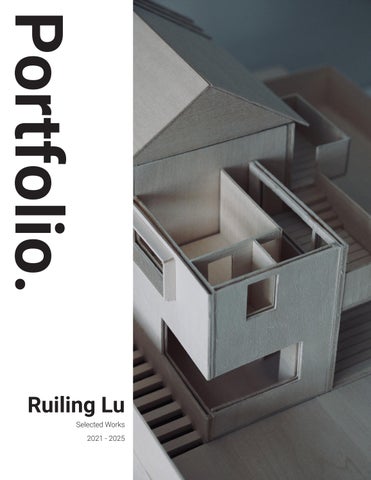

Portfolio.

Ruiling Lu

Selected Works

2021 - 2025

Ruiling Lu

Selected Works

2021 - 2025

+1 (785)-491-8131

ruiling0209@gmail.com

EDUCATION

University of Kansas

School of Architecture & Design

Expected graduation May 2026

Cumulative GPA: 3.78/4.0

SKILLS

3D Modeling: Rhino, SketchUp, Autodesk Revit

Rendering: Enscape

Graphics: InDesign, Illustrator, Photoshop AI Tools: Midjourney

Other: Sketching, Model Making, Photography

REFERENCES

Nils Gore

Professor of Architecture

University of Kansas School of Architecture & Design +1 (785)-864-4102 (cell) ngore@ku.edu

Marie-Alice L’Heureux

Professor of Architecture

University of Kansas School of Architecture & Design +1 (785)-864-1144 (work) +1 (785)-917-0826 (cell) malheur@ku.edu

Thom Allen

Associate Director, University Honors Program University of Kansas +1 (620)-212-4112 (cell) t273a306@ku.edu

INTERNSHIP EXPERIENCE

Architectural Design Intern HDR, Inc. Omaha, Nebraska | May 2025 – August 2025

Guest Curator

Shanghai Architecture Model Museum Shanghai, China | December 2024 – January 2025

PRACTICAL EXPERIENCE

Design Director

TEDxKU Executive Board Lawrence, Kansas | April 2024 – present

Poster Designer

University of Kansas Spring 2024 Identity Intersection Lecture Lawrence, Kansas | February 2024 – March 2024

PROJECT ACTIVITIES

University of Kansas Open AI Competition Lawrence, Kansas | January 2024

International Career Preparation Study Abroad London, Britain | March 2023

HONORS

University of Kansas Architecture Student Portfolio Award Spring 2025

University of Kansas Architecture Student Portfolio Honorable Mention Spring 2024

2020 – 2024 University of Kansas Academic Excellence Scholarship

Field:

Mixed Use Housing Project

Type:

Individual Work

Location:

Lawrence, Kansas, United States

Time:

Fall 2024 [Fourth Year]

Instructor:

Steve Padget

This residential building, located at the prominent intersection of 6th Street and Massachusetts Street in downtown Lawrence, reflects a visionary approach to sustainable urban living. The project embraces the integration of natural resources, where water and greenery become essential elements of the architecture. The design incorporates a thoughtful system that collects stormwater underground, filtering and repurposing it for irrigation and rooftop greenery, forming a sustainable water circulation system that reduces waste and promotes ecological balance.

A key feature of the building is the central atrium garden, an inviting green space that provides residents with opportunities for relaxation, recreation, and social interaction. This open, communal area not only enhances the sense of community but also introduces nature into the heart of the building, allowing residents to reconnect with the environment in an urban setting.

Privacy and comfort are also at the heart of the project’s design. Vertical louvers on the building facade provide residents with protection from prying eyes while still allowing ample natural light and ventilation. This architectural strategy manages heat and light to improve energy efficiency while ensuring a sense of personal space for each resident. Every tenant has the freedom to control the vertical louvers on their balconies, adjusting the angle to regulate the amount of natural light entering the interior. For a better open view, they can also slide the louvers to the side of the balcony. This flexibility not only adds a unique and dynamic visual element to the building’s façade but also offers a distinctive and adaptable streetscape in downtown Lawrence.

To blend in with the surrounding streets, the ground floor is designed as a commercial area. Above the ground floor are residential apartments.

Two public entrances are strategically placed on the ground floor to balance pedestrian flow, while a central public corridor connects the various shops.

Starting on the second floor, central atrium enhances natural light throughout the building, ensuring that each unit is bathed in plenty of sunlight.

To ensure that natural light from the atrium reaches the second floor, the walls of each residential unit are strategically recessed or extended.

The top floor of the building features a public garden and a community activity space designed for shared use and social engagement.

As the building is located in lawrence downtown, the project uses a movable facade to protect the privacy of each residential unit.

