Selfbuild

And much, much more including inspiration galleries, videos and podcasts, regular news updates and categorised advice sections

Europe’s leading, award-winning window brand for over 90 years. Innovative, high-performance architectural window and door systems for self-build, renovation and Passivhaus projects.

Outstanding quality, bespoke design, and exceptional thermal performance. For further information, please visit uk.internorm.com.

Roadstone FlowPlus is the next generation self-levelling cementitious screed developed in conjunction with the ARDEX Group.

Roadstone FlowPlus is the next generation self-levelling cementitious screed developed in conjunction with the ARDEX Group.

• Provides a quick, smooth and level surface with minimal leveling

• Ease and speed of installation

• Provides a quick, smooth and level surface with minimal leveling

• Suitable for all domestic and commercial applications

• Ease and speed of installation

• Suitable for all domestic and commercial applications

“What’s very clear is that self-builders really need all the help they can get at this point in time.”

Across the island of Ireland there are people, young and old, who are in the process of building their own home. Doing their research, getting their dream plans finalised. Pouring their blood, sweat and tears into their project, not to mention their life savings.

It’s a very rewarding journey to set out on and from the point of view of the housing crisis, a most commendable endeavour.

Yet, somehow, governments don’t seem that keen to help people build, be it in the countryside or not. After all, the ROI government’s plan to offer serviced sites in clusters hasn’t exactly panned out (page 12).

Some say the lack of enthusiasm is due to our rural landscape being a major feature of our tourism industry. In other words, dotting the countryside with one-off houses wouldn’t look the part. Others argue building out in the sticks encourages car use, at a time when we’re trying to reduce our dependence on fossil fuels.

But at the end of the day, don’t we need more homes to be built? They can’t all be apartments. There needs to be a mix of solutions. There’s no point complaining that there’s a rural exodus if we don’t allow people to build to live there.

What’s very clear is that selfbuilders really need all the help they

can get at this point in time.

Pre-Covid, homes we featured in the magazine were costing €250k to €350k, contractor led, now we’re looking at €400k homes. Sure, with house prices sky high it still makes sense to build, but economic uncertainty is putting many of us risk-averse folk off.

We have 2,600+ self-builders who’ve signed the petition to get rid of onerous development charges and water connection charges in ROI. We’re advocating for that waiver, which last year saved self-builders thousands and thousands of euros on their projects, to apply to self-builders only. There is no need to line the pockets of developers.

We’ve just sent a letter to the ROI government to reinstate the waiver on the back of the petition. Hopefully people power will prevail; we’ll keep you posted.

The second stage of being On Site deals with first and second fix. It will all move very fast at this stage, so preparation is key.

In the meantime, happy building!

Astrid Madsen - Editor astrid.madsen@selfbuild.ie

If you have a question, want to share some insights, or simply let us know how you’re getting on with your project, we’d love to hear from you for our Letters page. Email us at letters@selfbuild.ie

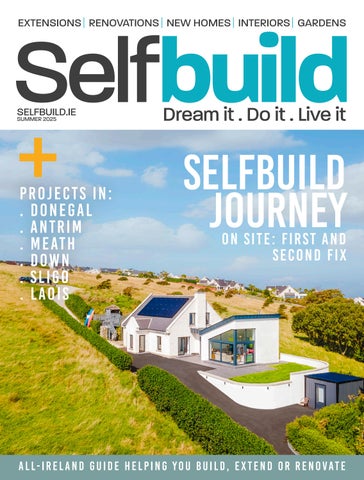

Front Cover Photograph: John Mee,

24 The test of time

Sarah and Paul Foster’s selfbuild in Co Meath shows what can be achieved with good design choices.

34 Framing the future

Ryan Daly chats about how his timber frame new build delivers on both energy efficiency and aesthetics.

46 A shore thing

How Michael and Tina Clancy transformed their coastal holiday home in Co Sligo into a sustainable, energy efficient, forever home.

56 Sydney vibes, Belfast style

All articles equally cover the 32 counties; when we refer to the Republic of Ireland the abbreviation is ROI. For Northern Ireland it’s NI.

Phil and Jennifer Baker’s Belfast home gets an Aussieinspired makeover, swapping a cold, disconnected sunroom for a bright, open extension that effortlessly blends indooroutdoor living.

64 Building a cosy home

Áine Carey’s direct labour new build in Co Donegal has the cosiness and character of a cottage that’s been lovingly restored.

70 Garden with levels

A Co Cavan garden design that deals with a sloped site and unsightly retaining walls.

74 Letters

Issues with upgrading the energy rating on an existing home, drying out the house, and how to flush €15k down the drain.

76 Is blockwork still the cheapest way to build?

Quantity surveyor Keith Kelliher looks at whether Ireland’s most popular building method is still the most cost effective.

78 Are roof windows a good idea?

Passive house consultant Seán McKenna weighs the benefits of incorporating roof windows into your design, and why you should steer clear of roof lights.

80 Throwing good money after bad

Eco builder Liam Walsh argues 40 per cent of grant-aided energy upgrades aren’t worth the money.

82 Savings room by room

Where to spend to save, plus some hacks to get the most bang for your buck on your new interiors.

84 Garage conversions

Engineer and architectural designer Les O’Donnell looks into how to transform your garage into a living space, and offers design ideas for granny flats.

88 Overview

An introduction to the second part of Stage 5 of your Selfbuild Journey: On site, dealing with first and second fix.

90 First fix

Watchpoints at the early stages of wiring and electrics.

96 Second fix

Watchpoints at the fit-out stage.

100

Watchpoints when it comes to finishing the external walls and putting up roof coverings.

Roof covering options, from traditional to more modern.

Liam Canavan chats through how he’s fitting out his timber frame extension, from installing the wall insulation himself, to tiling and drywalling.

Gavin Connolly shares the secret ingredients that’ll have you breeze through the construction phase of your self-build, with tips and advice from his own experience with the trades and suppliers.

CONTACT info@selfbuild.ie

EDITOR

Astrid Madsen astrid.madsen@selfbuild.ie

DEPUTY EDITOR

Heather Campbell heather.campbell@selfbuild.ie

DESIGN

Myles McCann myles.mccann@selfbuild.ie

Shannon Quinn shannon.quinn@selfbuild.ie

Megan Buckley megan.buckley@selfbuild.ie

MARKETING

Calum Lennon calum.lennon@selfbuild.ie

Victoria Hunter victoria.hunter@selfbuild.ie

Rebecca Ferris rebecca.ferris@selfbuild.ie

Erin Mason erin.mason@selfbuild.ie

SUBSCRIPTIONS

Becca Haslett becca.haslett@selfbuild.ie

ADVERTISING SALES

Emma Phillips emma.phillips@selfbuild.ie

Joanna McConvey joanna.mcconvey@selfbuild.ie

Lisa Killen lisa.killen@selfbuild.ie

Maria Toland maria.toland@selfbuild.ie

Nicola Delacour-Dunne nicola.delacour@selfbuild.ie

ACCOUNTS

Karen McLeigh karen.mcleigh@selfbuild.ie

Leanne Rodgers leanne.rodgers@selfbuild.ie

SALES DIRECTOR

Mark Duffin mark.duffin@selfbuild.ie

MANAGING DIRECTOR

Brian Corry brian.corry@selfbuild.ie

CHAIRMAN Clive Corry clive.corry@selfbuild.ie

DISTRIBUTION

Delivering windows and doors that are crafted to last generations.

Redefining quality and luxury for almost a century. Our windows and doors are not just built to last, but crafted to inspire.

For more information visit nordan.ie

NorDan’s Timber/Alu-Clad Windows combine the classic warmth and beauty of timber on the inside with a tough weather-resistant aluminium cladding on the outside.

Merging timeless elegance and enduring strength, NorDan’s Timber/Alu-Clad Doors are perfect for those seeking stylish yet practical modern living solutions.

