bgm PRO MRB Race-Tour 195/200 & 225/230 CYLINDER KITS 4. DRY BUILD RT 195 WITH 58 mm STROKE, 107 mm CON ROD CRANK

5. DRY BUILD RT 195 WITH 60 mm STROKE, 107 mm CON ROD CRANK

With casings from Italy, India, Spain and so many repaired and machined ones, it is very hard to cover every particular case. But nine times out of ten we got away with the basic setup to get the port timings and squish clearance right.

With casings from Italy, India, Spain and so many repaired and machined ones, it is very hard to cover every particular case. But nine times out of ten we got away with the basic setup to get the port timings and squish clearance right.

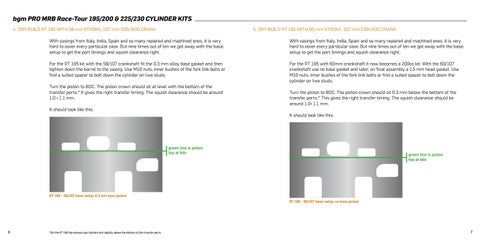

For the RT 195 kit with the 58/107 crankshaft fit the 0.3 mm alloy base gasket and then tighten down the barrel to the casing. Use M10 nuts, inner bushes of the fork link bolts or find a suited spacer to bolt down the cylinder on two studs.

For the RT 195 with 60mm crankshaft it now becomes a 200cc kit. With the 60/107 crankshaft use no base gasket and later, on final assembly a 1.5 mm head gasket. Use M10 nuts, inner bushes of the fork link bolts or find a suited spacer to bolt down the cylinder on two studs.

Turn the piston to BDC. The piston crown should sit at level with the bottom of the transfer ports.* It gives the right transfer timing. The squish clearance should be around 1.0 - 1.1 mm.

Turn the piston to BDC. The piston crown should sit 0.3 mm below the bottom of the transfer ports.* This gives the right transfer timing. The squish clearance should be around 1.0- 1.1 mm.

It should look like this: It should look like this:

green line is piston top at bdc

green line is piston top at bdc

RT 195 – 58/107 basic setup: 0,3 mm base gasket RT 195 – 60/107 basic setup: no base gasket

6

*On the RT 195 the exhaust port bottom sits slightly above the bottom of the transfer ports.

7