20 18 22 24 26 /// CONTENTS Volume 31 | Issue 3 06 EDITOR’S NOTE Transforming Your Parcel Operation By Amanda Armendariz 08 INDUSTRY INSIGHT Adapting Global Supply Chains in a Volatile Trade and Economic Environment By Hannah Testani 10 SUPPLY CHAIN SUCCESS A New Frontier? A Consultant’s First Pass at Analyzing an Amazon Parcel Proposal By Chelsea Snedden 12 REVERSE LOGISTICS Handling Big & Bulky Returns By Tony Sciarrotta 13 PARCEL COUNSEL Motor Carrier Liability, Cargo Liability Insurance, and Cargo Insurance: An Analysis By Brent Wm. Primus, JD 18 WHAT YOU DON’T KNOW YOUR SHIPPING DATA CAN DO FOR YOU By Caleb Nelson 20 SIMPLIFYING THE SHIFT FROM ON-PREMISES TO CLOUDBASED WAREHOUSE MANAGEMENT By Ninaad Acharya 22 TOP TIPS TO BUILDING YOUR BEST MULTI-CARRIER NETWORK By Kenneth Moyer 24 STREAMLINING E-COMMERCE SHIPPING AND FULFILLMENT: STRATEGIES FOR SMALL BUSINESS OWNERS By Eric S. Youngstrom 26 OPTIMIZING YOUR PACKAGING: REDUCING SHIPPING COSTS AND PRODUCT DAMAGE By Jeff

28 BEYOND THE BUZZ: CULTIVATING LASTING CUSTOMER SATISFACTION IN PARCEL SHIPPING By Dave Salter 30 CLOSING THOUGHTS The Leveling of Package Volumes By Merry Law SPONSORED CONTENT 07 REDEFINING THE CUSTOMER EXPERIENCE THROUGH UNBOXING 14 ARE YOU USING REGIONAL AND FINAL-MILE CARRIERS? 16 FINAL-MILE CARRIER SOLUTIONS MAP GET OUR NEWSLETTER? SUBSCRIBE FOR FREE 4 PARCELindustry.com MAY-JUNE 2024

Haushalter

PRESIDENT

CHAD GRIEPENTROG

PUBLISHER

KEN WADDELL

EDITOR

AMANDA ARMENDARIZ [ amanda.c@rbpub.com ]

AUDIENCE DEVELOPMENT MANAGER

RACHEL CHAPMAN [ rachel@rbpub.com ]

CREATIVE DIRECTOR

KELLI COOKE

ADVERTISING

KEN WADDELL (m) 608.235.2212 [ ken.w@rbpub.com ]

JOSH VOGT [ josh@rbpub.com ]

PARCEL (ISSN 1081-4035) is published 7 times a year by MadMen3. All material in this magazine is copyrighted 2024 © by MadMen3. All rights reserved. Nothing may be reproduced in whole or in part without written permission from the publisher. Any correspondence sent to PARCEL, MadMen3 or its staff becomes the property of MadMen3. The articles in this magazine represent the views of the authors and not those of MadMen3 or PARCEL. MadMen3 and/or PARCEL expressly disclaim any liability for the products or services sold or otherwise endorsed by advertisers or authors included in this magazine.

SUBSCRIPTIONS: Free to qualified recipients: $12 per year to all others in the United States. Subscription rate for Canada or Mexico is $35 for one year and for elsewhere outside of the United States is $55. Back-issue rate is $5.

Send subscriptions or change of address to: PARCEL, P.O. Box 259098 Madison WI 53725-9098

Allow six weeks for new subscriptions or address changes.

REPRINTS: For high quality reprints, please contact Chad Griepentrog, 608-241-8777, chad.g@rbpub.com

P.O. Box 259098 Madison WI 53725-9098 p: 608.241.8777 f: 608.241.8666

PARCELindustry.com

MAY-JUNE 2024 PARCELindustry.com 5 SUBSCRIBE FOR FREE!

TRANSFORMING YOUR PARCEL OPERATION

By Amanda Armendariz

The need for shippers’ carrier mixes to include multiple carriers has never been more obvious than in these post-pandemic times. There’s no question that UPS and FedEx do their jobs and do them well, but the time for putting all of one’s proverbial eggs in one basket is over. Supply chain disruptions, potential labor shortages, increasing surcharges, and capacity constraints mean that the most effective shippers are often ones who spread their volumes across multiple carriers. Each carrier has different strengths and

weaknesses, so the best carrier mix is the one that utilizes a variety of offerings.

Our annual regional carrier-focused issue aims to be an excellent resource as you get to know the various players in this market. Whether you already utilize regional carriers or are just thinking about implementing them, the companies profiled here would be happy to talk with you and see if their solutions meet your needs. And if you’re considering implementing regional carriers to make your peak season flow easier, the time to reach out is now.

Many of the companies mentioned in this issue will also be at this year’s PARCEL Forum, so if face-to-face meetings are more your style, there’s no better time than now to register. Visit PARCELforum.com for updates and more information. I’d love to see you at the Gaylord Texan this September.

As always, thanks for reading PARCEL.

6 PARCELindustry.com MAY-JUNE 2024

EDITOR’S NOTE

Redefining the Customer Experience Through Unboxing

Imagine you’ve placed an order online for a pair of running shoes, water bottle and t-shirt from an online store your friend recommended. Upon receiving the package, you find the items buried under a pile of plastic air pillows. Disappointed with the amount of waste associated with this purchase, you place the shipping box in the recycle bin and the void fill in the trash. You then make a mental note to find a different company for your next purchase.

In the world of e-commerce, customers have many alternatives. To stay competitive, you need to do more than offer a good product. You must also provide a memorable customer experience that goes beyond the product itself. An important aspect of the customer experience is the unboxing experience.

Improving Your Company’s Unboxing Experience

Historically, the customer experience revolved around brick-andmortar stores. Yet, with the rise of online shopping, the in-store experience becomes a smaller part of the equation. Once merely a method to deliver products intact, shipping has evolved towards fostering a positive and memorable experience — shifting focus from delivery speed to holistic experience creation. Today, achieving this goal involves a multifaceted strategy.

On-Package Branding

Ensuring a prominent display of your company branding is crucial. Incorporate your logo, tagline, or any visual elements that represent your brand. Integrating QR codes on the package also adds an interactive dimension to the unboxing experience, directing customers to product tutorials, personalized content, special promotions, and more.

Automated Fit-to-Size Packaging

Investing in automated fit-to-size packaging can further enhance the unboxing experience while streamlining warehouse operations and promoting sustainability. Receiving an order in a box perfectly tailored to its order contents leaves a lasting impression on customers. A right-sized box eliminates the need for void fill, reduces parcel volume by up to 50% and facilitates easier returns. With increased packaging speed, branded corrugate, and print-on-box capability, the right automated

packaging machine can establish a seamless eco-friendly process — leaving your customers impressed.

Is it Worth it?

The impact of the customer experience should not be underestimated. Research1 from Salesforce reveals 92% of consumers are more inclined to make repeat purchases from companies that deliver positive customer experiences. A critical element of this experience, particularly in e-commerce, is the unboxing experience.

By implementing the right technology, organizations can enrich the unboxing experience, and positively impact the customer journey in a cost-effective and efficient manner. Sparck’s autoboxing machines boast over 40 million box size options on demand. These machines offer heightened packaging speed, the capability for branded corrugate from multiple mills, internal and external print-on-box capabilities, and reduced reliance on labor.

The unboxing experience is not just a trend; it’s an essential component in creating a lasting connection with customers and fostering brand loyalty. Companies that invest in this aspect of their business not only meet current consumer demands but also position themselves ahead of the competition.

APPLICATION ARTICLE

https://sparcktechnologies.com/us/ info@sparcktechnologies.com 800.983.8157 1 “State of the Connected Consumer”, Salesforce, 2021

ADAPTING GLOBAL SUPPLY CHAINS IN A VOLATILE TRADE AND ECONOMIC ENVIRONMENT

By Hannah Testani

Navigating the complexities of the modern global trade environment poses a significant challenge for shippers worldwide. Shippers face a landscape marked by rapid shifts in trade patterns, substantial regulatory changes, and persistent inflationary pressures. Most notably, the increase in container shipments from China to Mexico signals broader shifts in global trade flows driven by geopolitical tensions, changing trade policies, and a concerted push towards supply chain diversification. These developments embody the dual nature of the challenges and opportunities confronting shippers today: the complexity of adapting to new routes and market dynamics on one side and the need to mitigate risks associated with relying on single markets on the other.

The evolving regulatory landscape further complicates global trade. The United States’ decision to expand import bans on Chinese companies underscores the shifting nature of trade policies and their direct impact on the global supply chain. Such measures disrupt existing trade relationships but also compel shippers to reassess their compliance strategies and supply chain configurations. Moreover, initiatives like President Biden’s executive order on supply chain resilience underscore the strategic importance of constructing robust supply networks capable of withstanding a range of disruptions. For shippers, navigating these regulatory changes is paramount. This task involves staying informed about policy developments, investing in compliance infrastructure, and fostering partnerships to enhance supply chain visibility and resilience.