The ideal solution for modern homes and commercial properties, offering a huge range of design possibilities, enhanced energy efficiency, and premium performance.

The perfect solution for the contemporary needs of residential and commercial properties that highlight energy efficiency, low maintenance, and versatile design options.

NorDan’s Entrance Doors have been designed with durability and energy efficiency at the core. With contemporary and traditional designs available, there is a perfect match available for your perfect welcome home.

New ROI planning minister John Cummins is considering making it easier to build modular and cabin-style homes in back gardens without needing planning permission, to help tackle the housing crisis.

Right now, you can build extensions up to 40sqm connected to your main home without needing permission. But if you want to put up a detached structure, even if it’s the same size, it has to get approval. The new proposal would change that, allowing freestanding modular units to be built under the same 40sqm limit without the usual planning red tape.

The proposal will go through public consultation; there will also be a government evaluation how feasible these changes might be. As it stands, there’s no specific timeline for when we might see new regulations.

“I see it as the ability of people to be able to have that intergenerational movement within their own community and for younger people to live independently,” said

Minister of State Cummins.

“I’m not saying that this is a panacea, that it’s the solution to the housing crisis. I’m saying that this is a potential option that will suit certain circumstances,” he said.

If these changes go through, the exemptions would apply only to structures up to 40sqm. Anything bigger would still need full planning permission. The Minister of State added that it would be down to local authorities to look after regulations for the dwellings – despite not being subject to planning.

“It’s a matter for the local authorities, in the context of ensuring that things are compliant with planning and building standards. In the same way as if it…was attached to the main dwelling house,” he said.

Self-builders in NI using the Planning Portal are facing higher costs. As of April 1, 2025 self-builders looking to secure outline planning permission had to pay £10 more, with fees increasing from £505 to £515. Reserved matters applications (following an outline approval, adding details like design) increased from £505 to £515 and a full planning application (detailed application for a single house) has increased from £1,014 to £1,035.

Planning applications for extensions, alterations or improvements to an existing house, new fences, walls, gates or outbuildings within a home’s boundary, increased from £340 to £347.

With a new ROI government in full swing, it seems grants and financing models that help more homeowners afford upgrades, particularly older people who may face financial or logistical barriers, are top of the agenda. Community-driven initiatives are also being supported, with group retrofitting schemes allowing neighbours to collaborate on upgrades and share costs.

Low-interest loans for energy improvements will remain available under the Home Energy Upgrade Loan Scheme, covering upgrades costing between €5,000 and €75,000. Measures to move older homes off oil-based heating systems are also being pushed, with sustainable biofuels promoted as a short-term alternative for homes unable to undergo immediate retrofits.

Grants for solar storage batteries could also be reintroduced; the government grants for batteries were axed in 2022.

Make the greener choice for your home, upgrade your existing central heating with an eco-friendly, low noise Midea Heat Pump. Air source heat pumps are the low-carbon future of home heating which integrates heating and domestic hot water into one system.

The future of heating, renewable energy is the greener, cleaner way to heat your home. Midea’s air source heat pumps are the costeffective way to lower your energy bills and switch to a low-carbon way of heating your home. Make yourself at home and start saving with Midea Heat Pumps.

OUR MIDEA MONOBLOC HEAT PUMP COMES WITH A MARKET LEADING 10 YEAR WARRANTY.

While Vacant

drawdowns have increased, the number of completed projects still falls short of government targets.

While the Vacant Property Refurbishment Grant (VPRG) has seen an increase in grant payments in 2024, a significant gap remains between the number of applications, approvals and actual drawdowns.

By the end of December 2024, over €77 million had been paid out for the refurbishment of 1,449 homes under the scheme. However, this figure is far below the government’s revised target of 4,000 homes by 2025.

Reflecting on the latest data, Minister for Housing James Browne said: “The rapid increase in grant payments shows the scheme is growing momentum, helping to tackle vacancy and providing much-needed housing.”

To date, Donegal County Council holds the highest number of applications (1,042), approvals (715) and grant payments (93). Cork County and Mayo County Councils had the second and third highest number of applications respectively.

The Vacant Property Refurbishment Grant scheme, introduced in 2022, aims

to revive vacant and derelict properties into permanent homes or rental units, with grants of up to €70,000 available upon completion of works. As of the end of 2024, over 11,300 applications had been received, and 7,700 approvals issued. But the number of drawdowns lags far behind the figures hoped for when the grant was first launched.

Critics point to one key obstacle in the programme: the requirement that homeowners fund the work upfront. Although 1,449 drawdowns were reported at the close of 2024, the scheme’s dependence on post-completion payments is a big hurdle for many homeowners, particularly those lacking the resources to cover refurbishment costs in advance.

That’s why Minister for Housing John Browne is considering stage payments for those availing of the grant, acknowledging that it’s difficult for families to avail of it as the grant has to be paid upfront. Mortgage providers must see that you can finance the entire cost of the work before starting.

According to the ROI Programme for Government, the vacant and derelict property refurbishment grants, worth up to €70k, will be extended to 2030. These grants, funded by the Croí Cónaithe (Towns) Fund, will undergo regular reviews.

The government has committed to ensuring every local authority has an expanded vacant property team in place to improve access to support. It will continue the Local Authority Home Loan bridging finance to support the use of the grants, and will roll out a new Local Authority Mortgage for vacant properties.

A new ‘Above the Shop’ Living Refurbishment Grant will be launched to convert vacant spaces above retail premises into residential use. Recognising the additional complexity involved in such projects, the scheme will provide extra funding, alongside pilot incentives like commercial rates reductions for property owners. The cost of infrastructure upgrades has also been flagged as a barrier to bringing derelict homes back into use. To tackle this, the programme includes a proposal to “credit existing water and wastewater connections” in the calculation of new connection charges.

In July 2024, in an attempt to help fill the funding gap, the government introduced the Local Authority Purchase and Renovation Scheme (LAPR), which applies to all properties eligible for VPRG.

Under the new LAPR, first-time buyers or Fresh Start applicants struggling to secure funding from commercial lenders can apply to their local authority for a LAPR to buy or renovate a VPRG eligible home. A key feature is the inclusion of a bridging loan. Tied to the VPRG this will boost applicants’ borrowing capacity and project viability. The bridging loan is repayable once the grant is paid out. This approach allows more funding for renovation works than typical bank loans.

The new ROI Programme for Government offers modest updates to existing schemes but falls short of providing the supports self-builders need.

The new Programme for Government takes a cautious approach towards helping selfbuilders and home improvers, focusing on protecting and expanding existing supports rather than introducing bold new initiatives.

While schemes such as Help to Buy, the First Home Scheme (FHS) and energy retrofit grants are set to continue with minor updates, the lack of substantial new measures is apparent.

Help to Buy will remain in place until 2030 and the FHS has been expanded to include first-time buyers of secondhand homes.

A major blow to self-builders

is the omission of any extension (or any reference at all) to the development levy waiver, which has been a key costsaving measure. Without this waiver, self-builders now face potentially thousands of euros in additional costs (see below). Instead, the new coalition government’s housing strategy centres on incremental improvements to existing schemes, such as streamlining grant processes, expanding refurbishment incentives and promoting energy efficiency. Proposals to cut VAT rates on building materials has also not been taken up by the new government.

The Local Authority Home Loan scheme, which is open to self-builders, will undergo significant changes, including the creation of a centralised administration point and adjustments to loan limits to reflect rising house prices. An expansion of the scheme to assist mortgage holders with non-bank lenders is also under consideration.

Addressing water infrastructure issues remains a key focus, with ongoing support for group water schemes and private well grants. Additionally, the rollout of the Special Rural Water Investment Scheme — also known as the

Unsewered Villages Scheme— aims to tackle long-standing issues in areas lacking adequate wastewater infrastructure.

Alongside these measures, the government is promoting Modern Methods of Construction (MMC) to speed up housing delivery and improve sustainability. A dedicated fund will support MMC but details are unclear. The initiative also includes a push for timber frame in new builds, as part of the government’s broader environmental goals.

