5 minute read

Furnaces: Sorg

Electrifying the industry

Sorg has offered all-electric melting since 1971. Its latest furnace has been increased to reach tonnage levels of up to 1200 tpd and could answer many of the challenges fl oat glass manufacturers face.

Nikolaus Sorg has led the way in allelectric melting since 1971 when its fi rst VSM (Vertical Super Melter) was built.

A radical furnace design with a rotating crown applied raw materials from the top to cover the entire surface of the glass bath with raw materials, forming an insulating blanket.

Heinz-Glas was the fi rst company to realise the potential of this new melting technology, using it to produce opal and fl int glass fl acons and jars. In 1972, the now widely recognised VSM received its patent and since then more than 100 ‘Vertical Super Melters’ have been supplied, producing all kinds of glass, especially high-quality glassware.

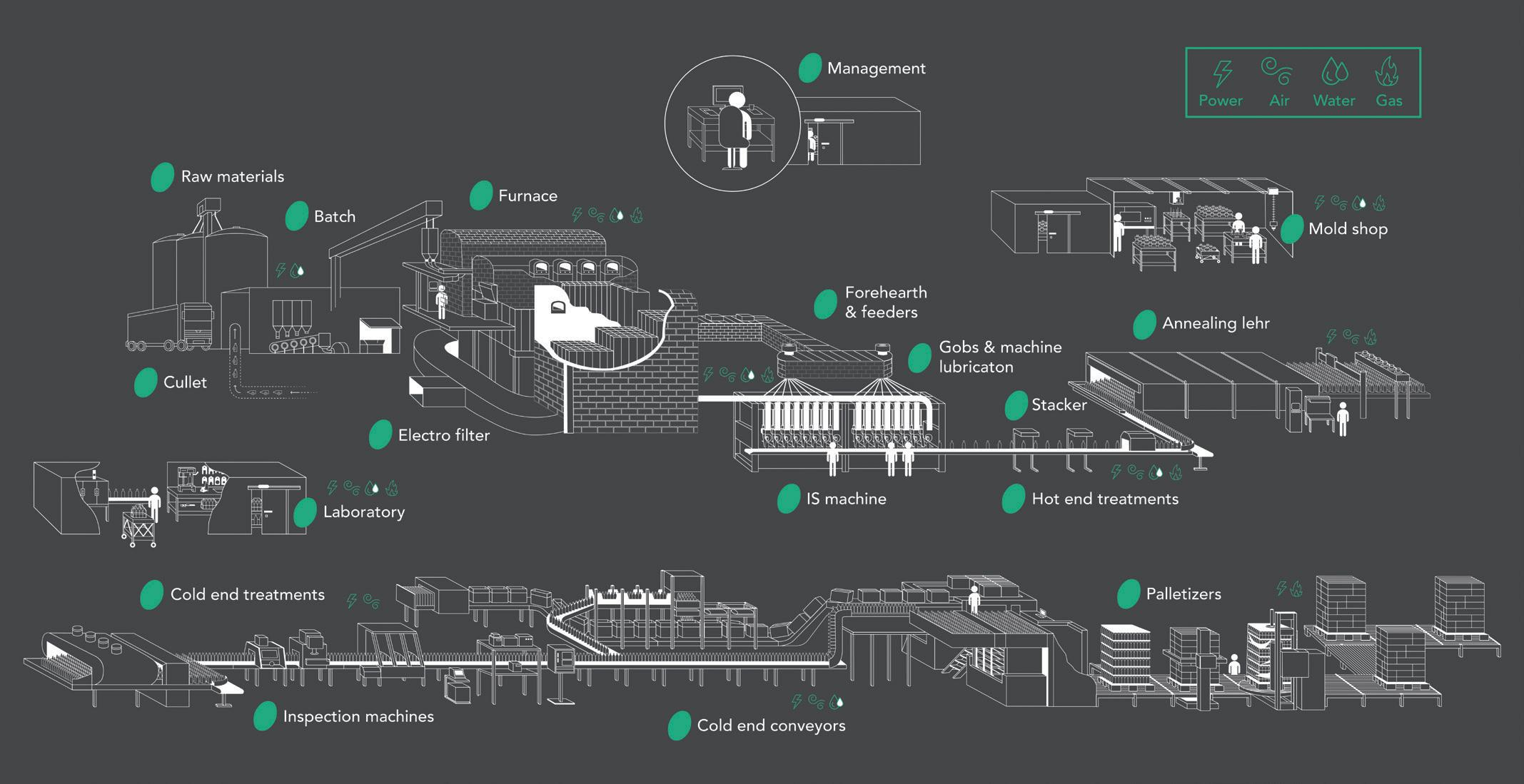

With only one moving part and an enclosed superstructure, the VSM ensures low waste and a dust-free factory environment for glass plants around the world. It also reduces energy consumption. With no combustion, no energy is lost from large quantities of waste gasses unlike other traditional methods (Fig 1).

The only gas stream generated is a relatively small amount from the decomposition of raw materials in the batch, as well as water vapour from raw material humidity.

This waste gas stream can be removed from the furnace superstructure, cleaned by means of a small baghouse fi lter and released into the environment without any further treatment – resulting in emission-free melting.

Challenges in all-electric tonnage

Zero emission melting through allelectric furnaces would have been widely adopted by glass plants if it wasn’t for the limitations on furnace size.

In addition to producing no emissions, the Sorg VSM can comfortably operate at 200 tpd and offers a host of benefi ts to glass plants in terms of energy and maintenance reduction.

The challenge in scaling the current VSM furnace design is the distance between opposite electrodes – either from top to bottom electrodes or from electrodes on one side of the furnace to the other.

Surge in sustainable melting

Around the world, every energy intensive industry is seeking low carbon alternatives to fossil fuels to stop climate change.

Governments and organisations

Fig 1. The VSM ensures low waste and a dust-free factory environment for glass plants around the world Fig 2. Below: The Clean Melter hybrid furnace combines electric and combustion technologies to achieve up to an 80% electric share.

