AILWAY G E

SERVING THE RAILWAY INDUSTRY SINCE 1856

SERVING THE RAILWAY INDUSTRY SINCE 1856

Presenting Our 2025 Influential Railroaders

RAILINC LOCOMOTIVE REPORT

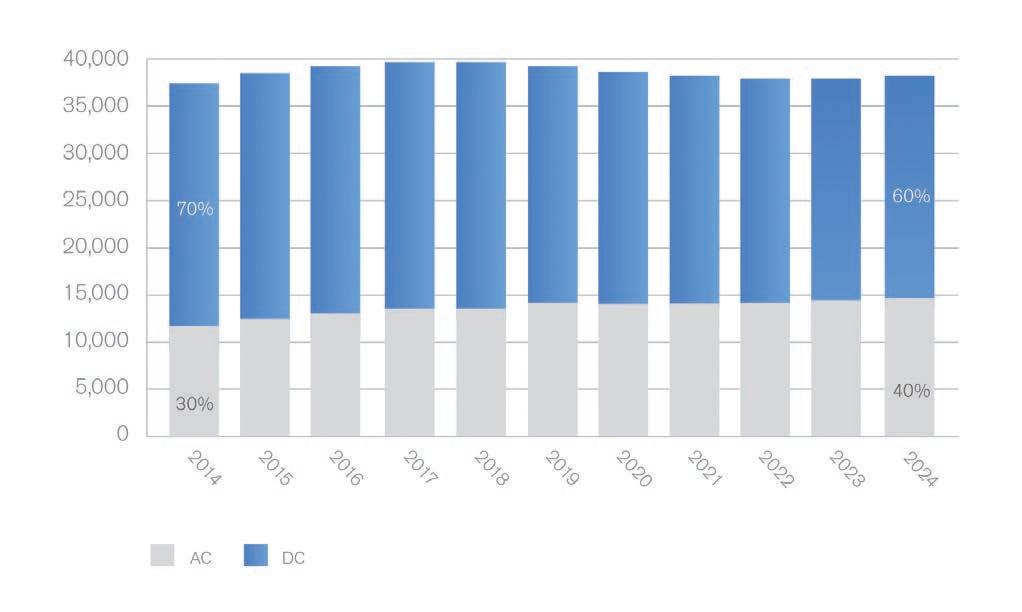

AC/DC Dynamics

passenger rail focus

Northern Indiana Commuter

Transportation District

Our strategy for ensuring your business stays on course includes our fleet of six manufacturing plants, five service centers, and 24 local sales offices.This diverse manufacturing capability allows us to offer flexibility while meeting your needs through our direct sales team and application engineering experts. Since 1878, Okonite has been a benchmark in the industry—all of our products are proudly made in the U.S.A.

Frank N. Wilner, in his “Watching Washington” column in this issue (p. 10) talks about “bridges of understanding” that could “be built between discordant rail labor and rail management, if only they would cease lecturing each other and engage ... As railroads function much as military units with mutual dependence on each other’s skills, it is astonishing that they prosper, given so many senior officers are aloof from workplace conditions, mid-level managers aggressively gumshoe workers for rules violations, and union websites aggressively disparage railroads and rail officials.”

There are encouraging examples of beneficial bridges being built. Norfolk Southern and CSX come to mind. But the idea of management and labor forging a more peaceful, friendly and productive relationship is nothing new, as Frank points out in this entertaining anecdote:

“I first floated this idea during the 1980s at the Association of American Railroads, but it went nowhere, as ‘Quality Circles’ was in vogue, and the college professor approach by Burlington Northern barely survived a few months.

“Gus Welty (Railway Age’s late Senior Editor) found it interesting, but thought labor would never go for it. Gus and I had dinner with a labor professor one night in Chicago and discussed it. I can’t remember the restaurant, as I usually do. I know it was not Jimmy Wong’s, which I loved and that Gus detested. It was not Miller’s Pub, where Gus maintained his ‘afternoon office’ at the end of the bar adjacent to the pub’s telephone. The professor was Ben Fisher. Ben

and I got into such a very loud and very heated discussion (we were and remained good friends) that the manager asked us to tone it down or finish our meal and leave.”

Frank told me that, prior to writing his column, he “asked a few young and upcoming rail labor ‘lower level’ officers about this idea. They see its value, but doubt carriers will go for it. So, we shall see if there is an echo.”

The late Pope Francis, a humble, unassuming Jesuit, in 2017 appealed for “bridges of understanding” and “not walls” during the current President’s first term. Just before we went to press, Frank came upon this quote from the president of Benedictine University in Illinois that echoed the Pope’s 2017 message to the “deaf and uncaring” POTUS 45—who as POTUS 47 is far more extreme and chaotic than during his first term. He shared it with me. It’s worth passing on:

“Pope Francis was a beacon of hope, a voice for the marginalized, and a tireless advocate for peace, justice, and care of God’s creation. His papacy ... [dared] us to embrace mercy, to walk with the poor, and to build bridges of understanding in a divided world. No previous Pope defended so forcefully the rights of migrants and refugees. Pope Francis’s ... words and actions continue to inspire countless individuals to serve others with generosity and joy. The title he gave his autobiography says much about the man: Hope.”

In these trying times when very little makes sense and where compassion, understanding, and “generosity and joy” are in short supply, hope is all we have.

WILLIAM C. VANTUONO Editor-in-Chief

Railway Age, descended from the American Rail-Road Journal (1832) and the Western Railroad Gazette (1856) and published under its present name since 1876, is indexed by the Business Periodicals Index and the Engineering Index Service.

Name registered in U.S. Patent Office and Trade Mark Office in Canada. Now indexed in ABI/Inform.

Change of address should reach us six weeks in advance of next issue date. Send both old and new addresses with address label to Subscription Department, Railway Age, PO Box 239, Lincolnshire IL 60069-0239 USA, or call (US, Canada and International) 847-559-7372, Fax +1 (847) 291-4816, e-mail railwayage@omeda.com. Post Office will not forward copies unless you provide extra postage.

POSTMASTER: Send changes of address to: Railway Age, PO Box 239, Lincolnshire, IL 60069-0239, USA.

Photocopy rights: Where necessary, permission is granted by the copyright owner for the libraries and others registered with the Copyright Clearance Center (CCC) to photocopy articles herein for the flat fee of $2.00 per copy of each article. Payment should be sent directly to CCC. Copying for other than personal or internal reference use without the

keeping or return of such material.

Member of:

SUBSCRIPTIONS: 847-559-7372

EDITORIAL AND EXECUTIVE OFFICES

Simmons-Boardman Publishing Corp. 1809 Capitol Avenue Omaha, NE 68102 (212) 620-7200 www.railwayage.com

ARTHUR J. McGINNIS, Jr. President and Chairman

JONATHAN CHALON Publisher jchalon@sbpub.com

WILLIAM C. VANTUONO Editor-in-Chief wvantuono@sbpub.com

MARYBETH LUCZAK Executive Editor mluczak@sbpub.com

CAROLINA WORRELL Senior Editor cworrell@sbpub.com

DAVID C. LESTER

Engineering Editor/Railway Track & Structures Editor-in-Chief dlester@sbpub.com

JENNIFER McLAWHORN

Managing Editor, RT&S jmclawhorn@sbpub.com

HEATHER ERVIN Ports and Intermodal Editor/Marine Log Editor-in-Chief hervin@sbpub.com

Contributing Editors

David Peter Alan, Jim Blaze, Nick Blenkey, Sonia Bot, Bob Cantwell, Alfred E. Fazio, Justin Franz, Gary Fry, Michael Iden, Don Itzkoff, Bruce Kelly, Joanna Marsh, David Nahass, Jason Seidl, Ron Sucik, David Thomas, Frank N. Wilner

Art Director: Nicole D’Antona Graphic Designer: Hillary Coleman

Corporate Production Director: Mary Conyers

Production Director: Eduardo Castaner

Marketing Director: Erica Hayes

Conference Director: Michelle Zolkos

Circulation Director: Joann Binz

INTERNATIONAL OFFICES

46 Killigrew Street, Falmouth, Cornwall TR11 3PP, United Kingdom 011-44-1326-313945

International Editors Kevin Smith

ks@railjournal.com

David Briginshaw db@railjournal.com

Robert Preston rp@railjournal.com

Mark Simmons msimmons@railjournal.com

CUSTOMER SERVICE: RAILWAYAGE@OMEDA.COM , OR CALL 847-559-7372

Reprints: PARS International Corp.

