2 minute read

Growing plants in controlled environments

from PNGAF MAG ISSUE # 9B - 5B4D3 Dr John Davidson Accompaniment "RAINBOW EUCALYPT MAN" Part 3 of 8 parts

by rbmccarthy

At each field location, five trees were sampled. (Note: These were different sets of five trees to the “five nearest neighbour trees” that were compared next to each candidate earlier for determining their growth advantage.) Candidate trees were selected at a rate of about 1 in 400, random trees at a rate of about 1 in 500 across the seven compartments assessed across most of the Fryar LA.

Samples were periodically airfreighted to the ANU in Canberra for wood density determination.

Advertisement

Growing plants in controlled environments

From the beginning of 1970 in Canberra, attention was directed to growing young plants of E. deglupta under controlled environment conditions.18 The Commonwealth Research Grant provided funds and access to the CSIRO CERES phytotron19 located off Clunies Ross Street in Acton and within easy walking distance from the Department of Forestry ANU.

Professor Pryor in December 1968, after his return from the Philippines, grew seedlings from seed collected near Goroka and Ossima, PNG and from New Bataan, Mindanao, Philippines in the Department of Botany ANU glasshouse. Both the Goroka and Ossima examples had shorter and broader leaves with less pronounced drip tips compared to the Mindanao specimen, which had longer and narrower leaves with very pronounced drip tips. This trend in the seedlings mirrored what was observed in the adult foliage in the field. I used the phytotron facilities to expand on this result.

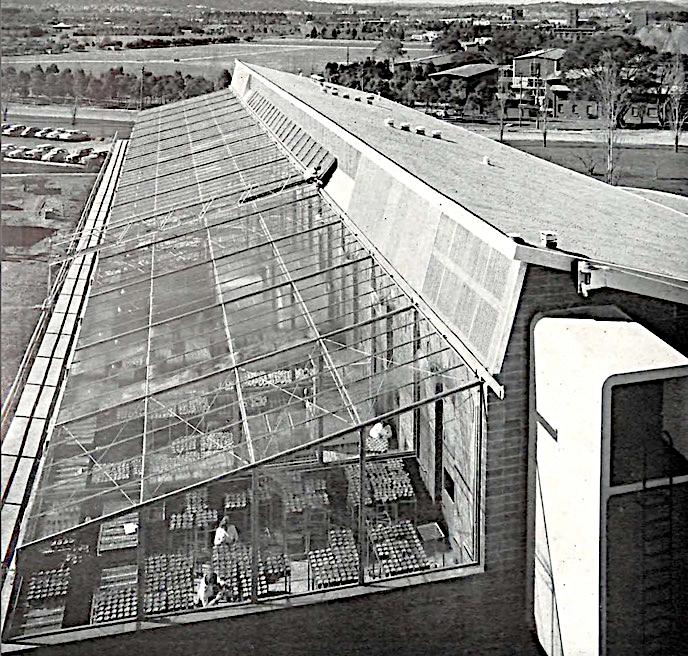

The CSIRO CERES phytotron was built in 1962, the third major facility of its type in the world. Seen here in 1970 it was associated with the former Division of Plant Industry of CSIRO. CERES is a two-storey building, 65 m long and 24 m wide, which still exists today. It had 15 naturally lit north-facing glasshouses each 14 m2 in area. In each glasshouse day and night temperature could be closely controlled. In addition there were portable cabinets in which plants could be grown under even more closely controlled conditions. Some of these cabinets (“C”-type cabinets) could be used inside the glasshouses as required. The building contained offices, preparation rooms, an engineering room, a workshop, dark rooms, and a "frost" room. There were strict quarantine procedures for the entry of personnel, equipment and biological materials.

18 See Chapter 8, pages 156 – 174 In Davidson J 1972 loc. cit. 19 CERES = Controlled Environment RESearch. See Morse R N and Evans L T 1962 Design and development of CERES – an Australian Phytotron. Journal of Agricultural Engineering Research, 7:128 –140. DrL T Evans and the phytotron staff were thanked for the provision of the controlled environment facilities across two years during my PhD studies, and for the care of the plants including routine watering and fertilizing in my extended absences from the phytotron while working in the nearby Forestry Department, ANU.