Westport Councillor slams development levy’s impact on young couples in rural areas, calling for exemptions.

Independent Councillor John O’Malley has renewed his call to remove development levies for young couples building homes, stressing the financial strain on those trying to settle in rural areas.

Cllr O’Malley criticised the levy, describing it as a barrier to homeownership for local families.

“Building a house already costs at least €300,000 if you’re fortunate enough to have a site. Adding the development levy on top of that makes it nearly impossible for young couples to get started,” he said. “We should be encouraging families to settle in rural Ireland, not penalising

them with additional costs.”

Cllr O’Malley called for fairer solutions, such as exempting local first-time homebuilders from development levies while applying them to wealthy buyers or large-scale developments.

Self-builders currently have to pay Section 48 development levies to their local authority to pay for infrastructure costs such as roads. These can amount to tens of thousands of euros in certain areas.

According to analysis by Selfbuild, for a 200sqm house self-builders were paying on average €6,805 to their local authority for the Section 48 levy, ranging from €1,080 in Co

Monaghan to €30,301.50 in Dún Laoghaire-Rathdown County Council’s new Cherrywood development area.

In April 2023, the ROI cabinet introduced a temporary 12-month development holiday as one of several measures to stimulate house building. The waiver period was extended a number of times, with the final deadline for commencement of qualifying new builds set for December 31, 2024.

Self-builders who started construction before that deadline now have until December 31, 2026, to complete their projects. The scheme originally required the house to

be completed by the end of 2025.

The Business Post reports Minister Browne doesn’t intend to extend the waiver, as developers haven’t started on many of the projects that got the waiver.

Selfbuild has sent a letter to the minister outlining that 2,600+ self-builders have signed a petition to scrap the scheme for self-builders only.

Get updates and sign the petition here:

An exclusive selfbuild.ie survey reveals painfully slow progress on the government’s goal of 2,000 serviced sites by 2025, as only 30 sites have been made available and been identified as suitable for sale.

Just 21 fully serviced sites are currently available to selfbuilders looking to build their own homes in ROI through the government’s Ready to Build Scheme. To date, an additional nine sites have been sold.

Under the scheme, launched in 2022 under the Croí Cónaithe (Towns) fund, local authorities directly sell sites to self-builders at a discounted price and also provide services such as water, wastewater, electricity and access to the sites. All local authorities in Ireland are administering the scheme.

The government’s Ready to Build Scheme was designed to provide 2,000 serviced sites for self-builders in regional towns and villages by 2025.

The Programme for Government 2025 reaffirmed this goal, stating that each local authority would be required to deliver serviced sites for 3 to 10 housing units in at least three locations every year. Based on these projections, the initiative was expected to create between 279 and 930 serviced sites annually.

Yet, an informal nationwide survey of local authorities carried out by Selfbuild paints a bleak picture. Only nine out of the 31 councils responded when asked how many serviced sites they currently have available, with those who did respond reporting only a handful of sites in place.

Despite the ambitious targets, many councils are still in the early planning stages or struggling to secure land. Several local authorities have yet to make any serviced sites available under the scheme.

Clare, Kilkenny, Meath and Waterford confirmed they have not sold or made any serviced sites available. However, they are taking steps to progress the scheme forward, carrying out site feasibility studies.

Kildare County Council has seven sites in Clogherinkoe village, priced at €45,000 each.

Tipperary County Council has three fully serviced sites in Boherlahan village, available for €25,000 each.

Wicklow County Council has five sites in Kilcommon, priced between €35,000 and €50,000, but further expansion remains uncertain.

Laois County Council has been the most proactive, selling eight sites in 2024 and planning to release six more this year, while evaluating additional locations.

According to the Department of Housing, a further 140+ sites are at various stages of consideration by the relevant local authorities and the Department is “working with those local authorities to progress the sites”.

A key issue blocking progress is the lack of available land banks. Meath County Council, for instance, stated that the scheme remains in its early stages due to land shortages. Similarly, other counties are still reviewing potential sites but have yet to make concrete headway.

Housing Minister Browne told Selfbuild that the scheme still played a central part in the government’s “drive to

tackle vacancy and dereliction in towns and villages around the country”, stating: “my Department will continue to work with local authorities to progress suitable sites”. Adding: “By providing alternative choices for people to live in our towns and villages we are supporting the growth and development of these places – strengthening Ireland’s rural urban fabric, and supporting the communities who live there.”

Whether you are upgrading an existing property or building new, the addition of an insulated thermal lining to the inside of a wall, roof slope or ceiling will dramatically improve the energy efficiency standards in your home.

Why choose Unilin Thermal Liners?

Optimum performance from a thinner board

Cost-effective

External wall appearance maintained

Easy to install

Readily available from your local builders merchant

For expert advice, contact our technical team on 046 906 6050 or discover the range below:

The Conservation Advice Grant for vacant traditional farmhouses has been cut by a third, as scheme exits pilot stage and gets rolled out.

If you own a vacant, traditional house then you may qualify for the Conservation Advice Grant launched by the ROI government in March – but you’ll be getting €5,000 or €2,500 less than the original pilot scheme grant amount offered in 2023.

Now in its second year, the Conservation Advice Grant Scheme for Vacant Traditional Farmhouses will provide grants of up to €5,000 (excluding VAT) to cover the cost of having a conservation expert with the right experience to conduct a survey and put together a tailored conservation advice for the property owner. The original maximum grant offered by the pilot scheme was €7,500.

The scheme is aimed at homeowners applying for or considering the Vacant Property Refurbishment Grant, which provides funding of up to €50,000 for vacant properties and up to €70,000 for derelict homes. The conservation grant covers up to 67 per cent of costs for expert advice on repairs, improvements and energy efficiency measures for traditional buildings.

This includes a report outlining the condition of the building and identifying repairs and improvements that would restore it to use while enhancing its

character, energy efficiency, integrity and amenity.

By partially offsetting the cost of engaging expert advice at an early stage, the scheme also helps owners to avoid the risk of damage to their properties, obtain the services of appropriately skilled tradespeople and ensure value for money in the completion of their projects.

For more about who qualifies and how to apply here

Climate rules ending boiler replacement grants in ROI from the beginning of January 2025 leave vulnerable homeowners facing high costs and winter hardships in poorly insulated homes.

The change is driven by the Energy Performance of Buildings Directive (EPBD), adopted in May 2024, which prohibits public funding for new fossil fuel boilers from January 1, 2025.

However, grants for repairing existing fossil fuel boilers remain unaffected. The directive is part of the EU’s efforts to improve energy performance and reduce emissions, but its rigid application has drawn criticism for disproportionately impacting Ireland’s elderly population.

The Department of Housing defends the measure, stating that the EU directive aims to prevent vulnerable households from being “locked into” fossil fuel systems. However, critics argue that the policy undermines the principle of a “just transition”, placing the burden of climate action on those least equipped to shoulder it.

The directive does not prohibit grant funding for renewable heating systems. Homeowners are being encouraged to explore options such as heat pumps, solar energy and hybrid systems. The Sustainable Energy Authority of Ireland (SEAI) offers grants for these systems, including free grants (fully funded work) for those on certain welfare payments, including those on job seekers allowance, under the Warmer Homes Scheme.

With updated fire safety regulations set to take effect in NI on May 6, 2025, here’s what you need to be aware of at the design and build stages.

The latest update to the Building (Amendment) Regulations (Northern Ireland) 2024 introduces several important fire safety measures under Technical Booklet E –Fire Safety. While most apply to multi-dwelling or high-rise buildings, some will affect selfbuilds.

These changes are about improving fire detection and making it easier for fire services to access your home in the event of a fire. Here’s what you need to know to stay ahead of the curve.