Amid these trade and regulatory challenges, inflation casts a long shadow, with recent surges in US producer

prices signaling persistent economic pressures that affect every aspect of the supply chain. From the cost of raw materials to transportation and warehousing, inflation impacts margins and necessitates strategic cost management. For shippers, addressing this economic backdrop means implementing proactive measures, such as securing contracts that provide some protection against fluctuating costs, exploring more cost-effective routing options, and leveraging technology to optimize operations and reduce inefficiencies.

In response to these challenges, shippers must be willing to assess their shipping operations and make necessary changes to have a strategy centered on resilience and adaptation. Diversifying supply sources and transportation routes emerges as a critical option to reduce risks associated with geopolitical tensions and regulatory shifts. Shippers utilizing supply chain visibility, facilitated by technological advancements, can have real-time tracking of shipments, monitoring of supplier performance, and effective inventory management. Having enhanced technology as a backbone, shippers can respond swiftly to disruptions, adjusting their shipping operations as needed.

To truly gain an advantage, shippers need to take a proactive approach. This industry is not for the weary and demands shippers to

stay ahead of regulatory changes, develop flexible compliance strategies, and engage proactively with legal and trade experts. Shifts from reactive to proactive strategies not only address current challenges but also position shippers to anticipate and prepare for future trends. Engaging in industry advocacy is also crucial, as it enables shippers to directly influence the development of trade policies that can benefit their operations in the long term. Moreover, addressing the challenges of inflation requires a focus on cost management. Shippers can mitigate the impact of economic fluctuations on their operations by negotiating contracts that buffer against price volatility, optimizing shipping strategies for cost savings, and utilizing advanced analytics for smarter decision-making, Additionally, embracing sustainability has become imperative. Implementing eco-friendly practices, such as route optimization for reduced emissions and selecting suppliers committed to sustainable production, supports environmental conservation and ensures compliance with evolving global trade standards. Through comprehensive planning and a commitment to innovation, shippers can ensure their operations are efficient and well-positioned for the future of global commerce.

Hannah Testani is CEO, Intelligent Audit.

8 PARCELindustry.com MAY-JUNE 2024

INDUSTRY INSIGHT

SUBSCRIBE FOR FREE!

A NEW FRONTIER? A CONSULTANT’S FIRST PASS AT ANALYZING AN AMAZON PARCEL PROPOSAL

By Chelsea Snedden

When I joined the supply chain field in 2021, there were whispers that Amazon would be entering the parcel shipping market as a carrier. This was greatly felt by my clients, who are retail and pharmaceutical shippers looking to save more money on their shipping contracts. I ignored it as sensationalist news, as the consequences would be great for the existing carriers, like UPS and FedEx, and it would be operationally difficult for Amazon to implement quickly. That is, until my team got to analyze a parcel proposal from them in March of 2024.

The following is a first pass look at Amazon’s proposal and its implicit impacts on the parcel market. This is not intended to serve as advertising for one carrier over another, but to study if Amazon has the correct feather wand to compete with the big cats like UPS and FedEx in the parcel industry.

Amazon Notable Contract Terms

Amazon’s contract terms were largely based around what we see for UPS contracts. It contained only five accessorials, a fair earned discount tier structure, a ramp-up period, good minimum charges, and an average DIM divisor. The real meat of the savings came from ground residential rates compared to the other carriers (along with the limited accessorials). Overall, my team was expecting higher savings and a few more bells and whistles, but it was competitive with the other carriers who had submitted proposals.

Amazon Shipping Pros

Cost-Effectiveness: Amazon’s contract contained no residential fees and focused on ground pricing, utilizing its highly capable ground network. Amazon’s entry could also drive down shipping costs due to increased competition from the other carriers.

Easy Technological Integration: Amazon’s advanced package tracking and logistics management mean shippers’ order tracking is streamlined and easily predictable for customers.

Speed: Amazon’s shipping network may offer faster delivery options by capitalizing on its existing infrastructure.

Scalability: Amazon is no rookie to the holiday peak

season. Amazon’s ability to handle large volumes of parcels benefits the shippers who want to minimize losses and keep customer satisfaction high as the year ends.

Our client mentioned that they’d keep Amazon in their back pocket for promotional periods or for areas there are higher mixes of residential in the future, but they didn’t currently have the technological capabilities to optimize the benefits of the Amazon contract.

Amazon Shipping Cons

Potential Market Disruption: Amazon’s entry may significantly disrupt current shipping rates and contracts with other carriers, straining longstanding business relationships and potentially angering employee unions

10 PARCELindustry.com MAY-JUNE 2024

SUPPLY CHAIN SUCCESS

such as the UPS Teamsters.

Dependency Risks: Shippers may begin to rely on a single provider like Amazon if its pricing is truly competitive over the incumbent carriers. This could be risky for shippers if Amazon alters terms or prices in the future, or if Amazon has outages due to peak season or a cyberattack on its warehouses, such as in 2023.

Limited Customization: Amazon’s processes tend to be highly standardized, potentially offering less flexibility for specialized shipping needs, such as medical shippers needing refrigeration and signature services, or outdoor companies needing to ship dangerous goods like gasoline or batteries.

Amazon Overall Impact and Outcome for Client

Overall, our client decided not to go for the Amazon proposal. Amazon was offering wonderful ground rates, but the contract did not contain the level of customization and care the client needed. They saw

it as a risk to be one of first testers of this service and did not want to strain their current business partnerships with FedEx and UPS. Our client mentioned that they’d keep Amazon in their back pocket for promotional periods or for areas there are higher mixes of residential in the future, but they didn’t currently have the technological capabilities to optimize the benefits of the Amazon contract. While Amazon’s shipping services could’ve offered a compelling alternative for our client, there were trade-offs

in terms of potential market volatility, damage to the business relationship, and Amazon’s (limited) time in the parcel market.

Chelsea Snedden is a Senior Consultant on Körber’s Transportation Consulting team, she specializes in parcel sourcing, benchmarking, as well as building out unique transportation solutions that drive ROI for clients. Additionally, as an advocate for sustainability, she often works with clients on carbon emissions reporting.

MAY-JUNE 2024 PARCELindustry.com 11

SUBSCRIBE FOR FREE!

HANDLING BIG & BULKY RETURNS

By Tony Sciarrotta

Consumers are returning more big and bulky items such as furniture and exercise equipment because of the ease and improved comfort level of purchasing such items online. In addition, like fast fashion, fast furniture, which is made using poor-quality materials and offered at lower prices, often ends up in landfills. According to the Environmental Protection Agency (EPA), Americans throw out more than 12 million tons of furniture annually.

From a sustainability perspective, we must keep items like furniture from entering landfills.

First, we need to understand why furniture and other big and bulky items are being returned and correct those reasons as best as possible. Typically, the reasons given for apparel and other smaller items returns are often the same for large items, such as damaged product, the color didn’t match what was on the website, or the size was incorrect.

Often, a return can be prevented by empowering call agents to provide consumer credits for such issues as slight damages and product variances.

But if a return is indeed made, it’s important to prepare for a seamless returns process:

Retailers and/or carriers should contact the consumer ahead of time to request measurements of entryways and appliance or furniture pathways to ensure the right equipment is used.

Texts and auto calls for confirmation of delivery days and times.

Think local when disposing of returned items by donating to a charity close by, reselling them locally via online platforms or through resellers such as FloorFound, or to large furniture retailers, such as Haverty’s, which resells in company-owned outlet stores.

The Big & Bulky Market

The US’s big and bulky last mile is growing and is estimated at $60 billion, according to Nando Cesarone, UPS President US. To take advantage, Cesarone announced a new service delivering big and bulky items via the company’s subsidiary, Roadie, during UPS’s recent Investor & Analyst Day. Still in its early days, Roadie XL has so far delivered over one million packages, such as minifridges. While it’s primarily focused on the last mile, it would not be a surprise if Roadie collaborates with UPS’s recent acquisition, Happy Returns, to pick up returned big and bulky items. However, Roadie will probably stick to handling big and bulky packages weighing 100 pounds or less, which is typically UPS’s “sweet spot.”

For larger items such as furniture and exercise equipment, less-than-truckload (LTL) carriers usually perform the last mile and the reverse.

For example, the largest LTL carrier, FedEx Freight, expanded its e-commerce solution for returns of big and bulky items in 2023. The service offers label-free returns, flexible pickup windows with proactive notifications, shipment visibility, and technology capabilities connecting the return to the original shipment.

Importance of a Reverse Logistics Strategy

According to the National Retail Federation and the Reverse Logistics Association, regardless of the size of the returned item, a comprehensive reverse logistics strategy helps companies reduce administrative, transportation, and support costs, increase product velocity and asset value recovery, and generate sustainability benefits by eliminating or significantly decreasing products and materials being sent to landfill.

Data plays an important role in developing a strategy, though it can be challenging to capture the right metrics or insights. Cross-functional collaboration and associate training and education are also important.