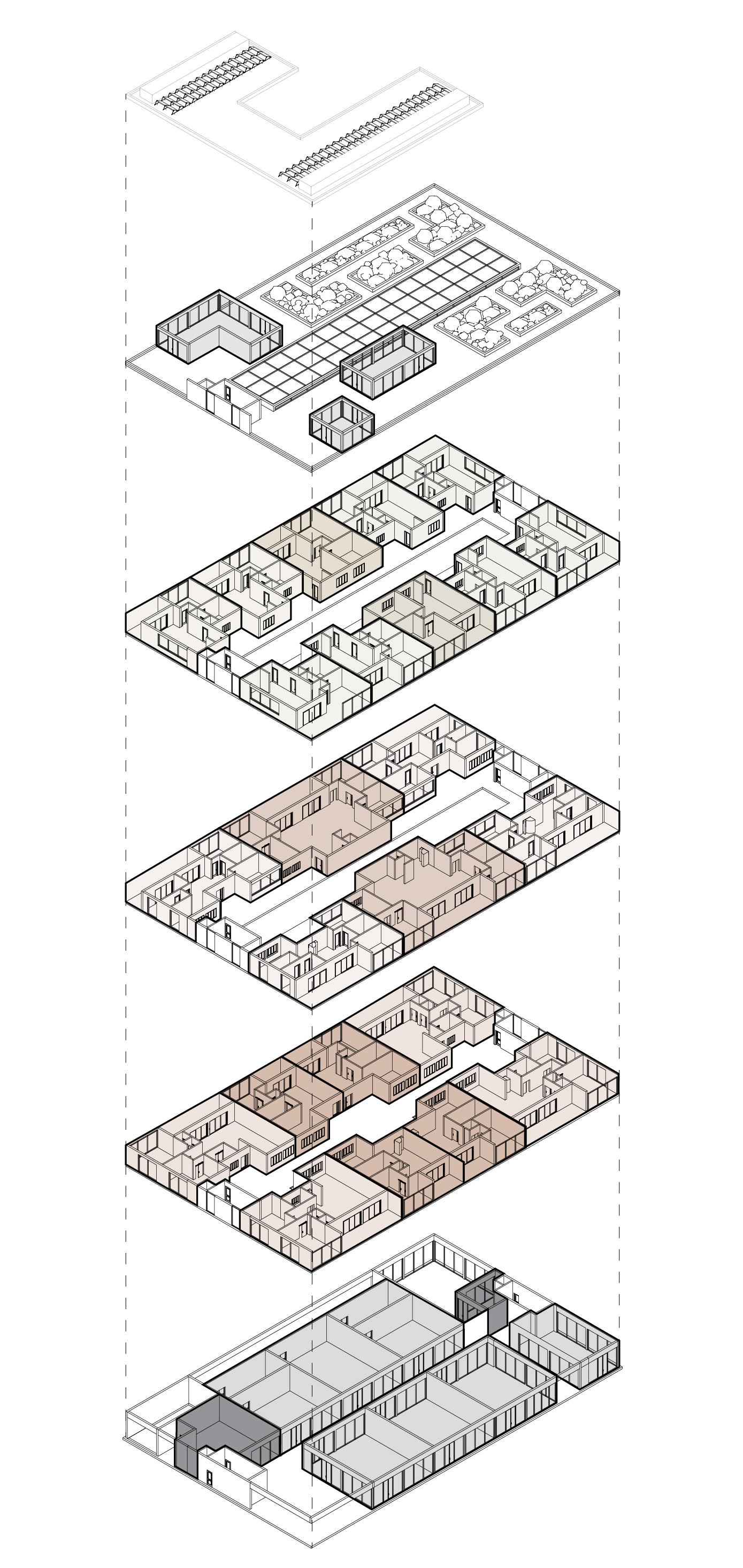

FIFTH FLOOR: GREEN GARDEN COMMUNITY ACTIVITY SPACE COMMUNITY LIBRARY

FOURTH FLOOR: YOUNG SINGLE UNIT

ADA YOUNG SINGLE UNIT

THIRD FLOOR: FAMILY UNIT

ADA FAMILY UNIT

SECOND FLOOR:

ADA ELDERLY UNIT

ADA EMPTY NESTER UNIT

FIRST FLOOR: PUBLIC GYM RESATRANT BOOKSHELF COFFEE SHOP GREEN GROCERY APARTMENT LOBBY

COMMUNITY ACTIVITY

SINGLE UNIT

ADA SINGLE UNIT

FAMILY UNIT

ADA FAMILY UNIT

ADA ELDERLY UNIT

ADA EMPTY NESTER UNIT

COMMERICAL AREA

ENTRY FOR RESIDENCE

EGRESS

MECHANICAL

Families Unit [3 Bedroom]

Scale: 1/16” = 1’ - 0”

ADA Families Unit [3 Bedroom]

Scale: 1/16” = 1’ - 0”

Young Singles Unit [1 Bedroom]

Scale: 1/16” = 1’ - 0”

ADA Young Singles Unit [1 Bedroom]

Scale: 1/16” = 1’

Bedroom]

Scale: 1/16” = 1’ - 0”

ADA Elderly Unit [2 Bedroom]

Scale: 1/16” = 1’ - 0”

SECOND FLOOR PLAN [ADA EMPTY NESTER UNIT & ELDERLY UNIT/8 UNIT]

FLOOR PLAN [SINGLE UNIT/10 UNIT]

FIFTH FLOOR PLAN [COMMUNITY ACTIVITY]

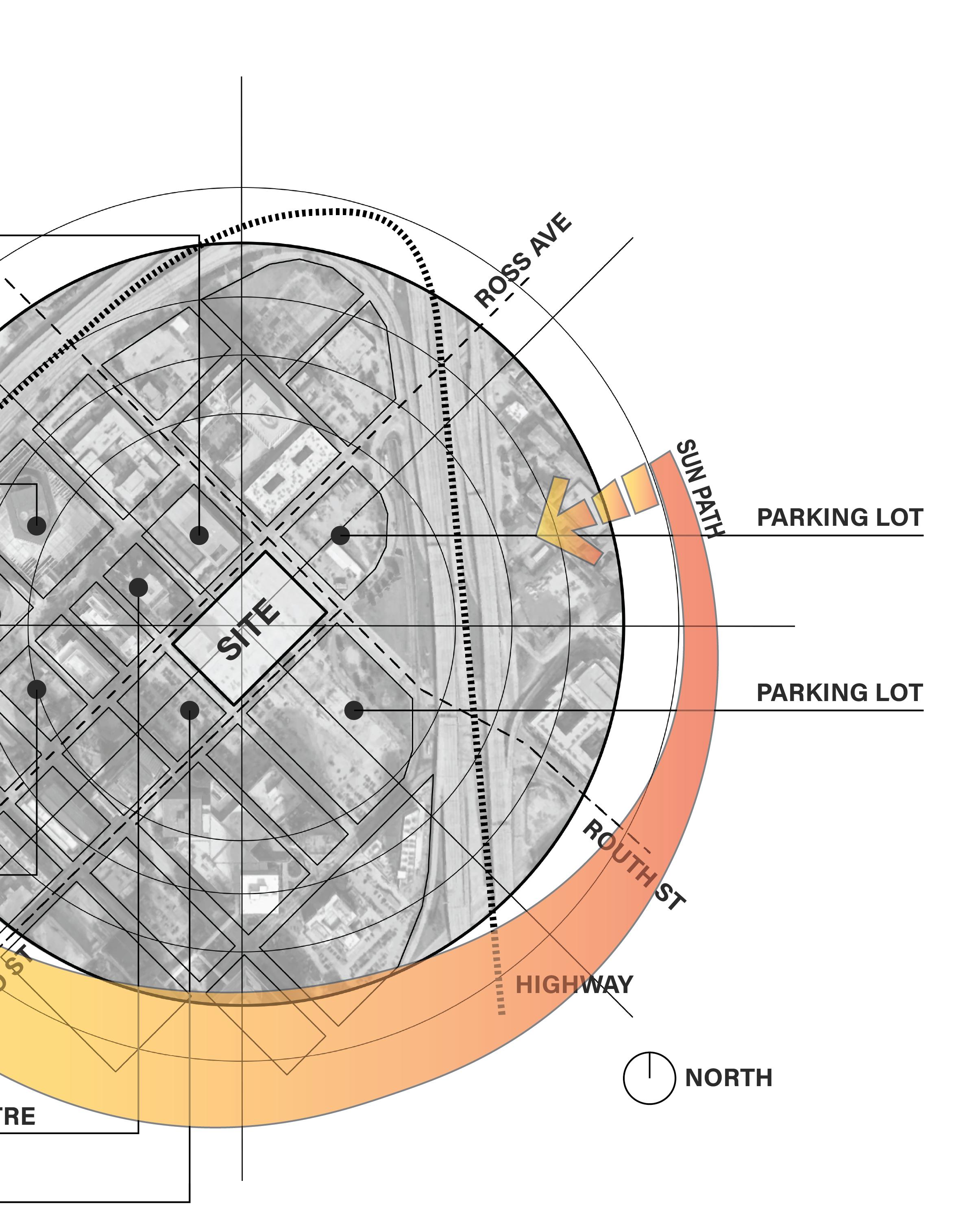

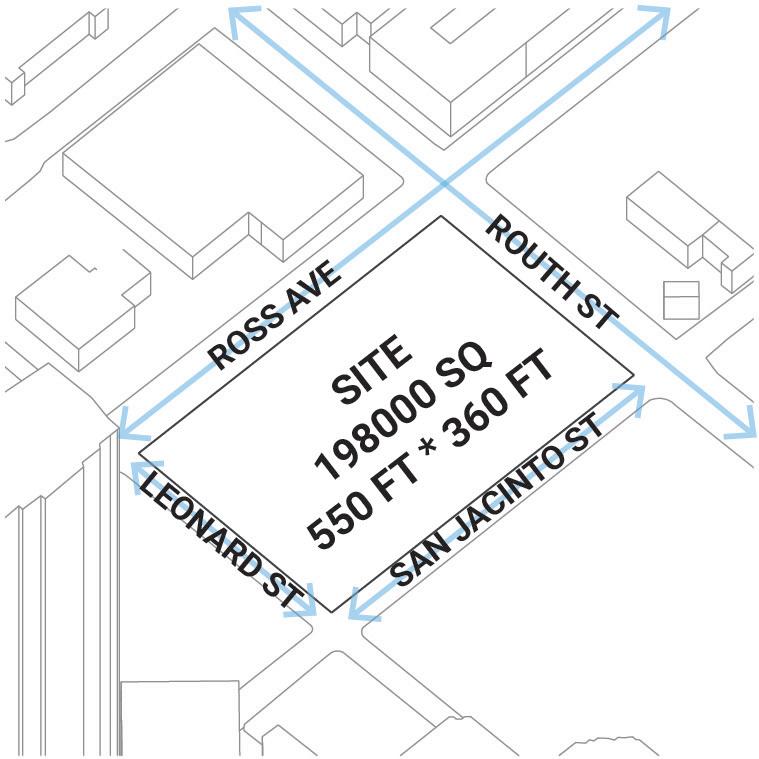

Field:

