AUTUMN 2022 | £4.95 DESIGN TECHNOLOGY SUSTAINABILITY INTERVIEWS NEWS ANALYSIS CASE STUDIES P24 Structural Timber Awards 2022 Rewarding inspirational projects and people from across the world of timber design and build P32 Sporting Timber Digital design, offsite thinking and engineered timber collide at the F51 Urban Sports Park P36 Moisture & Durability BM TRADA on understanding how to effectively protect CLT from moisture during construction CLIFFORD’S TOWER BRINGING CONTEMPORARY TIMBER DESIGN TO AN HISTORIC BUILDING STRUCTURAL TIMBER The latest in structural timber building design and technologies STRUCTURALTIMBERMAGAZINE.CO.UK

THE HOME OF OFFSITE TECHNOLOGY INNOVATION OFFSITE EXPO brings together those who are driving change in the construction sector – the event will play host to the leading UK and international offsite manufacturers and component suppliers showcasing a broad spectrum of panelised and volumetric modular systems, plus pod and prefabricated MEP solutions. ALIGN YOUR PRODUCTS AND SERVICES WITH THIS INCREASINGLY IMPORTANT SECTOR Maximise your business development potential at the UK’s biggest showcase of offsite manufactured construction technology and solutions. BOOK YOUR EXHIBITION SPACE NOW! For more information contact julie.williams@radar-communications.co.uk or call 01743 290042 OFFSITE EXCLUSIVE Exhibiting companies will have the exclusive opportunity to participate in the unique Offsite Connect Buyers and Specifiers Forum - a dynamic environment facilitating meetings with leading architects, contractors, specifiers and purchasing managers seeking the latest offsite innovation. WWW.OFFSITE-EXPO.CO.UK BUYERS AND SPECIFIERS FORUM

FOLLOW US ON TWITTER UNDER: twitter.com/STMagUK

ADVERTISING ENQUIRIES PLEASE CONTACT: DEBBIE PROSSER // T: 01743 290001 E: debbie.prosser@radar-communications.co.uk

BACK ISSUES VISIT: www.structuraltimbermagazine.co.uk

SUBSCRIPTIONS VISIT: www.structuraltimbermagazine.co.uk

FRONT COVER: Clifford’s Tower

PRINTED ON: FSC Mix paper by Buxton Press

PUBLISHER: Radar Communications Ltd, 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS T: 01743 290001 | www.radar-communications.co.uk

©Radar Communications Ltd.

RELATED EVENTS: www.structuraltimber.co.uk/events www.structuraltimberawards.co.uk www.offsite-expo.co.uk

DISCLAIMER: The content of Structural Timber Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

PRODUCTION

ADVERTISING

CIRCULATION

PRODUCTION

ACCOUNTS

Welcome to the latest issue of Structural Timber Magazine. A lot has happened since the last time this magazine hit desks – not least the debacle of the Liz Truss prime ministerial experiment that pitched the UK into autumn turmoil.

Without descending into the intricacies of global economics and geopolitics, I’m confident to say that the outlook is complicated and unpredictable. That unpredictability is where the problems rest for many within the construction industry – a sector that thrives on stability. For the timber sector, raw material price fluctuations, Ukraine conflict complications and loss of consumer confidence has dented any recovery reflected in the market postpandemic lockdowns.

Forecasts for 2023 are difficult to gauge as we seemingly enter a recession. One thing we can all be confident about however, is that timber is at the centre of the ongoing battle to achieve net zero targets and deliver the highest levels of sustainability to any project.

Inside this issue are several examples of what timber is capable of. We feature several winning projects from the recent Structural Timber Awards 2022. Not least York’s Clifford’s Tower, that was hailed the ‘Winner of Winners’ scoring the highest marks across the board – a transformational project that has blended timber technology, sympathetic architecture and the highest of functionality, plus the circular design renders the timber frame fully demountable and reusable.

Debbie Prosser 01743 290001

As CLT and glulam continue to provide architects and specifiers endless design options, Phil O’Leary, Technical Manager at BM TRADA, provides an overview on how moisture dynamics affect the durability of CLT – especially issues surrounding performance during the installation and building phase.

Elsewhere inside, we look at the F51 Urban Sports Park – more specifically, its second and third floors – where two indoor skateparks are an ‘oasis of engineered wood’ with the modular units comprising tens of thousands of unique parts, produced from birch and spruce plywood and is a perfect example of what timber, offsite assembly and the pioneering methods of CAD detailing, CAD/CAM workflows and CNC machining can deliver.

Finally, as 2022 comes to a close, a special thanks to all our contributors, advertisers and supporters for their help on the magazine, it is genuinely appreciated, and I do mean that. Enjoy the upcoming festivities and see you in 2023.

Gary Ramsay | Consultant Editor

E: gary.ramsay@structuraltimbermagazine.co.uk

debbie.prosser@radar-communications.co.uk

Louise Jones 01743 290048 louise.jones@radar-communications.co.uk

Catherine Bodley 01743 290001 design@structuraltimbermagazine.co.uk

Debra Brooks 01743 290016 debra.brooks@structuraltimbermagazine.co.uk

• Members of Structural Timber Association.

• Extensive experience of applying STA guidance and research.

• Determination of category of frame needed.

• Advice on appropriate solutions to reduce the risk of fire spread to surrounding buildings.

• Use of advanced computer modelling techniques to analyse timber frame proposals and provide a cost effective solution.

The multi-disciplinary team comprises both chartered and graduate engineers, with specialist experience in fire protection and fire engineering, and experienced fire safety professionals with backgrounds in local authority fire and rescue services.

For further information visit our website: www.cstodd.co.uk Tel: 01252 792088 Email: office@cstodd.co.uk

WELCOME

TECHNOLOGY

THE BUILDING

COMMUNICATION SPECIALISTS

Protecting people and property since 1982

FIRE ENGINEERING CONSULTANTS Certificate Number 860 ISO 9001

Our products and people continue to serve the housebuilding and construction industry with a wide range of wood panel products.

West Fraser trading as Norbord Europe Ltd.

uk.westfraser.com

New name. Same products.

Norbord is now West Fraser

THIS ISSUE...

COVER STORY - CLIFFORD’S TOWER

York’s historic Clifford’s Tower has been radically transformed with a modern timber staircase and engineered timber viewing area that breathes new life into this ancient monument. The structure is also ‘circular’ with the timber frame demountable and reusable, adding even more sustainability benefits.

P08

UK INDUSTRY NEWS

A quick round-up of some recent news stories from the timber and construction sectors that you may have missed including: the exploration of English hardwood forest products for construction use, preparations for the EUTR replacement, Lathams launch a new brand of weatherboards to the UK market and TDUK look to combat greenwash.

P22

THE NAME OF THE GAME

ABBA Voyage – the concert that sees music legends ABBA performing digitally with a live 10-piece band – takes place in the ABBA Arena, a purpose-built, state-of-the-art arena located at Queen Elizabeth Olympic Park. Designed by Stufish Entertainment Architects, the steel and CLT building is ‘a mysterious, intriguing object’.

P24

A CELEBRATION OF SUSTAINABLE CONSTRUCTION

Another fantastic evening at the NCC, Birmingham, saw the best of timber design and construction rewarded at the 2022 Structural Timber Awards – with so much inspirational activity in the sector, what were those outstanding projects and who were those inspiring winning individuals?

P28

TIMBER AT THE HEART OF THE COMMUNITY

De Matos Ryan has transformed The Alice Hawthorn with the addition of twelve guest bedrooms and the renovation of its Grade II listed pub – and used homegrown timber to do it.

P30 THE NINO REVOLUTION

Ernesto Callegari explains more about the changing world of angle brackets including the revolutionary new NINO bracket.

P32 A MARRIAGE MADE IN CONSTRUCTION

An overview of two projects showing why offsite design and timber is perfectly matched to provide hugely successful architecture including the F51 Urban Sports Park and March House.

P34 HEALING ENVIRONMENTS

The Catkin Centre and Sunflower House are part of Alder Hey in the Park – the first NHS health park for children in the UK and used engineered timber as part of a wider biophilic approach.