are uniting to tackle a global crisis of unimaginable consequences if action is not taken right now.

In recent years, extensive research and discussions on hybrid melting concepts and alternative combustion fuels, such as hydrogen, have been underway. These developments still have a long way to go – and due to the high capital cost and long lifetime of glass melting furnaces, the process is slow.

The conservative glass industry is hesitant to advance in these new fi elds without research and development support from governments to incentivise the use of more expensive low carbon alternatives like hydrogen.

We have seen great steps forward for glass, with industry and governmentfunded organisations such as Glass Futures and FEVE making great inroads with research and development projects that will advance the sector in due course.

Other leading technology brands in the

industry are also pushing the boundaries of technology, digitalisation and material exploration, with all playing a crucial role in paving the way for sustainable melting.

The Sorg brand and company has sustained 150 years of trading this year, representing a proven resilience to overcome the biggest challenges the industry has faced. Sorg marked this milestone by announcing an unwavering commitment to the industry with the launch of its Mission by Sorg vision.

The Lohr-Germany based company is putting all R&D efforts behind large scale sustainable melting and is advancing glass melting with innovations that will produce industrial glass at volume to achieve net zero glass.

Hybrid offered the answer

In 2021, the company launched its Sorg Clean Melter hybrid furnace, allowing larger furnace operations to reduce their carbon emissions and energy consumption by combining electric and combustion technologies to achieve up to an 80% electric share (Fig 2).

The launch was a welcome solution to glass operations with furnaces of larger capacities who require low emission melting and it has sparked a great amount of interest throughout the industry.

According to the company, its Clean Melter combines the bestknown technologies in all-electric and combustion furnaces, to offer many benefits: � Capacity of up to 400 tpd. � Up to 80% electric boosting, reducing CO2. � Substitution of gas with hydrogen has zero CO2 emissions from combustion. � Achieves required glass quality without limitation in pull and glass colour. � Can be started as a conventional furnace with boosting and later converted to a hybrid melter with up to 80% boosting.

The future

As we near 2023, Sorg has developed an industry-leading innovation once more.