Tony Sciarrotta is Executive Director of

the Reverse Logistics Association. The RLA offers various tools, white-papers, and monthly webinars that provide best practices in managing reverse logistics.

12 PARCELindustry.com MAY-JUNE 2024

REVERSE LOGISTICS

SUBSCRIBE FOR FREE!

MOTOR CARRIER LIABILITY, CARGO LIABILITY INSURANCE, AND CARGO INSURANCE: AN ANALYSIS

By Brent Wm. Primus, JD

In this installment of PARCEL Counsel, we will analyze the relationship between a motor carrier’s liability for loss and damage to cargo, cargo liability insurance, and cargo insurance. It is very important for a parcel shipper to understand these three concepts and how they come into play when a loss occurs.

Motor Carrier Liability. The basis of liability for regulated motor carriers is found in 49 U.S.C. 14706 — a federal statute known as the Carmack Amendment. This statute imposes strict liability on regulated motor carriers for loss and damage to cargo without proof of negligence on the part of the carrier.

The first thing for a shipper to be aware of is that this statute applies only to regulated motor carriers and not unregulated motor carriers. An example of the latter is a carrier hauling certain agricultural commodities.

This statute also does not apply to air carriers. This is important to note because many large transportation providers such as UPS or FedEx operate as both motor carriers and air carriers. Accordingly, when involved in a claim one must first determine the capacity in which the provider was operating.

There are five exceptions to a motor carrier’s liability under the Carmack Amendment. These are (i) act of the public authority, (ii) act of the public enemy, (iii) act of the shipper, (iv) inherent vice, and (v) an act of God. These have all been acknowledged by the United States Supreme Court. In order to establish one of these defenses with respect to a particular claim, the carrier must also be free of negligence.

In addition to the defenses described above, most carriers have published limits of liability in their tariffs. These can sometimes be as low as $1.00 per pound.

Cargo Liability Insurance.

Most motor carriers purchase cargo liability insurance. The most important thing to know about cargo liability insurance is that it will only pay a claim to the shipper if the carrier is liable for the loss or damage to the cargo. This means that if the carrier is not liable due to a defense such as “an act of God” or a valid limit of liability in a carrier’s tariff, there is no coverage that will pay the shipper.

There is also a misconception in the industry that the carrier is only responsible up to the amount of its insurance coverage. For example, if the amount of the claim is for $140,000.00 and the carrier only holds $100,000.00 in cargo liability insurance, many persons

believe that the carrier is only liable up to the amount of the insurance and not liable for the $40,000.00 not covered by the insurance. This simply isn’t so. While it is true that a carrier can establish a limit of liability in its tariff of $100,000.00, simply buying a cargo liability policy in that amount will not limit the carrier’s liability.

Cargo Insurance. Cargo insurance, also called shipper’s interest cargo insurance, is a policy purchased by a shipper to better protect itself. These policies are in the nature of casualty insurance as opposed to liability insurance. While subject to the exclusions and deductibles of the policy itself, it will pay regardless of the carrier’s liability. Shippers should give serious consideration to purchasing their own cargo insurance, especially for high value shipments, because “acts of God” do happen and there are numerous limits and exceptions in carriers’ tariffs.

All for now!

Brent Wm. Primus, J.D., is the CEO of Primus Law Office, P.A. and the Senior Editor of transportlawtexts, inc. Previous columns, including those of William J. Augello, may be found in the content library on PARCELindustry.com. Your questions are welcome at brent@primuslawoffice.com.

MAY-JUNE 2024 PARCELindustry.com 13

PARCEL COUNSEL

SUBSCRIBE FOR FREE!

ARE YOU USING REGIONAL AND FINAL-MILE CARRIERS?

Regional and final-mile carriers are a very effective way to get your shipments wherever they need to be, whether it's city to city, state to state, or coast to coast.

At ePost Global, we're your global business growth experts, simplifying international and domestic shipping. With a presence in over 200 countries and the largest last-mile carrier network, we offer competitive rates and top-notch service. Backed by 25 years of experience, we deliver customized endto-end solutions, navigating international complexities and new regulations. Our tech-driven approach ensures transparent tracking, providing full visibility into your shipments. With ePost Global, you get more options, better services, and tailored solutions to confidently reach more customers worldwide.

Choosing FirstMile for your shipping needs means opting for unmatched efficiency and reliability, particularly in final-mile delivery. Our proprietary shipping method, Xparcel, provides tailored solutions that optimize transportation costs and enhance service quality. Xparcel intelligently routes each package through the most cost-effective and reliable carrier network, ensuring timely and accurate deliveries. Our approach to a comprehensive shipping solution includes complimentary first-mile pickups, real-time tracking transparency, and dynamic routing capabilities. Partnering with FirstMile not only improves your delivery performance but also elevates customer satisfaction, making us the smart choice for businesses aiming

today’s competitive e-commerce landscape.

A shipper should work with GLS for final-mile solutions because we offer cost-effective, efficient, and reliable parcel delivery services both domestically and internationally, leveraging advanced technology for real-time tracking, route optimization, and seamless customer communication. Our commitment to sustainability, strategic partnerships for nationwide & international coverage, and industry specialization ensure superior last-mile delivery experiences, making us the trusted choice for businesses seeking streamlined global logistics solutions. | Marketing@gls-us.com | 888.SHIP.GLS | www.gls-us.com | https://www.gls-us.com/parcel/international-shipping

International Bridge provides 3-5 day small-parcel regional delivery to non-continental US locations. Our affordable, expedited service is fully trackable from the point of receipt at an IB warehouse to the door in Hawaii, Alaska, and Puerto Rico. For over 20 years this solution has been the cornerstone of our business, delivering millions of small parcels every year. With our end-to-end delivery expertise, you can ensure your products reach their destinations in these locations efficiently and cost-effectively.

14 PARCELindustry.com MAY-JUNE 2022

www.myib.com/non-continental | sales@myib.com | 877.727.2354 SPONSORED CONTENT

SEE LARGER MAP ON NEXT PAGE

epostglobalshipping.com | inquiries@epostglobalshipping.com | 866.784.8444

|

in

shipping@firstmile.com | 888.993.8594

to excel

OnTrac is the carrier of choice for last-mile e-commerce deliveries that helps retailers and shippers build a competitive advantage through faster delivery times, lower costs, coast-to-coast coverage, delivery innovation, and reliable on-time performance. The OnTrac delivery network encompasses 35 states and Washington, D.C. and enhances retailers’ ability to meet growing demand in the consumer e-commerce delivery market. With more than 65 years of experience, OnTrac has evolved into a critical part of the e-commerce infrastructure and is trusted by leading retailers and shippers that desire reduced transit times and increased flexibility within their supply chains.

| sales@ontrac.com | https://www.ontrac.com/residential-e-commerce-delivery/

Optima Overnight’s expedited ground delivery network offers unmatched service throughout New England. With over 40 years’ experience meeting the delivery needs of our customers, Optima continues to grow as the first choice in final-mile delivery for e-commerce, retail, meal kits, medical, and more! Our customized solutions can get you to your customers faster, with more consistent service and more cost-effectively than the competition. To learn more, please visit our website below or give us a call. We deliver, on-time, every time! www.shipoptima.com

For over 25 years, Pace has been a go-to final-mile, middle-mile, and courier solution in the Southeast. Our 16 facilities, ranging from the Carolinas, through Tennessee, Georgia, Alabama, Mississippi, Louisiana, and Texas serve our customers in e-commerce, retail, automotive, healthcare, and other business sectors. We rely heavily on our values to serve relentlessly, do the right thing, do what you say, and always improve to fulfill our most important value – get the job done. Pace’s solutions range from small vehicles, cargo vans, straight trucks, and tractor trailers. Pace is ready to fulfill our mission with you of Solving Logistics Together!

www.pace-usa.com | sales@pace-usa.com

Spee-Dee Delivery Service, Inc. is proud to be celebrating 46 years of providing reliable and costeffective service in the Midwest. Our company has grown to include 36 locations, serving over 12,000 daily shippers within 10 states. Spee-Dee Delivery most recently expanded service into the Kansas City market. We continue to add to our menu of service offerings including Spee-Dee On-Call, Spee-Dee LTL, and Spee-Dee Logistics. With our simplistic approach to pricing, Spee-Dee Delivery makes it easy for shippers to identify and realize cost savings.

