LIGHT STEEL FRAMING MAGAZINE LIGHT STEEL FRAMING MAGAZINE THE LATEST IN LIGHT STEEL FRAMING TECHNOLOGY DEVELOPMENT P18 SUSTAINABLE STEEL Verifying the Sustainable Benefits of LSF to Support Net Zero Construction P26 LIFECYCLE ANALYSIS A ‘Game Changer’ for the Light Steel Framing Sector in the Sustainability Stakes P32 PRODUCT INNOVATION A Ground-Breaking Through-Wall System that Incorporates a Range of Cladding Solutions LIGHTSTEELFRAMINGMAGAZINE.CO.UK ISSUE 6 | AUTUMN 2022 TRIED, TRUSTED AND RIGOROUSLY TESTED

PUBLISHING

FRONT COVER: Ayrshire Metals

PRINTED ON: FSC Mix paper by Buxton Press

In this issue...

Tried, Trusted and Rigorously Tested

Light steel frame - there are many advantages to this modern method of construction with the core ones being –cost, time and sustainability.

PUBLISHER:

Light Steel Framing Magazine is produced in partnership with the Light Steel Frame Association and published by Radar Communications: ©Radar Communications Ltd.

Radar Communications Ltd, 101 Longden Road, Shrewsbury, Shropshire, SY3 9PS

T: 01743 290001 www.radar-communications.co.uk

SUBSCRIBE TO RECEIVE: www.lightsteelframingmagazine.co.uk

ADVERTISING ENQUIRIES PLEASE CONTACT: Julie Williams // T: 01743 290001

E: julie.williams@radar-communications.co.uk

SEND US YOUR NEWS: T: 01743 290001 E: info@lsf-association.co.uk

FOR ENQUIRIES PLEASE CONTACT: E: info@lsf-association.co.uk

DISCLAIMER: The content of Light Steel Framing Magazine does not necessarily reflect the views of the editor or publishers and are the views of its contributors and advertisers. The digital edition may include hyperlinks to third-party content, advertising, or websites, provided for the sake of convenience and interest. The publishers accept no legal responsibility for loss arising from information in this publication and do not endorse any advertising or products available from external sources. The publisher does not accept any liability of any loss arising from the late appearance or non-publication of any advertisement. Content including images and illustrations supplied by third parties are accepted in good faith and the publishers expect third parties to have obtained appropriate permissions, consents, licences or otherwise. The publisher does not accept any liability or any loss arising in the absence of these permissions for material used in both physical and digital editions. No part of this publication may be reproduced or stored in a retrieval system without the written consent of the publishers. All rights reserved.

Industry News

Highlighting the latest construction industry initiatives, project developments and building technology innovations in the UK light steel framing sector.

Sustainability Guide

Timber may appear to have ‘greener’ credentials, but steel is one of the world’s most recycled materials with recovery and re-use rates in excess of 90%.

Offsite Awards –Best Use of Steel

At launch in 2015, the Offsite Awards were certainly ahead of the ‘MMC’ curve and now in their eighth year – 2022 witnessed record entries.

Passivhaus Case Study

Delivering substantially lower environmental impact whilst addressing the fuel poverty crisis through collaboration and a fabric first approach.

Building Safety

Coming in the wake of the Hackitt review, and receiving Royal Assent in April 2022, the Building Safety Act covers a raft of changes for developers.

3LIGHTSTEELFRAMINGMAGAZINE.CO.UK CONTENTS

04 06 18 24 36 41

TRIED, TRUSTED AND RIGOROUSLY TESTED

STEEL FRAMED BUILDINGS HAVE BEEN AROUND IN THE UK SINCE THE RITZ HOTEL (LONDON) WAS COMPLETED IN 1908 AND EVER SINCE THEN THE CONSTRUCTION INDUSTRY HAS BEEN WORKING HARD TO REDUCE WEIGHT AND COST ONSITE. STEEL FRAMING SYSTEMS (SFS) CONSIST OF LIGHT WEIGHT COLD-ROLLED SECTIONS RESULTING IN SAVINGS BOTH IN WEIGHT AND COST.

There are many advantages of this modern method of construction with the core ones being, cost, time and sustainability.

Costs can be saved in many ways by utilising steel framing systems, from reduced foundations, lower labour costs due to less time onsite and

savings on transport due to significantly less deliveries.

All projects are time critical and this is another area where steel framing systems come to the rescue. SFS is around 50% quicker than blockwork and takes the facade off the critical path.

Sustainability is so important and making sure we protect our environment for the future is crucial. Thankfully steel is 100% recyclable and a steel framing system can reduce the number of deliveries by over 90% therefore reducing the need for fossil fuels, lowering carbon emissions during construction.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK4 COVER STORY AYRSHIRE METALS

01

Further benefits of steel framing systems are:

• 66% less time to install over blockwork

• No hot-rolled support required unlike blockwork

• Material is not part of the fire triangle

• Not affected by wood eating insects

• Does not shrink, warp or rot

• System allows for movement of floors and facades

• Supports both the inner leaf of plasterboard and the outer facade

• Is able to achieve a high level of thermal performance

• Is lighter than blockwork or timber, therefore reducing foundation costs

Steel framing systems allows for the construction of pre-fabricated panels and modules offsite under factorycontrolled conditions, further reducing the time required onsite. Factory produced panels are highly accurate and easy to assemble onsite with no site waste. Early involvement with Ayrshire Metals and precise foundations are key with this form of construction. To gain the most from modular construction, it is best to start the design with this in mind and create as much duplication room-to-room as possible so that the minimum number of module designs are involved.

Ayrshire Metals have carried out fire testing gaining up to two hours fire rating on its steel framing systems, this coupled with the ability to achieve a high thermal U-value makes it the right choice for your project. Steel framing systems can be utilised on nearly any type of building from schools to apartments, hospitals to offices, and student accommodation to hotels. SFS does not just support a brickwork outer leaf but also render, cladding panels, terracotta tiles and more, therefore, providing the substructure to many different facade types to meet the architectural requirements for your project.

Early involvement and free indicative designs will help get your project started on the right path, making sure the structure is value engineered from the beginning. Ayrshire Metals’ engineers and sales team are on hand

to assist you with every stage of your project from concept to completion.

Get in touch to find out how we can help you, email: sales@ayrshire.co.uk or call 01327 300 990 .

For more information visit: www.ayrshire.co.uk

IMAGES 01-03. Factory produced light steel Framing systems are highly accurate and easy to assemble onsite. Images courtesy of Ayrshire Metals

5LIGHTSTEELFRAMINGMAGAZINE.CO.UK

COVER STORY AYRSHIRE METALS

02 03

OFFICIAL OPENING OF SIR JAMES DYSON FUNDED CENTRE FOR SCIENCE

Earlier this year, an official opening for the Dyson STEAM building took place at Gresham’s School in Holt, Norfolk. Following an £18.75 million investment in the project, construction of the centre was made possible by the generous donation from former Gresham’s School pupil Sir James Dyson.

The hub features state-of-the-art facilities, offering learning resources and opportunities in the STEAM disciplines of science, technology, engineering, art, and mathematics. It includes classrooms, laboratories, workshops, an auditorium staircase, and light, open, communal spaces.

Architects Wilkinson Eyre designed the Dyson STEAM building, working alongside the Dyson team, the school, local stakeholders, and the local authority. Kier won the contract for the build, located on the former site of the Britten Building, also constructed by Kier.

The structure combines a light steel frame with high-performance insulation, cladding and thermally efficient glazing. The 4,000m2 two-storey building features natural ventilation, photovoltaic panels, and ground source heat pumps to increase energy efficiency. The centres design complements the local environment while being sympathetic to its history and surrounding buildings. The light steel frame has been left exposed as part of the design feature, while the cladding is a mix of oxidised copper and large glass panels to enhance the light, modern aesthetic, with some of the panels set back to create open areas for outdoor learning.

Work on the centre began in 2021, and the project has since seen recognition from Constructing Excellence after being named regional winner (East of England) in the Integration and Collaborative Working category. Sir James Dyson attended the site in July to give a speech as part of an official opening event.

Speaking about the centre, Sir James said: “Gresham’s has a great tradition of nurturing creative minds, and I hope that the Dyson Building will inspire current and future pupils. The world needs radical and creative ideas which can solve the big problems we face, and I hope that many great minds will be fostered within these spaces. Having art and design in the same building as engineering, science and maths introduces the notion that engineering, and science are creative careers. Wilkinson Eyre’s floorto-ceiling glass and wide corridors evoke a sense of adventure, and the auditorium staircase encourages discussion and integration of the disciplines within.”

