FEATURES

countdown SEPTEMBER 2023 Paper chase

Kirkman, CEO Veolia Australia and New Zealand, asks if it’s time for a rethink on waste export bans.

SUPPORTED

PMS 380 PMS 376 PMS 355

Residual remedy Focus on mixed plastics Stewards of sustainability Waste Summit

Richard

PROUDLY

BY:

28 EARTH’S ALCHEMIST

In this issue

Features

07 RESIDUAL REMEDY

What are the answers for Australia’s residual waste?

10 THE BREAKDOWN

Key decision makers share their thoughts on the importance of industry events.

17 TECH TALK

20

Hitachi Zosen Inova’s Amal Jugdeo, breaks down the workings of a waste-to-energy plant.

TARGET ENGAGED

Renewable gases and the key role they play in helping Australia reach net zero targets.

22 CYCLION ENERGY

The next generation of energy-fromwaste could help remote islands tackle plastic pollution.

24 BIG APPETITE

Manco Environmental extends its smart solutions for waste management by taking on Bigbelly.

26 ACCO RETURNS

Australia’s longest-standing commercial vehicle nameplate, the ACCO makes a return to IVECO.

COVER STORY

PAPER CHASE

Is it time for a rethink on waste export bans? Veolia Australia and New Zealand Chief Executive Officer Richard Kirkman questions whether bans on paper and cardboard will work.

“THERE IS NO NEED TO BACKTRACK, BUT THERE’S NO SHAME IN PIVOTING IN THE BEST INTEREST OF THE COUNTRY”

- Richard Kirkman, Chief Executive Officer, Veolia Australia and New Zealand.

28

EARTH’S ALCHEMIST

A Western Australia company combines science and FOGO to improve soil health.

30 GOOD STEWARDS

32

ResourceCo’s credentials in resource recovery is helping others realise their sustainability objectives.

IN THE PINK

Sustainability expert Justin Frank joins the RecycleSmart advisory board.

34

MAKE THE GRADE

How does landfill machine guidance technology enhance operations and reporting?

36 SMART MOVES

Changes to everyday efficiencies have had a big impact on Cookers’ sustainability outcomes.

38 LOADING UP

The JCB CEA 457 Wheel Loader is feature-packed.

40 GODSWILL

With a Godswill baler, Martogg is improving its material recovery solutions for clients across Australia.

42

SHREDDING TO SUCCESS

The Komptech CEA Terminator can shred even the toughest waste.

44 SETTING THE STANDARD

Getting it wrong when it comes to hazardous chemicals can be costly. Polymaster is setting the standard.

47 SUMMIT SPECTACULAR

Waste Expo Australia 2023 unveils the first sessions of its multi-stream conference: The Waste Summit.

50 CIRCULARITY 101

Circularity 2023 aims to turn words into action and help build a circular economy.

52 HARNESSING HYDROPOWER

Goondiwindi Regional Council is a step closer to turning wastewater into hydrogen energy.

Regulars

54 PRODUCT SPOTLIGHT

57 LAST WORD

www.wastemanagementreview.com.au / WMR / 3

12

A Western Australia company is combining science and food organics/garden organics to improve soil health.

From the Editor

Bury or burn?

“There will come a day very soon when the last tonne of waste has nowhere to go.”

They’re sobering words from Mike Ritchie, Managing Director of MRA Consulting Group, discussing the challenges of dealing with Australia’s residual waste at this year’s Australasian Waste and Recycling Expo.

No matter how much we reuse, recycle, even reduce, there will always be some waste to dispose. If you’ve got a residual waste stream that you can’t do anything with in terms of higher order value, Mike says there are two choices – bury or burn.

Australia is running out of landfill but it’s difficult to get new licenses approved.

Earlier this year a proposal for a landfill in South-East Queensland was denied because, according to the government, there was no demonstrated requirement for additional capacity, insufficient economic benefit, and significant community concern and opposition.

Problem is, there’s also community concern and opposition to waste-to-energy. (WtE). While WtE facilities are common and widely accepted overseas, Australia hasn’t got there. Consultants preparing a study for the Waste Contractors and Recycling Association (WCRA) New South Wales, found investors in WtE regularly say it’s difficult to get the community on board.

Despite this, there’s shovel-ready projects, best available technology, and an industry ready and waiting to unlock the circular economy benefits of WtE within Australia.

In this edition, Hitachi Zosen Inova explains how decades of research and operating experience results in modern-day plants that meet strict emissions requirements.

Eneraque Renewables is looking to help industries decarbonise with a readily available fuel source that can be turned into power or renewable natural gas, while Cyclion Energy is patenting new technology that promises to help regional and remote areas manage their waste and electricity.

Industry insiders hope that these projects, and others, are given the go-ahead before the nation is left with a pile of waste on the kerbside and nowhere to put it.

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

GROUP MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

MANAGING EDITOR

Mike Wheeler mike.wheeler@primecreative.com.au

EDITOR

Lisa Korycki lisa.korycki@primecreative.com.au

JOURNALIST

Chris Edwards chris.edwards@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR Blake Storey blake.storey@primecreative.com.au

DESIGN

Louis Romero, Kerry Pert

BRAND MANAGER

Chelsea Daniel chelsea.daniel@primecreative.com.au

p: +61 425 699 878

CLIENT SUCCESS MANAGER

Justine Nardone justine.nardone@primecreative.com.au

ACCOUNT CO-ORDINATOR

Marina Milisavljevic marina.milisavljevic@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.wastemanagementreview.com.au

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Waste Management Review is available by subscription from the publisher. The rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Waste Management Review is owned by Prime Creative Media and published by John Murphy.

Lisa Korycki

All material in Waste Management Review is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Waste Management Review are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 / WMR / September 2023

Call: Email: Visit: 03 9706 8066 sales@appliedmachinery.com.au appliedmachinery.com.au genoxmachinery.com.au At Applied, our number one priority is ensuring that our customers across the country get the machinery they need, with the support they expect. With nearly 30 years’ experience, and thousands of satisfied customers across the country we’re here for the long term. We’re a true machinery partner – just ask Steve Morriss. Real Service. Real Support. Real People. That’s Applied Thinking.

ISSUE IS FIXED STRAIGHT AWAY. THAT’S

OF

“ANY

THE BENEFIT

A LOCAL SUPPLIER WITH FULL TECHNICAL SUPPORT AND BACK-UP.” STEVE MORRISS, CLOSE THE LOOP, SOMERTON, VIC

Residual remedy

That leaves 20 per cent of Australia’s waste – or residuals – that need to be disposed of.

But there’s no clear direction on how that will happen.

Mike Ritchie, Managing Director of MRA Consulting Group, says Australia has a residuals disposal problem, in spite of the work around recycling.

In 1996, Australia generated about 22 million tonnes of waste and almost all of it was landfilled. The recycling rate was just seven per cent. Today the recycling rate has increased to 60 per cent, but that must now hit 80 per cent in seven years.

At the same time, landfill is still growing because of population growth and per capita consumption.

The future of Australia’s waste resource recovery industry is facing a critical moment as the country struggles to address the increasing amount of residual waste being sent to landfills.

According to Rick Ralph, Chief Executive Officer of the National Waste and Recycling Industry Council, it’s time to change the narrative.

“It’s not about waste. It’s about the residuals from recycling and other processes that need to be managed,” he says. “As the population increases our reliance on what we use also increases. So regardless of what we’re trying to do in recycling, and processing, we’re still outstripping ourselves in our purchasing and what we’re using.

“As a result, we can have all the recycling in the world but we’re still going to have residuals that we have to get rid of.”

Speaking at a session at this year’s Australasian Waste and Recycling Expo that aimed to address the challenges of managing residual waste streams, explore solutions, and the need for effective nationwide policies and regulations, Rick said government needs to be held accountable for how residuals will be disposed of.

Australia’s Federal, State, and local governments have agreed to national waste targets including 80 per cent diversion from landfill by 2030 and a 50 per cent reduction in organic waste to landfill in the same time frame.

Mike says, New South Wales will run out of inert landfilling by 2028 and putrescible landfill in 2036, according to the government’s own forecasts, unless something is done.

“Doing something requires us to do a lot more than with the policy settings that we have today,” he says.

“Government set these targets, it needs to deliver us a plan that allows us to know what to invest in. Environment ministers from each state need a plan that says, this is how many resource recovery facilities we need, we need so many composting plants, and this is where they need to be.