www.speedeedelivery.com | sales@speedeedelivery.com | 800.862.5578

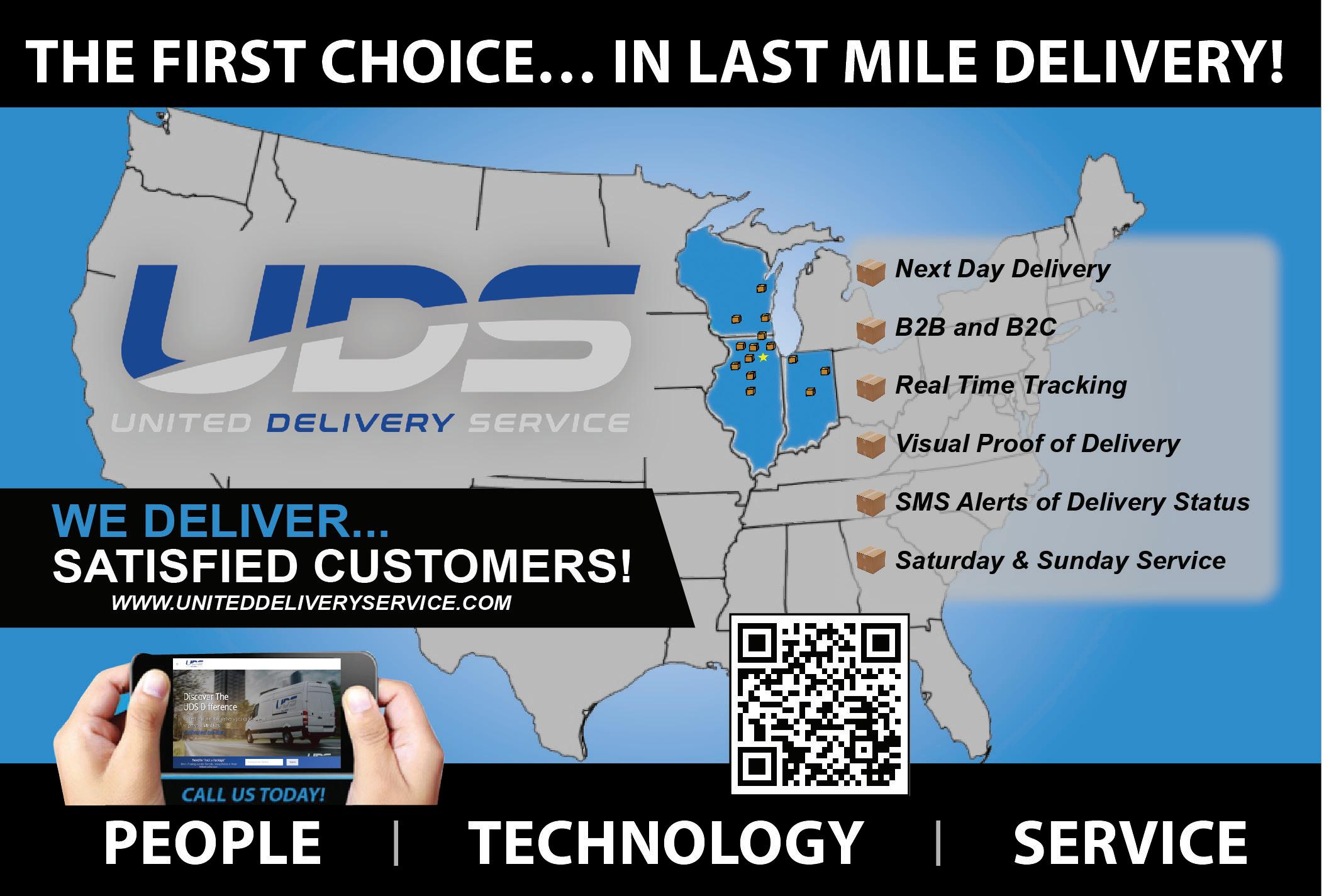

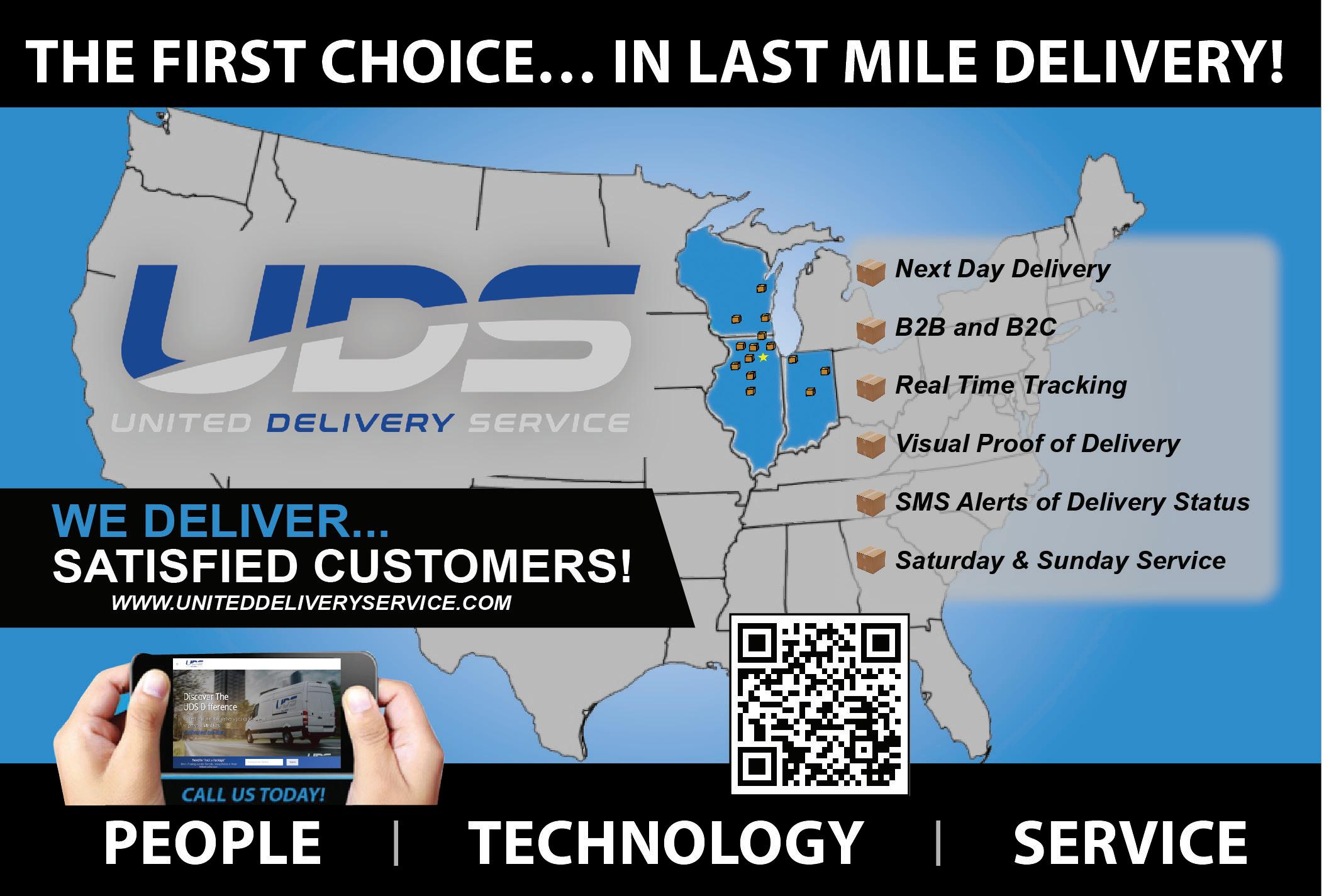

United Delivery Service (“UDS”) is a premier last-mile next-day regional courier. For more than 50 years, many of the world’s most trusted brands have partnered with UDS to enhance the delivery experience of their customers in the Midwest. UDS offers proprietary software that allows us the flexibility to develop solutions to meet the specific needs of our customers. Our technology stack offers real-time tracking including SMS notifications, Visual Proof of Delivery, and a suite of online tools for complete visibility of your shipment every step of the way. UDS . . . The First Name in Last-Mile Delivery

www.uniteddeliveryservice.com | Sales@uniteddeliveryservice.com

MAY-JUNE 2021 PARCELindustry.com 15

| 630.930.5201

| sales@shipoptima.com | 781.328.0081

16 PARCELindustry.com MAY-JUNE 2022 16 PARCELindustry.com MAY-JUNE 2024

US territories

Puerto Rico

F I N A L - M I L E C A R R I E R S O L U T I O N S

Washington, D.C.

Final-Mile Delivery Service Area

ePost Global

AL, AR, AZ, CA, CO, CT, DE, FL, GA, IA, ID, IL, IN, KS, KY, LA, ME, MA, MD, MI, MN, MO, MS, MT, NE, NC, ND, NH, NJ, NM, NV, NY, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VA, VT, WA, WI, WV, and WY

FirstMile

AR, AZ, CA, CO, CT, DE, FL, GA, ID, IL, IN, KS, KY, LA, MA, MD, MI, MN, MO, MS, NC, NH, NJ, NV, NY, OH, OK, OR, PA, RI, SC, TN, TX, UT, VA, WA, WI, WV, and Washington, D.C.

GLS

AL, AK, AR, AZ, CA, CO, CT, DE, FL, GA, HI, IA, ID, IL, IN, KS, KY, LA, ME, MA, MD, MI, MN, MO, MS, MT, NE, NC, ND, NH, NJ, NM, NV, NY, OH, OK, OR, PA, RI, SC, SD, TN, TX, UT, VA, VT, WA, WI, WV, and WY

International Bridge

AK, HI, US territories and PR

OnTrac

AR, AZ, CA, CO, CT, DE, FL, GA, ID, IL, IN, KY, MA, MD, MI, MN, MO, MS, NC, NH, NJ, NV, NY, OH, OR, PA, RI, SC, TN, TX, UT, VA, WA, WI, WV, and Washington, D.C.