P36

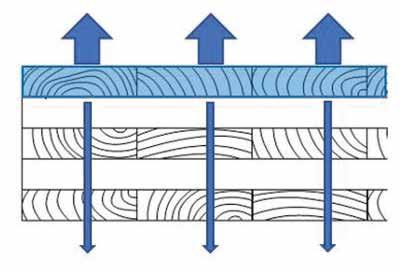

MOISTURE & DURABILITY OF CLT

To better understand how moisture dynamics can affect the durability of CLT, BM TRADA has conducted wide-ranging research to find out more about long term product performance.

P46

LIVING THE CITU LIFE

The Climate Innovation District located in Leeds city centre is demonstrating that there is a different and better way to live within in our cities, with timber playing a central part in delivering sustainable change.

P48 CHOOSING THE RIGHT MATERIAL IN THE RIGHT PLACE

Alex Brock, Pre-Construction Manager at B&K Structures, explains why hybrid mass timber structural systems can improve sustainability and help meet financial requirements.

P50

MOVING AT A PACE INTO 2023

The image of construction – and sometimes the reality – is that of an industry that tends to stick with what it knows works. But as Andrew Orriss of the STA explains, this year everything has started to change.

CONTENTS

P6

VIEW FROM A HILL

York’s historic Clifford’s Tower has been radically transformed with a modern timber staircase and engineered timber viewing area that breathes new life into this ancient monument.

Clifford’s Tower is the largest surviving structure from the medieval royal castle of York, built in the mid-13th century but has stood as a roofless ruin since 1684. The tower offers superb views over the city and following a £5million project to conserve and improve the interior of the 800-year-old landmark for English Heritage, it now incorporates a freestanding timber solution that protects the ruin, carries a timber viewing deck,

and sees new walkways and stairs give public access to features unseen for over 350 years.

Timber was ideally suited for the new structure, with its low carbon impact and lightweight nature. The glulam timber structure was designed so that all connections were concealed, and a neat appearance achieved. The main structure comprises primary beams supported on four columns, carrying a timber viewing deck and central atrium. The columns have recesses concealing drainage and services routes. New services were ducted through the new raft foundation and concealed within the glulam columns, allowing the deck to be used for functions and night-time events with LED lighting concealed in structure, finishes and handrails.

The design is ‘circular’ with the timber frame demountable and reusable, if needed at any point in the future. This gives further sustainability benefits where the carbon captured within the timber can stay locked into the material for a significantly longer period of time.

Using timber supplied by leading French softwood supplier Piveteaubois, Buckland Timber installed the engineered timber elements alongside Douglas fir decking. Buckland chose to work with Piveteaubois as they could supply the sapwood-free Douglas fir that was used to make the glulam for the larger elements. They were looking to cut down on in-house manufacturing work and Piveteaubois could supply the floor joists thanks to their cuttingedge CNC machining capabilities. Piveteaubois provides a consistent

STRUCTURALTIMBERMAGAZINE.CO.UK w 6 COVER STORY CLIFFORD’S TOWER

01 02

grade of sapwood-free Douglas fir. Being dried to 12% moisture content it is perfect for glulam manufacture, so it worked well for Buckland to call on them for any large volumes that are needed quickly. For the Clifford’s Tower project, having some of the beams delivered already machined was useful as it allowed a reduction in manufacture time.

Piveteaubois supplied 36m3 of 140mm x 350mm GL24h sapwood-free Douglas fir glulam, comprising of 55 beams, with 38 of them further processed by Piveteaubois’ state-of-the art SMC OIKOS 5-axis machining centre. This delivered precision cutting to any required length plus a wide range of machining capabilities. The 38 beams were cut into 129 pieces of various lengths and machined with mitre and bevel cut, as well as drillings and counterbores for easier installation.

Piveteaubois produces 50,000m3 of glulam and finger-jointed Douglas fir, Spruce and Pine glulam annually. With a permanent stock of around 3,000m3 in its 5,000m2 warehouse, they are ready to supply customers with standard 13m lengths or bespoke orders. This also includes a range of glulam treatment options including pressure treatment of Douglas Fir to Use Class 3.2 or prepressure treated UC4 Pine glulam for higher risk environments.

Douglas fir combines remarkable mechanical properties with excellent natural durability as its duramen is naturally Use Class 3.2 without treatment. Sapwood-free Douglas fir glulam, cladding and decking are excellent for use outdoors and age gracefully just like Larch and at a lower cost. Piveteaubois also offers Douglas fir C24, finger-jointed timber as well as CLT, making it a hugely versatile building material. All Piveteaubois Douglas fir comes from sustainable forestry and is PEFC-certified.

The non-slip timber deck was constructed using PEFC-certified Marley CitiDeck®, which is manufactured from premium grade European Redwood and was specified by Hugh Broughton Architects Ltd. The decking was installed, and carefully cut to a smooth curve following the line of the new metalwork guarding at the edge. There is also a large opening in the middle that allows visitors to look down to

the floor of the keep. The boards were also used to create seating areas and the guard structure around the central opening. CitiDeck® is an attractive and robust anti-slip timber decking solution ideal for use in public areas, the non-slip surface ensures the deck is safe to use all year round.

Working with Hugh Broughton Architects and conservation architect, Martin Ashley Architects on the detailed design, Ramboll provided the engineering design solution for this sustainable timber structure. This unique project introduced an architecturally stunning, structural timber intervention within the tower, to allow the public to fully access and appreciate the monument whilst

demonstrating exemplary conservation practice by respecting the significance of the monument and site. Clifford’s Tower re-opened in April 2022 and has been shortlisted and won several design and construction awards including Best Retail & Leisure Project and Winner of Winners Award at the Structural Timber Awards 2022.

www.uk.ramboll.com www.piveteaubois.com/en/ www.bucklandtimber.co.uk

IMAGES: 01-04. A hugely successful revamp using engineered timber has transformed one of York’s most iconic sites. Courtesy Dirk Lindner/Hugh Broughton Architects/English Heritage/Ramboll

COVER STORY CLIFFORD’S TOWER STRUCTURALTIMBERMAGAZINE.CO.UK w 7

03 04

ENGLISH WOODLANDS TIPPED FOR NEW CONSTRUCTION RESOURCE

A consortium of experts in timber construction and engineering is exploring ways to boost the use of English hardwood forest products across the built environment, in a move which could significantly improve the carbon footprint of the UK’s buildings and support diverse woodland ecosystems.

The project – led by the New Model Institute for Technology and Engineering’s (NMITE) Centre for Advanced Timber Technology (CATT) – is funded through the Forestry Commission’s Timber in Construction Innovation Fund, designed to increase the use of the natural carbon sequestering material in the built environment. Partners also include dRMM Architects, Ecosystems Technologies, Edinburgh Napier University and Built Environment – Smarter Transformation (BE-ST).

For the first time, researchers will examine the suitability of certain species of English homegrown trees for their use in construction, looking at sawn, engineered, and mass timber products including cross laminated timber (CLT) and glulam. The species will be chosen according to future availability, and timber potential based on existing data, including more common species such as oak, beech and sweet

chestnut, as well as birch, sycamore, ash, alder and willow, where existing research about their suitability is limited.

Focusing on the use of timber in MMC, partners will collate data on the potential strength grading of each species while also assessing the use of homegrown co-products such as wood fibre insulation. The three-year project could help to reduce the UK’s reliance on imported construction materials, as well as providing low-carbon alternatives to concrete and steel.

Kat Scott, Sustainability and Regenerative Design Manager at dRMM, said: “By manufacturing viable and scalable homegrown timber alternatives to carbonintensive materials, we are aiming to reduce the UK’s reliance on imported products. Widening the range of species that provide a domestic wood supply could also provide a boost for localised manufacturing facilities and supply chains.”

The research follows the success of the Innovate UK-funded Transforming Timber initiative which set out to prove the business case for using Scottish wood to create the structural elements of buildings. A demonstrator unit created using homegrown CLT, nail-laminated timber (NLT) and glulam was found to have an estimated

carbon sink of -142kg per m2, compared to +612 kg per m2 for an equivalent brick and block construction.

Sam Hart, Head of Modern Methods Of Construction at BE-ST, said: “As the UK faces a climate emergency, demand is growing rapidly for more sustainable construction approaches such as timberbased offsite design. By building a robust evidence base, we can inform future approaches to forestry and woodland management across England that includes the species best suited for use in the structure of buildings. At the same time, the trees will sequester significant amounts of carbon, helping to reduce the environmental impact of the built environment in the years to come.”