Mixed Use Community Project

Type:

Individual Work

Location:

Dallas, Texas, United States

Time:

Spring 2024 [Third Year]

Instructor:

Eddy Tavio

Dallas is a vibrant city located in the heart of Texas, renowned for its rich cultural tapestry, diverse geography, and dynamic blend of urban amenities and natural beauty. Situated in North Texas, Dallas boasts a unique blend of bustling city life and serene natural landscapes. The city’s cultural scene is thriving, with world-class museums, theaters, and galleries showcasing art, history, and performing arts.

Geographically, Dallas is characterized by gently rolling prairies and expansive green spaces that invite outdoor recreation. Central to the city’s landscape is the Trinity River, which flows through Dallas, offering water resources, recreational opportunities, and ecological diversity. Its meandering course provides scenic vistas and serves as a natural oasis, offering both residents and visitors a tranquil escape from the urban environment.

Moreover, the Trinity River plays a crucial role in Dallas’s environmental sustainability efforts, serving as a focal point for conservation initiatives and urban revitalization projects. Its importance extends beyond mere aesthetics, as efforts to preserve and enhance the river’s health contribute to the overall well-being and quality of life for Dallas residents. In essence, the Trinity River is not just a geographical feature but a cultural and ecological cornerstone of the city, embodying the spirit of Dallas’s commitment to balancing urban development with environmental stewardship.