Optima Overnight

CT, MA, NH, and RI

Pace

AL, FL (Panhandle), GA, KY, LA, MS, NC, SC, TN, TX

Spee-Dee Delivery Service

IA, IL, MN, ND, SD, WI and select ZIP Codes in KS, MI, MO, and NE

United Delivery Service

IL, IN, and WI

MAY-JUNE 2021 PARCELindustry.com 17

By Caleb Nelson

WHAT YOU DON’T KNOW YOUR SHIPPING DATA CAN DO FOR YOU

The growing importance of data, in all forms, has been one of the most definitive business trends of the 21st century. For example, board rooms have learned lessons from Moneyball, Matthew McConaughey called data “the new gold’ in a Super Bowl ad, and the US Bureau of Labor Statistics considers “Data Scientist” to be the third fastest-growing job category in the US.

The value of data hasn’t fallen on deaf ears for parcel shippers. Most know the “gold” that lies in their carrier invoices. Some of these benefits are simple, such as visualizing shipping spend and auditing for reimbursements. Others are more advanced, like analyzing the impacts of rate increases, modeling contract proposals, and running simulations to determine the best location for a new distribution center.

But what are some of the other applications for shipping data? What insights can be unlocked for savings that don’t get talked about as much?

Here are four opportunities for longterm savings hidden in your shipping and sales data that you might not know about.

1. Service Type Optimization

Thanks to the “Amazon Effect,” two-day shipping has become the expectation for online consumers, leading more ship-

pers (e-commerce businesses especially) to rely on express services when clients want their products delivered fast.

Be careful how often you use these services. It turns out that shippers use express services for a lot of packages that could have traveled their short distance in two days with a ground service.

If your invoices show frequent express shipments to zones 2 and 3, you’re guilty of this.

Luckily, your invoice data can help you build out a list of ZIP Codes that fall within those closer zones. Use this information to create rules in your TMS that doesn’t allow for shipments to these ZIP Codes to use an Express service, but instead routes them via ground. Take it a step further by eliminating two-day shipping options for these ZIP Codes in your point-of-sale system.

Opting for ground shipping over an overnight, two-day, or even three-day service can save you up to 50% in shipping costs for those packages. Plus, if sustainability is a focus for your organization, trucks produce far fewer emissions than cargo planes.

2. Strategic Inventory Placement

Many shippers understand the benefits of a diversified, optimized distribution network. Placing products closer to large customer bases results in faster

shipping, lower costs, and lower transportation emissions.

But most fail to take it a step further with product-specific network optimization. Many shippers and brands go for an equal-inventory strategy across their warehouses or 3PLs. This makes sense on the surface, but consider that not all products are going to be purchased equally across the country.

For example, a clothing company might find that they sell more swimwear in the warmer southern states, and more winter coats in the north. Keeping an equal amount of these items at distribution centers in Atlanta and Chicago isn’t the best strategy.

Compare SKU-based sales data with your network locations to determine the best locations for specific products. Optimized inventory placement can lower your average transit times, and similar to what was discussed in the last section, can lower your reliance on express services for time-sensitive shipments. It will also reduce your associated emissions by shortening travel distances.

3. Volume Discount Tier Monitoring

Since pandemic-era capacity constraints and labor tensions, carrier diversification has been one of the hottest parcel trends of the 2020s. While more shippers understand the value

18 PARCELindustry.com MAY-JUNE 2024

of a diverse carrier mix, many are still reluctant, worried they’ll lose discounts with existing partners.

This is a valid concern — although in many cases, savings from a new carrier can outweigh dropping a discount tier. Either way, keeping a close eye on where you stand in your volume tiers is a necessity for successful multi-carrier shipping.

Carriers use a rolling 52-week average to measure volume-based discount tiers. Keeping track of how your 52-week average changes week to week can highlight when you’re at risk of dropping a tier — eliminating any surprise increases in shipping costs. On the other end, you’ll find when you can shift volume to one carrier to go up a tier, earning greater discounts.

If you notice you’re well above the minimum for your top tier, your business has outgrown your contract. This is a clear sign that it’s time to renegotiate.

4. Returns Data to Uncover Manufacturing Defects

E-commerce returns are a massive headache. Consumers returned $247 billion worth of online purchases in 2023. Even worse, about 16.5% of returns are fraudulent.

Considering the extensive costs online retailers incur with returns, it’s shocking that many view them as a necessary evil. Major strides have been made in the past 20 years to optimize outbound logistics, but improving returns processes has been largely untapped.

Analyzing returns data can uncover if particular SKUs are returned at unusually high rates. This should raise the red flag that these items might suffer from a manufacturing defect. This may seem obvious, but few brands actually take advantage of these insights.

Check with your warehouse staff who handles returns inspections (this is data you should be tracking as well). If they’re reporting the same defect for a product at a high rate, then it’s time to have a conversation with the manufacturer to resolve the issue.

This pain could be self-inflicted, though. If a product is frequently returned damaged, but it’s not a consistent defect, then insufficient packaging protection might be to blame.

You won’t be able to find this from invoices alone, but new returns-focused software solutions are emerging.

Data Is the Future

The era of data-driven decision-making is upon us, and there’s no going back to “gut feelings.”

Shippers need to stay on top of trends in data analysis and technologies that help them make the most of it. Those who embrace this approach will stay ahead of the curve and pave the way for a more efficient, resilient, and profitable future for their business.

As the saying goes, “data is the new gold,” and those who mine it wisely will reap the rewards for years to come.

Caleb Nelson is Chief Growth Officer at Sifted, a Logistics Intelligence software company.

Caleb Nelson is Chief Growth Officer at Sifted, a Logistics Intelligence software company.

SUBSCRIBE FOR FREE!

By Ninaad Acharya

SIMPLIFYING THE SHIFT FROM ON-PREMISES TO CLOUD-BASED WAREHOUSE MANAGEMENT

Business success means staying efficient and agile. As supply chain digitalization evolves, warehouse management strategies must adapt at pace or leapfrog into the present day to keep up. With that in mind, no one should think that implementing a cloud-based WMS is a simple tech update. Instead, it’s a business-critical upgrade for any company that wants to survive and thrive.

Whether your organization has kept pace or you’re behind the curve, there’s a lot to consider when transitioning from on-premises to cloud-based WMS.

Why Is Change Necessary?

The traditional (a.k.a., on-premises) WMS has long been the backbone of warehouse operations but has limitations. For example, many companies find that outdated technology prevents easy connectivity and compatibility with other quickly advancing supply chain systems. Change and improvements can also come slowly for on-premises systems, leaving companies far from the leading edge of what a modern WMS can offer in terms of scalability, visibility, and accuracy.

The demands on warehouses are greater than ever in terms of maintaining the ability to accommodate fluctuations

in demand and shorter lead times. At the same time, companies must remain focused on streamlining inventory levels to avoid stock-out situations while minimizing inventory carrying costs and storage expenses. Balancing and managing these oft-conflicting objectives requires modern and connected systems that offer warehouses visibility and access to critical data to empower informed decision-making.

A cloud-based WMS also offers financial benefits. With a cloud-based WMS, businesses eliminate much of the upfront and maintenance costs of a traditional WMS, not to mention eventual investments in upgrades as they grow. Since most cloud-based systems operate on a subscription-based model, many extra system-related expenses decrease, allowing companies to utilize their resources more efficiently.

Transitioning to a cloud-based platform will not be without hurdles, however. Companies often have concerns about the implementation and data migration, as well as the security of sensitive data existing on external servers and networks. To safeguard against potential threats in a new digital environment, any plan needs to prioritize robust security measures, such as encryption protocols,

stringent access controls, and regular security audits.

Before Making the Move

Careful planning and consideration are important for a successful transition, implementation, and execution. For obvious reasons, choosing the right cloud-based WMS partner is the most important first step for companies deciding to upgrade.

1. Determine WMS Provider’s Reliability

Evaluating a cloud provider’s reliability is an excellent place to start.

Security measures are an important component of a provider’s reliability. Every business should thoroughly assess its track record when protecting customers’ data and look for certifications like SOC 2 or PCI DSS compliance.

2. Evaluate Service Level Agreements (SLAs) and Features

Next, inspect their uptime and system redundancies. Unplanned downtime will disrupt any warehouse operations with the potential to create a lot of extra expenses and lost revenue. Evaluating a potential provider’s Service Level Agreements (SLAs) to understand their uptime guarantees and disaster recovery plans should be part of your initial conversations. It’s also prudent to consider a provider with geographically redundant data centers — this ensures availability even during a regional outage.

