17 minute read

Editor’s Comment International news

GREG MORRIS, EDITOR

When will the energy crisis end?

Container glassmakers may be enjoying an unprecedented boom in demand for their packaging but they face a severe headache that could hobble production.

Like other heavy industries, glassmakers have been hit hard by soaring energy costs, which have been pushed up due to the Ukraine war.

This combined with snarled-up supply chains and the continued fall-out from the pandemic have exacerbated fears of a global recession over the winter months. Industry - like households have already felt the pain. Companies in other industries as diverse as aluminium and fertilisers have already reduced or stopped production altogether due to Russia’s squeeze on supply of gas.

One German glassmaker, Heinz-Glas said it faced a 10-20% increase in energy costs and suggested it was being pushed to the brink.

The shortage of Russian supply coincided with Europe’s worst drought in 500 years which also impacted industry. Alternative sources of power such as nuclear and hydropower were impacted as a result of low water levels, which in nuclear’s case could not be used to cool reactors.

There are of course plans in place to rely on energy sources other than Russian gas but the conversion of this will take time, with mid2024 an optimistic forecast.

The question is how long can industrial manufacturers last? It could be a long winter.

WWW.GLASS-INTERNATIONAL.COM

I N T E R N A T I O N A L

September 2022—Vol.45 No.8

A GLOBAL REVIEW OF GLASSMAKING

Glass International September 2022

REAL-TIME PERFORMANCE FOR A PERFECT BATCH

Visit us at glasstec 2022. Stand B38, Hall 15. eme.de

GI Cover sept.indd 1 02/09/2022 14:47:12 FRONT COVER IMAGE: www.sorg.de

Be first with the news! For breaking, up-to-date news

VISIT:

www.glass-international.com

for daily news updates.

Gerresheimer to invest $94 million in US facility

Gerresheimer is to invest in the rapid expansion of its manufacturing, supply and logistics capability for glass vials in the US.

The investment will expand Gerresheimer’s capacity by new vial forming lines, including dimensional inspection, annealing, cosmetic inspection and packaging.

The existing facility in North Carolina will be enlarged by the installation of new modernised vial forming lines and a new warehouse.

The project is supported by the Biomedical Advanced Research and Development Authority (BARDA) office in a 70/30 cost-share co-operative agreement. The office has agreed to provide up to approx. $66 million to Gerresheimer for the project.

Under the agreement, Gerresheimer will increase its annual production capacity in Morganton, NC with vials that can be used in vaccination campaigns against infectious diseases, such as Covid-19 and others.

Vitro discusses $400 million Egyptian glass plant investment

Mexican glass manufacturer Vitro discussed the construction of a flat and container glass plant in Egypt during a meeting with authorities.

The Mexican container and float glass producer wants to invest in a 350,000m2 flat glass factory and a 150,000m2 container glass facility under a free zone framework, with a total investment of $400 million.

The discussion took place in a recent meeting between Vitro CEO, Adrian Sada, Counsellor Mohamed Abdel Wahab, CEO of the General Authority for Investment and Free Zones, and Jose Octavio, Ambassador of Mexico in Cairo.

If approved the investment would lead to the creation of 1500 jobs.

War damage to Vetropack’s plant in Gostomel, Ukraine resulted in a reported loss of CHF 9.7 million ($10.04 million).

In its latest financial note, the glass container manufacturer said three major developments were dominant during the first half of 2022: the ongoing Ukraine conflict, increases in energy and production costs, and sustained high demand for packaging glass.

Sharp increases in energy and production costs led to major market price adjustments in the packaging glass industry.

Vetropack managed to compensate for most of these additional costs with an energy surcharge that is transparent for customers.

Nevertheless, unabated high demand for glass packaging and capacity reductions caused by the shutdown of the Ukrainian glass industry have already led to a number of bottlenecks in meeting customer demand throughout Europe.

The Vetropack Group sold 2.69 billion units of packaging glass in the first half of 2022.

Due to the absence of capacity at its Ukraine plant, sales volume was 6.9% below the prior year’s figure of 2.89 billion units.

The war damage in the plant meant that a value adjustment of CHF 46.5 million had to be debited to the half year, so the Vetropack Group is posting a loss of CHF -9.7 million (prior year: 40.4 million).

Damage also led to the loss of jobs at the facility in May.