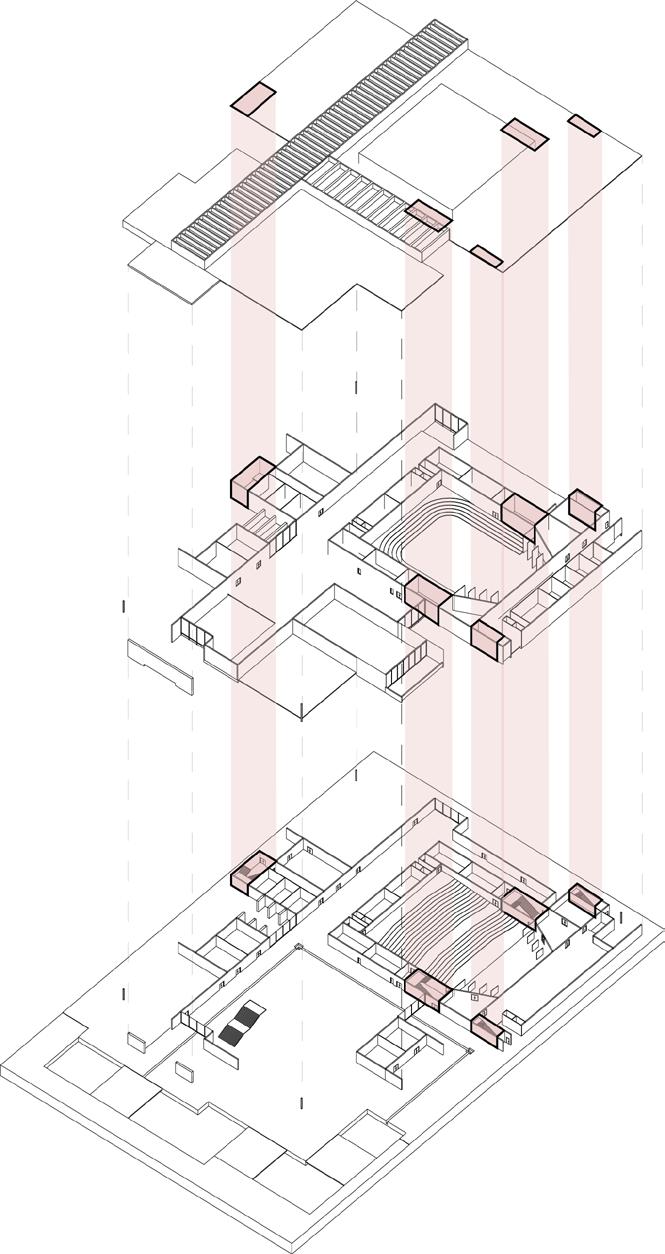

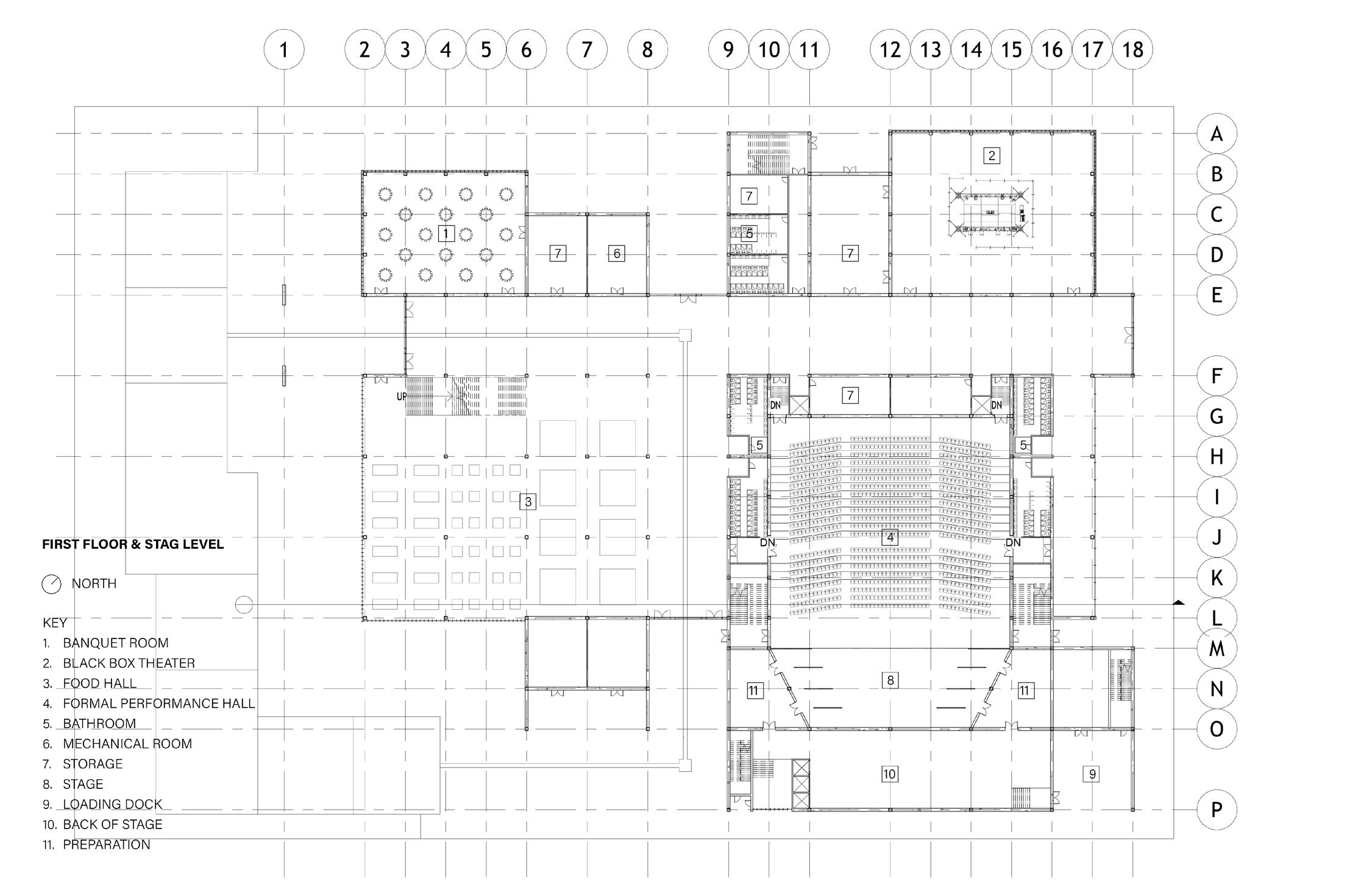

Drawing inspiration from the Trinity River’s integral role in Dallas, the proposed art assembly house in the Dallas Arts District seeks to mirror the river’s harmonious blend of nature and urban life. The design will evoke the fluidity and connectivity of the Trinity River, creating a dynamic environment where art, community, and nature intersect. Just as the river provides a natural refuge within the city’s landscape, this art assembly house will offer a serene yet vibrant space, fostering creativity and reflection within the bustling urban fabric of Dallas.

