WINTER EDITION 2022 THE OFFICIAL MAGAZINE OF THE STEEL ERECTORS ASSOCIATION OF AMERICA Best Practices of World Class Companies 16 20 34 Cyber Security for Construction Qualifying Ironworkers for Rigging How the Ladder is Hurting Retention Training & Safety GO TOGETHER

OUR SERVICES ERECTING DETAILING ESTIMATING FABRICATING DESIGN BUILD PROJECT MANAGEMENT BUILD HELPING YOU A FUTURE STRONGER WWW.COOPERSTEEL.COM NASHVILLE, TN SHELBYVILLE, TN FLORENCE, KY (9 3 1) 6 8 4 - 796 2

336-294-8880 • info@seaa.net MARCH 28 - 31, 2023 World Golf Village Renaissance Resort • St. Augustine, FL 2023 CONVENTION & TRADE SHOW Golf, Fishing & Excursions Panel Discussions Education Sessions on Business, Technical Field Practices, & Safety Trade Show and Live Demos Networking at Receptions & President’s Dinner Connecting Leaders, Creating Community Steel Strong in St. Augustine

seaa.net ONLINE HIGHLIGHTS Q Identify Task Specific Pinch Points to Prevent Injuries Q SEAA’s Ironworker Apprenticeship Standard now Includes Reinforcing Ironworkers Q Tips to Keep Equipment Fuel Costs Under Control Q Newest Album in the Photo Gallery Highlights 2022 Dave Schulz Memorial Golf Tournament The Steel Erectors Association of America (SEAA) is dedicated to advancing the common interests and needs of all engaged in building with steel. The Association’s objectives in achieving this goal include the promotion of safety, education and training programs for steel erector trades, development and promotion of standards and cooperation with others in activities which impact the commercial construction business. Check out our latest social media feeds. OPT-IN for our e-Newsletters web.seaa.net/publications/subscribe.aspx c•ntents WINTER EDITION December 2022 4 | THE STEEL ERECTORS ASSOCIATION OF AMERICA DEPARTMENTS 8 Perspective 10 Association News 14 Product Focus 34 Business Operations 38 Topping Out FEATURES Management Cyber Security for Construction Understanding the risk and protecting your company. Plus, a steel erector’s story and lessons learned. By

and Anthony Dolce In the Field Qualifying Ironworkers for Rigging Highlighting the need for formal training for all levels of riggers. Plus, a quiz to test your rigging knowledge.

Special Focus Golf Tournament Supports Safety & Education Thousands raised during Dave Schulz Memorial Golf Tournament. 20 24 16 Cover Story Getting Engaged – Training & Safety Go Together Best Practices of World Class Companies By Bryan McClure On the Cover: Gardner Watson Decking is one of eight companies that received Safety Excellence or Training Excellence awards from SEAA. The company attributes reduced employee turnover to putting a focus on safety. 26

David DeSilva

By Macie Murie

w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e m e n t p r a c t i c e s .

THE M&P DIFFERENCE IF YOU LIFT, ERECT, HAUL, OR RIG IT: M P S P E C I A L T Y . C O M C O N T A C T J A S O N M C E L R A T H T O D A Y 1 1 7 9 S u n s e t B l v d W e s t C o l u m b i a , S C 2 9 1 6 9 | 8 0 3 9 3 6 1 6 0 1 | J a s o n @ M P S p e c i a l t y c o m L i c e n s e d n a t i o n w i d e , M & P S p e c i a l t y I n s u r a n c e o f f e r s c o m p r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o f a l i g n m e n t b e t

THE M&P DIFFERENCE IF YOU LIFT, ERECT, HAUL, OR RIG IT: WE INSURE IT. M P S P E C I A L T Y . C O M C O N T A C T J A S O N M C E L R A T H T O D A Y 1 1 7 9 S u n s e t B l v d W e s t C o l u m b i a , S C 2 9 1 6 9 | 8 0 3 9 3 6 1 6 0 1 | J a s o n @ M P S p e c i a l t y c o m L i c e n s e d n a t

o n w

d e , M & P S p e c i a

n s u

n

r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o

m e n

. I N D U S T R Y S P E C I A L T I E S : THE M&P DIFFERENCE IF YOU LIFT, ERECT, HAUL, OR RIG IT: WE INSURE IT. M & P S p e c i a l t y I n s u r a n c e p r o v i d e s i n s u r a n c e a n d r i s k m a n a g e m e n t s e r v i c e s f o r h e a v y l i f t i n g a n d m o v i n g i n d u s t r i e s . M P S P E C I A L T Y . C O M S T E E L E R E C T O R S H E A V Y H A U L E R S C R A N E R E N T A L R I G G I N G F A B R I C A T O R S S T R U C T U A L M O V E R S C O N T A C T J A S O N M C E L R A T H T O D A Y 1 1 7 9 S u n s e t B l v d W e s t C o l u m b i a , S C 2 9 1 6 9 | 8 0 3 9 3 6 1 6 0 1 | J a s o n @ M P S p e c i a l t y c o m L i c e n s e d n a t i o n w i d e , M & P S p e c i a l t y I n s u r a n c e o f f e r s c o m p r e h e n s i v e c o v e r a g e , e x c e l l e n t c u s t o m e r s e r v i c e , a n d c o m p e t i t i v e p r e m i u m s . U n d e r w r i t t e n b y A + r a t e d c a r r i e r s , o u r t e a m e m p h a s i z e s t h e i m p o r t a n c e o f a l i g n m e n t b e t w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e m e n t p r a c t i c e s . N D U S T RY S P E I A LT I E : T E E L E R E C T O R S AV Y A U L E R S A R E N TA L G G N G A B R I C AT O R S T R U C T U R A L M OV E R S

i

i

l t y I

r a

c e o f f e r s c o m p

f a l i g n m e n t b e t w e e n i n s u r a n c e p r o d u c t s , c o n t r a c t u a l d e t a i l , a n d r i s k m a n a g e

t p r a c t i c e s

THE OFFICIAL MAGAZINE OF THE STEEL ERECTORS ASSOCIATION OF AMERICA

SEAA is the only national trade association representing the interests of steel erectors, fabricators, and related service providers. Connector reaches both small and large contractors working in union and open labor markets.

Steel Erectors Association of America

353 Jonestown Rd, Suite 207 Winston-Salem, NC 27104 336-294-8880 www.seaa.net

OFFICERS & EXECUTIVE STAFF

David Deem, President

Jack Nix, President Elect

Chris Legnon, Industry Member Vice President

Carrie Gulajan, Associate Member Vice President

Bryan McClure, Secretary

Greg Phillips, Treasurer

R. Pete Gum, Executive Director

PUBLISHING PARTNER

Chris Harrison, Publisher connectorsales@seaa.net Phone 660-287-7660

Tracy Bennett, Managing Editor editor@seaa.net Phone 816-536-7903

Macie Murie, Assistant Editor macie@mightymomedia.com

Tina Lawrence, Art Director tina@snowdesigngroup.net

ADVISORY COMMITTEE

Chris Legnon, Chairman, Cooper Steel

Glen Pisani, Vice Chairman, MAS Building & Bridge Nathan Bloch, SDS2

Nick Caratelli, Nelson Stud Welding

Oliver Gleize, OTH Rigging

John Hughes, Industrial Training International

Kris McLean, High Plains Steel Services

Jackson Nix, Shelby Erectors

Brian Schleicher, Superior Cranes

Jim Simonson, Steel Service

Michael Waltman, Group Steel Erectors

Connector™ is published quarterly by the Steel Erectors Association of America 353 Jonestown Rd, Suite 207 Winston-Salem, NC 27104

6 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

Copyright 2022 by the Steel Erectors Association of America. No material may be reprinted without permission from the Executive Director. While the information and recommendations contained in this publication have been compiled from sources believed to be reliable, the Steel Erectors Association

its affiliates, employees, contributors, writers, editors, designers, photographers, and media advisory committee, makes no guarantee as to, and assumes no responsibility for, the correctness, sufficiency or completeness of such information or recommendations and cannot be held responsible for the outcome of any action or decision based on the information contained in this publication or claims made by advertisers. No part of this publication may be reproduced in any form without prior written permission of the Publisher. Permission is only deemed valid if approval is in writing. NEED HELP WITH... HIGH VALUE MEMBERSHIP for Companies of All Sizes HIRING? Workforce Solutions Q Free Job Board & Low Cost Applicant Tracking Q Free Webinars on Recruiting & Hiring Q DOL Approved Ironworker Apprenticeship TRAINING? Safety & Training Resources Q Erector, Reinforcing Ironworker, Fabricator Curriculum Q Free Training Videos Q Get Help Implementing NCCER Curriculum Q Rigger, Signalperson, & Crane Operator Certifications Q Resources for OSHA’s Fall Prevention Stand Down NETWORKING? Industry Connections Q Partnerships with AISC, NISD, SDI, SJI, & Others for Discounts & Additional Resources Q Trade Show & Demos of Latest Tech & Products Q Peer Groups & Committees Open Doors to Business Relationships SEAA IS FOR YOU. Structural & Reinforcing Erectors • Decking Installers • Steel Fabricators • Specialty & General Contractors JOIN TODAY AT SEAA.NET GROWING YOUR BUSINESS? Marketing Tools Q National Awards Programs Q Free, Customizable Online Directory Listing

of America,

By David Deem

By David Deem

The Growth Dilemma

After the last board of directors meeting in Colorado, SEAA invited a small group of members and guests to participate in a peer group about recruiting and retaining top talent. This informal roundtable discussion provided a safe place for open dialog about one of the biggest challenges faced by erectors, and the construction industry in general. It came as no surprise that labor shortages negatively impact business growth for many companies.