Decarbonisation technologies aided by new study

Two articles on thermal radiation conductivity of glass melts have been published to aid in the design of low carbon glass melting technologies.

Accurate data is available on the viscosity behaviour of practically all industrial glasses. However, the existing data on the thermal radiation conductivity of glass melts is scarce and often unreliable.

But the guessing of this essential glass melt property is no longer necessary.

Two peer-reviewed articles with accurate models for quantifying the thermal radiation conductivity kR(T) of industrial silicate glass melts were recently published, see: Faber AJ et. al. in Int J Appl Glass Sci (2020*) & 2022**)), a journal of the American Ceramic Society.

For designing any industrial glass melting process, including low carbon melting technologies, by CFD modelling, the thermal transparency of the glass melt is a key property, next to viscosity.

For example, in electric glass furnaces, the transfer of the heat generated around the electrodes to the cold batch on top of the melt is strongly limited by the radiation conductivity of the melt.

A low radiation conductivity of the melt will result in a poor melting rate of the batch and thus in a low furnace pull rate.

The method for determining kR(T) has a sound scientific basis and can be applied to any silicate glass without or with (a combination of) the colouring ions Fe, Cr, Cu, Co, Mn and Ni.

Links *) https://doi.org/10.1111/ ijag.15111 **) 00:1-12. https://doi. org/10.1111/ijag.16603

NEWS IN BRIEF

German glass production research institute changes address

Germany’s Institut für Glas- und Rohstofftechnologie (IGR) has changed address.

The institute for glass and raw material technology is an independent provider of analysis and advice for all things related to glass.

Its new address is: Institut für Glas- und Rohstofftechnologie (IGR), Else-Krengel-Strasse 9, D-37079 Göttingen, Germany.

Horn secures Vetropack glass furnace contract

Vetropack has contracted Horn Glass Industries for a furnace repair at its Czech Republic glass production facility.

Furnace 52 at the Moravia plant in the Czech Republic will be repaired in 2023.

Equipped with the latest technology from Horn in the areas of gas heating, electrical control and e-fusion power boosting, the furnace is expected to go into operation in November 2023.

HFT adds Senior Manager to safety team

HFT has expanded its safety team with the hiring of safety veteran David Melendez.

Mr Melendez will serve as Senior Safety Manager and brings more than two decades of worldwide safety experience across multiple market sectors.

Safety is at the forefront HTF’s operations, with a fundamental imperative of zero incidents.

Scotch whisky brand switches to glass bottles

Scotch whisky brand Royal Salute is to switch to sustainable glass bottles.

The brand’s porcelain flagon - which has been used since its inception in 1963 – has been exchanged for a recyclable glass bottle. The bottles will result in a 70% reduction in the carbon footprint of the brand’s primary packaging.

NEWS IN BRIEF

Zippe starts construction of Vetropack plant

Zippe has started the construction of a batch house for Vetropack in Boffalora, near Milan, Italy.

The plant will supply two melting furnaces and two cullet return systems.

The plant is expected to go into operation in spring 2023.

Pilkington provides glazing for Elizabeth line project

Pilkington UK, part of the NSG Group, supplied 5,000 high performance glass panels to the Elizabeth line project in London.

In total, Knorr-Bremse Rail Systems UK installed almost four kilometres of high performance glazing across eight Elizabeth line stations in central London.

The glazing comprises two pieces of advanced toughened glass, addressing the current risk requirements including barrier safety and blast resistance.

Sisecam Conference to celebrate IYOG

Sisecam’s 37th International Glass Conference will take place in Istanbul, Turkey on 17-18 November 2022.

The conference will be held in hybrid form, both virtually and in-person, at the Sheraton Grand Istanbul Atasehir Hotel.

The event will acknowledge the significant role and technical potentialities of glass with this year’s theme of ‘Inspiration for Tomorrow’.

Canpack Group reveals new headquarters

Canpack Group has relocated its corporate headquarters to a new address in Kraków, Poland.

The offices are located in a modern MK29 complex in the heart of the city.

The offices will encourage co-operation and integration, encompassing new technology and befitting Canpack’s culture.

Durable anticorrosive glass launches in the UK

Pilkington OptiShower, a range of anticorrosive and durable glass by the NSG Group, has launched in the UK to support designers specifying glass for use in high-moisture environments.