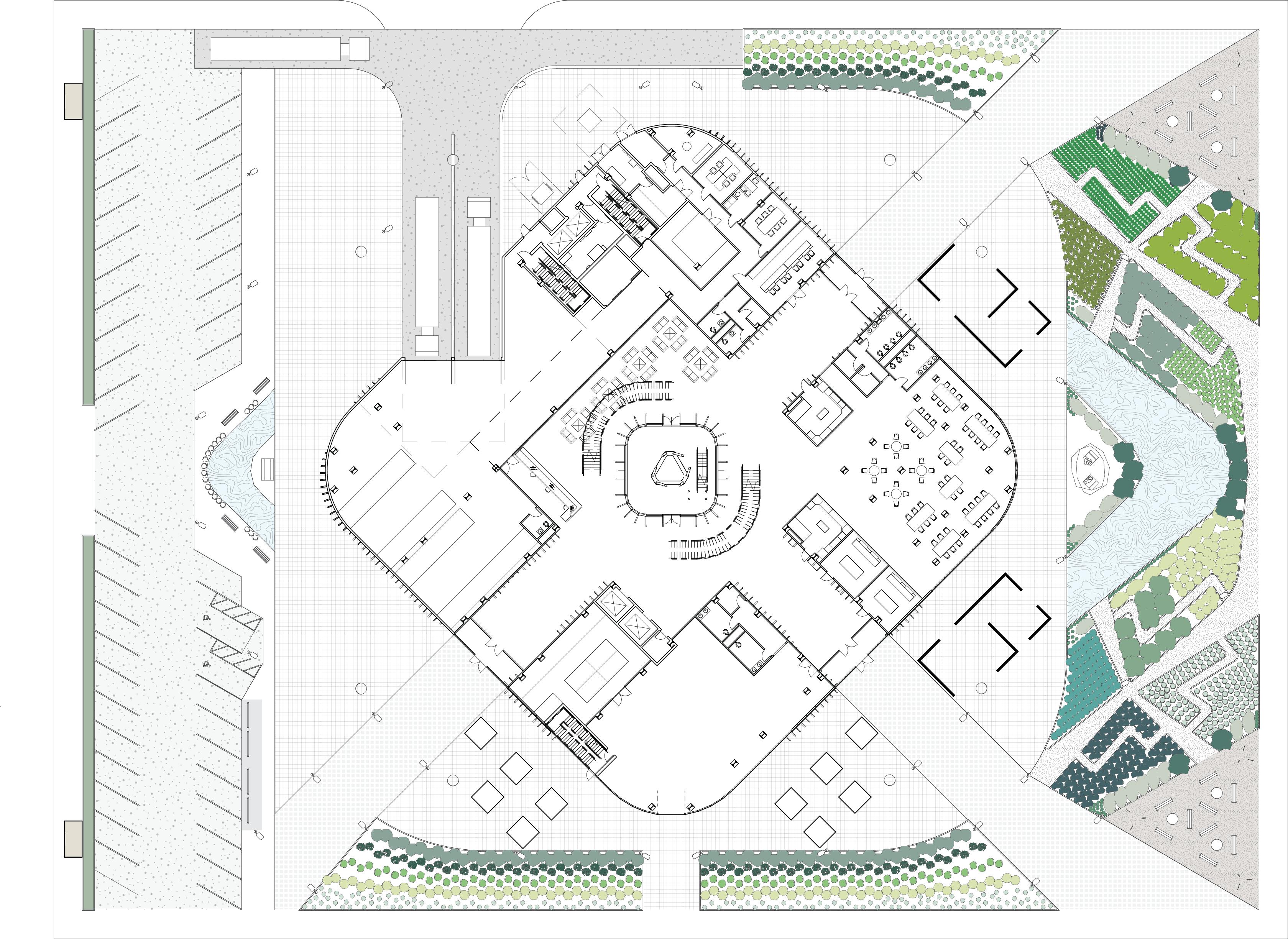

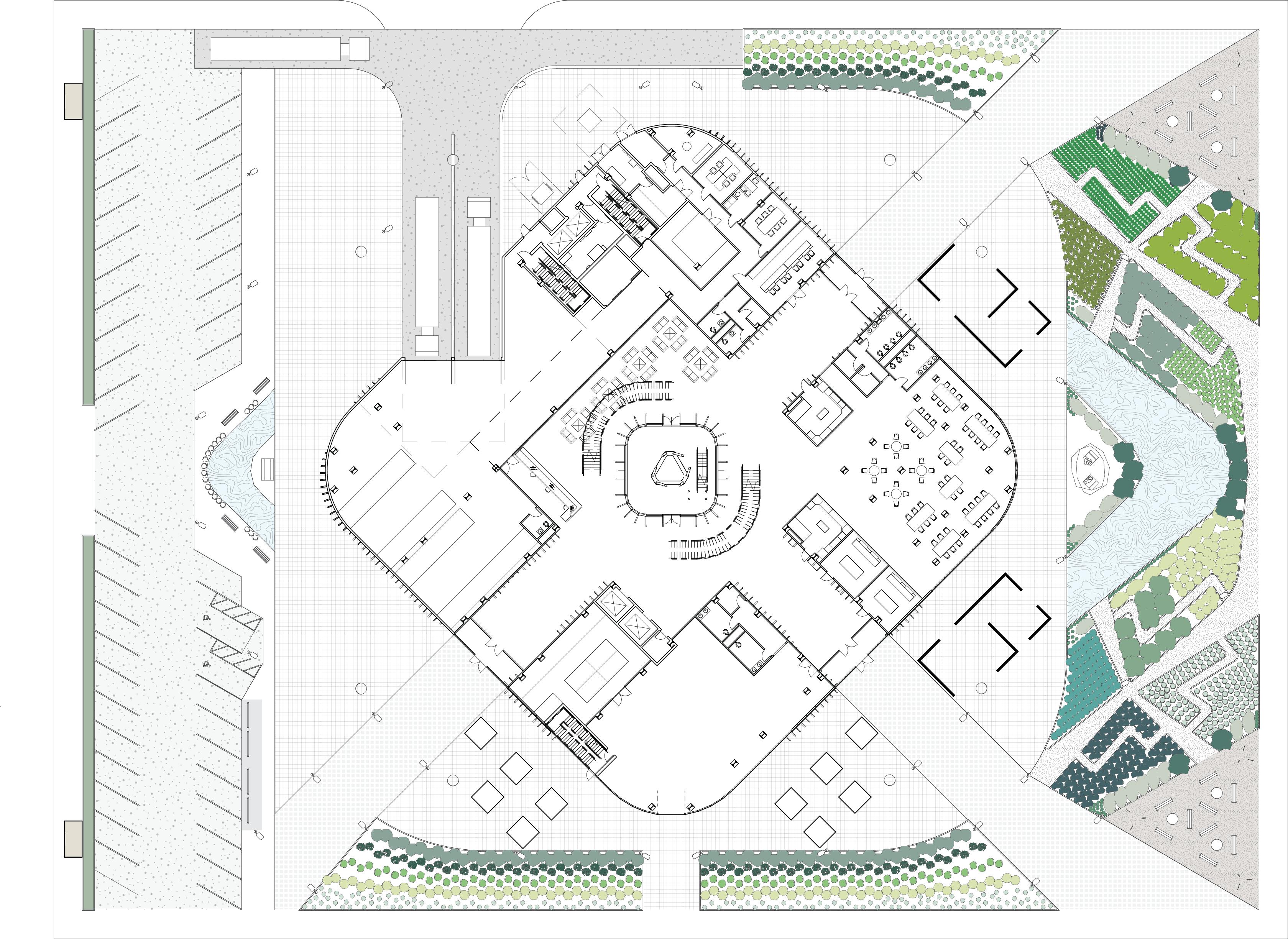

At the intersection of Routh Street and San Jacinto Street, two well-equipped car parks offer ample parking space for visitors and serve as convenient loading zones.

Facing Leonard Street, an outdoor pool serves as a distinctive feature, complemented by different walkway providing access to the building. The architectural design incorporates a flowing “river” concept, where the water enters the interior through the outdoor pool.

To enhance efficiency circulation, two intersecting nades have been meticulously throughout the entirety

efficiency of the building’s intersecting promemeticulously integrated entirety of the structure.

Careful attention has been given to the design of the loading and storage areas. The architecture incorporates a staggered facade, providing ample space for loading and unloading activities while minimizing disruptions to the visitor experience.

The roof design of the corridor serves a dual purpose: it ensures ample natural lighting within the interior while effectively mitigating the impact of intense direct sunlight.

