. Also, many codes limited the height of concrete buildings and a few cities—notably Chicago— prohibited the use of hollow concrete block in foundation walls at all. The effect of this ruling was disastrous. For example, while Detroit was consuming 15 barrels of cement per year per capita in 1923, Chicago was consuming less than one-half barrel, largely because of the restrictive Chicago building code.

Thus much of the early effort of the various organizations promoting concrete block was aimed at getting these building codes revised. It was a tough, no-holds-barred battle, fought on every front—and its principal battle lines were usually around the big city building departments. In some instances, public officials more-o r-less

openly solicited "contributions" to permit block construction, and in some instances contributions were made. On a slightly higher plane, the specifications then being drawn up by the American Concrete Institute to control the quality of block also helped build credence with cities developing codes guided by the ACI specifications.

Jack Freedman of the Plasticrete Corporation in Medford, Mass. recalls that "in the Boston area only solid 12" concrete block was permitted below grade, making it very hard to work because of the weight. In 1922, with the help of Professor Walter E. Voss, of Wentworth Institute, I went before the State Legislature to have this ruling changed to 12" hollow and from then on, blocks in the Boston area market were used almost exclusively for housing foundations until poured concrete came in to destroy our market."

Similar efforts were taking place all across the country, and they were remarkably successful. By 1928, more than eighty city building codes had been revised to eliminate practically all of the legal obstacles to the increased use of concrete block. And in changing the building codes, the PCA and CPA missionaries were making sizeable progress before the brick and tile competition awakened to the threat. Quickly they began deprecating concrete block on every front possible. They also urged the bricklayers and masons unions to oppose building code changes and the inroads of concrete block on construction sites.

Convincing the bricklayers they should handle concrete block — even in the face of a serious shortage of brick in the midst of a booming construction market — was a tough job, and sometimes it took tough measures to get it done. A. V. Johnson of Omaha's Ideal Cement Stone Co. recalls that when our firm started making concrete blocks, the bricklayers refused to handle them because they were fearful that the fewer hours of labor required to lay a block wall would seriously affect their annual income. The founders of our business, Earl Peterson's father and uncle and two others, were former stone masons so they not only made the blocks, but marched out of their plant, rounded up crews of masons, and laid up the block themselves. The bricklayers remained adamant for almost three years, then went to Nels Peterson and said: "Will you get out if we agree to lay the block?"

He got out—and that crisis was resolved, just as it was being resolved in dozens of other cities across the country. But even the successful modification of building codes in favor of concrete masonry sometimes created almost as many problems as it solved. In 1928, for example, a large concrete block manufacturer told a group of his associates:

"A building code, no matter how carefully worded, is worthless unless some provision is made for proper enforcement. In other words, it must have teeth. A properly enforced code is of priceless value to the reputable products manufacturer, for it not only guards him against shoddy and unscrupulous competitors, but is also an instrument of confidence—building in his community.”

"Everything hinges on proper enforcement, and it is here that the products manufacturer can play a large part in making his code of value to himself. In the first place. he should make his own product of a high enough quality to comply with the code and enough higher to allow himself a safe margin if he has to deliver green products in order to complete some specific job falling under the code. Second, he should assist his brother manufacturers in attaining this standard of quality through personal contact or his trade association. And if his competitor refuses to make a product that complies with code requirements, then steps should be taken to encourage rigid building inspection and see it put off the market as harmful to all concrete products."

Once the campaign to revise insurance rates and building codes was well underway, the concrete industry representatives turned their attention to standardizing the product coming out of concrete block plants. In the early 1920s, the concrete block industry was in a chaotic state with respect to the sizes of concrete block. In that year, block were manufactured in 30 different lengths, 20 different widths, and 26 different heights. Architects were severely handicapped because they had no way of knowing what sizes would be delivered to the job until the block actually arrived. They were, therefore, unable to dimension their buildings with any assurance that the units actually delivered would correspond to the dimensions.

During 1923, this confusion stimulated the industry to request the Division of Simplified Practices of the National Bureau of Standards to cooperate in establishing standard sizes for concrete block. The American Concrete Institute, the Portland Cement Association, the Concrete Masonry Association, and the machinery manufacturers were all represented in preliminary conferences, and on Oct. 16, 1924, a general conference was held in Chicago. A schedule of sizes of concrete block, proposed by Committee K-1 of the American Concrete Institute, was considered and standard sizes were adopted, restricting concrete block to one length, one height, and four widths, and by 1927, ninety-five per cent of all concrete block were produced in conformity with these standards.

Block had by then increased its share of the masonry market from 13 per cent (in 1922) to 20 per cent, and speakers at the CPA convention in 1927 emphasized the newly developing use of concrete block as a backup material. For the first time, overcapitalization was stressed by one speaker who pointed out: "I'm not making a plea to return to the backyard method of plant operation, but I do believe that the manufacturer who meets these new challenges successfully will have a plant capable of running two or even three shifts a day rather than a plant operating at capacity only part of the time."

An advertising agency executive named Austin F. Bement admonished that same convention:

“As an association, you can afford to undertake in cooperation, the important work of general public education. Five per cent of your last year's gross volume of sales would amount to $7 million. Many industries particularly while young, can and do afford to set aside 10 per cent, and

in some instances, even a larger proportion of their gross sales, for the purpose of protecting their present volume of business and to build new and enlarged markets.”

“Let us be extremely conservative in considering your problem from the standpoint of the industry as a whole and consider what you could accomplish through the appropriation of t w o p e r c e n t of your gross sales. With $2.8 million to expend annually in educating the American public to accept and demand concrete products, you could do a considerable job nationally, to supplement local and regional efforts.”