“We cannot create a zero-waste society and the sooner we front that, the better because we need disposal facilities. There will come a day very soon, when the last tonne of waste has nowhere to go.”

THERE’S NO SUCH THING AS A ZERO-WASTE SOCIETY. THERE WILL ALWAYS BE RESIDUALS THAT CAN’T BE REUSED, RECYCLED, OR RECOVERED. SO, WHAT DO WE DO WITH THEM?

FEATURE NEWS www.wastemanagementreview.com.au / WMR / 7

Mandatory commercial collection service for any business that generates large amounts of food waste should be on the national agenda according to MRA Consulting’s Mike Ritchie.

Mike says the industry should be lobbying for increased landfill levies across Australia. By his calculations, increasing levies by $6 per tonne per year for three years would raise about $240 million just in New South Wales. That money would then be used to fund resource recovery infrastructure and services.

Replicating that across all states will recover about eight million tonnes of additional material.

Also on the agenda should be a mandatory commercial collection service for any business that generates large amounts of food above a certain threshold. And there must be a food organics garden organics (FOGO) collection at every household. Nationally, that’s another seven million tonnes of the 27 million tonnes being landfilled today.

For residuals that have embodied energy – energy-from-waste. “Why would we landfill them when we can

extract their energy value?” Mike asks. “If you’ve got a residual waste stream, and you can’t do anything with it, in terms of higher order value, you’ve got a binary decision, burn or bury.

“In my view, always go energy-fromwaste subject, of course, to the normal environmental controls.”

However, he describes Australia’s energy-from-waste policy is a “basket case” with two plants currently being built in Western Australia, four or five in Victoria in the planning and approvals process and the New South Wales Government putting the line through

four or five projects that were promoted in urban areas.

“Where are we in terms of policy settings to deal with residuals? It’s a massive fail,” Mike says.

“We’re not going to hit the national packaging target; we’re not going to get anywhere near our targeted reducing residuals to landfill under current policy settings.

“We need to go harder, and we need to go faster. And we need to focus the debate. We need to get focused on the two or three things that matter and speak with one voice to government.”

8 / WMR / September 2023 FEATURE NEWS

“We cannot create a zero-waste society and the sooner we front that, the better because we need disposal facilities.”

Mike Ritchie Managing Director MRA Consulting

There will always be residual waste that cannot be recycled or recovered.

Recycling has been around for over 50 years, but less than 10% of waste is actually recycled. We’ve developed a world-first, patented solution utilising ‘green chemistry’.

Our proprietary technology converts plastics and biomass into electricity and energy – solving two great environmental challenges at a fraction of the cost of previous offers.

Join us in rolling out the waste management solution our planet needs.

The Breakdown

‘The Breakdown’ is a monthly column giving industry leaders and decision makers a chance to share their views on topics central to the sector.

This month we asked: ‘Why are events such as the Australasian Waste and Recycling Expo important for the industry?’

We need to get out with the customer, so they can see what we offer and what we can do. The EEA Group wants to supply the complete solution for the industry and the only way we can do that is to get the majority of our product range to events like this and let people know what we do.

It’s very important to connect with our customers and industry partners to understand the trends, both globally and domestically, that are evolving in the waste industry as well as showcasing our offering to the market.

These events are not just about promoting products and services. Certainly, we do get to connect with new customers – deciding to engage our team is an easy decision when you can see and feel the quality of our products. However, the real value in these events is the ongoing discussions that occurs with existing customers and industry leaders. Getting together outside of formal structures to talk with such a diverse group is a unique opportunity. Challenges are shared and connections made which often form the basis for future innovations. It’s our shared passion for change and willingness to work together which will see the industry continue to progress.

Some people look at whether being here is a success in terms of how many sales they get, but it’s hard to put a number on that because sales can happen many years later. As long as you have a presence for suppliers, distributors and manufacturers you can network with potential and existing clients. I think that’s the most important part.

If you or someone at your organisation is an industry leader and would like to be a part of this monthly column in 2023, please get in touch with Editor, Lisa Korycki lisa.korycki@primecreative.com.au

10 / WMR / September 2023

Dean Cuce National Business Sales Wastech Engineering

Peter Cruwys Managing Director Source Separation Systems

Gary Roberts General Manager, Recycling and Material Handling EEA Group

Peter Koueik Sales Manager Recycling Division Applied Machinery

OPINION

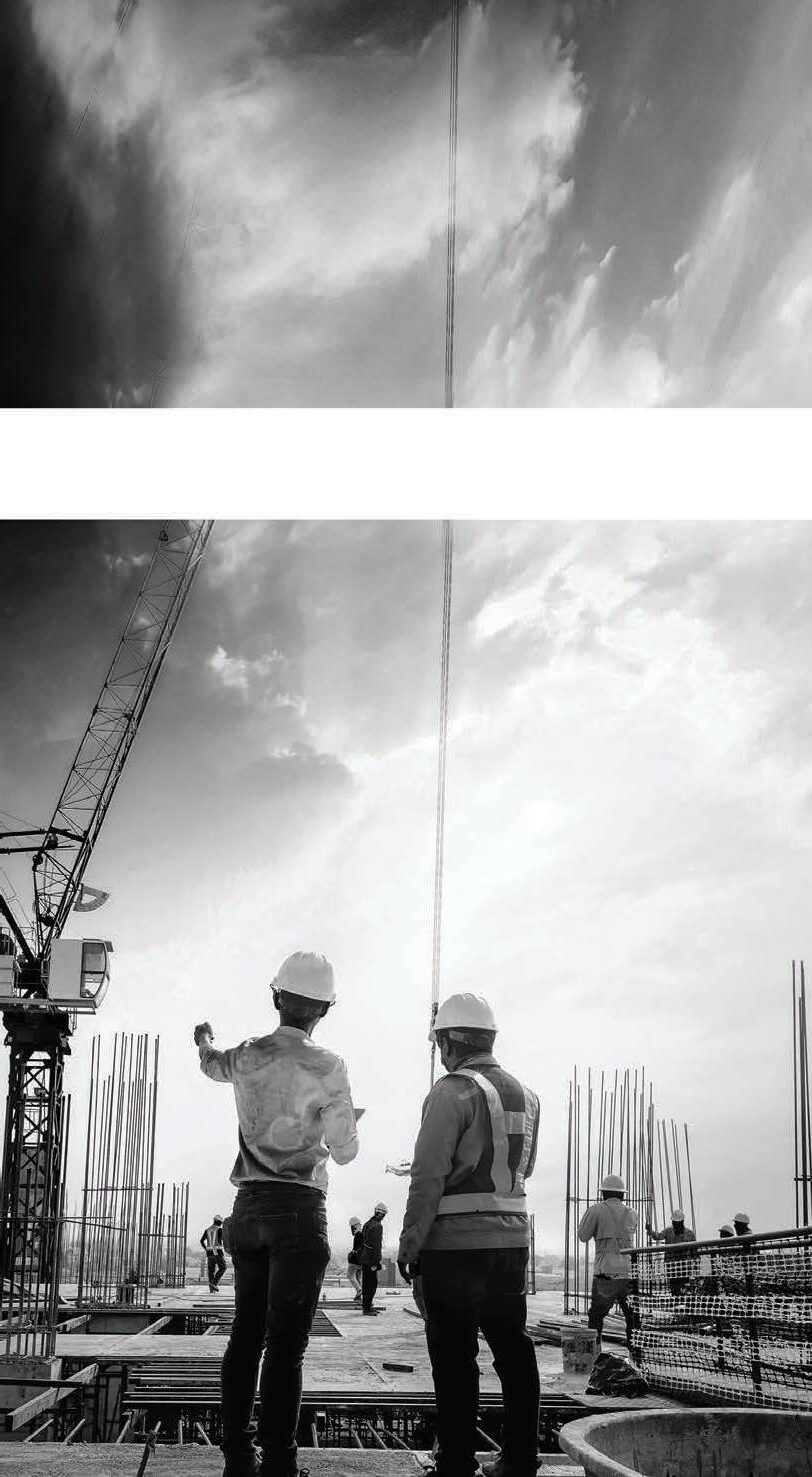

Paper chase

AS AN EXPORT BAN ON PAPER AND CARDBOARD WASTE LOOMS, RICHARD KIRKMAN, CHIEF EXECUTIVE OFFICER OF VEOLIA AUSTRALIA AND NEW ZEALAND, ASKS IF IT’S TIME FOR A RETHINK.

The Federal Government has pulled many levers in response to the China Sword Policy and its restrictions on foreign waste.