253 West 35th Street 7th Floor New York, NY 10001 212-221-9595; fax 212-221-9195 curt.ciesinski@parsintl.com

At FreightCar America, quality isn’t just a goal—it’s a promise. With over 125 years of experience, we’ve engineered railcars that have logged millions of miles with unwavering performance and reliability. With craftsmanship, a proprietary welding process and rigorous quality control procedures, we deliver durable, high-performance railcars that exceed industry standards. Our innovation is backed by a legacy of structural integrity, ensuring every car we produce reflects our deep-rooted commitment to excellence in railcar manufacturing. We’re proud to be Purpose-Built for You.

Scan the code to discover our Purpose-Built approach.

“Recent changes in U.S. trade policy represent a notable shift from previous approaches. These developments will affect multiple sectors, including freight rail, where global trade accounts for approximately 38% of unit volume and 37% of total revenue,” the Association of American Railroads reported last month. “Even in stable times, railroads must constantly adjust to evolving economic conditions; they are operationally equipped to adapt to this latest round of policy change as well.

“At present, rail traffic is holding steady. While some ‘soft’ economic indicators, such as consumer confidence, have weakened in recent months, many ‘hard’ economic metrics—including job gains, unemployment and consumer spending—remain resilient. That continued strength has supported modest gains in rail volumes. That said, manufacturing remains mired in a prolonged period of weakness, limiting growth in several carload categories.

“U.S. railroads originated 906,253 total carloads in March 2025, up 4.5% (39,342 carloads) over last March and the third year-over-year increase in total carloads over the past 15 months. Total carloads averaged 226,563 in March 2025, the most in six months and the most for March since 2022. For the first three months of 2025, U.S. railroads originated 2.76 million carloads, up 0.1% (1,758 carloads) over the same period in 2024. In our records that begin in 1988, only 2024 had fewer first-quarter total carloads than 2025 did.

“The decline in total carloads over the past 20 years has been due mainly to huge declines in carloads of coal. In March 2025, though, coal had the biggest year-over-year increase among all commodities—up 11.1% (23,963 carloads), its biggest percentage gain since February 2022 and its first year-over-year increase of any size in 15 months. For the first quarter, coal carloads were down 0.3%, or 2,305 carloads, to 739,272. That’s the lowest Q1 total for coal in our records.

“In March 2025, 12 of the 20 carload categories the AAR tracks had year-over-year carload gains. For the first quarter of 2025, ten of the 20 saw gains. Detailed March commodity data are shown in the chart (opposite, top).

“U.S. railroads also originated 1.10 million containers and trailers in March 2025, up 8.0% (82,151 units) from March 2024 and intermodal’s 19th consecutive year-overyear gain. In Q1 2025, U.S. railroads originated 3.54 million containers and trailers, up 8.3% over Q1 2024 and the second most for the first three months of a year on record (Q1 2021 was slightly higher).

“Rail volumes remain closely correlated with industrial production. Continued weakness in factory output poses a structural challenge for rail growth. As shown in the chart (facing page, top), total U.S. manufacturing output

declined slightly in both 2023 and 2024, pressuring rail volumes.

“That pattern is consistent with the Manufacturing PMI® from the Institute for Supply Management®, which registered at 49.0% in March. While readings above 50% indicate expansion, the index has hovered near or below that threshold for more than two years. The new orders component of the index fell to 45.2% in March, the lowest it has been in seven months. New auto sales were a seasonally adjusted and annualized 17.8 million in March 2025, the most for a month in nearly four years. Railroads move approximately 75% of the new cars and light trucks purchased in the U.S. There is also a close correlation between automobile assemblies and rail carloads of motor vehicles, as shown in the chart (facing page, bottom).

“Outside of manufacturing, economic signals remain mixed. Inflation-adjusted total consumer spending rose a preliminary 0.1% in February 2025 over January 2025, while spending on goods rose 0.7% in February. Both measures are significant improvements from January’s spending declines. Intermodal in particular is susceptible to changes in consumer spending, so the return to spending growth, especially for goods, is welcome news for railroads.

“The Conference Board’s consumer confidence index fell to 92.9 in March, its fourth straight decline after reaching 112.8 in November. It’s the lowest reading for the index since January 2021. If declining confidence does lead to weaker consumer spending, rail volumes will likely to be impacted.”

RECENT CHANGES TO ECONOMIC AND TRADE POLICIES ARE FUELING SIGNIFICANT CHALLENGES WITHIN THE FREIGHT RAIL INDUSTRY. As decision-makers face uncertainty, particularly around rail traffic and equipment demand, many are left to wonder whether they should proceed with caution or move forward as planned.

At Railway Interchange, taking place May 20-22 in Indianapolis, Joseph Towers, senior analyst for rail and intermodal at FTR Transportation Intelligence, will help attendees try to make sense of the current landscape. Ahead of that session, we spoke with him to understand how today’s economic outlook is impacting the freight rail industry and what leaders can keep in mind as they navigate this territory.

How are you seeing tariffs impact freight rail? What are some considerations leaders need to keep in mind? “During the past few months and weeks, we’ve seen a pull forward of rail freight for certain commodities in anticipation of tariffs, with intermodal and autos being the most notable. Those strong volumes, however, are expected to come at the expense of traffic later in the year, due in large part to the broad tariffs on nonUSMCA auto imports, and the 145% tariffs recently levied against Chinese imports. Our outlook for the other commodities is not

much better. With broad tariffs on steel and aluminum imports, much of which comes from Canada and Mexico, along with the tariffs on non-USMCA covered goods, and the possibility of reciprocal tariffs on some of our closest trade partners, we’re expecting rail traffic this year to be flat at best. On the equipment side, the uncertainty surrounding tariffs is arguably the most significant effect, even more so than the inflationary pressures. With tariff policy constantly changing, and the lead times required between the order and delivery of a car, few want to buy a piece of rail equipment that could cost substantially more than anticipated by the time it arrives.”

What changes in railcar demand are you anticipating this year, and how is that different from your expectations coming into 2025? “As we entered 2025, we were already anticipating softer railcar demand due to flat freight demand and diminishing industry backlogs. Since then, our expectations have become even less optimistic. Based on recent build and economic data, along with conversations with stakeholders across the industry, we now expect demand for new railcars to be even softer, with this weakness likely to affect a broad range of car types. Much of this softness appears to stem from the uncertainty surrounding tariff policies and the possibility of railcar owners and

lessees facing higher-than-anticipated costs for their equipment. Concerns about the strength of the industrial economy also seem to be contributing to this uncertainty. The effects of this hesitancy could manifest in various ways. We may see increased shop demand as operators look to extend the useful life of existing railcars, as well as higher lease rates, as demand for lessor-owned cars rises to fill the gap that would typically be filled by new cars. Lastly, if freight and economic conditions remain flat, we may see an uptick in scrappage levels as car owners look to offload idled rail equipment.”

What is your advice for leaders trying to navigate this uncertainty? “Whatever you think is going to happen, is not going to happen. This is usually the case, but it’s especially true now. My advice to leaders is to be as nimble as possible and create a strategy framework based on multiple scenarios, rather than a single base case. It’s also important that these scenarios are not static but are constantly updated as new information becomes available. I would also suggest trying to avoid unnecessarily postponing decisions until a time when there is less uncertainty in the market. Economic conditions will remain volatile for the foreseeable future, and in many cases the ability to course correct will serve you better than waiting for calmer seas.”

– Railway Supply Institute

Talos™ leverages machine learning and arti cial intelligence to create customized strategies for each train’s speci c makeup, managing and optimizing every mile of the journey.

By adapting to train behavior and customer operational objectives, Talos offers higher overall fuel savings up to 25% and equally impressive emissions reductions.

Talos also improves safety by rigorously managing train handling, helping prevent break-in-twos with the best in-train force management in the industry.

Saving fuel, reducing emissions, and improving operational safety — it’s how we keep you rolling.