Professor Robert Hairstans, Director of CATT at NMITE, added: “This research represents a strategic convergence of England’s forestry, manufacturing, and construction industries to drive the increased adoption of homegrown, renewable timber in construction. By so doing we can inform future forest strategies to ensure resilience against pests, diseases and climate change and be less reliant on imported resources and the current monoculture of commercial species.”

www.nmite.ac.uk

8 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

TIMBER CLADDING THAT MAKES A STATEMENT

The Naturally Perfect® Factory Finish for the perfect modern building.

Just because it’s black doesn’t mean it has to be charred. Sansin Precision Coat provides a stunning charcoal finish to this beautiful Siberian Larch timber cladding. Our specification program will help you achieve the perfect finish and protection.

Precision Coat factory finishes deliver the colour, transparency and performance that architects, engineers and builders can count on.

Teddington Cricket Club | London, England

Photography © Ben Tynegate

Teddington Cricket Club | London, England

Photography © Ben Tynegate

NEW DONALDSON DOOR SYSTEMS BRAND ANNOUNCED

supplying internal and external door sets, as well as staircases from its site in Plains, North Lanarkshire. Since its acquisition in February 2020, all colleagues and operations have moved over to the Donaldson Group, with Managing Director, Luke Roberts, and General Manager, Billy Cameron, continuing to drive the business.

We are proud to be a part of this trusted family business and we are certain that our customers will continue to benefit from the high-quality products and services that the Donaldson Group is known for.”

Scotland’s leading joinery manufacturer of door sets has a new identity. Following its acquisition by the Donaldson Group in 2020, Donaldson Door Systems (DDS) is the new brand of the business formerly known as Rowan Manufacturing Ltd (RML).

Established in 1979 as the manufacturing arm of the Rowan Group, DDS specialises in manufacturing, merchanting and

DDS is dedicated to delivering quality, exceptional service and product innovation. With vast experience and knowledge of joinery, DDS holds Secured By Design accreditation and is the only company in Scotland to be both Q Mark and Certifire certified. DDS will harness the expertise of the Donaldson Group, operating within its Offsite division, to continue servicing the UK housebuilding and construction market.

Luke Roberts, Managing Director, Donaldson Door Systems said: “The rebrand to Donaldson Door Systems is an exciting new chapter for the company. Our people will move forward with the business as we hone in on our market-leading door sets with safety and security front of mind.

Andrew Donaldson, CEO of the Donaldson Group, added: “The rebrand completely aligns Donaldson Door Systems with the Group, along with a new logo, branding and website. The response from everyone involved in the rebranding exercise has been overwhelmingly positive and we are excited to see Donaldson Door Systems develop and build on the strong foundations that were established in its 30 years of operation.”

Donaldson Door Systems is Scotland’s leading joinery manufacturer of internal and external door sets, as well as stairs. For 30 years, the business has been working with large housebuilders, local authorities and the domestic market, supplying them with high-quality doors and stairs.

www.donaldsondoorsystems.co.uk

TIME FOR TIMBER’S TREE GIVEAWAY DEMONSTRATES PUBLIC DEMAND FOR CHANGE

opportunity for transitioning to a much more carbon efficient method of construction.

The purpose of the tree giveaway was to increase awareness through the media and the public, that by planting and growing more trees, further carbon can be captured and stored. The timing of the campaign could not be more appropriate, coinciding a mere week before the COP27 Climate Change conference in Sharm el-Sheikh, where countries from around the world are coming together once again to try and form a plan to tackle climate change.

Furthermore, MMC/offsite allows us to pre-manufacture elements of the house building process, contributing 55% to quality and speed, which was confirmed by Homes England. This represents a quick and efficient way of meeting these ambitious targets. There is a real risk that if immediate change isn’t implemented, the net zero goal for 2050 will not be met, and the adverse effects of climate change will continue to worsen.”

On 1 November 2022, the Time for Timber team handed out trees at Manchester Piccadilly train station to raise awareness of its latest campaign to promote the use of timber as a low-carbon building material.

The UK has set itself ambitious targets of reaching net zero by 2050, and if the carbon output of the construction industry is not addressed, this goal will not be met. As such, the use of structural timber represents our greatest

Andrew Orriss of the STA said: “It was genuinely refreshing to chat with members of the general public and to hear how many support methods that strive to reverse the negative impacts of carbon intensive methods of construction. Real action must be taken now if we are to stand any chance of combatting climate change.

“The housebuilding industry has an enormous task to pick up the volume, and perhaps this is where the supply chain can help to alleviate some of the pressure.

Time for Timber’s overarching cause, which was explored through the tree giveaway, is to educate and promote the use of timber as a construction material as it presents itself as a truly vital solution to the ongoing climate crises. If the UK is to build more homes, schools and offices in a way that supports the UK’s commitment to net zero by 2050, timber must be utilised in an even greater capacity.

www.timefortimber.org

10 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

ZÜBLIN TIMBER BEGINS WORK FOR ROYAL FREE HOSPITAL MAGGIE’S

ZÜBLIN Timber has been commissioned by cancer charity Maggie’s to create a new ‘architectural highlight’ in London. ZÜBLIN are turning Daniel Libeskind’s sculptural design for a new cancer support centre into reality on the grounds of the Royal Free Hospital.

The ZÜBLIN subsidiary’s project team has started installing the parametric façade of the iconic new building designed by the renowned New York architectural firm.

The various curved timber elements for the elaborate construction were planned and individually prefabricated at ZÜBLIN Timber’s Aichach plant.

Maggie’s centres are built as warm, welcoming spaces, which offer free practical and emotional support to people living with cancer, and their family and friends. The unique architecture of each centre is part of the cancer charity’s concept and philosophy, based on the

conviction that a friendly design can facilitate the healing process.

ZÜBLIN Timber installed around 620sq m of laminated veneer lumber for the timber frame elements and for the façade panels of the parametric exterior. The two-storey cancer support centre provides 392sq m of space for a kitchen, library and exercise room, among other things. In addition to an outdoor garden, the building also features a winter garden on the spacious rooftop terrace that was designed as a place for outdoor rest and retreat for visitors.

ZÜBLIN Timber previously realised the timber construction work for the Maggie’s centres in Oxford (2014) and Oldham (2016). “We are very proud to be working on our third project for Maggie’s, contributing our expertise to this challenging façade,” said Daniel Kreissig, Sales and Estimation International at ZÜBLIN Timber.

With the new building in North London, Maggie’s will operate a total of 25 centres in the United Kingdom. Maggie Keswick died in 1995 and in the last two years before her death, she worked together with her husband and her cancer nurse, Laura Lee to develop the concept on which the centres are built today. Instead of a sterile hospital environment, she would have preferred to have had a more friendly space in which to process everything that comes with a cancer diagnosis: a flood of information to be evaluated and assessed, decisions regarding therapy options, questions concerning costs and financial support. Timber biophilic and natural properties are understood to have a calming and restorative effect. Dame Laura Lee is now the charity’s Chief Executive.

www.zueblin-timber.com

12 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

TIMBER DEVELOPMENT UK SIGNS ANTI-GREENWASH CHARTER

Timber Development UK (TDUK) has signed up to The Anti-Greenwash Charter as the next step in its sustainability journey.

The Charter is sponsored by the Alliance for Sustainable Building Products (ASBP) and requires organisations to make a public declaration to uphold good standards of marketing practice, adopt a Green Claims Policy and, by doing so, adhere to the Government’s Green Claims Code and Code for Construction Product Information (CCPI).

Having signed up to the Charter, TDUK has written a Green Claims Policy to set out the standards it has committed to in its marketing and communications. The organisation also requires all its members to abide by these standards, which are:

• Transparency: We commit to clear communication of what sustainability benefit our product or service offers and not to conceal or omit information

• Accountability: We substantiate our sustainability claims with accurate, and regularly evaluated empirical evidence. We commit to sharing facts, figures and statements that can be checked

• Fairness: We commit to using fair, clear and unambiguous language when providing comparisons with other products or organisations

• Honesty: We ensure we make specific statements about our organisation’s sustainability efforts and that our actions match those promises.

Charlie Law, Sustainability Director of Timber Development UK, explains: “The importance of sustainability is becoming clearer to industries across the country, but we have all seen examples of misleading or false information within the built environment industry. We are determined to ensure our members cannot be accused of ‘greenwashing’ and to help to champion responsible marketing practices across the timber supply chain, which is why we’ve

decided to sign The Anti-Greenwash Charter and develop our policy and associated guidance to help our members, and others in the industry make the correct claims.”