Australia’s National Waste Policy Action Plan was intended to reduce waste generation and increase resource recovery as the country transitions to a circular economy.

Export bans on waste tyres, glass and plastics have been phased in since 2021. From 1 July 2024, new regulations will mean only paper and cardboard that is processed or sorted to specific requirements can be exported.

Richard Kirkman, the Chief Executive Officer of Veolia Australia and New Zealand, says while he applauds the government’s bold policies, the paper and cardboard regulations will put financial pressure on legitimate operations.

He’s calling for flexibility to allow existing export arrangements to ethical, legal, and responsible outlets to continue.

“There is no need to backtrack, but there’s no shame in pivoting in the best interest of the country,” Richard says.

“This country has happily traded paper and cardboard for decades. Instead of implementing a blanket ban, we need finely tuned regulations and specifications to make sure this delivers desired results.

“There’s still work to do to strike the balance between promoting domestic processing and supporting an optimum level of international trade.”

THE FALLOUT

Richard says Veolia supports regulations that ensure high-quality recycling

commodities end up in the hands of manufacturers, not in landfills. He acknowledges that through the bans the Federal Government intended to boost local manufacturing and reduce environmental impacts. But a lack of domestic processing capacity, uncertainty around ban specifications, and visibility on long-term plans amid changing regulations has posed industry-wide challenges.

Veolia has been proactive, securing agreements ahead of the plastic ban and supporting traders in obtaining exemptions. It also upgraded some existing facilities with automation and sought strategic partnerships so its existing customer base was not affected. It also invested in a glass processing facility in New South Wales.

Richard says Veolia has adapted its business model as far as it can to pivot and continue growing.

The industry as a whole has always been on the front foot, seeking a solution, investing and warning of the unintended consequences while wrestling with the uncertainty of final export specifications. However, the impact of bans are being felt by local authorities, with recycling rates declining.

Averages vary across the country, but Richard says the plastic bans resulted in periods of no sales or price drops of up to 80 to 90 per cent for certain polymers when local processors recognised they were no longer competing on the international market.

“Bans are not a good way to create elastic demand which ensures best price point for local authorities who are bearing the cost of recycling other peoples’ waste,” Richard says.

“This is proven across the globe where these commercially driven moves

COVER STORY 12 / WMR / September 2023

Richard Kirkman, Chief Executive Officer Veolia Australia and New Zealand.

have taken place. Most countries have maintained buoyancy in the market to protect the taxpayers.”

LESSONS LEARNED

He foresees similar problems with the cardboard and paper bans. The lack of existing paper mills in regions such as Western Australia, coupled with ongoing uncertainties around the ban’s specifications, have been challenges in meeting the requirements from day one.

Building new processing plants and obtaining exemptions takes time. Limited infrastructure to handle the waste effectively means possible stockpiling and there’s only so long you can hold on to a stockpile before it goes to landfill.

“When a ban creates mass stockpiling and less likelihood of high-quality commodities being recycled, you have to wonder if it’s had the intended impact,”

Richard says. “We think the obvious flaw in an export ban on paper and cardboard is that it’s impossible to fix the available outlets to the arisings, so there will always be either too much or too little capacity.

“We don’t know any other resource sector being constrained in this way. It doesn’t work economically.”

He says Australia should be proud of its local processing capacity, but also its highquality recycling commodity exports – it’s a $4 billion industry that supports landfill diversion and a circular economy.

It’s also an opportunity to recover more by enabling exports where it makes sense.

“Waste is both a pressing global issue, but global trade of recycling commodities is also Australia’s opportunity,” Richard says.

“We firmly believe trade is essential to secure end markets for

recycling commodities and to keep prices competitive.”

NEW OPPORTUNITIES

He says positive conversation between industry and government is critical and the way forward to finding the right balance between local and offshore processing capacity to deliver a circular economy.

He adds that it’s time to set a clear path and direction as a nation – one that benefits Australia and not just one sector.

To achieve ecological transformation and realise the circular economy it can create; consumers, producers and industry need to work together. Richard says that means recyclability can’t continue to be a voluntary consideration for manufacturers.

When designers create products, they prioritise factors such as material choice, desirability, functionality, and cost, especially in the low-value packaging

www.wastemanagementreview.com.au / WMR / 13

On site at one of Veolia’s resource recovery facilities.

sector. Right now, manufacturing singleuse products is cheaper than recyclable products and manufacturing with virgin materials is cheaper than with recycled content.

Following a meeting of national environment ministers in June, Minister for the Environment and Water, Tanya Plibersek, announced mandatory packaging design standards and targets, including for recycled content and to address the use of harmful chemicals in food packaging.

Richard says the mandatory packaging rules are an opportunity to create a level playing field for best practise waste outcomes. But packaging rules alone won’t drive the change needed to meet waste targets. A strong market signal is required, and Veolia proposes a ‘Pay-AsYou-Buy scheme’.

A Pay-As-You-Buy scheme incentivises the supply chain to design for recyclability, including using recycled content, and ensures producers pay their fair share of waste and resource recovery costs.

When this cost is incorporated into the purchase price of materials, higher levies can be placed on items that are difficult to recycle, incentivising recyclability.

Veolia has committed to several big projects within Australia that incentivise recycling, landfill diversion and ecological transformation in line with supporting the Federal Government to meet National Waste Plan targets.

The projects also introduce technology and solutions to Australia that have been proven to support a country’s move

14 / WMR / September 2023 COVER STORY

Richard Kirkman joins a panel discussion on plastic waste and recycling.

up the waste hierarchy and towards a circular economy.

Energy recovery facilities might be new to Australia, but they have been widely used overseas for more than 30 years. Veolia operates 65 energy recovery facilities around the world. These facilities reduce the use of fossil fuels, cut emissions of greenhouse gases, and reduce dependence on landfill.

Veolia currently has a proposal for an Advanced Energy Recovery Centre at Woodlawn, New South Wales before

the NSW Department of Planning. If approved, the centre would produce up to 30 megawatts of electrical energy from about 380,000 tonnes of residual waste each year.

“Veolia is always bringing the best solutions from around the world to Australia, including in energyfrom-waste and anaerobic digestion,” Richard says.

“We support everything the federal and state governments are trying to achieve – they all have the right ambition.

“We would like to think we can help with our international perspective on what works, what creates wealth and is fair across the supply chain.”

THE WAY FORWARD

Richard says Veolia’s strategy so far has set the company up for future success, despite tough market conditions.

He sees a big opportunity for Veolia to lead the charge and to bring together the right people – across government and industry – but also to develop the required infrastructure to achieve the goals set and provide skills and training needed for the circular economy.

Every day, more than 6000 Veolia employees in Australia and New Zealand collect waste, recover materials and energy, remediate the land and water, treat pollution, and produce clean drinking water.

Richard says Veolia’s purpose is a special one, and it wants to support governments to create long-term solutions and pathways that enable communities to live healthy, well and quality lives, in balance with the environment.

This means creating a positive impact on climate, biodiversity, and communities.

“Everyone needs to do more – from consumers and their behaviour to governments on streamlined policies, to industry and manufacturers – we all have a role to play, and we are prepared to play ours,” Richard says.

“I think steps are being taken to move forward, bit by bit. There’s a renewed focus on resource recovery and greater government collaboration with industry so Australia can incrementally get closer to where it needs to get.”

For more information, visit: www.veolia.com/anz

www.wastemanagementreview.com.au / WMR / 15

Veolia’s dog-botics have been trained to collect littered waste. Richard Kirkman put them through their paces.

DELIVERING A GREENER FUTURE

Komptech CEA is a leading supplier of machinery and systems for the treatment of solid waste through mechanical and mechanical biological treatments, as well as the treatment of biomass as a renewable energy source. Komptech CEA is proud to provide innovative solutions for handling waste and biomass.

Komptech CEA’s extensive range of products cover all key processing steps in modern waste handling. At Komptech CEA the focus is always on innovative technology and solutions ensuring maximum benefit to the customer. Like to know more? why not speak to one of our team today?

SHREDDERS TROMMEL SCREENS STAR SCREENS WINDROW TURNERS

1300 788 757

TERMINATOR

Where Function Meets Technology

A slow-running, single-shaft shredder suited to all types of waste.

CRAMBO

Less Fuel, More Power

Ideal for shredding all types of wood and green cuttings.

TOPTURN X

The Ideal Combination of Performance and Design

With a sturdy frame, powerful hydraulics and large drum, the Topturn X is ready to handle any work situation.