“You gentlemen are interested in a fundamental thing—building a market for concrete products— and you have banded yourselves together behind a program which seems admirably well rounded—on paper. If it fails it is not the fault of the program—it is your fault. Your potential. market lies in the 2.4 million homes o f the United States. In the final analysis, there is no reason for you to expect the architect, builder or contractor to do your selling for you.”

The conventions in 1928 and 1929 that ended concrete block's golden decade began to take on the overtones of conservatism that tend to infiltrate revolutions once they have achieved their original goals. In 1928, most of the talks at the CPA convention dealt with relatively sophisticated programs of sales promotion to meet the competition now acutely aware of the inroads of this new industry. Rock Products reported that “Conversation in the lobbies adjacent to the convention hall indicated that the industry had ‘grown up’ and was assuming a seriousness not recognizable at previous conventions.” The same atmosphere prevailed in 1929, when one of the CPA's prime movers, Wallace I. Harris, suggested that the Association's work was too big to be left to volunteer workers and the CPA now needed some paid employees to give full time to the job of popularizing concrete block with the public. This was in February, 1929, when the economy was still burgeoning and the prosperity balloon gave promise that it might grow indefinitely without bursting.

Block producers were still looking ahead then. Had they been inclined to take a backward look in 1929, they would have seen the most spectacular decade of growth and progress in the concrete block industry, before or since. Production of concrete block during this period increased 774 per cent, from 50 million units in 1919 to a peak of 387 million equivalent 8 x 8 x 16" units in 1928. Production increased every year with the exception of 1920, when a cement shortage forced some plants to close.

During this same period, the number of concrete block plants declined about 40 per cent. In 1920, there were about 7,000 plants in the United States; this had decreased to 4,140 plants by 1928. Immediately after World War 1, the number of block plants increased dramatically, and very quickly capacity began to outstrip demand not only by the influx of new producers, but even more by the increased productivity of improved

block machines, and this resulted in intensified competition that drove many of the smaller block producers out of business. The 4,140 plants in 1928 were producing 700 per cent more block than 7,000 plants in 1920. Between 1921 and 1928, the number of concrete block manufacturers making more than one million units annually increased from one to 28.

Jesse Besser, thinking back on the golden decade of concrete block, singles out two developments as the most important of that era: The substitution of plain, smoothfaced block for the rock facing of virtually all block up to that time, and the development of modular dimensions when a good many new block makers needing such boundaries were coming into the business. At the beginning of this decade, a plant producing a thousand block a day was large, and there was a conscious effort to make the units look like rock; after all, stone was used to build basements, and wasn't that what block was for? By the end of the decade, this point of view seemed as obsolete as the pyramids of Egypt — or the possibility that anything could happen to derail the headlong express plummeting the American economy to progressively more spectacular way stations of prosperity.

The greatest coup of the block promoters in the early days—or in any period, for that matter— was the building of the replica of the concrete house that inspired the writing of Home Sweet H o m e on the grounds of the White House where it was seen by hundreds of thousands of visitors. Then Sec. of Commerce Herbert Hoover turns over the first shovelful of dirt for the foundation of the house. Workers swarm over the halffinished structure. After completion it is dedicated by President Warren G. Harding, standing at the front door, surrounded by assembled dignitaries.

TYPICAL COST OF MANUFACTURING, 1928 1,200 block per 10 hr. day Size standard 8” x 8” x 16”

Materials & Labor

Cement Aggregate Direct Labor 1 operator at $6.00 1 off Bearer at 4.00 2 helpers at 3.50 1 Mixer Man at 4.00 250 operating days per year Cost for 1,200 block 70 sacks at $0.65 $45.50 18 cu. Yds. at $2.00 36.00

6.00 4.00 7.00 4.00

Daily Labor Manufacturing Liability Insurance

Expense Water (Per Day) Fuel (Curing & Heat) Power & light Repairs to equipment Breakage Miscellaneous 21.00 1.50 .60 1.50 1.50 1.00 1.75 1.00

TOTAL DIRECT COST 110.40 Cost for block .037

.018

.007 .092

General Expense

Depreciation-Equip. 25% of $4,750.00 Depreciation-Bldgs. 5% of 5,400.00 Interest on Invest. 7% of 20,150.00 Taxes & Insurance $1,187.50 270.00 1,410.50 300.00

Land rental 6% of 5,000.00 300.00

General Expense Per Year General Expense Total Daily Cost General Expense Total Yard Cost Per Block 3,468.00 13.87 .012 124.27

$.104

To this cost must be added selling expense, delivery cost and profit to determine selling cost.

TYPICAL ESTIMATE CONCRETE BLOCK MANUFACTURE, 1928 Production – 1,200 – 8’ x 8’ x 16” block daily. MACHINERY SCHEDULE BUILDING INVESTIMENT

Machine Pallets at 30¢ each Cars and Tracks or

Lift Trucks and Racks Mixer Motor $1,500.00 450.00

1,100.00 400.00 200.00 Main Building Curing equipment, including boiler and pricing Curing Tunnels Material Bins $2,500.00

900.00 1,200.00 600.00

Shafting, Belts, Etc. Screen and Material conveyor Installation 7 wiring Tools 100.00

500.00 250.00 100.00 Contingent 200.00

Miscellaneous 150.00

TOTAL MACHINERY TOTAL BUILDING TOTAL PLANT INVESTMENT ADDITIONAL OPERATING CAPITAL TOTAL CAPITAL INVESTMENT $4,750.00 5,400.00

$10,150.00 10,000.00

$20,150.00