A key change is that smoke alarms must now be installed in every single room, an increase from the old rule that only required them in the main living room, circulation spaces and kitchens. The technical booklet wording is: “an automatic fire detection and fire alarm system complying with BS 5839-6 of at least D2 Category LD2 standard including a smoke alarm or

alarms in every habitable room and a heat alarm or alarms in every kitchen”.

Under the previous rules, the fire service had to reach the front door with a hose, within 45 metres of the fire engine. The new regs, however, stipulate that they need to be able to reach every part of your home within that same 45-metre distance from the fire engine. This change could affect the

layout and design of your home, particularly if you’re in a rural or remote area. These changes are designed to improve the safety and accessibility of new build homes, making sure that both the occupants and emergency responders are better protected.

More information on Department of Finance’s website, finance-ni.gov.uk

Get expert architectural advice and support a great cause at the same time.

If you’re planning a new build or renovation, you probably have plenty of questions and may not know where to start. The good news? Two great initiatives allow you to get expert guidance from a registered architect while making a meaningful difference. By making a donation to charity, you’ll receive a onehour consultation with an experienced architect who can help you refine your ideas and plans.

It’s important to note that all participating architects volunteer their time and expertise, ensuring that 100 per cent of donations go to charity. This is a fantastic opportunity to receive expert advice tailored to your project while supporting a cause that changes lives.

In ROI: The RIAI Simon Open Door initiative, which opened on March 10th 2025, sees you make a donation of €125 to Simon Communities, and book an hour-long consultation with a Royal Institute of the Architects of Ireland (RIAI) registered architect.

Simon Communities provide housing and vital services for people experiencing homelessness across Ireland.

Your donation supports this important work while giving you access to expert architectural advice on building, renovating, or retrofitting your home.

Consultations will be held between April 7–13, book you spot at: riaisimonopendoor.ie.

In NI: Ask an Architect

is back this spring, offering homeowners in Northern Ireland a chance to meet with a registered architect. For a minimum donation to Friends of the Cancer Centre at Belfast City Hospital, you’ll receive a one-hour consultation with an architect registered with the Royal Society of Ulster Architects (RSUA).

Friends of the Cancer Centre

is one of Northern Ireland’s leading cancer charities, focusing on clinical care, patient comfort, and cancer research. Every penny raised through Ask an Architect goes directly to supporting local cancer research.

Book your consultation at askanarchitect-ni.com.

The Federation of Master Builders Awards 2025 are all about clebrating quality of workmanship. Here, we’ve got a treat in store… the Sustainability Building Award entries for Northern Ireland. Enjoy!

The Federation of Master Builders (FMB) Master Builder Awards are the pinnacle of recognition for small to medium-sized building firms across the UK, a celebration of exceptional craftsmanship, client satisfaction and building excellence. Recognised as the gold standard in the industry, these awards champion the very best in construction, from sustainability and innovation to heritage restoration and customer care.

On 23 May 2025, Northern Ireland’s most skilled builders will gather at The Malone Hotel, Belfast to honour the regional winners, each of whom will then go on to represent Northern Ireland at the UKwide finals in September. Finalists have a chance to win a brand-new Isuzu Pick-Up Truck worth £42,000, courtesy of headline sponsor Isuzu, as well as national exposure.

For builders, the awards are not only a mark of professional pride but a platform for future growth, showing clients they uphold the highest standards. For homeowners, they’re a reminder that when you choose an FMB Master Builder, you’re choosing quality, accountability and proven expertise.

More information on fmb.org.uk

Set high above Strangford Lough, this once energyinefficient 200-year-old cottage has been transformed into an EPC (Energy Performance Certificate) A-rated eco home. Despite recommendations to demolish the property, the clients chose a full retrofit, preserving the home’s character and embedded

carbon while dramatically improving sustainability and comfort. The property was modestly extended and reimagined with help from McAdam Stewart Architects and Daly Renewables.

Environmental upgrades included external wall insulation by Soltherm EWI, triple glazing, 600mm loft insulation, mechanical ventilation with heat recovery (MVHR) system, an air source heat pump and photovoltaic (PV) panels on the new garage. Locally sourced materials and trades helped reduce

carbon emissions, while careful logistics planning and waste minimisation protected the surrounding Area of Outstanding Natural Beauty. The result is a modernised, all-electric home with dramatically lower bills (under £800/year) and a deep respect for its historic footprint. The project reflects both the builder’s technical skill and the client’s values, achieving sustainable, low-impact living without compromise.

Set high on the North Antrim coast, this two-storey timberframe holiday home is a blueprint for all-electric, low-carbon living. Designed in collaboration with John Kennedy Architects, the house was built to operate entirely on renewable energy, combining a smart integration of PV, battery storage, and intelligent energy tech to dramatically cut emissions and reduce dependence on the grid.

Built using airtight construction, high levels of insulation, and triple glazing, the home also features a

Built on a brownfield site with panoramic coastal views, this bespoke detached family home in Greenisland blends cutting-edge energy technology with modern,

ventilation and heating Nilan air system with Helios backup. The Electric Storage Company’s PARIS Greentech system allows the home to learn usage patterns and optimise energy flow-storing, using, or even selling excess electricity.

This was Setanta’s first fully electric new build, requiring complex modelling and close collaboration with stakeholders. Despite site access challenges, the team delivered a highly efficient home that meets Passivhaus principles, futureproofed for technological advances and backed by a strong clientbuilder partnership.

elegant design. Designed with saleability in mind, the property was sold off-plan early in the build and completed in collaboration with its new owners, who moved from Germany to Northern Ireland. The home achieves a Standards Assessment Procedure or SAP of 102, meaning it generates more energy than it consumes.

Sustainability features include an air source heat

pump, PV system, battery storage, underfloor heating and an MVHR system, all controlled via an intelligent eco-smart management system. The build also prioritised airtightness, local materials and upskilling the site team to roll out lowenergy principles across future projects.

Thoughtful touches like retaining native hedgerows for biodiversity, introducing

a user welcome pack and providing personalised support throughout the project reflect a commitment not just to performance, but to people. This project sets a new benchmark for combining luxury and low-carbon living in Northern Ireland.

Perched on a 1.2-acre woodland plot with sweeping views of Belfast Lough, this 5,100sqft Georgian-style family home combines period aesthetics with cutting-edge sustainability. Delivered by Distinguished Homes

in collaboration with the developer and architect, the project features timber frame construction, handmade clay brick, sash windows and premium finishes, all designed with energy efficiency and environmental sensitivity at its core.

The property includes a 50kW battery, 20 solar PV panels, air source heat pump, underfloor heating across three levels and a smart home system to monitor energy

performance. Built on a former derelict site (containing asbestos and bats), the team took a conservation-first approach, working with ecologists and recycling all site materials, including repurposed rubble, wood chippings and rainwater harvesting. Despite 177 tree preservation orders, all removed trees were replanted, with deadwood repurposed for wildlife habitats.

With the buyers living in Los

Angeles throughout the build, Distinguished Homes managed the project seamlessly through remote Zoom meetings, detailed updates and collaborative selections. The result is a home that achieved a SAP of 94, was delivered on time and on budget, and demonstrates what’s possible when craftsmanship meets climate consciousness.

GP McManus

This Grade B1 listed Georgian property underwent a meticulous restoration and renovation, returning a near 200-year-old home to its original grandeur. Led by GP McManus in collaboration with Taylor and Boyd structural engineers, the project involved complex structural work, including the replacement of the entire roof, extensive dry rot treatment, and the preservation of historic features like original trusses, cornicing, stained glass and sash windows.

Key challenges included maintaining full waterproofing during the roof removal to protect ornate interiors and navigating countless design changes while adhering to strict heritage guidelines. All work was documented and reinstated like-for-like, from parapets and battlements to intricate ceiling mouldings, with care taken to photograph and preserve details throughout.

The team also improved the building’s energy performance using Isover’s Optima insulation system, specially suited to heritage properties. Regular site meetings, clear stakeholder communication, and a passionate client-builder relationship helped ensure the project was delivered to a high standard, on time and within budget.