MULTI STAR

Screening with a Star

Makes waste wood and biomass processing highly efficient.

NEMUS

Robust and Reliable

Combining the practice-proven virtues of its predecessors with new solutions for even greater performance.

AXTOR

Shredding and Chipping Made Easy

One of the most versatile machines around for processing wood and green cuttings.

komptechcea.com.au

Tech talk

HOW DO WE KNOW THAT WASTE-TO-ENERGY (WTE) PLANTS IN AUSTRALIA WILL APPLY STATE-OF-THE-ART TECHNOLOGY THAT’S SAFE FOR PEOPLE AND THE ENVIRONMENT, EFFICIENT AND A SUSTAINABLE ALTERNATIVE TO LANDFILLS? HITACHI ZOSEN INOVA’S AMAL JUGDEO, BREAKS DOWN A WTE PLANT.

When it comes to waste-to-energy (WtE), the term ‘best available technology’ often comes up in industry circles.

Amal Jugdeo, Business Development Manager at global cleantech company Hitachi Zosen Inova’s (HZI’s) subsidiary in Australia, says decades of research and operating experience result in modernday plants meeting strict emissions requirements and, at the same time, almost 100 per cent circularity. Soon, carbon capture will also enable these facilities to become carbon negative.

RECEPTION AND STORAGE

This is the start of the process where waste trucks tip the waste into a waste bunker. The bunker typically has capacity for about four days of waste storage. A crane with a claw picks up the waste and drops it into a chute, leading to a moving grate in the combustion and energy recovery section. When not feeding the chute, the crane constantly moves the waste around to ensure mixing and homogeneity.

COMBUSTION AND RECOVERY

The residual waste combusts on the moving grate. Air and some flue gas recycled from the back end combine with fuel (the waste) and heat to sustain the drying, pyrolysis/gasification, combustion, and reduction reactions.

The moving grate is a complex piece of equipment made of moving sections – zones, lanes, and elements are the technical terms – that allow for

continuous adjustments of the waste bed height and any fluctuating waste properties to ensure a stable flame. The hot gases then enter the boiler, where water is heated indirectly to produce steam.

Critical for keeping oxides of nitrogen formation in check is tight control of the ‘excess air’ fed to the boiler. This is the quantity of air above the stoichiometrically required oxygen for complete combustion.

Lower excess air reduces the uncontrolled formation of nitrous oxides but, at the same time, increases carbon monoxide, which is another air pollutant. The goal is to operate at the lowest excess air while meeting the carbon monoxide emissions limits.

Strategically placed air injection points maximise the swirling and mixing of recycled and fresh air, ensuring low levels of excess air at the boiler outlet, less flue gas, less additive for nitrous oxide control and stable steam flow.

Recycling flue gas enhances the clean burning and the overall energy efficiency of the process.

The process ensures complete combustion of the waste, resulting in ash dropping off the end of the moving grate, called bottom ash.

Amal says there are often claims that gasification technology is environmentally superior to modern moving grate WtE plants. Fundamentally, the gasification process produces syngas by limiting the amount of oxygen fed into a

FEATURED TOPIC – WASTE-TO-ENERGY www.wastemanagementreview.com.au / WMR / 17

A waste-to-energy plant in Thun, Switzerland, designed by HZI.

gasifier reactor. The syngas is fed into a downstream oxidation chamber for combustion of the syngas. The gasification process merely separates the gasification, combustion and reduction reactions that occur in a moving grate design into different chambers.

Amal says this comes with the added risk of incomplete burn-out of the ash due to starved oxygen levels, a more complex process and more expensive equipment.

FLUE GAS TREATMENT

The European Union has the leading regulatory framework for WtE. Its experts regularly review the framework and, from time to time, adjust the emissions limits in line with advances in technology development, defining updates to ‘best available technology’. Then, WtE plants must upgrade their facility within a specified time frame to meet these tighter emissions specifications. Hence, the communities around these facilities and local regulators can have confidence that the most advanced state-of-the-art technologies safeguard the environment.

Proof of the European leadership is that most countries, including most Australian states, copy-paste the European emissions framework and limits.

HZI’s advanced SemiDry flue gas treatment technology allows WtE plants

to meet and exceed the strict regulatory requirements. In addition, designs and plants are future-proofed in anticipation of future tighter emissions specifications.

A byproduct of the process is flue gas treatment residue which is about four per cent of the mass of the feed waste. The residue is treated with carbon dioxide to create a carbon-negative aggregate for construction industry use. This process has been deployed in the United Kingdom for more than a decade.

Amal says further work with regulators is required before this process will be allowed in Australia.

Earlier in 2023 in Sweden, HZI commissioned the world’s first facility for recycling commercial salts from flue gas residue.

HZI’s Ash2Salt process extracts salts such as potassium chloride, sodium chloride and calcium chloride from the residue that has a 90 per cent lower climate footprint than traditional salt production methods.

These materials can then be reused for industrial or chemical purposes.

ENERGY USE

The steam generated in the boiler can either be used directly in other commercial and industrial processes or in an on-site turbine to generate electricity.

Amal says that even in a hot and dusty climate such as Dubai, HZI’s 1.8 million tonnes per annum WtE plant currently under construction will achieve an energy efficiency of more than 30 per cent because of an optimised turbinecondenser design.

Typically, residual waste has about 50-60 per cent biogenic material, so more than half the electricity produced from a WtE plant is a non-fossil source of baseload electricity.

BOTTOM ASH

The bottom ash coming from the moving grate is about 25-30 per cent of the mass of the original waste.

The bottom ash is then processed to recover ferrous and non-ferrous metals. This eliminates the carbon and environmental impact of equivalent virgin metals.

In the European Union and UK, the remaining aggregate is recycled in the roads and building industry. Amal acknowledges “the positive leadership by the Victorian regulators to define approval pathways for bottom ash reuse in the local market.”

100 PER CENT CIRCULAR, SAFE

Applying ‘best available technology’ such as HZI’s SemiDry flue gas treatment ensures compliance with strict emissions requirements.

Advanced control systems and equipment design allow tight control of the combustion and energy recovery processes, increasing energy efficiency. The recovery of solid byproducts from the facility has a net positive carbon footprint on the environment.

Amal says WtE is a compelling story, and HZI, with decades of design and operation experience under its belt, has been pushing the technology boundaries to offer a more circular, safe and efficient future-proof solution for the world and the Australian market.

He says that beyond the potential for 100 per cent recycling of solid byproducts from the process, WtE plants, in the near future, will capture carbon dioxide from their flue gas. This will make WtE an overall carbon-negative process where carbon from fossil sources in the waste will be recovered from the flue gas.

As more and more councils roll out organics collection, integration with organics processing facilities presents further opportunities for carbon and energy efficiencies offering a one-stopshop alternative to landfill.

For more information, visit: www.hz-inova.com

18 / WMR / September 2023 FEATURED TOPIC – WASTE-TO-ENERGY

First fire of waste at the HZI Dubai waste-to-energy plant in May 2023 –the largest WtE plant in the world.

The Smart Oil Solution

Cookers is Australia’s leading bulk cooking oil supplier focused on bringing efficiency and sustainability to the foodservice industry since 2000.

With a customer-first approach, we provide high quality cooking oils and a complete system to streamline the entire process of oil management. From supply and delivery of fresh cooking oil to the collection and recycling of used cooking oil, you have one direct point of contact.

Choose Sustainability, Choose Cookers.

1300 88 22 99

cookers.com.au

No Lock-in Contracts Sustainable Solutions Equipment Free on Loan Scheduled Delivery & Collection

P:

Targets engaged

RENEWABLE GASES HAVE A KEY ROLE TO PLAY IN HELPING AUSTRALIA REACH NET ZERO TARGETS. ENERAQUE DIRECTOR JEREMY PRINGLE EXPLAINS.

There’s an untapped bounty of renewable gas that has the potential to help Australia reach it’s decarbonisation targets, while offering a practical – and lucrative – way to manage waste.

Existing landfills and wastewater treatment plants across the Asia-Pacific region are already producing biogas – a fuel source that can be used to provide heat and power to sites, or be upgraded to renewable natural gas (RNG) and injected back into the gas network.

It’s that fuel source that Jeremy Pringle, Director of Eneraque Renewables, wants to unlock to improve waste management and drive down emissions as Australia aims for net zero targets by 2050.

