11 minute read

Product Showcase

Tilting spindle moulder profil 92 M e-motion

The new 92 M table spindle moulder is the Format4 premium model for maximum operating comfort and guarantees absolute efficiency with minimal set-up times when milling. The sophisticated electro-spindle is equipped with an HSK 63F interface for an automatic tool quick-change system with pneumatic clamping. The tilting range of +/- 46° allows unlimited processing possibilities. The rotation speed, spindle height, angle, and spindle moulder fence and table opening can be adjusted intuitively and precisely with the self-explanatory e-motion control in the 15” touchscreen control panel. The memory for tools, spindles, and mortising programs enable perfect repeatability and short set-up times.

Advertisement

Altendorf Hand Guard panel saw

The new Altendorf Hand Guard panel saw from Akhurst was developed to detect hazardous situations early and eliminate them. The handguard is not only safe but also highly versatile. It is a true all-rounder thanks to its wide range of configuration options. The safety system works with gloves, can handle nearly every saw blade, and is designed for virtually any material. The hand guard’s two-camera earlyrecognition system secures your employees and safeguards your jobs and your cost estimation. After triggering the system, the machine is immediately ready for use again, with no damage to the device, saw blade, or material.

RG Series Modular Pulse Jet

Dust Collector

The RG Series from Belfab is an enclosed modular dust collector equipped with a continuous pulse jet cleaning system ranging from 1500 to 5000 CFM. Its design meets the most stringent NorthAmerican safety regulations for an indoor installation by incorporating flameless venting and a fire extinguishing system as a standard. The unit’s fan is equipped with a variable speed drive which controls the airflow while maximizing energy efficiency. Our engineering team has also developed an HMI (Human Machine Interface) that monitors airflow performance and maintains optimal filter efficiency. This equipment has been designed with the concept of modularity.

Laguna JX16 Sheartec Jointer

The Laguna JX16 ShearTec II from busy Bee is loaded with premium features to make jointing safer and more enjoyable. Parallelogram Table Adjustments allow for table depth adjustments to travel along an arc to keep the same distance to the cutterhead through its travel. The knee stop uses a body-length bar at knee height to shut off the JX jointer. This allows the operator to stop the machine quickly at any position along the front, keeping hands on the workpiece. The new machine body has been redesigned with a toe-kick to allow the user to position themselves closer to the machine tables and to move safer and easier along the length of the machine.

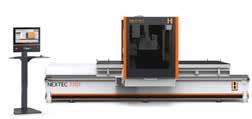

NEXTEC

The new NEXTEC from HOLZ-HER revolutionizes the way carpentry shops work. In presentations, sales, and production. Now also available as a high-flexible 5-axis version. One advantage of the new technology is the simple handling, allowing custom furniture production without programming work. The central feature is that this is not standard furniture - every workpiece can be custom designed. Other central advantages include specific efficiency control, cost savings, increased innovative capability, and reduction of personnel resources. Compared to conventional CNC machining, the primary difference is that NEXTEC allows CNC machining without any programming work.

Opera 5

Opera 5 is the new finishing centre from Biesse designed to satisfy the needs of small and medium-sized enterprises that require versatility with a high technology content. The Opera 5 is a piece of simple, functional cutting-edge technology with high-tech solutions available for any processing operation requirement, only covering a minimal footprint. Opera 5 is equipped with a substantial, wear-resistant steel worktable that guarantees precision and sturdiness for any processing operation. The worktable is positioned at 900 mm from the ground, thus ensuring ease of panel loading and unloading. This solution makes it possible to incorporate Opera 5 into automatic production lines.

Vertical Panel Saws SawTrax Series 3000

Normand’s 3000 Series panel saw has an accessory package recommended for custom woodworking shops that want to take advantage of the variety and benefits of using 10” saw blades. This series unit is ideal for breaking down material up to 2” thick with precision cuts. The 3000 Series features the exclusive Accu-Glide bearing system and the factory set patented Accu-Square preventing it from ever going out of square. Steel sleeves are used to cover the material rollers avoiding damage to the material rollers. The dust collection system uses a shroud brush containing the sawdust to allow the larger diameter dust hose to evacuate.