Before we begin to address solutions, we need to face the reality of what got us here—a shrinking labor pool, an aging workforce, and growing industry. During the Baby Boom years the average household consisted of 3.6 children; today that number is 1.7. Currently, 52% of Ironworkers are over the age of 40, 29% are 30-40 years of age, and only 19% are younger than 30.

Meanwhile, the industry is growing. The construction industry is predicted to grow 4% annually through 2026. The steel construction segment is even more impressive with expected growth of 13%, which will require an additional 11,400 employees through 2026.

All of the above points to a great opportunity for cur rent and future populations to find gainful employment in our industry. We, as managers of our companies and stewards of the industry, can take proactive steps to create solutions versus reacting to the crisis.

Get the word out

Participate in job fairs and career days, reach out to the local high schools, community colleges, etc. The fact that there are over 11,000 opportunities should be attractive. Make the industry “cool” again, highlighting not just the wage opportunities but also the camaraderie and pride that comes with doing something that not just anyone can do.

Target the right recruits

The US Bureau of Labor “quick facts” for ironworkers describes our work as follows – “Ironworkers perform physically demanding and dangerous work often at great heights.” To some, that might not seem like a good mar keting angle, but that’s exactly what attracted me to the industry! This is a job description that is likely interesting to former athletes and military veterans.

It also is beneficial to have bilingual people in your Human Resources Department. PolicyAdvice.net esti mates that 30% of our current workforce is Latino or Hispanic. I would guess that percent is larger in many geographical areas.

Show a clear career path

The upcoming workforce wants to be invested. They want to know the expectations and for there to be sys tems in place to measure their progress. A first step in doing this is to establish work-based learning options for students and current workers. According to the National Center for Construction Education and Research (NCCER), a growing number of construction workers are seeking to develop multiple skills to align with their personal career growth. In fact, in the top 10 dual-skill pairings there are three ironworker combinations:

• Ironworker and Pipefitter

• Ironworker and Carpenter

• Ironworker and Crane Operator

In addition to these solutions, there are some import ant long-term ones that involve industry, education, and government working together to overhaul technical edu cation in this country. Read more about this in the report “Restoring the Dignity of Work,” developed by NCCER, Construction Users Roundtable, Ironworkers/IMPACT, and Construction Industry Institute. (Find the report under the Research tab at NCCER.org.)

Tools to recruit, train, retain

The good news is that SEAA has current programs in place (with more to come) to help us succeed in recruitment, training and retention.

A job board and applicant tracking system powered by CareerPlug is available at a deeply discounted rate to help our members with hiring.

Companies that want to become an NCCER Training Unit or Assessment Site using SEAA’s custom ironworker curriculum get admin and implementation support from SEAA, which is valued at nearly $12,000 per member. This is truly a personal service, customized to your needs. According to an article by Tim Taylor, NCCER’s Director of Research, “The most important workforce development element is a firm’s formal policy for or commitment to providing a formal craft skills training program.”

In addition, by January SEAA’s new Learning Manage ment System will have launched. Every member gets one license to access more than 70 ironworker training videos and hundreds more free content from third-party providers. This is a tool that would cost members more than $10,000 to set up on their own, and SEAA is providing it at no charge.

Last but not least, SEAA will hold a career fair on January 20, 2023, hosted by GMF Steel Group in Lakeland, Florida. I encourage all members in the southeast to reserve booth space to promote your company and show what being “Steel Strong” is all about. •

8 | THE STEEL ERECTORS ASSOCIATION OF AMERICA PERSPECTIVE

David Deem is President of Deem Structural Services LLC, AISC (CSEA/MEE), and is President of the SEAA Board of Directors.

Evol vewith ®PNEUTEK Colts Stadium Indianapolis, IN PNEUTEK® See th e ad va ntag es at www.pneutek .com Evol vewith become Don’ t ex ti nct. Cowboys Stadium Dallas, TX TD Banknort h Garden Boston, MA The Air/Safe® Fastening System by Pneutek® has consistently allowed steel erectors and construction companies around the country to complete high profile desking projects with superior quality, lower costs and faster completion time. Pneutek’s® Air/Safe® innovative design is completely pneumatic. It is safer, faster and more reliable than dangerous powder tools or inconsistent welding methods. The Boston Celtics, Dallas Cowboys and the Indianapolis Colts are all leaders in their fields. They became leaders by adopting innovations which were ahead of their times. If you are ready to move beyond obsolete methods of steel deck attachment, join the hundreds of innovative users of Pneutek® tools. To learn more, call or go online. When you visit the champions, look up. We’ll be ther e. 17 Friars Drive • Hudson, NH 03051 • Ph:8 00 -431-866 5 • Fax: 603- 882- 9165 PNEUTEK

EVENTS & ACTIVITIES

January Board of Directors Meeting

Tampa, Fla.

January 19, 2023

January Meet & Greet

Tampa, Fla.

January 19, 2023

Career Fair

Lakeland, Fla.

January 20, 2023

ConExpo-Con/Agg

Las Vegas, Nev.

March 14-18, 2023

■ SEAA to Launch Learning Management System with Custom Ironworker Training Materials

SEAA announces it is in the final stages of Beta Testing of its new Learning Management System. SteelPros Train ing Portal will be exclusively for members. Developed in partnership with Industrial Training International (ITI) and built on ITI’s Learning Hub platform, SEAA members now have easy access to custom content for ironworkers.

Each of three Learning Paths—Ironworker Level 1, 2, and 3—contains multiple videos, which align with specific learning modules in the SEAA/NCCER Ironworker Custom Curriculum. “SEAA has invested more than $120,000 to bring these professionally produced videos to our mem bers,” said Pete Gum, Executive Director.

The SEAA/NCCER Ironworker Custom Curriculum, which meets U.S. DOL apprenticeship standards, provides members with a tool for delivering nationally recognized ironworker credentials to their employees. “SEAA’s SteelPros Training Portal enhances the delivery of that training and opens access to additional training resources to all members, whether they are set up as an official SEAA/ NCCER training unit or not,” said Gum.

Every SEAA member will receive one free account and one license to access this member benefit. Additional licenses can be purchased for $35 each per year. “This is

a vital resource for your safety directors or training man agers—a member benefit valued at more than $10,000 per member,” said Jack Nix, Membership Committee Chairman.

SEAA members will receive a 25% discount on ITI’s custom content for Field Leadership, Mobile Crane Maintenance and Operations, Rigging, and Site Hazard Recognition. Hundreds more third-party training content from organizations such as Crosby, Liebherr, Manitowoc, and Verton is free to access.

In a separate agreement with The Crosby Group, SEAA members can purchase Crosby’s “User’s Guide for Lifting,” at 20% off the regular price. This training resource cov ers rigging fundamentals through a series of self-paced lessons that explain the Crosby User’s Guide for Lifting pocket rigging card. Each topic includes a video and a corresponding quiz.

“More than just a library of training materials, SEAA’s SteelPros Training Portal Learning Management System provides administrative features to track progress of learners, manage certifications, and create custom reports for individuals or groups inside your organization,” said Nix.

“ITI is excited to partner with SEAA by bringing its members new digital learning content. Most companies today find it challenging to recruit, on-board, train and deploy people efficiently. SEAA and ITI will help solve that problem,” said Zack Parnell, CEO and President of ITI.

2023 Convention & Trade Show

St. Augustine, Fla.

March 28-31, 2023

10 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

ASSOCIATION NEWS

The SteelPros Training Portal features a robust learning management system with custom content and access to hundreds more third-party training resources.

At the 2022 Career Fair, about 300 attendees rotated through stations where they learned about the steel construction industry and met with employers.

CAREER FAIR

INFORMATION

Who

The Career Fair will target high school students and active job seekers, including veterans and post-secondary technical school students.

■ SEAA to Host Second Career Fair

SEAA invites members to participate in a Career Fair promoting the steel construction industry, to be hosted by member GMF Steel Group in Lakeland, Fla. The event is free to SEAA members, but space is limited to about 20 stations. SEAA is also seeking sponsors to help to defer costs. Contact bryttany@seaa.net to reserve your Career Fair station or to sponsor the event.