“In many cases, biogas is simply flared off,” says Jeremy. “Instead, we can collect and extract the gas and treat it to remove impurities like H2S and other contaminants, before using the cleaned gas to fuel gas engines or turbines, or create heat and power through cogeneration.”

In Europe and the United States, biogas usage is common and mature, but Australia and New Zealand have been slower to adopt the technology.

“We’re all racing for net zero,” Jeremy says.

“We’ve got this readily available fuel source that can be quite simply turned into power or renewable natural gas and reduce reliance on the grid.

“The technology is there we just need an aggressive uptake. There’s up to $350 million in shovel ready projects in Australia ready to go.”

In October 2021, the then Federal Government released a technology-driven Long Term Emissions Reduction Plan, which sets a path to net zero by 2050.

At the time, the government’s $20 billion investment in low emissions technology was tipped to unlock an $80 billion investment in green technologies including energy storage and carbon capture.

In an address to the Clean Energy Council in July 2023, Chris Bowen, Minister for Climate Change and Energy, said Australia won’t reach its emissions

FEATURED TOPIC – WASTE-TO-ENERGY 20 / WMR / September 2023

An Eneraque Renewables wasteto-energy plant under construction.

target without aggressive uptake of technologies.

Jeremy says waste-to-energy is a quick way for industries to decarbonise. Those that could benefit the most include food and beverage, agriculture, wastewater treatment plants, landfill sites and meat processing facilities.

The rule of thumb is that anywhere that generates about 14,000 tonnes of waste per annum can put it to use.

“Anywhere there’s a waste, gas can be produced,” Jeremy says. “The big ones to benefit will be the agriculture industry –feedlots, abattoirs, dairy farms – they’re the big emitters and generally in a good position to put power on the grid.

“The industry is making steps to change. It knows it needs to decarbonise and there is a fuel source that can be used. Eneraque Renewables can give them a performance guarantee on emissions reduced, power provided or renewable natural gas, flow rate and quality.”

For the past four decades, Eneraque has predominantly worked with clients behind the meter – designing, engineering and manufacturing

equipment to turn wastewater and landfill gas into heat and power for utility clients. In August 2023, the company launched Eneraque Renewables, a new division with a focus on the role renewable gas will play in achieving decarbonisation targets.

Eneraque will continue to have a team for traditional projects, as well as a new team focused on renewable energy projects.

The company delivers turnkey projects that include complete design, engineering, procurement, construction and maintenance. On project completion, clients can choose to manage and operate the site internally, or access the company’s five or 10-year maintenance plans.

Solutions can range from anaerobic digesters and gas scrubbing or storage, through to complete biogas plants. The technology used is designed on a projectby-project basis considering feedstock and location.

To produce a renewable natural gas requires a gas pipeline close by so that biomethane can be injected into the network. Industries close to an electricity

source and connection can clean biogas and put it into the power grid or use it behind the meter to reduce their own power usage and emissions.

Eneraque Renewables uses a simulator tool to analyse the best product fit for a project. It will analyse what opportunities are available in power production, or thermal energy, for a site and provide a return on investment “guarantee”.

“It gives clients comfort that they can look at all options and work out where they want to invest in order to recoup their Capex costs in the shortest time frame,” Jeremy says.

“We’re offering a free audit and some high-level desk top numbers for clients across the region. That’s giving them some comfort and more interest to take their investment to the next level.”

Jeremy says the technology continues to evolve and Eneraque Renewables is doing what it can to stay on the front foot to adapt emerging technologies for the APAC region without compromising standards and quality.

“We all know we need to get to net zero. We’ve asked how is Eneraque going to support the Asia-Pacific region to get there?” Jeremy says

“With an increased number of projects in the renewable space, that’s where we feel we’ll be putting in the investment.

“We’re excited about the industry and we’re doing everything we can to support the client base in their decarbonisation targets and their journey.”

With the launch of the new division, Jeremy wants Eneraque Renewables to be front of mind in the renewable natural gas and waste gas to energy space.

“I hope that if there’s a waste and it needs to be producing power, Eneraque Renewables is there,” Jeremy says.

“If there’s waste to renewable natural gas, Eneraque Renewables is the one people turn to.”

For more information, visit: www.eneraquerenewables.com

www.wastemanagementreview.com.au / WMR / 21

Eneraque Renewables has a team dedicated to the growth of renewable gas technology including Pritesh Keshra, Grant Lihou and Daniel Politylo.

It all comes out in the wash

CYCLION ENERGY IS ON A MISSION TO OFFER A SOLUTION FOR MIXED PLASTICS AND BIOMASS THAT IS BEING SENT TO LANDFILL, STOCKPILES OR IN THE SEA.

Awashing machine for mixed organic and plastic waste.

It’s a simple explanation for a complex process of converting plastics and biomass to fuel or electricity. And it has potential to alleviate mounting rubbish and pollution problems in remote areas.

Philip Major, Founder and Chief Executive Officer of Cyclion Energy, has proof of concept for the patentpending technology that liquifies and depolymerises waste. In addition, Cyclion is commencing preparations for a large-scale commercial project in the Philippines due to start in 2025. It will process up to 900 tonnes a day of municipal solid waste.

Throughout September and October, Cyclion Energy is launching a crowdsourced funding campaign via Birchal to facilitate a pilot plant in an Australian university for the beginning of 2024.

As part of the patent pending, IP Australia conducted global patent searches and found no one is doing anything like this process.

“It’s incredibly exciting,” says Philip.

His journey in waste-to-energy (WtE) started in 2014 with a chance conversation that set him on his current path. He says, at the time he thought WtE was too good to be true.

“I did my own research and looked at solutions at that time and identified the problems,” Philip says.

“I wanted to know why this wasn’t happening in Australia.”

In 2017 he had a pilot plant up and running in China. Philip says while it was unfortunate that the commercialisation of that particular pilot plant did not eventuate, the process allowed him to reconsider and develop a more cost effective WtE process.

Philip completed a Bachelors in Biomedical Science in 2023 and has spent a long time researching other elements of converting waste, particularly mixed waste. He was inspired to take his research a step further when confronted with images of dying whales that had consumed plastic waste and a 62-metrehigh rubbish mountain in India.

This time around the technology is very different. The business name,

Cyclion Energy gives a hint to the direction being taken – short for recycling and ion – Cyclion’s process uses ion to break down both biomass and plastics.

“In the past, we had to separate mixed waste into plastics and biomass, which takes a lot of equipment. That equipment also uses mechanical force to reduce the size of the waste, therefore takes a lot of electricity and is not 100 per cent effective,” Philip says.“I focused on that and using a catalyst to cause liquification to break down plastics and biomass.

“In essence, I created a sophisticated washing machine.”

Think of it as a load of mixed waste, including rubbish bags, being emptied

FEATURED TOPIC – WASTE-TO-ENERGY 22 / WMR / September 2023

Philip Major, Founder and CEO, Cyclion Energy.

Cyclion Energy is partnering with the Sea World Foundation to help its research, rescue and conservation of the marine environment.

into the ‘washing machine’ and run through various cycles. At each cycle the waste is liquified and degraded until in the end all that’s left in the tank is inorganic matter – solid glass or metals –that can be separated and recovered.

What’s been degraded becomes an oil that can then be further processed as fuel or converted into a flammable gas to generate electricity.

Philip says the technique is effective and by using chemical energy rather than electrical or mechanical, is more efficient.

One of the key differences to other techniques is there’s no need to preprocess. The recycling is done after the biomass and plastics have been removed.

The second difference is the system is modular. While other techniques require large facilities to be economically viable, Philip’s goal is to use large containers so recycling plants can be placed in regional and remote areas, including island nations.

“Currently, island nations have to export their waste because they don’t have room for landfill,” Philip says.

“I want to be able to provide these plants into island nations or remote locations. They would be empowered to deal with their own waste and generate their own energy.”

A problem, apart from feedstock, when using waste-to-energy to process mixed waste, is emissions. Higher temperatures generate gases.

Cyclion is using catalytic decolonisation because it works at low temperature, which means less emissions, lower operational costs and therefore requires less capital.

“Incinerators operate anywhere from 800 to 1000 degrees Celsius,” Philip says. “Operators try to deal with the emissions from incinerators by scrubbing gases, which is expensive. Then gasification runs at 1300 to 1500 degrees Celsius. As the temperature goes up, the energy required also goes up.

“Our system operates between 240 to 310 degrees Celsius. We don’t produce the gases that some other technologies do. Existing technologies are not doing it, or they’re limited in their scope.”