LIGHTSTEELFRAMINGMAGAZINE.CO.UK6 INDUSTRY NEWS

Images: Gresham’s School/Wilkinson Eyre

FRAME ANY SPACE IN A FLASH. To find out more, visit Howickltd.com Trim time off every job with the innovative telescopic steel framing that extends to fit the most difficult spaces. With no re-work and zero wastage, X-TENDA™ 3600 can cut installation time by up to 50%.

METEK TAKE HOME AWARD FOR WATERFRONT PLAZA

Leaders in light steel construction solutions, Metek PLC, are celebrating a prestigious award win following this year’s Construction News Specialist Awards on 22 September. The Waterfront Plaza project, Phase 2, was named ‘Project of the Year by a Specialist Contractor (subcontract from £1m to £5m)’ in a ceremony held at The Brewery, London.

Located in Leith, Edinburgh, Waterfront Plaza is a high-profile residential, mixed-use development scheme on a key gateway site. Metek was selected to provide the light steel structure, balconies, and steel purlin roof for the buildings, which offer a mix of apartments and commercial studios.

Judges at the Construction News Specialist Awards cited Metek’s efficiency, forward-thinking, and commitment to social value, sustainability, and innovation as being among the reasons for selecting the project as the winner.

Managing Director of Metek, Oliver Rogan said of the team’s win: “To say I am proud of this business is an understatement. Every day our incredible team here at Metek outperforms the market, and it is their commitment and passion that have enabled us to stay at the top of our game and achieve this prestigious accolade.”

Waterfront Plaza offers spacious, contemporary apartment homes in an area named by The Sunday

Times as the ‘Best Place to Live in Scotland’ and offers waterside views across Victoria Quay. The development also provides excellent connectivity to the city centre, with cycle paths, public transport, and a planned tram extension giving access to Edinburgh and the nearby airport.

Image: Cala Homes/Metek

Leading manufacturer of cold rolled steel components and panellised structural steel frames, Sigmat – has won the contract to deliver a new residential development on the site of a former brewery. The project, which commenced in August and will last 32-weeks, will see the construction of two 25-apartment housing blocks in Riverside, Sunderland.

The development forms part of plans to encourage people to take up residence in the city centre, and will eventually offer up to 2,500 new homes across a number of newly created neighbourhoods. Working collaboratively with developers Tolent, Sigmat will be integral in ensuring the project achieves its goals of delivering homes that offer modern living built to 2025 Future Homes Standard and 21 to Passivhaus standard.

Sigmat were selected to provide the steel structures for the development due to the sustainability benefits of steel usage, and their ability to deliver a cost-efficient and rapid solution to ensure faster build times.

Sigmat’s Pre-Construction Manager, John Ritchie spoke of their involvement in the project, saying: “It is great to be working with the Tolent team to deliver sustainable housing in the region. We are delighted to see more main contractors embracing modern methods of construction helping to reduce the overall carbon footprint of the development.”

Sunderland Council have plans to establish four neighbourhoods in total, the project forming part of a development road map that aims to double the residential population in the city centre, increase job opportunities and promote commercial and leisure offerings by creating homes for up to 2,500 people.

Image: Sunderland Council/Tolent

LIGHTSTEELFRAMINGMAGAZINE.CO.UK8 INDUSTRY NEWS

SECURE BREWERY PROJECT CONTRACT

SIGMAT

WATES GROUP DELIVER FOR DEPARTMENT OF EDUCATION

Construction of a 72,300sq2 multimillion-pound secondary school building in Middleton, the first of six within the northwest via the Department for Education’s (DfE’s) Modern Methods of Construction Framework, has been completed by the Wates Group.

Edgar Wood Academy welcomed its first intake of students in September. The school, designed by architects Sheppard Robson, will provide state-ofthe-art education facilities for pupils between 11 and 16 years old. The building is operated by the Altus Education Partnership and features 23 general classrooms and 34 specialist classrooms alongside sporting facilities and outdoor recreation and leisure spaces.

Speaking about the project’s completion Dave Saville, Managing Director, Wates Construction North, said: “Edgar Wood’s completion provides a stellar example of how offsite construction can revolutionise the delivery of education builds. The lessons learnt on this build will support both Wates’ other DfE projects procured via the Modern

Methods of Construction Framework and help champion the use of MMC on other schemes across the country. Delivering this project efficiently was imperative to allow students to benefit from their improved facilities as quickly as possible. We hope the students and staff enjoy their new school and we look forward to our next completion as part of this framework.”

The successful completion of the project came as a result of collaborative workings between Wates, the architects, and other parties involved in the construction. Wates appointed EOS Framing to design, engineer, and manufacture their advanced light steel Pre-Assembled Frames (PAF) infill system for the school. EOS successfully delivered on the project, the steel frame ensuring compliance with the regulatory 70% PMV set within the DfE’s MMC framework agreement.

The precision engineered PAF infill system was manufactured, prefabricated and preassembled offsite in controlled factory conditions. EOS delivered the system to the site as assembled panelised units encapsulating light steel framing and external

Siniat Weather Defence sheathing ready for glass mineral wool insulation and Siniat internal wall linings to be applied onsite. By using this system, speed of construction was faster than alternative build methods. EOS also provided professional guidance and support throughout the project to ensure maximum PMV.

Patrick Heisel, Projects Director, The Department for Education said: “We are excited and proud of the new facilities that have been provided to meet the educational needs of families in the Rochdale community, and we look forward to welcoming students from the surrounding areas to their new school.”

Wates is currently working to deliver more schools through the same framework, with construction going ahead on the Star Salford Academy in Little Hulton, due for completion for the 2023-2024 school year.

INDUSTRY NEWS 9LIGHTSTEELFRAMINGMAGAZINE.CO.UK

Images: DfE/Sheppard Robson/ Wates Construction/EOS Framing

EXTENSIVE 20 YEAR PROGRAMME IN FINAL PHASE

Kidbrooke Village, an extensive project encompassing multiple residential, leisure, and community facilities in one of London’s most popular areas, has already seen more than 1,500 new homes provided by Berkeley Group. Located on the former site of the Ferrier Estate, Kidbrooke Village is a £1 billion regeneration plan to transform the area.

The development plan, spanning a twenty-year programme which began in 2009, includes four neighbourhoods and eighty-six acres of open space. The scheme has already brought significant improvements to the Royal Borough of Greenwich, which will increase as the regeneration continues.

The scheme will utilise light steel framing systems for the external walls along with a vapour control layer. The light steel system used for Blocks E and J were given Green Guide ratings of A+ by Hodkinson Consultancy, a specialist energy and environmental consultancy for planning and development, according to the BRE’s Green Guide to Specification.

Kidbrooke Village will offer 4,882 mixed-tenure homes, healthcare facilities, shops, and a railway station. The neighbourhoods include City Point, The Village Collection, The Nature Collection and The Blackheath Collection (freehold townhouses, apartments and podium houses) and is anticipated to inject £65.7 million in contributions to local infrastructure and services. There are also 70 homes specifically designed for elderly residents, located closer to local amenities for easier access and a number of affordable homes.

Kidbrooke Village offers local community living within the city, ensuring green, sustainable spaces with open parkland to foster community events and socialisation. New trees, paths, and parkland have been created to ensure environmental sustainability to support local green infrastructure. There are seven phases to the scheme in total. Phases 1 and 2a of the project were delivered between 2010 and 2014, with over 1,000 new homes built and 8,000 new jobs created. The final phase is due to be completed in 2030. The latest batch of homes, which will be completed by 2025, were released for purchase this month.

PATCHWORKS DEVELOPMENT BRINGS NEW HOMES TO WALTHAM FOREST

completed onsite, with the steel frame systems installed by Keylon Interiors.

The Blackheath Collection offers one, two, and three bed apartments with modern design inside and out.

Images: Berkeley Group

Waltham Forest Council granted permission for work to begin on the former Homebase site in 2021, which will feature energy-efficient buildings, environmental improvements, and the planting of new trees to create green spaces.

The Patchworks development is currently under construction, with a target completion date of March 2025. Significant work has already been

The Patchworks development is part of this larger-scale project, and will offer around 580 new homes, combining affordable housing, community and commercial space with gardens and play areas. The scheme is part of a plan to meet ambitious targets set by the council to solve the growing demand for housing in the borough.

The development will consist of a mix of four to seven-storey buildings. There will also be a focus on creating community amenities and

leisure spaces, including cycle paths, a cycle hire scheme, EV charging points, and a mobility hub. Groundwork commenced in February of this year, as work began on Blocks A and C of the project.

Light steel framing specialists, Voestalpine Metsec will provide site inspections and reports as part of the design service and collateral warranty. The development is being managed by Inland Homes, an AIM-listed specialist house builder and brown field developer dedicated to achieving excellence in sustainability and design.