The Career Fair will target high school students and active job seekers, including veterans

and post-secondary technical school students. Participating companies will provide a short presentation or hands-on demonstration that highlights skills needed for working in steel fabrication or construction.

The day prior to the Career Fair, SEAA will hold its first quarter board meeting and a Meet & Greet Reception on January 19 at Hyatt Place Downtown Tampa, Florida. Meet & Greet Spon sorships are available. Get more info and RSVP at seaa.net/meetings

When January 20, 2023 from 9 am to 3 pm. Morning session is for high school students. Afternoon session is for adults.

Where

Hosted by SEAA member GMF Steel Group, 4600 Drane Field Rd., Lakeland, FL 33811

What

Members should prepare a 10–15-minute presentation or hands-on demonstration to share with attendees that highlights skills needed for working in steel fabrication or construction.

■ Rudy to Open 2023 Convention

SEAA announces Daniel “Rudy” Ruettiger as the 2023 keynote speaker for its convention and trade show in St. Augustine, Fla., March 28-31, 2023.

2023 marks 30 years since Tristar Productions immortalized Rudy’s life story in the blockbuster film named for him. It is a story of adversity and triumph about the “five-foot nothin’, a hundred and nothin’” Notre Dame football player who sacked the quarterback in the last 27 seconds of the only play in the only game of his college football career.

Ruettiger delivers a powerful message of “Never Quit” and “Yes I Can” that comes from his experiences as the son of an oil refinery worker and third of 14 children.

Register by January 31 to receive Early Bird Discounts. For more info, visit seaa.net/events

12 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

■ Eliminate Manual Steel to Concrete Connections

The V Chamber from Connect-EZ, Harveysburg, Ohio, provides a secure mechanical connection from structural steel to concrete without field welding. The V Chamber transfers loads from the steel frame structure to the concrete structure in a fashion similar to the traditional embedded steel plate with studs.

The chamber and bearing seat engage remotely, eliminating the manual connection and the need for a welder on scaffolding or a hydraulic lift. The interlocking bearing seat is fabricated with slotted holes allowing up to 2 inches of lateral tolerance. The result is reduced labor, reduced equipment cost, and increased job site safety during steel erection.

■ Zero-Emission Hydrogen Power Generators from United Rentals

United Rentals, Inc., Stamford, Conn., has added several hydrogen power generators to its North American rental fleets. The EODev GEH2 fuel cell electro-hydrogen generators bring companies the energy they need, without emissions of car bon dioxide (CO2), hydrocarbons (HC), nitrogen oxides (NOx) or other particulate matter (PM). With a compact footprint of about 4 feet by 11 feet, the generators deliver power up to 110 kVA (88 kW) which can charge electric vehicles, tools, and other equipment. United Rentals has acquired the generators from Generac, a distribution partner for EODev.

Generac EODev electro-hydrogen generators

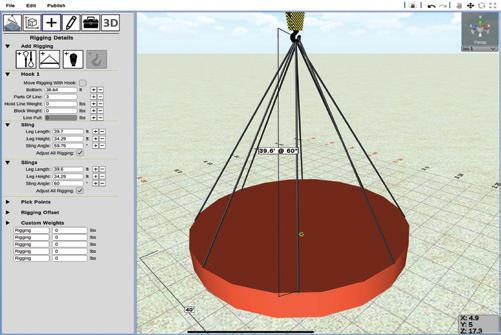

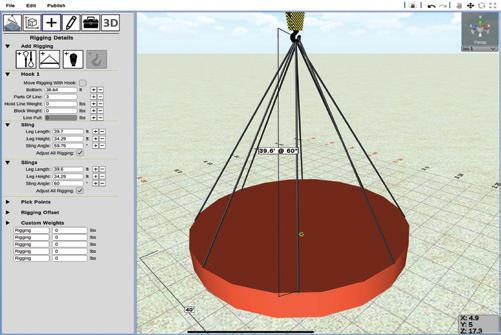

■ Custom Rigging Tool is Now Available in the App Store

A1A Software, Fernandina Beach, Fla., has released the first lift planning tool in its new application-based A1A Product Suite. The Rigging Designer app enables users to create custom rigging plans, and is ideal for any application where loads must be rigged. Whether that’s for lifting by a mobile crane, overhead crane, a gantry, or industrial forklift. Point/Click and Drag/Drop functionality makes it easy to create custom rigging designs, or choose from hundreds of pre-built rigging products, loads, and objects. Users of A1A Software’s 3D Lift Plan can also import their rigging designs into the lift planning software for use later.

14 | THE STEEL ERECTORS ASSOCIATION OF AMERICA PRODUCT FOCUS

The V Chamber from Connect-EZ

Rigging Designer

■ ClearLight Optics Provide Realistic View for Welding

Miller Electric Mfg., Appleton, Wis., has introduced the ClearLight 2.0 enhanced lens technology for its Digital Performance, Digital Elite, Digital Infinity, and T94 series welding helmets. It offers nat ural, accurate color tones, giving the welder a crisp, high-definition view of the work piece. The lens has a 1/1/1/2 optical clarity rating that allows welders to keep their hoods down between welds and non-welding tasks within arm’s reach of the workpiece.

■ Compact Mini Crawler Crane

The Track-O Mini Crawler Crane by Movex Innovation, Quebec, Canada, is fully electric and operated by a remote control. The mini crane has a capacity up to 1,100 lbs. and a reach of 16.5 feet. The compact body of the mini crane enables it to fit through tight spaces, such as doorways, and the uniquely designed tracks allow it to go up and down stairs without physi cal labor. The crane is equipped with outriggers to provide stability during lifting operations.

■ ITI Releases Rigging Engineering Calculations Collection

Industrial Training International, Woodland, Wash., has introduced a new course that provides an overview of common Rigging Engineering topics and how to analyze example problems from Rigging Engineering Calculations, by Keith Anderson.

The six-part collection is comprised of Rigging Engineering topics, including calculating problems related to Drifting Loads, Forces in Spreader Systems, Load Distribution Beneath Mobile Cranes, Upending Using Two Lifting Devices, Forces in Bridle Slings, and Assessing Wind Forces. Many of the modules include interactive surveys, ensuring that learners are engaged and challenged throughout the learning process. •

Connector | WINTER EDITION December 2022 | 15

ClearLight™ 2.0 Lens

Traditional Lens

1-866-733-3272

Track-O Mini Crawler Crane

ClearLight 2.0

MANAGEMENT

Cyber Security for Construction

Understanding the risk and protecting your company

The time when cyber risk was mostly a data breach-related issue is over. With the explosion in ransomware attacks, business email compromises, fraud and stolen credentials, cyber is now everyone’s risk. And as it continues to increase, construction companies have become a target.

Ransomware: The No. 1 Cyber Threat

The construction industry may not seem like an obvious target of cyber criminals compared to industries like health care, retail or technology – but that’s chang ing. Earlier this year, Canadian contractor Bird Construction and French contractor Bouygues Construction were both hit by ransomware attacks. Ransomware attacks often focus on companies that will be immediately impacted by the disruption caused by the attack. Construction companies are likely being targeted because of their limited

awareness of cyber risks and their lack of cybersecurity.

In addition, ransomware can cause a sub stantial interruption to the complex supply chain of construction projects. And as attacks become more sophisticated, ransom demands have gone up dramatically. In fact, it’s not uncommon to have ransom demands in the range of several millions of dollars – that’s on top of the interruption loss incurred even when the ransom is paid.

Business Email Fraud

A unique feature of the construction indus try is the extensive use of sub-contractors and suppliers, which involves a high degree of payments flowing to and from construction companies. Additionally, construction proj ects are often part of a public bidding process. The details in this process include information about the project and the winners. This makes construction companies an attractive target for business email compromise fraud. This

is a deception scam where cyber criminals send fraudulent email messages disguised as legitimate invoices or wire transfer requests. The money is then transferred to the criminal’s account instead of the actual payee. In 2019, almost 24,000 of these incidents were reported to the FBI for a total of $1.8 billion in stolen funds.

Many times, contractors have open data connections with their customers for things like electronic bill paying and project man agement. When these connections are linked to their customers’ other important systems, it creates an environment for cyber attack ers who’d like nothing more than to steal as much information as they can. And once they have the contractor’s credentials, those cybercriminals can take valuable information from the contractor’s customers.

Protecting Your Company

Everything has to start with cyber risk awareness and understanding what the

he is also an

16 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

By David DeSilva and Anthony Dolce

David DeSilva is head of Construction for The Hartford’s Middle and Large Commercial division. He is an experienced construction underwriter with capabilities in workers’ compensation, general liability, and excess lines of coverage for contractors and subcontractors. Anthony Dolce is Head of Professional Liability for The Hartford. He manages multiple underwriting groups that handle a variety of lines of business including miscellaneous professional liability, architects and engineers, cyber and technology errors and omissions. With over 20 years of experience in specialty coverages for the financial industry,

attorney with a focus on insurance coverage and commercial litigation.