Timber Development UK has now completed the merger of the Timber Trade Federation (TTF) and Timber Research and Development Association (TRADA). The TRADA website went offline 31 October 2022 with TRADA’s social media accounts, including Twitter and LinkedIn, now no longer in operation. If you are currently a member of TRADA, you are now automatically a member of TDUK and can access your membership benefits via the TDUK website.

www.timberdevelopment.uk

• Remote monitoring

• Fully backed, developed and supported by Koppers

• Can help with treatment efficiencies

• Detailed reporting for industry compliance

• On-site system training and support available

• Customisable alarms and reporting

Introducing the new cutting-edge in control systems. With its user-friendly interface, ease of installation, live information and accurate plant mirroring, ProTreat delivers a new level of efficiency in timber treatment. www.kopperspc.eu | kpc.uk.sales@koppers.eu | +44 (0)1628 486644

CHARGED AND IN CONTROL.

™ Protim Solignum Limited trading as Koppers Performance Chemicals. Koppers is a registered Trademark of Koppers Delaware, Inc. Whilst every attempt has been made to ensure the accuracy and reliability of the information contained in this document, Protim Solignum Limited gives no undertaking to that eect and no responsibility can be accepted for reliance on this information. Information will be updated when the need arises. Please ensure you have an up to date copy. All products are produced by independently owned and operated wood processing facilities. All other trademarks are trademarks of their respective owners. Koppers Performance Chemicals, Protim Solignum Limited, Fieldhouse Lane, Marlow, Buckinghamshire, SL7 1LS. Visit: www. kopperspc.eu, Email: kpc@koppers.eu, Call: +44 (0)1628 486644, Fax: +44 (0)1628 476757. Registered in England 3037845. © Copyright 2020. UK INDUSTRY NEWS

LATHAMS INTRODUCES

WEATHERTEX® SELFLOK ECOGROOVE WEATHERBOARDS TO UK MARKET

Lathams has announced the introduction of Weathertex® sustainable Selflok Ecogroove Weatherboards to the UK and Irish building products market. Exclusive to the distributor in the UK and Ireland, Lathams has added the popular products to its cladding range in response to a growing demand for a more sustainable, natural option to traditional lapped timber planks.

Selflok is also delivering a greener alternative to the carbon-intensive cementbased boards popular in the booming domestic cladding sector, reducing a home’s carbon footprint whilst achieving a robust, resistant and attractive façade. The engineered boards are ideal for a wide range of external cladding applications and can withstand harsh weather conditions, retaining their aesthetic appeal without compromising on technical performance. Considered a green solution for cladding and facings, both boards contain no added formaldehyde or chemicals; just 97% PEFC Eucalyptus hardwood fibre and 3% natural waxes.

The Natural board is un-primed and features deep cuts and patterns to show the knots, cracks, and imperfections of the raw and organic timber. Customers can choose to stain the product, or to leave unsealed, allowing a natural ageing process to take place, eventually providing a mellow, weathered finish. In contrast, Selflok Ecogroove Woodsman features the same face texture, but is factory primed, meaning it can be painted or coated immediately, without pre-treatment.

With the panels measuring 3660mm in length and 300mm across the width with a 15mm groove running straight down the middle, they replicate two 150mm boards, meaning installation time is halved. Hardwearing, cost-effective, and versatile, the Weathertex Selflok range can be applied internally to any flat or curved surface (with a minimum radius of 2.5m) and can also be used for walls or ceilings. Simple to cut to the required size, both boards are easy to install, by simply overlapping the edge of the next board over the previous one, leaving the full face visible.

Both products are also perfect for horizontal outdoor use, especially in locations with harsher climates, as they can withstand most meteorological conditions without bowing or warping. Furthermore, the low sugar and starch content ensures both Weathertex boards also make the material resistant to insect attacks.

Commenting on the introduction of Weathertex to the Lathams catalogue, Technical Timber Sales Development Manager Justin Hayward said: “These new cladding boards respond to a number of challenges across the industry, particularly the need to balance aesthetics with longevity, and stability with sustainability. When we became aware of Weathertex‘s Selflok range we instantly knew we wanted to have exclusive access to distributing these high-performance products here in the UK, offering one of the greenest cladding solutions currently available.”

Weathertex’s Matteo Bossi added: “Preserving, protecting, and enhancing the environment is at the heart of our business model, so it’s essential we work with like-minded partners who share our values. Lathams, which has consistently demonstrated its commitment to sustainable business, was an obvious choice to introduce the Weatherboards to the UK and Ireland design and build community. We’re excited to collaborate with them, raising awareness around the Selflok range, and helping suppliers, specifiers, and developers across the industry make more sustainable material choices.”

Lathams also recently introduced WISA®’s new BioBond technology to its full range of WISA-Spruce plywood. A landmark development in plywood adhesive, BioBond replaces at least 50% of standard glue’s fossil-based phenol with lignin, timber’s inherent bonding agent. Its introduction and standardisation across the brand’s high-performance spruce range is a gamechanger, offering the best quality with a reduced carbon footprint.

www.lathamtimber.co.uk

14 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

With the introduction of Gang-Nail’s new iPanel software, timber frame panel designers can now take their drafting to the next level. iPanel provides new tools to ensure maximum efficiency and accuracy for timber frame panel designers. iPanel is a robust panel design tool that manages all the information needed to draft, estimate, manufacture and install wall panels.

Using iPanel and STITCHER® in conjunction with ITW Construction Products Offsite’s new award-winning Gang-Nail Truss Frame walls, timber frame panel designers can now get a complete panel solution.

Gang-Nail iPanel

itwcp-offsite.co.uk +44(0)1592 771132 orders@itwcp.com ITW Construction Products Offsite @ITWCPOffsite ITW Construction Products Offsite Brands for the offsite industry

NEW

timber frame software

BE PREPARED FOR EUDR

With the new European Union Deforestation Regulation (EUDR) soon to be replacing the European Union Timber Regulation (EUTR), research from iov42 has revealed that timber importers across the UK, Belgium, Austria, France and Italy are worryingly unprepared for the upcoming changes in regulation.

The EUDR, which will cover timber, soy, coffee, cocoa, beef, palm oil and some derived products, sets mandatory due diligence obligations for both operators and larger traders further down the supply chain.

The Food and Agriculture Organization of the United Nations (FAO) has estimated that 420 million hectares of forest were lost to deforestation between 1990 and 2020. It is very likely that EUDR will now set mandatory due diligence obligations for importers that place commodities on the EU market for the first time. The requirement to prove due diligence all the way back to the source will require a step change from the industry globally.

The research revealed that 74% of those surveyed admitted to not being fully prepared for the incoming regulation, likely because the regulation is yet to be formally agreed. However, when looking at specific regions, worryingly 12% of Belgian

importers were completely unaware of the incoming regulations, while 51% of those in the UK said they were only somewhat prepared.

However, 72% of those surveyed revealed they were in fact keen to get ahead of the regulation, with 43% claiming they felt positive about full traceability solutions. What’s holding them back though is their misplaced fears and lack of understanding of how traceability solutions, such as Distributed Ledger Technology, (or more commonly referred to just as Blockchain), can provide due diligence.

Of those surveyed, 46% did not fully understand the regulations and how they will affect them, while 56% felt that using traceability technology like blockchain could give away trade secrets. Interestingly, 48% also noted more traceability may expose gaps or problems within the supply chain, highlighting why regulation is needed.

David Coleman, Chief Product Officer at iov42 said: “We are at a critical time in the timber industry. With sweeping new regulations on the horizon, it’s essential that those in the sector ready themselves. Our research shows a degree of openness among importers in Europe to get ahead of these regulations, but there remains hesitation and a lack of understanding of

how traceability solutions can support them. Distributed Ledger Technology (DLT), is perfectly placed to help businesses increase the traceability of their timber in the face of the upcoming regulation changes, as well as build bonds of trust across the entire timber ecosystem.”

iov42’s research also found that an average of 83% of respondents spent half or more of their time tracking down information for customers, meaning far less time spent on revenue driving activity. At present, it’s not uncommon for companies to store evidence of due diligence in one place. This means documents are tied to single employees, meaning they’re not easily accessible to the wider business, customers and enforcement, and can even be lost if that person leaves the company. However, law enforcement can request to see evidence from timber transactions carried out years ago, leading to difficulties in locating documents.