The durable, clear glass is specifically designed to prevent surface corrosion when exposed to water, moisture and humid environments.

The highly transparent glass is easier to keep clean due to its special pyrolytic anticorrosion coating which acts as a barrier on the surface of the glass.

The glass has a wide range of residential and commercial applications, such as shower cubicles or back plates against cooking surfaces in kitchens.

Pilkington OptiShower’s anticorrosion properties also make it suitable for marine applications, such as aquariums and maritime vessels.

The range has been extensively laboratory tested at high temperatures and levels of humidity, where it demonstrated that it resists corrosion far better than untreated glass.

It meets stringent EN 1096-2 standards, which certifies the products as able to withstand challenging outdoor weather conditions and abrasion.

Kirk Green, Regional Sales Manager at Pilkington United Kingdom Limited, part of the NSG Group, said: “We’re excited to launch this product in the UK to help new customers identify applications where the glass can deliver long term durability, no matter the conditions.”

The range is coated ‘online’, meaning the anticorrosive coating is applied while the glass is still hot, rather than as a post-manufacture spray like many other products on the market with similar properties. This makes the product easier to process, as well as harder and more robust when in use.

Mexican and Andean demand boosts O-I’s glass results

Strong demand for glass containers in Mexico, the Andean countries and southwest Europe boosted O-I’s results.

The world’s largest container glass manufacturer reported a1% increase in shipments in the second quarter of this year, which comes on top of an 18% improvement in the prior year quarter.

Volume was up nearly 1% in both Americas and Europe, said the company’s CEO Andres Lopez.

Its balance sheet is now in the best position since prior to its acquisition of O-I Mexico in 2015, he added.

Year-to-date shipments were up 3% about 5% in Europe and 2% in the Americas.

Mr Lopez said market trends clearly favour glass resulting in the strongest market fundamentals in over 20 years.

He said: “Across Latin America, a structural shift in demand is driving sustainable growth.

“Customers and consumers increasingly favour premium products and our customers are localising international brands that had been successfully imported to these markets for several years.

“Premiumisation favours one-way glass containers, while consumer affordability and sustainability considerations are prompting greater use of returnable bottles.

“For example glass now holds 50% market share in the Brazil beer category as both one-way and returnable glass gain share.”

PSR SYSTEM 500 FOREHEARTH

Achieves the best glass thermal homogeneity and energy efficiency.

NEWS IN BRIEF

Saverglass to double Mexican capacity in $116 million investment

Saverglass is to double capacity at its Guadalajara, Mexico, production facility and increase its decoration capability.

The $116 million investment will include a 200,000 tonnes a year furnace capable of manufacturing 200 million bottles in three colours: extra-white, antique green, and dark yellow.