EGRESS

MECHANICAL

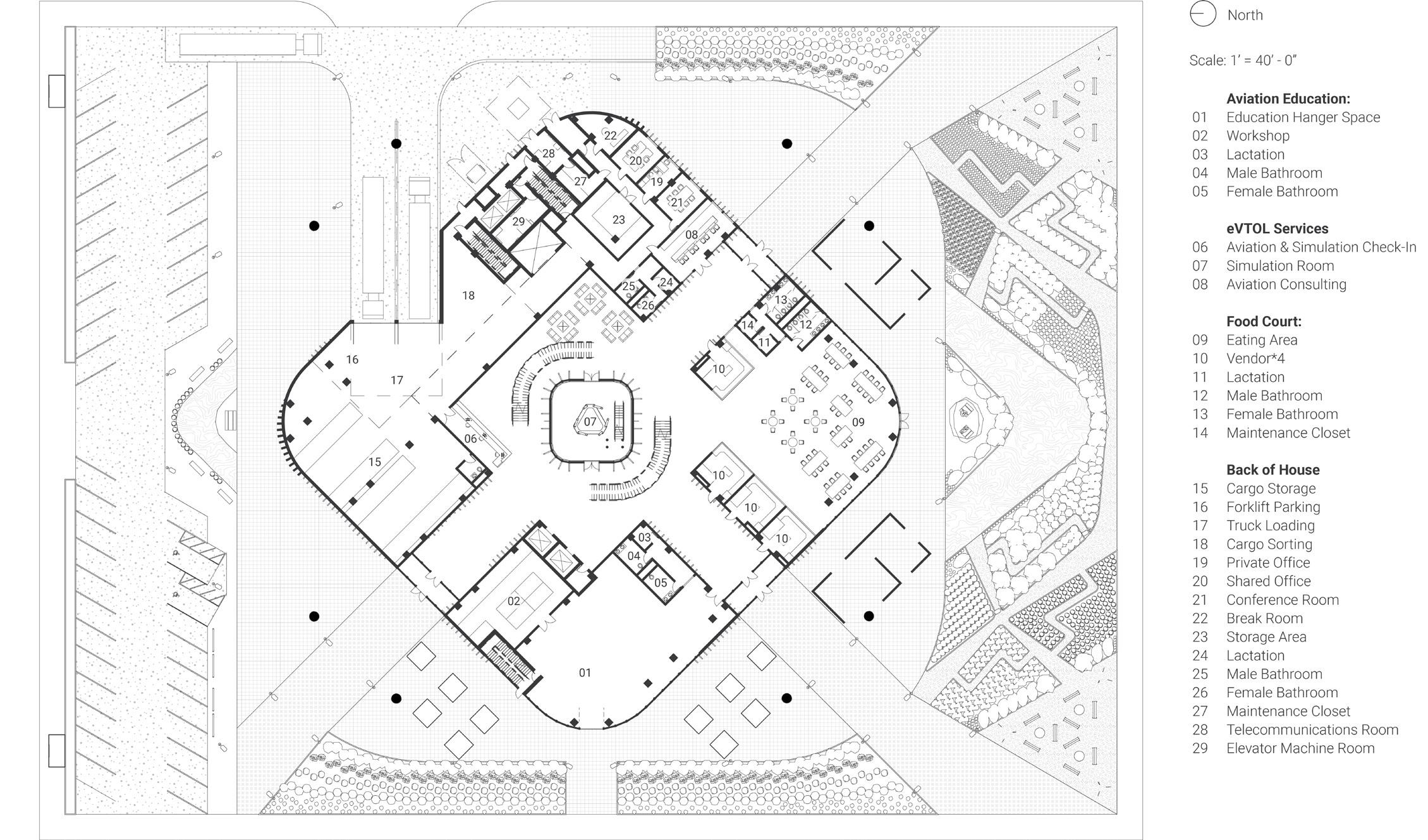

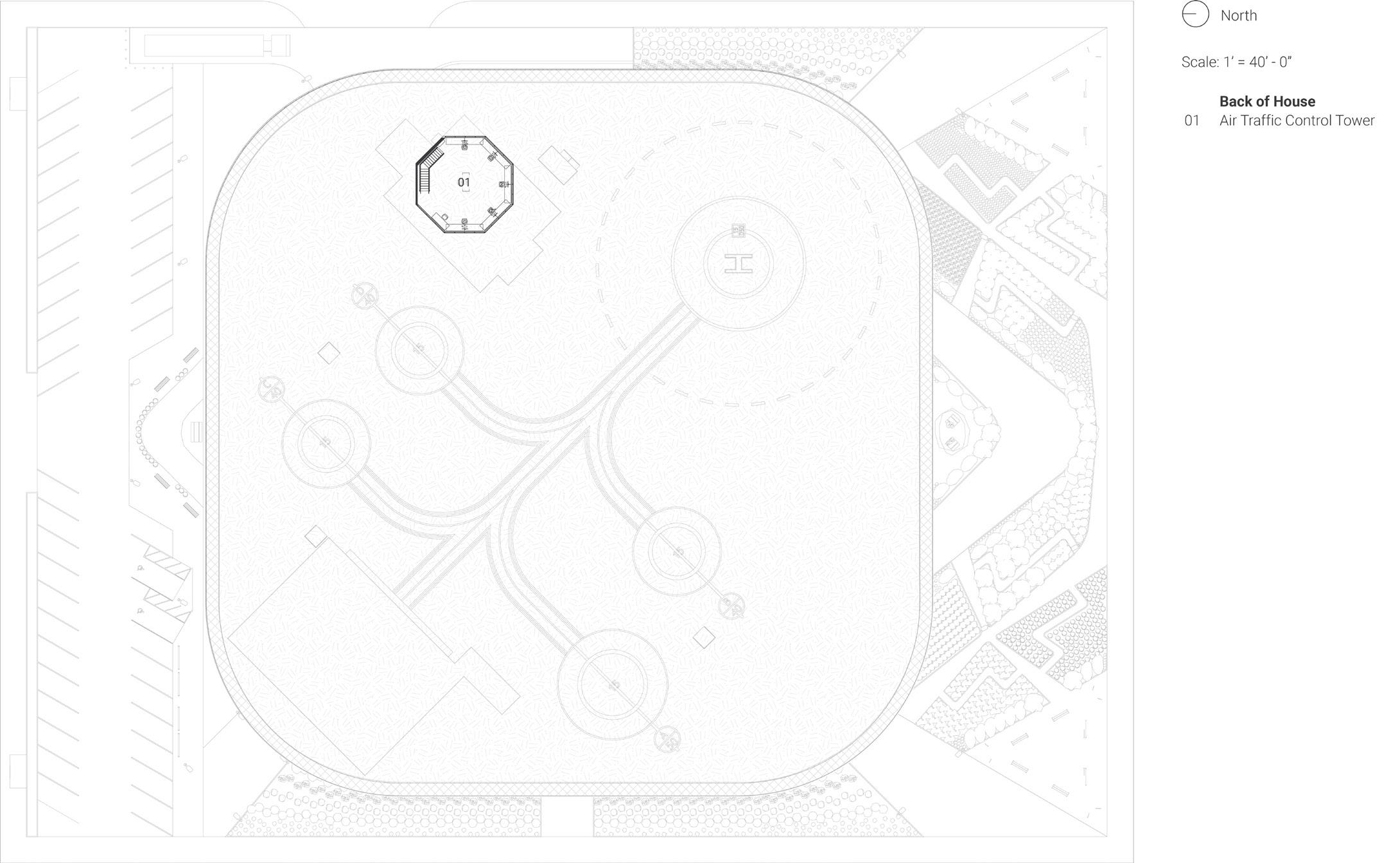

Field:

eVTOL Airport

Type:

Group Work

Partner: Joseph Kenworthey

Location:

Wichita, Kansas, United States

Time: Spring 2025 [Fourth Year]

Instructor: Amy Van de Riet

The eVTOL industry holds immense potential for the future of aviation. As a symbol of next-generation transportation, eVTOL represents innovation and sustainable progress. Wichita, once known as the “Air Capital of the World,” has seen a gradual decline in its aviation prominence. This project aims to reignite Wichita’s aviation legacy by showcasing eVTOL technology and inspiring the public to envision the future of air mobility.

Currently, eVTOLs are primarily used for cargo transport, limiting public exposure to this emerging industry. Our project seeks to bridge that gap by creating a space where people can engage with, learn about, and experience the future of aviation firsthand.

To achieve this, the building will incorporate a variety of functional spaces, including:

1. Aviation Education Center – to inform and inspire future generations.

2. Aviation Consulting Hub – to support industry development and collaboration.

3. Cargo Transportation Facilities – to demonstrate current eVTOL applications.

4. Urban Mobility – to envision and simulate passenger transport in urban settings.

Through this project, we aim to make eVTOL technology more accessible to the public, revitalizing Wichita’s aviation industry and fostering a forward-looking community.

(1) Enhancing Regional Air Mobility Networks

• The development of an eVTOL airport will create a short-distance, rapid air transportation network, improving connectivity between Wichita and cities like Kansas City, Oklahoma City, and Topeka.

• Currently, commuting between Wichita and Kansas City or Oklahoma City takes around 2.5-3 hours by car, whereas eVTOLs could reduce this to 30-45 minutes, significantly boosting business and logistics efficiency.

(2) Attracting Advanced Manufacturing and R&D Collaboration

• Wichita is a global hub for aerospace manufacturing, home to companies like Boeing, Spirit AeroSystems, and Textron Aviation. An eVTOL airport could attract additional supply chain businesses in battery production, lightweight materials, and autonomous flight systems, fostering a new aviation technology cluster.

• Kansas City and Oklahoma City’s industries (such as automotive, energy, and aerospace) could integrate with Wichita’s eVTOL sector, promoting knowledge exchange and technological innovation.

(3) Upgrading Logistics and Emergency Response Systems

• eVTOLs can be used for express delivery, medical evacuation, and emergency supply transport, improving service efficiency.

• For example, Oklahoma City’s Tinker Air Force Base and Wichita’s aerospace firms could use eVTOLs for rapid component transportation, while Kansas City’s large hospital networks could deploy them for medical supply distribution.

City Key Industries

Interaction

Wichita Aerospace manufacturing, Engineering eVTOL R&D and production hub

Kansas City Logistics, Technology, Finance

Oklahoma City Aerospace, Energy, Healthcare

Smart city infrastructure, eVTOL logistics hub

Military applications, Energy solutions, Medical transport

Topeka Government, Agriculture, Manufacturing Policy support, Agricultural & Industrial Logistics

East Lewis St South Broadway South Topeka Wichita Downtown Kansas River

Divide the building into three distinct zones in a concentric model around a central core, which serves as a monument to the future.

Rotate the building orientation optimize site utilization, further central core by having it be

Design three corridors to provide clear sightlines to the building's central core.

Slant the walls of central core outwards emphasize and connect it

orientation by 45 degrees to further emphasizing the be the axis of rotation

Soften building edges to create a sleek, fluid form that enhances the futuristic aesthetic, reinforcing the vision of innovation.

outwards to further it to the roof.

This transfers the central core’s status as a monument to the future to the rooftop.

Transportation

Car Parking

Bike Parking

Bus Stop

Truck Loading

Aviation Gallery

Didactics

Display Case

Park

Site Garden

Seating Area

Back of House Dumpster

Yard

Mimosa Plant

Annual Plant

Height: 1 - 5 ft | Spread: 1 - 5 ft

Hardstem Bulrush

Perennial Plant

Height: 3 - 10 ft | Spread: 2 - 3 ft

Common Milkweed

Perennial Plant

Height: Up to 5 ft | Spread: 2 - 3 ft

Big Bluestem Grass

Perennial Plant

Height: 3 - 9 ft | Spread: 2 - 3 ft

Little Bluestem Grass

Perennial Plant

Height: 4 - 5 ft | Spread: 1.5 - 2 ft

Butterfly Weed

Perennial Plant

Height: 1 - 3.5 ft | Spread: 1 - 2 ft

Penstemon Cobaea

Perennial Plant

Height: Up to 3 ft | Spread: 1 - 2 ft

White/Purple Prairie Clover

Perennial Plant

Height: 8 - 35 in | Spread: 1 - 2 ft

Leadplant

Perennial Plant

Height: 3 - 5 ft | Spread: 3 - 4 ft

Aromatic Asters

Perennial Plant

Height: 1 - 2 ft | Spread: 3 - 4 ft

Car & Bike Parking

Bioswales

Retention Pond

Exterior Entry

First Level:

Large Hanger Space for Aviation Trainning

Second Level:

Classroom for Education

First Level: Food Court

Second Level: Event Hall

Back of the Building: Cago Area & Loading Dock

Front of the Building: Exterior Gallery

Scale: 3/64” = 1’ - 0”

Site Garden Retention Pond

Curved Beam

Truss Structure

Shear Wall Branch Column

Beam Depth: 24 in Max 36ft Span [W24x84]

Column Size: 2ft* 2ft [W18x119]

01| Truss Structure in the Roof Hanger Space [Level 3]

Max Truss Span: 73 ft

Truss Depth = 73 ft/15 = 5ft

Using shear walls to support truss system.