FreightCar America (FCA) on April 24 reported receiving orders totaling 1,250 freight railcars, valued at approximately $141 million, during first-quarter 2025. FCA did not specify the railcar types ordered. Its Castaños, Mexico, plant produces covered hoppers, open-top hoppers, gondolas, flat cars, intermodal cars and boxcars. FCA said that it “continues to gain share within its core railcar markets, driven by strategic initiatives aimed at increasing operational efficiency, product innovation, and commercial excellence.” The firstquarter orders, it noted, represent approximately 25% of all new railcars ordered in North America during the quarter ended March 31, 2025, and 36% in its addressable market, “marking the largest new railcar market share quarter intake in 15 years.” “We are pleased to see sustained customer interest across our product portfolio, particularly in gondolas, open-top hoppers, and covered hopper cars, which remain an integral part of our diverse portfolio of railcar types,” FCA President and CEO Nick Randall (pictured) said. “Our manufacturing agility and ability to capture these opportunities highlights our competitive strengths.” Randall reported that the Chicago-based company has been “monitoring recent tariff developments and based on our current understanding, railcars sold by FCA in North America are not subject to tariffs due to their compliance with the USMCA (United States-Mexico-Canada Agreement).” FCA, he said, will monitor any developments. “With our supply chain strategy, operational excellence initiatives at our manufacturing facility and continued commercial momentum, we remain confident in our forward trajectory,” he concluded. According to FCA, “certain orders” referenced in its announcement are “subject to customary documentation and completion of terms.”

Overall freight railcar orders in first-quarter 2025 increased by 13%, but deliveries fell 22% from fourth-quarter 2024, according to the latest RAILWAY SUPPLY INSTITUTE (RSI) AMERICAN RAILWAY CAR INSTITUTE COMMITTEE (ARCI) report. Backlog dipped 8% sequentially. For the three-months ending March 31, 2025, orders came in at 5,085 railcars, up 13% from fourth-quarter 2024’s 4,520 and down 15% from first-quarter 2024’s 5,864. Deliveries were 7,810 units, down 22% from fourthquarter 2024’s 9,999 and down 30% from first-quarter 2024. Backlog for this year’s first quarter was 31,548, decreasing 8% sequentially and 47% year-over-year.

“We continued to experience solid demand for our assets globally,” GATX President and CEO said Robert C. Lyons said during a report on first-quarter 2025 financials, which included Rail North America fleet utilization of 99.2% and a renewal success rate of 85.1%.

“The renewal lease rate change of GATX’s Lease Price Index (LPI) was 24.5% with an average renewal term of 61 months. We continued to optimize our fleet by selectively selling railcars in the secondary market, generating more than $30 million of remarketing

income in the quarter.” In 1Q25, GATX reported net income of $78.6 million, or $2.15 per diluted share, compared to $74.3 million, or $2.03 per diluted share, in the prior-year period. The 2024 year-to-date results include a net positive impact of $0.6 million, or $0.02 per diluted share, “from Tax Adjustments and Other Items,” GATX noted. “Investment volume during the quarter was approximately $300 million, reflective of the fact that we continued to find attractive opportunities to put capital to work in each of our business segments. Additionally, demand in the secondary market for GATX assets remains robust, as evidenced by the railcar sales activity in the first quarter, and we remain optimistic about continued interest from potential buyers. GATX’s Rail North America segment reported a profit of $88.8 million in 1Q25, compared to $90.3 million in 1Q24. Higher 1Q25 lease revenue was offset by “higher interest and maintenance expenses.” Rail North America’s wholly owned fleet totaled 111,300 cars, including 7,990 boxcars. The following fleet statistics and performance discussion exclude the boxcar fleet. Fleet utilization was 99.2% at the end of 1Q25, compared to 99.1% at the end of the prior quarter and 99.4% at the end of 1Q24.

WABTEC “started the year strong, delivering over 20% in earnings per share growth and highlighting the continued business momentum across both the Freight and Transit segments,” President and CEO Rafael Santana reported April 23 during a firstquarter 2025 financial report. He noted the company is “approaching the remainder of the year with caution, but with the discipline and focus to take the necessary actions to deliver against our commitments in an uncertain and volatile economic landscape.” Firstquarter 2025 sales came in at $2.61 billion, up 4.5% from the same quarter in 2024, which Wabtec attributed to higher sales in both the Freight and Transit segments. Among the key drivers, Services “increased sales from higher modernization deliveries and overhauls.” Equipment saw “lower locomotive deliveries as planned.” Components saw “portfolio optimization and lower North American railcar build,” which Wabtec noted was “partially offset by growth in industrial products.” Digital Intelligence saw “higher sales from international, signaling and next-generation on-board locomotive products, partially offset by lower sales in North America.” Transit saw “higher OE sales and aftermarket sales, up 7.9% on a constant-currency basis.”

The E thical Culture Fieldston School and University Heights High School, both in the Bronx, N.Y., are but minutes apart by public transit, yet otherwise at opposite extremes.

Annual tuition at the private Fieldston School, in the affluent Riverdale section of the Bronx, tops $65,000, while at public University Heights High School, in the largely impoverished South Bronx, 85% of students are considered economically disadvantaged.

Could bridges of understanding be built between these disparate groups—one of privilege and the other not? An exercise in “radical empathy” proved they can, as was explained in a May 4, 2014, New York Times Magazine article.

Bridges of understanding might similarly be built between discordant rail labor and rail management if only they would cease lecturing each other and engage, as did the Fieldston and University Heights students who found they had much in common.

As railroads function much as military units with mutual dependence on each other’s skills, it is astonishing railroads prosper, given so many senior officers are aloof from workplace conditions, mid-level managers aggressively gumshoe workers for rules violations, and union websites aggressively disparage railroads and rail officials.

Building bridges of understanding between labor and management is equally relevant to shippers seeking world-class service, and to courts, regulatory agencies and Congress—the latter often sucked into labor-management strife as third-party arbitrators when workplace frustrations boil over into job actions.

In the Bronx experiment, the two schools’ students paired off to share stories of themselves, their

environment and aspirations. They later gathered as a group, each responsible for telling the other’s story.

Imagine that exercise at rail facilities. Union members would pairoff with managers to explain to the other how their job relates to the railroad’s mission; challenges faced; and what each expects of the other. Excluded would be talk of wages, benefits and work rules subject to collective bargaining.

At an immediately subsequent video-recorded group session, each participant would retell their opposite’s story with the video made available on carrier and union websites.

A duplicate exercise involving CEOs and union presidents could be conducted at union regional meetings and similarly video-recorded for on-line viewing.

Such an exercise differs significantly from once-in-vogue “quality circles” led by management and focused on improving product and productivity; and from a failed 1980s railroad experiment where a college professor lectured employees on corporate income statements, making comparisons with family finances and considered by many employees a “talking-down” to them.

Building bridges of understanding begins with respectful dialogue so that each participant is comfortable retelling the other’s story. Topics of discussion might include:

• O pposing points of view on the implementation of Precision Scheduled Railroading.

• S etting first-and-last-mile service standards.

• C hallenges to balancing leisure and work.

• T he meaning of job satisfaction; quality of training and opportunities for skills improvement.

• O n-the-job personal safety and security.

• L ocomotive cab sanitary conditions.

• Terminal-to-lodging taxi service.

• H ow technology is changing the nature of work.

• H ow top-down directives differ from collaborative leadership in encouraging motivation and teamwork.

Required of participants is a commitment to listen objectively (empathy), retell the other’s story accurately and a willingness to move beyond entrenched positions. Traditional fuzzy corporatespeak of “workplace engagement” and “safety is our highest priority” when things go wrong are as antithetical to building bridges of understanding as are union criticisms of profits and providers of capital.

It will take courage for labor and management to accept that neither is the enemy of the other and join in building bridges of understanding, recognizing the real enemy are forces adversely affecting railroad market share. To borrow from “The Road Not Taken” by Robert Frost, “I took the one less traveled by, and that has made all the difference.”

Railway Age Capitol Hill Contributing Editor Frank N. Wilner held managerial posts at two Class I railroads, was assistant vice president for policy at the Association of American Railroads, director of public relations for the United Transportation Union and its SMART-TD successor, and a White House appointed chief of staff at the Surface Transportation Board. He is author of “Railroads & Economic Regulation,” available from SimmonsBoardman Books, 800-228-9670.

FRANK N. WILNER

Who doesn’t need a break from government these days? If the tariff instigated stock market rollercoaster isn’t nightmarish enough, the $200 million ad campaign of the Department of Homeland Security should make anyone wonder why “Chainsaw” Musk hasn’t reclaimed some of that cash for the taxpayer. (I’m not even going to touch the Easter weekend purse and security badge snatching from DHS Secretary Noem at a D.C. restaurant.)