Build your dream energy-efficient home with CavityTherm, the ultimate insulation for cavity walls. Perfect for self-builders, CavityTherm delivers passivhaus-level U-values as low as 0.12 W/ m²K, ensuring top-tier energy efficiency and thermal performance.

Outstanding U-Values: Achieve passive-level insulation in cavities under 150mm wide.

Smart Design: Engineered edge joints, easy-to-use accessories, and detailed guides for smooth installation and Part L compliance.

Moisture Control: Unique HIPS facing directs moisture safely away from your home’s structure.

Eco-Friendly: Sustainable PIR insulation designed to reduce carbon impact.

Trusted across Ireland and the UK for both new builds and renovations, CavityTherm is the reliable, high-performance solution for self-builders seeking easy installation, superior insulation, and building code compliance.

Take the next step toward your energy efficient home with CavityTherm. For expert advice and technical support, contact SIG today!

Belfast: +44 28 9038 0060

Omagh: +44 28 8224 6220

Dublin: +353 1 623 4541

Limerick: +353 61 531 381

Cork: +353 21 432 1868

enquiries@sig.ie

www.sig.ie

House size: 230sqm (270sqm including attic)

Bedrooms: 4

Heating system: Air to water heat pump and under floor heating

Ventilation: Centralised mechanical ventilation with heat recovery

Build method: Block BER: A3

Completed nearly seven years ago, Sarah and Paul Foster’s self-build in Co Meath shows what can be achieved with good design choices and tender loving care.

or Sarah and Paul, building their own home was all about creating a space for their family to grow and connecting with Sarah’s deep ties to the family farm. It’s a project that blends the past with the future, honouring history while looking ahead to a new chapter.

F“Building a house on the family farm had probably been a subconscious dream of mine for years, even from a young age. I’d always imagined using the stone from a ruin on the farm if I ever got the chance to build,” Sarah says. “The connection to the land was a huge factor. Our house is directly across from the family farm, where my dad farmed. That tie to my roots and the area has always been really meaningful to me.”

After spending about 10 years away, Sarah returned to the area, and it was during that return that the idea of building their dream home took shape. “Coming back home really brought the idea to life,” Sarah reflects. “It felt like the right time, and the idea of having a place where our family could grow, surrounded by the land I grew up on, was exactly what we needed.”

From the beginning, Sarah and Paul had a clear vision for what their new home should look like. They wanted a modern farmhouse style that would

complement the 100-year-old farmhouse already on the property, blending the old with the new.

“We were really intentional about incorporating local sandstone from the farm into the build,” Sarah explains. “That stone was important to us. It felt like a way of connecting the house to the land and to the history of the place.”

The design process was a collaborative effort between Sarah, Paul and their architectural team. “We worked closely with our architectural designer to design a home that fit where we are in life, especially with a young family,” Sarah says.

The couple’s priorities were clear: functionality, comfort and a sense of connection to their surroundings. They wanted a home that would not only serve their needs today but also adapt as their family grew.

One of the key decisions was the layout. “We knew we wanted an open plan living space, with the kitchen as the central hub. The kitchen is where we spend most of our time together, so we wanted it to be spacious and functional,” Sarah explains.

They also included a window seat in the design, a feature that has since become one of their favourite parts of the house. “It’s such a cosy spot, and it’s where we often gather to relax and chat.”

While staying within budget was

important, Sarah and Paul were willing to invest in key features that would make the house feel like home. “Creating the home we wanted was more important than sticking to a strict budget, but we still tried to make cost effective choices where we could,” Sarah says.

For example, they decided to build the garage later, to help manage costs, and opted for an air to water heat pump instead of geothermal.

But it wasn’t just about the design and layout. The statutory process was not without its challenges, particularly when it came to gaining planning permission. The couple faced unexpected delays due to a system crash in the online planning portal.

“It was more complicated than we thought,” Sarah admits. “We had to jump through a lot of hoops just to get things moving. At one point, we even had to go to our TD to try to get things changed. It was stressful.”

To make matters even more difficult, Sarah’s father passed away during this time, adding an emotional layer to an already demanding situation. “It was an incredibly emotional time,” Sarah reflects. “Losing my dad while we were trying to navigate all these planning issues felt overwhelming.”

One of the most meaningful parts of the build was incorporating a personal memento from Sarah’s late father. “I wanted to honour my dad’s memory

by embedding a coin of his into the foundations, beneath the kitchen window seat,” Sarah shares. “It was a way to keep a part of him in the home.”

In the end, the build, which was originally expected to take 12 months, stretched to 15 months, largely due to the three-month delay caused by the planning difficulties. Despite the setbacks, Sarah and Paul remained determined to create the home they

envisioned.

“We were so grateful to have such expertise during the planning process,” Sarah says. “It really helped us navigate all the paperwork and red tape. Without that, I don’t know how we would have managed.”

The couple was also lucky to have a strong support system in their builder, who helped manage the timeline and coordinate the various trades. Paul also

What is your favourite design feature?

I’d have to say the kitchen — it’s our favourite spot in the house. We spend most of our time there, and it feels like the heart of the home. I especially love the window seat; you get a great view and can see right through the rest of the ground floor from that spot.

What would you change or do differently?

Looking back, I wouldn’t change much about it, really. I’m so happy with how it turned out. This house feels like home — a place where we can simply enjoy living without constantly thinking about what needs to be fixed or improved.

What surprised you?

I didn’t expect it to be as complicated as it was. You go into it a bit naively, thinking there won’t be any issues, but there are so many decisions to make, and when you’re completely new to building, it can feel overwhelming. The process can be overwhelming at times, especially for first time builders. I remember trying to deal with all of those decisions while climbing up ladders with a new baby — it was a lot. But when you’re in the thick of it, you just keep going, and then, when you finally move in, there’s this moment where you think, “oh my God, did we really do this?”

It feels like such an achievement. That said, the sheer number of decisions along the way is definitely something to prepare for.

single piece

advice would you give a budding selfbuilder?

My main advice would be to remember that the house you’re building is your home. Don’t get too stressed or caught up in things like design features, the size of your kitchen island, or what type of flooring you choose. Because once you move in, it’ll just be home— the place where you live and make memories.

And try to enjoy it for what it is instead of focusing on the things you might want to change or do differently later. That’s the mindset we’ve tried to keep throughout.

contributed his plumbing expertise, which helped streamline the process.

Throughout the build, Sarah and Paul remained highly involved in the decision making. “We were really hands-on, from the design and layout to the material choices,” Sarah says. They made a few key changes during construction, like adjusting the kitchen layout, showing just how involved they were in shaping the house.

“It was important to us that we were in control of the vision, but we also relied on the professionals to handle the day-today work,” adds Sarah.

The home’s insulation and energy efficiency were top priorities, for Paul in particular. “We made sure the walls were well insulated with 150mm of insulation,” he explains. “That’s one of the things I’m

most proud of — it makes the house so efficient.”

For the exterior cladding, they used sandstone from the ruins of a previous house on the farm, connecting the new build to the family’s history.

One of the standout features of the house is the vaulted roof over the barnlike living area. “The vaulted, triangular design was something we really wanted,” Sarah says. “We boxed it in and painted it, turning it into an architectural feature.”

The interior of the house reflects Sarah and Paul’s attention to detail. “We chose herringbone tile flooring for the main living areas,” Sarah says. “Paul’s dad laid the tiles himself, and it took him three weeks to finish. It’s such a labour of love, and it really makes the space feel special.”

Paul’s father also crafted bespoke base

units for the bathroom, adding a personal touch to the design.

The house is filled with natural light, thanks to extensive double glazing and high-level windows in the kitchen. “We decided not to use blinds or curtains,” Sarah says. “We wanted to keep the views open and unobstructed.”

For heating, they installed an air to water heat pump system, which runs the underfloor heating throughout the house and supplies hot water. The system runs on a day/night meter, helping them manage energy costs effectively.