RETYX

Doucet’s RETYX, an articulated arm with a vacuum grip, automates the handling of the panels at the infeed and outfeed of your edgebander. With similar features to a typical return conveyor, it can present the parts in the correct orientation for the next pass, allowing automatic stacking and unstacking in the areas provided for this purpose. The RETYX has 40” vertical and 120” horizontal translation or stroke or movement and rotation capabilities from -90° to +180°. The tool has a receiving conveyor with six motorized belts 9’ long, including motorized infeed arms to interface with the edgebander.

Alpha-Brush Infinity Brush Machine

Taurus Craco’s Alpha-Brush Infinity Brush Machine is the perfect cost-effective solution for small to medium-sized production shops. The Infinity incorporates innovative Alpha-Brush abrasives and is available in 600 mm, 1000mm, and 1350 mm widths and can be ordered with two, three, and four sanding stations. The Infinity brush machine is adaptable for a wide variety of sanding applications. It can be fitted with sanding rollers or sanding discs driven by a heavy-duty conveyor system. All sanding rollers or disc stations are adjustable for speed, height, and rotation. The height adjustment is measured down to 0.1 mm with SIKO counters.

MP180 Jointer Planer Moulder

The MP180 Jointer Planer Moulder from Wood-Mizer is a three-inone woodworking machine that produces tongue and groove paneling, shiplap, trim, and more. The MP180 takes the versatile functionality of the MP160 Jointer/Planer and adds a vertical side cutter head to the planer table. The MP180 joins the established Wood-Mizer range of woodworking products, including jointer/planers, two-sided planer/ moulders, four-sided planer/moulders, slab flattening machines, dust collection systems, planer blades, moulder knives, and more. Switching between jointing and planing is done quickly by moving the board from one table to the other without adjusting the table or stopping the cutter or extractor.

Drawer Slides for

Functional Outdoor Furniture

Berenson’s outdoor slide series provide durability with corrosion-resistant stainless steel while offering functional characteristics ideal for external applications. Stainless steel is a favoured material for exterior applications, from outdoor appliances and hardware to the cabinet door and drawer fronts. It is a highly rust-resistant material and impervious to temperature extremes. Unlike drawer slides with plastic parts or liquid dampers, ball-bearing slides keep smooth and consistent movement in sub-zero temperatures. Outdoor drawers need to store more than food, with heavy-duty load capacities, store appliances, propane, and everything you need for the perfect cookout.

Pocket Cutter/Screw Inserter Machine

Castle’s CSI-1.5D Pocket Cutter/Screw Inserter saves time, reduces waste, and eliminates non-value-added labor in high-capacity production joinery. The patented technology reduces assembly time by 50%. Using patented ScrewIn-Pocket technology, CSI-1.5D cuts Castle’s distinctive, low-angle screw pocket, drills a low-angle pilot hole, and inserts a flush screw in 1.5 seconds. CSI1.5D provides stackable parts in faster production times by eliminating screw handling at assembly. Use the CSI-1.5D with composites, panels, and hard or softwood. This machine is designed for high-capacity, continuous production joinery for a maximum throughput of stackable parts.

SIBO IS BACK

The latest products and innovation

By Grace Tatigian

For years, the Salon Industriel du Bois Ouvré (SIBO) was the cornerstone event of secondary wood products in Quebec, but it hasn’t been active since 2009. Quebec is an essential part of the industry in Canada, representing $8.2 billion worth of wood products, so it is high time that this show makes a comeback.

“While the pandemic has stymied in-person events around the globe for the past two years, it has not prevented the Quebec wood products industry from growing,” said Harry Urban, SIBO show manager. “Nor has it stopped the development of new technology, supplies, and materials. SIBO 2022 will serve as an important gathering place for industry suppliers to showcase three years’ worth of new product introductions.”

The show will not only give manufacturers and distributors to connect to the Quebec market but will provide attendees with various workshops and presentations on topics from management to technology, covering issues that are pertinent to everyone in the industry.

The event’s keynote will be delivered by Bastien Larouche, President and CEO of Roboistic RMC (Robotmade Cabinets). Larouche launched his company ten years ago as a oneperson, one-robot operation to produce ready-to-assemble cabinets. Roboistic mainly sells its cabinets to cabinet shops and developers of large housing projects across North America from his Saint-Apollinaire factory. The presentation will delve into the key challenges and benefits of implementing robotic automation. Larouche will also provide an overview of the hands-free, fully-automated line that consists of a Kuka robot, Thermwood CNC nesting router, Favrol edgebander, and Omal drill and dowel inserting machine.