Unfortunately, this column is all about the government—but due to tariff induced nausea, railcar and locomotive tariffs can wait until next month. Instead let’s talk about high-speed rail. Railway Age’s David Peter Alan has been doing the yeoman’s work of covering the government’s flim-flam judgements on grants issued and revoked for high-speed rail investment in the U.S.

There are four major high-speed rail projects discussed or operating in the U.S. right now: Brightline Florida (operating), Brightline West between Los Angeles and Las Vegas (about to break ground), Texas Central Railway (TCR), Houston to Dallas—not yet broken ground, and California High Speed Rail (CHSR), Los Angeles to San Francisco—ground broken. How are they doing?

• Brightline Florida is a feel-good story as long as profitability is not the happy ending. FL lost $493 million, and that was after a 211% increase in YOY revenue (cost $6 billion, with further buildouts to come).

• Brightline West is expecting to begin heavy construction and recently completed a $2.5 billion bond offering (unrated) for yields around 10% (estimated cost $6 billion).

• TCR has lost some federal funding and is now working with a private equity investor (estimated cost $40 billion).

• CHSR’s federal funds are under evaluation for proper use, and project costs are off the chart with Dave Alan noting that costs could go as high as $100 billion. Government funding and/or intervention under POTUS 45, 46 and 47 has been an odd

mixed bag. The DOT has applied a slightly mini version of Musk’s chainsaw on the TCR and on CHSR while praising Brightline West. This follows the pace and enthusiasm for high-speed rail and passenger rail in general. While Amtrak ex-CEO Stephen Gardener (who pre-emptively resigned on March 19) deserves his “props” for building ridership, Amtrak still recorded a $635 million operating loss in 2024. A self-aware Amtrak publicly and bluntly acknowledges that profitability is not its objective.

Each of these projects shows one part of the problem with high-speed rail in general. Brightline Florida continues to require federal funding due to its large operating losses (didn’t see any news clawing back those funds anywhere). TCR is a great idea: Almost anyone who has arduously driven between Houston and Dallas would gladly confirm that Houston and Dallas are sprawling, massive cities lacking commuter infrastructure. It eliminates one part of the car problem, but it does not eliminate the car problem. Even if Californians want CHSR to get built, Los Angeles has the same sprawl problem (not so much in San Francisco). Brightline West may seem to make more sense. After all, who needs a car in Vegas? But how can the economics of a $6 billion high-speed train at $100 a ticket make sense for something that feels like a one-way ticket? Are that many Los Angelenos really holding back attending shows at the Sphere over traffic delays?

One reason the Northeast Corridor remains profitable above the rail (operationally profitable, capex and SOGR are huge costs) is that New York City, Boston, Philadelphia and D.C. are easier to get around when the train drops passengers in a center city train station.

Outside of the Northeast, the U.S. has a car culture, and as one friend has put it, getting momentum behind the use of high-speed rail would require a significant cultural shift in the West Coast mindset.

Passenger rail remains a divisive political football that is more about opposition than about rhyme or reason. Rail funding/ support is either a “your tax dollars” or “my tax dollars” issue.

High-speed rail is the perfect

IS a game of hot potato played with billions of taxpayer dollars. Using redirection and obfuscation, it shields the participants from accountability for money spent.”

political football. One side claims the other has misappropriated funds. Another side claims that the project approved by a previous Administration is not taxpayer worthy. Someone else claims the project not approved by the previous Administra tion is taxpayer worthy. It’s a game of hot potato played with billions of taxpayer dollars. Using redirection and obfuscation, it shields the participants from accountabil ity for money spent.

What is the net result? Special interests run clandestine ops to undercut or support projects for their own benefit. No local poli tician wants to be accused of not support ing local infrastructure, so they spend more money and kick the can down the road. It is headache-inducing.

Maybe discussing tariffs isn’t so bad after all?

Got questions? Set them free at dnahass@ railfin.com.

DAVID NAHASS President Railroad

Railway Age’s 2025 subscriber-selected honorees are making a difference through their commitment to service, safety and sustainability.

Railway Age’s sixth annual Readers’ Most Influential Leaders online poll garnered nominations for many active (non-retired) people from all areas of the North American railway industry. We are pleased to present the top 10 nominees, plus three Honorable Mentions.

Brian Comstock

Executive Vice President, President The Americas

The Greenbrier Companies

Brian Comstock, a 45-year rail industry

Brian Comstock Executive Vice President, President The Americas

veteran, is committed to expanding Greenbrier’s capabilities, entering new markets, and taking calculated risks— with customer needs first. He has played a key role in transforming the company from a niche railcar manufacturer operating a single production facility to an international freight equipment and services supplier that has expanded into Mexico, Brazil, Poland and Romania. Comstock joined in 1998 taking on every aspect of operations—from welding and sandblasting to painting and lining and mobile repair. From there, he moved into sales positions and to leadership of all production, leasing/fleet management, and commercial sales across North and South America. In the late 2010s, when there was a steep decline in sand car demand, with thousands of recently built cars set to be sent to storage, Comstock worked with customers to repurpose existing fleets to carry other commodities. Also to his credit, Comstock championed the development of the coil steel gondola before there was a clear market for it. When demand arose, the company was ready and collaborated with customers and steel suppliers to develop it with lighter, high-strength

steel. Additionally, Comstock is executive sponsor of Greenbrier’s insourcing initiatives in Mexico, which are slated for completion this year.

Phillip Eng

General Manager and CEO

Massachusetts Bay Transportation Authority (MBTA)

A civil engineer with nearly 40 years of transportation experience, Phillip Eng came out of retirement in 2023 to join MBTA. Previously, he served the New York State DOT, starting as a junior engineer and culminating as Executive

Phillip

Eng General Manager and CEO

cpkcr.com

Congratulations to CPKC’s Tina Sheaves, Vice President Operations East, on being honoured as one of Railway Age’s Women in Rail.

Congratulations to CPKC’s Nicholas C. Walker, Senior Vice President Operations Eastern Region, on being selected as one of Railway Age’s 2025 Readers’ Most Influential Leaders.

Gehringer Executive Vice President–Operations, Union Pacific

Deputy Commissioner, and later the New York MTA, where he became head of Long Island Rail Road. At MBTA, Eng is spearheading infrastructure and service delivery improvement and commuter rail expansion initiatives. To address decades of deferred maintenance, he launched an overhaul of subway track infrastructure, including reconstruction of 15,400-plus feet of full-depth track, replacement of some 38,000 ties, and installation of nearly 251,500 feet of new rail. Work wrapped up in just 14 months, removing more than 220 speed restrictions. Roundtrip travel time has been reduced by more than 20 minutes on the Orange Line, nearly an hour on the Red Line, four minutes on the Blue Line, and almost nine minutes on the Green Line. Other work under way: North Station Draw 1 Movable Bridge Replacement over the Charles River to increase rail connectivity, and station upgrades. MBTA and Eng on March 24 celebrated the launch of South Coast Rail, a 36-mile commuter rail extension providing public transportation to southeastern Massachusetts for the first time in 65 years.

Eric Gehringer

Executive Vice President–Operations Union Pacific (UP)

Eric Gehringer has served as UP’s Executive Vice President–Operations since 2021. In this role, he is responsible for all aspects of UP’s operations, including the Transportation, Engineering, Mechanical, Dispatching, Customer

Care and Support, and Premium Operations departments. Gehringer joined UP in 2006 as a management trainee. He previously served in numerous positions, including Senior Vice President-Transportation, Operating’s Chief Mechanical Officer, as well as Chief Engineer. Prior to joining UP, he held positions at Northwest Airlines and Daimler Chrysler. A graduate of St. Louis University with a degree in aerospace engineering, Gehringer received an MBA from the University of Nebraska–Lincoln. He serves on the Board of Directors for Children’s Nebraska Foundation and is a member of the United States Strategic Command Council.

Craig Morehouse

Vice President, North Region Operations, BNSF Railway (BNSF)

Craig Morehouse was appointed BNSF Vice President, North Region Operations in 2020. In this role, he is responsible for operations across BNSF’s Northwest, Montana, Twin Cities, Powder River and Heartland divisions. Morehouse joined BNSF in 2006 as a management trainee and subsequently served for 11 years in a variety of leadership roles with increasing responsibility in engineering. His last engineering role was General Director of Line Maintenance in the Class I’s California Division before transitioning to General Director of Transportation for the Twin Cities Division. Prior to his current role, Morehouse served

Morehouse Vice President, North Region Operations, BNSF Railway

Executive Vice President and Chief Operating Officer

as General Manager of BNSF’s Northwest Division. Morehouse received a bachelor’s degree in civil engineering from Michigan Technological University and an MBA from the Carlson School of Management from the University of Minnesota.