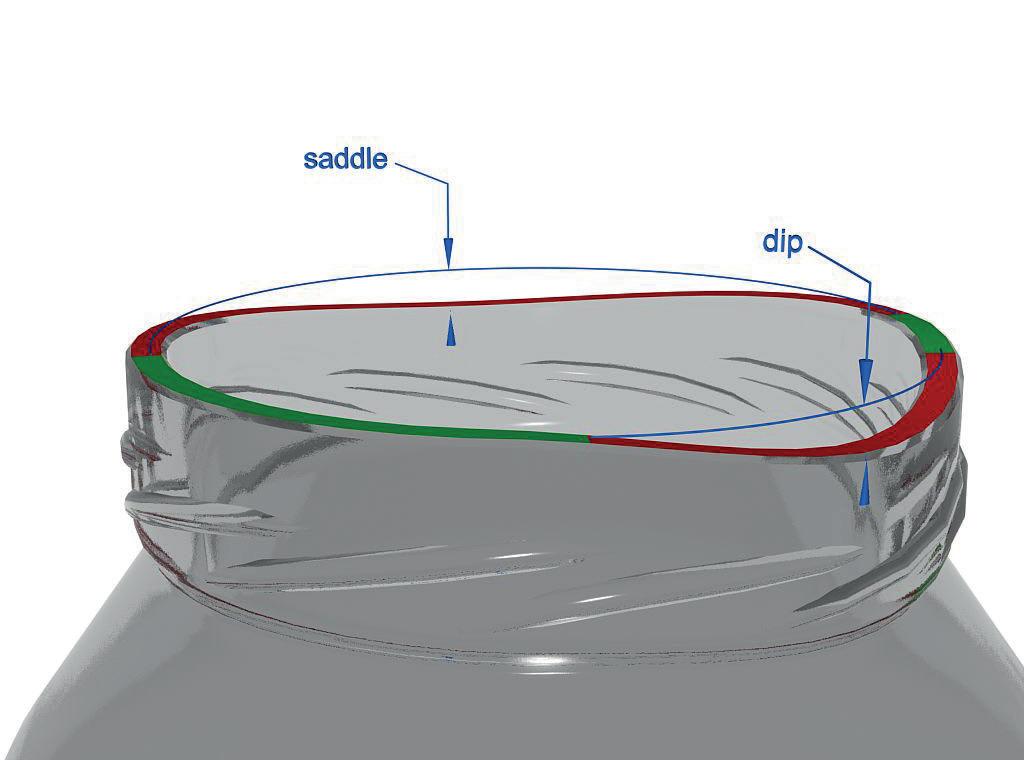

Agr to introduce new measurement systems at glasstec 2022

Agr International will feature its high-precision laboratory dimensional measurement system at glasstec 2022 in Düsseldorf, Germany.

Agr will display several new product developments in quality management equipment for glass containers at glasstec.

Sefpro and Tecsiglass form partnership

Sefpro has formed a strategic partnership in Italy with Tecsiglass.

The recently founded company Tecsiglass is managed dynamically by experts with more than 25 years of experience in furnace design, reconstruction and project management.

As Sefpro agent, Tecsiglass will further improve the company’s customer proximity with customers in the Italian market and work closely with its European Customer Service.

Gerresheimer to invest in North Macedonian facility

German pharmaceutical company Gerresheimer is to invest in a new factory in the Technological-Industrial Development Zones (TIRZs), Skopje, North Macedonia.

The start of construction on its existing premise in the TIRZ is planned in the third quarter of this year, while series production should begin in 2024.

Top 10 stories in the news

Our most popular news over the past month, as determined by our website traffi c. All full stories can be found on our website.

� 1. O-I to build $240 million MAGMA facility in USA � 2. Soda ash company bids to acquire Indian glass manufacturer � 3. Vitro discusses $400 million Egyptian glass plant investment � 4. Verallia to electrify Cognac plant in Fives partnership � 5. Gerresheimer to invest $94 million in US facility � 6. Glass leak at Vitro’s Wichita Falls facility � 7. Sisecam contracts Zippe for triple batch plant project � 8. Grenzebach and Sorg form glass technology alliance � 9. Schott establishes stand-alone company for pharma industry � 10. Ukraine war damage impacts Vetropack’s glass sales

For the latest Industry News scan the QR CODE using your iOS or Android device

Italian glass manufacturer Vetrerie Riunite has began reconstruction work on its second furnace, known as the Centauro, in order to increase its production capacity.

The vault, superstructure and regeneration chamber of the old structure have been maintained.

All glass conditioning and distribution channels, and other parts of the furnace in direct contact with the glass, are under construction.

Tecsiglass handled the design, demolition and reconstruction, as well as the updating the software, along with Fila termoidraulica, which executed the construction of the compressed air, methane and technological water systems.

C.D.M. undertook the heavy carpentry and Alca handled the upgrading of the electrical system.

The reconstruction of the furnace will allow the production of 190 tons of glass per day, instead of 175, so as to be increasingly competitive in the market.

In this way, Vetrerie Riunite consolidates its position in the global market for glass doors for washing machines and dryers.

Forglass performs hot overcoating at fl at glass manufacturer

Forglass has partnered with one of the world’s largest producers of automotive and architectural glass to perform a hot overcoating of its fl oat furnace in Europe.

Hot overcoating of a large fl oat furnace is one of the most demanding types of furnace repair, requiring organisation and teamwork.

During the repair, the furnace is kept around its operating temperature, so those working around the furnace must wear special equipment to protect them from exposure to extreme heat.

Scheduling this type of work also has to account human endurance while working in extreme conditions.

Teams must work in short intervals giving them time to rest and cool off.

Hot overcoating of a large fl oat furnace is planned to minimise glass-to-glass time and there is no room for delay.

Detailed planning is key, allowing exactly the right amount of time to complete each task.

The effi ciency and quality of work has to be 100%, as there is no time to redo a mistake.