By Tracy Bennet

Construction is the third most common industry to be targeted by cyber criminals, and in 2020 to 2021, nearly one out of every six construction firms have experienced a ransomware attack, reported Tom Jackson on EquipmentWorld.com. Steel erection contractors are not immune.

Earlier this year, SEAA member S&R Enterprises LLC, Harrisburg, Pa., was the victim of an email breach, which cost them more than $400,000. Stephen Burkholder, CEO, says the experience has made him realize how easy it is to fall prey and how common the problem is.

S&R Enterprises wired “payment” to the hackers, who were posing as one of S&R’s subcontractors. When the scam was revealed, the Department of Homeland Security got involved. Through their efforts, Burkholder has come to understand what happened.

Initially, a mole email was planted with benign

content using the subcontractor’s name. Burkholder notes that after the scam was revealed he real ized that there was just one letter transposed in the url address that redirected the emails to the cyber criminals. “That’s not something most busy people are going to notice,” he said.

For a period of three to six months, the cyber criminals used this to watch the email communi cations between Burkholder and the real subcontractor and emails to and from the accounting department. This gave the cyber criminals the intel to later insert themselves into a dialog with Burkholder that appeared to be a real interchange with the subcontractor.

“The mole knew when work on a specific project had been completed and started asking for payment. We don’t normally make payments by wire transfer, but we had done so on one occasion with this company previously,” he said.

“I’m friendly with the people at this company. We know each other well. It was surprising to me how accurately the mole replicated the typical banter we have,” he said. Initially Burkholder refused the wire

payment request, telling the “subcontractor” it would come in the normal time frame and fashion. But when the request came again sometime later, convinced he was dealing with the real company, he relented because of his relationship. The whole scam was revealed when weeks later the President of the real company called to ask why they had not ever been paid for the job.

During a short window after the wire transfer was made, the hackers made other attempts. In both these cases it was requests from customers to make payment to S&R Enterprises, rather than the other way around. Burkholder says he has learned this is common. Fortu nately, they had already been alerted and the accounting department was wary of the requests.

LESSONS LEARNED

• The company no longer shares account information in the body of an email.

• Only rarely, will they wire funds. In those cases, they require the organization to fill out a form and sign it. And all requests are followed up with a phone call to confirm the veracity of the request.

• Burkholder also advises that you check up on the protocols of your bank. “The first attempt to do the transfer was kicked back to the bank. They never should have attempted it a second time,” he said. Since then, the company has changed banks to one that requires an in-person request to complete the transfer. He noted that this type of situation is not covered by the FDIC.

• And pay attention to the url domain name in emails. If something is off—assume it’s a hacker.

Connector | WINTER EDITION December 2022 | 17 • 2-3/8" Diameter x 3" Depth • Hidden Motor Cord • 3 Speed - 250 / 450 / 700 RPM • Use HSS or Carbide Cutters • 100% Hougen Reliability • Available Accessories • Two Year Warranty Pat. Pending Drill

Every Day HMD920 Mag Drill 800-426-7818 SERVICE • INTEGRITY • RELIABILITY HOUGEN.COM Hou-757-SEAA-third.indd 1 2/23/22 8:37 AM A STEEL ERECTOR’S STORY

All Day,

Stephen Burkholder, S&R Enterprises

financial impact can be to the business in the event of a successful attack. Social engi neering continues to be an integral part of many attacks simply because it’s the path of least resistance. As it relates to business email compromise fraud, it’s the main attack method.

When it comes to ransomware attacks, criminals exploit a number of critical vulner abilities in systems and applications that are

used by most businesses, such as Microsoft’s operating system and VPN applications for remote access.

Outside of standard technical cybersecurity protections, the following measures can greatly reduce construction companies’ exposure to cyber threats.

Provide cyber risk awareness training, including anti-phishing exercises, for employ ees. In addition, require employees to use

strong passwords. For users with access to critical data and applications or who are involved with wire transfer changes or approvals, it is a good practice to require multi-factor authentication. In addition, have procedures to authenticate the legitimacy of requests for payment and changes to wire transfer instructions.

When it comes to operating systems, maintain good open port hygiene and only running those operating system services that are absolutely required for the network operation. Remote desktop protocol is an example of a commonly exploited service in ransomware attacks that is rarely critical to operations and should be shut off. When vulnerabilities are identified, ensure that critical areas are patched within 30 days of release by the vendor.

Frequent back-ups and encrypting or storing back-ups off-line can prevent cyber criminals from encrypting or destroying the back-up as part of the attack. Use VPN for remote access. For organizations with remote users, the VPN provides a secure channel through the Internet to the organization’s private network.

Finally, prepare for the worst with an incident response plan (IRP). This prescribes the way a business will respond to and manage the effects of a security attack.

Cyber Risk Coverage

Even with strong security in place, businesses can still fall victim to costly cyberattacks. That’s why cyber risk coverage is important to help protect a business. For example, CyberChoice from The Hartford, offers customers complimentary ransom ware prevention services. These services can help protect businesses against phishing attacks and open-port vulnerabilities, which are the root causes of nearly 90% of ransomware attacks.

This coverage includes Bitsight reporting, which can help businesses identify and address open-port vulnerabilities. The report can provide a measurement of a company’s cybersecurity performance. Customers can get a complementary consultation with Bitsight to help them understand and respond to the results.

For more information about The Hartford’s CyberChoice and to access The Hartford Cyber Center resources, go to:

https://www.thehartford.com/commercialinsurance-agents/specialized-cybertech •

18 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

300 Scarlet Blvd. Oldsmar, FL 34677 Phone: 813.891.9849 Fax: 813.891.4105 Duke Perry, VP of Sales/Operations 404-808-0504 Duke.p@gwstuds.com SAFE. PRECISE. ON TIME. gwstuds.com

Are Your Ironworkers Qualified for Rigging?

The

importance of formal training

Ironworkers are required to do rigging on a regular basis. In many cases, rigging involves repetitive, routine types of lifts, but not always. When faced with rigging uniquely designed sections, trusses, or com ponents, these less common rigging activities require an elevated level of knowledge and skill that can’t always be taught in the field.

While rigging unique structures can be complicated, OSHA does not require formal certification for riggers. OSHA 1926.753(c) (2), only requires rigging activities to be performed by a “qualified” person, and it’s up to the employer to determine whether a person is qualified. Rigger qualification is specific to the rigging task at hand. This doesn’t mean that once rigger has been deemed qualified for one type of activity, such as lifting indi vidual joists or beams, they are now able to perform all rigging activities moving forward.

Some employers find that on-the-job train ing and experience is sufficient to deem an employee qualified to perform routine rig ging activities, but that is not sufficient when working with uncommon rigging scenarios. Here’s an example.

Last year, Illinois steel erector Area Erectors, Inc., used seven cranes to lift two 40 ft. x 250 ft. long trusses that made up the walls and two 40 ft. x 80 ft. cantilever trusses that became the entrance on the Pritzker Military Archives Center in Somers, Wis. Each of the two cantilever trusses was pitched in different directions while being tied into the existing structure and wall trusses. Advanced rigging

knowledge is necessary for this type of lift. To assist them with pre-planning, the com pany used A1A Software's 3D Lift Plan. In all, the company created more than 20 3D Lift Plans for this project. This year, A1A Software has released a new tool specifically for rigging planning called Rigging Designer, which enables users to create custom rigging plans.

The Need for Formal Training

“Many well-intentioned riggers depend on the equipment or hardware’s design factor to compensate for the lack of knowledge on correct rigging practices. Ironworkers are often posed with erecting unique structures that could have multiple attachment points or an off-set center of gravity. These rigging scenar ios require an advanced level of knowledge in order ensure the load can be rigged and hoisted safely,” said Jim Cox, Master Trainer, Industrial Training International (ITI).

“I recently went through a rigger and signal person training course as a refresher, and it was really eye-opening. After being in the industry for almost 40 years I thought I was going to know everything but I didn’t. I actually learned a lot,” said Jack Nix, Chief Operations Officer of Shelby Erectors. “I realized that it’s easy when everything is balanced, but with unbalanced loads you really need to know what you are doing,” he continued.

SEAA members that are accredited SEAA/ NCCER Ironworker Craft Training Units are able to deliver basic rigger and signal person training, which is a requirement for individuals to complete. Once established, SEAA Craft Training Units and Assessment Sites can additionally decide whether to offer Basic, Intermediate or Advanced Rigger and Signal Person training and NCCER certification to the general public, or restrict the service to employees only.

“It’s important for everyone to receive rigger and signal person training to under stand the basics and overall best practices. When everyone on the job is on the same page, knows what’s going on, and knows what to expect during lifting operations, it increases productivity, safety, and efficiency,” said Tim Eldridge, President of Education Services Unlimited and SEAA’s Craft Training and Assessment Administrator.