John Orr

Executive Vice President and Chief Operating Officer, Norfolk Southern A proud fourth-generation railroader, John Orr began his career as a craft railroader and union leader, bringing decades of hands-on experience to his leadership. He has held a range of operational and management roles throughout his career and is known across the industry as a proven transformation leader with a strong track record of implementing scheduled railroading to achieve safety and service excellence. Since being appointed Executive Vice President and Chief Operating Officer in 2024, Orr—a 2023 Influentials honoree when Executive Vice President and Chief Transformation Officer at Canadian Pacific Kansas City (CPKC)—has led Norfolk Southern’s (NS) railway operations—including safety, transportation, network planning, engineering, and mechanical—with a clear focus on performance, accountability, and culture. Orr’s positive impact can be seen in key performance metrics. These include the lowest FRA Personal Injury ratio at NS in a decade; a 24% year-over-year reduction for 2024 in FRA Reportable

csx.com

Since joining CSX in 2005, Sean Pelkey has been a strategic force behind the company’s financial strength, helping the company exceed shareholder expectations while championing innovation and sustainable growth. As Executive Vice President and Chief Financial Officer, he demonstrates inspiring leadership that goes beyond financial expertise, cultivating a collaborative, high-performing finance team and guiding the next generation of leaders through dedicated mentorship. Sean’s vision and dedication continue to position CSX as an industry leader, and this well-deserved recognition celebrates his outstanding impact on freight transportation and the future of transportation.

Train Accidents; a 44% year-over-year reduction for 2024 in FRA Main Line Train Accident Rates; a 10% improvement in car-miles per day; improved dwell and velocity across the network, with record fuel efficiency in 2024; and 5% volume growth in 2024 despite a challenged freight environment.

Orr’s “PSR 2.0” approach has driven rapid and sustainable improvements in service reliability and operating efficiency, again successfully delivering significant transformation at a Class I railroad. Orr is also committed to building long-term leadership capability across the organization. He championed the launch of the Thoroughbred Academy, which is helping embed a culture of safety, service, and operational excellence across all levels of the company. By investing in people and process, he is developing the next generation of railroaders benefitting NS’s employees, customers and railserved communities.

Sean Pelkey

Executive Vice President and Chief Financial Officer, CSX

Since joining CSX in 2005, Sean Pelkey has been a key force behind the Class I railroad’s financial strength and longterm strategic positioning. He has held

We are thrilled to celebrate Ryan Ratledge

Ryan Ratledge President and CEO

Railroad Company

roles of increasing responsibility across capital markets, performance analysis, IT finance and investor relations. In his current position, Pelkey leads all financial operations, including accounting, tax, financial planning and analysis, investor relations, procurement, and treasury. Under Pelkey’s leadership, the

finance team has become known not only for technical excellence, but for its collaborative, high-impact role in driving CSX forward. Additionally, CSX has consistently earned returns that exceed shareholder expectations since he was named CFO in 2022. Beyond financial results, Pelkey is a champion for talent development and cultural cohesion. He also strongly advocates mentoring and serves as a mentor, emphasizing continuous improvement, professional development and crossfunctional collaboration. Pelkey serves on the Board for TTX, Conrail and Pan Am Southern.

Ryan Ratledge President and CEO

Pinsly Railroad Company

Ryan Ratledge, President and CEO of Pinsly Railroad Company, joined the company in 2022 following its acquisition by Macquarie Infrastructure Partners, bringing with him more than 30

years of experience in the rail industry. Under Ratledge’s leadership, Pinsly has grown from two to eight short line railroads through three successful acquisitions. Throughout his career, Ratledge has led high-performing teams through complex challenges, consistently improving safety, earnings

and customer satisfaction. One of his most notable accomplishments was leading the turnaround of the bankrupt Montreal, Maine & Atlantic Railway. From 2014 to 2020, Ratledge and his team transformed the line into the Central Maine & Quebec Railway (CMQR). Following the sale of CMQR to Canadian Pacific (CP, now CPKC) in 2020, Ratledge founded LERN, LLC, where he advised clients across the freight rail sector, including operators, investors and insurers. In 2021, he also served on the Board of Directors for the Iowa Interstate Railroad.

President, ENSCO, Inc.

In 2022, Jeff Stevens was named President of ENSCO, Inc., and its five wholly owned subsidiaries. He leads a 750-person, $190 million enterprise supporting mission-critical programs across the space, defense and transportation sectors. This includes ENSCO

Rail and KLD Labs, globally recognized leaders in automated track and rolling stock inspection technologies. Stevens began his career at ENSCO in 1999, joining the Railway Division to support important modernization efforts in automated track measurement. Prior to his current role, he held several leadership positions within the company, most recently as Senior Vice President of the Surface Transportation Group. In that role, he expanded ENSCO’s presence in international and federal markets, including operation of the Federal Railroad Administration’s (FRA) Transportation Technology Center (TTC) in Pueblo, Colo.

Nicholas C. Walker

Senior Vice President Operations Eastern Region, Canadian Pacific Kansas City (CPKC)

A third-generation railroader with more 20 years’ experience, Nicholas C. Walker started as a conductor and

has risen through the ranks covering regions across Canada and the United States. In 2016, he became CP’s Superintendent Operations in Bensenville, Ill. Immediately recognizing a need for change, he unified the Mechanical, Engineering, and Train & Engine teams, aligning their goals and adjusting the

Matt Walsh

Executive Vice President, Corporate Development Genesee & Wyoming

terminal clock. After just one year, the company recognized the group as Terminal of the Year and named Walker as Railroader of the Year for his contributions to Bensenville’s turnaround. Walker has since led other teams to earn Terminal of the Year awards and continues to deliver year-over-year

improvements in safety metrics, terminal, train and industrial performance, and locomotive productivity. In addition to Walker’s current role overseeing approximately 2,000 employees across CPKC’s Eastern operating region, he is actively involved in the Class I’s Leadership Legacy Committee, mentoring the next generation of railroaders. Walker was named a 2022 Railway Age “25 Under 40” Honoree when he was Vice President Operations-West for CP, which merged with Kansas City Southern in 2023 to form CPKC.

Matt Walsh

Executive Vice President, Corporate Development Genesee & Wyoming (G&W)

Since joining G&W’s two-person corporate development team in 2001, Matt Walsh has played a leading role spearheading the company’s investment and acquisition efforts that have resulted in G&W becoming the largest

Since 1936, the Model 10 Signal has set the standard for railroad crossing warning devices.

The Model 10 can be configured to your specifications with a 3590 series gate mechanism, plus a gate arm up to forty feet long. Then, either LED or incandescent light units, along with either a mechanical or an electronic warning bell, and the proper signage complete the signal assembly.

Please contact Western-Cullen-Hayes, for Model 10 details.

WESTERN-CULLEN-HAYES, INC.

2700W. 36th Place • Chicago, IL 60632

(773)254-9600 • Fax (773) 254-1110

Web Site: www.wch.com

E-mail:wch@wch.com

owner of short line and regional railroads in the U.S. and Canada, with more than 110 operations that cover more than 13,000 miles in 43 states and five Canadian provinces, extending reach into communities with a heavy industrial presence or strong potential for industrial growth. Walsh’s current role continues to be the oversight of capital deployment for internal and external business development, including major projects, acquisitions, divestitures, leases and contracts. He also oversees G&W’s government affairs team and joint facilities function. An advocate for the short line railroad industry, Walsh has served on and off the Executive Committee of the Board of the American Short Line and Regional Railroad Association (ASLRRA) since 2011 and has been its Chair since 2023. Between 2021 and 2023, he served as the Chair of the Short Line Safety Institute (SLSI).

Congratulations to GM & CEO

Phil Eng and all the workers moving the MBTA

Bob Babcock

President and CEO, Livonia, Avon & Lakeville Railroad

As President and CEO of the Livonia, Avon & Lakeville Railroad, Bob Babcock is responsible for the overall operational and financial performance of the LA&L and three other privately owned railroads (B&H Rail, Ontario Midland and Western New York & Pennsylvania). A 35-year railroad industry veteran, he joined the LA&L in 2022 after spending 15 years on the Indiana Rail Road Company where he was Senior Vice President of Operations and Business Development, responsible for all facets of field operations, encompassing train service, mechanical, and engineering.

