4 minute read

CASE STUDY: MEASURING UP TO NASA’S JAMES WEBB SPACE TELESCOPE

H. Philip Stahl

Senior Optical Physicist, NASA

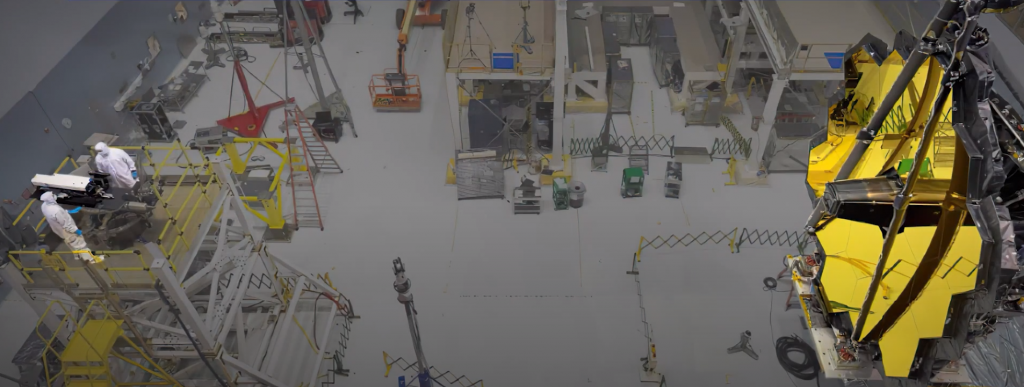

Measuring optics for space-based optical systems, like the James Webb Space Telescope, comes with a high risk-profile After all, it’s difficult to get systems into space, and once deployed, it can be very hard to make a repair visit. NASA is understandably careful not to leave their next big optics project to chance, and they have reformulated their testing criteria over the years NASA senior optical physicist H. Philip Stahl has written extensively on the approach they have chosen...

The 18 mirror segments, the secondary mirror, and the tertiary mirror were measured individually and in sets, for surface figure and surface roughness They were re-measured in cryogenic vacuum conditions It required a giant helium refrigeration chamber to bring the optics to -240 °C (30K). With pump vibrations surrounding the mirrors, the vibration would be high

4D Technology was designated primary metrology supplier, providing instruments for several measurements of the optics and the support structure. The selection was in part because of our dynamic metrology technology, and in part because of our willingness to engineer and design to the extremely stringent requirements.

Probably the most difficult metrology project in a generation of astronomical optics

The reason Twyman-Green was best

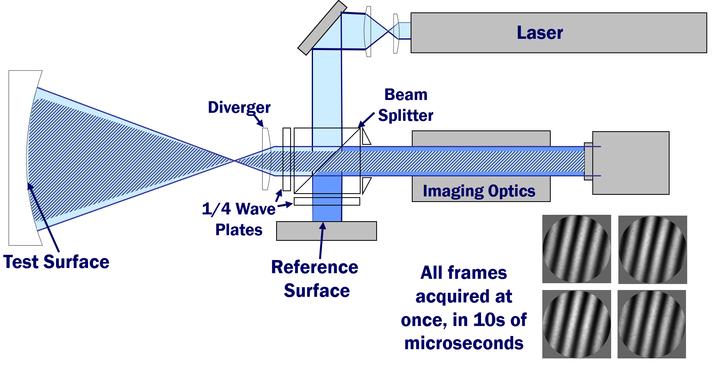

A Twyman-Green configuration of interferometer is capable of retaining light, and expanding to large spherical surfaces.

Measuring concave segmented mirrors

One challenge of measuring a segmented mirror, using interferometry, is that the interferometer has a small tolerance for measuring step discontinuities that is, the difference in Z of one mirror segment to its neighbours in the array The system is prone to vibration, because the focal lengths and the size of the array could not permit the interferometer and the optical array to be coupled together

To ensure NASA could make a measurement that 1) would be vibration immune, 2) could tolerate the step discontinuities, and 3) could capture enough light in a light-absorbing computer generated hologram measurement, we offered our dynamic interferometry technique in a Twyman-Green interferometer, using two wavelength measurements.

The ability of an interferometer to differentiate step discontinuities is just ¼ of the wavelength used to measure. By using two-wavelength interferometry, the dynamic range increases dramatically by creating a longer functional wavelength The downside is that the time taken to acquire two measurements makes the results more likely to be obscured by vibration. In one proof of concept test, we demonstrated two wavelength acquisitions in less than 100 millionths of a second – effectively making ‘stopaction’ out of any vibration

The 4D PhaseCam line of Twyman-Green dynamic interferometers we first released for this project served in both the ambient and cryochamber tests, and the end-to-end test.

PhaseCam Models

Shorter frequency measurements

The simultaneous phase-shift architecture of the PhaseCam permits rapid measurement of the surface shape for specular reflecting objects.

A Tywman-Green interferometer, measuring surface figure, is unable to resolve the microscopic variances and roughness of polish that affect scatter. In space telescopes attempting to image exoplanets, and in X-ray telescopes, ultralow surface roughness and the complex shapes of the optics themselves require tools capable of rapidly measuring surface quality across a very large aperture.

----------------------------------

----------------------------------

About 4D Technology

4D Technology is the leader in high-resolution surface and wavefront measurements for challenging locations and applications

4D pioneered “dynamic” measurement technology, paving the way for entirely new classes of instruments that change how manufacturers and scientists think about measurement From the world’s premiere astronomical observatories, to optical manufacturing shops, to aircraft flight lines, 4D gages and instruments provide 3D measures accurately, despite vibration and noise that stop other instruments in their tracks.

To discuss 4D Technology, Twyman-Green interferometers and YOUR APPLICATION, please get in touch with our Technical Sales Manager, Dr. Luke Nicholls, by email luke@qd-uki.co.uk or call (01372) 378822.

-----------------------------------------------------