The SIBO Live stage will also host presentations from universities, trade associations, and other industry partners on essential topics like finishing advancements, workforce development, and advanced technologies, including Industry 4.0 and artificial intelligence.

“Our goal is to provide Quebec’s wood product manufacturers, both large and small, with the latest products and information that will help them improve their operational efficiencies and increase their bottom lines,” said Urban. “In turn, SIBO 2022 will provide a valuable forum for industry suppliers to display and demonstrate their latest products to grow their business in the unique Quebec wood products market.”

And the market in Quebec is only set to grow. Recently, the Ministère de l’Économie et de l’Innovation announced the Furniture and Kitchen Cabinet Marketing Support Project, which will provide $3 million in financial assistance to enable companies in the furniture and kitchen industry to modernize their marketing methods. SIBO is another such tool to help manufacturers reach outside the province.

“Finally, Quebec will have an industrial woodworking show,” said Urban. “We’re pleased that exhibit inquiries and sales have really started to pick up now that the apparent end of the pandemic is upon us. We expect a sold-out show.”

AUTOMATION ON DISPLAY

Big plans for IWF

By Bill Esler, Editor and Analyst at International Woodworking Fair

There is no doubt that automation is the future of our industry, which is why the International Woodworking Fair (IWF) is putting such a strong emphasis on woodworking robots this year. IWF is known to deliver the latest solutions in architectural woodwork, cabinetry, furniture manufacturing, engineered products, doors, windows, machinery, tools, and more. The show highlights the largest collection of the woodworking industry’s newest technologies available anywhere, including hundreds of product introductions. From raw materials, supplies, and finishing accessories to woodworking and material processing machinery. Attendees will find more new products, from more sources, in more selection and variety.

In short, IWF is where the woodworking business does business. The 2022 show will highlight ways to harness the power of new technologies to increase production efficiencies, new products to drive sales, and new connections to tap emerging markets.

The show floor promises to be full of the latest innovations in automation, including robots integrated into vertical machining centers from Stiles, dowel drilling and insertion from CNC Factory, and operating beam saws from Biesse. Alongside long-standing exhibitors such as IMA Schelling and Weinig Holz-Her USA, attendees will also see new exhibitors such as AutomaTech Robotik, Robotic Solutions, ABB Robotics, 7robotics, and Con-Vey. But the benefits of automation aren’t exclusively on the show floor.

Day one is scheduled to start with a full-day Process Automation Symposium, presented by 2020. This educational session will discuss how to automate sales, purchasing, engineering, production, and finance processes within a modern woodworking company. Led by industry thought leaders, practitioners, and machinery experts, the goal is to discover best practices and gather ideas on how to apply these practices in your company. The session will cover process automation, increasing production, key performance indicators, and streamlining product engineering. It will also include breakout rooms devoted to architectural millwork, kitchen design, and residential furniture.

Another session, Robotic Evolution in the Wood Factory, promises to cover product delivery systems, automated spraying robots, machine tending, sanding, curing technologies, equipment integration issues, and programming. This session, delivered by Robotic Solutions, LLC, is all about understanding the advantages and disadvantages of new technology is critical when building a continuing success strategy, and understanding total operating costs and the return on investment associated with purchasing robots.

It isn’t all about the flashy machines, the ones that look so impressive on the showroom floor. Robots are becoming less visible as they pick up critical roles in finishing, directing spray heads, and sanding tools over varying shaped workpieces with a consistency of control and diligence that alleviates another woodworking industry constant — the shortage of skilled workers. Robotically enhanced finishing systems from SCM, Biesse, Cefla, and others will be plentiful at IWF.

This year’s show promises hundreds of exhibitors and tens of thousands of attendees from across the globe, with a strong North American representation. Thousands of innovative products, services, and technologies will be showcased by the world’s top manufacturers and emerging brands with cutting-edge demonstrations of machinery, tools, and other products live on the show floor.

The show will take place August 23-26, 2022, at the Georgia World Congress Center in Atlanta, GA.

TOP: Robotic arms in the Biesse Viet sanders wield adapted conventional sanding tools. LEFT: A Stiles Homag Feedbot keeps a Drillteq machining center busy RIGHT: Visitors at IWF Atlanta