Kyle Hawthorn

Senior Vice President, Field Operations, RailPros

Kyle Hawthorn has more than 20 years of experience in the rail industry. As RailPros’ Senior Vice President, Field Operations, he leads the company’s nationwide Roadway Worker-In-Charge (RWIC) business, which provides services to freight and commuter agencies across the U.S. He also oversees RailPros’ Right of Way Services, which encompass real estate and construction observation. He possesses an in-depth understanding of railroad construction and job-site protocol and is an expert in railroad safety and operations.

Congratulations!

Congratulations to Kyle Hawthorn, SVP Field Operations, for his honorable mention on the Most Influential Industry Leaders list! Through his strong leadership, Kyle is driving progress within RailPros and the industry. Join our Team at: Go.RailPros.com/Career

Gina Trombley

Executive Vice President of Sales and Marketing and Chief Commercial Officer–Americas, Wabtec Corporation

Gina Trombley oversees commercial sales, marketing, and corporate strategy functions for the U.S., Canada, Mexico and Latin America. Prior to Wabtec, Trombley was Vice President of Americas Ecosystem Sales for Bombardier Transportation and a 2018 Railway Age Women in Rail honoree. She holds a bachelor’s degree in environmental studies from the U.S. Military Academy at West Point, and she served for six years in the U.S. Army as an intelligence officer.

Union Pacific congratulates Eric Gehringer, executive vice president – Operations, for being named one of Railway Age’s 2025 Most Influential Leaders.

SERVING THE RAILWAY INDUSTRY SINCE 1856

As the industry’s partner for generations, Railway Age recognizes the importance of the customer interface. We’re pleased to present our 2025 Innovations Showcase, spotlighting products and services from innovative, dedicated providers.

Acting as a never-distracted assistant, HORUS is an AI powered multi-sensor perception and warning system designed by 4AI Systems to aid the situational awareness of train operators. It can be used for the real-time detection of immediate or long-distance objects on or about the rail corridor. Identification of potential hazards is core to safer operations. A railroad engineer’s ability to reliably see the track ahead is often hampered by environmental factors including night-time, sun glare, low-light areas or during inclement weather conditions. The HORUS SensorBar mounted to the front (or back) of a locomotive can detect track objects such as signs, signal aspects, adjacent tracks, switch position and points. The classification of objects is done onboard using a ruggedized rail-rated computer loaded with the HORUS processing

software, which can be integrated with existing Train Control Systems. An in-cab Advanced Driver Advisory System monitors the train’s speed, braking curve and upcoming signals, and provides real-time updates and alerts to the railroad engineer. Earlier warning for potential hazards can result in earlier intervention, in an environment where every second counts. HORUS can also be integrated into yard operations to aid in safe and efficient movements. Benefits include real-time object and infrastructure detection; accurate location reporting; real-time onboard processing; all-weather and light detection; sensors that can be configured to address specific operating requirements; integration with existing train control systems as an overlay solution; and data connectivity for in specific use cases. www.4aisys.com.

Built for high-mileage, heavy axle load operations where weight and durability are critical, Amsted Rail’s TrakMaster is the most advanced three-piece freight bogie system available in North America. The system successfully meets the latest AAR M-976 specification criteria, including updated track profiles, and is available for both standard and broad track gauges. Key benefits are reduced maintenance costs; improved wheel life; prolonged component life; better curving performance; and improved brake system alignment. Advanced design features include innovative suspension components with improved steering with the Adapter Plus® bearing adapter system, optimized dual rate suspension and advanced friction materials; a unique pocket and wedge design with proprietary material that improves overall

vertical and lateral performance, lowers maintenance costs and extends overall uptime and utilization; and an integrated IBEX® truck mounted brake system that

improves brake shoe-to-wheel tread surface alignment for an average 25% better wheel wear life and fewer premature wheelset removals. www.amstedrail.com.

At Dayton-Phoenix Group, we’ve spent decades building reliable solutions for railroads. But in recent years, the conversation has changed. Railroads started asking tough questions about fuel costs, emissions, and how to modernize without tearing apart everything that already works. That’s what led us to create VOLT. VOLT is the answer to the growing need for a flexible, battery-electric locomotive option. It allows existing locomotives to operate in battery-electric, hybrid, or standard diesel-electric mode. We designed it as a modular, portable-swappable power tender that works with your fleet, not against it. We focused on practical gains. VOLT captures regenerative braking energy, delivers up to 150 miles of battery range, and eliminates

emissions in confined areas like yards, ports, and urban corridors. In hybrid mode, it stretches range further while significantly reducing diesel fuel use and engine wear. One of VOLT’s key advantages is speed and simplicity. Depleted VOLT units can be swapped for fully charged ones in under 30 minutes (comparable to diesel fueling) eliminating the need to wait for charging. This makes high uptime possible, even on demanding short and longhaul routes. To lower operating costs, VOLT can be slow-charged using offgrid or renewable generation sources, taking advantage of low-cost electricity and eliminating the need for highvoltage infrastructure. Railroads can deploy VOLT based on their operational needs, starting small or scaling up. It’s

The power and value of the Railcar Inspection Portal (RIP®) now has the ease and affordability of Software-as-aService (SaaS). For nearly a decade, the patented RIP® has been a vital tool for Class I freight and passenger railroads, enhancing safety and efficiency. Capturing high-resolution, 360-degree images of railcars at speeds up to 125 mph, the RIP® provides real-time visual data for system operators and inspectors. AI/ ML models rapidly analyze images to automatically identify anomalies, enabling faster, prioritized inspections. Centraco®, the RIP’s intuitive interface, delivers comprehensive railcar views, offering insights traditionally accessible only through manual examination. By merging advanced remote visualization with AI, the RIP® empowers railroads

to uphold strict safety standards while streamlining operations. Now, this transformative technology is available as a cloud-based SaaS, extending real-time railcar data access to owners, operators, shippers, and manufacturers—without hardware investment. The subscription model allows you to scale from monitoring a single car to an entire fleet, delivering real-time insights that enable proactive decisions and reduce costly repairs. Shippers can monitor cargo condition throughout transit, railcar owners gain fleet-wide health visibility, and manufacturers can improve designs through in-field data. Key features include real-time notifications of defects and anomalies; proactive maintenance strategy enablement; historical condition tracking with

electrification without overcommitment. VOLT is built to meet railroads where they are today, while helping them move toward where they want to be tomorrow. www.dayton-phoenix.com.

visual records; simple, web-based access with a modern, intuitive UI; and affordable SaaS with immediate activation and no hardware setup. By democratizing access to critical railcar information, we’re fostering a collaborative commitment to safety, efficiency, and sustainability. www.duostech.com.

Greenbrier proudly presents the GBX Training Tank Car™, a state-of-the-art rolling classroom designed to elevate tank car education and strengthen safety standards across the rail industry. Equipped with the latest engineering and safety technology, this mobile platform delivers hands-on training at customer sites, Greenbrier facilities and industry events. Key features include display racks with all major valves, gauging devices and fittings; rooftop platform with safety railing for training of all major topfittings arrangements; jacket cut-out view of entire thermal protection system including heating coils and insulation; and a 15-person climate-controlled classroom with stadium seating. Join us in shaping the future of rail safety. Learn more at www.gbrx.com/classroom.

With more than 90 years in the railway industry and more than 50 years of mobile flash-butt welding experience, Holland is dedicated to providing railways with innovative maintenance-of-way products and services. One of these innovative service offerings is Holland’s Automated Manganese Repair (HAMR®). Our teams use robotically controlled welding procedures to build back the damaged areas on frogs and diamond inserts. While replacing these specialty track components is expensive and time-consuming, HAMR gives them new life at a fraction of the cost. Compared to traditional repair methods, this service is two to three times faster and has proven to last significantly longer. The latest development to our track geometry suite is our Argus 2.0 Track Inspector. The Track Inspector can be mounted to any conventional hi-rail vehicle with a standard hitch receiver, converting it to an

inspection vehicle within minutes. Our adjustable hitch insert fits all standard hitches with no modifications. This system delivers realtime track geometry and rail profile measurements and features a non-contact encoder. The non-contact encoder provides improved accuracy and less maintenance to the system itself.

Depending on your railway’s measurement needs, this system can operate in three different software applications: Attended Operation, Heads-Up, or Autonomous. See this system in action in booth 3021 at Railway Interchange or contact us at sales@hollandco.com to book a demo for your railway.

