7 minute read

COVER STORY- Decking Safety Essentials

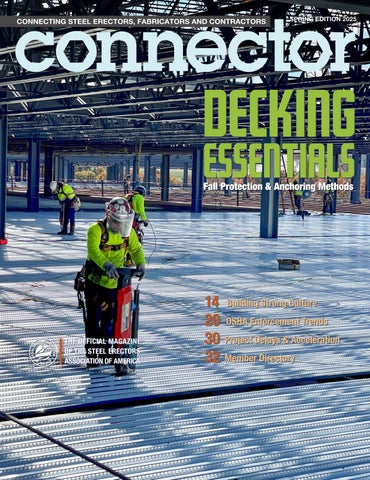

On this joint Gardner-Watson Decking and Gardner-Watson Studs project in Phoenix, Arizona, the companies placed 1.2 million sq ft of decking and 59,500 shear studs, along with some deformed bar anchors shot on bent plate. This photo, taken by Duke Perry, Vice President of Sales and Operations for Gardner-Watson Studs, was the winner of SEAA’s Summer Photo Contest. Perry’s photo captures the spirit of teamwork and dedication that defines the steel erection industry. He said: “This project was done in partnership with our customer was delivered safely, precisely, and on time!”

DECKING SAFETY ESSENTIALS

Navigating OSHA Regulations and Best Practices for Fall Protection and Anchoring Methods

Installation of metal decking during steel erection activities comes with inherent risks that must not be underestimated. This crucial process provides structural support but can pose a range of hazards if not executed properly. Training and safety of workers is paramount during decking operations. Despite existing OSHA regulations [1926.754(e) and1926.757(e)(4] related to sheet metal installation, there is little guidance on correct fall protection procedures for this type of work. Derr and Gruenewald Construction conducted drop testing on a training tower

in order to establish best tie off practices when throwing decking, which are shared below. But first, let’s explore other key safety requirements.

Shaking out deck

It is a common misconception that the metal banding wrapped around deck bundles can be used for lifting the bundle. While it may seem like a convenient place to hook onto, the band will likely break. When the band snaps it can cause significant injury. Instead, always use properly rated wire rope slings in choker hitches. Before hoisting the decking bundle, don’t forget to check for hitch hikers— dunnage, flashing, or other materials

that are loose on the bundle. If those materials are being hoisted with the deck bundle they must be secured. Don’t forget hand protection. Cut resistant gloves are recommended for workers handling metal deck sheets, which have sharp edges.

Use qualified riggers

The rigger responsible for unloading, moving, or hoisting deck bundles MUST be qualified and competent. Riggers must know the weights of each bundle, and the capacity of the rigging and hoisting equipment. Rigging should also be inspected prior to use. When hoisting decking, make sure the small eyes of both chokers are on

Watch Drop Test Demo

Video of two drop test scenarios using different fall protection systems provides clarity for leading edge fall protection best practices.

the same side of the decking bundle. This ensures a good bite on the bundle, avoids load twisting, and makes the likelihood of the bundle shifting lessened.

The rigger should go through these steps prior to each pick. To put it bluntly, it’s a life-or-death choice every time if proper procedures are not followed.

Landing deck bundles

Before landing deck bundles upon the structure, verify that the framing members are able to support the bundle without

the possibility of being dislodged when unbanded. Before landing bundles on steel joists, all joist bridging must be installed and anchored, and all joist ends must be attached unless the following conditions are met.

• The employer has first determined from a qualified person and documented in a site-specific erection plan that the structure or portion of the structure is capable of supporting the load.

• The bundle of decking is placed on a minimum of three steel joists.

• The joists supporting the bundle of decking are attached at both ends.

• At least one row of bridging is installed and anchored.

• The total weight of the bundle of decking does not exceed 4,000 pounds (1816 kg).

• The edge of the construction load shall be placed within 1 foot (.30 m) of the bearing surface of the joist end.

Fall protection best practices

There are some gray areas when it comes to OSHA requirements for fall protection when throwing decking. That’s why Derr and Gruenewald did some testing using common tie off procedures.

Ironworkers are often tied off to a long

SRL anchored to an elevated HLL. We wanted to determine what would happen in this scenario if a worker fell over the deck edge of an unsecured decking sheet. The objectives of this test were 1) to evaluate the structural integrity and performance of the steel deck under impact conditions and 2) compare the results utilizing different fall protection scenarios.

First drop test: Elevated SRL

In the initial test, a 315 lb test weight was suspended 5 feet above the walking/working surface of the deck sheet. The test weight was connected to a 50 ft leading edge self-retracting lifeline (SRL), which was anchored to a horizontal lifeline (HLL) and elevated 6 ft above the deck. The SRL was extended 25 feet from its anchor point to the test weight located at the deck edge, where the sheet was unsecured.

Upon release, the test weight dropped 5 feet before the SRL cable began to bear the weight on the unsecured decking sheet. This action caused the non-working side of the deck sheet to lift slightly and be forced 3 feet back toward the anchor point. The unsecured deck sheet stopped when its high and low hats settled into the deck sheet that was secured behind it. The total fall distance was 14 feet.

Second drop test: SRL to swivel deck anchor

For the second test, the same 315 lb weight was suspended 5 feet above the leading edge of the unsecured deck sheet. This time, the weight was connected to a 50 ft leading edge SRL connected to a swivel deckmounted anchor secured into the deck. The anchor point was mounted 12 feet away from the test weight.

When test weight was released over the deck edge, the unsecured sheet remained in place. Although the SRL’s shock- absorbing pack deployed against the deck edge, it did not sustain any cuts or other indications of damage at the impact site. The total fall distance was 9 feet.

Key findings

The second test highlights why it’s critical to not use dorsal D-ring extensions with leading-edge applications. Doing so would prevent the shock-absorbing pack from deploying properly, leading to higher impact forces on the worker and connecting devices. It’s always best practice to anchor workers directly overhead.

While some believe that anchoring an SRL to a 6-foot HLL will ensure safety during decking operations, the first test demonstrates the risks. If a worker falls and another employee is standing behind an unsecured deck sheet, that loose deck could shift, potentially causing injury to the worker at the non-working end. In contrast, the second test showed that using a deckmounted anchor point at foot level led to a safer outcome, with the unsecured sheet remaining stable and a reduced fall distance, minimizing the risk of injury to others.

The installation of metal decking during steel erection activities is a critical process that requires stringent safety measures. Despite existing OSHA regulations, there are still gray areas that need to be addressed to ensure the safety of workers. Derr & Gruenewald Construction's drop tests highlight the importance of using proper fall protection systems and anchoring methods. By continuously exploring new tools and PPE, and adhering to best practices, we can create a safer work environment and foster a culture of accountability on the jobsite •

It’s critical to not use dorsal D-ring extensions with leading-edge applications.