INDUSTRY NEWS

LIGHTSTEELFRAMINGMAGAZINE.CO.UK10

A regeneration project across the London borough of Waltham Forest, is set to put the London Plan vision into operation ultimately bringing 18,000 new homes to the area.

The completion of a multi-million pound deal between leading housebuilder Wilmott Dixon and Cambridgeshire-based housing provider Cross Keys Homes will see 315 new affordable houses constructed in Peterborough. Partially funded by a £12.5 million grant from the Cambridgeshire and Peterborough Combined Authority, the project is due to be completed by October 2024.

The ten-storey Northminster scheme will consist of one to three-bedroom apartments, which will be available for rent, with the first homes expected to be ready for occupants in autumn 2024. The project valued at £70 million, will be located on the site of a former multi-storey car park and nightclub. The previous buildings have already been demolished, with Wilmott Dixon handling groundwork onsite before the completion of the development contract.

The project will use offsite construction elements, including a light steel frame structure, clad in brick slips, and the use of modular bathroom pods manufactured offsite to exact specifications. The use of offsite manufacturing will enhance the performance, quality, and sustainability benefits of the build. Wilmott Dixon will be working alongside a specially selected project team which includes architects Corstorphine & Wright, planning consultants ELG, structural engineers SBK, and mechanical and electrical engineers Briggs & Forrester.

Speaking about the project, Wilmott Dixon’s Director, David McCallion, said: “We’re pleased to have now signed contracts with Cross Keys Homes for this fantastic ten-storey flagship development. This is a hugely significant regeneration project, and we will be using innovative construction methods to build better, greener, and smarter.”

Cross Keys Homes Chief Executive, Claire Higgins, further added to the comments saying: “We are delighted to have signed contracts with Willmott Dixon to deliver this flagship scheme for the city, which will provide 315 new affordable homes. Willmott Dixon’s purpose is to deliver brilliant buildings, transform lives, strengthen communities and enhance the environment, which goes hand-inhand with our core objectives and makes them the ideal partner for this exciting development.”

LIGHTSTEELFRAMINGMAGAZINE.CO.UK12 INDUSTRY NEWS

Images: Cross Keys Homes/Wilmott Dixon

WILMOTT DIXON DEAL WILL SEE AFFORDABLE HOMES IN PETERBOROUGH

The Baird Family Hospital and Anchor Centre, a £224.8 million development in Aberdeen is one of the largest NHS projects in the UK, with the first buildings due for completion in 2023.

The healthcare facilities will include state-of-the-art research and development space, and enhance the provision of clinical care in the area. The main construction began in January 2021, following site preparation and enabling works.

Light Steel Frame Association member TekBuild has been involved with the project, supplying the structural steel framing systems for the development, and working with main contractor Graham’s, to deliver and install the system.

The Baird Family Hospital, located at the Foresterhill Health Campus, will vastly improve access to healthcare and clinical support including community led maternity, neonatology, and radiology services together with operating theatres. The hospital is due

to open in 2024, while the Anchor Centre will open next year. Progress on the site can be seen via a number of time lapse videos which are available at www.bairdanchor.org

Image: Baird Anchor Trust

INDUSTRY NEWS Vertex BDVertex BD One BIM software platform to drive your entire building project from start to finish Increase Productivity, Improve Quality, Minimise costs. how we canContact our Harrogate based team today to learn help you with your next project. • Automated steel framing, boarding and insulation generation • Architectural design • Automated drawings, BOM and CNC data • Precise project documentation • One software, one model. It’s All About BIM Vertex BD Marketing Project Archive IFC Collaboration File Format Conversions Production Automation Sales Architectural Design Framing www.VertexCad.comwww.vertex.fi It’s All About BIM Vertex BD Marketing Project Archive IFC Collaboration File Format Conversions Production Automation Sales Architectural Design Framing T +44 (0)1423 500211

AMBITIOUS NHS PROJECT BEGINS SECOND PHASE

ETEX MAP OUT ROAD TO SUSTAINABILITY BY 2030

Light Steel Frame Association member and leader in lightweight construction solutions, Etex, have published its Sustainability Report, detailing its commitment to achieving ambitious environmental goals across five priority focus areas. The report, full details of which are available to download from the Etex website, sets out their Road to Sustainability 2030.

The eighty-one-page report looks at Etex's achievements in driving the sustainability conversation forward over the past twelve months. It also contains guidance on the changes needed –particularly regarding health and safety, engagement, diversity and inclusion, decarbonisation, and circularity.

The report also stresses the importance of sustainability as a key strategic driver in the construction sector, particularly in light of the long way the UK still has to go to meet carbon reduction targets. The report highlights the commitment Etex has made to establishing themselves not only as sustainability leaders, but champions of positive change.

Amongst these achievements, improvements made by Etex in their production processes has led to reduced wastage, amounting to more than 45,000 tonnes of waste avoided in 2021. In recognition of this and other efforts to drive sustainability, Etex received a silver medal from EcoVadis, the world’s largest and most trusted provider of business

SFS EXTENSION FOR YORK HOSPITAL

York Hospital is building a multi-million pound two-storey light steel frame extension to improve the emergency department.

This requires significant work to deliver a vital new eight bedded resuscitation area, along with improvements to both the waiting room and the consultation and treatment areas to increase capacity and provide better care for patients.

Work is due to take 60 weeks to expand and redesign the department’s urgent and emergency care facilities. The extension to the emergency department includes twelve new assessment and treatment cubicles. The children’s waiting and treatment area will

sustainability ratings, for best-in-class sustainability management. The silver medal gives Etex a position in the top 25% of all companies evaluated by EcoVadis.

Bernard Delvaux, CEO said: “Today Etex has sustainability as a guiding compass of business transformation, with objectives that reflect the company’s ambition. We are on an exciting journey

towards improving sustainability in the short and long term. We know there is a long road ahead, which is why we invite all our stakeholders to further support us in becoming a leading benchmark in our industry.”

To read the Etex Sustainability report, go to: www.etexgroup.com

be separate from the adult area. There is a new resuscitation zone which will increase capacity significantly, with a dedicated area for children. There will also be a new infectious diseases cubicle that includes a point of care testing laboratory and glazed

cubicles for privacy and infection control. The project is being managed by Kier with Brebur delivering the steel framing systems package.

Image: York Hospital/Kier/ Curtins

LIGHTSTEELFRAMINGMAGAZINE.CO.UK14 INDUSTRY NEWS

T Lott recently announced the completion of Spa Road student accommodation in South London for Graham Construction. Their scope included both internal and external works on the new-build project including the installation of the light steel framing system supplied as part of an Etex Group package.

Designed by Maber, the development comprises 185 student rooms based across six storeys with a

Setting

range of amenities including a gym and bike storage. There is also a number of indoor and outdoor areas dedicated to socialising, such as a rooftop terrace and external courtyard.

Graham Construction was awarded the contract in June 2021 by Student Urban Living Bermondsey to build the new £13 million accommodation block.

Graham Regional Director Rob Joyce said: “Southwark is home to six of London’s universities

and requires high-quality accommodation to support its growing and diverse student population. This is a strong scheme that puts the student experience at its heart, giving them independence in a professionally managed environment that allows them to thrive, learn, and socialise.”

Image: Graham Construction/T Lott

BeA ssured

INDUSTRY NEWS

THE POWER OF FASTENING BeA your partner for offsite timber and light gauge steel frame construction BeA Autotec Made in Germany

the standards for offsite fastening 01482 889 911 sales@uk.bea-group.com www.bea-group.uk

for

names in timber

Across Europe and worldwide, BeA’s fastening technology, tools and consumables are the trusted choice

some of the biggest and best known

frame offsite construction

products, competitive prices and the

of service and delivery you can depend on

STUDENT ACCOMMODATION FOR SOUTHWARK

Reliable

kind

from BeA. NEW

CONSTRUCTION TO START ON NEW BIRMINGHAM ACADEMY

A project to deliver a new school in Winson Green will utilise sustainable building methods as part of the Department of Education (DfE) strategy to make all schools net zero by 2030. The Windsor Olympus Academy will be designed in accordance with sustainability strategies laid out by the Windsor Academy Trust, which has appointed BAM construction as the principal contractor.

The project will run until August 2023, with the first intake of students scheduled for September 2023. The tenth school to join the Windsor Academy Trust, Windsor Olympus, will offer state-of-the-art facilities, specialised classrooms, and extensive sports and performing arts facilities. The academy will provide 900 spaces for 11 to 16 year old students.

It aims to be a thriving part of the local community and includes an eco garden and learning resource centre.