If businesses are found not to be conducting their due diligence, not only can this lead to reputational damage, but more serious cases of non-compliance can lead to fines, arrests and, in the worst cases, custodial sentences. The report can be read at: http://bit.ly/3FL6E8T

www.iov42.com

16 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

The new Velindre Cancer Centre in South Wales has taken another step forward submitting detailed plans to Cardiff Council’s for approval.

The Acorn team, led by developer and investor Kajima, has submitted a Reserved Matters submission including details such as building design and landscape plans for the council’s approval. With an estimated internal floor plan of around 32,000sq m, the new Velindre Cancer Centre, designed by architects White Arkitekter as a clear and ambitious sustainability focus.

The Velindre Cancer Centre is set to become the UK’s most sustainable hospital. The buildings are designed with circular economy principles, using low-carbon materials and making a minimal impact on the surrounding countryside. It will consist of low-carbon, bio-based materials with timber specified for the lounge, radiotherapy

and waiting areas. Lime and clay are used as internal materials and contributes to a calming environment for patients, visitors, and staff. Additionally, a sustainable urban drainage system will be integrated.

The building will achieve a minimum BREEAM rating of Excellent and is planned to be all electric using green energy sources including photovoltaic panels on the roof. The heating and cooling power will come from ground and air source heat pumps. “The plans for Velindre Cancer Centre represent a huge step forward for healthcare provision in the UK,” said Michael Woodford, London Studio Director, White Arkitekter. “The combination of circular economy principles, low carbon materials and respect for the local landscape will make it the country’s most sustainable hospital, where the environment is designed to support and complement patients’ medical treatment.”

The new Velindre Cancer Centre is surrounded by a landscape garden and the centre has been designed to ensure minimum impact on the site. The centre will be gently integrated within the Welsh landscape to keep it as wild as possible. By

creating new landscape places such as an orchard and a community kitchen garden the plan is to create new habits. The plan is also to create informal play areas and a multitude of walking, cycling and relaxation areas. The building is being developed to comply with the Well-being of Future Generations (Wales) Act 2015. This means the new Velindre Cancer Centre’s internal spaces can easily be adaptable to future innovation in treatment and equipment.

www.whitearkitekter.com

UK INDUSTRY NEWS

Techno Metal Post helical piles are engineered and guaranteed. • Fast and effective • Specialized installation equipment 18/5477 WORLD LEADER IN HELICAL PILE FOUNDATIONS • No excavation • In-house engineering services technometalpost.co.uk info.uk@technometalpost.co.uk SUSTAINABLE PLANS FOR VELINDRE CANCER CENTRE

LOFT CONVERSION SPECIALIST FINDS MULTIPLE USES FOR STERLINGOSB ZERO

contracts across South London, Surrey, Sussex and Kent. Typically, the company completes up to a dozen loft conversions and other projects each year. Mark purchases his SterlingOSB Zero from Selhurst Timber and other builders’ merchants local to client’s properties. While he mainly prefers to use 18mm tongue and groove boards for their strength and excellent alignment when laid, some of MB Loft Conversions’ builds also use quantities of 11mm (square edge) SterlingOSB Zero.

cheeks of the dormer windows, while we switch to the 11mm for internal walls. There are also many applications for SterlingOSB Zero when it comes to our garden rooms.”

A family-run firm which specialises in loft conversions and the creation of bespoke garden rooms, is making extensive use of SterlingOSB Zero from panel product manufacturer West Fraser, based on the board’s value, performance and ease of installation.

MB Loft Conversions, based in Caterham, was established eight years ago by Mark Bell and undertakes

Mark Bell commented: “I started out in the building trade as a carpenter but soon began concentrating on loft conversions and really enjoy the work which is all for private clients. The jobs vary in size; we have done quite a number of larger projects typically with two rooms in the loft, along with two en-suites. The garden rooms can be very large as well.

“There is a number of reasons why we prefer to use both West Fraser’s 8x4 and 8x2 T&G Sterling OSB Zero, apart from it being a product I’m very familiar with. We know we can rely on the quality, while the 18 mm T&G boards are like gold when it comes to doing flat roofs and make a really good deck. We also use them for the

As part of a comprehensive, overall carbon negative product range, SterlingOSB Zero T&G presents specifiers with precision-engineered tongue and groove boards, which are typically specified for pitched or flat roof decking and timber frame construction, as well as for flooring and other applications. Also from an environmental viewpoint, the ‘Zero’ in the name means no formaldehyde is added during its manufacture, which is a first in the UK – encouraging its specification on improved health and safety grounds.

Available in thicknesses of 18 and 22mm, the boards are produced in 2400 x 1200mm and 2440 x 1220mm sizes with T&G joints on two edges, as well as an 18mm thick version with T&G profiles around all four edges and face dimensions of 2400mm or 2440mm by 625mm.

www.uk.westfraser.com/housebuilders

BOKLOK UK APPOINT NEW DIRECTOR

BoKlok UK the innovative and sustainable home provider, jointly owned by Skanska and IKEA has appointed Emma Plumridge as Sales and Marketing Director.

Emma joins after 12 years at Stubbings Property Marketing consultancy, which has also been BoKlok’s trusted advisor since 2019. Prior to this, Emma successfully ran her own development company and has a breadth of experience and knowledge in residential housing development and land planning.

Graeme Culliton, BoKlok UK Managing Director and Country Manager said: “Emma has first-hand knowledge of our customers and how they perceive our offering, her experience brings another dimension to our business, and we now welcome her to the BoKlok family to lead our sales, marketing, customer care and satisfaction teams. She has been instrumental in tailoring the BoKlok brand to the UK residential home market and building our sales and customer care approach.”

Emma replaces Jerrie Kristiansson who for the last four years has been responsible

for establishing BoKlok’s marketing, sales, and customer processes in the UK. Jerrie has been with BoKlok Group for over 10 years and will continue to work within the company as senior advisor and resource for business-critical initiatives across the international markets.

BoKlok is a residential housing concept providing sustainable homes and communities ‘for the many people’ offering well-designed and functional, high-quality homes with people and planet in mind. BoKlok homes are built primarily from timber using an industrialised and efficient process minimising the environmental and climate impact. They are committed to becoming net zero carbon (climate neutral) throughout the BoKlok value chain by 2030. BoKlok currently has three home development sites in Bristol, Worthing and Littlehampton.

www.boklok.co.uk

18 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

TIMBER FASTENERS & FIXINGS MANUFACTURERS URGED

UKCA TESTING

Having successfully achieved UKAS accreditation for its new Fastener Testing Laboratory, Warringtonfire is reminding manufacturers that the UKCA marking deadline is looming, and that new or updated products planned for launch in 2023 need to be tested to be able to be sold in the UK.

Under the UK Construction Products Regulation, from 1 January 2023, manufacturers of structural timber fasteners and fixings within the scope of the UK Designated Standard BS EN 14592 must successfully complete the UKCA testing process for any new product to be placed on the GB market.

The move comes as the UK transitions away from the EU-recognised CE Marking. Products undergoing a change in their specification, for instance, fasteners and fixings that have a change in design or coatings, will also need to be re-tested to gain the UKCA marking and confirm their stated performance.

For this reason, Warringtonfire has launched its state-of-the-art Fastener Testing Laboratory, located in High Wycombe. One of only a select few UKAS-accredited ‘Approved Laboratory’ facilities, the laboratory can undertake assessments of performance for structural timber fastener and fixing products, so that manufacturers can UKCA mark them to BS EN 14592.

The organisation will offer a range of geometric and mechanical testing procedures for dowel type fasteners from a particular group of structural timber fixings, comprising of nails, screws, staples, dowels and bolts with nuts. The laboratory will also test steel fixings used to create joints between timber components or to attach other materials to timber.

Ben Sharples, Commercial Lead at BM TRADA, said: “The deadline for the changes in the way UKCA marking is achieved for manufacturers of structural timber fasteners and fixings is now less than two

months away. While the testing process itself may not take too long, a lack of accredited laboratory space within the UK means manufacturers placing new or updated products on the GB market after the 1 January 2023 deadline should not delay with arranging testing. However, to further support our customer base within the construction products sphere, we have invested heavily into our High Wycombe Fastener Testing Laboratory to achieve UKAS accreditation and undertake UKCA testing.”