“We also have a mechanical ventilation system, which is crucial for keeping the air quality consistent,” Sarah adds. “If we turn it off, condensation builds up, so it’s definitely something we rely on.”

When it came to water, Sarah and Paul opted to connect to a managed private water scheme in the area, avoiding the need to drill their own well. “It was an easy solution and worked out really well for us,” Paul says.

The house is fully electric, with no gas connections, and they installed a smart meter to help monitor their energy usage.

The kitchen was a focal point of the design. “We worked with our architectural designer to design the layout,” Sarah says. “The countertops are made from a white marble-like material with subtle blue veining, and we originally planned to have navy blue cabinets. But in the end, we chose

“I wanted to honour my dad’s memory by embedding a coin of his into the foundations, beneath the kitchen window seat...”

May 2016

Applied for planning

November 2016

Planning permission granted

March 2017

Build start

March 2018

Moved in

a shade with more blue tones, and it worked out beautifully.”

Lighting was a big consideration in the design process. “We added extra lighting options in the main living areas,” Sarah explains. “We wanted a mix of spotlights and pendant lights to create different ambiances. It’s all about creating the right mood in each space.”

In the bathrooms, Sarah and Paul chose hexagon shaped tiles and a black and white scheme for the ensuite. They also had custom built vanity units made to fit the spaces perfectly. “We kept the walls white at first, which helped us get a better sense of the spaces before deciding on colours and furnishings,” Sarah says.

When it came to landscaping, the couple didn’t take on any major projects immediately after the build was completed. “The builders left the site in such good condition that we didn’t have to do much,” Sarah says.

However, during the pandemic, they took the opportunity to put in what they call their ‘Covid garden’. “It was a great chance to make some landscaping improvements after we moved in.”

The garage was built separately after the main house was completed. “Looking back, we wish we’d done it at the same time,” Sarah admits. “It ended up being more hassle to tackle it later.”

Now, with three kids, Sarah and Paul’s home is everything they hoped for and more. “The layout works so well for our growing family,” Sarah says. “The open plan areas are perfect for when we’re all together, but we also have separate spaces for when we need some quiet time.”

The house has become a home that supports their day-to-day lives and adapts as their needs change. “One of

my favourite things is how flexible the space is,” Sarah says. “I’ve been able to use one of the downstairs bedrooms as a home office, and that’s been a lifesaver. It’s reassuring to know that the space can grow with us.”

Looking back on the whole experience, Sarah is rightly proud of what they’ve accomplished. “When we set out on this self-build, our goal was to create a functional, family friendly home. I’m thrilled to say we’ve achieved that and more. This house has become exactly what we envisioned — a space that supports us and grows with us as a family.”

In the end, Sarah and Paul’s home is a blend of history and modernity, built on Sarah’s childhood farm to provide a lasting space for their growing family. Combining local sandstone and a thoughtful design, they’ve created a home that reflects their roots while offering the flexibility to adapt to their future needs.

Architectural design

Donal McPhillips Architecture, mcphillipsarchitecture.com, tel. 048 677 41813

Engineer

Derek Conor Consulting Engineer, Enniskillen

Contractor (builder)

Barry Kieran of P.K. & Son Ltd., Co Monaghan, mobile 086 382 2509

Internal doors and floors

P.S. Supplies, Co Meath, pssupplies.ie

Tiles

Tilermade, Co Cavan, tilermade.ie

Design SAP and airtightness test

BM Energy Consultants, bmenergy.ie

Windows Munster Joinery

Roof covering

Western natural slate supplied by Slate Supplies Cavan, slatesupplies.com

Photography

Damien Kelly, damienkellyphotography.com

NI calling ROI prefix with 00353 and drop the first 0

Find out more about Sarah and Paul’s new build project in Co Meath...

Roof: 500x250x6mm premier grade slate with matching ridge caps fixed to treated timber battens. Roofing felt over rafters, lapped 150mm min. horizontally and vertically, carried well into gutters and 150x50 C16 rafters at 400mm cts fixed to 100 x 75/50mm treated wall plate(s) fixed down at 12000mm cts with galvanised steel straps fixed down 2 no. courses of blockwork. Provided lateral support to gable walls along top of gable wall and at ceiling level with 5x50x900mm galvanised steel straps at 1.8m cts, built into blockwork as the wall is constructed and turned down 100mm tight against outside face of internal leaf. Provide horizontal noggings to prevent twisting of straps. 150x50mm C16 ceiling joists at 400mm cts with 200mm fibreglass insulation tightly packed between joists, 200mm of same cross-layered above. Ceiling finish to consist of 12.5mm plasterboard backed with a vapour control layer fixed to underside of rafters and finished with skim coat and painted to selected colour. U-value 0.12W/sqmK.

Flat roof: Fiberglass on 18mm marine ply deck screw fixed to treated timber firring pieces to falls, screw fixed to 150x50mm C16 flat roof joists at 400mm cts, full fill spray foam insulation between joists, vapour barrier installed to warm side of insulation, 62.5mm insulated plasterboard and skim finish. U-value 0.18W/sqmK.

Walls: 100mm concrete block inner leaf with bonding and skim finish, 150mm cavity with 100mm PIRinsulation, held in place with ss. wall ties located at 450mm cts vertically and 750mm cts horizontally and staggered, remainder of cavity pumped with platinum beads. 100mm concrete block outer leaf with smooth floated render finish in chalk white. U-value 0.16W/sqmK.

Floor: Concrete strip foundations reinforced with layer of A393 mesh located 75mm from bottom of foundation. Foundations min. 3x width of wall wide and 1x width in dept min. Bottom of foundation to be 600mm minimum below finished external ground level. Floor construction consisting of 100mm concrete screed, with a 25mm insulation upstand along the entire perimeter of the external walls on 125mm PIR insulation, on radon resisting membrane to equivalent of 2000-gauge continuous polythene dpm lapped and bonded to dpc, on 150mm C30/20 newton conc. subfloor, on 225mm min. and 600mm max. hardcore compacted in 225mm layers. U-value 0.14W/sqmK.

First floor: Finish on 100mm concrete screed, on 150mm prestressed hollow core slabs to manufacturer’s layout, grout between all slabs with dryish C35 Newton concrete immediately after placing of units.

House size: 317sqm

Bedrooms: 4

Plot size: 1 acre

Timber frame cost: £100K

Steelwork cost: £30k

Heating system: Geothermal heat pump with PV

Ventilation: centralised mechanical ventilation with heat recovery

Build method: timber frame

EPC (SAP): A (97)

Ryan and Joanne Daly’s search for a home that could accommodate their growing family led them to a timber frame new build solution in Co Down; this is their story.

When Ryan and Joanne decided it was time to move out of their three-bed semi-d in south Belfast, they ran into the same problem as many other families — there just weren’t enough suitable homes on the market. With three children and the need for more space, they started looking for a four-bedroom house nearby but quickly

realised their options were limited. That’s when Ryan, an engineer with years of experience working with self-builders, suggested a different approach: why not build their own home?

They were both attracted to the idea of rural living and found the ideal opportunity when they came across a farmer selling a site with planning permission. After negotiating the purchase, they began their self-build

journey in earnest. Ryan took on the role of project manager, overseeing the entire process.

“We had our architect, John Lavery, design the house, and were really happy with what his team came up with,” Ryan recalls. “We gave them a two-page brief outlining what we wanted, and their first design was almost spot-on. We only needed a few minor tweaks.”

The house they envisioned was spacious, functional and highly energy efficient. It has a modern layout and futureproof features for their growing family. At 317 sqm, there are four bedrooms and a unique design featuring four different levels on the ground floor.

Ryan’s decision to use a timber frame construction method was rooted in his professional experience. “I’ve worked in the low energy housing sector as a renewable energy engineer for the last 16 years,” he explains. “The best-performing houses I’ve seen in terms of comfort and low running costs were those built with timber frame.”