The team behind BAM Construction have amassed unparalleled experience in delivering projects in the education sector, having worked with the DfE and the CIBSE school design group to drive improvements in construction programmes relating to sustainability and carbon neutrality. The company was recognised for its achievements in 2019 when they were named Education Contractor of the Year at the Education Estates Conference. Since 2009, Bam Construction has created more than 89,000 pupil places and 661,000m2 of education facilities.

The DfE published its framework for the construction of schools in April 2022, outlining aims to make

MMC REPRESENTATIVE BODY IN IRELAND

Following the commitments made by the Irish government to promote the use of Modern Methods of Construction (MMC) as a sustainable, high-performing construction process, industry professionals have established a new representative body, MMC Ireland.

Engineering consultants, Evolusion Innovation, have collaborated with C+W O’Brien Architects, and intend for MMC Ireland to be instrumental

in promoting Ireland’s offsite sector, both locally and internationally.

The representative body will work to develop a deeper knowledge and understanding of Modern Methods of Construction, both within the industry and end consumers. MMC Ireland will also address legislative and regulatory changes and issues, giving a voice to offsite construction professionals, offer guidance and support, and look at routes for further

the UK a global leader in sustainability by reducing direct and indirect carbon emissions from education buildings. Over the next few years, the DfE plans to accelerate the implementation of ultra-low carbon education projects built via their Gen Zero Platform. BAM has worked with the DfE on a Pathfinder project, researching and developing best practise to achieve net zero carbon schools.

Alongside Bam Construction, the midlands-based company DCL will work on the academy, with DCL providing the steel framing systems engineered and manufactured by EOS Framing.

Images: Windsor Olympus Academy/ BAM Construction

expansion of the sector through advocacy and engagement.

The inaugural meeting of MMC Ireland took place in May of this year; however, companies wishing to register interest or join the organisation can find more information at the MMC Ireland website: www.mmcireland.ie

LIGHTSTEELFRAMINGMAGAZINE.CO.UK16 INDUSTRY NEWS

CREATING SYNERGY ACROSS THE SUPPLY CHAIN Supporting the Circular Economy ACADEMICS SPECIFIERS Clients Architects Supply ChainInstallers ENGINEERS CONSULTANTS Manufacturers WWW.LSF-ASSOCIATION.CO.UK To be part of something bigger, contact us today… Call: 01743 290 030 Email: helen.martin@lsf-association.co.uk Light Steel Frame Association @LSF_Association LSFA MEMBERSHIP PROVIDES: Forward thinking with an inclusive culture – the Light Steel Frame Association unifies and unites construction professionals through: • Collaboration, joint venture and networking opportunities • Valuable industry intel and gaining direct access to the UK’s leading manufacturers • Opportunity to explore project parameters by joining the Design for Manufacture and Assembly debate • Key industry contacts and business development opportunities • Light steel frame insight and technical offsite manufacturing expertise • Access to the latest research and information sharing with industry pioneers

VERIFYING THE SUSTAINABILITY BENEFITS

When designers research build systems fire resistance, thermal and acoustic performance together with structural stability and cost are key drivers. However, the sustainability benefits of light steel systems are not widely understood.

With an objective to support specification through developing a better understanding of the benefits, the LSFA has launched an informative Sustainability Guide to verify the environmental credentials of light steel technology. Timber may appear to have a ‘greener’ image, but it is well documented that steel is one of the world’s most recycled materials with recovery and re-use rates in excess of 90%. So, steel performs better than timber when all factors are taken into consideration across the whole life of the building.

Sustainability is quantified in terms of various measures of environmental, social and economic performance. According to the World Green Building Council, construction and buildings in use are responsible for 39% of all carbon emissions in the world. This is broken down into two elements with 11% being linked to the manufacture of materials and construction processes known as embodied carbon emissions and 28% associated with operational emissions caused by heating, cooling and lighting systems when a building is in use.

Light steel performs well in embodied carbon and operational emission assessments. The key sustainability benefits show this to be a construction method which is highly sustainable and suitable for all sectors of the construction industry including

residential, commercial, education and healthcare. Light steel technologies include loadbearing and nonloadbearing elements which can be formed from panelised and modular systems or as steel studs for erecting as infill or oversail walling solutions.

HM Government ‘Construction 2025 (July 2013 Report)’ stated that the light steel frame sector was ‘an industry that has become dramatically more sustainable through its efficient approach to delivering low carbon assets more quickly and at lower cost, underpinned by strong, integrated supply chains and productive long-term relationships.’

As time has progressed steel has become part of a carbon neutral solution and sustainability is back at the top of the construction agenda.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK18

LIGHT STEEL FRAME ASSOCIATION

LIGHT STEEL FRAME TECHNOLOGY IS WIDELY SPECIFIED THROUGHOUT THE UK CONSTRUCTION INDUSTRY AND MEMBERS OF THE LIGHT STEEL FRAME ASSOCIATION (LSFA) HAVE DEMONSTRATED THAT IT IS A HIGHLY RELIABLE, ROBUST AND SUSTAINABLE METHOD OF CONSTRUCTION.

However, when budgets come into play it is safety, cost, programme, design adaptability and structural integrity which are more often the deciding factors, but the importance of sustainability must not be overlooked when assessing build systems.

The LSFA passionately believe that the answer to complex sustainability questions lie in a lightweight response. This is where light steel frame cannot be beaten, with the best strength to weight ratio of all construction materials.

This is particularly relevant when looking at lifecycle analysis including recycling at the end of a building’s life which must be factored in to any sustainability discussions. The Steel Construction Institute (SCI) publication ‘Protocol for Reusing Structural Steel’ concludes that the environmental advantages of re-using reclaimed structural steel are considerable, compared to the common practice of recycling by re-melting scrap. There are also potential cost savings to be considered which influence the system selected.

This protocol notes that material characteristics declared under CE marking procedures are designed to ensure that the material is as specified in design. When using reclaimed steel,

the design is based on the material properties (tested or conservatively assumed), maintaining the relationship between design assumptions and material resistance. It is therefore appropriate that re-fabricated, reclaimed structural steelwork may be CE Marked in accordance with EN 1090, which demonstrates its suitability for re-use.

It is also worth noting that the steel manufacturing environment is more automated than more traditional build technologies and the industry has become incredibly efficient at value engineering and minimising waste through design for manufacture and assembly (DfMA) approaches. This is assisted by the advances in digital engineering with better use of Building Information Modelling (BIM).

LIGHT STEEL FRAME - KEY ENVIRONMENTAL BENEFITS

Enhanced Speed of Build Leads to reduced build programmes and embodied carbon during construction.

Energy/Thermal performance

High levels of thermal insulation and airtightness reduce operational emissions by circa 20%.

Recycled Content

Higher levels of recycled content, industry norm of circa 40% based on manufacturers data.

End of Life Recyclability

Steel is one of the most recycled materials with a potential recovery/re-use factor in excess of 90%.

Lightweight

Allowing significant reduction in foundations, circa 70% relative to concrete/masonry construction.

Production Waste

Wastage is minimised as all steel off-cuts and drill swarf are recycled into new steel components.

Construction Site Waste Is virtually eliminated using prefabricated components, contributing to zero waste site targets.

Design for Reuse

Lightweight structures can be modified, extended and repurposed as they can be disassembled.

Durability

Light steel walls/ floors in warm frame applications have a predicted design life of up to 250 years.

Reduced Transportation Less vehicle deliveries, reduced by typically 60%, minimising environmental impact and pollution.