Alongside offering fastener and fixing testing, the laboratory can also offer thirdparty certification through its BM TRADA Q-Mark certification scheme.

www.warringtonfire.com

UK INDUSTRY NEWS

TO GET AHEAD WITH

NEW DESIGN GUIDE TO TRANSFORM SCOTLAND’S APPROACH TO AFFORDABLE

HOUSING

Ainslie McLaughin, Chair of the Edinburgh Home Demonstrator Programme Project Board, said: “Our ambition is to reduce the carbon footprint of the housing sector by designing new homes that ultimately consume less energy. Affordable housing plays a significant role among many communities and we want to create homes that are better suited for future generations. The flats we are delivering in Granton will be highly energy efficient and will also encourage residents to make low carbon lifestyle choices in relation to services like transport and travel.

“A key output of the pilot project is the evidence we will collect on the performance of the homes. Not only will it inform the next stages of building work here in Edinburgh and the City Deal but it could also influence future designs and procurement practices across all of Scotland’s affordable housing.”

A new catalogue of net zero carbon building designs could provide a significant boost to Scotland’s affordable housing sector, as part of a standardised approach for local authorities and housing associations to adopt across a range of future developments.

The energy-efficient design and performance standards have been created by the Edinburgh Home Demonstrator (EHD) programme. The catalogue covers different housing typologies, such as flats, houses and cottage flats, which combine fabricfirst energy efficient standards, renewable energy technology, and modern methods of construction – also known as offsite manufacturing.

The £1million EHD programme – involving partners from the City of Edinburgh Council, Offsite Solutions Scotland, Edinburgh Napier University, the University of Edinburgh, Built Environment – Smarter Transformation (BEST) and Scottish Futures Trust – is trialling the new approach for high-performing affordable homes.

The first pilot project of the EHD in Granton includes the creation of 75 net zero carbon ready one, two and three-bed flats being constructed by offsite construction specialists, CCG (Scotland), and is funded by the Scottish Government’s Affordable Housing Supply Programme and the City of Edinburgh Council. The first homes designed using the performance standard are expected to be completed in the summer of 2023 and once occupied, will be monitored to test the approach in the guide.

With the new design and performance standards, the programme hopes to inform new build developments across the Edinburgh and South East Scotland City Region Deal, providing a route map to net zero carbon homes that utilise offsite manufacturing. While the guide recommends common parts, including floorplans and zero gas heating systems, elements such as the external materials and appearance of homes can be customised to ensure buildings remain in keeping with local surroundings.

Sam Hart, Head of Modern Methods of Construction at BE-ST, said: “We are facing a climate emergency and need to rapidly transform all aspects of the built environment to reduce its carbon footprint. Compared to carrying out the majority of works on site, offsite manufacturing is proven to be more accurate and more efficient, while also reducing waste. This programme is helping to provide local authorities and developers with information about what zero carbon looks like in practice, as well as building evidence to support offsite specialists and other supply chain partners.”

Nicola Jackson, Chair of Offsite Solutions Scotland, added: “With advancing building performance requirements and increasing levels of technology required to be integrated in new homes to improve operational performance, we can better assure this is delivered through manufacturing homes in a controlled, dry factory environment to improve build quality. Offsite Solutions Scotland members have come together as a network of leading offsite timber manufacturing companies to deliver pilot projects as part of the Edinburgh Home Demonstrator programme. This will support the development of a new delivery model for net zero affordable homes using offsite manufacturing.”

20 STRUCTURALTIMBERMAGAZINE.CO.UK w UK INDUSTRY NEWS

www.be-st.build

ACCSYS INCREASES ACCOYA® WOOD CAPACITY

Accsys, the manufacturer of Accoya wood, has successfully expanded production capacity at its facilities in Arnhem, the Netherlands. The first commercial batch of Accoya wood has been produced from its new, fourth acetylation chamber.

Accsys has invested over €30million in expanding the Arnhem site, including improving the wood handling for the whole site. The new acetylation chamber, which weighs in at 65 tonnes and over 14m long, increases the production capacity at Arnhem by a third, up from 60,000m3 to 80,000m3 (25.4 to 34.0 million board feet) a year.

In addition to the new acetylation chamber, Accsys has also invested in developing the Arnhem plant’s facilities. The improvements include: new capabilities to support safe and rapid handling and logistics of the increased volumes of wood and a new quality monitoring and assurance technology with cameras, infrared

scattering and x-rays to examine every board to ensure customer satisfaction with the products. A new 20,000m2 (200,000sq. ft.) warehouse opened in October at Hoevers, which will provide 35,000m3 of raw material storage close to the Arnhem site.

Rob Harris, CEO Accsys commented: “The world urgently needs solutions for sustainable construction. Durable, sustainable, and with incredibly high performance, Accoya is in high demand –and we’re working as hard as we can to produce much more of it. We have earned a loyal customer base and our priority is to deliver more of what they need. Our expansion at Arnhem is a significant step in the right direction of getting more Accoya out to the market. It’s part of our ambitious growth plan to expand production and fulfil

John Alexander, Group Sales Director, Accsys: “Reduced output from the Accoya facility in Arnhem over the past 12 months due to the engineering work on site for the 33% capacity expansion has created some challenges for our customers. We now have the benefit from that work addressing the demand and significantly increasing supply to our distributors. As we look ahead to early 2024, having two world scale facilities for production of Accoya provides for continued market growth and increased resilience of supply.” Accoya wood has been on the market since 2007 and is now sold by stocking distributors in more than 35 countries.

www.warringtonfire.com

Structural timber and offsite construction

Member’s quality assurance scheme AS SURE

• Ensures current legislation and regulatory requirements are met

• Recognised by all leading warranty providers

• Independently audited scheme and certified competency programme

UK INDUSTRY NEWS

www.structuraltimber.co.uk Follow us on twitter @STAtimber •

• Low

•

•

5635 STA Offsite Awards LS Advert 127x190 v1_P.indd 1 20/10/2022 09:52

Predictable quality through offsite manufacture and assembly

embodied carbon aligns with Net Zero targets

Proven through research and testing

Design versatility and flexibility

our purpose of changing wood to change the world.”

ABBA ARENA

the large ABBA logo is integrated onto two facades with LED light strips following the timber.

THE NAME R OF THE GAME

The PEFC-certified CLT was produced and supplied by Austria’s Hasslacher Norica Timber, with Bristol-based Xylotek leading the technical design, procurement and installation alongside Glulam Solutions.

A key challenge was to maximise the ease of disassembly of the structure to allow for its future relocation. CLT panels are typically joined together with large screws which are challenging to remove so Xylotek developed –alongside engineers Corbett and Tasker Structural Engineering – a system that mainly uses bolted connections and makes the dismantling and reuse of CLT panels easier and keeps the carbon captured in the timber longer.

with the structure designed as fully demountable.

With a footprint of approx. 80 x 50m, the ABBA Arena auditorium is four storeys tall, and consists of 1650 unique CLT panels with dimensions up to 9.9m long and sits within – and structurally independent of – the steel-framed enveloping walls and roof of the arena.

ABBA Voyage – the revolutionary concert that sees music legends ABBA performing digitally with a live 10-piece band – takes place in the ABBA Arena, a purpose-built, state-ofthe-art 3000 capacity arena located at Queen Elizabeth Olympic Park, London.

Designed by Stufish Entertainment Architects, the steel and cross laminated timber (CLT) building has been conceived as ‘a mysterious, intriguing object’. The 25.5m high hexagonal form of the arena responds to the requirements of the show and cuttingedge staging by director Baillie Walsh and Industrial Light & Magic, the company founded by Star Wars creator George Lucas, in what is the company’s first foray into music. The Arena is also in keeping with the concept of sustainability and material circularity,

At the heart of the arena, the auditorium offers a unique high-tech, immersive entertainment experience to enjoy the ‘ABBAtars’ and is designed to fit 1650 seats and space for a standing audience of 1350. The structure of the venue that sits on concrete pads and is designed to create an internal clear span of 70m to allow for a large 360° immersive production. Built by ES Global, it has been optimised to be as light as possible to minimise the load on foundations.