Cyclion Energy is developing its first commercial project in the Philippines where, according to Our World in Data, the population of 114 million people across 7641 islands produces more than one-third of all oceanic plastic waste in the world.

Philip is hoping the project will be commissioned by 2025 and be a reference point to establish one in Australia.

In the meantime, Cyclion Energy is in the process of setting up a sponsorship with the Sea World Foundation as part of a holistic approach to help solve the world’s plastic pollution problem.

“The Sea World Foundation does a lot of research with animals affected by plastics rubbish,” Philip says.

“By reducing the amount of plastic in the ocean and rubbish that goes into waterways, hopefully we will help them.”

For more information, visit: www.cyclionenergy

www.wastemanagementreview.com.au / WMR / 23

It was images like these, of people scavenging in waste piles in India, that inspired Philip Major to pick up his work again.

Big appetite for change

MANCO ENVIRONMENTAL EXTENDS ITS SMART SOLUTIONS FOR WASTE MANAGEMENT IN AUSTRALIA BY TAKING ON BIGBELLY.

strong relationship with Bigbelly. “The success of this relationship, and Bigbelly’s continued support, dedication to their products and innovation, make this an ideal fit for Manco,” she says.

Manco Environmental has a depth of knowledge and expertise within the waste industry, specialising in waste and recycling equipment including collection vehicles, bespoke recycling hubs, glass crushers, bin washers and electric sweepers. Bigbelly adds another level to Manco’s public space waste solutions.

“Manco has been recognised globally for its continued innovations in the waste industry, with equipment designed to make life simpler for the end-user and contribute to better environmental outcomes,” Jaclyn says.

management software means the bin continues to operate during low sunlight conditions.

The ‘smarts’ are housed beneath the top door, clear from weather. The CLEAN software system can be set up to manage and optimise bins from a desktop dashboard or mobile app. Autogenerated notifications and other alerts means the waste collector knows what’s happening on the street and when bins need to be collected.

The modular system can be tailored for specific sites depending on capacity and waste streams including mixed waste, single-stream recycling or compost.

Overflowing rubbish bins are more than an eyesore. The environmental risks can include air and water contamination, disease-carrying pests and missed recycling opportunities.

But there’s one bin to rue them all. For more than 20 years, Bigbelly smart bins have helped make communities and public spaces, greener and cleaner.

Manco Environmental, a division of Manco Engineering Australia, has been the distributor of Bigbelly in New Zealand for the past decade and is now taking the reins in Australia.

Jaclyn Vanderent, General Manager, Manco, says the company has built a

“Consistent and uniform recycling is key for communities to achieve their zero-waste and sustainability goals. Manco and Bigbelly can have an important role to play.”

Bigbelly began in 2003 with a focus on enhancing productivity while reducing costs, fuel consumption and labour for waste collections. The solarpowered compacting waste bin has five times the capacity of a traditional bin and is connected to a cloud-driven software management platform that provides real-time alerts for overflow or other issues.

A solar panel on the top of the bin harvests energy to charge the battery to operate the compactor. Energy

Jaclyn says that by eliminating windblown litter and waste overflows, the Bigbelly is contributing to cleaner streets and public spaces. Fully enclosed bins also eliminate a food source for rats and other pests.

While the visual impact the Bigbelly makes is important, Jaclyn says deploying a Bigbelly has flowon effects for fuel economy and emissions reduction.

According to the Environment Protection Authority, transportation is the greatest contributor to greenhouse gas emissions. The Bigbelly can reduce waste collections by an average of 80 per cent.

Bigbelly data shows that in one city, the installation of 354 high and standard capacity waste and recycling stations

FEATURED TOPIC – WASTE COLLECTION AND TRANSPORT 24 / WMR / September 2023

Bigbelly smart bins can reduce waste collections by an average of 80 per cent.

across 170 locations resulted in an 88 per cent reduction in collections.

“Fewer collections mean fewer kilometres driven, reducing greenhouse gas emissions,” Jaclyn says. “Fewer collections also mean reduced vehicle use, maintenance and fuel consumption.

“Some locations where Bigbelly is deployed have reduced greenhouse gas emissions by 92 per cent.

“Regardless of vehicle and fuel type, Bigbelly provides an opportunity to reduce environmental impacts.”

PROVEN RELIABLE AND PRODUCTIVE

Jaclyn says Manco is committed to helping organisations and communities improve sustainability with leading equipment and customer service.

“Our dedication to customer satisfaction is important to us,” she says. “We’re proud to be able to continue to offer Bigbelly within Australia.”

For more information, visit: www.mancoeng.com.au

JCB WHEEL LOADERS 1300 522 232 jcbcea.com.au

The JCB range of wheel loaders are built to be strong, reliable and provide comfort for long days in the cab. Designed for ultimate productivity, and offering superb performance the JCB wheel loader range features best-in-class comfort, visibility, safety ergonomics and superior serviceability plus a whole lot more.

“Consistent and uniform recycling is key for communities to achieve their zero-waste and sustainability goals.”

Jaclyn Vanderent, General Manager, Manco

Bigbelly bins have five times the capacity of a traditional bin.

ACCO set to make big return for IVECO

AUSTRALIA’S LONGEST-STANDING COMMERCIAL VEHICLE NAMEPLATE,

THE ACCO, IS SET TO MAKE A RETURN TO THE IVECO PRODUCT LINE-UP WITH A NEW MODEL GEARED TO THE WASTE INDUSTRY.

IVECO Australia engineers are currently testing and validating the latest ACCO model prior to release.

The new ACCO range shares its fundamental architecture with the recently launched S-Way, but is being developed to target specialist vocational applications, namely refuse work, and will include locally engineered dual control variants.

The range will be available in both 6x4 and 8x4 configurations and will feature IVECO’s 8.7L, Euro6 (Step E) Cursor 9 engine – buyers will be able to select from three output ratings spanning from 310hp and 1300Nm to 360hp and 1650Nm. The standard transmission across all

models will be the proven Allison 3200 6-speed full automatic, a favourite for demanding stop and start applications.

Available exclusively with a day cab, the interior of the ACCO has been refined to provide more usable space and accommodate dual control hardware for those relevant models.

Driver storage solutions have also been amplified with additional areas allocated for Personal Protective Equipment (PPE) and stowage of personal belongings.

Previous generation ACCO models were a favourite for bodybuilders owing to their clean chassis rails and mounting options; this is a legacy that will be

continued in the new ACCO, with a chassis layout that’s been honed to closely align with requirements of waste industry bodies in consultation with popular body manufacturers and leading companies within the waste sector.

New systems for improved integration between the cab chassis and bodies will also be featured. Other waste industryspecific adjustments include redesigned steps that provide extra ground clearance, an engine hour meter and three-blade windscreen wiper system.

The latest ACCO will also receive the advanced safety equipment featured in the new S-Way including Advanced

FEATURED TOPIC – WASTE COLLECTION AND TRANSPORT 26 / WMR / September 2023

The latest ACCO range features a locally engineered dual control system.

Emergency Braking System, Brake Assistance System, Adaptive Cruise Control, Lane Departure Warning System, Electronic Stability Program with ABS (disc brakes all round) and ASR (Anti-Slip Regulation).

For added visibility on the road, ACCO will also be equipped with full LED lighting.

Emiliano Foieri, IVECO Trucks Australia – Heavy Vehicle Product Manager, says preparations for the introduction of the new ACCO range are progressing well.

“Development of the new ACCO has been an involved process, particularly the design of the dual control system, which has been engineered locally, specifically to meet the preferences of Australian and New Zealand customers,” Emiliano says. “The overall model line-up is heavily

geared towards the waste industry and will closely meet the needs of operators using side and rear loading compactors, overhead front lift trucks and skip bin vehicles.

“Given the long heritage and strong reputation that ACCO boasts, particularly

in the waste market, we’re working hard to ensure its standing as an industry favourite continues with this new generation model.”

For more information, visit: www.iveco.com.au

The new model features a locally developed dual control system.

Earth’s alchemist

GO ORGANICS IS CHANGING THE LANDSCAPE IN WESTERN AUSTRALIA, COMBINING SCIENCE AND FOOD ORGANICS GARDEN ORGANICS TO IMPROVE SOIL HEALTH.

“It’s all very well for everyone to be taking on food organics garden organics (FOGO), but it has to go somewhere.”

It’s that somewhere that Donovan Farrell, Manager Go Organics in Western Australia, is focused on.