3. Ability to Scale with Your Business

Part of your choice in a new cloudbased WMS should be its ability to accommodate your company’s future growth in terms of inventory levels, order volume, or even product line expansions. It is shortsighted not to emphasize finding a scalable solution that can adapt to your evolving business needs without requiring a major system upgrade. The good news is that modern cloud-based systems are constantly innovating and adding new features, so finding a provider firmly committed to ongoing development is possible.

4. Determine the Total Cost

Finally, you need to understand the total cost of ownership. There are almost always costs that go beyond a subscription fee that are different based on the

20 PARCELindustry.com MAY-JUNE 2024

provider. While a cloud-based WMS typically involves fees based on usage and storage, there’s a bigger picture to consider — factor in potential migration costs, data transfer fees, additional user licenses, and ongoing support charges. Remember that the pay-as-you-go model means a business can scale storage and processing power up or down as needed.

Best Practices for a Smooth Transition

Migrating to a cloud-based WMS can present a golden opportunity to streamline operations but will also require careful planning, execution, and ongoing optimization. To ensure a seamless migration, there are several best practices you should adopt.

1. Use a Phased Approach for Implementation

A sound recommendation for more companies is to use a phased-in approach. The implementation should be incremental — meaning data and functionality should be migrated in stages. Critical functions should be prioritized, which will minimize disruption to

warehouse operations and give you time to identify and address any unforeseen challenges and risks. Doing so also allows for more thorough testing and validation of each stage before proceeding.

2. Arrange Adequate User Training for Your Staff

Don’t forget the staff members who will use your new system. Ensure they’re adequately trained since the successful adoption of any new system will rely heavily on the knowledge and proficiency of users. Successful implementations occur when companies invest in comprehensive training sessions across all levels to ensure everyone understands the system, its capabilities, and how it will impact them. And training shouldn’t be one-size-fits-all; it should be tailored to the specific needs of different user groups.

3. Constant Monitoring of KPIs

Once your migration is complete, you will always need to monitor your new system. Track KPIs such as picking accuracy, order processing times, and inventory levels so you can identify areas

for improvement. The need to constantly analyze the data and look for opportunities to find and optimize workflows or configurations doesn’t disappear with a cloud-based WMS, but it definitely gets easier and more effective.

Staying on the Leading Edge

Depending on where you are starting from, the shift from on-premises to a cloud-based WMS may be a small step, a pivot, or a giant leap. Regardless, it represents a strategic move towards operational efficiency, scalability, and digital transformation. It’s also a way to save money and gain competitive advantages. Logistics and supply chain professionals who want to simplify the shift and position their businesses for future growth and success must embrace the move with a strategic, informed, and proactive mindset.

MAY-JUNE 2024 PARCELindustry.com 21

Ninaad Acharya is CEO and Co-founder of Fulfillment IQ.

SUBSCRIBE FOR FREE!

TOP TIPS TO BUILDING YOUR BEST MULTI-CARRIER NETWORK

BY KENNETH MOYER

Carrier capacity constraints, looming labor disruptions, shifting consumer behaviors, and shuttered carrier facilities are just a sampling of the hurdles parcel supply chains have had to navigate in the past several years. While shippers gleaned valuable lessons from navigating these challenges, a reverberating refrain has been, “I can no longer risk putting all my eggs in one basket.”

Thankfully, we find ourselves in a more carrier-rich environment than has historically been the case. The traditional national carriers and a rich assortment of effective tertiary regional carriers and regional consolidators make this an excellent time to explore a multi-carrier strategy.

Benefits of a Multi-Carrier Network

The advantages of a diverse carrier pool are significant and touch multiple aspects of a modern supply chain. Depending upon a shipper’s annual volume, many shipper segments can realize significant cost savings by building out an effective multi-carrier solution. A robust rate shopping solution will allow you to take advantage of areas of savings with each carrier, optimizing what each one does best.

With diversity comes flexibility. Having some “capacity overlap” can aid when one carrier is delayed by weather, scarce equipment, labor disruption, or conflicts with operating hours and pick-up time. Having multiple carrier options can also help should peak season capacity constraints surface again and could even assist in mitigating peak season surcharges by spreading volumes over multiple carrier networks.

The end consumer experience is often improved by providing a variety of carrier options. The delivery time and method flexibility, cost savings, and improved time-in-transit derived from the ability to choose between multiple delivery options can all lead to a more rewarding delivery experience. This shift isn’t without challenges, however.

Technology Tips

The most common roadblock to implementing an effective multi-carrier solution is usually technological constraints. The

limitations of carrier-provided shipping systems, or home-grown legacy systems which were designed with a single carrier in mind, often torpedo multi-carrier solutions before they even launch. I have observed shippers leaving millions of dollars of annual savings on the table due to their inability to generate a label for a second carrier. Thankfully, there are ways to mitigate this roadblock and take full advantage of our current environment.

First, evaluate your current shipping platform to determine if the functionality to support multiple carriers already exists or if it would require a simple upgrade. Many systems have bolt-on solutions that are easy to implement and are relatively inexpensive. If this solution isn’t available, there are a bevy of effective carrier-agnostic third-party shipping systems on the market that effectively manage multiple carriers.

There are even third-party systems that consolidate multiple carrier systems into one. A parcel consolidator platform from Orchestro AI has stitched together a network of regional and national carriers on its technology platform, which eliminates the need for shippers to integrate with multiple carriers. The cloud-based platform is an exceptional fit for shippers who want to explore multiple national or regional carriers without making any adjustments or upgrades to their current technology platform.

Contract Tips

Introducing a second, or even a third or fourth carrier, into your supply chain will certainly impact the contractual relationship you have with the incumbent carrier. The majority of carrier agreements, particularly those with UPS and FedEx, have a “self-regulating” element to them. This performance tier-based structure bases discount levels on shipper spend over a period of time, typically 52 weeks. Due to this “carrot & stick” contract structure, diverting spend to other carriers may trigger cost increases with the incumbent. Some carrier agreements even contain “poison pill” provisions such as minimum commitment language or primary carrier provisions, which may risk invalidating the existing contract if a significant diversion is made.

It is critical to the success of any multi-carrier initiative that contractual constraints be fully understood and their impact quantified. Often, shippers have enough flexibility in their

22 PARCELindustry.com MAY-JUNE 2024

carrier agreements to engage an additional carrier without significant penalty, but not always. If you are unsure, seek some professional assistance in the evaluation. It is possible your existing agreement may need to be re-negotiated to make room for your new strategy.

Facilities & Staff Tips

With multiple carriers comes multiple processes. Each carrier will have different methods for tasks such as returns, claims, adult-signatures, HAZMAT, size restrictions, etc. The process multiplication can create an employee training burden both for the logistics department and the customer service function. The introduction of multiple carrier invoices will mean a larger lift for finance when it comes to auditing, GL coding, and invoice payment. These departments should be engaged from the start to ensure complete organizational buy-in for the new carrier strategy.

Oftentimes, carriers are eager to assist in overcoming these hurdles to win your business. Carrier-led training sessions and detailed process documentation are typically available and encouraged. We have found most carriers to be receptive to requests for assistance with items such as training, payment terms, and operational accommodation.

The most difficult restriction to overcome when attempting to introduce additional carriers to your supply chain has traditionally been facility constraints. Multiple carriers mean multiple trucks, and some locations suffer from a shortage of adequate bays or floor space for staging packages. These shortcomings can some-

times be overcome with careful planning and collaboration. For example, we have a client who launched an initiative to improve same-day order throughput. To achieve this, they altered their operation to run later in the day to process a higher percentage of orders on the day they are received. Their bottleneck became the incumbent carrier pull-time. Due to the distance of the carrier hub from the shipper’s facility, the carrier could not push out the pull-time to match the new extended operational hours. An added constraint was the limited dock space at the facility, removing the possibility of a drop-trailer from a second carrier. The solution was to introduce a second carrier that had the ability to pull later. The first trailer was pulled, then the second was live-loaded and swept the orders processed between the exit of the first carrier and the close of business. This remedy allowed the shipper to process more orders on the day they were received without requiring any facility upgrades.

With some creativity and openness with the carriers about your goals and your constraints, there is often a mutually beneficial solution that can be unearthed and implemented.

Kenneth Moyer has leveraged his 30 years of industry experience to effectively serve as a Partner & V.P. of Supply Chain Strategies for LJM Group. In his role, Kenneth combines his carrier pricing and consulting experience to aid shippers in implementing robust Supply Chain solutions and negotiating best in class parcel agreements. He can be reached at kmoyer@myljm.com.

SUBSCRIBE FOR FREE!

STREAMLINING E-COMMERCE SHIPPING AND FULFILLMENT:

STRATEGIES FOR SMALL BUSINESS OWNERS

BY ERIC S. YOUNGSTROM

In e-commerce, where every dollar counts and efficiency is king, lies a battleground of logistics. The art of moving goods from warehouse to doorstep is the story of survival, told in the margins of profit and loss. The strategy to navigate this terrain is simple: reduce costs, increase sales. The execution, however, is complex. Below are some tips to streamline your shipping and fulfillment.