NEWS IN BRIEF

Vivix to construct Brazil’s largest glass manufacturing furnace

Brazilian flat glass manufacturer Vivix is to build a BRZ1.3 billion ($248.1 million) production factory.

The site in Goiana, Brazil, will be constructed next to its current glass manufacturing facility and be fully operational in the second half of 2025 and have a capacity of 1000t/day.

This will make it the largest in operation in Brazil.

The plant, the company’s second, will increase the organisation’s total capacity to 1900t/day and become the second largest float manufacturer in the domestic market.

French manufacturer completes successful hydrogen test

French borosilicate glass manufacturer La Maison Française du Verre has completed its injection tests of up to 20% (in power) of hydrogen mixed in natural gas at its Châteauroux site.

The company was able to validate this approach to decarbonisation at a true glass melting scale with a full load. The first results were very encouraging.

British Glass Focus Awards dates

This year’s British Glass Focus awards will take place on November 17.

The annual celebratory event of the glass industry’s achievements over the year will be held at Sefton Park Palm House, Liverpool, UK.

SGD Pharma appoints former Verallia boss as CEO

Global glass primary packaging supplier SGD Pharma has appointed Olivier Rousseau as its new Chief Executive Officer.

Mr Rousseau joins the business after four years as CEO & President of container glass manufacturer Verallia France, and with 30 years experience in the industry.

O-I Glass partners with Ivalua

futronic bids farewell to two long-time companions

O-I Glass has selected Ivalua to streamline its Global Direct and Indirect Source-to-Pay (S2P) Processes

O-I Glass chose Ivalua after assessing technology and process gaps related to strategic sourcing, supplier relationship management, category management, vendor quality, sustainability, and compliance.

O-I Glass also intends to provide an optimised buying process with catalogues, guided buying, and an Amazon-like user experience.

Supported by Ivalua’s solution, O-I’s strategic S2P initiative aims at generating significant cost-reduction across several key business process areas including savings on indirect categories through process standardisation and spend consolidation.

Furthermore, the project will deliver an improved user experience throughout the buying process, a reduction in administrative activities and, crucially, an optimised supplier base driven by a comprehensive assessment of suppliers.

Lastly, Ivalua will ensure seamless integration with O-I’s existing ERP platform, as well as several third-party solutions.

India’s largest container glass producer by capacity, Hindustan National Glass Limited (HNGL) may see a new owner and management soon.

Soda ash producer, Nirma has submitted an INR 16,500 million ($206 million) plan to acquire the bankrupt company.

Africa-based bottle maker Madhvani Group and container glass producer AGI Greenpac have also submitted separate resolution plans for the company.

Danish beer maker Carlsberg, private equity funds Oaktree Capital and SNJ Distilleries are among a dozen entities that have shown interest in acquiring the company.

At a committee of creditors meeting recently, HNGL lenders rejected an INR 12,50013,000 million ($156-162 million) one-time settlement (OTS) offered by the promoter.

The resolution professional Girish Juneja, backed by EY, has admitted INR 33,280 million ($416 million) claims from financial creditors.

HNGL has made several attempts since 2018 to settle the loans, but the negotiations did not progress due to the promoter’s inability to tie up funds.

In its latest attempt a year ago, HNG offered an INR 14,000 million ($175 million) settlement over ten years and a conversion of the INR 5,000 million ($62.5 million) loan into equity.

However, the settlement offer was not unanimously approved - a precondition to the deal. Edelweiss ARC, which holds 21% of the debt, rejected the proposal claiming it to be below expectation.

In 2019, an OTS backed by Carlsberg could not be concluded after it failed to get approval from the Competition Commission of India.

HNGL was admitted for insolvency proceedings in October 2021 based on an application filed by DBS Bank.

Two long-serving colleagues at glass production technology company futronic, Johannes Dimmler and Bernhard Kubik, have retired.

Bernhard Kubik was with futronic for almost 37 years and Johannes Dimmler for 38. Both of them had become part of the furniture, as it were, and they’re already sorely missed.

Dimmler and Kubik played a crucial role in the development of the CIMOG machine control system. Without them there would also have been no EPRO, no FMT24S and no EPRO Upgrade Kit.

They’re both people who know a tremendous amount about the complex processes involved in container glass production.

It’s fair to say that without Johannes Dimmler and without Bernd Kubik, futronic would be a different company.