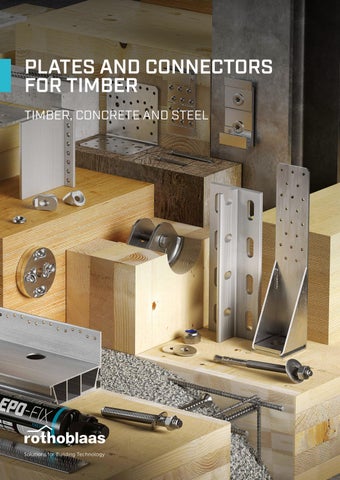

PLATES AND CONNECTORS FOR TIMBER TIMBER, CONCRETE AND STEEL

Issuu converts static files into: digital portfolios, online yearbooks, online catalogs, digital photo albums and more. Sign up and create your flipbook.

PLATES AND CONNECTORS FOR TIMBER TIMBER, CONCRETE AND STEEL