Timber frame offered several advantages, including speed of construction, airtightness and excellent

insulation performance. “While masonry builds can also be airtight and energy efficient, they require a contractor with specific knowledge of airtightness and thermal bridging techniques, which isn’t always easy to find,” Ryan adds. “The precise engineering and even surfaces of a timber frame build also simplify the installation process.”

Ryan and Joanne chose a timber frame supplier they had worked with in the

past. “I was impressed by their attention to detail and the feedback from their previous customers. I had seen first hand the quality of their work — everything from the insulation to the airtightness membranes and tapes.”

The timber frame company played a pivotal role in the build, supplying not only the timber frame kit but also the associated steel frame to support the structure, the windows and a complete

airtight solution. This package was particularly appealing to the couple, as it ensured a seamless integration of all components.

“The timber frame team provided detailed technical drawings and worked closely with us to make sure everything was perfect before installation,” Ryan says. “Their involvement didn’t stop there — they offered great advice on other aspects of the build, even though we were using direct labour.”

The company’s airtight solution, which included intelligent membranes and high performance tapes, was a key factor in achieving the house’s exceptional energy performance.

“We brought in a builder for the foundations and a groundworks contractor to prepare the site,” Ryan explains. “After that, the timber frame company came in to install the frame. It was great to see everything come together.”

One of the most exciting moments for the family was seeing the timber frame kit arrive on site. “It came on a

“The best-performing houses I’ve seen in terms of comfort and low running costs were those built with timber frame.”

lorry one day and was erected the next,” Ryan recalls. “The speed of construction was incredible — it all came together so quickly.”

Energy efficiency was a top priority for Ryan and Joanne, and their choice of heating and cooling systems reflects this commitment. The house features a geothermal heat pump (GSHP) integrated with a photovoltaic (PV) system.

“Timber frame houses perform exceptionally well in winter, but their airtightness and insulation can lead to overheating in summer,” Ryan explains. “The GSHP solves this by offering cooling capabilities, and because it’s powered by our solar PV system, the running costs are minimal.”

The couple’s first year energy bill for heating, hot water and cooling was a reassuring low £132. With the increase in electricity prices over the last two years, this is averaging now at £360/annum which is less than £1 per day. This level of efficiency illustrates the benefits of integrating renewable energy systems with a well designed timber frame structure.

The family also installed a rainwater

Choose passionate and enthusiastic contractors even if they may be slightly more expensive. We noticed a difference in the quality of work between contractors who showed a genuine interest and commitment to our project versus those who were not as invested.

Document VAT reclaim records from the start. It will save a lot of hassle later on when you are claiming your VAT back from HMRC.

Get high spec windows. We designed our house with a lot of south facing glass. The quality of the window system supplied by Neil Orr from the timber frame company means our house is heated naturally on cold sunny days. Having lots of glass is only okay if your heat pump can cool as well as heat. Having a poor quality window system could have the opposite effect, contributing to the heat loss of the fabric.

harvesting system for gardening and car washing, reflecting their commitment to sustainability. Inside, a smart home system adds convenience with features like motion-sensor lighting and automated heating controls. “With four kids now, life is busy. We wanted a ‘fit and forget’ system — everything just works without us having to think about it,” says Ryan.

Ryan and Joanne worked closely with their architect to make certain the house met their family’s needs. The layout features distinct zones that create a sense of flow and separation without losing

connectivity.

“We wanted to walk through the house as if we were moving through different zones,” says Ryan. This approach led to clever touches like a half wall and a few steps between the kitchen, dining and living areas, giving each room its own character.

The roof design features three mono pitch flat roofs, which contribute to the home’s modern aesthetic. “We opted for an aluminium alternative to zinc, for the roofing material,” Ryan says. “It was a cost effective choice that didn’t compromise on style.”

The timber frame company not only installed the structure but also provided the glazing package, which included triple glazed aluclad windows. “One of the reasons we wanted to get the window package through them was that they set out the openings for the windows. It made sense for them to install the windows and carry out the airtightness system around the frames,” Ryan says. “For me, that was a really good package to get.”

Joanne took charge of the interior design, carefully selecting tiles, finishes and lighting to balance style and practicality. “She worked with a consultant at the tile showroom to find the right options for our bathrooms,” says Ryan. The lighting design was another key focus, with the couple opting for minimal spotlights and more mood lighting to create a warm atmosphere. Outside, the landscaping is about 75 per cent complete. A professional contractor handled the stone masonry, driveway and kerbing, while an outdoor lighting expert created a soft, understated effect. “We love how the lighting highlights the stone walls and trees,” Ryan says.

No self-build project is without its challenges, and Ryan and Joanne’s experience was no exception. A delay in the roofing contractor’s schedule meant the house was left exposed to the elements for several weeks during the

June 2020 Build start

December 2021

Moved in

January 2022 Build end

winter of 2021.

“Moisture got into the timber, but the timber frame company reassured us that their system, which includes an intelligent airtightness membrane, would allow the moisture to escape,” Ryan explains.

Another hiccup occurred during the window installation. “One of the installers accidentally dropped a piece of scaffolding, smashing the glass on one of our solar panels,” Ryan recalls. “Thankfully, the timber frame company immediately offered to replace the panel at no extra cost. Their response gave us a lot of confidence — we felt like we were in safe hands.”

A further challenge came with the prefabricated spiral staircase. Originally, Ryan had decided to leave out 25mm

of insulation in the floor above where the staircase meets the first floor to create more headspace. However, the timber frame company recommended reinstating the insulation for better soundproofing. Ryan agreed to the change, but in the rush, he forgot to inform the staircase company. When the installers arrived to fit the staircase, it didn’t fit. “I had to use my kango hammer to dig out the base plate and lower it to make it work,” says Ryan.

“Not everything is going to go right — it’s about minimising mistakes and having the right team to address issues when they arise.”

For anyone else considering a timber frame build, Ryan stresses the importance of choosing a reputable supplier. “The success of a timber frame

build depends heavily on the quality of the materials and the expertise of the team,” he says. “It’s always worth investing in people who care about their work.”

The couple also highlights the value of clear communication and thorough planning. By working closely with their architect and timber frame company, they were able to streamline the design and construction process, making sure everything came together with minimal disruptions.

Today, Ryan and Joanne’s home is more than just a house. It’s a testament to what can be achieved with careful planning, expert collaboration and a commitment to sustainability. From its energy efficient

design to its smart heating and cooling systems, the house is perfectly tailored to their family’s needs.

“People who visit are always amazed at how easy everything is,” Ryan says. “We hardly have to adjust anything — lights, heating, hot water — it’s all automated and just works.”

In the end, by choosing a versatile and sustainable design, they not only gained the space they needed but also created a futureproof, energy efficient home that blends functionality with style.

But for the couple, their self-build journey was about more than creating a comfortable living space. It was an opportunity to reflect their values and support their way of life. “We’re thrilled with the result,” Ryan concludes. “It’s everything we wanted, and more.”

What is your favourite design feature?

We love the snug, which is set down about three steps from the dining room floor. This design gives it a cosy, 1970s-style feel. We specifically requested this type of sunken space in my initial brief to the architect, and love how it turned out. It’s a comfortable, intimate spot with a large TV on the wall, and the layout works perfectly with the rest of the house.

What would you change or do differently?

We would probably go for a slightly larger utility and boot room area if we could do it over. Originally, the architect had designed it better, but our kitchen designer convinced us to make the pantry bigger while reducing the boot room and utility space. In hindsight, we probably should have stuck with the architect’s initial design for that part.

What surprised you?

One thing that surprised us, looking back, was the VAT reclaim process for the project. We should have downloaded the template at the start to keep track of all the invoices and documents we’d need instead of doing it after the build. Also that a big empty house is an acoustic challenge. We need to add more soft furnishings to help absorb some of the noise.

single piece of advice would you give a budding self-builder?