Outside the auditorium an extended concourse area is sheltered from the elements by a large timber canopy built by Stage One. Like the superstructure itself, the canopy is a modular system that can be removed in sections and can be reconfigured to meet the needs of a new site once it has relocated. These timber modules follow the hexagonal shape of the venue to accommodate food and beverage options, retail, toilets, and a guest lounge. To contrast with high-tech show inside, the external structure that braces the steel dome roof and auditorium, is clad with a porous screen of timber battens – here

Xylotek also worked on the demountable timber rainscreen that envelops the Arena. Covering an area of over 7000sq m, the screen consists of 1400 finger-jointed larch fins with a total length of about 15km. It also incorporates an insect mesh and is factory fire treated and stained with a pre grey accelerated aging oil to ‘homogenise’ the timber as it ages naturally towards silver grey. The PEFCcertified larch was sourced from French supplier Piveteaubois, in elements up to 15m long, which were preassembled by Xylotek into 204 independent panels, each optimised for road transport to site and for future relocation of the theatre.

As well as being a huge music and technology attraction, the Arena is being hailed as the world’s largest demountable temporary venue. The original scheme design also had around 144 tonnes of steel plus 630m3 of CLT but was reconfigured by Xylotek to 900m3 of CLT – which approximately halves the embodied carbon. As such the ABBA Arena is a perfect example of a fresh approach to timber design – building in deconstruction from the beginning and employing a sustainable circular mindset with a view to the building’s future reuse and carbon capture.

www.stufish.com www.xylotek.co.uk www.pefc.co.uk

IMAGES: 01-02. CLT is central to the world of ABBA’s new music venture. Courtesy Dirk Lindner/Stufish Architects

22 STRUCTURALTIMBERMAGAZINE.CO.UK w

02

01

NEW FOR 2023 SHOWCASING THE BEST IN STRUCTURAL TIMBER FOR MORE INFORMATION EMAIL RHIAN.MORRIS@RADAR-COMMUNICATIONS.CO.UK In partnership with: SAVE THE DATE 28.03.23 STRUCTURAL TIMBER MAGAZINE

A CELEBRATION OF SUSTAINABLE CONSTRUCTION

Another fantastic evening saw the best of timber design and construction rewarded at the 2022 Structural Timber Awards – what were those outstanding projects and who were those inspiring individuals?

Timber continues to stand at the core of success across so many sustainable construction projects. Its natural, organic and aesthetic benefits combine with structural and architectural strengths to provide a low carbon and high-performance material.

Construction professionals were once again invited to congregate at this prestigious awards ceremony on 12 October at the National Conference Centre, Birmingham to celebrate the best the industry has to offer.

The 2022 Structural Timber Awards were hosted by Holly Walsh, who ensured that the celebrations were not only inspirational, but also highly entertaining. With 16 categories, nearly 250 entrants and over 60 companies shortlisted, the Structural Timber Awards judges had a difficult task.

The big winner on the night was Ramboll for Clifford’s Tower, picking up the trophy for Retail & Leisure Project of the Year, alongside the all-important Winner of Winners award. The judge’s commendations for Clifford’s Tower ranged from: ‘one of the best interventions in a historical structure I’ve seen’ to ‘elegant and memorable… brings the monument back to life’. You can read more about this project in the centre of York inside this issue.

The Head of the

the night: “I have been hugely impressed with the breadth and quality of entries that have been received. It is truly inspiring to see so much activity in the sector and to witness so much innovation taking place.”

STRUCTURAL TIMBER AWARDS 2022

judging panel and Chief Executive of the Structural Timber Association, Andrew Carpenter said of

24 STRUCTURALTIMBERMAGAZINE.CO.UK w

THE

FULL LIST OF 2022 AWARD WINNERS ARE...

Architect of the Year

Historic Environment ScotlandDoune Castle: Ardoch Burn Crossing

Client of the Year

Historic Environment ScotlandDoune Castle: Ardoch Burn Crossing

Commercial Project of the Year De Matos Ryan - The Alice Hawthorn

Custom & Self-Build Project of the Year

Hayhurst & Co - Green House

Healthcare Project of the Year

B&K Structures, Stora Enso and Ramboll - Alder Hey Children’s Hospital

Installer of the Year

WIEHAG GmbH - Eton College ESAC

Project of the Year

B&K Structures, HTS and Studio RHEThe Gramophone Works

Retail & Leisure Project of the Year

Ramboll - Clifford’s Tower

SIPs Project of the Year Glosford SIPS - Fuggles Pocket

Social Housing Project of the Year

Ramboll UK - Beechwood West

Education Project of the Year

Tate+Co

Centre

Engineer of the Year

Engenuiti - Crosfields Senior School Building

Low Energy Project of the Year

Adam Knibb Architects - Tarn Moor

Pioneer Award dRMM - Alex de Rijke

Private Housing Project of the Year

Citu - Climate Innovation District

Solid Wood Project of the Year

B&K Structures, HTS and Studio RHEThe Gramophone Works

Timber Frame Project of the Year Citu - Climate Innovation District

Winner of Winners

Ramboll - Clifford’s Tower

Product Innovation Award

Innovaré - Psi-Fast – Next Generation Panelised System

2023 STRUCTURAL TIMBER AWARDS

There has already been a large amount of attention focused on next year’s awards, which will be returning in October 2023 and will again spotlight excellence and celebrate expertise in timber technology and the ways it contributes to an attractive, energy efficient and sustainable built environment.

Remember that the Structural Timber Awards provide one of the most effective platforms to promote brands or companies alongside the best of the best. For details on sponsorship packages and promotional opportunities for 2023 and to register your interest to enter your projects and people visit: www.structuraltimberawards.co.uk Please note that the submission deadline for entries into the 2023 Structural Timber Awards is 23 June 2023.

26 STRUCTURALTIMBERMAGAZINE.CO.UK w STRUCTURAL TIMBER

AWARDS 2022

Architects for York St. John University Creative

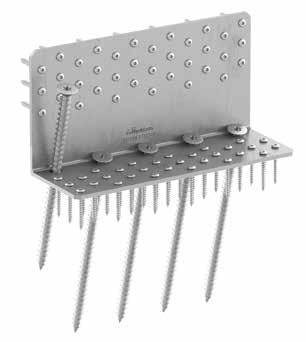

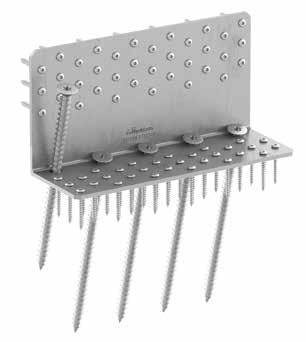

Structural Post Connection, Evolved.

Introducing the new PBWS single piece post base for post-to-concrete connections. With the same load-rated capacity as a standard post base, the unique folded build uses 45% less steel, making it better for the environment and easier to handle. And our innovative ZPRO coating provides the same protection against the elements as a hot dip galvanised coating, but with a neater, shinier finish.

Extending the life of outdoor structures, economically.

www.strongtie.co.uk

For more information visit

TIMBER AT THE HEART OF THE COMMUNITY

sense of quiet enclosure and a notional extension of the village green.

The homegrown Douglas fir framed buildings use authentic agricultural building materials, such as galvanised corrugated steel roofing and larch cladding. A simple and honest construction typology ensures that the project looks like the way it was built. The guest bedrooms are supported by new ancillary service areas, including housekeeping and linen stores, and staff accommodation.

The new timber frame buildings include the Sheds, Field Barn, Stables and Tack Room. Double member ‘cloister’ columns engage stainless steel feet sitting on cast concrete upstands. Adjacent to the front gate, the Sheds is a single-storey infill building between existing brick outbuildings with two staff bedrooms and a bathroom. It is clad in larch with a pan-tile roof to match the outbuildings. The Field Barn is a south facing, two-storey structure with four guestrooms. The lower level is clad in larch while the upper level is sinusoidal galvanised steel. There are no windows to the north and west to prevent overlooking and light pollution to the neighbours. The Tack Room, a single-storey structure with a wheelchair accessible guestroom, sits adjacent to the west boundary and the Field Barn.

Set in the Yorkshire village of Nun Monkton and named after a famous 19th Century racehorse, the Alice Hawthorn is the village’s last remaining pub. In recent years, this critical meeting point and social hub for the local community was in economic decline and had come under threat. Creating an innovative new economy around assets such as the village pub is essential to the health and well-being of any rural community.