With capacity limitations in the design of the current all-electric Sorg VSM, its engineers have designed a pioneering breakthrough that will see an all-electric furnace reach tonnage levels of up to 1200 tpd.

This size of furnace would answer many of the challenges that global float glass operations have been faced with. This new VSM is set to become the world’s first large scale all-electric melter thanks to its advanced design that ensures the distance between electrodes across the glass melt is never compromised.

A hollow core means Sorg electrodes can be placed in the inner ring of the furnace, ensuring that the distance of electrodes from one side of the furnace to the other is consistent all the way up the furnace walls. The design can expand in width and height yet maintain the desired distance of electrodes from each other.

Sorg is set to showcase the possibilities of its breakthrough technology at this month’s glasstec and looks forward to healthy discussions on what it means for glassmakers around the world when the technology comes online in the near future. �

Visit the team at glasstec 2022 – Stand B38, Hall 15.

Sorg, Lohr-am-Main, Germany www.sorg.de

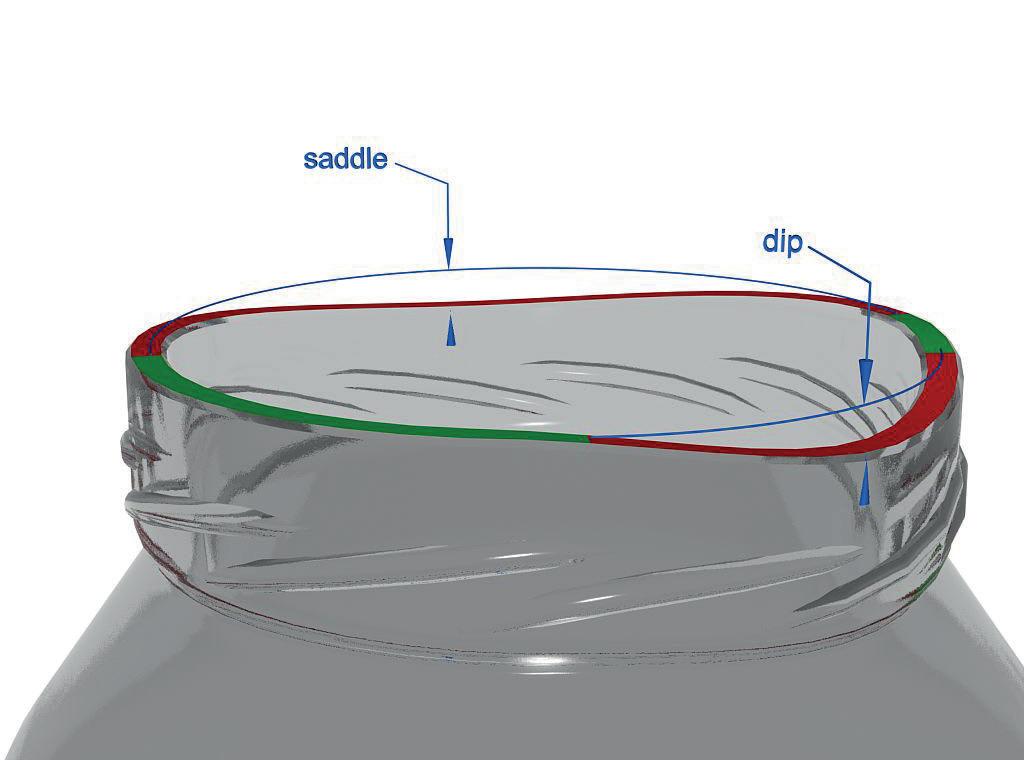

ON-LINE SAMPLING

LABORATORY TESTING SUPERIOR MEASUREMENT AND TESTING FOR THE

COLD END

PRESSURE & VOLUME DIMENSIONAL

COATING PRESSURE DIMENSIONAL

THE HIGHEST ACCURACY ★ THE FASTEST THROUGHPUT ★ THE BEST OVERALL VALUE

Visit our booth at glasstec

Sept 20–23 Düsseldorf booth 14C34

+1.724.482.2163 AGRINTL.COM