19LIGHTSTEELFRAMINGMAGAZINE.CO.UK LIGHT

ASSOCIATION

STEEL FRAME

02 4 SustainabilityGuideKey Sustainability Benefitsof LSF ConstructionLSFconstructionhasmanybenefitsincluding cost-effectivestructures,durability,sitesafety, quality,predictabilityofdeliveryandversatility. However,in worldwhereagreen,sustainable wayofliving/operatingisessentialthesustainable natureof offersmanybenefitswhichinclude:Speed build:Productivityandthespeedofconstruction on build due componentsbeingmanufacturedoffsite reducestheimpact thelocalenvironment.Fasterconstructionbringsanearlierwatertightenvelope,whichallowsearlieraccess follow trades.This to reduced buildprogrammesofcirca20%reduction compared traditionalconstruction. Energy/Thermalperformance: EmbodiedCarbonAssessmentsshowOperational Energy 67% theoverallcarbontotalthehighlevels thermalinsulationand tightnessachievedinLSFconstructionassist greatlyin area. Reduced Carbon Emissions: Substantialreduction (circa 20%) overallcarbonfootprintofabuilding. Recycled Content: LSF structuresbuiltusingsteelwith highlevel recycled content circa40%recycledcontentbasedon manufacturers data. End LifeRecyclability: is known thatsteelisoneoftheworld’smostrecycled materialswith potentialrecovery/re-usefactorinexcessof90%,andthere nowaste at unbolted/disconnectedSteelcomponentscanalsobe and dismantled for reuse the Lightweight:Lightgaugeframedsteel structuresaresubstantiallylighterthan atraditionalsteelframedbuildingsallowing ofsignificantreductionintheconstruction foundations,circa70%reductionrelativetoconcreteandmasonryaccordingtoSCIdata. Productionwaste:Steelwastageis minimisedbytheefficientuseofmaterials. drillfactoryproduction,allsteeloff-cutsand swarf sent re-cyclingbackintonewsteelcomponents. Construction Waste: Sitewaste virtuallyeliminatedusingpre-engineeredand fabricatedproductsocontributestozero wastetargetsonsite. Design Reuse:Thismaybe new thedisciplinetosomedesigners–however, deconstructedprocessisnotdifficult.Forexample, sectionsareinspectedandtested properties.verifytheirdimensionalandstrength Thesection thenshotorsandblastedtoremove coatings,refabricatedandprimed therequirements thenewproject.Lightweightstructurescan theymodified,easilyextendedandrepurposed bedis-assembled. • Durability:Lightsteelwallsandfloorsin warmframeapplicationshaveapredicted designlifeofup 250years. Reducedtransportation: thevolumematerialwhich be includedtypicaldelivery increasedwith therelessvehicledeliveries theproject(reduced typically60%).Thisassistsinreducing impactontheenvironmentandminimisespollution. maximise the benefits offsite construction,earlyidentificationofthetype offsitesystem construction.beusedleadstomorecost-efficient Thebenefitsofearlyincorporation ‘SpecificationLSFtechnologyisnotedinLSFApublication &EngineeringGuideforLight SteelFrameConstruction’.ThisGuideclearly demonstrates LSF theproducttochoose.Referto LSFAdocument more detail. www.lsf-association.co.uk Embodied Carbon There misconceptionaboutLSFconstructionandsteelinparticularin embodiedcarbondebate, steel notasgoodanoption astimberwheresustainabilityisconcerned. However,thestrengthoftheLSFstructurewhen assessedagainstthelowweightofthesteel usedequates improvedefficiencies lotofstructurecanbeformedwithnot lotofweight.reduces embodied carbon and where LSF technologiescome the aslighterstructures thenotonlyreducematerialconsumptionbutreduce concreterequired thegroundEmbodied carbon assessments known ascarbonfoot-printing)lookatmaterialsused, energyuse/performance,waste,transportation and based RICS and Standard guidanceandincludeinformationfromrelevant EnvironmentalProduct Declarations (EPDs) and publiclyavailableembodiedcarbondata.These assessmentsreviewthestructurefromfacilitating works/demolitionthrough fixturesandfittings/ buildingservicesaspartofthe60-yearwhole-life embodiedcarbonassessmentincluding:product, constructionprocess, use–maintenance/repairandrefurbishment,inuse waterandenergyand end life. Embodiedcarbonassessmentsarequite straightforwardinvolvingthemultiplicationof quantitiesofconstructionproductsandmaterials

carbon coefficients carbon emission factors. Quantities generallyderivedfroma‘takeoff’fromconstructiondrawings directlyfrom ofQuantities.Increasingly,designsoftwareisbeing

Embodied carbon assessment subset toolfullLifeCycleAssessment(LCA)whichisthe DeclarationsusedtodevelopEnvironmentalProduct (EPD)whichareincreasingly used constructionquantifytheenvironmentalimpactsof products. Tovalidatethesepositivestatements,whole-life carboncycleanalysishavebeencarriedout toassesscredentials/performancewhencompared construction.structuresformedusingothermethodsof Theseassessmentsshowthatlightframe structures demonstrate substantial reduction theoverallcarbonfootprintofbuildingof to20%. assessment medium scale residentialpropertyhasbeencarriedoutbytheLSF industryandcan foundinareporton SteelConstruction.infowebsite.Thefigures thisreportshowthebreakdown thekeyelements are follows: is clearthat the ‘bigwins’are the operationalenergyand product/materials and these areas arewhere benefits LSFtechnologycan be seen. Embodied CarbonAssessments and LCA’s may available from manufacturerswhich can demonstrate the green credentials ofthe relevant LSFsystem. Manufactureofconcretegenerates the carbonemissions almost times much entireaviationindustry. OperationalEnergy 67% Product Materials21% Maintenance 8% Transport 2% Endof disposal1% Construction <1% LSFA SUSTAINABILITY GUIDE For Light Steel Frame Construction www.lsf-association.co.uk

SUSTAINABILITY GUIDE

the guide

environmental and key sustainability

reducing embodied

download the Sustainability Guide, go to: www.lsf-association.co.uk

(generallyonaweightbasis)withembodied

developedtoautomatetheassessmentprocess.

LSFA

Areas covered in

include

benefits of light steel frame construction, means of

carbon, accommodating environmental enhancements now and in the future. There are also references for further reading which covers the subject of sustainability in more detail. To

A TRIUMPH FOR OFFSITE CONSTRUCTION AND LIGHTWEIGHT STEEL

constructed in unison – chasing the finished steel modules up the building.

Offsite construction of the building’s steel framed modules not only ensured time saving benefits compared to more traditional methods, but also quality of product with each one being manufactured in optimal facility conditions for consistency of quality. Furthermore, carbon reduction efforts were achieved through the reduction in transportation movements to and from site meaning less trucks needing to complete journeys for the finalised modules.

Lewisham Exchange

One project that has benefited from offsite technology is the Lewisham Exchange development. Offsite construction methods were chosen due to the time saving properties and cost benefits provided. However, the development did not concede on design or aesthetics.

The Lewisham Exchange stands more than 100m at its highest point, making it the tallest modular student accommodation building in Europe. It is built from 3D volumetric structural steel modules, which were completed offsite by specialists Vison Modular. The innovative volumetric modules are manufactured using integrated structural steel framing with solid concrete floors built-in.

The twin-tower block structure consists of 35 and 20 storeys and accommodates more than 750 student

apartments and around 70 affordable homes. Meanwhile its commercial properties at the foot of the structure achieved an ‘Excellent’ BREEAM rating, putting them in the top 10% of buildings from a performance perspective.

Structural Steel for Offsite Construction

The use of 3D volumetric structural steel framed modules enabled on site construction to be streamlined and contributed to the impressive 35-week completion of the brick slip cladding installation by Century Facades Ltd, who also carried out the window installation offsite.

The build saw the housing ‘mods’ manufactured in optimal facility conditions, including windows, which were then delivered to site where they were erected around the building’s lift cores. Then once ten or so storeys were complete, the external envelope’s Mechslip brick cladding was

Importantly, the development also breaks the narrative surrounding modular structure builds and their limited design availabilities that come with the technique. As, although the modular construction method was used, Lewisham Exchange showcases incredible architectural and aesthetically pleasing detail thanks to the synergy between lightweight structural steel solutions and the latest innovations in cladding technology.

The Lewisham Exchange development is an example of how innovative technologies such as offsite assembled steel frames and complementary lightweight cladding systems can combine with the increasingly popular offsite construction processes to make real-world gains on sustainability, time, and cost efforts across a modern new build – all without compromising on aesthetics and quality.

For more information visit: www.ashandlacy.com

LIGHTSTEELFRAMINGMAGAZINE.CO.UK20 ADVERTORIAL

THE

CONSTRUCTION

SITE HAS CHANGED DRAMATICALLY OVER THE YEARS, WITH SAFETY, SUSTAINABILITY, EFFICIENCY, AND LEGISLATION ALL DRIVING FACTORS THAT HAVE LED TO PRODUCT INNOVATION AND MATERIALS USED, AFFECTING HOW

CONSTRUCTION

METHODS ARE APPROACHED. BUT NOW DEVELOPERS AND

CONTRACTORS

ARE LOOKING AT OTHER MEANS TO MAKE GAINS. MOST NOTABLY THE

CONSTRUCTION

PROCESS AND METHOD ITSELF.

Ideal for high-rise recladding and refurbishment schemes, Ash & Lacy rainscreen cladding systems allow you to create complex and interesting non-combustible façades with the reassurance of comprehensive testing and accreditation to the latest industry standards, as well as an A1 or A2,s1-d0 fire rating.

Scan the QR Code to fi nd out how we can really make a difference.

T. 0121 525 1444 E. facade@ashandlacy.com W. ashandlacy.com Recladding with Confidence

SIGN UP EARLY FOR OFFSITE EXPO 2023

The floorplan is filling up fast so book your space today and be part of the UK’s biggest offsite manufacturing showcase.