If you don’t have family members with construction experience, I’d advise hiring a project manager to oversee the work. While it may add to your costs, it can still be more affordable than hiring a full contractor. And you’ll avoid the challenges of managing the project yourself without the necessary expertise.

Would you do it again?

Yes, we really enjoyed it, it wasn’t too stressful.

At Coolestone, we specialize in providing an exceptional range of natural stone, landscaping materials, paving solutions, porcelain tiles, and cobblestones.

With our extensive knowledge and passion for quality, we carefully source and import the finest materials from around the globe, ensuring that every product meets our high standards. With decades of expertise in the industry, we understand the importance of quality, durability, and aesthetic appeal in every project!

Renewable systems

Ryan Daly, Daly Renewables

Architect

BGA Architects, bga-ni.com

Timber frame company Kudos, buildingkudos.com

Smart home, home cinema and motorised blinds

Epitome Living, Co Armagh, tel. 028 (048 from ROI) 3881 0102

Stonework Coolestone, coolestone.co.uk

Photography Paul Lindsay, paullindsayphoto.co.uk

Walls: timber frame with cellulose, PIR and hemp insulation, U-value 0.13 W/sqmK

Roof: monopitched sloped and flat roofs both

U-value 0.12 W/sqmK, insulation hemp, PIR, cellulose

Floor: suspended timber floors with insulation between joists, screed over 125mm PIR insulation, U-value 0.13 W/sqmK

Windows: triple glazed, aluclad, overall U-values from 0.78 to 0.90W/sqmK

Airtightness: 1.97 m3/h.sqm

Established in 2010, Daly Renewables are MCS certified installers helping self builders transition to low carbon heating with renewable technology solutions, not just standalone technologies.

We’re different because we bring an uniquely engineerled approach to the design, installation and commissioning of renewable energy heating systems for modern day living.

We work across residential, public and commerical sectors.

If

Words: Heather Campbell

Size before extension: 135sqm

Size after extension: 173sqm

Bedrooms: 4

Plot size: 1 acre

Heating system: Condensing oil bolier

Ventilation: Natural

Build method: Concrete blockwork

Michael and Tina Clancy transformed their coastal holiday home in Co Sligo into a sustainable, energy efficient retirement haven, blending modern upgrades with the charm of their much loved family retreat.

In 1994, Michael and Tina built a holiday home in a beautiful coastal village. Over the years, this beloved property became more than just a getaway; it became the heart of their family’s life. Now retired, they decided to transform the house into their ideal retirement haven, a place where they could embrace the next chapter of their lives.

With their children grown and moved on, the couple no longer needed the large vacation house they built for their growing family. Instead, they imagined a space that was just right for their current needs, offering comfort, practicality and room for the occasional family visit.

The project was not only about creating a home that fitted their lifestyle but also about modernising the property. Michael and Tina focused on upgrading the insulation, heating and windows while incorporating energy efficient and environmentally friendly features. These changes made sure their home was futureproof and matched their wish to live sustainably.

The original house had a classic dormer cottage look, with concrete barge gables and a traditional feel. Michael wanted to keep that charm but bring in more modern touches, especially natural light and better views.

The process began with applying for planning permission through Sligo County Council, which, to their relief, went smoothly. “We were fortunate to

avoid any obstacles, which meant we could concentrate fully on the design and construction,” Michael explains.

The couple brought in architectural designer Martin McLaughlin to translate their ideas into a practical and well executed design. “Martin worked with us to design a space that maximised natural light and made the most of the scenic views surrounding the house.”

“We were especially keen on blending the old with the new — keeping the character of the original cottage while introducing a modern style. Once we approved the plans, Martin handled everything with the council, which made the whole process seamless.”

“Our builder Peter McNulty and his team were fantastic to work with, completing the entire project in just four months.”

The work involved an extensive renovation of the entire property as well as constructing a large extension.

The new extension was built with concrete blocks finished in white plaster to match the original house. The roof of

“We are delighted with the performance and reliability of our heat pump, in particular when the weather has been damp and cold.”

The Grant Aerona R290 air to water heat pump is an excellent choice for self-builders throughout the UK and Ireland seeking an efficient and environmentally friendly home heating solution. Designed specifically for the UK and Ireland climate, the Aerona R290 range utilises the natural refrigerant R290, which boasts a remarkably low Global Warming Potential (GWP) of 3, compared to R32 refrigerant which has a GWP index of 657.

Its sleek design, combined with exceptional perfoamnce and ultra-low noise levels, recognised by Quiet Mark, ensures it integrates seamlessly into modern homes without disruption. Available in outputsranging from 4kW to 16kW, the Aerona R290 caters to properties of various sizes, offering flexibility for diverse self-build projects.

“Since installing my 9kW Grant Aerona R290 heat pump I have noticed a consistent, balanced heat throughout my home. It heats water faster than my previous heat pump and has demonstrated superb performance throughout the winter, in particular when the weather has been damp and cold. We

are delighted with the reliability of our heat pump and it is so quiet we barely know it is there.” Michael M, Co. Laois.

As a self-builder, choosing the right heating system is a key decision - and demand has never been higher for solutions that combine performance, efficiency, and suitability for the Irish and UK climate. Grant’s Aerona R290 air-to-water heat pump ticks all those boxes, making it a standout option for those aiming to build a home with low energy consumption.

Specifically designed and tested for the changeable conditions in Ireland and the UK, the Aerona R290 delivers performance where it counts. Many air source heat pumps struggle with frost build-up in damp conditions, triggering frequent defrost cycles that sap efficiency and shorten lifespan. The Aerona R290 has been designed and tested to handle these conditions, with enhanced drainage, protective coatings, and smart controls that minimise energy waste - keeping homes warm, efficient, and comfortable all year round.

Featuring five models ranging from 4kW to 16kW, the Aerona R290 heat pump range offers the flexibility needed to match the requirements of different sized new build homes - and at present is the only heat pump that offers this range of outputs within a single product line.

For self-builders focused on long-term efficiency and comfort, every unit in the Aerona R290 range achieves an impressive A+++ energy rating (at 35°C flow temperature) and -5°C outdoor air and 55°C flow temperatures. This means that self-builders can feel assured that Grant’s Aerona R290 range will deliver consistent warmth at low running costs, even during damp and frosty winters.

Choosing R290 refrigerant also means self-builders are building with the future in mind. With EU and UK regulations shifting towards natural refrigerants, systems like the Aerona R290 are set to play a big role in the next generation of low-carbon homes.

Grant’s significant investment in developing the Aerona R290 shows their commitment to helping homes meet today’s energy goals—without compromising on performance and comfort for the homeowner.

If you are currently in the process of building a new build home, let Grant design your heating system free of charge. Simply send planning drawings and your preferred choice of heat emitters (underfloor heating and / or aluminium radiators) to heatpump@grant.ie / heatpump@grantni.com

For further information visit www.grant.ie / grantni.com

the extension was fitted with a high quality uPVC roofing system, while the original slate roof remained intact. Polished tiles finished the concrete floors, creating a sleek yet practical look throughout.

“Because we’re so close to the Atlantic, where storms can be fierce, additional steel reinforcing was used in the extension to support the larger spans of windows,” explains Michael. The new triple glazed uPVC windows not only allow for incredible views of the sea and mountains but also provide excellent insulation and protection against the elements.

“Energy efficiency was a major priority for us, especially as we plan to live here full time,” says Michael. “We installed a 5.8kW solar photovoltaic (PV) system, which helps keep our electricity costs down and makes sure we have a sustainable energy source. This system also delivers a continuous supply of hot water without using fossil fuels.”

“We installed a new condenser oil burner, but we are considering upgrading to a heat pump system in the future to further improve the energy efficiency of the home. We’re

just waiting for the technology to improve and become more suitable for our needs.”

“We opted for underfloor heating throughout the house, which has proven to be both efficient and comfortable. For backup heating, we installed a wood burning stove, which adds a cosy

ambience to the living area.”