Donovan is in the middle of a multi-million-dollar expansion of the Go Organics compost facility in Boonanarring, in the Gingin area, to accommodate the state’s burgeoning FOGO industry.

He’s also working with universities, local government, and the agriculture sector to ensure FOGO becomes a valuable resource.

“This is the problem everyone is facing,” Donovan says. “We’re pushing FOGO out of landfill, which is great for the environment. But where does it go?

“We have to do it in a way that’s going to work for everyone, commercially and environmentally.”

Donovan is no stranger to the compost industry – Go Organics is a subsidiary of national horticultural and garden supplier Brunnings, which has been in existence for more than a century, supplying compost to retailers such as Coles, Woolworths and Big W for the past 30 years.

With the purchase of Go Organics in 2010, Donovan established the 500-acre facility at Boonanarring. He built a forced aeration shed to compost chicken manure but began studying whether FOGO could be composted into an Australian standard product. For two years, Go Organics has composted 50,000 tonnes of organics annually, including 15,000 to 20,000 tonnes of FOGO.

When the Western Australian Government mandated that all local governments in the Perth and Peel regions adopt FOGO by 2025, Donovan recognised a lot of that would end up as compost. He’s growing the business to try and absorb the influx and avoid poor quality products flooding the market.

He has works approval to expand Boonanarring to process up to 124,000 tonnes. Plans include constructing an enclosed forced aerated concrete bunker, hard stands (engineered environmental barriers to stop the composting process affecting groundwater) and more leachate ponds.

“We’ve got a bunker system to do all the pasteurisation, but the magic happens on the hard stands,” Donovan says. “We let nature do its bit and keep feeding the process with water and air.”

WASTE MANAGEMENT IN ACTION – ORGANICS 28 / WMR / September 2023

Go Organics Boonanarring is undergoing expansion to cater for an increase in food organics garden organics waste in Western Australia.

John McKew, National Executive Officer of the Australian Organics Recycling Association (AORA),

visited Donovan and his Boonanarring site in early May 2023.

“There is a real entrepreneurial spirit within the organics recycling sector in Western Australia,” John says.

“Donovan and Go Organics are a great example of that in action – Donovan has recognised the need for additional FOGO processing potential in WA, has committed to this and is pursuing new end-use markets to manage the increased supply of compost.”

Donovan is an advocate of letting nature do its bit. Brunnings’ ethos has always been to provide Earthfriendly products and reduce environmental impact.

That has flowed through to Boonanarring – 250 acres of the property have been left as natural vegetation to offset emissions and produce oxygen. Donovan describes it as an oxygen factory.

Additionally, any water captured in leachate dams is reused in the compost process and a 130-kilowatt solar system on the shed roofs adds to the company’s good environmental story.

It’s a story for which Donovan is writing new chapters through his work to unlock more value of organic waste.

Go Organic is supplying about 20,000 tonnes of bagged compost to retailers. About 25 per cent of that will comprise FOGO. Another 15,000 tonnes will go to the bulk soil market.

Donovan’s hoping there’ll be some offtake for commercial landscape and infrastructure projects.

He recently partnered with the Southern Metro Regional Council to add soil conditioner to the parks and gardens in a new suburb redevelopment and has worked with Main Roads and the Public Transport Authority of Western Australia to create a growing media to support plant growth on roadside verges.

He says there’s an opportunity for the government to create a circular economy for compost by mandating a percentage be used in new suburb developments.

“We put a FOGO compost landscape mix in the amenities along the road and got a good result out of it,” Donovan says. “There were a few challenges. The high nutrient value of compost means you need to mix a lot of sand with it because too much phosphorus will

damage native plants. We got some good results. It was good to get this project off the ground.

“It’s a bit of a trailblazer for suburb and infrastructure development.”

Similar principles have been used to rehabilitate a zircon mine in Boonanarring. Donovan worked with the Murdoch University and Soil CRC to create a high-performance soil by blending compost and clay from the mine.

In the sandy soils of WA, combined with long hot summers, compost will burn off. By adding some clay, the compost ‘held’ onto the soil. Studies showed it also required 20 per cent less water to produce the same plant yield.

Donovan says the soil product shows promise to help drought-proof the state.

He’s also hopeful work with the Murdoch University and local farmers will future proof the agriculture industry. They’re developing soil products with regenerative benefits such as water retention and carbon sequestration to improve farmland.

He says plants have broken their relationship with soil because they rely on fertilisers. Putting compost into the soil acts as a catalyst to put life back into the soil and start using nature’s processes.

The results have been encouraging, but Donovan says it’s just the beginning. He’s already working on what he calls the second and third generation compost research – biochar and vermicomposting.

“The earthworm is like an alchemist,” Donovan says. “Once FOGO has gone through the biology of an earthworm it’s chemically changed to a high value product.

“What we’re doing now is really first generation. The real value-add comes when you start working the natural biology that God gave us.”

For more information, visit: www.goorganics.com.au

www.wastemanagementreview.com.au / WMR / 29

The 500-acre Boonanarring site includes 250-acres of natural vegetation.

Good stewards

RESOURCECO’S GLOBAL EXPERIENCE AND CREDENTIALS IN RESOURCE RECOVERY IS HELPING OTHERS REALISE THEIR SUSTAINABILITY OBJECTIVES.

ResourceCo has been at the forefront of recovery and remanufacturing of primary resources across Australia and Asia. The philosophy has always been that the rubble the company handles, the tyres it recovers and the waste it collects, does not go to landfill but is remade as high quality products.

Sanj says while most companies now have sustainability goals and net zero aspirations, the focus on Australia reaching a circular economy has elevated the conversation and the need for greener supply chains.

She says organisations are not just ensuring their waste is recycled – they want traceability.

ResourceCo’s brand promise is to leave the world in a better state than it was found.

Thirty years ago, when the company was founded, there were no net zero targets or sustainable development goals, just a deep-seated belief that industry can work within a circular economy for a sustainable future.

Sanj de Silva, Director Corporate Affairs and Sustainability, says the brand promise on which the company was built is more relevant today than ever.

“There’s been a big mindset change, not just in boardrooms but right across the community,” Sanj says. “Communities are demanding organisations do the right thing when it comes to sustainability.

“This industry has a big role to play in coming years and is well placed

to drive sustainability aspirations, progressing Australia’s circular economy.

“The resource recovery sector forms a key component in the supply chain of several industries and plays a vital role in promoting and supporting sustainability and circular economy priorities for organisations.”

Industry is transitioning from a linear to a circular model, driven by low emissions targets, government policies and regulatory pressures to divert waste from landfill to achieve the 80 per cent national resource recovery target by 2030.

“Sustainability is at the heart of ResourceCo – we are steadfast in our commitment to maximise the potential of all the material we handle,” Sanj says. “That makes us a valuable business partner to deliver on the sustainability aspirations of our customers.”

“Where did it end up? What happened to it? What percentage is recycled? Organisations are asking those questions, and rightfully so,” Sanj says. “They should know where their waste ends up. People need to go beyond just handing their waste over to a collector.

“This genuine interest in waste traceability and landfill minimisation is encouraging, but what we’re really looking forward to is the evolution of this interest into further action – when organisations go from asking questions for their sustainability reporting to committing to buy recycled material.”

ResourceCo has a track record of diverting waste from landfill. Construction and demolition waste or commercial and industrial waste is recycled either as products that go back into the industry, or as processed engineered fuel.

Up to 99 per cent of end-oflife tyres the company receives are

WASTE MANAGEMENT IN ACTION – SUSTAINABILITY IN BUSINESS 30 / WMR / September 2023

ResourceCo has an integrated companywide commitment to sustainability.

recycled as crumb rubber for local use, or Tyre Derived Fuel (TDF), an alternative fuel.

Sanj says that having repurposed more than 60 million tonnes of materials, ResourceCo is one of the largest energy-from-waste producers in Australasia, and in doing so is a big contributor to carbon abatement and reducing greenhouse gas emissions.

She says other organisations can leverage ResourceCo’s experience and success to help them reach their own sustainability targets.

“Our business model is uniquely placed to deliver on sustainability aspirations of our customers, embracing innovations and expanding our operations for sustainable circular outcomes.”

The ResourceCo sustainability framework provides a clear platform for reporting and communications, allowing for a meaningful dialogue with stakeholders and a consistency of focus that makes reporting more transparent.

With more than 20 years’ experience in driving and embedding the concepts of sustainability, Sanj has witnessed the evolution of sustainability from a buzz word in boardrooms to be the centre of globally recognised guidelines.