To book your stand or to request a floorplan, contact julie.williams@radar-communications.co.uk or call 01743 290042 WWW.OFFSITE-EXPO.CO.UK AN IMPRESSIVE DISPLAY OF LIGHT STEEL FRAME TECHNOLOGY AT OFFSITE EXPO 2022

LIGHT STEEL TECHNOLOGY TAKES CENTRE STAGE

As an advanced and versatile technology in the offsite portfolio, light steel framing systems featured throughout the categories including Education Project of the Year, Private Housing Project of the Year, Infrastructure Project of the Year – not to mention the Product Innovation Award. But the Best Use of Steel was the most fiercely contested category. Winner – Best Use of Steel Technology There can only be one winner and the teams at Broadland Housing Association, Sigmat and R G Carter triumphed on the evening for their Canary Quay project – a four-phased light steel framed development of 323 high specification waterside apartments on the River Wensum near the centre of Norwich.

Phases 1 - 3 comprise 222 one and two-bedroom apartments in three separate developments which were completed in May 2021. The remaining 101 apartments of Phase 4 are planned to complete in December 2022. The development will contribute significantly to easing the pressure on housing waiting lists and will help those needing housing.

Offsite Awards 2023

The awards recognise projects large and small – it is technical innovation that catches the judge’s eye. So, if you have an outstanding project, now is the time to start planning for the 2023 awards. Supporting information and good imagery is also crucial to success, so start taking a photographic record which charts your offsite construction project from the ground up. The judges love technical detail of the structural system, so do not wait until the building is finished to appoint a photographer!

Taking place on the 19 September next year, the Offsite Awards submission portal will be open for entries early in 2023.

For more details on how to enter and the 2022 winners go to: www.offsiteawards.co.uk

IMAGES

01. Winners of Best Use of Steel - Broadland Housing Association, R G Carter and Sigmat 02. Best Use of Steel winning projectCanary Quay

LIGHTSTEELFRAMINGMAGAZINE.CO.UK24 OFFSITE AWARDS

AT LAUNCH IN 2015, THE OFFSITE AWARDS WERE CERTAINLY AHEAD OF THE ‘MMC’ CURVE AND NOW IN THEIR EIGHTH YEAR, 2022 WITNESSED RECORD ENTRIES. IT WAS NOT ONLY THE NUMBER OF ENTRIES THAT WERE EXCEPTIONAL, BUT THE CALIBRE OF SUBMISSIONS REVEALED HOW THE INDUSTRY HAS MOVED ON.

01 02

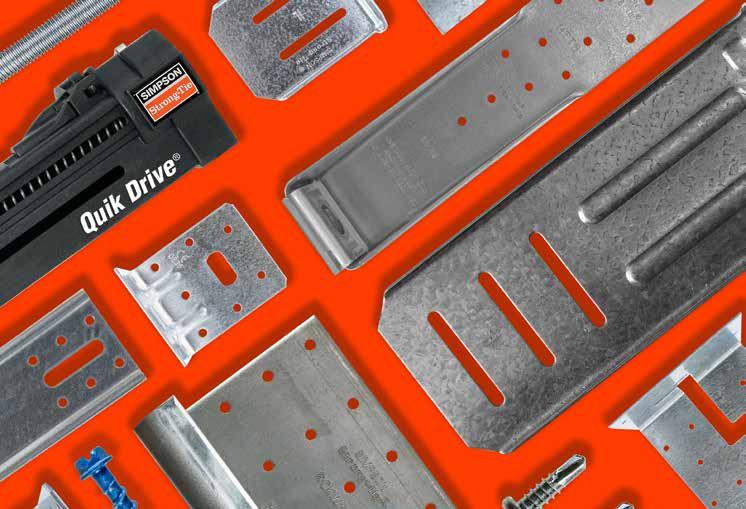

Connect with us: 01827 255600 | www.strongtie.co.uk | @strongtieUK Manufactured and performance tested for fast, cost efficient off-site construction. Introducing our dedicated range of connectors and fasteners for light gauge steel. t: 0121 389 1603 | e: info@metstructures.uk.com www.metstructures.uk.com MetStructures LIGHT GAUGE STEEL FRAMING SPECIALISTS Collaboration in Light Gauge Steel Frame The complete o site solution! • NHBC / SCI approved for up to 15 storeys Concrete decked mid-floors to all levels • Enhanced scope of works available for quicker access for follow-on trades • UKAS Fire-rated to 120 minutes • Steel Staircases included as standard • Cantilevered and Inset Balconies • Li Sha s including li guides • Full in-house service from design to installation • Suitable for Passive projects A leading supplier to the BTR, Residential and Multiroom sectors. MetStructures provides a fully engineered LGSF solution, collaborating from the earliest stages of a project. Pre-Construction // Design // Manufacture // Assemble // Installation Collaboration at all stages: 11 STOREY: 259 BTR APARTMENTS, DERBY Lighter // Stronger // Faster // Lower embodied CO2

LIFECYCLE ANALYSIS

EOS RAISING THE SUSTAINABILITY STAKES

ONCE ENVIRONMENTAL DISCUSSIONS FOCUSED

ON

LIFECYCLE ANALYSIS

INCLUDING RECYCLING BUILDINGS AT THE END OF LIFE. MORE RECENTLY THE FOCUS HAS BEEN ON EMBODIED CARBON. BUT THIS IS ONLY PART OF THE SUSTAINABILITY EQUATION WHICH REFLECTS THE MANUFACTURING AND CONSTRUCTION PHASE.

As part of Etex Group, sustainability is a key driving force in EOS Framing’s strategy and as innovators in light steel systems, the leading light steel frame manufacturer wants to inspire construction professionals to develop buildings that are not only safer but more sustainable.

Light steel frame construction is used extensively in the UK in a wide range of developments. The overriding benefits of safety, quality, speed, strength and value are widely acknowledged. But the sustainability benefits are often overlooked.

Environmental Product Declaration EOS has been awarded an Environmental Product Declaration (EPD) in accordance with EN 15804+A2 and ISO 14025 / ISO 21930. The

scope of the EPD is cradle to gate which provides information about the light steel framing systems impact upon the environment and includes a comprehensive Lifecycle Assessment. This assessment considers the extraction of raw materials, the manufacturing process, distribution and also its end-of-life value, such as whether it can be recycled or reused. Steel is an example of a highly sustainable building material with qualities well-suited to circular economic use and capable of being reused and infinitely recycled without loss of quality.

An EPD is an important validation tool for manufacturers such as EOS to provide transparent data about the environmental sustainability of its products and for specifiers to make

informed purchasing decisions. Taking EPDs into consideration when selecting materials for construction projects can help specifiers meet client sustainability requirements.

EPDs can also be used by specifiers to help control building waste, a significant environmental and costly issue currently faced by the construction industry and encourage the re-use and recycling of building materials at the end of their life. Furthermore, making informed product choices at the specification stage can contribute to the reduction of the developer’s carbon footprint over the lifecycle of the building helping reach net zero targets.

Recycle and Reuse

Manufactured from the most abundant component on earth, steel can be

LIGHTSTEELFRAMINGMAGAZINE.CO.UK26

01

recycled or reused endlessly without detriment to its properties. This unique characteristic gives steel a high value at all stages of its lifecycle. The recovery infrastructure for steel recycling is highly developed and extremely efficient and has been in place for decades. Current recovery rates from demolition sites in the UK are 99% for structural steelwork and 96% for all steel construction products – figures that far exceed those for any other building material.

Site waste is virtually eliminated by the use of prefabricated light steel systems compared to the industry average wastage of 10% in construction materials. Cold rolled steel components are manufactured to length, the swarf and offcuts produced which are minimal, can be recycled so there is no production waste.

A lifecycle approach will be a ‘game changer’ for the light steel framing sector in the sustainability stakes and long-term analysis will show that steel is intrinsically more sustainable than other construction materials. Its properties make it the ultimate sustainable construction solution in terms of its longevity, material and recycling properties and most importantly, enhancing the safety credentials of new buildings.

About EOS

In collaboration with Etex group partners, Siniat, a leading expert in plasterboard and drylining, together with fire protection specialists Promat and FSi – EOS has developed light steel frame infill non-loadbearing and loadbearing walling and flooring systems. The steel used is made from 59% recycled content and is 100% recyclable.

The EOS range of Pre-Assembled Frames (PAF), Thruwall® and Thrubuild® systems have been developed to eliminate uncertainty surrounding specification decisions and are covered in the EPD. All components – light steel frame, external and internal boards, glass mineral wool insulation, fixtures and fixings – have been rigorously tested together for fire, acoustic, weathering, airtightness,

and mechanical performance. Only tested configurations are available for specification. Following a validation process, Etex certify the EOS systems range and offer a 30-year product and performance warranty.