Basic rigger training is an excellent start, but it is important to have crew members go through intermediate or advanced training so that there is always someone on the job site that is qualified to handle unique rigging scenarios.

SEAA member ITI provides accredited rigger and signal person training for basic, intermediate, and advanced levels, and issues a qualification certificate after an individual takes a training course and passes the qualification exam. This can be an excellent way

20 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

IN THE

FIELD

By Macie Murie

Macie Murie is the Associate Editor of Connector. She can be reached at macie@mightymomedia.com

300 Scarlet Blvd. Oldsmar, FL 34677 Phone: 813.891.9849 Fax: 813.891.4105 Estimating: Geoff Kress: 727.463.3074 Jason Kulvinskas: 727.463.3078 FL CGC1514810 SAFE. PRECISE. ON TIME .

Test Your Knowledge

The following quiz is from ITI’s blog. You’ll find this and others at iti.com/blog/topic/rigging-quiz

Some loads can be single point picked, and the rigging is selected based on suspended weight.

Other times, a rigging task will require that we use a few steps to get to the solution. Note that in some cases the distribution of weight is required, then the sling tension is discovered as a 2-step process. In the assignment below, we can determine the sling tension in the 9.2' leg and the 6.7' leg by using the formula on the Master Rigger Reference Card, Panel 10 (left side of the panel).

Once we find the tension of side 1 (TS1) and then tension of side 2 (TS2), we can select the correct size of alloy chain for the lift.

In the assignment on the right, the ADOS stands for “Adjustable, Double (leg), Oblong (link at the top), Standard or Sling (hook at the bottom)”.

Let’s see how you do.

Adjustable 2-Leg Chain Sling

for employers to verify if a rigger is qualified to perform the rigging activity at hand. “The ITI qualification lasts for five years after passing the exam, but we always encourage students to take continuing education courses or skill building workshops throughout the year,” said Cox.

“It’s important to stay current on your training, and if someone wonders whether their skills are getting rusty, its best to take a refresher course. It’s one of the reasons why ITI developed the ITI Basics Courses. They are 20-minute, e-learning courses which help those in the field to reflect on skills and principles needed to complete work safely,” continued Cox.

A Multiskilled Workforce

Rigging is one of those skills that overlaps with other primary tasks throughout construction activities. According to research conducted by the Construction Industry Institute (CII RT-370), rigger is in the top two skills paired with other positions. In fact, research shows that the increase in employees seeking multiple skills is driven organically by workers, not by employers. Workers are choosing to be dual trained in order to find consistent work, earn higher wages by expanding their role at work, and challenge themselves to learn a new skill.

“Employers would be wise to acknowledge the desire of workers to learn new skills and provide the opportunity for doing so,” said Tim Taylor, Director of Research for the National Center for Construction Education and Research (NCCER). Taylor has four sug gestions for employers.

Determine the tension and the alloy chain sling size necessary to make the lift.

Leg 1 (9.2') Tension = __________ lb.

Leg 2 (6.7') Tension = __________ lb.

Sling Description: ADOS __________" ×10'

Answers found on Topping Out, page 38.

• Provide opportunities for new industry entrants to explore different trades to identify an area of interest.

• Communicate defined career path options within your organization.

• Give employees credit for related knowledge, skills, and abilities that contribute to competency in the new skill area.

• Provide resources for adult learners— training that is flexible and self-paced. •

22 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

OSHA requires rigging activities to be performed by a “qualified” person, and it’s up to the employer to determine whether a person is qualified.

Formal training is necessary when it comes to complex rigging scenarios.

Modulift’s versatile and cost-effective Modular Spreader Beams along with pewag’s state-of-the-art quality lifting chain and components provide the ideal solution to simplify your lift! 800.526.3924 sales@pewagchain.com pewagchain.com

SPECIAL FOCUS

Thousands Raised for Safety and Education

The sold-out Dave Schulz Memorial Golf Tournament supporting SEAA’s safety and education projects raised about $13,000. “For our first venture west, turnout for the tournament and participation in the Meet & Greet held the previous night was outstanding,” said Pete Gum, Executive Director. More than 80 people registered for the Meet & Greet and 60 golfers competed in the tournament. “We appreciate the support of sponsors, who made this a successful meeting,” said Gum.

The tournament was held at the Omni Interlocken Golf Club in Broomfield, Colo., on September 16, where a scramble was played on three adjacent courses. Golfers repeatedly claimed that the greens, fairways, and mountain scenery made this one of the most beautiful courses they had ever played. The tournament returns to its original location in North Carolina in 2023.

“We were thrilled that Denver local Kayleen McCabe, representing the McCabe Foundation, joined us,” said Carrie Gulajan, SEAA Events Chairperson. McCabe, who is a construction industry celebrity and former SEAA convention keynote speaker, is an advo cate for careers in the construction trades. Learn more at kayleenmccabe.com.

Peer Group Discusses Recruiting, Retention

The meeting also included its first-ever Peer Group, a small discussion group of local companies which met the previous day, prior to the Meet & Greet. The theme of the discussion was recruiting and retention. “Two years ago, SEAA’s Board of Directors made a strategic decision to re-form committees, opening them up to members at large in order to provide more opportunities for member engagement. As those positions have been filled, we are now implementing phase two— local peer groups,” said Jack Nix, Membership Chairperson.

Facilitated by Tucker Smith of BBSI and Victor Garcia of Denver’s Flawless Steel Weld ing, the group of about 10 shared struggles and best practices. “Peer groups are a safe place to speak openly. That dialog is critical to giving SEAA members in a local area con nections and resources for improving their businesses and the industry,” said Nix.

Following the Peer Group, area erectors, fabricators, engineering firms, and suppliers learned about new benefits of SEAA member ship and heard about product and services solutions from sponsors Kenwood, Nelson Stud Welding, and Well Works. •

24 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

Members remember Dave Schulz at Colorado Golf Tournament

First Place Team: JD Daniels, Zack Ganzell, Brian Hildebrand, and Austin Mouw of Bigge Crane and Rigging Co., presented with the award by SEAA President David Deem.

Sponsors are a critical piece of the fundraising project.

Denver local Kayleen McCabe, representing the McCabe Foundation, tees off.

Lee Shaw of S.L. Shaw company and Nathan Bloch with SDS2 share ideas during Peer Group discussion.

conduct association business the day before the golf tournament.

Sponsor Columbia Safety welcomed golfers on the course.

Tournament Winners

The following golfers took home prizes provided by our sponsors.

First Place Team, Total Gross Score of 60: Zack Ganzell, JD Daniels, Austin Mouw, and Brian Hildebrand of Bigge Crane and Rigging Co. Hildebrand was also one of two people that got the ball Closest to the Pin.

Second Place Team: Jerad Degenhart, Knight Hinman, Scott Hughes, and Randy Phillips of BBSI.

Third Place Team: Don Laro and Jimmy Zolty of GWY and Erich Posdzich and Brice Davison of BDB Fabrication. Zolty also made the Longest Drive.

Fourth Place Team: Drew Heron of Empire Steel, Pat Dunn of L&D Steel USA Inc., Glen Pisani of MAS Building & Bridge, and Nate Bloch of SDS2. Pisani was the other golfer that got the ball Closest to the Pin.

Four individuals qualified for the putting contest: Brandon Rowbottom of Columbia Safety, Jack Nix of Shelby Erectors, Scott Seppers of Trivent Safety Consultants, and Zack Ganzell of Bigge Crane and Rigging.

The Boom Lift Ball Drop, sponsored by United Rentals, brought in $1700. Half of the raffle pot is contributed to Safety & Education projects and half goes to the winner Thomas Newman of Trivent Safety Consultants.

The Boom Lift Ball Drop, sponsored by United Rentals, raised $1700.

Celebrating an awesome putt on a course with “the most beautiful scenery” as backdrop.

Anderson Jones, PLLC

Big B Crane

Bigge Crane & Rigging Co.

Buckner Heavylift Cranes

Building Zone Industries

Columbia Safety and Supply

Construction Insurance Agency

Cooper Steel

Deem Structural Services

Empire Steel

Flawless Steel Welding

Gardner Watson Decking

Gardner Watson Studs

Hanes Supply

Hilti

M&P Specialty Insurance Magni America

MAS Building & Bridge S&R Enterprises

Shelby Erectors

Steel Service Corp

Connector | WINTER EDITION December 2022 | 25 $ 13,000 Raised for Safety & Education Projects

2022 Broomfield,

THANK YOU

September

CO

SPONSORS

Wellworks MEET & GREET SPONSORS See you next year! October 2023 Raleigh,

The McCabe Foundation Titan Steel Erectors TJ's Travel Trivent Safety Consulting United Rentals Kenwood Nelson Stud Welding OTH Pioneer Rigging

NC

Board members and guests

Getting Engaged

Training & Safety GO TOGETHER

Best Practices of World Class Companies

Companies that invest in training and safety initiatives understand the cost benefits of doing so. Studies show that for every $1 spent on safety, there is a savings of 4 to 6 times that by reducing direct costs associated with incidents.