02| Branch Column [Level 1&2]

Each top point of branch column is attatched to the intersection of beams.

03| Truss Structure in the Central Atrium Ceiling [Level 2]

Max Truss Span: 86 ft

Truss Depth = 86 ft/15 = 6ft

04| Curved Beam on the Edge of the Building [Level 1&2]

Two Columns are located at the edge of the building to support curved beams.

05| Beam Systm in the Central Atrium [Level 1]

Beam system is expanded in order to make sure there are no columns in the central atrium.

06| Truss System in the Food Court [Level 1]

Max Truss Span: 73 ft

Truss Depth = 73 ft/15 = 5ft

07| Shear Walls in the Truck Loading Area [Level1 ]

Shear wall is used to make sure there are no columns in the truck and forklift parking area.

08| Truss Structure in the Education Hanger Space [Level 1]

Max Truss Span: 51 ft

Truss Depth = 51 ft/12 = 4ft 3in

EPDM Rubber Membrane

Portland Cement Concrete (PCC) (Thickness: 24")

3 Inch Composite Floor Deck PLW3-36 Formlok™

W 24x104 Steel Beam

1 x 6 Poplar Wood V-Groove Ceiling

Vapor Retarder SA 31 (Thickness: 0.8 mm) OSB Sheathing (Thickness: 15/32”)

Sikalastic® WR | Eco-friendly Liquid Applied Waterproofing Solution (Thickness: 0.5 mm)

C23J PLYWOOD FURRING STRIP (Thickness: 3/4”)

WoodPlank Thermo Poplar Modern Exterior Wood Cladding (Thickness: 7/8”)

Pressure Treated White Pine Wood Fins (Thickness: 4”) (Distance between Fins: 8”) (Depth: 6” - 24”)

GE-UL-1 Steel Cleat

80 mm x 80 mm x 4 mm

Scale: 1.5” = 1’0”

WoodPlank Thermo Poplar Modern Exterior Wood Cladding (Thickness: 7/8”)

C23J PLYWOOD FURRING STRIP (Thickness: 3/4”)

OSB Sheathing (Thickness: 15/32”)

Sikalastic® WR | Eco-friendly Liquid Applied Waterproofing Solution (Thickness: 0.5 mm)

Bailey Metal Products 4” x 4” 90 Degree Base Flashing

Arcana Pavers (Thickness: 2”)

MAPEI Keraflex Plus Gray Thinset/Medium bed Tile Mortar (Thickness: 2”)

Type 2 CF2 (aka Recycled 6F2 / Crushed Hardcore) (Thickness: 4”)

Duraweave Geotextile Fabric

Pine Landscape Construction Gravel (1.5” Stones) (Thickness: 6”)

Drainage Mat | Sika Drainage Mat 420 (Thickness: 0.4”)

PVC Drainage Pipe (Diameter: 4")

12” Sonotube Deep Foundation Pier (12” x 24” x 24”

Footing with Two #4 Rebar)

OSB Sheathing (Thickness: 15/32”)

Gypsum Board (Thickness: 5/8”)

L4x4x7.5-97 Clip Angle

Owens Corning R-49 Kraft Faced Fiberglass Insulation Batts (Thickness: 14”) (R-Value: 49)

W 24x104 Steel Beam

W 27×178 Steel Girder

HVAC Return Duct Space (Thickness: 24")

Sprinkler Space (Thickness: 6")

Electrical Space (Thickness: 6")

Armstrong CEILINGS 24 in. x 24 in. Tegular Single Raised Ceiling Tile (Thickness: 1”)

3 x 4 Wood Studs (Thickness: 3 1/2”)

Kraft Faced R15 High Performance (Thickness: 3 1/2”) (R-Value: 15)

EnerfoilTM Rigid Foam Faced Insulation (Thickness: 1”) (R-Value: 6.2)

GE-UL-1 Steel Cleat 80 mm x 80 mm x 4 mm

Pressure Treated White Pine Wood Fins (Thickness: 4”) (Distance between Fins: 8”) (Depth: 3” - 24”)

Vapor Retarder SA 31 (Thickness: 0.8 mm)

EnerfoilTM Rigid Foam Faced Insulation (Thickness: 1”) (R-Value: 6.2)

Gypsum Board (Thickness: 5/8”)

OSB Sheathing (Thickness: 15/32”)

3 x 4 Wood Studs (Thickness: 3.5”) Kraft Faced R15 High Performance (Total: 3.5”) (R-Value: 15)

Custom Printed Rolled Eko Vinyl Flooring (Thickness: 0.002”)

Eco Cork Foam Underlayment (Thickness: 3.2 mm)

T&G Premium OSB Subfloor (Thickness: 23/32")

Air Fixture UFAD (Thickness: 42")

EnerfoilTM Rigid Foam Faced Insulation (Thickness: 5”) (R-Value: 31)

Vapor Retarder SA 31 (Thickness: 0.8 mm)

Quikrete Concrete Slab (Thickness: 6")

Sikalastic® WR | Eco-friendly Liquid Applied Waterproofing Solution (Thickness: 0.5 mm)

SCALE: 1.5” = 1’ - 0”