As an authorized reseller of SpaceX’s Starlink solution designed specifically for trains, Icomera’s satellite connectivity solution for trains enhances transport operators’ onboard connectivity strategy by integrating high-throughput, low-latency Internet. The Starlink Electronic Phased Array Tiles for Rail are fully certified for installation on rolling stock, offering

high-throughput, low-latency connectivity for rail transport. Recent results of LEO satellite connectivity have been impressive, delivering the equivalent of innercity 5G capacity to trains in rural environments with throughput consistently in the range of 200+ Mbps when aggregating dual Starlink terminals for rolling stock, and a latency of less than 40 milliseconds on average. To truly make the most of Starlink connectivity and ensure a fully versatile, future-proof connectivity solution, transport operators can use Icomera’s SureWAN™ technology to simultaneously aggregate all available sources of capacity, including cellular and trackside networks. By adding Starlink, which

is largely uncorrelated with cellular networks, operators improve availability even further, while significantly increasing the throughput performance of their existing onboard networks—Demonstrating the effectiveness of combining cellular and satellite networks for trainto-ground connectivity. Icomera has demonstrated that operators can achieve more than 99.99% availability by aggregating cellular links from multiple MNOs. Today, as a trusted reseller of Starlink solutions for rail, Icomera is bringing Internet connectivity closer to millions of passengers accessing onboard Wi-Fi services to stream entertainment content or conduct video calls. www.icomera.com.

Michigan State University’s four-week Railway Management Certificate Program is the only North American program that covers the breadth and depth of the complex railway industry ecosystem from both a conceptual and practical business perspective. The program is aimed at individuals in the rail industry with the potential to become senior managers and leaders in their organizations. Content is applicable to the whole rail industry: freight and passenger railroads, transit authorities, industry & regulatory agencies, suppliers, and shippers. Critical and topical subjects are covered in a classroom setting with interactive discussions. Site visits aid learning and include railroad facilities, customers, suppliers, associations, and agencies. The program was developed by MSU Railway Management Program staff, evaluated and improved by a curriculum committee of railroad industry leaders. Subject matter experts for the program include distinguished railroaders, transportation industry leaders and experienced MSU faculty. Want to learn more? Reach out to us at crre@broad.msu.edu or www.raileducation.com.

A global leader in bulk material flow technology, Martin Engineering has introduced a heavy-duty air cannon mounting system. The Martin® X-Stand is an organization system that safely keeps air cannons away from superheated or potentially hazardous areas while offering easy service access. The result is clearer walkways, improved safety, and greater maintenance efficiency for a lower cost of operation. Though secure when held in place by pipework, air cannons can be precariously placed around preheaters, hoppers, and drop chutes, making them hard to get around or reach by maintenance crews Some of these applications can also be in high-heat environments in loading zones, so we worked with customers to formulate a more practical and long-term

solution. The X-Stand is a rugged steel cube frame that comes in three sizes to fit 35-liter, 70-liter, and 150-liter air cannon tanks. These fit Martin® Hurricane and Typhoon Air Cannons. The largest model measures 36 inches square and weighs 175 pounds. Each cube has a sturdy crossbar frame designed to distribute weight and absorb vibration from the cannon’s firing. The central top hole allows easy access to the valve and attachments, while the bottom hole accommodates a standard 4-inch, 150-pound, 8-bolt ANSI flange to hold the cannon securely in place. The open sides allow easy access to the flange, hose connection, and tank removal. Solenoid boxes that enable manual firing and control the firing sequence can be conveniently mounted on the side of the rack. www.martin-eng.com.

Introduced in 2018, Miner’s Friction Cushioning Systems—Miner FCS™—have revolutionized railcar cushioning systems by protecting assets, reducing costs, and improving operations. Almost 10,000 railcars in service are equipped with Miner FCS with a combined 400 million miles traveled. Now that’s a Miner Milestone. Many railcars are inadequately protected by hydraulic cushioning units. Energy is not efficiently managed, and short life cycles lead to costly maintenance, not only for the hydraulic units but also for the assets they were supposed to protect.

Miner FCS units utilize Miner’s proven draft gear technology to achieve greater slack management, increased draft protection, and better control over run-in and run-out events. This results in significant reductions in train consist restrictions,

fewer unplanned service interruptions, and improved operations throughout the network. The Miner FCS is a straightforward application on box, refrigerated box, coil, bulkhead, centerbeam and general service flat cars that provides years of reliable service. Miner FCS improves operations and provides car owners and operators with a far greater return on their investment. Miner never stops looking for solutions to improve car performance and ownership. Stay tuned—another breakthrough

innovation in cushioning solutions will be released soon. With more than 127 years of experience in railcar equipment design and manufacturing, Miner Enterprises is one of the industry’s top suppliers of draft gears, brake beams, outlet gates, constant contact side bearings, and other high-performance components. The company’s products are currently used across North America and by international railroads worldwide. www.minerent.com/Friction_Cushioning_ Systems.php.

Pettibone offers the Speed Swing 445F2, the newest version of the industry’s original do-itall rail crane. Developed with customer input, the 445F2 is designed to accept more than a dozen attachments for laying rails, setting ties and numerous other maintenance-of-way tasks. Powered by a fuel-efficient 163-horsepower Cummins QSB4.5 Tier 4 diesel engine, the Speed Swing 445F2 offers a 49-gallon fuel tank, a 29-percent increase over the previous model’s tank. The added fuel capacity allows for extended working intervals, especially when covering longer stretches of rail maintenance or relocating to a remote jobsite. The 445F2 offers a maximum front load capacity of 10,000 pounds and maximum side load capacity of 8,000 pounds. Providing 180-degree boom rotation, the machine is primarily used to thread out old rail and thread in new rail. An optional magnet package quickly cleans up old

plates, spikes and small pieces of rail. The Speed Swing quickly transitions between jobsites, traveling at 25 mph on hi-rail and 20 mph with all-terrain rubber tires. A standard feature for the 445F2 is X-Command®,

a Pettibone telematics program that offers real-time access to machine data. The platform allows for remote diagnosis, eliminating the need for certain field service calls. www.gopettibone.com.

The patented PowerHouse™ Hybrid from Power Drives, Inc., is the newest model in the company’s Idle Reduction/fuel savings technology line-up. A USEPA Smartway Verified Technology, the system heats the engine oil and circulates heated coolant through the locomotive engine block and cooling system to maintain a fluid temperature above 100 degrees F, allowing operators to eliminate idling in cold weather. Idling locomotives use between 5 and 8 gallons of fuel per hour while the PowerHouse™ uses only 0.38 gallons/hour. The PowerHouse Hybrid model eliminates the need for either shore power or an additional engine as a power source. The PowerHouse Hybrid is powered directly from the locomotive battery bank and can run off the locomotive batteries for up to 7 days without starting the engine. Alternatively, the Hybrid can be plugged into an external 120 VAC power source and will operate while charging the locomotive batteries. More stringent regulatory restrictions on emissions, as well as cost savings resulting from reduced fuel consumption are driving increased demand. Customer savings have surpassed the investment in as few as three months. Typical usage savings is more than 10,000 gallons of fuel in one season. www.powerdrives.com.