SEAA members who received World Class recognition in the association’s 2022 Craft Training Excellence and Safety Excellence awards programs embrace safety at the high est levels of their organizations. But it is more than a philosophical involvement—these are people who are actively engaged. During a panel discussion with these companies at the 2022 Convention & Trade Show in Charleston, S.C., we heard from one executive who took

Bryan McClure is a partner in Trivent Safety Consultants and Chairman of SEAA’s Safety & Education Committee. He has served on the Board of Directors since 2017. Contact him at bryanm@triventsc.com

Derr & Gruenewald Construction was one of several SEAA members that held Safety Stand Downs during Fall Prevention Week. Find resources for your own stand-down event at seaa.net/standdown

it upon himself to re-take rigger training so that he understood what he was asking from his employees. Another saw the need to balance the responsibilities being put on field foremen and instead to support them with full time safety professionals.

I encourage SEAA members to take the two hours needed to submit an application for either the Craft Training Excellence or the Safety Excellence award. The information requested should all come from documen tation that you already have. The reward for recognition is more than just a trophy. Past winners will tell you it makes a difference in setting you apart from competitors, especially for subcontractors competing on price. Submissions for the 2023 awards are due January 31. Learn more at seaa.net/awards

The following Q&A is excerpted from the panel discussion. These best practices demonstrate that training and safety go hand-in-hand.

How has your company maintained your safety culture with the challenge of a high turnover rate in the steel erection industry?

Ed Valencia: New employees go through evaluation, orientation, and then they are teamed up with other employees who serve as mentors.

Jason Kulvinskas: The first introduction to our company is to our safety team. New employees see from the beginning the impor tance we put on safety. We believe this has reduced turnover—now 60 to 70 percent of our guys have been with us at least five years.

What are some strategies your company uses to keep employees engaged in safety?

Ed Valencia: We have safety meetings with all employees every day, then we split up into individual team meetings, which encourages them get talking because it’s a smaller group.

26 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

COVER STORY By

Bryan McClure

A faster cladding connection is finally here.

Install cladding and curtain-wall connections with the new Edge-Tie™ system from Simpson Strong-Tie. This innovative solution utilizes bolts that allow installers to easily position and adjust anchors along a continuous slot. A reusable guardrail also can be bolted to the beam while it’s still on the ground. By eliminating field welding, the Edge-Tie system saves time and labor costs while increasing safety at the jobsite. It’s simply a smarter, faster way to get the job done. Put all of our structural steel solutions to work on your next project. To learn more, visit go.strongtie.com/edgetiesystem or call (800) 999-5099

©2022 Simpson Strong-Tie Company Inc. ETS22-F

We also have a behavioral safety program, where workers can turn in cards identifying both positive and negative actions that they’ve identified. One is drawn and we give out gifts to the person whose card we drew.

Jason Kulvinskas: We have meetings at the start of every day, to make sure the team is focused on safety. We also have meetings that focus on training employees that may need certifications, such as OSHA 10 or OSHA 30.

Pay raises are tied to achieving safety certi fications. We also create awareness about accidents we learn about in the field (not necessarily GW projects) and we share this information with our crews so that they are aware of the potential risks and the measures that can be used to avoid those dangers.

John Ross McCartney: I don’t know that there is a magic answer to keeping employees engaged in safety. I believe that those strategies vary from company to company. Regardless of your trade or industry it all comes down to the people you employ and their willingness to buy into the company safety culture. It’s our obligation as owners and managers to get know our employees and their families, which creates a level of accountability for both the employer and employee to ensure everyone makes it home safe from work every day. Keeping those val ues at the core of our safety culture is what we strive to maintain on a daily basis.

You are a World Class Safety in Excellence winner; what are your plans to make your program even better this year?

Ed Valencia: Every year we evaluate our injury lists and incidents to look for areas that need improvement. For example, we are using a new drop test tower to look for better ways to tie off.

Jason Kulvinskas: We look for trends and then modify training to address those trends.

Jeremy McAllister: To add to that, we are doing more training with safety managers

Who’s Who. 2022 World Class Winners.

Bracken Companies

Formed by three partners in 1956, today Bracken Companies includes construction and crane rental divisions. The company currently employs 300 workers, focusing on heavy industrial projects in the Central and Southeastern United States. When it comes to safety and training, the company’s philosophy is that success depends on cooperation—not only between management and employees, but also between each employee and their fellow workers.

In 2022, the Bracken Companies received World Class recognition for Safety.

Panelist

• John Ross McCartney, President Derr & Gruenewald

Construction

Derr & Gruenewald Construction is a full-service steel fabrication, steel erection, detailing, metal decking and precast concrete contractor. Based in Colorado, the company performs work throughout the United States. Founded in 1977, the company asserts that the key to maintaining a productive and profitable worksite is making sure employees are properly trained in the latest safety measures.

In 2022, Derr & Gruenewald Construction received World Class recognition for both its Craft Training and Safety programs. As a Category 1 employer, they employ more than 121 ironworkers annually.

Panelists

• Austin Reiner, Safety Manager

• Ed Valencia, Corporate Safety Director

Gardner-Watson Decking

Gardner-Watson Decking began in 2005 as a one crew operation in Florida with one truck and one client. The full-service metal decking installation company now employs 190 plus and operates more than 20 crews nationwide. Floor and roof deck projects include distribution facilities, data centers, hospitals, arenas, cold storage, warehouses, and other jobs.

In 2022, Gardner-Watson Decking received World Class recognition for Safety.

Panelists

• Jason Kulvinskas, Vice President

• Jeremy McAllister, Director of Safety Operations

Shelby Erectors, Inc.

Founded in 1997, Shelby Erectors is a labor subcon tractor that specializes in bridge construction—the installation of reinforcing steel and Stay-in-Place metal decking. The family-owned business is led by Jennifer Nix, owner and President, and employs workers on job sites across Florida. The company aims to elevate the integrity of the construction industry through technol ogy, training, and innovation.

In 2022, Shelby Erectors received a World Class Craft Training Award (Category 2; 61-120 Ironworkers employed annually), and a Premier Class Safety Excellence Award.

Panelists

• Jack Nix, Chief Operating Officer

• Jason Zyla, Safety Manager

Other 2022

World Class award winning companies are invited to partipate in a panel discussion at SEAA’s Convention.

Excellence

Winners Empire Steel Erectors, Premier Class Black Cat Erectors, Gold Class FM Steel Construction, Gold Class LR Wilson & Sons, Inc., Gold Class

Safety

Award

The team from Gardner-Watson Decking receives its World Class Safety award during Convention.

to elevate their education so that they can become OSHA trainers.

Jack Nix: Employees who complete online training courses receive a financial stipend attached to successful completion. That’s something we do to incentivize our employees to continue to do additional online training.

John Ross McCartney: Our affiliation with the Delta Indemnity Group Captive Insurance Program has been a great tool to challenge us as a company to continue to improve our practices and avoid complacency within our safety culture.

What is one hard lesson that your company has learned in Safety? What advice can you give to other steel erectors to help them avoid this same lesson?

Ed Valencia: It is easy to get complacent, especially with small incidents. It is import ant to treat the small incidents as seriously as the big ones so that you can get into the why and how that it happened. Without that knowledge, you can change the outcome.

Jack Nix: We had an incident last year—a smashed toenail. We didn’t think this was a serious injury. However, the employee didn’t keep the injury clean, and the toe got infected. This ended up as an amputated toe for some thing that should have been a first aid claim. He wasn’t taking care of it, and we weren’t checking up to make sure it was being taken care of. Ended up being $150-160,000 claim.

Jason Kulvinskas: When we made the decision to focus on safety, the lesson we learned was that you can’t just have safety docu ments and plans. We were putting too much responsibility on our Foreman for safety. We

determined that we had to have a full-time safety director and safety professionals in the field. One of the best decisions was hiring Jeremy. Unless you have someone that is committed solely to safety you will not reach your safety objectives.

Is your company exploring new technologies that will help make your company safer?

Ed Valencia: We recently invested in a drop test tower that we are using to conduct drop tests and provide rescue training.

Jeremy McAllister: Gardner-Watson Decking is a manufacturer’s representative of FallTech and SafeWaze. They regularly give us updates and samples of new product. We test new equipment in the field and give feedback on products.

Jason Zyla: When I started with Shelby Erectors, I could send an email or text. When Jack said

we were going to go paperless I thought, “Ok so does that mean we aren’t going to keep any records?” Now everything is going the way of digital. There are a lot of systems out there that can help to make this easier for the you and for the employees in the field. Something as easy as scanning a QR card that takes an employee right to their profile. They don’t have to log in or know a password. It takes them straight to the training videos or other information they need. It is able to be personalized, and everything is documented.