While sustainability has been on the corporate agenda for some time, she believes the COVID-19 pandemic acted as a tipping point and forced the issue into the spotlight.

She’s encouraged by a call to action across the industry and has been responsible for ResourceCo’s own

sustainability journey with the first Sustainability Report, released in 2022.

Sanj says everyone at ResourceCo is driven by a sustainable future.

“We’re focused on engaging with our customers, broader industry and governments to demonstrate how the resource recovery industry can deliver a unique package of positive sustainability and economic outcomes.”

While ResourceCo’s business helps others with their sustainability goals, it too has an integrated companywide commitment.

“All of us are responsible for delivering our aspirations, goals and targets, which impact our organisation, environment and customers,” Sanj says. “ResourceCo has been doing this for the past 30 years but putting it into a framework that resonates globally has been an exciting journey.”

For more information, visit: www.resourceco.com.au

www.wastemanagementreview.com.au / WMR / 31

Sanj de Silva, Director Corporate Affairs and Sustainability, ResourceCo.

ResourceCo’s joint venture resource recovery facility with Cleanaway in Wetherill Park NSW, celebrated five years of operation in July 2023. Diverting more than 350,000 tonnes of waste from landfill, this facility has abated more than 260,000 tonnes of carbon dioxide emissions – equivalent to taking 70,000 cars off the road.

In the pink

AS UBER SUCCESSFUL RECYCLESMART CELEBRATES ITS FOURTH ANNIVERSARY, SUSTAINABILITY EXPERT JUSTIN FRANK JOINS THE ADVISORY BOARD TO HELP THE COMPANY CONTINUE TO GROW.

It’s known as the uber of waste, is easily recognisable with bright pink collection bags, and has built up a 40,000 plus community of Recycle Heroes.

RecycleSmart is a cheerful brand, but it’s making serious inroads into some of Australia’s difficult to recycle materials. Just four years since its inception, the on-demand recycling service has completed 125,000 Power Pickups, collected more than 500,000 kilograms of valuable resources, and diverted them from landfill.

The company’s rapid growth is driven by a team whose passion to make a difference is contagious, says Justin Frank. It’s one of the reasons why the former Chief Strategy, Sustainability and Communication’s Officer at Suez has joined RecycleSmart’s advisory board.

“I really wanted to stay within the circular economy,” Justin says. “After 20 years working in B2B industrial circular economies, I’m very passionate and very concerned about what the future holds for our next generation. In future, I want to be able to look my son in the eye and say, ‘I did my best’.”

Justin worked for global pallet and container company CHEP, a subsidiary of Brambles, for 14 years and says it’s one of the best examples of a regenerative circular economy at scale you’ll see, with one of the best sustainable development business strategy he’s come across.

He worked his way up the ranks from “licking envelopes” to logistics

in the United Kingdom, relocating to Australia where he took on the role of strategy and marketing director, before moving to Suez.

Following the acquisition of Suez by Veolia in 2021 Justin took a sabbatical to spend time with family, travel and published a children’s book, Disgusting Justin, that he dedicated to his son.

He’s now consulting on various circular economy and sustainable development projects, including recently joining Edge Impact as Senior Associate, Circular Economy and Lifecycle Thinking, and the RecycleSmart advisory board in March.

He’s keen to use his experience to guide RecycleSmart as it continues to grow.

“I can give them insight into the overall supply chain and the challenges we have in Australia in terms of end solutions and a lack of investment,” Justin says.

“We have to be cautious about having material collections without an end market – we saw through the collapse of REDcycle how good ideas can end in decline without that offtake.”

Justin says Australia’s waste and recycling industry is in a state of transition. An environment ministers meeting in June 2023 fired a clear shot across the bow that industry needs to be on board when it comes to extended responsibility.

However, he says the collection infrastructure in Australia needs

WASTE MANAGEMENT IN ACTION – RECYCLING 32 / WMR / September 2023

In four years,RecycleSmart has built a community of more than 40,000 Recycle Heroes.

upgrading, waste levies should be harmonised across the country and reinvested into infrastructure and actions that drive increased recycling rates.

He sees RecycleSmart providing the solutions where infrastructure is lacking, by bridging the gap between the residents and recycling or reuse infrastructures.

“The waste industry needs to jump on board with new ways of recycling, rather than feeding the beast,” Justin says.

“We need to see more solutions that are reuse and repair rather than just treat or dispose. RecycleSmart is finding that offtake. If you look at the type of things it’s collecting and the volumes, it’s on the smaller end, the bits and bobs that are not as attractive for large industry to get involved in.

“It provides that innovative solution that can start to make an inroad into these materials. That’s its niche and where the traction will be made.”

Justin says while RecycleSmart has off-takers for its main collection sources now, it’s important to continue to look at new technology and ensure it maintains pace with innovation and legislation to ensure longterm success.

He believes the company can go national and make a positive dent in getting as much recyclable material out of the red-lid rubbish bin to be repaired, reused, or recycled in an environmentally and sustainable way.

“I’m excited to see RecycleSmart moving into the business-to-business space as well,” Justin says.

“Finding source segregated waste streams and turning them into a valuable commodity is where they need to focus.”

RecycleSmart has built its brand on offering solutions for items that can be tricky to recycle. Justin says the combination of a niche offering and

branding that grabs your attention, is powerful. RecycleSmart also plays to its strength with digital innovation and customer service.

He says the automation around reminders, feedback and encouragement makes recycling fun for participants and they feel like they are making a genuine difference.

“Service with a smile and overall ease of getting on board is one of the reasons why RecycleSmart is really growing,” Justin says.

“Sometimes people think innovation must be so complicated. I’m sure in the background of RecycleSmart’s system it is more complicated, but to make it so simple for users, that’s what they’ve done really well.”

Giorgio Baracchi, RecycleSmart Chief Executive Officer and CoFounder, says the company’s growth in just four years is something to be proud of.

Reflecting on the journey, he says what fills him with pride is the incredible team behind the company and the community of Recycle Heroes.

“Our team is a tightknit and passionate group, working together to make a difference,” he says. “We must also acknowledge the immense contribution of our dedicated local drivers, who are the backbone of our service. Their unwavering engagement and loyalty are invaluable.

“Equally inspiring is our community of 40,000 plus Recycle Heroes, actively engaged in our mission.

“A recent example of their support is our successful crowdfunding campaign, which closed a few weeks ago, raising more than $1 million with the backing of 900 plus investors.”

Giorgio says addressing a genuine problem is a major part of the company success.

“Recycling, as great as it sounds on paper, often proves to be confusing and lacking transparency,” he says.

“We recognised this and decided to provide a convenient and easy solution, empowering individuals to take action in one of the few areas where they have control over building a more sustainable future.”

Looking ahead, Giorgio says both short- and long-term prospects are exciting. Thanks to the success of the crowdfunding campaign, RecycleSmart has ambitious plans.

An expansion into Melbourne has already begun and the company is eager to expand its reach into new cities. Additionally, it aims to enhance its services by accepting a wider range of challenging-to-recycle items, positioning itself as the go-to solution for all recycling needs.

“We have our sights set on accelerating our program for businesses, workplaces, and retailers” Giorgio says. “We are committed to forging partnerships that accelerate Australia’s transition to a more circular economy.

“The future looks promising, and we’re ready to seize every opportunity that comes our way.”

For more information, visit: www.recyclesmart.com

www.wastemanagementreview.com.au / WMR / 33

Justin Frank has taken on an advisory role with RecycleSmart.

Make the grade

ENVIRO NZ ENHANCES OPERATIONS AND REPORTING WITH LANDFILL MACHINE GUIDANCE TECHNOLOGY. LANDFILL MANAGER TIM PAGE EXPLAINS.

As one of New Zealand’s largest waste management operators, Enviro NZ has a commitment to responsible, innovative, and sustainable resource recovery and management. Preserving the country’s natural beauty and environment is at the heart of the company’s ethos, investing in innovation and technology to operate as sustainably and efficiently as possible.

About 12 months ago, Enviro NZ invested in landfill machine guidance technology at the Hampton Downs landfill in North Waikato. The site is one of the largest waste management facilities in the country, servicing a large part of the upper North Island, including Auckland.

Carlson Landfillgrade machine guidance technology was installed on the company’s two Tana 50-tonne

landfill compactors, to further enhance on-site safety and reduce machine operating hours through more efficient compaction.