The team of railroad professionals at RailPros are deeply committed to the rail industry. RailPros’ Strategic Consulting service assists freight railroads, short lines, passenger agencies, and industrial rail properties across North America to optimize their railroads, plans, and operations. This highly specialized consulting brings our in-depth market analysis, engineering assessments, infrastructure inspection, and risk management to the table. We design, manage construction, and lead projects to safely operate passenger and freight rail carriers without impacting existing rail service. We take pride in our role as active participants in developing the railroad industry’s railway engineering standards and industry practices. This ensures that our expertise is always on the leading edge, directly benefiting our clients. Strategic Consulting can help with Rules, Procedures, & Standards: Conduct general safety audits and provide recommendations for improvement, including

auditing and developing rule books, timetables, operating manuals, and standards for compliance and continuity; Regulatory Compliance: evaluate operations, practices, and programs to drive a safety-conscious culture for your team and clients; Industrial Railroad Training: custom and “off the shelf” training for rail-based operations and industrial plant disciplines, designed for non-railroad

employees working in and around facilities that interact with rail; Complex Projects: independent verification and validation services; Project Development: design, review and analysis; Capital Plan and SOGR Program Development; Grant Writing; Market Research; Financial and Budget Analysis; and KPI Development and Monitoring. www.RailPros.com/services/consulting/

Product innovation plays a crucial role in enhancing both the efficiency and effectiveness of the railroad maintenance industry. A notable advancement in this field is the introduction of the MOW multi-function spike puller combined with the Racine TOWD, a tow-behind OTM reclaimer. This innovative solution redefines traditional maintenance practices by offering a multifunctional approach that significantly improves operational workflows. Integration of these two machines allows one operator to manage equipment that would typically require the coordination of three separate machines. This consolidation not only simplifies operations but also boosts productivity by allowing for quicker response times and streamlined workhead execution. With the m/w spike puller and Racine TOWD,

crews can complete essential maintenance tasks such as spike pulling and anchor spreading and reclaiming scrap materials more effectively, reducing downtime and maximizing work output. Additionally, this innovation leads to decreased maintenance costs. By utilizing fewer machines, operators experience reduced wear and tear, leading to lower repair and service needs. The efficient design of the MOW and TOWD combo minimizes the complexity of machine management, facilitating better maintenance practices and extending the lifespan of the equipment. The combination of the MOW multi-function spike puller and Racine TOWD represents a significant leap in product innovation within the rail maintenance industry and available for lease from RELAM. It exemplifies how advanced engineering solutions

can drive increased productivity, enhance operational efficiency, and lower maintenance costs, ultimately contributing to the sustainability and effectiveness of railroad operations. WWW.Relaminc.com.

The R. J. Corman Signaling Wiring Shop is a premier facility dedicated to delivering topnotch rail signaling solutions. Located on R. J. Corman’s corporate campus in Nicholasville, Ky., the shop spans 110,000 square feet with meticulously planned case and house wiring, signal assembly space, and indoor storage. This extensive setup ensures the ability to handle multiple projects simultaneously, meeting the diverse needs of customers with efficiency and precision. R. J. Corman’s Wiring Shop has streamlined its production process by implementing compartmentalized wiring stations, complete with simulation and test fixtures, as well as a wellstocked warehouse for all critical components. This organization enables them to uphold the highest industry standards and deliver consistent, superior results. The team of experienced professionals adheres to controlled and thoroughly documented processes, ensuring visibility

of scheduled work and fostering continuous improvement. Innovation drives their operations. Over the past five years, the company has expanded its Wire Shop capacity. Capital investments have enabled the company to accommodate higher numbers of bungalows per year and create a gate mechanism signal assembly area, saving customers time and money with pre-assembled gate mechanisms. Its strategic goals of on-time delivery and defect-free quality

demonstrate the company’s dedication to excellence. The company optimizes production planning, inventory control, and scheduling by utilizing inventory and supply chain management software for material requirements planning, ensuring that delivery targets are met. R. J. Corman Signaling is committed to providing reliable, high-quality signaling solutions that improve safety and efficiency in the rail industry. www.rjcorman.com/companies/signaling.

Strato proudly introduces SENTRY, a gamechanging cushion unit engineered to elevate autorack performance and reduce lifecycle costs compared to traditional hydraulic Endof-Car Cushioning (EOCC) systems. SENTRY sets a new standard by delivering significantly lower in-train forces and dynamic travel. This advancement helps prevent common rail issues like knuckle breakage, air hose separations, and high-force derailment risks—particularly critical as trains get longer. When paired with another SENTRY-equipped car, bridge plate spacing remains consistent, eliminating alignment headaches. Boasting Best-in-Class Non-hydraulic Impact Performance, SENTRY features 9.5 inches of travel and absorbs impacts for vehicular autorack cars up to 180K GRL at speeds exceeding 7 mph, offering outstanding protection for valuable lading. A high preload with rapid ramp-up minimizes draft

system movement and pocket wear, extending component life. Designed for easy integration, SENTRY is a direct drop-in replacement for EOC-27 pockets, keeping retrofit costs low. It’s also a smart capital investment, with a lifespan up to three times longer than hydraulic units—translating into significantly reduced maintenance costs and eligibility for 15-year depreciation. SENTRY has successfully passed AAR MSRP RP-810 impact testing (including

reverse impacts) with no jumped chocks, and modeling under AAR RP-906 shows a dramatic improvement in train action. Performance aligns with AAR M-921D standards. Conditional AAR approval is pending final review. Strato’s SENTRY isn’t just a cushion unit —it’s a next-gen railcar upgrade. Experience SENTRY firsthand at Strato’s booth at Railway Interchange 2025, we look forward to seeing you there. www.stratoinc.com.

TekTracking’s XPASS ALERT is a low cost, industrial surveillance product designed to detect and automatically alert when people are trespassing in critical areas, particularly where life safety may be a concern. XPASS ALERT utilizes native camera sensors with built-in Artificial Intelligence focused on accurate person detection. When a person is detected a pre-recorded alert message is announced through an attached loudspeaker. Simultaneously, an SMS text message is broadcast to all authorized users within an organization. The text contains a link to the specific XPASS ALERT initiating the alarm. When any user clicks on the link, a livestream of the trespasser is viewable from their mobile device. If the user wants to audibly engage the trespassing offender, there is another link to directly control the

loudspeaker. This means from your cell phone the user may view and communicate to the person causing the trespasser event. XPASS ALERT is lightweight and portable and quickly can be attached to any pole or a location high on a wall. There is a builtin GPS receiver to allow precise location of detection events. Users of XPASS ALERT may also review recorded

detection events on the included web portal. The portal provides a livestream request to any XPASS ALERT unit, at any time. The portal also stores device images showing the detection event. A user may request a recorded video previously saved on the XPASS ALERT to transfer to the portal for viewing and analysis. www.tektracking.com.

For decades, TrinityRail has been a leader in the rail transportation industry by providing innovative products and services to meet its customers’ needs. TrinityRail has a well-established history as an innovator with solutions like its Rapid Discharge® line of open hoppers that automatically unload coal and aggregates and the Hourglass Autorack®, which features additional interior width for enhanced ergonomics and operational efficiencies to help protect automotive shipper’s vehicles. More recently, with the integration of RSI Logistics, TrinityRail delivers a portfolio of innovative digital products and software, such as Rail Command®, which is designed to make shipping by rail easier and more efficient for the customer as well as gain greater visibility into the location of their railcars. On May 21, TrinityRail will host a hands-on event at the Indiana Rail

Road yard in Indianapolis, in conjunction with Railway Interchange 2025. The event, titled Innovate, Collaborate and Elevate, will allow visitors to experience the latest in railcar technology and highlight multiple innovative products and features from both TrinityRail and its partners. On display will be one of TrinityRail’s 5,211 cubic foot covered hoppers with longitudinal gate

technology, as well as a demo of EcoFab’s automatic hatch cover system, autonomous movement via technology provided by Intramotev, composite applications by C.A.G. and real-time demonstrations of RSI Logistics’ suite of railcar management software solutions. Visit TrinityRail’s booth at the Railway Interchange Expo on May 20 to learn more about the event. www.trinityrail.com.

TrinityRail’s 5,211 cubic foot covered hopper featuring EcoFab’s automatic hatch cover.

Railroads continually look for ways to improve labor efficiency and free up valuable resources for their more mission-critical tasks. LOCOTROL® Remote Control Locomotive (RCL) helps railroads achieve that goal by providing enhanced crew optimization, increased automation, and efficient train operations. LOCOTROL® has been a pioneer of remote control and communication solutions for the rail industry. Wabtec has expanded the capabilities of the LOCOTROL® platform with RCL. This groundbreaking technology enables an operator to remotely control a train on main line track or in a yard via a handheld Operator Control Unit (OCU). The system delivers information to the operator through the dynamic interface and audible

alarms, ensuring the operator always knows the current state of the locomotive. Additionally, RCL communicates system status, events and faults to the railroad via text messages. RCL technology has a wide range of applications. It enables a single operator to conduct local pickups and dropoffs and set out bad order cars. The operator also can bring stranded trains into congested yards if the road crews’ time expires. A yard crew member can hostel main line power around the yard, conduct switching operations and build a train for departure. The solution also enables main line power to be used on the hump in the remote-control operation thus reducing the need for low-horsepower fleet. Road RCL can be utilized in slow-speed loading and unloading operations, reducing

the burden on road crews and leading to efficient operations. Find out more about this technology at www.wabteccorp.com/digital-intelligence/remote-train-operation/ locotrol-remote-control-locomotive-rcl.