What specific safety milestone are you most proud of for last year?

Jack Nix: Achieving 60% of our team with NCCER credentials was a six-year process. This doesn’t happen overnight, and it won’t happen if the priority does not come from the top. I started with myself getting creden tials, then our superintendents. It took a long time to get traction but now it’s the standard.

Jason Zyla: Personnel evaluations happen twice a year, and 30% of that is based on personal development. It’s not just about being an ironworker, it’s about the individual improving themselves. This could be anything—like getting help with finances and money management or learning a new lan guage. We are not looking to get anything back in return. Of course we want loyalty from our employees, but creating better, well-rounded individual and environment is important to our company.

Austin Reiner: Getting our old school iron workers to buy in. Once you have done that you’ve won. Everyone looks up to those guys in the field. You have to build a relationship

30 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

Daily safety meetings at Gardner Watson allow team members to share information about accidents they’ve heard about in the industry. They discuss potential risks and measures that can be used to avoid those dangers.

controlled deck zone is super dangerous, and creates confusion with inspectors and general contractors.”

Jeremy McAllister, Gardner Watson Decking

“The

Connector | WINTER EDITION December 2022 | 31 FEBRUARY 12-15, 2023 HILTON NEW ORLEANS RIVERSIDE HOTEL 2023 NORTH AMERICAN IRON WORKERS/IMPACT CONFERENCE 1750 NEW YORK AVENUE NW LOBBY WASHINGTON D.C. 20006 Contact Us (202) 393-1147 info@impact-net.org www.impact-net.org IMPACT - COLLABORATION - SUCCESS

with them first before you will be successful with the rest.

John Ross McCartney: In the last two years, the company reached the highest employment headcount and logged the most exposure hours ever in our 66 years of busi ness. To have achieved no lost time incidents during that period is an incredible accom plishment. I could not be more proud of our team—from the top down—for the level of commitment it took to achieve this milestone.

Do you feel it is time to update Subpart R? What parts do you feel are outdated?

Ed Valencia: Fall protection triggers at 15 or 30 feet—it really should be 6 feet for everyone.

Jeremy McAllister: The controlled deck zone is super dangerous and creates confusion with inspectors and general contractors. Compa nies with 100% tie-off requirements always supersede Subpart R.

Jack Nix: I think the consensus here is that fall protection requirements need to change. The technology exists now; there is no reason not to tie-off, and it’s economical. Until it is changed it gives people an excuse to not use fall protection.

Can you share some individual success stories about your apprenticeship program? What impact have these individuals had on your company?

Jack Nix: Over 60% of our craft workers are NCCER-certified. Joining our apprenticeship program is not optional. If an individual lacks enough experience to be considered journeyman ironworker, then they are automatically enrolled in our apprenticeship program. If they have some experience we give them an assessment to see what they know. They can get up to 50% credit for that. We also set our pay scales around the levels of training achieved.

Jason Zyla: There is a certain camaraderie gained from participation in our training and apprenticeship which helps make our safety culture stronger.

Austin Reiner: During Covid a lot of train ing facilities were shut down causing some apprentices to fall behind. One individual came to me needing help to finish his appren ticeship on time instead of waiting for training facilities to open. Derr has created a wide variety of training recourses and material including our own training tower. Using these resources, I was able to help this apprentice complete the program in a timely matter. Even though certain facilities were closed down, Derr and Gruenewald kept its drive and motivation in training apprentices and help ing out our future generation of ironworkers.

What strategies do you find are most effective for training Ironworkers?

Jack Nix: There is no one answer for that. We are a completely paperless company. We use online training with eLearning platform. All training is in powerpoint and video format with audio and visual. In addition, we also invested in a training trailer that we use as a traveling classroom that we take to the job site.

We use this a variety of ways—convenient to pull people off the job for a while and some times for training at the end of a shift. Field training is enhanced with webinars.

Jason Zyla: Our corporate culture is that by investing in training we are creating a better industry overall. We want to improve the individual worker, whether they choose to stay with us or not.

Austin Reiner: Apart from traditional class room training, we take that classroom instruction and apply it in the field. We have a new ironworker training tower that we use for this. The guys learn fast on it.

What benefits does your company receive as a result of your apprentice program?

Jack Nix: When we work on prevailing wage jobs this give us a big advantage to discount wages if workers are not journeyman level. By having this program, we can pay based on percentage of the journeyman level, and makes us more competitive.

Jason Zyla: Our apprenticeship program is five years in the making. It has been a process to get where we are today. The best advice I can give others is to stay committed, be willing to change. Apprenticeship enables us to stay consistent in training all workers.

How do you plan on using the training grant money that SEAA awarded you?

Jack Nix: We are going to invest it to convert all of our training materials into English and Spanish. We have hired outside professionals to help with the translation process. This is important to effectively communicate and not exclude anyone.

Austin Reiner: I’m not sure, but we are also looking at moving to digital recordkeeping. I’m interested in seeing how simulators could be used in training. •

32 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

“Our new ironworker training tower is an efficient method for training workers.”

Austin Reiner, Derr & Gruenewald Construction

“We encourage employees to invest in their own personal development.”

Jason Zyla, Shelby Erectors

Your projects need exper tise and equipment

W ith a fleet of 650,000 pieces of equipment - 80% of which are equipped with telematics capabilities - United Rentals is the largest equipment-rental provider. We maintain the highest safety standards, offering quality general equipment solutions, including scissor lifts and boom lifts, and we also provide solutions that require a more specialized skill set, including Trench Safety, Power & HVAC, Fluid Management and more. Visit UnitedRentals.com or call 800.UR.RENTS to lear n more.

. © 2021 United Rentals, Inc.

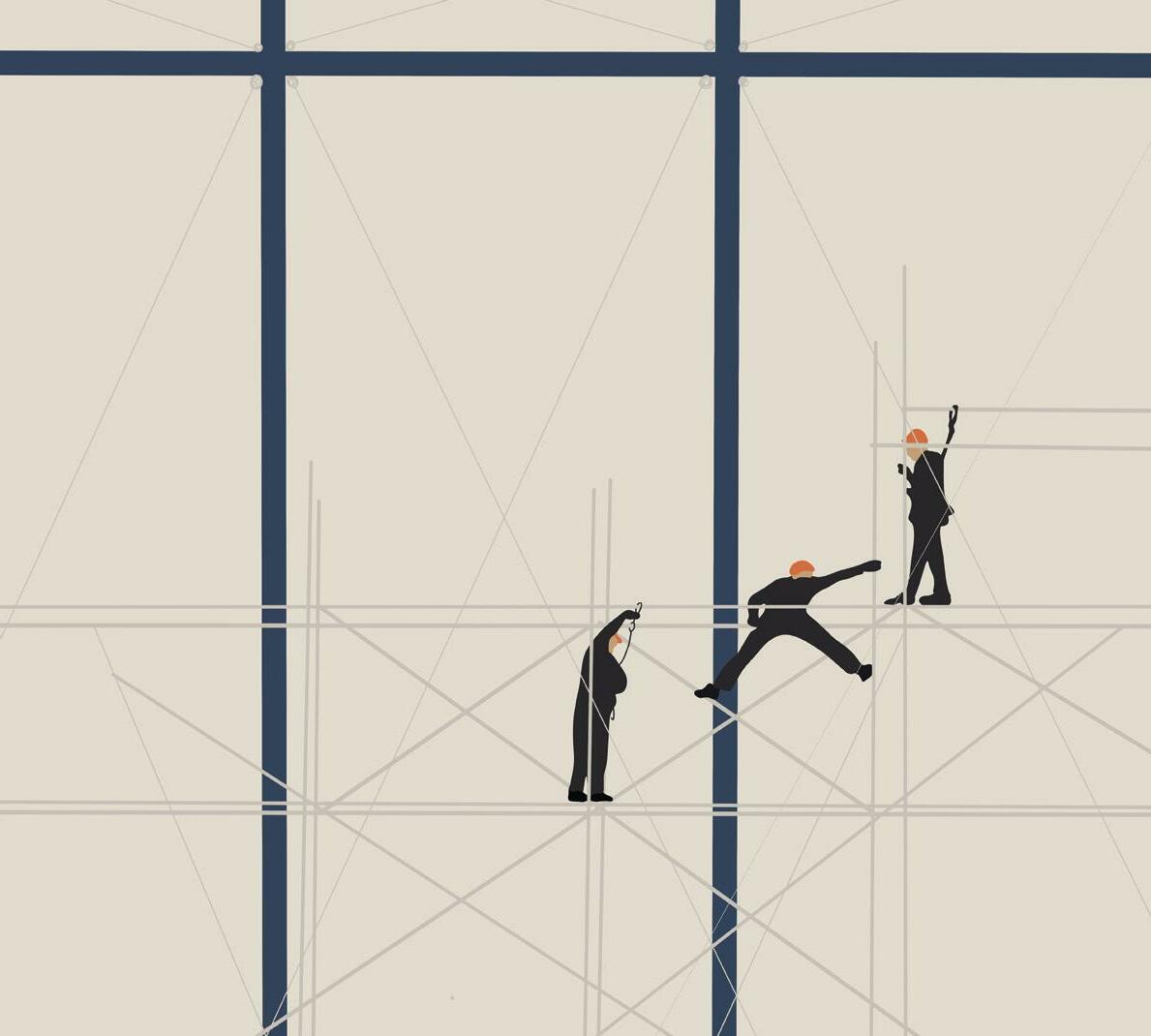

Strictly Vertical Mobility is Hurting Retention in Construction

Most of my industry experience was in commercial General Contracting, where I worked from project engineering up to project management. I loved these roles and saw endless opportunities to grow in them. While I became very proficient at the processes (which can quickly become mundane and increase our risk of getting bored with our jobs), it was counterbalanced by the challenge of managing, leading, and motivating people.