Close, collaborative consultations with Harrogate Borough Council and the local community informed the project’s design. The scheme includes twelve ensuite guest bedrooms, four on the first floor of the pub and eight around a new courtyard, which extends the village green into the pub’s rear garden. The project takes its inspiration from the Norse ‘garth’ (‘grassy cloister’ or ‘clearing in the woods’), creating a

The structural frame is UK-grown Douglas Fir, the external cladding is FSC-certified larch and the internal sarking is PEFC-certified poplar plywood. The Douglas fir frames were prefabricated as components and then assembled as two-dimensional ‘layups’ in the workshop before being delivered and re-assembled on site. In the workshop, traditional carpentry techniques were used alongside more modern routers and jigs to aid the repeated nature of the structure.

28 STRUCTURALTIMBERMAGAZINE.CO.UK w COMMERCIAL

01

De Matos Ryan has transformed The Alice Hawthorn with the addition of twelve guest bedrooms and the renovation of its Grade II listed pub – and used homegrown timber to do it.

This sense of readiness allowed for each building to only take approximately one week to erect on-site and then once cloaked in sarking allowed for both internal and external teams to make progress simultaneously thereby cutting typical site times.

Internally, in contrast to traditional pub interiors, the newbuild elements have no plaster and are lined with larch boarding and poplar plywood. Subtle distinctions between the timber species are blurred by a tinted treatment. A ground source heat pump provides heating and hot water, supplied by bore holes and supported with high

levels of non-combustible mineral wool insulation and airtightness to a standard higher than current Part L2A building regulations. The timber frame buildings are naturally ventilated through use of high-level clerestory windows and rooflights on actuators. To ensure accessibility for all, level threshold access is provided to all buildings. On completion, the new builds scored an EPC ‘A’ rating.

Client and Nun Monkton local Kate Harpin said: “We were very excited with the shape of the plans as they evolved, and the finished result has exceeded our expectations. We have

twelve beautiful guest bedrooms, every one of them perfect in its own way.” De Matos Ryan Director Angus MorroghRyan added: “It has been an honour to collaborate with such a brilliant client and contractor team, and together ensure that this village pub will continue to sustainably service its community but also welcome visitors from afar.”

www.dematosryan.co.uk

IMAGES: 01-03. The Alice Hawthorn has won many plaudits for its mix of architectural detail and sustainability. Courtesy De Matos Ryan/Hufton+Crow

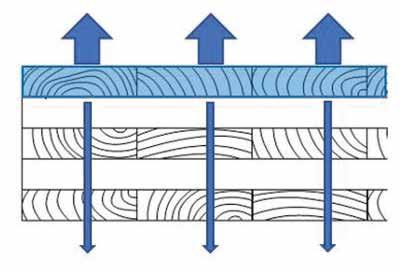

Building Product Design – and in particular Glidevale Protect – offer a tailored consultancy service for offsite manufacturers and work closely with modular partners including manufacturers of structural timber, CLT, SIPS, light gauge steel and hybrid frame systems to ensure its products are suited to offsite construction.

The company’s extensive product ranges from its three subsidiaries – Glidevale Protect, Passivent and Kingfisher Louvres – is designed to meet strict environmental criteria and create buildings which are pleasant places to live or work in. The range encompasses products for thermal efficiency, airtightness, ventilation and condensation control, making them ideal for offsite projects in the residential, education, commercial and public sectors – and all of which is covered in Building Product Design’s new offsite solutions brochure.

Optimising materials delivery direct into factories and supplying a unique combination of high-performance construction membranes as part of a closed panel system, is just one way that the company can support the offsite manufacturing process, working with offsite manufacturers to enhance the pre-manufactured value (PMV) of the overall construction. It also offers timed deliveries to fit into often rigid offsite construction programmes, as well as undertaking site visits, and providing airflow calculations, thermal modelling, U-value calculations and condensation risk analysis, as part of its early design support.

Building Product Design’s products are manufactured in its two UK factories and

have all been developed specifically for UK and Irish requirements under the ISO 9001 quality standard. The manufacturer is also accredited to the international health and safety standard ISO 45001 and environmental standard ISO 14001. Many products are accredited to BM TRADA for extra peace of mind.

To download a copy of the new Building Product Design offsite solutions brochure visit: https://glidevaleprotect.com/sectors/offsite or email: info@glidevaleprotect.com to request a printed copy.

IMAGES: 01. Protect VC Foil Ultra

COMMERCIAL 29 STRUCTURALTIMBERMAGAZINE.CO.UK w

03 02

Combining innovation and technical expertise with almost 40 years’ experience as a supply chain partner, Building Product Design is adept at building healthy solutions for the offsite sector.

ALL WRAPPED UP

01

THE NINO REVOLUTION

Rothoblaas Engineer

Ernesto Callegari explains how angle brackets are developing and how the revolutionary NINO bracket could help deliver innovative timber structures.

Everything starts with the WBRs, the classic ‘squares’ for wood. This product family dates back to many years ago when timber buildings were small, simple, and standard. The family consisted of some great classics, such as the 70, 90, and 100 corner angles, widespread everywhere and present on all the shelves of building retailers. In short, they were honest, simple and cheap products.

As new construction systems began to emerge in the 2000s, the WBR became inadequate in some cases. The brackets were the same, but the evolving

structural regulations had to keep up with the increasing use of mass timber and the necessity to build tall multistorey buildings.

At Rothoblaas, we took on the challenge of creating a new angle bracket to cater to new market needs. We dared to change the classics and worked to develop three additional brackets specialised for mass timber structures – the TITAN N was born. These were not only larger but also modern and specialist: TNC200 and TCN240 are optimised for timberconcrete connections while TTN240 was developed for all-timber connections.

The Strength of TITAN

The small TITAN N family quickly gained interest among designers and builders throughout Europe, soon becoming a point of reference for cross laminated timber (CLT) construction. As the buildings needed to be higher and higher, there was a subsequent need to further develop the TITAN line, so we got to work and created specific products within the family.

TITAN F: lowered version of the TITAN N angle pieces and optimised for timber frame walls

TITAN WASHER: thick plate, to be superimposed on the bracket, to increase its resistance and stiffness in the most complicated situations

TITAN S: version with screws for 8mm diameter plates, with exceptional resistance and with the advantage of large diameter screws given by the speed of installation and the simplicity of uninstalling

TITAN SILENT: possibility of coupling a resilient profile to the angle, to ensure exceptional acoustic performance to the connection.

Thanks to the collaboration with its technical network, Rothoblaas patented another completely new concept: an angle in which small diameter nails or screws (4 or 5mm respectively) are used together with large diameter (11mm) all-threaded connectors. This is to obtain an angle with the strength and stiffness of all threaded connectors, combined with the ductility

30 STRUCTURALTIMBERMAGAZINE.CO.UK w PRODUCT INNOVATION

01

of small-diameter connectors. In doing this another strong product was born –the TITAN V opened up new paths and ways of designing timber buildings.

NINO Brackets

In a globalised and constantly evolving world, those who stop evolving are lost. Innovations are ‘interpreted’ by the competition and therefore it is essential to continue investing in research and development. For this reason, after developing TITAN, Rothoblaas has decided to open the research to another concept – even small structures deserve great solutions.

This is how we created NINO, a family of small universal angle brackets: versatility at the highest levels, low cost, and lots of technique, the result of an extremely optimised design. The NINO brackets introduce the new concept of the universal bracket to the Rothoblaas range: designed for shear or tensile timber–concrete and all-timber joints, NINO is the bracket suitable for multiple fields of use.

It performs well on solid and laminated wood, CLT and LVL, timber frame structures, and other wood-based panels. The certified resistance values according to ETA-22/0089 for forces in all directions, allow multiple configurations both for fixing CLT walls and timber frames. Thanks to its versatility, NINO manages to solve unforeseen situations such as a raised installation from the wall laid on bedding mortar or root beam or by the presence of a plasterboard counterwall.

NINO is truly flexible and surprises in terms of yield and saving time and money. Key uses include:

Raised Installation on Concrete

For curbs up to 12cm high, the application of NINO guarantees the perfect transfer of forces thanks to the resistance values provided by Rothoblaas and is available to all professionals in the sector. On concrete, the additional washer allows for obtaining surprising resistances.

All-Timber