To Outsource or Not

Many e-commerce businesses attempt to fulfill on their own, resulting in warehouse teeming with goods. Yet, not all businesses need to be self-fulfilled. Third-party logistics (3PL) providers allow you to offload operationally complex activities so you can focus on growth. 3PL services offer economies of scale, reducing per-unit shipping costs via extensive networks of facilities that can position inventory closer to your customers. Outsourcing doesn’t mean you can take your eye off performance metrics. You should negotiate service levels and hold your 3PL accountable for meeting and exceeding those requirements. This will ensure your customers are delighted with the delivery process.

Action Steps:

1. Research and select a 3PL that aligns with your business needs and size.

2. Consider 3PLs with multiple

fulfillment centers to reduce last-mile delivery costs.

3. Monitor performance and adjust based on customer feedback and cost-effectiveness.

The Route Less Traveled

Efficiency in shipping is crucial. Optimize your routes for speed and economy. And deliver above the expectations of your customers, not simply being first, but most cost-effective. Advanced logistics software can help identify the most efficient shipping routes, considering factors such as distance, carrier performance, and cost. By optimizing routes, businesses can minimize transportation expenses and improve delivery times, enhancing customer satisfaction and loyalty.

Action Steps:

1. Implement route optimization software.

2. Regularly analyze shipping data to identify potential improvements.

3. Adjust routes based on real-time traffic and weather conditions.

The Last Mile

The “last mile” of delivery is usually the most expensive part of the shipping process. By utilizing multiple, strategically located warehouses, businesses can decrease the distance to the final delivery destination, which will reduce delivery costs. This strategy not only cuts expenses

but also speeds up delivery times, offering a significant competitive advantage. Proximity reduces cost, and speed delights the customer. Both are victories.

Action Steps:

1. Use data to identify geographic concentrations of customers.

2. Choose a 3PL with fulfillment centers located near your customers.

3. Consider a local courier service for urban deliveries to reduce costs and improve delivery times.

The Gift of Packaging

Carriers often offer free packaging. It’s a gift that benefits you and the carrier. Their boxes are lightweight and durable, designed to survive the journey and move as efficiently as possible through their networks. This can be a simple yet effective way to reduce material costs. And since it’s got their logo on it, it’s easy for their employees to sort and move along to the final destination.

Action Steps:

1. Request packaging supplies from your carriers.

2. Design your product packaging to fit within these free materials when possible.

3. Train your team on how to efficiently pack using these materials to reduce dimensional weight.

The Shipping Investment

Invest in shipping software that allows you to compare shipping rates across carriers in real time. Such software often comes with built-in discounts negotiated by the software providers with various carriers, which can lead to substantial cost savings. Additionally, these tools can automate the shipping process, reducing manual labor costs and errors.

Action Steps:

1. Choose shipping software that integrates with your e-commerce platform.

2. Set up automation rules for choosing the lowest cost carrier based on package size, weight, and destination.

3. Utilize batch processing for high-volume shipping days.

The Negotiated Passage

Never accept the first price. Carriers expect negotiations. Your shipping

24 PARCELindustry.com MAY-JUNE 2024

volume is leverage to reduce your costs. Even small e-commerce businesses can negotiate better rates with carriers, especially if they can demonstrate consistent shipping volumes or commit to certain volume thresholds. It’s important to regularly review your shipping needs and discuss them with your carriers, as rates can fluctuate based on market conditions and your shipping profile.

Action Steps:

1. Gather your shipping volume data to leverage in negotiations.

2. Contact carrier representatives to discuss your business and potential discounts.

3. Regularly review your shipping volume to confirm discounts are being applied and renegotiate as your business grows.

What Gets Measured

The shipping and fulfillment landscape is dynamic, with rates and services constantly changing. Regular analysis of your shipping data can reveal trends and areas for improvement. Adjust

your strategies based on performance metrics, seasonal fluctuations, and changes in carrier rates and services.

Action Steps:

1. Schedule monthly reviews of your shipping costs, carrier performance, and customer feedback.

2. Experiment with different strategies to see what works best for your business and customers.

3. Stay informed on industry trends and new technologies that can improve efficiency and reduce costs.

Educate Your Customers

Offer choices. Speed for cost, or economy for patience. Transparent communication about shipping costs and delivery times can help manage customer expectations and satisfaction. Consider offering multiple shipping options, including slower but more affordable choices, and clearly explain the costs and benefits of each. This approach can enhance the customer experience and encourage repeat business. Transparency builds trust, and trust builds loyalty.

Action Steps:

1. Include a shipping cost calculator on your e-commerce site.

2. Offer multiple shipping options at checkout.

3. Educate customers on the impact of their shipping choices on costs and delivery times.

For small e-commerce business owners, the path to increased sales and profitability often involves optimizing shipping and fulfillment processes. Continuous analysis, adjustment, and effective communication with both carriers and customers are essential to maximizing the benefits of the strategies mentioned above.

Eric S. Youngstrom is Founder and CEO of Austin-based Onramp Funds, an innovative funding provider that supports the growth of e-commerce businesses. Eric leads a team steeped in e-commerce, providing financing and other resources to empower online merchants to scale their businesses and achieve their dreams.

MAY-JUNE 2024 PARCELindustry.com 25

SUBSCRIBE FOR FREE!

By Jeff Haushalter

OPTIMIZING YOUR PACKAGING: REDUCING SHIPPING COSTS AND PRODUCT DAMAGE

Packaging plays a pivotal role in safeguarding products, promoting sustainability, minimizing shipping expenses, and maximizing customer satisfaction. And now, a powerful new tool called packaging optimization significantly reduces shipping costs and product damage.

Any optimization begins with a thorough understanding of supply chain, sales, and operations. As a first step, gather a baseline profile of the items and quantities you sell, the rates (transportation, warehousing, and packaging) you have negotiated, the packaging (material, size, and grade) utilized, damage reports, and any “secret sauce” used to attract and retain customers.

Next, talk with stakeholders about defining the project goals and identifying any relevant constraints. There are two types of constraints that influence the end solution. Hard constraints must be satisfied. Soft constraints are preferences that would be nice to have.

Packaging optimization takes a holistic approach. It goes beyond cutting costs — it’s about creating value for your business and your customers. It finds the sweet spot where companies protect without overdoing it on packaging materials or costs. It is good for the environment, it is good for bottom lines, and it ensures online orders arrive safely and securely.

Optimization balances tradeoffs to arrive at a solution that is better than all other solutions. Simpler solutions can

be developed in spreadsheets. For more complicated situations, companies may rent analytical engines or use artificial intelligence (AI) techniques to quickly model all permutations.

Packaging solutions cannot be developed in a vacuum. They rely on the skill and sophistication of warehouse operators. There is no use designing for optimality if the warehouse is unable to pick the right box and fill it correctly. Here are some common outcomes that organizations realize once they have optimized their packaging.

Right-sized Packaging

The size and weight of packages directly influence shipping costs. Right-sizing packaging involves selecting the smallest possible packaging that still provides adequate product protection as opposed to merely using standard-sized boxes or envelopes.

Invest in flexible packaging solutions such as variable dimension boxes, mailers with variable depths, or custom-sized on-demand cartons to eliminate excess space. Total shipping costs decrease from minimizing dimensional weight, the tare weight from dunnage, and reduced damage from products shifting during transit.

Utilize Lightweight Alternate Materials

In addition to size, the weight of packaging materials directly impacts shipping costs. Lightweight materials reduce the tare weight of packages and

are often more sustainable.

The choice of packaging materials significantly impacts both product protection and shipping costs. Opt-in for materials that strike a balance between durability and weight to ensure adequate protection during transit. Also consider packaging that serves multiple purposes, such as protective cushioning that also acts as branding material.

Alternative materials can replace heavier materials. Some weight minimizing examples are upgraded singlewall vs. doublewall corrugated, different fluting, different liner combinations, different ECT strengths, and wall thickness changes.

Additionally, consider padded envelopes or pouches for smaller non-breakable items, as these can provide sufficient protection while minimizing weight. Reducing the weight of your packaging not only cuts shipping costs but also demonstrates your commitment to environmental stewardship.

Enhance Product Protection

Product damage during transit not only incurs replacement costs but also damages your brand’s reputation and diminishes customer satisfaction. Enhancing product protection through optimized packaging is essential for reducing these risks.

Investigate packaging solutions such as cushioning materials, shock-absorbent inserts, or custom foam packaging tailored to the specific fragility and shape of your products. Conduct thorough

26 PARCELindustry.com MAY-JUNE 2024

testing to simulate real-world shipping conditions and ensure that the packaging effectively protects items from impacts, vibrations, and compression forces.

One quick win to minimize damage is to isolate out incompatible items. This could be a light damage-prone item with a heavy item, liquids, hazardous materials, etc. There are two options: ship these items by themselves or use custom-designed packaging inserts or dividers to securely hold products in place and prevent shifting.

Streamline Packaging Processes

Inefficient packaging processes not only waste time and resources but also contribute to higher shipping costs.

Evaluate your packaging workflow from order fulfillment to shipping and identify opportunities for optimization. Now is the time to automate repetitive tasks and reduce manual labor.