But here’s the kicker—I ended up leaving the company because of one rather large barrier—the wooden ladder. The “ladder” represents an outdated, fixed, vertical, and very linear advancement expectation for those working in the industry.

When recruiting, we boast about the many pathways to careers in the industry. You can attend college or not and still become a CEO. Career options are plentiful because we need so many people with different strengths, skills, and abilities to create and build the things we do.

The problem starts on the other side of recruitment. Once hired, all the different pathways seem to dissipate

Amy Powell is the owner and founder of Well Works, which designs and conducts leadership training for the construction industry.

With over 18 years of construction experience, the majority of it as a Project Manager for a Commercial GC, she noticed the lack of training for Field Leaders As a result, she pursued a Master’s of Education in Adult Education to build the tools to equip construction field leaders. Learn more at livingwellworks.org.

when it comes to advancement. The only option is to move up the ladder to executive level, without acknowledging the importance of field leaders. This directly impacts retention. To retain our current workforce, we have to consider upgrading the wooden ladder to something more flexible like a “scaffold.”

Get Stuck or Exit the Ladder

While I respected my executive team, it wasn’t a role I was motivated toward. I still wanted to advance, learn, and grow in my role but I needed support, time, feedback, resources, and training. Yet, in order to retain my value in the corporate structure, I had to continue to ascend the ladder. If I didn’t, I would be at risk of career stagnation, in growth and in pay.

So, I found myself stuck. I couldn’t move outward to reach those skills I wanted and needed (and be com pensated as such); I didn’t want to go down the ladder (demotion and humiliation); I couldn’t stay where I was (stagnation), and I didn’t want to move up. I had one option left—exit the ladder altogether.

I will make an educated guess that 26- to 40-year-olds have the largest impact on current retention stats and are the people most at risk of leaving the industry. People in this age bracket are frequently described as “entitled” and are often criticized for not being loyal to their employers. In reality, according to 2016 Gallup research, 55% are simply disengaged at work. What is frequently seen as entitled may be confused for indifference. “Indifferent

34 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

BUSINESS OPERATIONS By Amy Powell

and entitled are not synonymous. Many millennials likely don’t want to switch jobs, but their companies are not giving them compelling reasons to stay,” reports Gallup.

The same research reports: “A striking 87% of millennials rate ‘professional or career growth and development opportunities’ as important to them in a job.” If these opportunities are not available within their current companies, they will leave in search of them elsewhere. And while millennials may be more vocal, internal mobil ity and career development opportunities increase retention and benefit for all age groups within the workforce. A 2018 Workplace Learning report from LinkedIn Learning says: “94% of employees say

By Julie Davis

Nowadays, the competition by companies to find great people and keep them “is extremely competitive and expensive,” says Chris Czarnik, a career search and talent acquisition expert. According to the Society of Human Resource Management, it costs between 25% to 35% of any employee’s annual wages to lose them and recruit a replacement.

Czarnik says that many organizations worry about job openings, but they do not always spend enough time nurturing the employees they have hired. With younger generations now switching jobs roughly every 3.5 years, it is critical to keep workers engaged and challenged to stop the cycle of reoccurring openings.

Here are some of Czarnik’s strategies for holding on to employees:

1. Great retention starts with being much more particular about the person you bring into your organization. Many companies, because they have such difficulty hiring people, are now considering people they would never considered several years ago.

2. Make a concerted effort to improve manager-employee relationships. The top reason people leave their jobs is a poor relationship with their direct supervisor or manager.

3. Advise all supervisors and managers that every question that comes to them be answered not only with what they want the employee to do but why they want them to do it. Especially in the case of Millennials – people born in the 1980s or 1990s.

4. Use a buddy system for new employees, which is a great aid in onboarding new employees.

5. Focus on the first 90 days. Check in with new hires within the 30- to 60-day timeframe. Get to know them on a personal level and be prepared to realign them to a different type of job, if necessary, rather than lose them.

Julie Davis is senior director of workforce development for the Association of Equipment Manufacturers, an international trade group representing off-road equipment manufacturers and suppliers. Get more ideas from AEM’s Workforce Solutions Toolkit online at aem.org/workforce-solutions

Connector | WINTER EDITION December 2022 | 35 2023 National Awards Program Accepting Award Nominations SUBMISSIONS DUE JANUARY 31, 2023 Q 3 Categories based on Number of Ironworkers employed Q World Class, Premier, and Gold Level Recognitions Q NEW! $1500 in Craft Training Grants awarded to each World Class winner CRAFT TRAINING Excellence SUBMISSIONS DUE DECEMBER 31, 2022 Q 4 Contract Class Categories for Structural Steel Q NEW! 2 Contract Class Categories for Miscellaneous Metals Q 24 month Topping Out Period from Jan. 1, 2021 to Dec. 31, 2022 NEW! Earlier Deadlines Open to Member Companies of All Sizes Submit at SEAA.net/awards Q Industry-Wide Publicity Q Profiles in Connector magazine Q Presentations at SEAA & AISC Conventions Sponsored by SUBMISSIONS DUE JANUARY 31, 2023 Q World Class, Premier, and Gold Level Recognitions Q Based on Safety Metrics for the previous year SAFETY Excellence

WORKFORCE

TIPS FROM AEM’S

SOLUTIONS SUMMIT

that they would stay at a company longer if it invested in their career development.”

Remodel Growth Pathways

We need strong, competent, and skilled people at every level of our industry to successfully design, bid, and build our projects. While yes, executive roles are critical, without skilled labor and middle managers, these roles largely become obsolete. And while we should not cease the development of future executives, this should not be our sole focus regarding advancement, compensation, training, development, and feedback.

Some foremen want to be the best foreman they can be, they don’t

all want to be superintendents. This may mean they want to build more skills to be the best version of themself at that level. Or they may want to explore a parallel role within the same company (inter nal mobility). Keeping respected and trusted individuals within the company is still more cost-efficient and cost-effective than having to train someone new on the company’s processes, culture, and values.

Give Employees Flexibility

Allow employees to have a voice in defining and building their own skills, pathway, and advancement plan. Instead of assuming what is helpful or motivational to each individual and role, consider allowing individuals to submit growth potential opportunities and to explain how it adds value to the company or their teams.

Employers can decide whether to provide the training in-house, outsource or subcontract it, or provide a monetary and time allow ance for the individual to earn those advancement skills on their own. Taking this approach is a win-win. The employee avoids stagnation and the company gains valuable insight from all levels that could result in a competitive edge within the industry.

A Word of Caution

Use training and development as a reward, not a punishment. If people do something wrong, they need feedback, not training. Training is an expensive and ineffective discipline tool. When you mandate someone be at training, especially as a punishment, learning transfer (how much usable information you get from a learning event) significantly declines along with their motivation to attend any fol lowing training and development opportunities. •

36 | THE STEEL ERECTORS ASSOCIATION OF AMERICA

A barrier to retention in construction is the “wooden ladder,” which represents an outdated, linear-only advancement concept. To retain our current workforce, we have to consider upgrading the wooden ladder to something more flexible like a “scaffold.”

STRONGER TOGETHER World Class Workforce Management Tools

RECRUIT

Get Help with Hiring using the SEAA Job Board and CareerPlug Applicant Tracking System

Upgrade to PRO account for only $595/year to promote openings across multiple platforms, schedule interviews using text messages, and more.

TRAIN

Become an NCCER Training Unit or Assessment Site for Ironworkers

Get admin and implementation support from SEAA to create Ironworker Craft Training and provide nationally recognized credentials to your workers.

Use SEAA’s US DOL-Approved Apprenticeship for Structural & Reinforcing Ironworkers.

RETAIN

SteelPros Training Portal is a robust Learning Management System with Hundreds of Ironworker Training Content