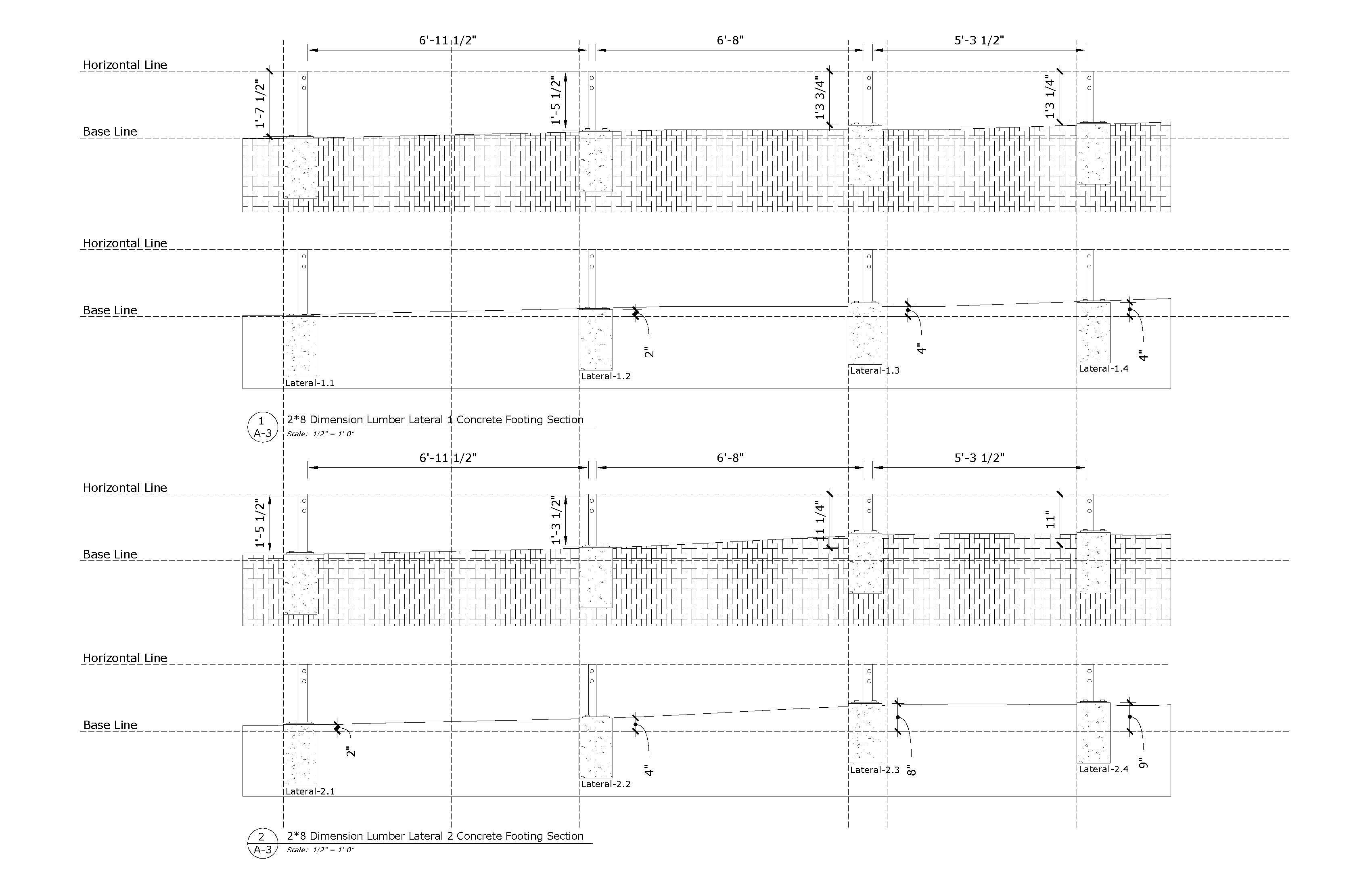

Field:

Design Build Project

Type:

Studio Group Work

Location:

Kansas City, Kansas, United States

Time:

Fall 2023 [Third Year]

Instructor:

Nils Gore

The project, situated in Kansas City, Kansas, is focused on redefining the utilization of the church’s external space. Community events take place on weekends, and during the summer, the church hosts regular camps attended by approximately 40-50 children. To accommodate the growing demand for activities, there is a need to explore additional outdoor areas. Following a visit to the site, several key proposals have emerged.

Firstly, there is a requirement for the design and construction of a new fence. The existing one, worn from years of use, poses an obstacle to the church’s further development. Another consideration is the potential design of a deck—a versatile outdoor space intended for seating, regular events, and a small music stage. Lastly, there is an opportunity to explore the development of a playground. With the demolition of the existing play area, there is a chance to design a structure that aligns with high creative standards and offers technical complexity.

The deck is proposed as an outdoor multi-use area. There is a big tree with deep roots outside. To avoid problems caused by tree roots, we decided to divide the deck into two parts and mark the tree as the center of the deck. Splitting the deck to accommodate the existing large tree roots was a practical design decision. It solves the challenges posed by construction and reduces the budget. By marking the tree as the center of the deck not only creates a visually appealing design, it also ensures that the tree remains the focal point of the outdoor space. Incorporating nature into the design not only adds aesthetic value, but also contributes to the harmonious coexistence between the built environment and natural elements. In addition, the strategic split of the deck allows for multiple uses, including seating, outdoor events and music stage space. This versatile functionality enhances the usability and enjoyment of the outdoor space, making it a dynamic and engaging area for a variety of activities.

Fill the area of deck as solid

Hollow out the center of deck to reduce the impact on tree roots

Soften sharp right angles of the deck

Continue to separate decks for use diversity

Leave space for people to walk past the deck

Fill the area of deck as solid

Hollow out the center of deck to reduce the impact on tree roots

Add play facilities to provide leisure space for the community

Continue to separate decks for use diversity

Leave space for people to walk past the deck

Add play facilities to provide leisure space for the community

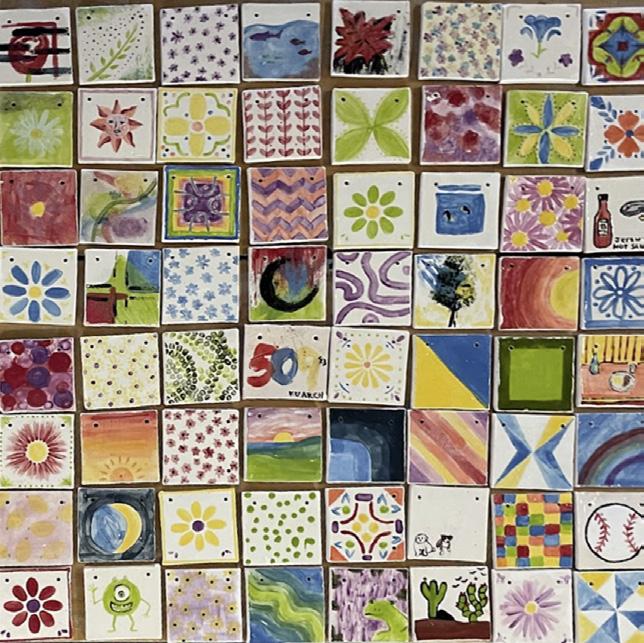

The fence serves as more than a barrier. It fosters interaction between the church and the surrounding community. The neighborhood is surrounded by a largely Latino population, and the fence design is inspired by Latin tiles. This innovative design transforms the fence into an adaptable, decorative element. Additionally, the project incorporates a sustainable children’s program where children engage in creating selfmade Latin tiles. They can paint patterns on square clay provided by the church. Once fired, these clay tiles are hung on the church fence for public display.

To ensure efficiency in construction, the fence’s structure is partially prefabricated. Adapting to the site’s slope, providing room for error, cost-effectiveness, and minimizing waste are key considerations. The project initiates with excavating holes for concrete pours. Pour concrete, set sonotube and anchor bolt jigs. After steel is galvanized, the assembly of the fence steel frame takes place. When the frames are in place, lower horizontal members are attached to complete the frames. Each member is fitted between the panels and cut to its appropriate length on site. When the frames are completed, Hog Mesh Panels are attached to the frames with P-clips and self-tapping screws. Lastly, concrete is sculpted beneath the base plates and piers to fill in gaps created by leveling the frames.

Fence Construction Steps:

• Excavate holes for concrete pours.

• Pour concrete, set sonotube and anchor bolt jigs.

• Steel prefabrication.

• Galvanizing steel.

• Steel installation on site.

• The fence steel frame takes place.

• Lower horizontal members were attached to complete the steel frames.

• Hog Mesh Panels were attached to frames with P-clips and self-tapping screws.

• Concrete was sculpted beneath the base plates and piers to fill in gaps created by leveling the frames.

Tiles Fabrication Steps:

• Roll out slab of 3/8” think clay.

• Cut out 5” by 5” squares.

• Drill holes in corners at 3/4” on center from edges.

• Dry and bisque fire.

Leave a set of bisque fired tiles and glaze to be used for the church kids program.

• Apply wax to sides and back. Glaze and fire.

• Hang the finished tiles on the fence.

MYSELF

film photography, 2024-2025