EOS Framing take their responsibilities as a manufacturer extremely seriously. Light steel frame systems are rigorously tested, manufactured under ISO 9001:2015 quality management standards together with specifications and durability standards CE/ UKCA EN1090 and are backed by Buildoffsite Property Assurance Scheme (BOPAS) Accreditation.

Delivering confidence and certainty in the construction process, EOS empower specifiers to be technical forerunners in the offsite sector and our Environmental Product Declaration can help reduce the carbon footprint of new buildings across all construction sectors.

For more information visit: www.eosframing.co.uk

IMAGES 01-03. Steel used is made from 59% recycled content and is 100% recyclable

27LIGHTSTEELFRAMINGMAGAZINE.CO.UK LIFECYCLE ANALYSIS

02 03

A CHANGE IN DESIGN PHILOSOPHY

Despite widespread agreement that offsite construction will feature heavily in the industry’s future landscape, some professionals question why the focus is primarily on the construction stage. Getting offsite right from the design stage maximises the potential savings and efficiencies, which influences the overall success of a project. If offsite construction is to meet the industry’s challenge of keeping up with demand, then offsite methods need to be baked

into the very design of a project. This will inevitably need a change in thinking and mindset.

Design for Manufacture and Assembly

Some industry experts are proposing that instead of ‘offsite construction’ being the accepted term, the industry should start to adopt DfMA, short for Design for Manufacture and Assembly to describe designs that are prepared with ease of manufacture

and assembly in mind. In DfMA, all aspects of a building are broken down into prefabricated components, with both the manufacture and assembly designed and optimised by engineering teams. This approach uses design as a way to create manufacturing solutions with standardised parts that are digitally tested, manufactured precisely, and assembled easily. We agree that language is important, however, this is arguably unnecessary and overly prescriptive, excluding projects that integrate elements of MMC at later stages. It is at best premature or overly optimistic. But putting the acronym of DfMA aside, putting design first results in highly efficient assembly lines and production facilities can be further developed, which benefit long-term supplier relationships while improving safety and ensuring consistently superior quality products. Building Information Modelling, or BIM, has an important role to play in enhancing workflows.

Benefits to Assembly and Manufacture

Through the use of digital design, offsite manufacturing allows facilities to develop highly precise fabrication methods that can be tested digitally first. The design-first approach means light steel structural components like panelised walls, for example, can be guaranteed to withstand construction pressures and fit seamlessly. Because offsite construction can make use of standardised components, these can be first modelled in a virtual environment and tested to ensure every stage of construction works as it should. Using design here means any potential issues with the component will be flagged before assembly. This is in contrast to traditional methods, where problems may not be unearthed until construction is in progress onsite.

About Horizon Offsite

Horizon Offsite is one of Europe’s leading players in Offsite Construction and Modern Methods of Construction (MMC), providing a fully accredited structural light gauge steel systems to the residential, industrial, commercial, healthcare and educational sectors.

For more information visit: www.horizonoffsite.ie

LIGHTSTEELFRAMINGMAGAZINE.CO.UK28 DfMA

OFFSITE CONSTRUCTION IS ON THE RISE, WITH GOVERNMENTS GLOBALLY PLACING THEIR TRUST IN IT AS A CREDIBLE WAY TO DELIVER MORE SUSTAINABLE, HIGH-QUALITY HOUSING QUICKLY. HERE EXPERTS FROM STRUCTURAL LIGHT STEEL SPECIALIST, HORIZON OFFSITE –CONSIDER IF THE ‘OFFSITE’ EMPHASIS SHOULD BE MORE ON DESIGN THAN CONSTRUCTION.

Our dedicated Supply Only team are happy to help with customers design and installation queries. Our product range and crushed end finish are perfect for the light gauge solution. Due to demand, our dedicated production line manages large volumes and quick delivery times. DEDICATED LIGHT GAUGE DIVISION FLOOR DECK SOLUTIONS DEDICATED PRODUCTION LINE FLOOR DECK FOR LIGHT STEEL FRAME CONSTRUCTION. www.smdltd.co.uk @SCIsteel steel-construction-institute assessment@steel-sci.com | +44 (0)1344 636525 www.sci-assessed.com Construction is an increasingly performance driven industry, there is an increasing requirement for products and services to be formally and independently assessed. Companies investing in assessment with the SCI are getting; an industry recognised brand, proven expertise and established supporting services. Manufacturers are using product assessment as a cost effective method of differentiating their product and accessing new markets. Join the growing list of companies that are investing in SCI Assessed by adding assurance for specifiers that products and processes meet current standards and regulations. Trusted independent assessment of your design process, product performance data or software. SCI Assessed

HEATON HOUSE

THE JEWELLERY QUARTER, BIRMINGHAM

The scheme consists of 14 townhouses having terraced gardens, onsite gated car parking and 42 apartments including six lofts. The landmark site dates back to the beginning of Birmingham’s Jewellery Quarter – circa 1795. The logistically challenging project, developed around a Grade 2 listed building, was completed by the Sigmat team in 23 weeks.

Aidan O'Gara of Kavannagh

Construction said: “This was our first project working with Sigmat, and we've been delighted with the results. The MMC advantage of programme surety and speed of installation onsite has encouraged us to select the Sigmat light steel frame system for our next project. We look forward to working with the team again.”

This mixed use development within Birmingham's Jewellery Quarter Conservation Area involves the redevelopment of the site with three, four and five storey buildings and refurbishment of Heaton House, which dates back to the Jewellery Quarters Georgian pre-industrial age.

The whole development will provide 57 dwellings including apartments and houses, plus 4,316ft2 of commercial floor space for A1, A2, B1(a) and/or D1 uses.

Dan Plater, Sigmat Site Manager said: “It's been a really enjoyable project to have worked on which presented certain logistical elements, such as its size and location, which made it a challenging and rewarding project. The client and installation crew made the build process a great environment to

have worked in. A special mention to those behind the scenes at Sigmat in transport, purchasing, design, detailing and CSC – a fantastic team effort.”

Architects D5 offered more detail.

The construction programme consisted of four elements:

• Refurbishment of Heaton House

• New build apartments to street fronting blocks

• New build townhouses to rear courtyards

• New build commercial space to the Powell Street frontage

These elements have allowed a clear hierarchy of building form and style to be established for the site within the wider Jewellery Quarter typology of development to the back of the pavement with more elaborate frontages enclosing courts of smaller, simpler forms creating inner spaces arranged perpendicular to the highway. Within the space created behind the perimeter blocks the courtyards are then arranged around the retained Heaton House. The courtyards are formed to illustrate the evolution of the site around from its original open pastoral setting to its entombed consumption by the expanding urban sprawl as the city developed.

For more information visit: www.sigmat.co.uk

IMAGES

Kavannagh

LIGHTSTEELFRAMINGMAGAZINE.CO.UK30 CASE STUDY

SUPPORTING ELEVATE PROPERTY GROUP AND KAVANNAGH CONSTRUCTION IN THE PRESTIGIOUS RESTORATION OF THE HISTORIC 19TH CENTURY GEORGIAN VILLA ‘HEATON HOUSE’ – LEADING MANUFACTURER SIGMAT, SUPPLIED 2,424 M2 TOTAL GIFA OF LIGHT STEEL FRAMING FOR THE PROJECT.

Construction/Elevate Property Group/Sigmat

Protected by Magnelis HyPer high strength steels Protected by Magnelis® coating industry.arcelormittal.com/framing • Stronger and more durable structures • Longer spans for flexible spaces • Outstanding protection against corrosion with Magnelis® • Lighter, for a lower carbon footprint S420GDHyPer®, S450GDHyPer®, S550GDHyPer® The HyPer range is compliant with Eurocode 3. image © beSteel Village of Dundrum, Co. Tipperary, Ireland Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Fabrication & Welding Workshop Capacity to produce 1000 fabrications per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw and drill line Peddinghaus plate processing Village of Dundrum, Co. Tipperary, Ireland Call Us at: (+353) 62 71102 email: info@dwyersteel.ie Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Stores Admin & Design Office Fabrication & Welding Workshop Capacity to produce 1000 fabrications per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw and drill line Peddinghaus plate processing Peddinghaus angle master machine 6m x 2m flat bed plasma bed www.odwyersteel.ie Village of Dundrum, Co. Tipperary, Ireland Call Us at: (+353) 62 71102 email: info@dwyersteel.ie Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Stores Admin & Design Office Fabrication & Welding Workshop Capacity to produce 1000 fabrications per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw and drill line Peddinghaus plate processing Peddinghaus angle master machine 6m x 2m flat bed plasma bed www.odwyersteel.ie Village of Dundrum, Co. Tipperary, Ireland Call Us at: (+353) 62 71102 email: info@dwyersteel.ie Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Stores Admin & Design Office Fabrication & Welding Workshop Capacity to produce 1000 fabrications per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw and drill line Peddinghaus plate processing Peddinghaus angle master machine 6m x 2m flat bed plasma bed www.odwyersteel.ie Village of Dundrum, Co. Tipperary, Ireland Call Us at: (+353) 62 71102 email: info@dwyersteel.ie Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Stores Admin & Design Office Fabrication & Welding Capacity to produce 1000 per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw Peddinghaus plate processing Peddinghaus angle master 6m x 2m flat bed plasma Village of Dundrum, Co. Tipperary, Ireland Stock yard Over 1000 tonnes held in stock 2.5 Acres Storage Area Heated Paint Shop Stores Admin & Design Office Fabrication & Welding Workshop Capacity to produce 1000 fabrications per week. (80 to 200 tonnes) CNC Machinery hall Gietart Shotblaster 2.No Ficep endeavour saw and drill line Peddinghaus plate processing Peddinghaus angle master machine 6m x 2m flat bed plasma bed One of Ireland’s & the U.K’s leading suppliers of CE certified structural steel