Invest in packaging automation solutions such as carton erectors, carton sealers, on-demand packaging, and automated labeling systems. Automation accelerates packaging efficiency,

ensures consistency and accuracy, and reduces reducing the likelihood of damage and errors.

Additionally, consider the shape of the package and eliminate irregular shapes that may be more difficult to transport efficiently. Collaborate with your manufacturing partners to produce more conforming product that decreases costly accessorials.

By correctly packaging products upfront at the manufacturer, you can reduce warehouse handling, decrease additional packaging, and lower the risk of damage enroute to customers.

Promote Sustainability

Linking sustainability with a reduction in packaging is not only logical but imperative in today’s environmentally conscious world. Sustainable practices minimize the environmental impact of packaging materials throughout their lifecycle, from production to disposal.

Less packaging means fewer natural resources used in production. This translates to reduced energy consumption, decreased water usage, and minimized

extraction of raw materials, all of which contribute to a lower carbon footprint.

Streamlining packaging and minimalistic packaging designs reduce waste generation and waste sent to landfills. This promotes a circular economy where materials are reused, recycled, or composted.

Sustainable packaging often involves the use of eco-friendly materials such as recycled paper, molded pulp, biodegradable plastics, or compostable alternatives. These materials break down more easily in the environment, reducing their ecological impact and mitigating harm to wildlife.

Moreover, sustainable packaging practices resonate with consumers. By aligning with sustainable values, businesses can enhance their brand reputation, attract eco-conscious customers, and foster long-term loyalty.

where he focuses on decreasing costs and improving service via warehouse operations, parcel spend management, and optimal packaging practices, among others.

MAY-JUNE 2024 PARCELindustry.com 27

Jeff Haushalter is Partner at Chicago Consulting

SUBSCRIBE FOR FREE!

BY DAVE SALTER

BEYOND THE BUZZ: CULTIVATING LASTING CUSTOMER SATISFACTION IN PARCEL SHIPPING

The e-commerce revolution has fundamentally reshaped consumer expectations. Today’s online shoppers crave convenience, transparency, and lightning-fast delivery. In this competitive landscape, efficient parcel shipping has become a cornerstone of success for any online business. But simply getting orders out the door isn’t enough. The key to thriving lies in cultivating lasting customer satisfaction, not just during peak seasons, but throughout the entire year.

However, achieving this level of customer satisfaction can be challenging, especially when managing the complexities of parcel shipping. Let’s look closer at that customer journey to see where we can improve the customer experience (CX).

Understanding the Customer Journey

The customer journey doesn’t end at checkout. A seamless parcel shipping experience plays a crucial role in shaping a customer’s overall impression of your brand. Some key touchpoints that can make or break a positive CX include: Pre-Purchase: During the product browsing stage, clear and accurate shipping cost information is vital, as well as expec-

tations for potential shipping discounts. Customers appreciate transparency — unexpected shipping charges at checkout can lead to cart abandonment.

Order Placement: A user-friendly checkout process with multiple shipping options empowers customers to choose the delivery speed and cost that best suit their needs.

Order Confirmation: A timely confirmation email with order details and estimated delivery timeframe sets clear expectations and fosters trust.

Order Fulfillment: Accurate order picking, packing, and timely shipment creation times are crucial. Delays or errors can significantly disrupt the CX.

Delivery: Prompt and reliable delivery within the promised timeframe or estimated delivery date (EDD) is essential. Realtime tracking updates empower customers to stay informed about their shipment’s progress.

Returns: A streamlined returns process minimizes hassle and encourages repeat business. Consider offering pre-paid return labels.

The Pitfalls of Neglecting Customer Satisfaction

Neglecting the customer experience in parcel shipping can have significant consequences. Here are some common pitfalls to avoid:

Hidden Shipping Costs: Unexpectedly high shipping charges at checkout create a perception of dishonesty and can lead to cart abandonment. Transparency in pricing throughout the checkout process is critical.

Order Fulfillment Errors: Incorrectly shipped items or missing products can be a major headache for customers, requiring them to jump through hoops to get the issue resolved.

Communication Black Holes: Customers appreciate clear and consistent tracking updates about their shipments. Being left in the dark about the status of their order, with no information on potential delays or unexpected changes, can lead to anxiety and frustration.

Delayed Deliveries: Late deliveries disrupt plans and erode customer trust. Imagine a customer waiting for a birthday gift to arrive on time, and it doesn’t — a delay can turn a joyful occasion into a disappointment.

Cumbersome Returns: A complex and time-consuming returns process discourages customers from making future purchases. Imagine having to print multiple forms, wait in long lines, and pay excessive return shipping fees — it’s enough to deter even the most loyal of customers.

Investing in Continuous Improvement

Building lasting customer satisfaction is a continuous journey. Here’s how businesses can leverage data and feedback to refine their parcel shipping strategies:

Data-Driven Decision-Making: Parcel shipping software generates valuable data on metrics like delivery times, error rates, and customer inquiries. Analyzing this data allows businesses to identify areas for improvement and make datadriven decisions to optimize their shipping processes. This

28 PARCELindustry.com MAY-JUNE 2024

includes strategically selecting the right carrier mix based on factors like cost, speed, reliability, and service area. Advanced multi-carrier shipping software (MCSS) can provide insights and recommendations to help businesses optimize carrier selection in a volatile market.

The Power of Customer Feedback: Actively solicit customer feedback through surveys, reviews, and social media interactions. Understanding customer pain points and concerns empowers businesses to address these issues and continuously improve the overall shipping experience.

Embrace Innovation: The parcel landscape is constantly evolving. Staying informed about the latest advancements in areas like automation, machine learning, AI, and data analytics allows businesses to leverage cutting-edge solutions for a more efficient and customer-centric shipping experience. Additionally, adopting an agile approach allows businesses to adapt their carrier mix and shipping strategies quickly in response to market volatility. By using MCSS with features like dynamic carrier selection, businesses can easily turn carriers on or off depending on real-time performance and cost factors.

The Road to Success: A Customer-Centric Approach

By prioritizing a customer-centric approach throughout the entire parcel shipping journey, businesses can cultivate lasting customer satisfaction and build brand loyalty. Here are some additional strategies to consider:

Personalization: Personalize the shipping experience whenever possible. For example, offering express shipping options at checkout caters to customers who prioritize speed.

Loyalty Programs: Rewarding repeat customers with loyalty programs that offer benefits like free shipping or priority processing incentivizes them to return for future purchases.

Transparency Is Key: Be upfront about shipping costs and estimated delivery timeframes throughout the checkout process. Avoid any hidden fees or unexpected charges that can negatively affect customer trust.

Proactive Communication: Keep customers informed about their orders. Send timely updates on shipment status, potential delays, and any other relevant information.

In the competitive world of e-commerce, customer satisfaction is the key differentiator. By prioritizing a customer-centric approach, leveraging advanced multi-carrier shipping software, and continuously seeking improvement, businesses can cultivate a lasting positive CX, build customer loyalty, and solidify their path to success.

Dave Salter is in Business Development at ProShip, where he works with prospects, partners, and consultants to determine the right fit for clients’ multi-carrier shipping solution needs. Dave’s approach is to try to find the client the right solution, even if it means sending them somewhere else. Dave is involved in the supply chain and logistics community as he serves on the board of the Wisconsin Chapter of ASCM (Association of Supply Chain Management).

MAY-JUNE 2024 PARCELindustry.com 29

SUBSCRIBE FOR FREE!

CLOSING THOUGHTS

THE LEVELING OF PACKAGE VOLUMES

By Merry Law

Editor's Note: This column originally appeared in the May/June issue of our sister publication, Mailing Systems Technology, but we thought our PARCEL readers would find it informative, as well.

Beginning in the first quarter of 2020, the world quickly went from a few ill with a new coronavirus to shutting down international passenger flights, office closures, and stay-home orders. As we all know, this was followed by major supply chain problems.

For many, the home delivery of everything from clothes to groceries to medicines to toys to office supplies became the main way to get what they needed — or wanted. This was

accompanied by closures of retail stores and restaurants, some of which never reopened. This created a phenomenal increase in packages delivered to individuals and families, small businesses, and those working at home. And it happened almost worldwide.

In most countries, this increase was a boon for the country’s postal service, as well as other delivery companies. (Some postal services suffered under shutdown or essential business regulations during the pandemic.) While much of this increased volume was domestic, a substantial increase in international package volumes also occurred. Analysts predicted a continuing increase as consumers found the convenience of home delivery preferable to retail shopping. International volumes were also predicted to grow as consumers enjoyed access to goods from other countries with lower prices or with limited local availability.

Shortly before the beginning of the pandemic, the EU countries and others began imposing import duties and taxes on small imports sent directly to consumers. That has expanded to additional countries and to, at least theoretically, more through controls on imports. The increase in duties and other taxes has raided the cost of goods from other countries to consumers. While international consumer orders increased during the pandemic, international delivery became more difficult, including increased paperwork and tax payments.

Following the pandemic, some early signs emerged that the increased volume of small packages to consumers might not continue, particularly