FUSION’S

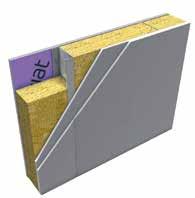

RANGE OF FIRE TESTED WALLING SYSTEMS IS EVOLVING

FUSION STEEL FRAMING HAS COMBINED TWO DECADES OF INDUSTRY EXPERIENCE AND TECHNICAL KNOWLEDGE TO EXPAND THEIR AWARDWINNING RANGE OF SOLUTIONS. PROVIDING PRECISION-ENGINEERED LIGHT STEEL FRAMING SYSTEMS OFFERING HIGH PERFORMANCE

COMBINED WITH NUMEROUS SAFETY AND SUSTAINABILITY BENEFITS, FUSION WORKS WITH CLIENTS TO ACHIEVE EXCEPTIONAL PROGRAMME BENEFITS THROUGH A RANGE OF FULLY INTEGRATED SOLUTIONS, INCLUDING THROUGH-WALL SYSTEMS, PODS AND PREFABRICATED UTILITY CUPBOARDS.

Established as a sector leader for over twenty years, Fusion offers unparalleled experience in design, manufacture and installation of light steel framing systems. Working at the forefront of high-performance structures, the company has collaborated with some of the largest contractors and developers in the UK construction sector to deliver over 20,000 student bed spaces, apartments, care homes and low-rise homes.

Tried and Tested FusionX™ FusionX™ is a fully tested noncombustible unitised walling solution which has been developed in response to Building Regulation changes. Approved by the NHBC, registered under NHBC Accepts, FusionX™ also holds LABC Warranty and is BOPAS accredited. This loadbearing system is SCI and NHBC certified up to 10 storeys and can form part of a structure up to 14 storeys.

Enhancing onsite productivity through maximised Pre-Manufactured Value (PMV) – FusionX™ is factory assembled for fast, cost-effective and qualityassured construction. Precision manufactured for rapid installation, FusionX™ can achieve U-values of 0.20W/m2k. The system provides developers and investors with a solution that offers a better strength to weight ratio than concrete, minimising groundworks and aiding sustainability outputs.

LIGHTSTEELFRAMINGMAGAZINE.CO.UK32

PRODUCT INNOVATION

01

Fusion garnered further recognition for the FusionX™ system, with the company named as one of the finalists at this year’s Offsite Construction Awards for their work on Holburne Park in the Best Use of Steel category. The project was an ambitious £26 million high-end residential development in the World Heritage City of Bath. By utilising the FusionX™ system for the superstructure, the project achieved a fast-track building programme. Fusion Steel Framing supplied the coldrolled light steel system, delivered in collaboration with lead construction contractor, BECT.

Introducing Xterion™

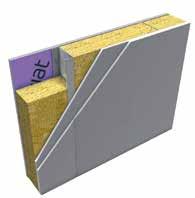

Through technical know-how gained by delivering more light steel structures than any other European producer, Fusion has created Xterion™ – an innovative through-wall solution that incorporates a range of cladding solutions researched and developed specifically to enhance their FusionX™ system.

Launched at Offsite Expo 2022 to great acclaim, Xterion™ is the result of an extensive research and development programme which involved close collaboration with leading cladding and facade companies such as Benx.

Creating a rapid dry building envelope, when combined with FusionX™ this warm frame solution delivers optimum performance values from 0.18W/m2K to Passivhaus standards – depending on the specification. The 2D panelised system has factory fitted non-combustible external boarding and is completed onsite with a range of lightweight render, brick and contemporary cladding finishes. Stringently tested to assure outstanding fire, thermal and acoustic performance, Xterion™ reduces the overall weight of the superstructure for lighter foundations but most importantly, delivers a watertight structure for synchronised activity with follow-on trades.

Talking about the addition of Xterion™ to the product portfolio, Fusion Managing Director, Mike Fairey said: “Our team has put a lot of research, time and expert knowledge into

creating the Xterion™ through-wall system and the attention to detail shows in the result. FusionX™ is well established as one of the best light steel frame systems in the market and launching Xterion™ allows us to enhance the innovation that Fusion has become known for over two decades.”

Delivering Exceptional Performance FusionX™ with the Xterion™ cladding range has been tested thoroughly as a unitised system for thermal performance and fire resistance at 60, 90 and 120-minute durations –permitting accurate value-engineering and exacting performance. This complete through-wall system is manufactured with a standard buildup of insulation between the studs and a 100mm mineral wool slab outside the frame. The complete unitised system has been developed to meet exceptional environmental performance and offers generous acoustic values with ratings up to Rw + Ctr 55dB - subject to build-up. This is further enhanced by the addition of the Xterion™ cladding range.

Outstanding Benefits

Fusion produces bespoke systems offsite at their advanced 80,000sqft lean manufacturing facility in Northampton, where they can output more than 30,000m2 of light steel frame annually

on a single shift pattern. The long-term benefits of light steel frame usage such as its recyclable nature and the fact that steel does not shrink or warp over time – are well-evidenced and Fusion’s portfolio of third-party accreditations underpins this.

Fusion is committed to furthering the advancement of steel as a material that offers significant performance and sustainability benefits. As Fusion continues to further its reputation as a market leader at the forefront of the offsite sector, adding bathroom and en-suite pods and prefabricated utility cupboard supply to the portfolio, enhancing the available levels of PMV and minimising follow-on trades co-ordination.

Fusion also offers tours of their advanced manufacturing facility in Northampton at selected intervals throughout the year. You can register interest by contacting the Fusion team.

For more information visit: www.fusionsteelframing.co.uk

IMAGES

01. Holburne Park, Bath

02. The new Xterion™ system offers significant performance and sustainability benefits

33LIGHTSTEELFRAMINGMAGAZINE.CO.UK PRODUCT INNOVATION

02

DUTCH COURAGE DELIVERS

OFFSITE BENEFITS

LIGHTWEIGHT STEEL FRAMING SYSTEMS ARE A CORE APPROACH WITHIN THE OFFSITE SECTOR AND AS VOESTALPINE METSEC ARE PROVING, ITS VARIED SHAPES, SIZES AND PROFILES ARE PLAYING A MAJOR PART IN A LANDMARK NEW DEVELOPMENT IN AMSTERDAM.

Framing components are then manufactured to the precise needs of the project, coded for ease of assembly onsite and delivered ready for immediate installation in accordance with construction schedules.

In addition to its ability to deliver efficiency and precision throughout the building process, steel framing also contributes towards the sustainability credentials of a project, particularly when it comes to end-of-life. Whereas many other building materials are not readily recycled or repurposed at the end of their working life, steel has a re-use and recovery rate approaching 100%, making it one of the most recyclable materials on earth.

With governments working towards net zero carbon emissions manufacturers will need to up their game when it comes to environmental responsibility. As part of voestalpine AG’s Metal Forming Division, voestalpine Metsec is a signatory to the group’s target of achieving net zero by 2035 and has already published an Environmental Product Declaration (EPD) covering its purlins and framing systems.

Verified by independent EPD authority, EPD Hub, the declaration provides designers, specifiers and developers with comprehensive information to include in a project’s sustainability assessment. It includes a lifecycle assessment and environmental impact data, comprising core environmental impact indicators, use of natural resources and end of life information.

The demands to provide quality, affordable buildings, particularly in the residential sector, whilst delivering speed, efficiency, safety and sustainability are not exclusive to the UK construction industry. They are challenges faced by building professionals throughout the world –professionals who are adopting modern methods of construction (MMC) and digitalisation to help satisfy these demands.

Offsite construction techniques lend themselves perfectly to this drive towards productivity and environmental responsibility, with data-driven design contributing through enhancements in the flow of information from initial

design concepts through to completion as well as the subsequent management and maintenance of the buildings.